Page 1

DMOS DUAL FULL BRIDGEDRIVER

2 INDEPENDENTLYCONTROLLED

H-BRIDGES

DS,ON

R

<0.9Ω @T

0.8ADC CURRENTWITHOUT HEATSINK

LOW QUIESCENTMODEI

THEMALPROTECTION

CROSSCONDUCTIONPROTECTION

SUPPLYVOLTAGEUP TO 40V

CMOSCOMPATIBLEINPUTS

OUTPUTSHORT-CIRCUIT PROTECTION

amb

=25°C,VS= 14V

q <200µA

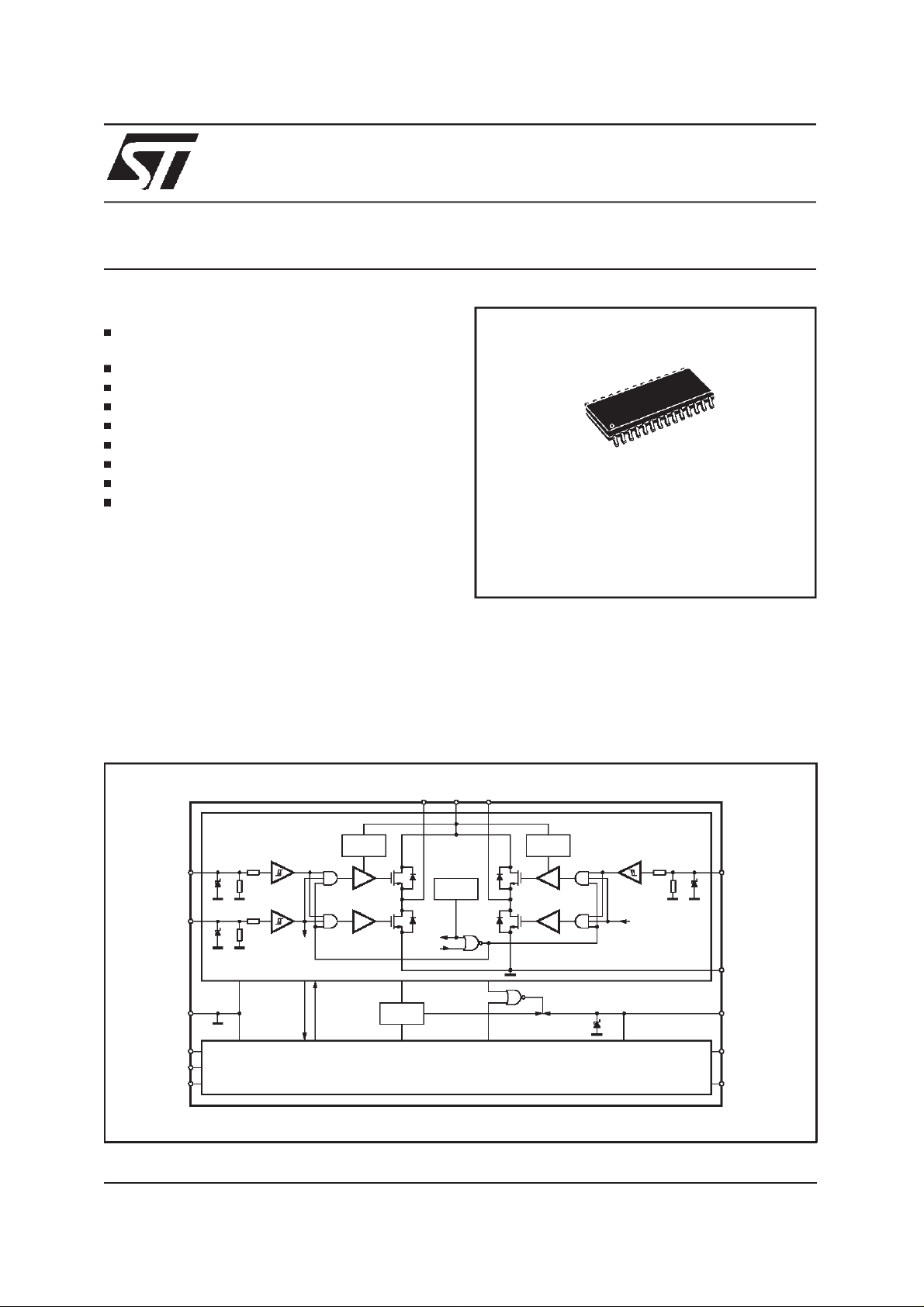

L9925

SO28

DESCRIPTION

The L9925 is a dual full bridge driver for stepper

motor applications. Realized in BCD (Bipolar,

CMOS & DOS) techology, logic circuits, precise

linear blocks and power transistors are combined

to optimize circuit performance and minimize off

chip components.Schmitttriggers are used for all

input stages and are fully compatible with 5V

CMOS logic levels. When both enable signalsare

low, the IC is commanded to a low quiescentcurrent state and will draw less than 200µA from the

battery.

BLOCK DIAGRAM

OUT1 VS1 OUT2

CHARGE

PUMP

IN1

EN1

7V T1

1st FULLBRIDGE

EN1

T1T2T2

ORDERING NUMBER: L9925

The charge pump is integrated on chip; no external componentsare required. Full performanceis

maintaned for 9V <V

6V <<V

S <9V and 16V <VS <40V yields full func-

S <16V. Extended ranges of

tionally but with relaxed performance. Over temperature protectionand ESD protectionto all pins

ensures relability and reduces system integration

failures.

CHARGE

PUMP

IN2

TEMP

EN1

EN1

7V7V

PGND1

GND

EN2

IN3

IN4

2nd FULLBRIDGE

T1 T2

5V

REGULATOR

40V

EN2

D99AT423

VS2

OUT3

OUT4

March 1999

...............................................................................................................................................................................................................

1/9

Page 2

L9925

ABSOLUTEMAXIMUMRATINGS

Absolute Maximum Ratings are those values beyond whih damage to the device may occur. Functional

operation underthese conditionisn’t implied.

For voltages andcurrents applied externallyto the device:

Symbol Parameter Value Unit

V

VSDC Dc Supply Voltage -0.3 to 26 V

V

VSP Supply Voltage Pulse (T ≤400ms)

I

OUT

I

OUT MAX

DC Output Load Current

DC Output Current:for VOUT > VVS +0.3V or VOUT < -0.3V

the internal DMOS reverse and/or substrate diode become

conductive and the applied current should not exceedthe

specified limit.

V

IN1,2

V

T

stg,Tj

P

EN

tot

DC Input Voltage -0.3 to 7 V

Enable Input Voltage -0.3 to 7 V

Storage and Junction Temperature -40 to 150 °C

Total Power Dissipation (T

(T

(T

(1) Device may be overstressed if pulsed simultaneous with short circuit at one or more of the outputs willbe present.

(1)

=80°C)

pins

=70°C no copper area on PCB)

amb

amb =70°C 8cm

2

copperareaon PCB)

40 V

1.2 A

±

1.8 A

±

5

1.23

2

W

W

W

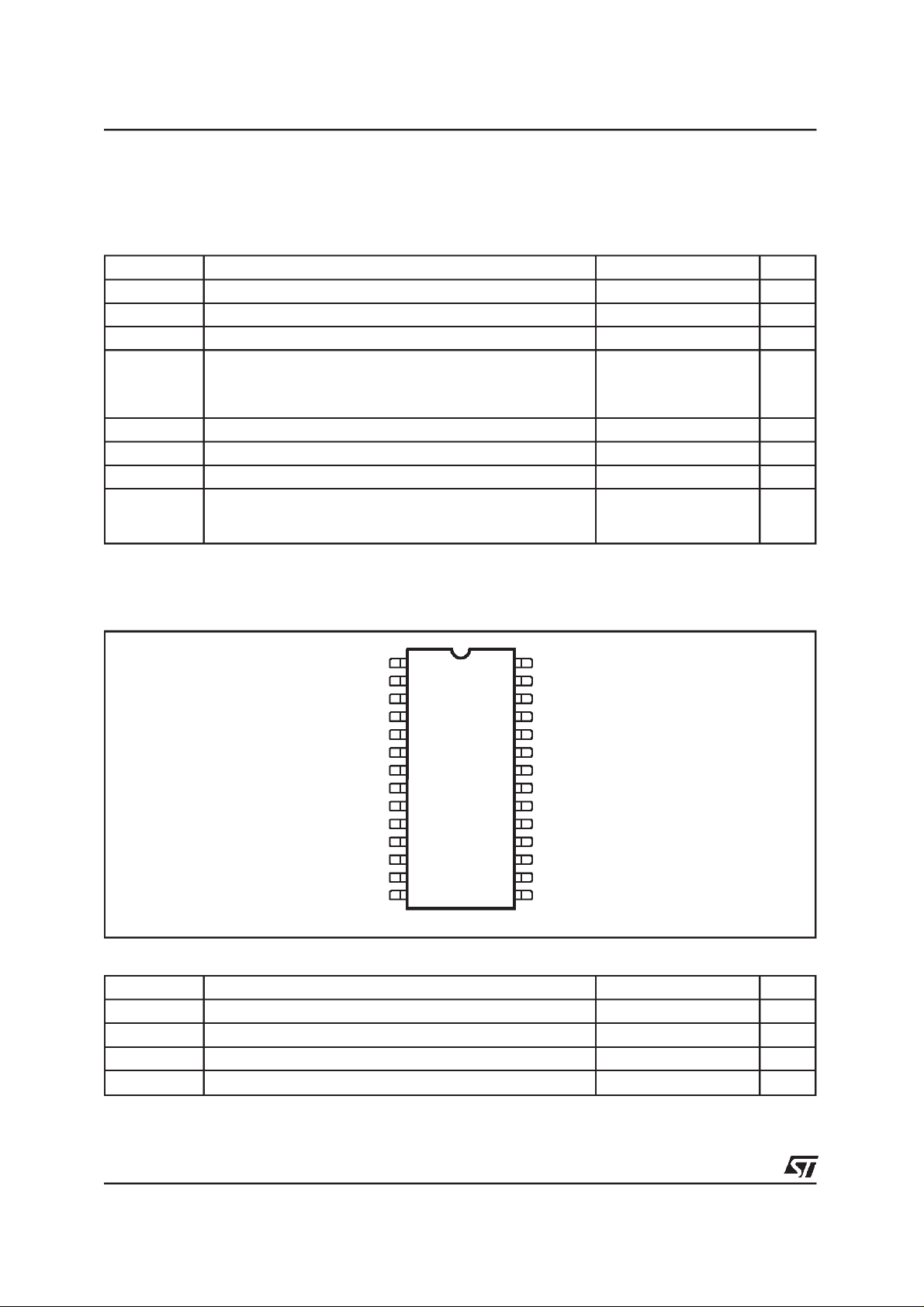

PIN CONNECTION

PGND

IN1

EN1

N.C.

N.C.

OUT1

GND

GND

OUT3 VS2

N.C. N.C.

N.C.

EN2

IN3 IN4

2

3

4

5

6

7

8

9

10

12

13

D88AT424

28

27

26

25

24

23

22

21

20

19

18

17

16

1514PGND N.C.

N.C.1

IN2

OUT2

N.C.

N.C.

VS1

GND

GND

N.C.11

OUT4

THERMAL DATA

Symbol Parameter Value Unit

T

jTS

T

jTSH

R

th j-amb

R

th j-pins

(2)

With 6cm2on board heat sink area

Thermal Shut-downjunction temperature min. 150 °C

Thermal Shut-downthereshold hysteresis typ. 25 °C

Thermal Resistance Junction-ambient

(2)

50 °C/W

Thermal Resistance Junction-pins 15 °C/W

2/9

Page 3

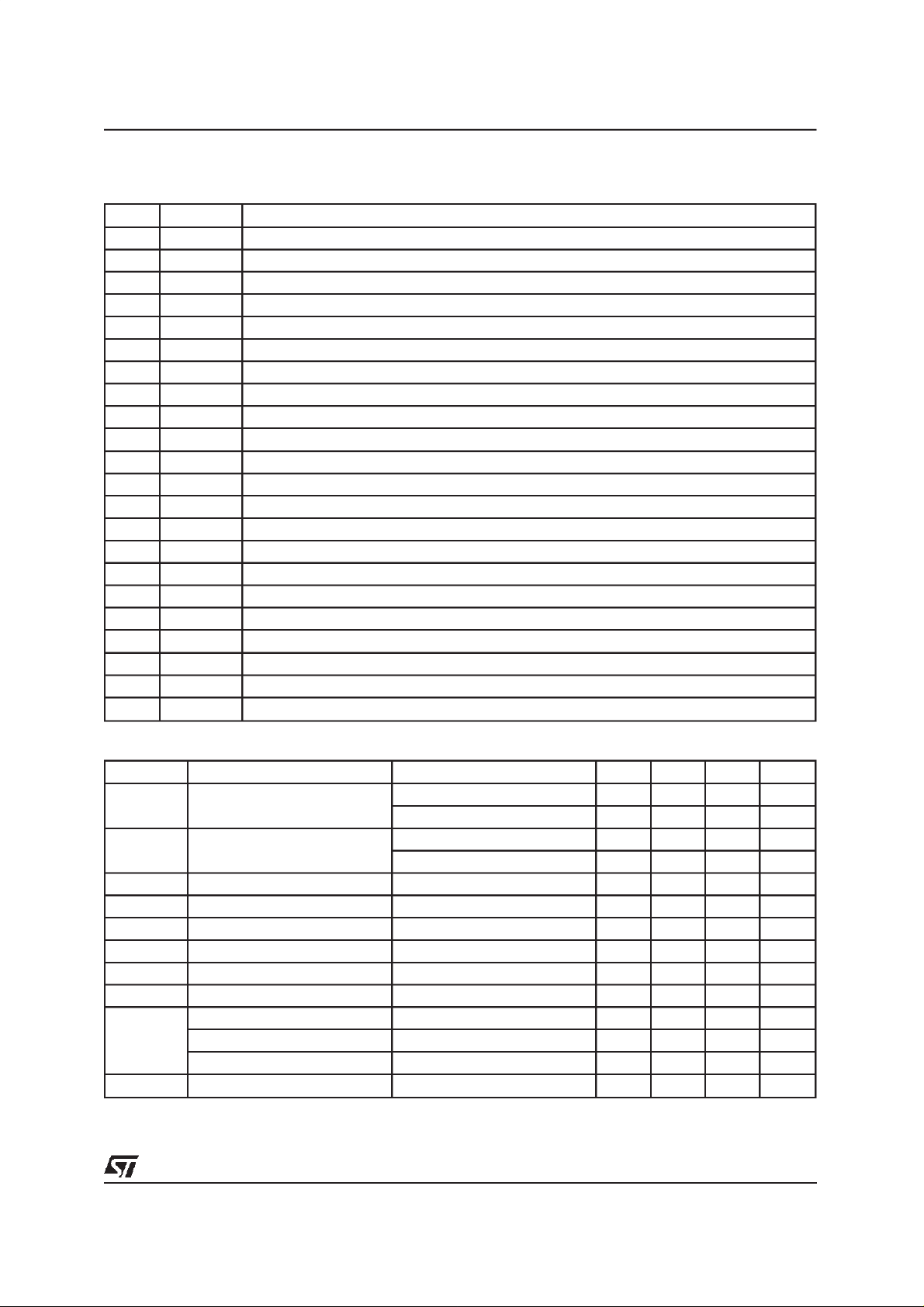

PIN FUNCTIONS

N. Name Function

1 PGND1 Ground for DMOS sources in bridge 1

2 IN1 Digital Input from motor controller for bridge 1

3 EN1 Logic enable/disable for bridge 1 (active high)

4, 5 NC No connect

6 OUT1 Output of one half of bridge1

7, 8 GND Ground

9 OUT3 Output of one half of bridge2

10, 11 NC No connect

12 EN2 Logic enable/disable for bridge 2 (active high)

13 IN3 Digital Input from motor controller for bridge 2

14 PGND2 Ground for DMOS sources in bridge 2

15 NC No connect

16 IN4 Digital Input from motor controller for bridge 2

17 OUT4 Output of one half of bridge 2

18, 19 NC No connect

20 VS2 Supply Voltage for bridge 2

21, 22 GND Ground

23 VS1 Supply Voltage for bridge 1

24, 25 NC No connect

26 OUT2 Output of one half of bridge 1

27 IN2 Digital Input from motor controller for bridge 1

28 NC No connect

L9925

ELECTRICALCHARACTERISTICS (VS = 9 to 16V; Tj =-40 to 150°C

(3)

, unlessotherwise specified.)

Symbol Parameter Test Condition Min. Typ. Max. Unit

T

T

T

I

R

d-on

d-SB

d-off

t

rise

t

fall

IL

S

ds

Quiescent Current EN1 = EN2 =0V; Tj=85°C 200

EN1 = EN2 =5V; I

= 0A 5 12 mA

load

Switch on Resistance Tj=25°C; VS= 14V; Io=300mA 0.75 0.8

= 125°C; VS= 6V; Io=300mA 1.5 1.9

T

j

Turn-on delay See Fig 1 10 50

Standby setting time See Fig 1 50 200

Turn-off delay See Fig 1 10 50

Output rise time (10 to 90%) See Fig 1 0.5 5 20

Output fall time (90to 10%) See Fig 1 0.5 5 20

o Output leakage current EN = 0V;Vo =VS or GND -10 10 mA

INx, ENx Logic Input Lowvoltage -0.3 1.5 V

Logic Input High voltage 3.5 6 V

Hysteresis 0.5 1.0 2.0 V

Ibias Input bias current -50 300 µA

The voltage referedto GND and currents are assumed positive, when the current flows into thepin.

(3) Tested up to 125°C, parameter guaranted by correlation up to150°C

A

µ

Ω

Ω

s

µ

s

µ

s

µ

s

µ

s

µ

3/9

Page 4

L9925

Logic Levels

All inputs are positive,non invertinglogic

Logic State Voltage Range

0 -0.3 to 1.5V

1 3.5 to 6.0V

Truth Table

Enable/Disable

EN1 EN0 Bridge 1 Bridge 2 Iq

0 0 Disabled Disabled <200µA

0 1 Disabled Enabled <12mA

1 0 Enabled Disabled <12mA

1 1 Enabled Enabled <12mA

Figure 1. TimingDiagram

STANDBY MODE OPERATING MODE OVERTEMPERATURE STANDBY MODE

EN2

EN1

IN1

GeneralOperation

With the bridge enabled, each input INx, maps directly to thecorrespondingoutput OUTx.

The output voltage will be equal to the difference

between the supply rail and the product of the

load current ad the on resistance of the output

switch.V

out =Vsupply -(RDS,ON ⋅ ILOAD).

Sourcedload currentsare positive.

IN1 OUT1 IN2 OUT2 IN3 OUT3 IN4 OUT4

00000000

1V

1VS1VS1VS

S

IN2

OUT1

OUT2

Tristate

Tristate

t

t

dSB

dON

50%

10%

t

dSB

t

r

t

r

t

dOFF

90%

t

f

t

dOFF

Figure 2. Typical RON - Characteristicsof Source

and Sink Stage

RON

(Ω)

2

1

-20 0 20 40 60 80 100 120 140 160 T(°C)

-40

V

V

D99AT426

VS

VS

=6V

=12V

t

dSB

t

f

Tristate

t

dON

Tristate

D99AT425

Tristate

Tristate

t

dSB

Figure3. ON - Resistance vs SupplyVoltage

RON

(Ω)

1.9

1.5

0.9

0.75

6

I

OUT1/2

=±0.3A

12 16.5 V

max for TJ≤125°C

typ. for T

=25°C

J

(V)

VS

D99AT427

4/9

Page 5

Figure 4. ApplicationDiagram

L9925

CEN

100nF

D

0

+5V

D

0

I/O

µP

10KΩ

I/O

I/O

EN1

O

GND

O

EN2O

OOIN3

D

R

IN1

IN4

0

1 D

1st FULL BRIDGE

2nd FULL BRIDGE

CB

100nF

CB40V

100µF

EN1

T1T2T2

T1 T2

2

40V

7V T1

CHARGE

PUMP

REGULATOR

CEN

100nF

OUT1 VS1 OUT2

TEMP

5V

R

0

10KΩ

EN1

EN2

A

CHARGE

PUMP

STEPPER MOTOR

B

IN2

7V7V

EN1

PGND1

VS2

40V

OUT3

CEX

100nF

OUT4

CEX

PGND2

100nF

D99AT423

Figure 4 shows a typical application diagram for

DC motordriving. To assure the safety of the circuit in the reverse battery conditiona reverse protetion diode D

tection diode D

supply voltage V

V

BAT line will be limited to a value lower than the

absolute maximu ratings for V

B are used to lower VS-EMR and its values de-

C

1 is necessary. The transient pro-

2 must assure that themaximum

S during the transients at the

VSP. The capacities

pend on the driving load.

The resistance feedback loop realized by R

o lim-

ited to theµP power supply line by the diode D

allows open load detection. To protect the device

at the outputsagainst EMI or ESD> 2KV external

capacitorsC

ex maybe used.

CIRCUIT DESCRIPTION

L9925 is a dual full bridge IC designed to drive

DC motors, stepper motors and other inductive

loads. Eah bridge has 4 power DMOS transistor

with R

DSon = 0.75Ω and the relative protection

and control circuitry (see fig. 5). Tthe 4 half

bridges can be controlled independently by

means of the 4 inputs IN1, IN3, IN4 and 2 enable

inputs ENABLE1and ENABLE2.

LOGIC DRIVE(true table for the two full bridges)

INPUTS

IN1

IN2

IN3

IN4

EN1 =EN2 = H L

L

H

L

L

H

H

H

@Tj > 150°C X X All transistors turned OFF

o

EN1 =EN2 = L X X All transistorsturned OFF

OUTPUT

MOSFETS

Sink 1, Sink2

Sink1, Source2

Source1, Sink2

Source1, Source2

L = Low; H = High; X = Don’t care

CROSSCONDUCTION

The device guaranteesthe absenceof cross-conduction by watching internal gate-source voltage

of the driving power DMOS.

TRANSISTOR OPERATION

ON STATE

When one of POWER DMOS transistors is ON it

can be consideredas a resistor R

DS(ON) = 0.75

at a junctiontemperatureof 25°C

Ω

5/9

Page 6

L9925

In this conditionthe dissipated power is ginen by:

P

ON =RDS(ON) ⋅ IDS

2

The low RDS(ON) of the Multipower BCD process

can provide high currents with low power dissipation.

OFF STATE

When one of the POWER DMOS transistor is

OFF the V

age and only the leakage currentI

DS voltage is equal to the supply volt-

DSSflows.

The power dissipation during this period is given

by:

P

OFF =VS ⋅IDSS

Figure 5a. Two phasechopping

EN

IN1

IN1 =

IN2 =

EN1 = H

H

L

D99AT429

IN2

TRANSITIONS

Like all MOS power transistors the DMOS

POWER transistors have an intrinsic diode between their source and drain that can operate as

a fast freewheeling diode in switched mode applications. During recirculation with the ENABLE input is low, the POWER MOS is OFF and the diode voltage it is clamped to its characteristics.

When the ENABLE input is low, the POWER

MOS is OFF and the diode carries all of the recirculationcurrent. The power dissipatedin the transitional times in the cycle depends upon the voltage and current waveformsin theapplication.

trans =IDS(t)⋅ VDS(t)

P

EN

IN1

IN1 =

IN2 =

EN1 = H

L

H

D99AT430

IN2

Figure 5b. Onephase chopping

EN

IN1

IN1 =

H

IN2 =

L

EN1 = H

Figure 5c. Enable chopping

EN

IN1

IN1 =

H

IN2 =

L

EN1 = H

D99AT431

D99AT433

EN

IN2

IN1

IN1 =

H

IN2 =

H

EN1 = H

EN

IN2

IN1

IN1 =

X

IN2 =

X

EN1 = L

D99AT432

D99AT434

IN2

IN2

6/9

Page 7

L9925

THERMAL PROTECTION

A thermalprotectioncircuit has been included that

will disable the device if the junction temperature

reaches 150°C. When the temperature has fallen

to a safe level the device restarts under the control of the input and enable signals.

APPLICATIONINFORMATION

RECIRCULATION

During recirculationwith the ENALBE input high,

the voltage drop across the transistor is R

DS(ON).

for voltages less than 0.6V and is clamped at a

voltages depending on the characteristics of the

source-drain diode for greater voltages. Although

the deviceis protectedagainstcross conduction.

POWERDISSIPATION each bridge

In order to achieve the high performanceprovided

by the L9925 some attention must be paid t ensure that it has an adequate PCB area to dissipate the heat. The forst stage of any thermal design is to calculate the dissipated power in the

application, for this example the half step operation shown in Fig. 6 is considered.

RISE TIMET

R

When an arm of the half bridge is turned on current begins to flow in the inductive load until the

maximum current I

The dissipatedenergy E

OFF/ON =[RDS(ON)

E

L is reached after a time TR,

OFF/ON.

2

I

L

⋅

2

T

R]

⋅

⋅

3

Figure 6.

commutationE

transistorsare ON E

COM. As two of the POWER DMOS

ON isgiven by:

2

ON =IL

E

⋅RDS(ON) ⋅ 2 ⋅ TON

In the commutationthe energy dissipatedis:

CON =VS ⋅IL ⋅TCOM ⋅ fSWITCH ⋅ TON

E

Where:

T

COM =CommunicationTimeandit isassumedthat:;

T

COM =trise =tfall

T

SWITCH=Chopperfrequency

FALL TIME T

F

≤20µ

s

For this example it is assumed that the energy

dissipated in this part of the cycle takes the same

form as that shown for therise time:

OFF/ON =[RDS(ON) ⋅ IL

E

2

⋅ TF] ⋅

2

3

QUIESCENTENERGY

The last contribution of the energy dissipation is

due to the quiescrent supply current and is given

by:

E

QUIESCENT =IQUIESCENT ⋅ VS ⋅ T

TOTALENERGY PER CYCLE

TOT =(2 ⋅EOFF/ON +EON +ECOM) bridge1+

E

+(2 ⋅E

OFF/ON +EON +ECOM) bridg2 +EQUIESCENT

T

switch

I

L

ON TIME T

TRT

ON

ON

T

T

OFF

F

D99AT435

During this time the energy dissipated is due to

the ON resistance of the transistors E

ON and the

The total power dissipationPDIS issimply:

E

tot

=

P

DIS

=Rise time

T

R

T

=ON time

ON

T

= Fall time

F

T

= OFF time

OFF

T

T =Period

T=T

R+TON +TF +TOFF

7/9

Page 8

L9925

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 2.65 0.104

a1 0.1 0.3 0.004 0.012

b 0.35 0.49 0.014 0.019

b1 0.23 0.32 0.009 0.013

C 0.5 0.020

c1 45° (typ.)

D 17.7 18.1 0.697 0.713

E 10 10.65 0.394 0.419

e 1.27 0.050

e3 16.51 0.65

F 7.4 7.6 0.291 0.299

L 0.4 1.27 0.016 0.050

S8°(max.)

mm inch

OUTLINE AND

MECHANICAL DATA

SO28

8/9

Page 9

L9925

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is

granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mentioned in this publication are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registeredtrademark of STMicroelectronics

1999 STMicroelectronics – Printedin Italy – All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Mexico - Morocco - The Netherlands -

Singapore- Spain - Sweden- Switzerland - Taiwan - Thailand - United Kingdom- U.S.A.

http://www.st.com

9/9

Loading...

Loading...