Page 1

MOTOR BRIDGE FOR HEADLIGHT ADJUSTMENT

FULL BRIDGE OUTPUT CONFIGURATION

WITH LOW SATURATION VOLTAGE LESS

THAN 3.2V AT OUTPUTCURRENT 0.7A

OPERATING SUPPLY VOLTAGE RANGE 7V

TO 18V.SUPPLYOVERVOLTAGEUP TO 50V

HIGH POSITIONING PRECISION AND HIGH

NOISE IMMUNITY DUE TO TRANSFER

CHARACTERISTICS WITH NEUTRAL ZONE

AND STOP RANGE THRESHOLD

FAST STOP THROUGH SHORT-CIRCUITING

THE MOTOR

MOTOR STOP STATUS IN CASE OF OPEN

INPUT CONDITION

SUPPLY OVERVOLTAGE PROTECTION

FUNCTION FOR Vs MORE THAN 18V, UP

TO 50V

INPUT PROTECTION AGAINST TRANSIENTS ON THE BATTERY LINE AND THE

REVERSEBATTERYCONDITION

THERMALOVERLOADPROTECTION

ESDPROTECTEDACCORDINGTO MIL883C

L9907N

SO20L(12+4+4)

ORDERING NUMBER: L9907ND (SO20L)

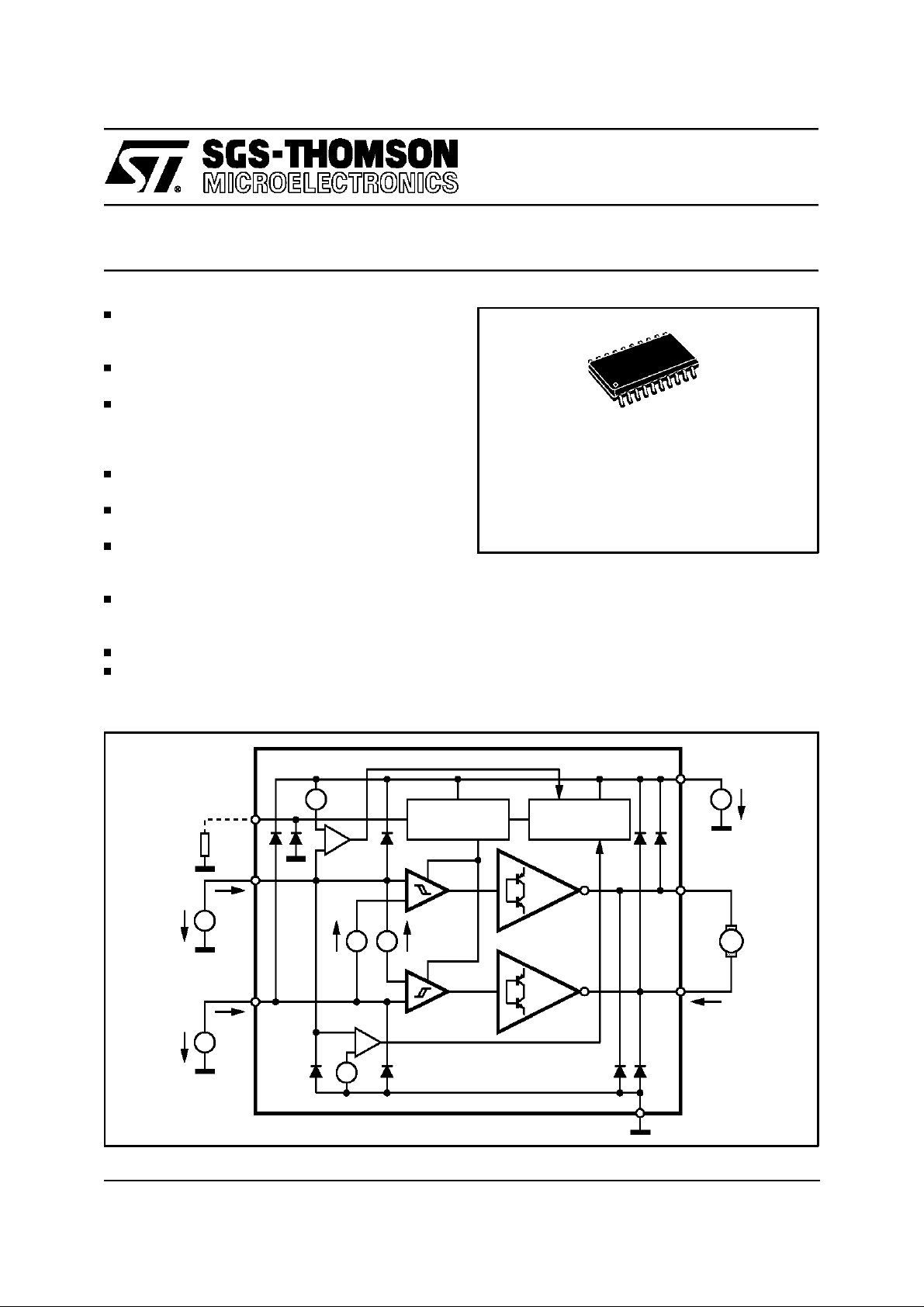

DESCRIPTION

The L9907N is a monolithic integrated power

comparator with full bridge output configuration,

intended for driving DC motors in positioning systems, optimized for headlight adjustment application and respecting the automotiveelectronics environmentalconditions.

BLOCK DIAGRAM

R

PR

V

INC

=

V

INF

=

PR

INC

I

INC

INF

I

INF

V

S

V

S

OUT C

OUT F

I

M

=

M

1.2V

=

REFERENCE

BIAS

-

+

=

=

+

-

=

1.2V

PROTECTION

FUNCTIONS

L9907N

D95AT189

GND

December 1996

1/8

Page 2

L9907N

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

SDC

V

SP

I

OUT_DC

I

OUT_P

I

IN

I

IN

T

s

(*) Recommended maximal T

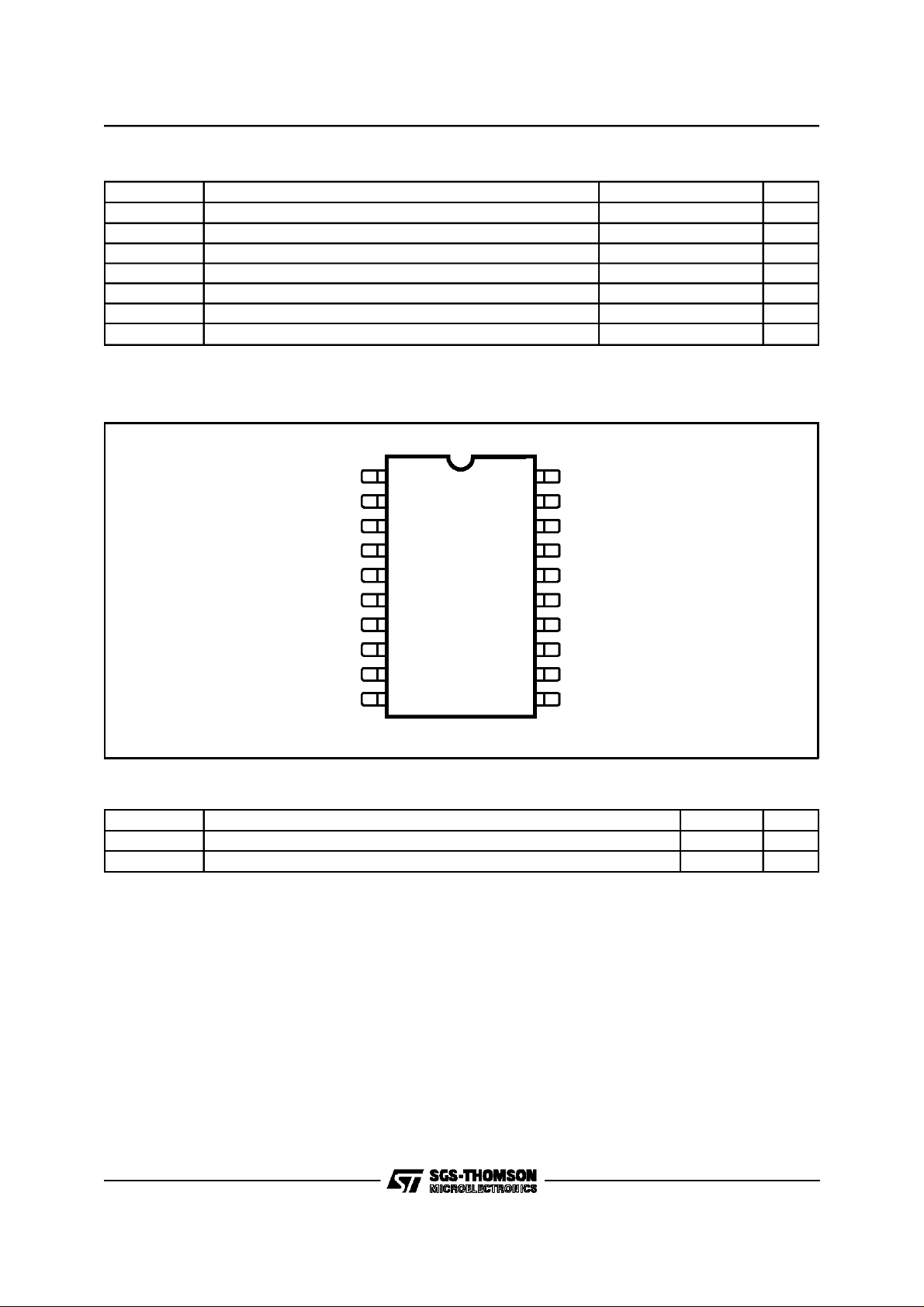

PIN CONNECTION

DC Supply Voltage 26 V

Supply Voltage Pulse (T ≤ 400ms) 50 V

DC Output Current ±0.4 A

Output Current Pulsed (100ms) 0.8 A

DC Input Current ±10 mA

Input Current Pulse (2ms) ±40 mA

Storage Shutdown Junction Temperature Range (*) 150 °C

≤ 105°C

amb

V

S

OUT

C

N.C.

GND

GND

GND

GND

N.C.

IN

C

PR N.C.

2

3

4

5

6

7

8

9

10

D95AT181

20

19

18

17

16

15

14

13

12

11

N.C.1

OUT

N.C.

GND

GND

GND

GND

N.C.

IN

F

F

THERMAL DATA

Symbol Parameter SO20L Unit

R

th j-amb

R

th j-pins

(1) with 6cm2on board heat sink area

Thermal Resistance Junction-ambient (1) 50 °C/W

Thermal Resistance Junction-pins 15 °C/W

2/8

Page 3

L9907N

ELECTRICALCHARACTERISTICS

(7V < V

< 18V, –40°C<Tj< 150°C; unless otherwise specified.)

S

Symbol Parameter Test Condition Min. Typ. Max. Unit

-V

N

-V

ST-,VST+

V

V

INCH

V

CH (3)

I

q

-, V

INCL

Quiescent Current I

Neutral Zone Threshold (2) 1.5 < V

N+

Stop Range Threshold 1.5< VINC < VS-2V;VS=12V

Control Input LOW Disable

Threshold

Control Input HIGH Disable

Threshold (4)

= 0, (Output Open)

OUT

|V

| < 20mV (stop)

din

|V

| < 200mV (L or R)

din

INC<VS

R

= ∞

PR

R

=0

PR

R

= ∞

PR

R

=0

PR

Tj= -40 to +25ºC

T

= >25ºC

j

Outputs = ON

with RINC = 0Ω

with R

with R

INC

INC

=5KΩ

= 10K

-2V; VS= 12V

Ω

3xV

3xV

25

50

0.8

0.6

ST

ST

7

6

9

7

120

2404xVST

4xV

38

76

1.2

1.2

V

V

60

100

1.5

1.5

V

S

S

S

-1.5

-1.4

mA

mA

mV

mV

ST

mV

mV

V

V

-2

V

V

V

Outputs = OFF

with R

with R

with R

I

IN

V

OSI

V

OSO

(2) With a programming resistor RPRbetweenthe PR pin and GND the N+ and N- thresholds can be adjusted from the nominalvalue (RPR= ∞

, pin PR open) up to two times the nominal value (R

The formula defining V

for R

=∞ this formula reduced to:

PR

-V

N+(RPR

in V and RPRin KΩ theseformulas result in mV

for V

s

is the controlinput voltage applied to the pin INCthrough a serial resistor R

(3) V

CH

(4) OUTPUTS = UNDEFINED for: VS-2V < VCH(R

Input Bias Current 1.5 < V

Output Saturation Voltage

Sink Stage

Output Saturation Voltage

Source Stage

PR

typicalvalue as a function of RPRand VSis: –VN−= VN+=(36mV + 0.017⋅ VS) ⋅

N+,VN-

= ∞)=VN+(RPR= ∞) = 18mV + 0.0086 ⋅ VS.

-1.5V< VCH(R

V

S

-1.4V< VCH(R

V

S

INC

INC

INC

V

din

V

din

V

din

V

din

I

OUT

I

OUT

I

OUT

I

OUT

= 0,pin PR shorted to GND).

=0Ω)<VS-0.8V

=5KΩ)<VS-0.6V

= 10KΩ)<VS-0.4V

=0Ω

INC

=5K

= 10KΩ

INC<VS

Ω

-2V; VS= 12V

∞

INC

INC

=0;RPR=

= ± 200mV; RPR= ∞

=0;RPR=0

=±200mV; RPR=0

= 0.7A

= 0.35A

= 0.7A

= 0.35A

INC

V

-0.8

S

V

-0.6

S

V

-0.4

S

R

PR

R

PR

9.5KΩ

2.0

4.0

3.6

6.8

1.4

1.1

2

1.5

.

1 +

1 + 2 ⋅

0.45

0.9

0.8

1.5

1.1

0.8

1.2

0.9

9.5KΩ

V

V

V

µ

µA

µA

µ

V

V

V

V

A

A

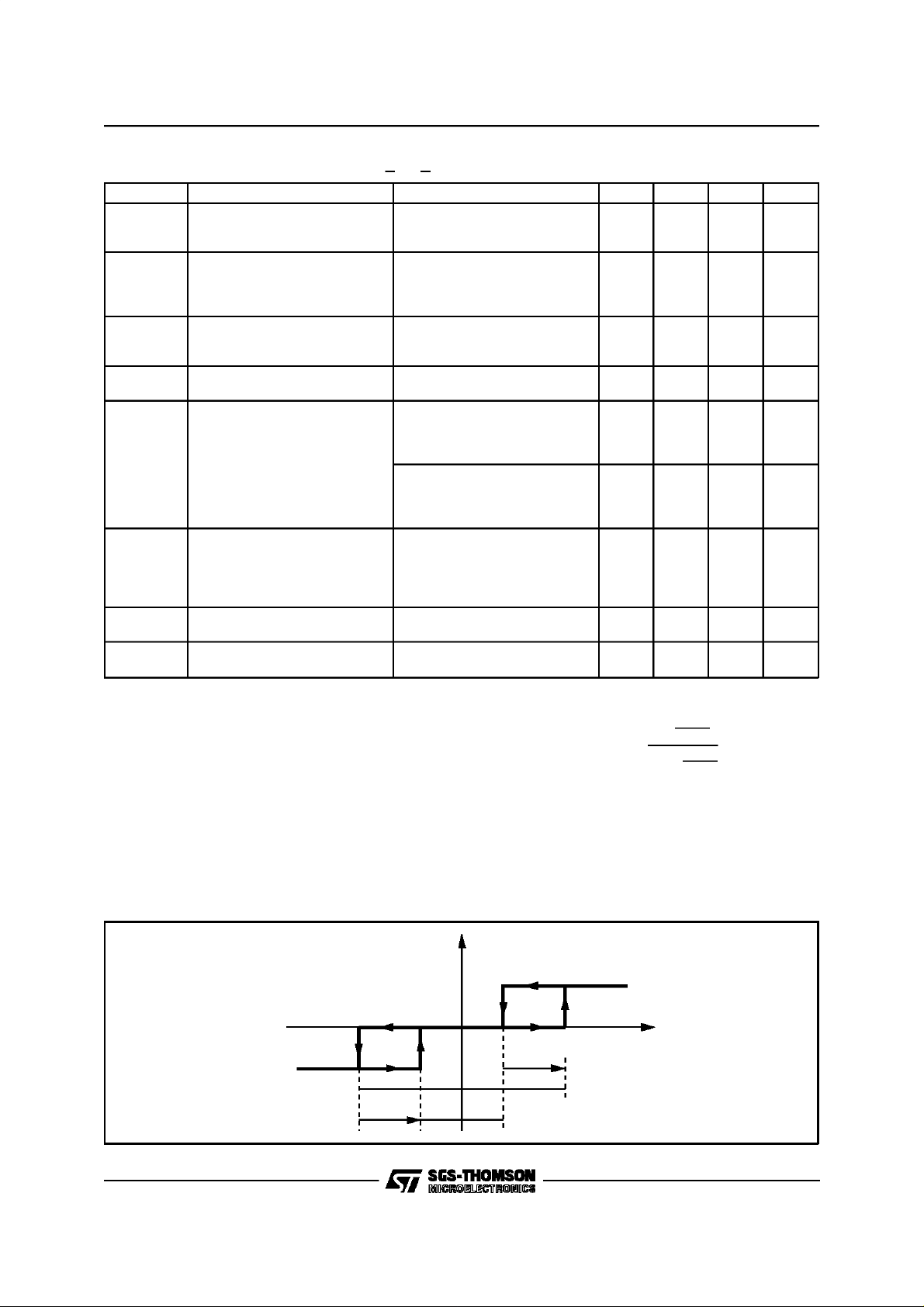

Figure 1: L9907NDifferential Input to OutputTransfer Characteristics

VM=V

OUTC-VOUTF

V

N-

MOTOR

DIRECTION RIGHT

D95AT182

V

H-

V

N+

V

H+

STOP RANGE

MOTOR

DIRECTION LEFT

V

INC-VINF

NEUTRALZONE

3/8

Page 4

L9907N

FUNCTIONAL DESCRIPTION

The L9907N is a power comparator with fullbridge push-pull outputs, intended for driving a

DC motor in the headlingadjustmentsystem.

The basic function of the device is shown in the

input-outputtranfer characteristic, Fig. 1.

For differential input voltage (V

INC-VINF

than the negativeNEUTRALZONE threshold, V

) lower

N-

the output voltage is negative (corresponds to

motor direction right), for increasingdifferential input voltage,this status changesto the zero output

voltage (motor is actively braked), when the differential input voltage exceeds the V

stop range

ST-

threshold. The outputstatusremains in thiscondition as long as the differential input voltage remains within the NEUTRAL ZONE. If the input

voltage increases above the positive NEUTRAL

ZONE threshold V

, the output voltage become

N+

positive(motor direction left).

Similar behaviour is obtained for decreasing the

input voltage. The output status transitions are

marked with the arrows showing the corresponding direction of the output status variation. The

active braking mode is got with both outputs in

”HIGH” status

The above described behaviour assures high positioning precision, corresponding to the STOP

RANGE and high noise immunity in the adjusted

condition due to the NEUTRAL ZONE hysteresis

thresholds.

Both the above described thresholds are defined

referring to I

Figure 3:

RecommendedApplicationCircuit Diagram with L9907N for trackingregulation

(V

NC,INF

F=VC

pins. The error due to voltage

for 1.5V < VC<VS-2V):

drop over the input signal source resistances

R

INC,RINF

bias currents I

The above mentioned resistors (R

is minimized with extremely low input

INC,IINF

.

,R

INF

) are

INC

necessary for the input current limitation during

the transients on the V

line. The input source

BAT

resistors must be dimensioned so that in case of

a line transient the input current in the input pin,

clamped with the internal input protection diodes

do not increase over the specified absolute maximum value.

Figure2: Controlto feedbacktransf ercharacter i s ti c

-2V

S

within

D95AT183A

V

BAT

for trackingregulation (V

the nominal V

V

BAT

VS-2V

V

F

1.5V

0

1.5V V

operatingrange):

INC

V

C

F=VC

V

BAT

R

Note:

Recommended value of R

input voltage |V

motor will not change its previous position.

INC-VINF

INC,RINF

| remains withintheNEUTRAL ZONE, when the control signal wire become broken. When this condition is fulfiled the

D1

D2 C

C

V

C

(equivalent input resistance to INCand INF)is5KΩto 10KΩ. Resistor RCFshould assure that the differential

4/8

MODULE

I

Q

V

S

R

PR

R

INC

V

R

CF

INC

R

INF

V

INF

I

I

PR

INC

INC

INF

INF

S

L9907N

GND

OUT C

M

OUT F

D95AT184

R

F

MV

V

I

M

F

Page 5

L9907N

An external resistor RCFis recommended between the slider of the control and feedback potentiometer.

This resistor assures that in the case of input control or input feedback wire interruption the input

differential voltage will be within the NEUTRAL

ZONE and the motor position remains frozen.

The circuit features an overvoltage disable function referred to the supply voltage V

higher than

S

18V, both outputs are forced to tristatein thiscondition.

The thermal overload function disables the outputs (tristate) when the junction temperature increases above the thermal shutdown threshold

temperatureof min. 150°C.

For the start of a heavyloaded motor, if the motor

current reaches the max. value it is necessary to

respect the dynamical thermal resistance junction

to ambient. The maximum output current is 0.8A.

The maximum junction temperature in this phase

should not increase above the thermal shutdown

threshold. In case of output disable due to thermal overload the output remains disabled till the

junction temperaturedecreasesunder the thermal

enable threshold. This behaviour is assured with

the thermal shutdownhysteresis threshold, which

minimum value is 20°C.

Figure 3, 5 and 7 show typical application diagrams for headlight adjustment applications. To

assurethe safety ofthe circuitsin the reversebattery condition a reverse protection diode D

,is

1

necessary.

The input currents in this condition are limited by

the resistors R

tion diode D

ing forV

2

during the transients at V

S

and R

INC

must assure that the maximum rat-

. The transient protec-

INF

line will be

BAT

limited to a value lower than absolute maximum

Figure4:

Controlto feedbacktransfercharacteris tic

for proportionalregulatio n withextended

operating range:

V

C

V

BAT

D95AT185A

V

BAT

VS-2V

V

F

1.5V

0

1.5V V

V

C

-2V

S

Figure 5:

Note:

Recommended value of R

the control signal wire become open, R

Recomm end edApplicationCircuitDiagramwith L9907Nfor proportionalregulationwith extended

operatingrange. For ideal adjusted condition VF=

V

C

V

BAT

R

INC,RINF

D1

D2 C

C

V

(equivalentinput resistanceto INCand INF)is5KΩto10KΩ. If themotor shouldnot change itsposition, when

R

INC2

R

+ R

INC1

I

Q

V

S

R

PR

R

INC1

V

R

INC2

C

INC1

and R

should be rated so that V

INC2

INC

R

INF

V

INF

I

I

PR

INC

INC

INF

INF

S

L9907N

GND

≤

0.4V in this condition.

INC

INC2

OUT C

M

OUT F

D95AT186

⋅ VC:

I

M

MODULE

R

F

MV

V

F

5/8

Page 6

L9907N

Figure 6: Controlto feedbacktransfercharacteris tic

forproportionalregulation with reduced

operatingrange:

V

C

-2V

S

D95AT187A

V

V

C

BAT

V

BAT

VS-2V

V

F

1.5V

Figure 7:

0

1.5V V

ALLOWED VC OPERATINGRANGE

RecommendedApplicationCircuitDiagramwith L9907Nfor proportionalregulationwith reduced

operatingrange. For ideal adjusted condition VF=

V

C

rating for VS. The device features an output disable function in case of controlinput voltage overdrive.

When the control input voltage increases above

the HIGH control input disable threshold V

V

, typically VS-1.2V or decreases below the

INCH

LOW control input disable threshold V

INC

INC>VINCH

typically 1.2V, then both outputs will be forced to

tristate.

NC

The potential of the I

pin is clamped at the Control Input HIGH disable threshold potential with a

series resistor of 5KΩ typ. To activate the HIGH

disable comparator an input current of 35µA typ.

is needed. To respect this behaviour in the applicationV

isspecified for differentR

CR

R

R

INF2

INF2

+

R

⋅ VC:

INF2

INC.

MODULE

>

,

V

BAT

R

Note:

Recommended value of R

input voltage |V

motor will not change its previous position.

INC-VINF

INC,RINF

| remainswithin the NEUTRAL ZONE,when the control signal wire become broken. When this condition is fulfilled the

D1

D2 C

C

V

C

(equivalent input resistance to INCand INF)is5KΩto 10KΩ. Resistor RCFshould assure that the differential

I

Q

V

S

R

PR

R

INC

V

R

CF

INC

R

INF1

V

INF

I

I

INC

INF

INC

INF

R

PR

INF2

S

L9907N

GND

OUT C

M

OUT F

D95AT188

R

F

MV

V

I

M

F

6/8

Page 7

SO20 PACKAGEMECHANICAL DATA

L9907N

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 2.65 0.104

a1 0.1 0.3 0.004 0.012

a2 2.45 0.096

b 0.35 0.49 0.014 0.019

b1 0.23 0.32 0.009 0.013

C 0.5 0.020

c1 45° (typ.)

D 12.6 13.0 0.496 0.512

E 10 10.65 0.394 0.419

e 1.27 0.050

e3 11.43 0.450

F 7.4 7.6 0.291 0.299

L 0.5 1.27 0.020 0.050

M 0.75 0.030

S8°(max.)

mm inch

7/8

Page 8

L9907N

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implicationor otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specification mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are notauthorized foruseas criticalcomponents in life support devices or systems without express

written approval of SGS-THOMSON Microelectronics.

1996 SGS-THOMSON Microelectronics – Printedin Italy – AllRights Reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - France - Germany - HongKong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland- Taiwan- Thailand - United Kingdom - U.S.A.

8/8

Loading...

Loading...