Page 1

Overview

The LC65P29 is a one-time programmable (on-chip

PROM) version of Sanyo's LC6529N/F/L 4-bit single-chip

CMOS microcontroller. It provides identical functionality

to, and pin compatibility with, the mask ROM versions of

the LC6529N/F/L, and provides a 1-KB internal PROM.

The LC65P29 is provided in DIP24S and MFP30S plastic

packages and the program can be written by the customer,

thus makes this IC appropriate for the limited-run products

and the startup of initial production of new products.

Furthermore, it can provide reduced changeover periods

when end product specifications change.

Additionally, the LC65P29 can function as a one-time

programmable PROM version of the Sanyo LC6527N/F/L

and LC6528N/F/L by using the 29T27 adapter socket.

Features

• Mask option settings can be switched by setting PROM

data.

All options, except for the port output circuit type can be

set with PROM data.

• 1-KB PROM

• PROM data security function

• Pin compatible with the mask ROM version

• Instruction cycle time: 0.92 µs to 20 µs

• Packages: DIP24S and MFP30S

Package Dimensions

unit: mm

3067-DIP24S(300mil)

unit: mm

3216-MFP30S(375mil)

Note: The package dimension figures are provide for reference purposes

without dimensional tolerances. Contact your Sanyo representative

for the official package dimension figures.

CMOS IC

61298RM (OT) No. 5894-1/14

SANYO: DIP24S(300mil)

[LC65P29]

SANYO: MFP30S(375mil)

[LC65P29]

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

One-Time Programmable 4-Bit Single-Chip

Microcontroller

LC65P29

Ordering number : EN5894

Page 2

No. 5894-2/14

LC65P29

Product Series Structure

Notes on Sanyo ROM Writing Services

Sanyo provides a for-fee ROM writing service that consists of writing the one-time programmable ROM , printing,

screening, and readout verification. Contact your Sanyo representative for details.

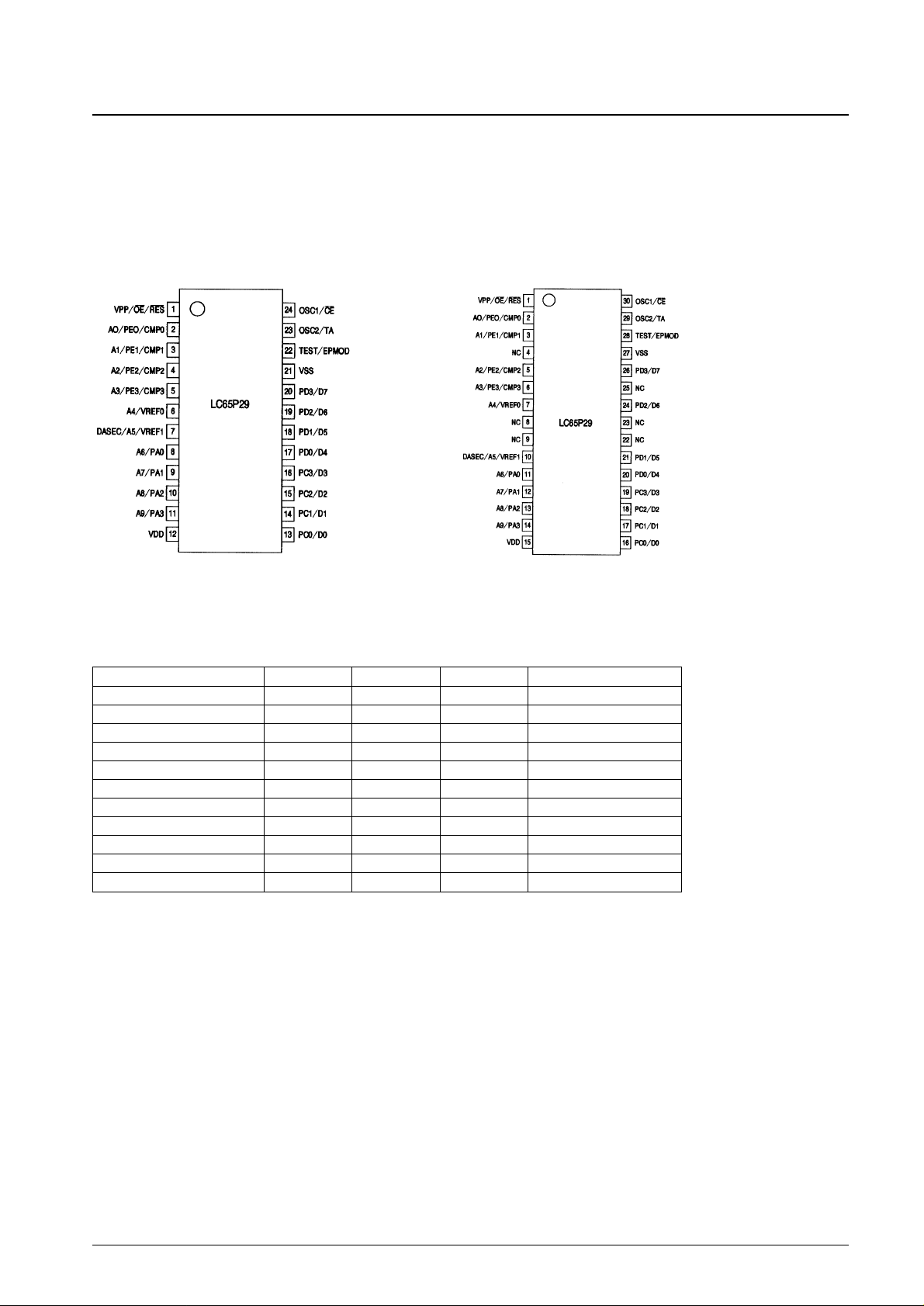

Pin Assignments

DIP24S

Type number. Number of pins ROM capacity RAM capacity Package

LC6527N/F/L, LC6528N/F/L 18 1K, 0.5K 64W, 32W DIP18, MFP18

LC6529N/F/L 24/30 1K 64W DIP24S, SSOP24, MFP30S

LC65E29 24/30 1K 64W DIC24S, MFC30S

LC65P29 24/30 1K 64W DIP24S, MFP30S

LC6543N/F/L, LC6546N/F/L 30 2K, 1K 128W, 64W DIP30S, MFP30S

LC65E43 30 2K 128W, 64W DIC30S, MFC30S

LC65P43 30 2K 128W, 64W DIP30S, MFP30S

LC651104N/F/L, LC651102N/F/L 30 4K, 2K 256W DIP30S, MFP30S

LC651204N/F/L, LC651202N/F/L 30 4K, 2K 256W DIP30S, MFP30S

LC65E1104 30 4K 256W DIC30S, MFC30S

LC65P1104 30 4K 256W DIP30S, MFP30S

MFP30S

Top view Top view

Page 3

Usage Notes

The LC65P29 is designed for program development and evaluation for systems that use the LC6529N/F/L. The following

points require attention when using this product.

• Mounting notes

Due to the nature of the device, one-time programmable microcontrollers cannot be fully tested prior to shipment. This

means that users must perform the screening process described on page 14.

• ROM ordering procedure when using the Sanyo for-fee ROM writing service

The customer must abide by the following when using the Sanyo for-fee ROM writing service:

— When ordering both one-time programmable and mask versions at the same time

The customer must provide an EPROM for the mask version, the mask version order forms, and the one-time

programmable version order forms.

— When order only the one-time programmable version

The customer must provide an EPROM for the one-time programmable version and the one-time programmable

version order forms. The end area in the EPROM (locations 400 to 404H) is the option specification area and the

customer must program the option specification data in that area. The customer must use the cross assembler

specified by Sanyo.

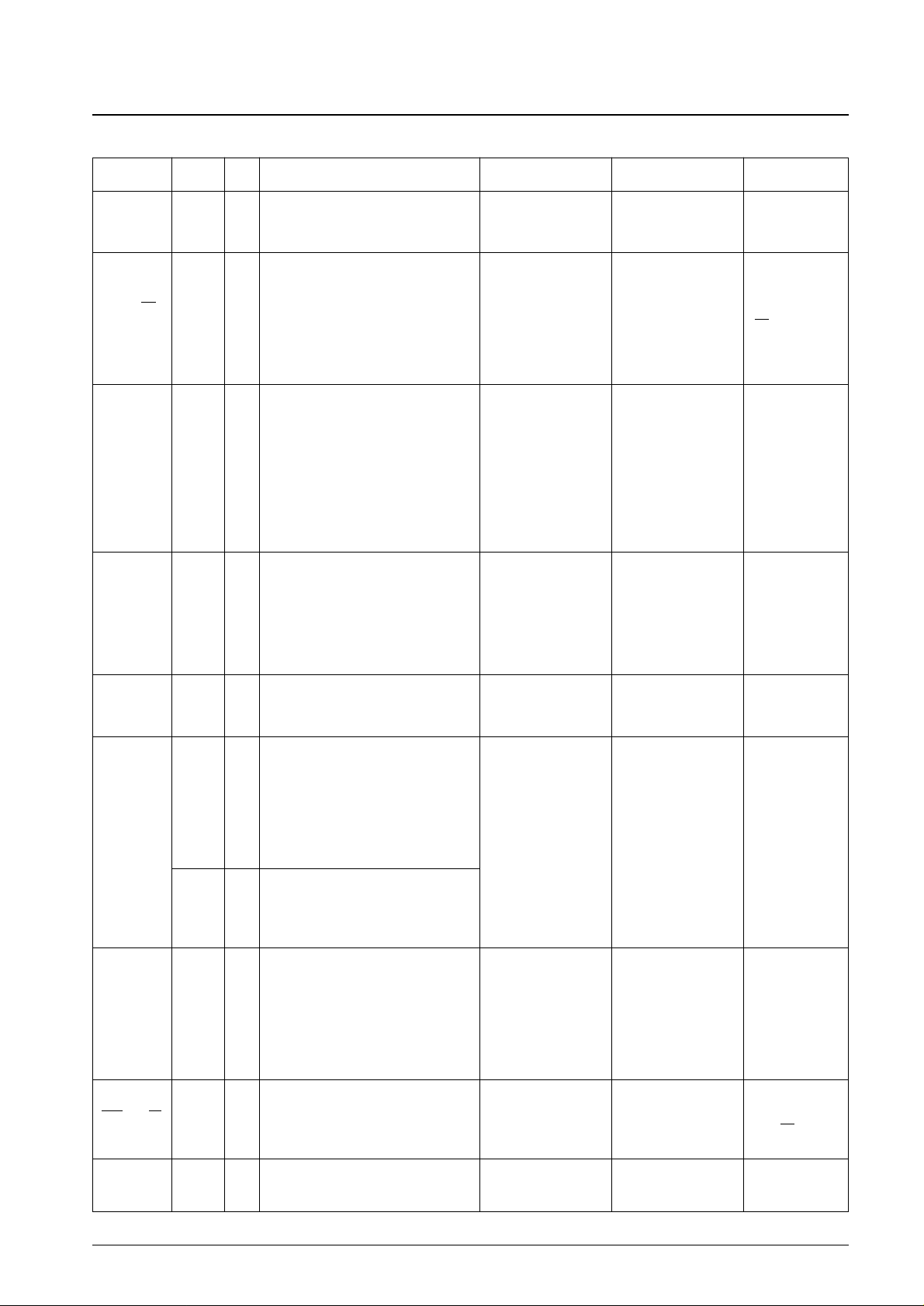

• Differences between the LC65P29 and the LC6529N/F/L

No. 5894-3/14

LC65P29

Parameter LC65P29 LC6529N LC6529F LC6529L

OptionCharacteristicOther items

Ports C and D output option

during reset

High or low can be

specified (option code)

High or low can be specified (mask option)

Port output type during reset

Open-drain output only

(ports A, C, and D)

Open-drain or pull-up register can be specified (mask option)

Oscillator circuit option

CF/RC or EXT can be

specified (option code)

CF/RC or EXT can be

specified (mask option)

CF or EXT can be

specified (mask option)

CF/RC or EXT can be

specified (mask option)

Divider circuit option

1/1, 1/3, or 1/4 can be

specified (option code)

1/1,1/3 or 1/4 can be

specified (mask option)

Only 1/1 is possible

(mask option)

1/1,1/3 or 1/4 can be

specified (mask option)

Comparator input and port E input

option

Comparator or port E can

be specified (option code)

Comparator or port E can be specified (mask option)

Comparator function option

Feedback resistor present

or absent can be specified

(option code)

Feedback resistor present or absent can be specified (mask option)

Minimum cycle time

0.92 µs (VDD≥ 3.0 V) 2.77 µs (VDD≥ 3.0 V) 0.92 µs (VDD≥ 3.0 V) 3.84 µs (VDD≥ 2.2 V)

Operating temperature –30 to +70°C –40 to +85°C

Supply voltage 3.0 to 6.0 V 3.0 to 6.0 V 3.0 to 6.0 V 2.2 to 6.0 V

Current drain 5.0 mA typ. 2.0 mA typ. 2.5 mA typ. 2.0 mA typ.

Reset port input low-level current –50 µA typ. –10 µA typ.

Package DIP24S, MFP30S DIP24S, SSOP24, MFP30S

Page 4

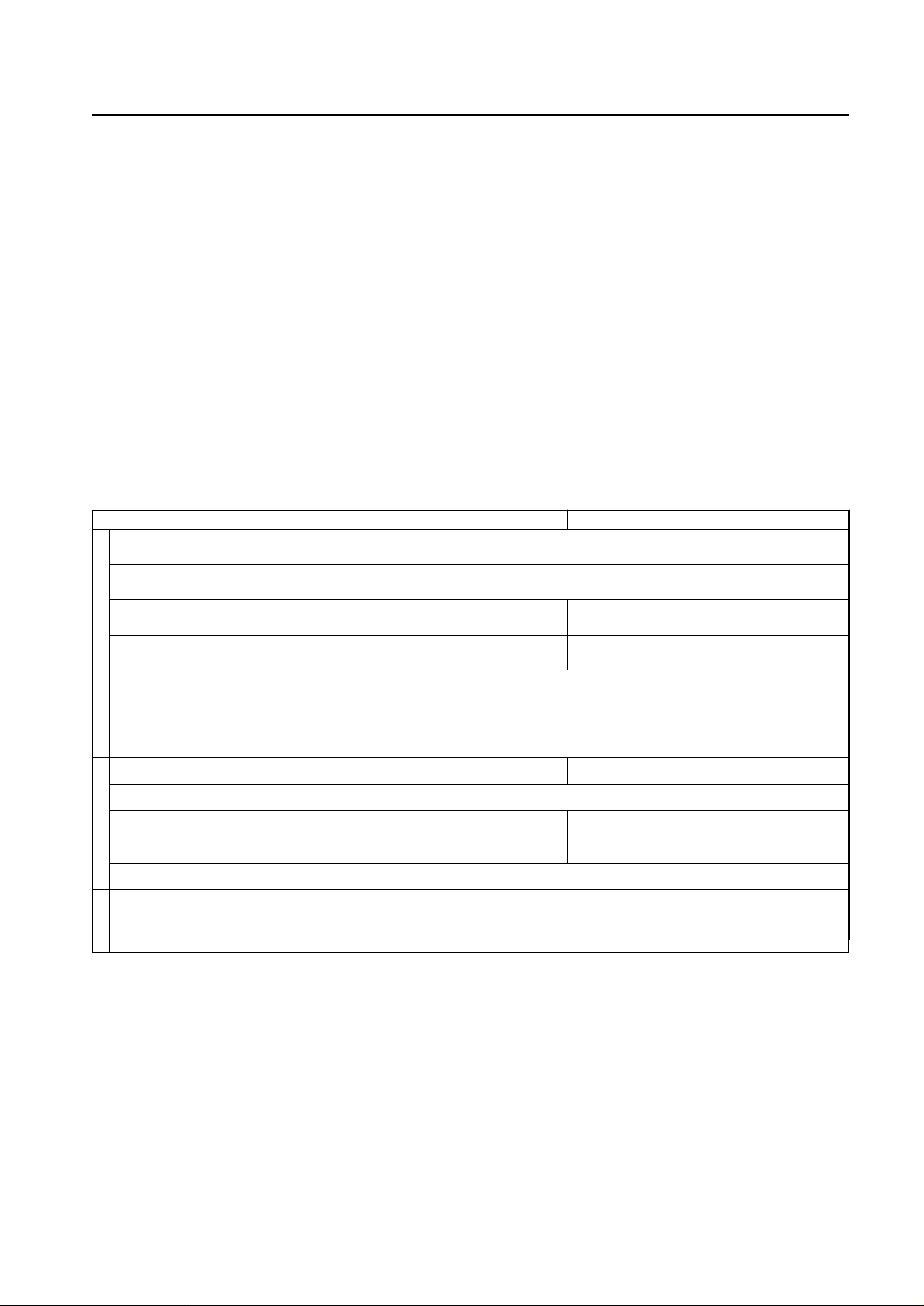

System Block Diagram

No. 5894-4/14

LC65P29

RAM:Data memory

ALU: Arithmetic and logic unit

DP: Data pointer

E: E register

AC: Accumulator

OSC: Oscillator circuit

TM: Timer

STS: Status register

EPROM: Program memory

PC: Program counter

I.R: Instruction register

I.DEC: Instruction decoder

CF: Carry flag

ZF: Zero flag

TMF: Timer overflow flag

to

toto

to

to

A0 to A9

D0 to D7

Page 5

No. 5894-5/14

LC65P29

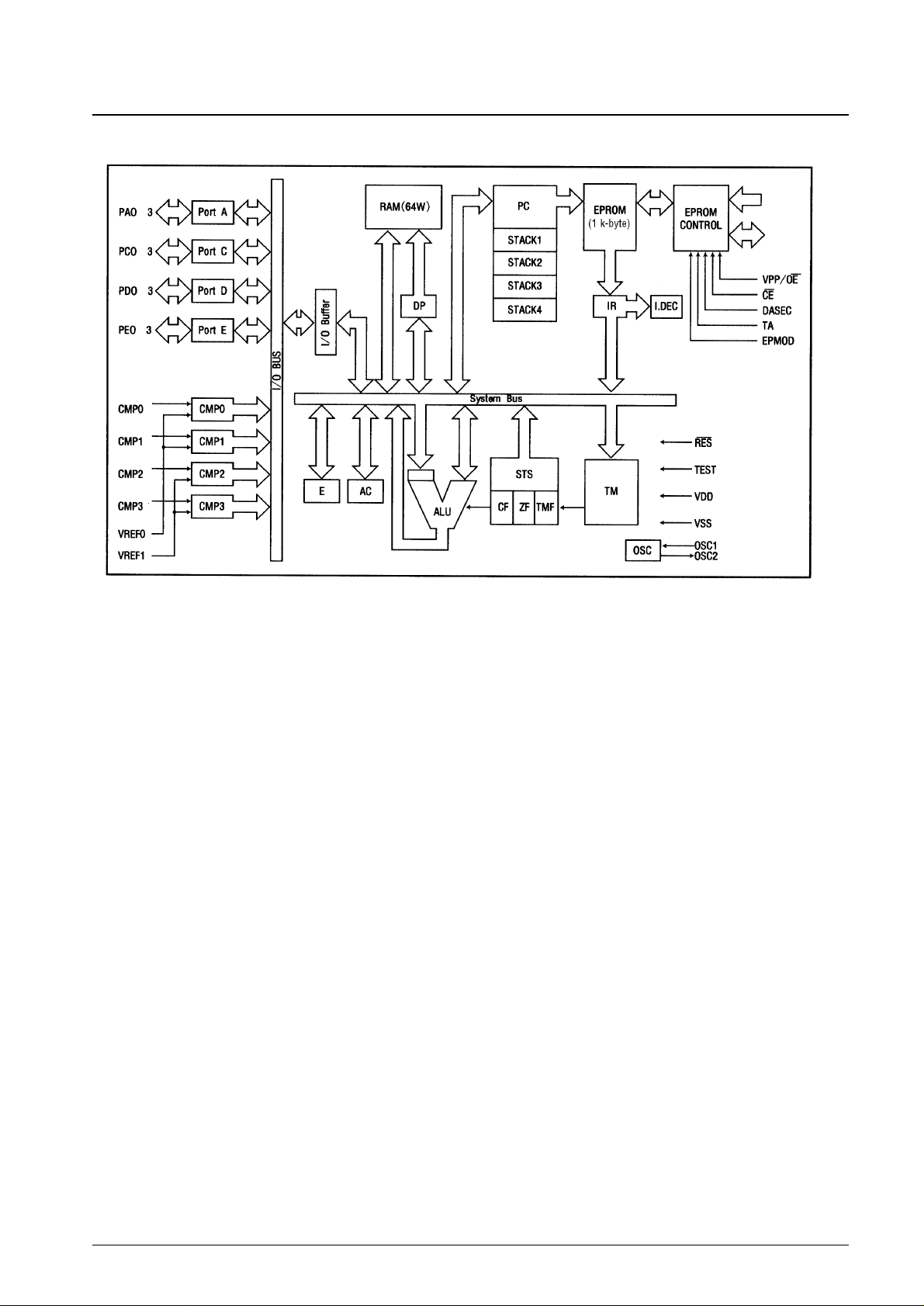

Pin Descriptions

Pin name

Number

I/O Function Option State during reset

Function in

of pins PROM mode

Power supply. Must be connected to +5 V

during normal operation.

Power supply. Must be connected to 0 V

during normal operation.

—

—

V

DD

V

SS

1

1

—

—

System clock oscillator connections. Leave

OSC2 open and input the external clock to

OSC1 if an external clock is used.

1.Two-pin RC oscillator

(Single-pin external

clock input)

2.Two-pin ceramic

oscillator

3.Divisor option: 1/1, 1/3,

or 1/4

EPROM contorol

signal inputs

CE

TA

OSC1/CE

OSC2/TA

1

I

O

• I/O ports A0 to A3

Input in 4-bit units (IP instruction)

Output in 4-bit units (OP instruction)

Data testing in 1-bit units (BP and BNP

instructions)

Data set and clear operations in 1-bit units

(SPB and RPB instructions)

• PA3 is used for standby mode control.

• Applications must assure that chattering

(key bounce) noise is not input during a

HALT instruction execution cycle.

Open-drain output

• High-level output (The

n-channel output

transistor turned off.)

• Address inputs

A6 to A9

PA0/A6

PA1/A7

PA2/A8

PA3/A9

4 I/O

• I/O ports C0 to C3

The pin functions are identical to those of

pins A0 to A3.

However, there is no standby mode

control function.

• The output during a reset can be specified

to be either high or low as an option.

1. Open-drain output

2. High-level output

during reset

3. Low-level output

during reset

• Selection of items 2 or

3 is in 4-bit units.

• High-level output

• Low-level output

(Depending on an

option selection.)

• Data I/O

D0 to D3

PC0/D0

PC1/D1

PC2/D2

PC3/D3

4 I/O

• I/O ports D0 to D3

The pin functions are identical to those of

pins PC0 to PC3.

The same as for pins

PC0 to PC3

The same as pins PC0 to

PC3

• Data I/O

D4 to D7

PD0/D4

PD1/D5

PD2/D6

PD3/D7

4 I/O

• When comparator input is selected:

CMP0 and CMP1 use V

REF

0 as the

reference voltage,

CMP2 and CMP3 use V

REF

1 as the

reference voltage,

• Comparator inputs CMP0 to CMP3

Data input in 4-bit units (IP instruction)

• Data testing in 1-bit units (BP and BNP

instructions)

1. Comparator input

2. Port E input

3. No feedback resistor

4. Feedback resistor

present

• Selection of items 1 or

2 is in 4-bit units.

• Items 3 and 4 are only

specified when item 1

is selected.

• Address inputs

A0 to A3

PE0/CMP0/A0

PE1/CMP1/A1

PE2/CMP2/A2

PE3/CMP3/A3

4 I

• Comparator reference voltage inputs

V

REF

0 and V

REF

1

V

REF

0 is the reference voltage input for

CMP0 and CMP1.

V

REF

1 is the reference voltage input for

CMP2 and CMP3.

• When PE0/CMP0 to PE3/CMP3 are

selected to function as port E inputs,

these pins are connected to V

SS

.

• Address inputs

A4 and A5

• EPROM control

signal input

DASEC

V

REF

0/A4

V

REF

1/A5/

DASEC

2 I

• System reset input

• Connect an external capacitor to effect the

power-on reset.

• Input a low level for at least 4 clock cycles

to effect a reset restart.

• EPROM control

signal input

V

PP

/ OE

RES/V

PP

/OE

1 I

• IC test pin

This pin must be connected to V

SS

during

normal operation.

• EPROM control

signal input

EPMOD

TEST/EPMOD 1 I

• When input is selected for port E

• Input ports E0 to E3

Input in 4-bit units (IP instruction)

• Data testing in 1-bit units (BP and BNP

instructions)

4 I

Page 6

User Options

• Ports C and D output level during reset option

One of the following two options for the output level during a reset can be selected for each of the ports C and D in

4-bit units.

• Port output circuit type option

The I/O ports A, C, and D are always set up as open-drain outputs.

No. 5894-6/14

LC65P29

Option Conditions and notes

High-level output at reset Ports C and D in 4-bit units

Low-level output at reset Ports C and D in 4-bit units

Option Circuit

Open-drain output (OD)

• Oscillator circuit options

Option Circuit Conditions and notes

The OSC2 pin must be left open.External clock

Two-pin RC oscillator

Two-pin ceramic oscillator

• Divisor option

Option Circuit Conditions and notes

Can be used with any of the 3 oscillator options. (N, F,

and L versions)

Can only be used with the external clock and ceramic

oscillator options. (N and L versions)

Can only be used with the external clock and ceramic

oscillator options. (N and L versions)

No divisor (1/1)

Divide-by-3 circuit (1/3)

Divide-by-4 circuit (1/4)

Page 7

• Comparator input/port E input option

Whether the 4 port pins PE0/CMP0, PE1/CMP1, PE2/CMP2, and PE3/CMP3 function as comparator inputs or as port

E inputs can be selected.

No. 5894-7/14

LC65P29

Option Conditions and notes

Comparator inputs All 4 bits specified together

Port E inputs All 4 bits specified together

• Comparator function option

One of two options relating to the comparator function can be selected.

Usage Procedures

• Option specification procedures

User options can be selected interactively by running the LC6529 option entry software (SU60K). This creates an

option file (file.opt).

Assembling the user program with the macro assembler (M60K) creates an object file. An evaluation file (file.eva) can

be created by linking the object file and the option file with the linker (L60K). Then, a HEX format object file, which

includes both the user program and the mask options, can be created by converting the evaluation file with the file

conversion software (E2H60K). This creates the option codes in the option specification area (locations 400 to 404H).

It is also possible to store data directly to the option specification area. Refer to the option code creation table on page 9

to do this.

Refer to the “LC65/66K Software Manual” for details.

• EPROM programming procedure

A general-purpose EPROM programmer can be used to write the created data to the LC65P29 by using a specialpurpose write conversion board (either the W65EP29D or the W65EP29M).

— The EPROM programmers listed below can be used.

— The “27512 (VPP: 12.5 V) Intel fast write” method must be used for writing. Specify locations 0 to 404 as the

address settings, and make sure that the DASEC jumper is in the off position.

• Using the data security function

The data security function is a function that prevents data written previously to the microcontroller EPROM from being

read out. Use the following procedure to apply the data security to the LC65P29.

1. Set the DASEC jumper on the write conversion board to the on position.

2. Write the data once again.

At this point, the EPROM writer will indicate an error since this function has operated, but actually, no error has

occurred in either the programmer or the IC.

Notes: • The data security function will not be applied if the data value FF is written to all address in step 2.

• The data security function will not be applied if the sequence BLANK → PROGRAM → VERIFY is performed

at step 2.

• Always return the jumper to the off position after performing this procedure.

Option Circuit Conditions and notes

The comparator can be used without hysteresis.

When used with an added external resistor, the

comparator can be used with hysteresis.

No feedback resistor

Feedback resistor present

Manufacturer Models that can be used

ADVANTEST R4945, R4944A, R4943 or equivalent

ANDO —

AVAL —

MINATO Electronics —

Page 8

LC65P29 (DIP24S)

Pin 1

Insert the LC65P29 into the socket correctly

No. 5894-8/14

LC65P29

LC65P29 (MFP30S)

Pin 1

W65EP29D

Pin 1

DASEC setting

• For normal writing • For writing with the security function applied

SW DASEC SW DASEC

W65EP29M

Pin 1

Page 9

• Option data area and definition

Bits specified to be 0 must be set to 0.

00 ... Illegal value

01 ... Illegal value

10 ... Two-pin RC oscillator, 1-pin external drive

(2PORT RC OSC, 1PORT EXT)

11 ... Two-pin ceramic oscillator

(2PORT CF OSC)

Oscillator divider specification

Oscillator type specification

00 1/1 (direct)

01 1/3

10 1/4

11 ... Illegal value

Port C output level at initial reset

0 Low-level output

1 High-level output

Port D output level at initial reset

0 Low-level output

1 High-level output

Comparator function specification

0 No feedback resistor

1 Feedback resistor present

Port input function specification

0 Comparator input

1 Port E input

Port C output type specification

0 Open-drain output

1 Pull-up resistor output

Port A output type specification

Port C output type specification

These bits must be set to 0.

Note: Although all ports are set up to be open-drain outputs regardless of the port option data in the LC65P29, be sure to specify the port option data if you

are using the LC6529N/F/L (mask ROM version).

0 Open-drain output

1 Pull-up resistor output

These bits must be set to 0.

0 Open-drain output

1 Pull-up resistor output

These bits must be set to 0.

Port D output type specification

0 Open-drain output

1 Pull-up resistor output

No. 5894-9/14

LC65P29

Page 10

No. 5894-10/14

LC65P29

Parameter Symbol

Applicable

Conditions

Ratings

Unit

pins/notes min typ max

Maximum supply voltage V

DD

max V

DD

–0.3 +7.0 V

Output voltage V

O

OSC2 Values up to the generated voltage

are allowed. V

VI1 OSC1*

1

–0.3 VDD+ 0.3 V

Input voltage

V

I

2 TEST, RES –0.3 VDD+ 0.3 V

V

I

3

Ports with

–0.3 VDD+ 0.3 V

PE specifications

I/O voltage V

IO

PA, PC, PD –0.3 +15 mA

Peak output current I

OP

PA, PC, PD –2 +20 mA

I

OA

PA, PC, PD The 100 ms average per pin –2 +20 mA

Average output current

Σ I

OA

1 PA The total current for pins PA0 to PA3*

2

–6 +40 mA

Σ I

OA

2 PC, PD

The total current for pins PC0 to PC3 and

–14 +90 mA

PD0 to PD3*

3

Allowable power dissipation

Pdmax1 Ta = –30 to +70°C(DIP24S) 360 mW

Pdmax2 Ta = –30 to +70°C(MFP30S) 150 mW

Operating temperature Topr –30 +70 °C

Storage temperature Tstg –55 +125 °C

Absolute Maximum Ratings at Ta = 25°C, V

SS

= 0 V

Parameter Symbol

Applicable

Conditions

Ratings

Unit

pins/notes V

DD

[V] min typ max

Operating supply voltage V

DDVDD

3.0 6.0 V

Standby supply voltage V

ST

V

DD

RAM and register retention * 1.8 6.0 V

V

IH

1 PA, PC, PD Output n-channel transistor off 0.7 V

DD

13.5 V

V

IH

2 PE

When the port E input option

0.7 V

DD

V

DD

V

High-level input voltage

is selected

V

IH

3 RES 1.8 to6.0 0.8 V

DD

V

DD

V

V

IH

4 OSC1

When the RC oscillator and

0.8 V

DD

V

DD

V

external clock option is selected

VIL1 PA, PC, PD Output n-channel transistor off V

SS

0.3 V

DD

V

V

IL

2 PE

When the port E input option

V

SS

0.3 V

DD

V

is selected

Low-level input voltage

V

IL

3 OSC1

When the RC oscillator and

V

SS

0.25 V

DD

V

external clock option is selected

VIL4 TEST V

SS

0.3 V

DD

V

V

IL

5 RES V

SS

0.25 V

DD

V

Operating frequency (cycle time)

fop(t

CYC

) 200 (20)

4330 (0.92)

kHz (µs)

Frequency fext(text) OSC1 See Figure 1 200 (20)

4330 (0.92)

kHz (µs)

Pulse width

textH, textL

OSC1 See Figure 1 69 ns

Rise and fall times

textR, textF

OSC1 See Figure 1 50 ns

Cext OSC1, OSC2 See Figure 2 4 to 6 220 ±5% pF

Two-pin RC oscillator

Cext OSC1, OSC2 See Figure 2 220 ±5% pF

Rext OSC1, OSC2 See Figure 2 4 to 6 6.8 ±1% kΩ

Rext OSC1, OSC2 See Figure 2 15.0 ±1% kΩ

Ceramic oscillator See Figure 2 See Table 1

Allowable Operating Conditions at Ta = –30 to +70°C, VSS= 0 V, VDD= 3.0 to 6.0 V

Notes: 1. Values up to the generated oscillator amplitude are allowed when driven internally using the guaranteed circuit constant values with the oscillator

circuit shown in figure 2.

2. The average over a 100 ms period.

Note *: Applications must maintain the operating supply voltage (V

DD

) until the IC has entered the standby state when a HALT instruction is executed.

Also, applications must assure that chattering (key bounce) noise is not input to the PA3 pin during a HALT instruction execution cycle.

External clock

conditions

Guaranteed oscillator

circuit constants

Page 11

No. 5894-11/14

LC65P29

Parameter Symbol

Applicable

Conditions

Ratings

Unit

pins/notes V

DD

[V] min typ max

Output n-channel transistor off

I

IH

1 PA, PC, PD

(Includes the n-channel

5.0 µA

transistor off leakage current)

V

IN

= 13.5 V

High-level input current

I

IH

2 PE

When the port E input option

5.0 µA

is selected V

IN

= V

DD

When the RC oscillator and

IIH3 OSC1

external clock option is selected

1.0 µA

V

IN

= V

DD

Output n-channel transistor off

IIL1 PA, PC, PD

(Includes the n-channel

–1.0 µA

transistor off leakage current)

V

IN

= V

SS

Low-level input current

I

IL

2 PE

When the port E input option –1.0 µA

is selected V

IN

= V

SS

IIL3 RES VIN= V

SS

–80 –50 µA

When the RC oscillator and

IIL4 OSC1

external clock option is selected

–1.0 µA

V

IN

= V

SS

VOL1 PA, PC, PD IOL= 10 mA 1.5 V

Low-level output voltage VOL2 PA, PC, PD

I

OL

= 1.8 mA

0.4 V(When all port I/O levels are

Under 1 mA)

Hysteresis voltage

V

HIS

1 RES 0.1 V

DD

V

V

IHS

2 OSC1*

1

When the RC oscillator and

0.1 V

DD

V

external clock option is selected

RC oscillator

ID

DOP

1 V

DD

Figure 2. 850 kHz (TYP) 5 8 mA

ID

DOP

2 V

DD

Figure 2. 400 kHz (TYP) 4.5 7 mA

ID

DOP

3 V

DD

Figure 3. 4 MHz, 1/1, 1/3, and

5 8 mA

1/4 divisor ratios

ID

DOP

4 V

DD

Figure 3. 2 MHz, 1/1, 1/3, and

4.5 7 mA

Ceramic oscillator*

2

1/4 divisor ratios

ID

DOP

5 V

DD

Figure 3. 800 kHz, 1/1 divisor

5 8 mA

ratio

ID

DOP

6 V

DD

Figure 3. 400 kHz, 1/1 divisor

4.5 7 mA

ratio

External clock*

2

ID

DOP

7 V

DD

200 to 4330 kHz, 1/1, 1/3, and 5 8 mA

1/4 divisor ratios

IDDst1 V

DD

Output n-channel transistor off

6 0.05 10 µA

Standby mode

Port = V

DD

IDDst2 V

DD

Output n-channel transistor off

3 0.025 5 µA

Port = V

DD

OSC1, OSC2

Figure 2. Cext = 220 pF ±5%

275 400 711 kHz

Oscillator frequency fMOSC

Rext = 15.0 kΩ ±1%

OSC1, OSC2

Figure 2. Cext = 220 pF ±5%

4 to 6 579 850 1179 kHz

Rext = 6.8 kΩ ±1%

OSC1, OSC2 Figure 3. fo = 4 MHz 3840 4000 4160 kHz

Oscillator frequency fFOSC*

3

OSC1, OSC2 Figure 3. fo = 2 MHz 1920 2000 2080 kHz

OSC1, OSC2 Figure 3. fo = 800 kHz 768 800 832 kHz

OSC1, OSC2 Figure 3. fo = 400 kHz 384 400 416 kHz

Figure 4. fo = 4 MHz 10 ms

Oscillator stabilization time tCFS

Figure 4. fo = 2 MHz

fo = 800 kHz 10 ms

fo = 400 kHz

Pull-up resistor reset port Ru V

IN

= V

SS

5 70 100 150 kΩ

External reset characteristics:

tRST

See Figure 6.

ms

reset time

f = 1 MHz

Pin capacitance Cp V

IN

= VSSfor all input pins 10 pF

other than the measured pin

Electrical Characteristics at Ta = –30 to +70°C, VSS= 0 V, VDD= 3.0 to 6.0 V

Current drainOscillator characteristics

RC oscillator

Ceramic oscillator

Notes: 1. The OSC1 pin has Schmitt characteristics when the RC oscillator and external clock input oscillator option is selected.

2. The current drain during normal operation with the output n-channel transistors off and the port at V

DD

.

3. fCFOSC indicates frequencies at which oscillator operation is possible.

Page 12

No. 5894-12/14

LC65P29

Parameter Symbol

Applicable

Conditions

Ratings

Unit

pins/notes V

DD

[V] min typ max

Reference input voltage range VRF

INVREF

0, 1 VSS+ 0.3 VDD– 1.7 V

Common-mode input voltage range VCM

IN

CMP0 to 3 V

SS

VDD– 1.7 V

Offset voltage V

OFF

VCMIN = VSSto VDD– 1.7 V ±50 ±300 mV

Response speed

TRS1 See Figure 5. 4 to 6 1.0 5.0 µs

TRS2 See Figure 5. 1.0 200 µs

I

IH

1 V

REF

0, 1 1.0 µA

High-level input current

I

IH

2 CMP0 to 3

When the feedback resistor

5.0 µA

option is not selected

I

IL

1 V

REF

0, 1 –1.0 µA

Low-level input current

I

IL

2 CMP0 to 3

When the feedback resistor

–1.0 µA

option is not selected

Feedback resistance RCMFB CMP0 to 3

When the feedback resistor

460 kΩ

option is selected

Comparator characteristics (When the comparator input option is selected)

at Ta = –30 to +70°C, VSS= 0 V, VDD= 3.0 to 6.0 V

Table 1 Guaranteed Ceramic Oscillator Circuit Constants

Figure 1 External Clock Input Waveform

Standard type Chip type

Oscillator type

Manufacturer

Oscillator

C1 C2 Rd Manufacturer

Oscillator

C1 C2

element element

4 MHz

Murata Mfg. Co., Ltd.

CSA4.00MG 33 pF ±10% 33 pF ±10% —

Murata Mfg. Co., Ltd.

CSAC4.00MGC 33 pF ±10% 33 pF ±10%

Kyocera Corporation

KBR-4.0MSA 33 pF ±10% 33 pF ±10% — — — — —

2 MHz

Murata Mfg. Co., Ltd.

CSA2.00MG 33 pF ±10% 33 pF ±10% —

Murata Mfg. Co., Ltd.

CSAC2.00MGC 33 pF ±10% 33 pF ±10%

Kyocera Corporation

KBR-2.0MS 47 pF ±10% 47 pF ±10% — — — — —

800 kHz

Murata Mfg. Co., Ltd.

CSB800J 100 pF ±10% 100 pF ±10% 3.3 KΩ — — — —

Kyocera Corporation

KBR-800F/Y 150 pF ±10% 150 pF ±10% — — — — —

400 kHz

Murata Mfg. Co., Ltd.

CSB400P 220 pF ±10% 220 pF ±10% 3.3 KΩ — — — —

Kyocera Corporation KBR-400BK/Y

330 pF ±10% 330 pF ±10% — — — — —

4 MHz

Murata Mfg. Co., Ltd.

CST4.00MGW

— — — — — — —

Kyocera Corporation

KBR-4.0MKS — — —

Kyocera Corporation

KBR-4.0MWS — —

2 MHz

Murata Mfg. Co., Ltd.

CST2.00MG

— — — — — — —

— — — — —

Kyocera Corporation

KBR-2.0MWS — —

External capacitor type

Internal capacitor type

Page 13

No. 5894-13/14

LC65P29

Figure 2 Two-Pin RC Oscillator Circuit Figure 3 Ceramic Oscillator Circuit

Figure 4 Oscillator Stabilization Time

Figure 5 Comparator Response Speed TRS Timing

Note: The reset period due to a CRES with a value of 0.68 µF will be 10 to 100 ms

when the power supply rise time is zero.

If the power supply rise time is relatively long, increase the value of CRES

so that the reset time is at least 10 ms, which is the oscillator stabilization

time.

Figure 6 Reset Circuit

Page 14

PS No. 5894-14/14

LC65P29

Notes on Mounting Preconditions for One-Time Programmable Microcontrollers

This product is provided in both DIP and MFP packages. Since the mounting preconditions are different for these two

package types, implement the flowchart appropriate for the product used.

See the following item for details on the screening conditions.

Notes on One-Time Programmable Microcontroller Screening

Due to the structure of their circuits, it is not possible for Sanyo to fully test one-time programmable microcontroller

products before the PROM has been written. To increase the reliability after the PROM has been written, we strongly

recommend screening these products after writing according to the following flowchart.

This catalog provides information as of June, 1998. Specifications and information herein are subject to change

without notice.

■ No products described or contained herein are intended for use in surgical implants, life-support systems, aerospace

equipment, nuclear power control systems, vehicles, disaster/crime-prevention equipment and the like, the failure of

which may directly or indirectly cause injury, death or property loss.

■ Anyone purchasing any products described or contained herein for an above-mentioned use shall:

➀ Accept full responsibility and indemnify and defend SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and

distributors and all their officers and employees, jointly and severally, against any and all claims and litigation and all

damages, cost and expenses associated with such use:

➁ Not impose any responsibility for any fault or negligence which may be cited in any such claim or litigation on

SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and distributors or any of their officers and employees

jointly or severally.

■ Information (including circuit diagrams and circuit parameters) herein is for example only; it is not guaranteed for

volume production. SANYO believes information herein is accurate and reliable, but no guarantees are made or implied

regarding its use or any infringements of intellectual property rights or other rights of third parties.

Due to the structure of the one-time programmable microcontroller PROM circuit in the state before writing, it is not

possible to write test all the bits in the device. This means that it is impossible to guarantee a yield of 100%.

Recommended Screening Flowchart

High-temperature bake

with no power applied

+1

150 ±5°C, 24 Hr

–0

Program readout

verification

V

DD

= 5 V ±0.5 V

DIP product

Program write and verify

Screening

Mounting

MFP product

Program write and verify

Screening

Mounting

Loading...

Loading...