Page 1

CMOS LSI

Ordering number : EN*5155

91195HA (OT) No. 5155-1/5

Preliminary

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Image-Processing LSI

for Fax, Copier and OCR Products

LC82102, LC82102W

Overview

The LC82102 and LC82102W convert analog video

signals from CCD or contact image sensors to highquality binary video data. The LC82102/W converts the

input analog data to multi-valued data and uses twodimensional filtering and an error diffusion technique that

produces high-quality images to produce a two-valued

image. Finally, the LC82102 reduces the image in the

main and subsidiary scan directions. The LC82102

requires absolutely no external memory since it limits the

number of pixels processed to 2040 per line. This LSI can

implement the image processing used by FAX, copier and

OCR products.

Features

• Number of pixels processed: 2040 pixels/line

• Processing speed: 500 ns/pixel maximum (when the

CLKIN input frequency is 32 MHz)

• Built-in 8-bit A/D converter (includes a sensor signal

delay adjustment function)

• Built-in 6-bit D/A converter for setting the A/D

converter high reference potential

• Sensor drive circuit (supports CCD and all CIS types)

• Digital clamp (single-point clamp, even/odd clamp)

• Distortion correction (white correction: 8-pixel

averaging correction, black correction: black correction

subtraction data setting)

• Gamma correction (supports user-defined curves)

• Simple binary-conversion processing (fixed threshold

level, density-adaptive threshold level)

• Intermediate processing error diffusion (64 levels)

• Image reduction (thinning, fine black line retaining, fine

white line retaining)

• Single-voltage 5 V supply and low power due to CMOS

process fabrication

Package Dimensions

unit: mm

3159-QFP64E

unit: mm

3190-SQFP64

SANYO: SQFP64

[LC82102W]

[LC82102]

SANYO: QIP64E

Page 2

Specifications

Absolute Maximum Ratings at Ta = 25°C, GND = 0 V

Allowable Operating Ranges at Ta = –30 to +70°C, GND = 0 V

DC Characteristics at Ta = –30 to +70°C, GND = 0 V, VDD= 4.5 to 5.5 V

Analog Characteristics

No. 5155-2/5

LC82102, LC82102W

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage V

DD

max –0.3 to +7.0 V

Maximum I/O voltages V

I

, VOmax –0.3 to VDD+ 0.3 V

Allowable power dissipation Pd max Ta ≤ 70°C 350 mW

Operating temperature Topr –30 to +70 °C

Storage temperature Tstg –55 to +125 °C

Soldering conditions

Hand soldering: 3 seconds 350 °C

Reflow soldering: 10 seconds 235 °C

Parameter Symbol Conditions min typ max Unit

Supply voltage V

DD

4.5 5.5 V

Input voltage V

IN

0 V

DD

V

Parameter Symbol Conditions min typ max Unit

Input high level voltage V

IH

2.2 V

Input low level voltage V

IL

0.8 V

Input leakage current I

L

VIN= VDD, V

SS

–25 +25 µA

Output high level voltage V

OHIOH

= –3 mA 2.4 V

Output low level voltage V

OL

IOL= 3 mA 0.4 V

Output leakage current I

L

For high-impedance output –100 +100 µA

Current drain I

DD

CLKIN = 32 MHz 40 70 mA

Parameter Symbol Conditions min typ max Unit

[D/A Converter]

Resolution 6 bit

Internal resistance 5.0 kΩ

[A/D Converter] when ADREFL = 0 V, and the ATAP potential is 4.2 V

Resolution 8 bit

Linearity error ±1 LSB

Differential linearity error ±1 LSB

Internal resistance 300 Ω

Page 3

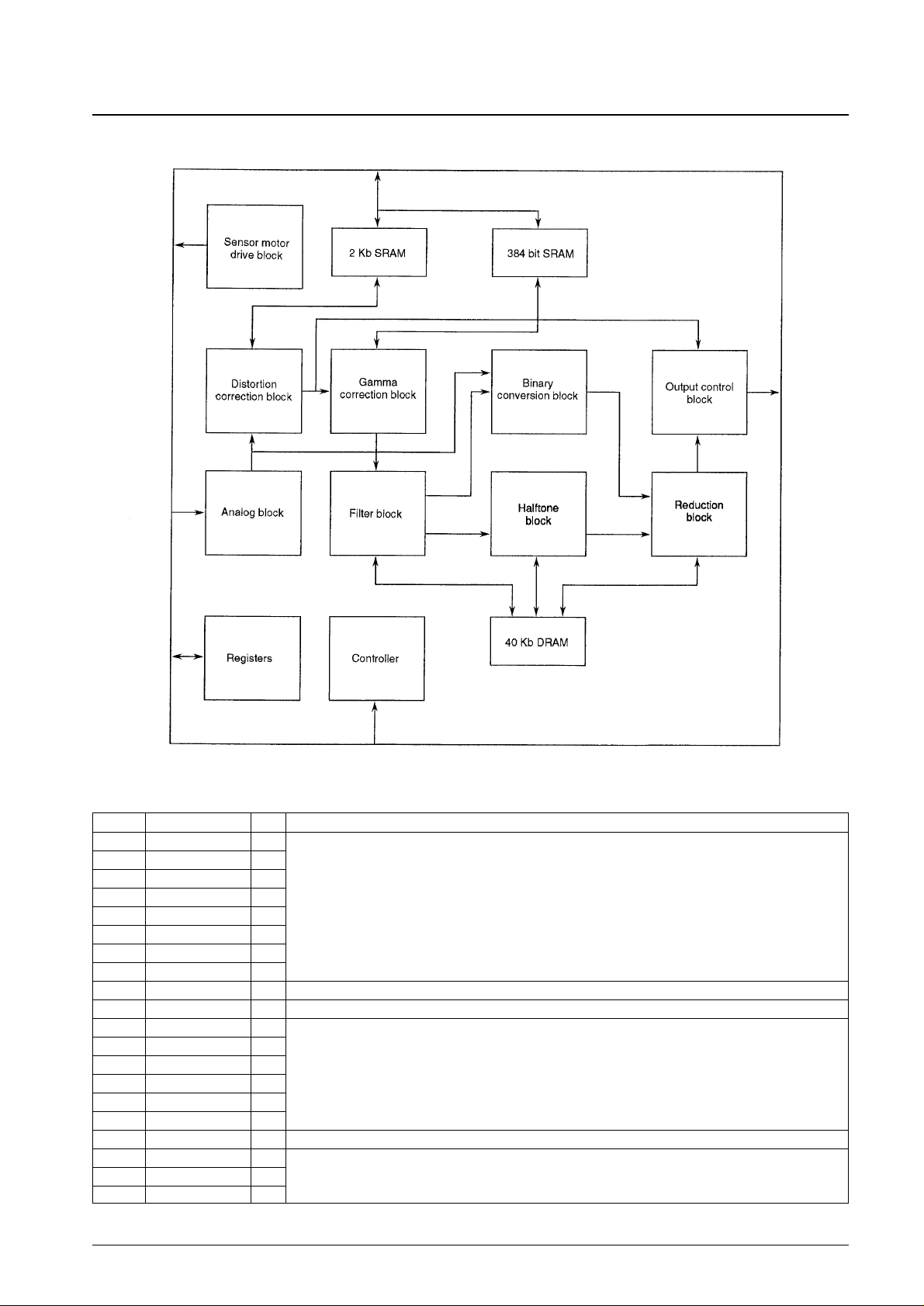

Block Diagram

Pin Functions

Type: I: Input pin, O: Output pin, B: Bidirectional pin, P: Power supply pin, NC: No connection

No. 5155-3/5

LC82102, LC82102W

Pin No. Symbol I/O Function

1 D7 B

2 D6 B

3 D5 B

4 D4 B

CPU interface data bus

5 D3 B

D7 is the MSB and D0 is the LSB.

6 D2 B

7 D1 B

8 D0 B

9 DGND P Digital system ground

10 DV

DD

P Digital system power supply

11 A8 I

12 A7 I

13 A6 I

CPU interface address bus

14 A5 I

A8 is the MSB and A0 is the LSB.

15 A4 I

16 A3 I

17 DGND P Digital system ground

18 A2 I

19 A1 I CPU interface address bus

20 A0 I

Continued on next page.

Page 4

Continued from preceding page.

Type: I: Input pin, O: Output pin, B: Bidirectional pin, P: Power supply pin, NC: No connection

No. 5155-4/5

LC82102, LC82102W

Pin No. Symbol I/O Function

21 WR I CPU interface write signal

22 RD I CPU interface read signal

23 ME I CPU interface memory enable signal

24 DV

DD

P Digital system power supply

25 CLKIN I System clock input

26 TEST I Test pin (Connect to ground in normal use.)

27 IOE I CPU interface I/O enable signal

28 MCS I CPU interface memory chip select signal

29 IOCS I CPU interface I/O chip select signal

30 ICLK I External sampling point signal input

31 TRIG I External trigger signal input

32 RESET I System reset

33 SAMP/LININT O A/D converter sampling point monitor signal output/LINE signal output

34 AP3 O

General-purpose analog ports

35 AP2 O

36 AGND P Digital system ground

37 ADREFL I A/D converter low reference voltage

38 DAREFL I D/A converter low reference voltage

39 AIN I Sensor signal input

40 TEMP I Temperature signal input

41 ATAP O Intermediate analog connection

42 DAREFH I D/A converter high reference voltage

43 AV

DD

P Analog system power supply

44 AP1 O

General-purpose analog ports

45 AP0 O

46 AGND P Analog system ground

47 PD7/SD B DMA output/serial data output

48 PD6/SDCK B DMA output/serial data transfer clock

49 DGND P Digital system ground

50 PD5/SDE B DMA output/serial data output valid signal

51 PD4/PP4 B

52 PD3/PP3 B

53 PD2/PP2 B DMA output/general-purpose I/O ports

54 PD1/PP1 B

55 PD0/PP0 B

56 DV

DD

P Digital system power supply

57 DACK/PP5 B DMA data acknowledge signal input/general-purpose I/O port

58 DREQ/PP5 B DMA data request signal output/general-purpose I/O port

59 MTP/PP7 B Motor drive timing signal output/general-purpose I/O port

60 CLK2 O

61 CLK1 O

Sensor drive signal output

62 RS O

63 SH O

64 DGND P Digital system ground

Page 5

PS No. 5155-5/5

LC82102, LC82102W

This catalog provides information as of September, 1995. Specifications and information herein are subject to

change without notice.

■ No products described or contained herein are intended for use in surgical implants, life-support systems, aerospace

equipment, nuclear power control systems, vehicles, disaster/crime-prevention equipment and the like, the failure of

which may directly or indirectly cause injury, death or property loss.

■ Anyone purchasing any products described or contained herein for an above-mentioned use shall:

➀ Accept full responsibility and indemnify and defend SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and

distributors and all their officers and employees, jointly and severally, against any and all claims and litigation and all

damages, cost and expenses associated with such use:

➁ Not impose any responsibility for any fault or negligence which may be cited in any such claim or litigation on

SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and distributors or any of their officers and employees

jointly or severally.

■ Information (including circuit diagrams and circuit parameters) herein is for example only; it is not guaranteed for

volume production. SANYO believes information herein is accurate and reliable, but no guarantees are made or implied

regarding its use or any infringements of intellectual property rights or other rights of third parties.

Sample Application

1. C1: Use a 0.01 µF laminated ceramic capacitor.

2. Set up the polarity of the image signal from the sensor so that white data is represented by the highest potential and

black data by the lowest potential. A level conversion circuit can allow the whole dynamic range of the built-in A/D

converter to be used effectively if the maximum output level of the peaks in the image signal from the sensor does

not reach 4.2 V.

3. Although AGND and DGND are completely isolated internally in this LSI, AVDDand DVDDare connected through

the substrate. Therefore, the power supply system must be designed so that no potential difference between AV

DD

and DVDDcan occur. Also, when power is applied or removed, the time lag between the power supplies must be

under 3 ms.

Loading...

Loading...