Page 1

DEVICES INCORPORATED

DEVICES INCORPORATED

LF2272

Colorspace Converter/

LF2272

Corrector (3 x 12-bits)

Colorspace Converter/

Corrector (3 x 12-bits)

FEATURES

❑❑

❑ 50 MHz Data and Computation

❑❑

Rate

❑❑

❑ Full Precision Internal Calculations

❑❑

with Output Rounding

❑❑

❑ On-board 10-bit Coefficient Storage

❑❑

❑❑

❑ Overflow Capability in Low

❑❑

Resolution Applications

❑❑

❑ Two’s Complement Input and

❑❑

Output Data Format

❑❑

❑ 3 Simultaneous 12-bit Channels

❑❑

(64 Giga Colors)

❑❑

❑ Applications:

❑❑

• Component Color Standards

Translations (RGB, YIQ, YUV)

• Color-Temperature Conversion

• Image Capturing and Manipulation

• Composite Color Encoding/

Decoding

• Three-Dimensional Perspective

Translation

❑❑

❑ Replaces TRW/Raytheon/Fairchild

❑❑

TMC2272

❑❑

❑ 120-pin PQFP

❑❑

DESCRIPTION

The LF2272 is a high-speed digital

colorspace converter/corrector

consisting of three simultaneous 12-bit

input and output channels for functionality up to 64 Giga (236) colors.

Some of the applications the LF2272

can be used for include phosphor

colorimetry correction, image capturing and manipulation, composite color

encoding/decoding, color matching,

and composite color standards

conversion/transcoding.

The 3 x 3 matrix multiplier (triple dot

product) allows users to easily perform three-dimensional perspective

translations or video format conversions at real-time video rates. By

using the LF2272, conversions can be

made from the RGB (color component) format to the YIQ (quadrature

encoded chrominance) or YUV (color

difference) formats and vice versa

(YIQ or YUV to RGB). Differing signal

formats in each stage of a system can

be disregarded. For example, using

an LF2272 at each format interface

allows each stage of a system to

operate on the data while in the

appropriate format.

All inputs and outputs, as well as all

control lines, are registered on the

rising edge of clock. The LF2272

operates at clock rates up to 50 MHz

over the full commercial temperature

and supply voltage ranges. A narrower data path can be used to allow

the LF2272 to work with many

different imaging applications.

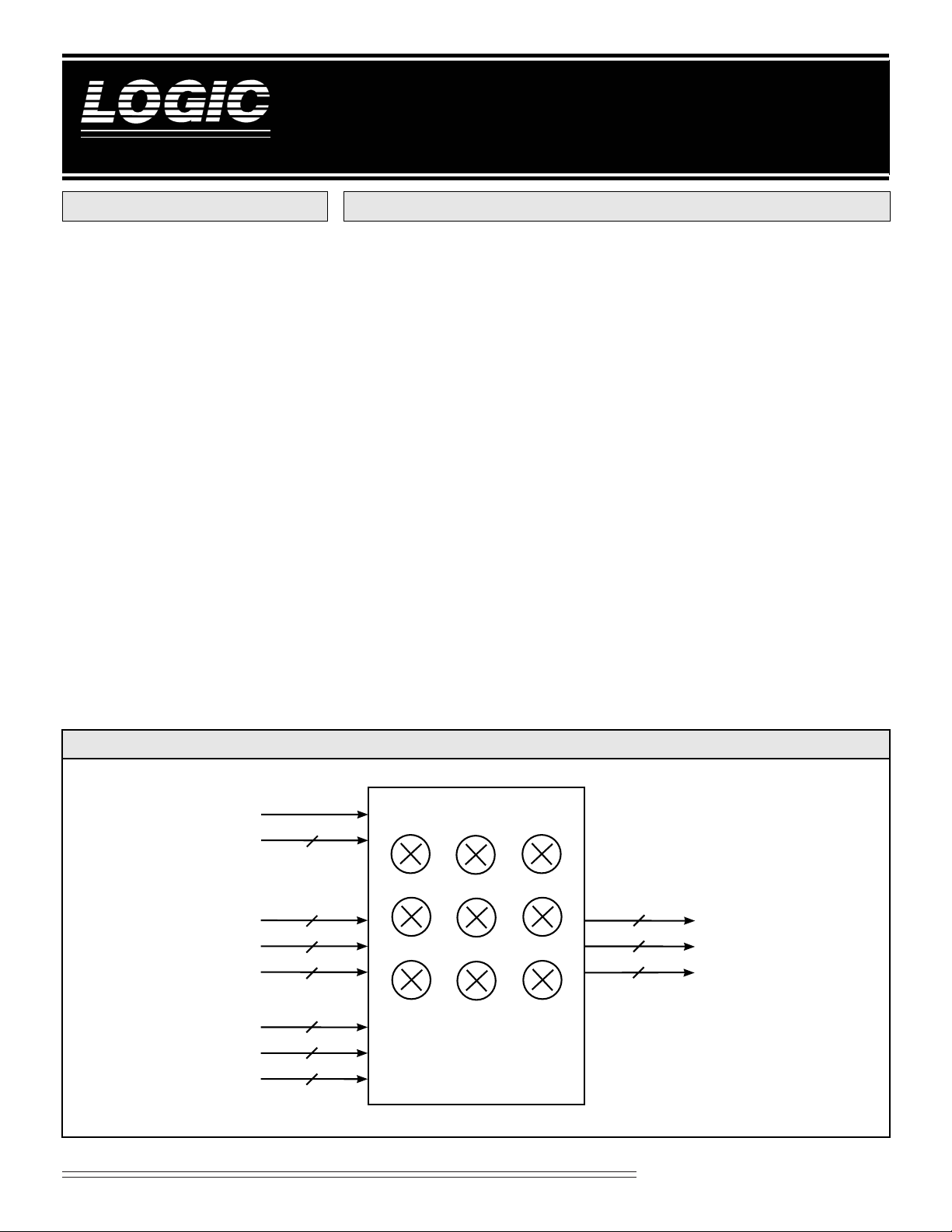

DETAILS OF OPERATION

All three input ports (A, B, C) and all

three output ports (X, Y, Z) are

utilized to implement a 3 x 3 matrix

multiplication (triple dot product).

Each truncated 12-bit output is the

sum of all three input words multiplied by the appropriate coefficients

(Table 1). The pipeline latency is five

clock cycles. Therefore, the sum of

LF2272 BLOCK DIAGRAM

CLK

1-0

CWEL

A

11-0

DATA

INPUTS

COEFFICIENT

INPUTS

{

{

B

C

KA

KB

KC

11-0

11-0

9-0

9-0

9-0

10

10

10

12

12

12

2

12

12

12

X

Y

Z

11-0

11-0

11-0

{

DATA

OUTPUTS

9-MULTIPLIER

ARRAY

Video Imaging Products

1

08/16/2000–LDS.2272-I

Page 2

DEVICES INCORPORATED

LF2272

Colorspace Converter/

Corrector (3 x 12-bits)

products will be output five clock

cycles after the input data has been

registered. New output data is

subsequently available every clock

cycle thereafter.

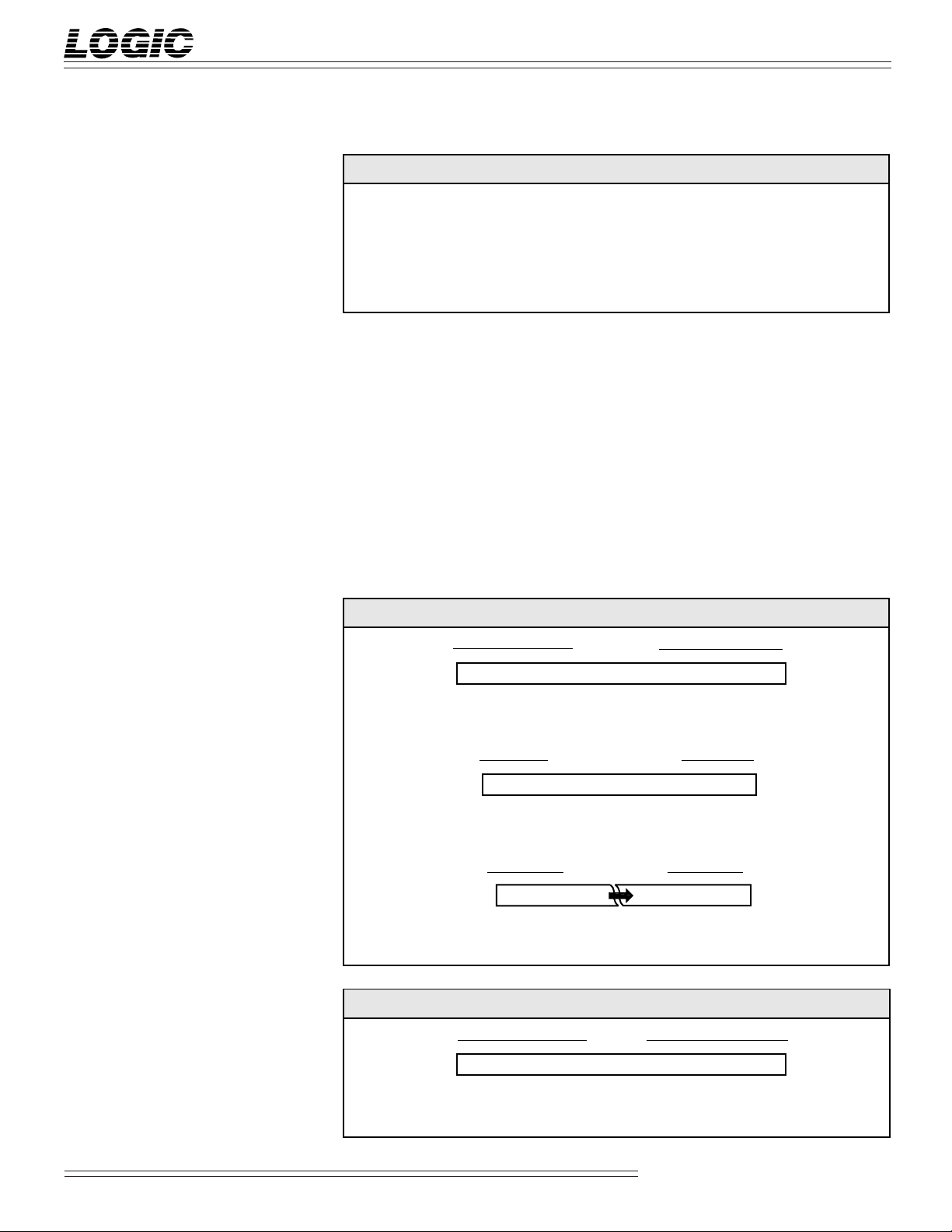

DATA FORMATTING

The data input ports (A, B, C) and

data output ports (X, Y, Z) are 12-bit

integer two’s complement format.

The coefficient input ports (KA, KB,

KC) are 10-bit fractional two’s

complement format. Refer to

Figures 1a and 1b.

BIT WEIGHTING

The internal sum of products of the

LF2272 can grow to 23 bits. However,

in order to keep the output format

identical to the input format, the X, Y,

and Z outputs are rounded to 12-bit

integer words. The rounding is done

only at the final output stage to allow

accuracy, with correct rounding and

overflow, for applications requiring

less than 12-bit integer words. The

user may adjust the bit weighting by

applying an identical scaling correction factor to both the input and

output data streams.

TABLE 1. LATENCY EQUATIONS

X(n+4) = A(n)KA1(n) + B(n)KB1(n) + C(n)KC1(n)

Y(n+4) = A(n)KA2(n) + B(n)KB2(n) + C(n)KC2(n)

Z(n+4) = A(n)KA3(n) + B(n)KB3(n) + C(n)KC3(n)

DATA OVERFLOW

Because the LF2272’s matched input

and output data formats accommodate unity gain (0 dB), input conditions that could lead to numeric

overflow may exist. To ensure that no

overflow conditions occur, the user

must be aware of the maximum input

data and coefficient word sizes

allowable for each specific algorithm

being performed.

FIGURE 1A.INPUT FORMATS

Data Input

11 10 9 6 5 487 3210

1121029

–2

(Sign)

7

282

Coefficient Input

SYSTEMS SMALLER THAN 12-BITS

Using a data path less than 12-bits

requires the input data to be right

justified and sign extended to 12-bits

because the LF2272 carries out all

calculations to full precision. Since all

least-significant bits are used, the

desired X, Y, and Z outputs are

rounded correctly and upper-order

output bits are used for overflow.

26252

4

2322212

0

987 43265 10

02–12–2

–2

(Sign)

20 19 18 3 2 117 0

1121029

–2

(Sign)

FIGURE 1B.OUTPUT FORMAT

11 10 9 6 5 487 3210

1121029

–2

(Sign)

2

282

–4

2–32

2–52–62

Internal Sum

8

2

2–62–72

Result

7

26252

Video Imaging Products

–7

2–82

–8

2

4

2322212

–9

–9

0

08/16/2000–LDS.2272-I

Page 3

DEVICES INCORPORATED

LF2272

Colorspace Converter/

Corrector (3 x 12-bits)

SIGNAL DEFINITIONS

Power

VCC and GND

+5 V power supply. All pins must be

connected.

Clock

CLK — Master Clock

The rising edge of CLK strobes all

enabled registers. All timing specifications are referenced to the rising

edge of CLK.

Inputs

A11-0, B11-0, C11-0 — Data Inputs

A, B, and C are the 12-bit registered

data input ports. Data presented to

these ports is latched into the multiplier input registers.

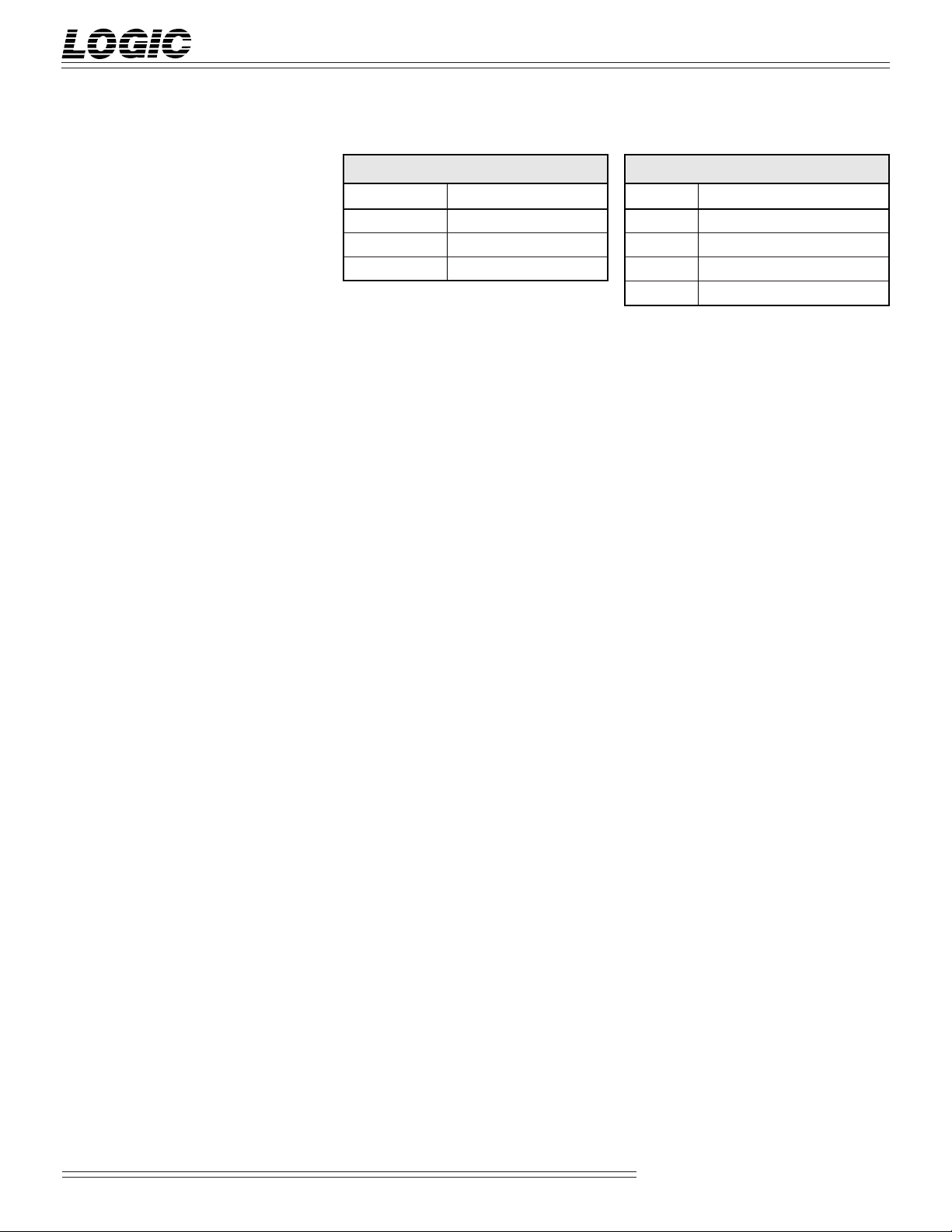

TABLE 2. COEFFICIENT INPUTS

INPUT PORT REG. AVAILABLE

KA KA1, KA2, KA3

KB KB1, KB2, KB3

KC KC1, KC2, KC3

Outputs

X11-0, Y11-0, Z11-0 — Data Outputs

X, Y, and Z are the 12-bit registered

data output ports.

Controls

CWEL1-0 — Coefficient Write Enable

The registered coefficient write enable

inputs determine which internal

coefficient register set to update

(Table 3) on the next clock cycle.

TABLE 3. COEFF. REG. UPDATE

CWEL1-0 COEFFICIENT SET

00 Hold All Registers

01 KA1, KB1, KC1

10 KA2, KB2, KC2

11 KA3, KB3, KC3

KA9-0, KB9-0, KC9-0 — Coefficient Inputs

KA, KB, and KC are the 10-bit registered coefficient input ports. Data

presented to these ports is latched into

the corresponding internal coefficient

register set defined by CWEL1-0

(Table 3) on the next rising edge of

CLK. Table 2 shows which coefficient

registers are available for each coefficient input port.

Video Imaging Products

3

08/16/2000–LDS.2272-I

Page 4

DEVICES INCORPORATED

FIGURE 2. DETAILED FUNCTIONAL DIAGRAM

12

A

KA1 KA2 KA3

10

KA

12

B

LF2272

Colorspace Converter/

Corrector (3 x 12-bits)

21 21 21

KB

KC

CWEL

KB3KB2KB1

10

21 21 21

12

C

KC1 KC2 KC3

10

21 21 21

2

12 (MSB) 12 (MSB) 12 (MSB)

XYZ

Video Imaging Products

4

08/16/2000–LDS.2272-I

Page 5

DEVICES INCORPORATED

LF2272

Colorspace Converter/

Corrector (3 x 12-bits)

MAXIMUM RATINGS

Storage temperature ........................................................................................................... –65°C to +150°C

Operating ambient temperature........................................................................................... –55°C to +125°C

VCC supply voltage with respect to ground............................................................................ –0.5 V to +7.0V

Input signal with respect to ground ............................................................................... –0.5V to VCC + 0.5 V

Signal applied to high impedance output ...................................................................... –0.5 V to VCC + 0.5 V

Output current into low outputs............................................................................................................. 25 mA

Latchup current ............................................................................................................................... > 400 mA

OPERATING CONDITIONS

Active Operation, Commercial 0°C to +70°C 4.75 V ≤ VCC ≤ 5.25 V

Active Operation, Military –55°C to +125°C 4.50 V ≤ VCC ≤ 5.50 V

ELECTRICAL CHARACTERISTICS

Above which useful life may be impaired (Notes 1, 2, 3, 8)

To meet specified electrical and switching characteristics

Mode Temperature Range (Ambient) Supply Voltage

Over Operating Conditions (Note 4)

Symbol Parameter Test Condition Min Typ Max Unit

VOH Output High Voltage Vcc = Min., IOH = –2.0 mA 2.4 V

VOL Output Low Voltage Vcc = Min., IOL = 4.0 mA 0.4 V

VIH Input High Voltage 2.0 VCC V

VIL Input Low Voltage (Note 3) 0.0 0.8 V

IIX Input Current Ground ≤ VIN ≤ VCC (Note 12) ±10 µA

IOZ Output Leakage Current (Note 12) ±40 µA

ICC1 VCC Current, Dynamic (Notes 5, 6) 160 mA

ICC2 VCC Current, Quiescent (Note 7) 12 mA

CIN Input Capacitance TA = 25°C, f = 1 MHz 10 pF

COUT Output Capacitance TA = 25°C, f = 1 MHz 10 pF

Video Imaging Products

5

08/16/2000–LDS.2272-I

Page 6

DEVICES INCORPORATED

1234567890123456789012345678901212

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1234567890123456789012345678901212

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

4

SWITCHING CHARACTERISTICS

LF2272

Colorspace Converter/

Corrector (3 x 12-bits)

COMMERCIAL OPERATING RANGE (0°C to +70°C)

Notes 9, 10 (ns)

LF2272–

2345678901234567

2345678901234567

2345678901234567

Symbol Parameter Min Max Min Max Min Max

tCYC Cycle Time 33 25 20

tPWL Clock Pulse Width Low 15 10 6

tPWH Clock Pulse Width High 10 10 8

tS Input Setup Time 8 6 6

tH Input Hold Time 0 0 0

tD Output Delay 18 16 15

MILITARY OPERATING RANGE (–55°C to +125°C)

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

2345678901234567

Notes 9, 10 (ns)

Symbol Parameter Min Max Min Max

tCYC Cycle Time 33 25

tPWL Clock Pulse Width Low 15 10

tPWH Clock Pulse Width High 10 10

tS Input Setup Time 12 9

tH Input Hold Time 0 0

tD Output Delay 25 20

33

*

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

23456789012345678901234567890121

25 20

LF2272–

*

33

25

*

SWITCHING WAVEFORM

1234 678

CLK

t

S

1-0

CWEL

KA, KB, KC

A, B, C

X

11-0

Y

11-0

Z

11-0

2345678901234567890123

*DISCONTINUED SPEED GRADE

01

t

H

Kx1 Kx2 Kx3

001.0000

t

t

PWH

PWL

10 11 00

6

5

t

D

KA1 + KB1 + KC1

KA2 + KB2 + KC2

KA3 + KB3 + KC3

Video Imaging Products

08/16/2000–LDS.2272-I

Page 7

DEVICES INCORPORATED

OE

0.2 V

t

DIS

t

ENA

0.2 V

1.5 V 1.5 V

3.0V Vth

1

Z

0

Z

Z

1

Z

0

1.5 V

1.5 V

0V Vth

VOL*

V

OH

*

V

OL

*

V

OH

*

Measured V

OL

with IOH = –10mA and IOL = 10mA

Measured V

OH

with IOH = –10mA and IOL = 10mA

S1

I

OH

I

OL

V

TH

C

L

DUT

NOTES

LF2272

Colorspace Converter/

Corrector (3 x 12-bits)

1. Maximum Ratings indicate stress

specifications only. Functional operation of these products at values beyond

those indicated in the Operating Conditions table is not implied. Exposure to

maximum rating conditions for extended periods may affect reliability.

2. The products described by this specification include internal circuitry designed to protect the chip from damaging substrate injection currents and accumulations of static charge. Nevertheless, conventional precautions should

be observed during storage, handling,

and use of these circuits in order to

avoid exposure to excessive electrical

stress values.

3. This device provides hard clamping of

transient undershoot and overshoot. Input levels below ground or above VCC

will be clamped beginning at –0.6 V and

VCC + 0.6 V. The device can withstand

indefinite operation with inputs in the

range of –0.5 V to +7.0 V. Device operation will not be adversely affected, however, input current levels will be well in

excess of 100 mA.

9. AC specifications are tested with

input transition times less than 3 ns,

output reference levels of 1.5 V (except

tDIS test), and input levels of nominally

0 to 3.0 V. Output loading may be a

resistive divider which provides for

specified IOH and IOL at an output

voltage of VOH min and VOL max

respectively. Alternatively, a diode

bridge with upper and lower current

sources of IOH and IOL respectively,

and a balancing voltage of 1.5 V may be

used. Parasitic capacitance is 30 pF

minimum, and may be distributed.

This device has high-speed outputs capable of large instantaneous current

pulses and fast turn-on/turn-off times.

As a result, care must be exercised in the

testing of this device. The following

measures are recommended:

a. A 0.1 µF ceramic capacitor should be

installed between VCC and Ground

leads as close to the Device Under Test

(DUT) as possible. Similar capacitors

should be installed between device VCC

and the tester common, and device

ground and tester common.

11. For the tENA test, the transition is

measured to the 1.5 V crossing point

with datasheet loads. For the tDIS test,

the transition is measured to the

±200mV level from the measured

steady-state output voltage with

±10mA loads. The balancing voltage, VTH, is set at 3.5 V for Z-to-0

and 0-to-Z tests, and set at 0 V for Zto-1 and 1-to-Z tests.

12. These parameters are only tested at

the high temperature extreme, which is

the worst case for leakage current.

FIGURE A. OUTPUT LOADING CIRCUIT

FIGURE B. THRESHOLD LEVELS

4. Actual test conditions may vary from

those designated but operation is guaranteed as specified.

5. Supply current for a given application can be accurately approximated by:

2

NCV F

where

4

N = total number of device outputs

C = capacitive load per output

V = supply voltage

F = clock frequency

6. Tested with all outputs changing every cycle and no load, at a 20 MHz clock

rate.

7. Tested with all inputs within 0.1 V of

VCC or Ground, no load.

8. These parameters are guaranteed

but not 100% tested.

b. Ground and VCC supply planes

must be brought directly to the DUT

socket or contactor fingers.

c. Input voltages should be adjusted to

compensate for inductive ground and VCC

noise to maintain required DUT input

levels relative to the DUT ground pin.

10. Each parameter is shown as a minimum or maximum value. Input requirements are specified from the point

of view of the external system driving

the chip. Setup time, for example, is

specified as a minimum since the external system must supply at least that

much time to meet the worst-case requirements of all parts. Responses from

the internal circuitry are specified from

the point of view of the device. Output

delay, for example, is specified as a

maximum since worst-case operation of

any device always provides data within

that time.

7

Video Imaging Products

08/16/2000–LDS.2272-I

Page 8

DEVICES INCORPORATED

ORDERING INFORMATION

LF2272

Colorspace Converter/

Corrector (3 x 12-bits)

120-pin

GND

Y

Y

V

GND

V

GND

X7X8VCCX9X10X11GND

120

119

118

X

6

1

X

5

2

X

4

3

X

3

4

X

2

5

X

1

6

X

0

7

8

11

9

10

10

Y

9

11

CC

12

Y

8

13

Y

7

14

Y

6

15

16

Y

5

17

Y

4

18

Y

0

19

CC

20

Y

1

21

Y

2

22

Y

3

23

24

0

Z

25

Z

1

26

Z

2

27

Z

3

28

Z

4

29

Z

5

30

117

3132333435363738394041424344454647484950515253545556575859

116

115

114

GND

113

GND

112

C11C10C9C8C7GND

111

110

109

108

107

106

Top

View

C6C5C4VCCC3C2C1C0B11B10B9B8B7B6B

105

104

103

999897969594939291

102

101

100

5

90

B

4

B

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

3

CLK

2

B

B

1

B

0

A

11

A

10

A

9

A

8

A

7

A

6

A

5

A

4

A

3

A

2

A

1

A

0

GND

CWE

CWE

KA

KA

KA

KA

KA

KA

KA

KA

KA

0

1

9

8

7

6

5

4

3

2

1

Speed

25 ns

20 ns

8

9

GND

Z

Z10Z

Z6Z7Z

0°C to +70°C — COMMERCIAL SCREENING

–40°C to +85°C — COMMERCIAL SCREENING

3

11

KC0KC1KC2KC

GND

4KC5KC6

KC

Plastic Quad Flatpack

(Q1)

LF2272QC25

LF2272QC20

9KB0KB1KB2KB3KB4KB5KB6KB7KB8KB9KA0

CC

KC7KC8KC

V

Video Imaging Products

8

08/16/2000–LDS.2272-I

Page 9

DEVICES INCORPORATED

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Colorspace Converter/

Corrector (3 x 12-bits)

ORDERING INFORMATION

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

120-pin

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

Speed

0°C to +70°C — COMMERCIAL SCREENING

–55°C to +125°C — COMMERCIAL SCREENING

–55°C to +125°C — MIL-STD-883 COMPLIANT

12345

A

X

9

X

7

X

B

X

5

X

4

X

C

X

2

X

1

X

D

X

0

Y

11

X

E

Y

10

Y

9

GND

F

Y

8

Y

7

V

G

Y

6

Y

5

GND

H

V

Y

0

Y

4

J

Y

2

Y

1

GND

K

Z

Z

0

Y

3

L

Z

4

Z

1

Z

M

Z

7

Z

2

Z

N

Z

8

Z

5

Z

6

GND

C

11

C

8

C

9

C

10

KEY

Top View

GND

CC

10

X

11

8

6

GND

V

CC

GND

3

Through Package

(i.e., Component Side Pinout)

CC

3

GND

6

Z

9

KC

10

0

GND

KC

KC

KC

KC

2

4

3

KC

5

11

1

Discontinued Package

Ceramic Pin Grid Array

(G4)

9

7 8 9 10 11

C

7

C

5

C

3

C

1

C

6

C

4

C

2

B

11

V

CC

C

0

B

8

CC

KB

0

KB

V

KC

KC

6

KC

7

KC

4

KB

8

9

KB

2

KB

5

8

KB

1

KB

3

12 13

B

10

B

7

B

4

B

9

B

6

B

2

B

5

B

3

B

1

CLK

B

0

A

10

11

A

9

A

KA

KA

KA

KB

8

A

6

A

5

A

2

A

4

A

0

A

1

1

CWEL

0

7

KA

9

5

KA

6

2

KA

3

7

KA

0

A

A

7

A

3

GND

KA

8

CWEL

KA

4

KA

1

KB

9

KB

6

Video Imaging Products

LF2272

08/16/2000–LDS.2272-I

Loading...

Loading...