Page 1

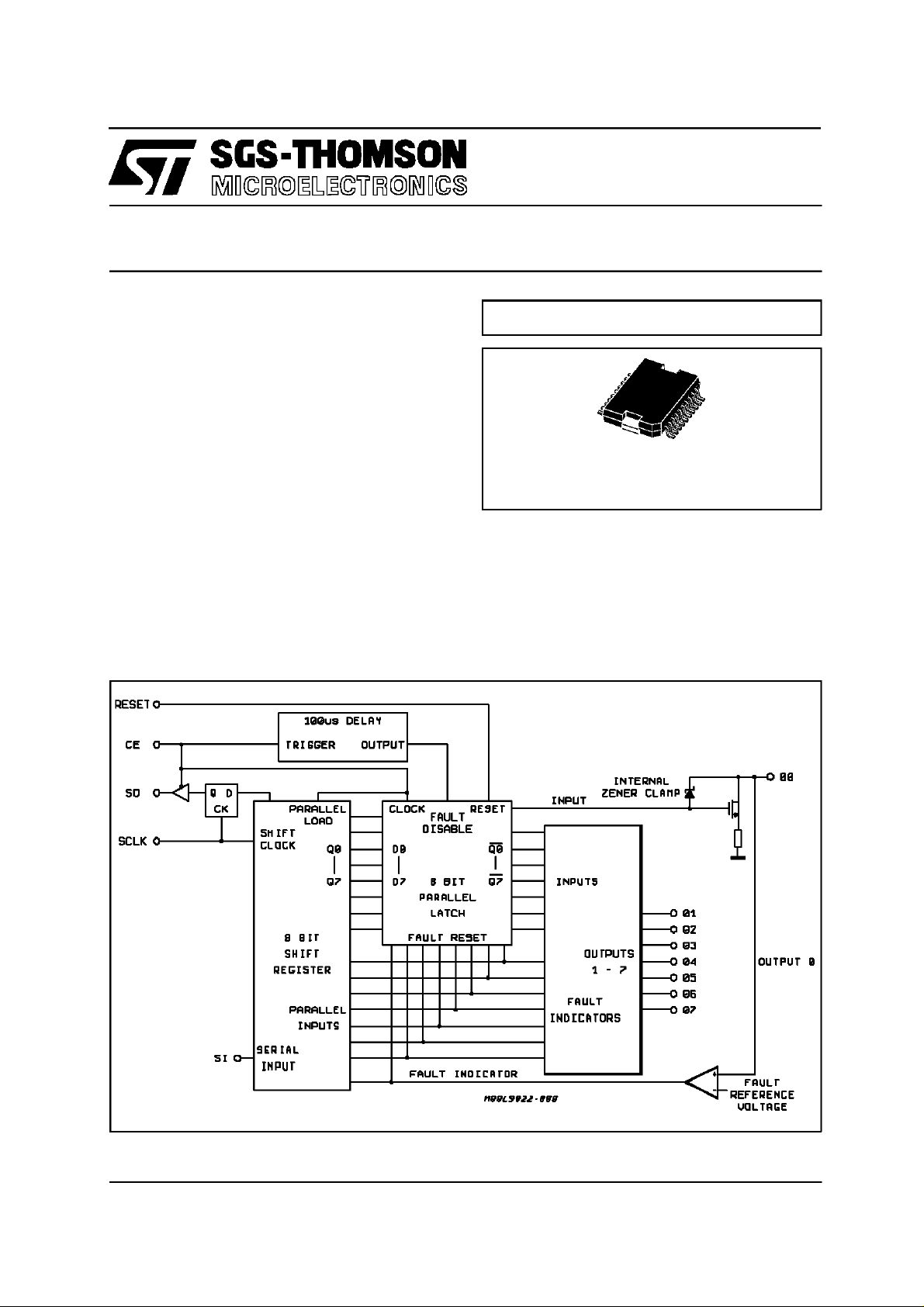

L9822N

OCTALSERIAL SOLENOID DRIVER

.EIGHTLOWR

(0.5ΩATI

=1A@25°CVCC=5V±5%)

O

DMOSOUTPUTS

DSon

.8 BITSERIAL INPUT DATA (SPI)

.

8 BIT SERIAL DIAGNOSTIC OUTPUT FOR

OVERLOADANDOPENCIRCUITCONDITIONS

.

OUTPUT SHORT CIRCUITPROTECTION

.CHIPENABLESELECTFUNCTION(activelow)

.INTERNAL 35V CLAMPINGFOR EACH OUT-

PUT

.CASCADABLE WITH ANOTHER OCTAL

DRIVER

.LOWQUIESCENTCURRENT (10mAMAX.)

.

PACKAGE PowerSO20

DESCRIPTION

TheL9822N is an octal low side solenoiddriver

realizedin Multipower-BCDtechnologyparticularly

suitedfor drivinglamps,relaysandsolenoidsin au-

BLOCKDIAGRAM

MULTIPO WER BCD TECHNOLOG Y

PowerSO20

ORDERINGNUMBER: L9822N

tomotive environment. The DMOS outpts L9822N

has a verylow power consumption.

Data is transmitted serially to the device usingthe

SerialPeripheralInterface(SPI)protocol.

The L9822Nfeaturestheoutputsstatusmonitoring

function.

October1997

1/9

Page 2

L9822N

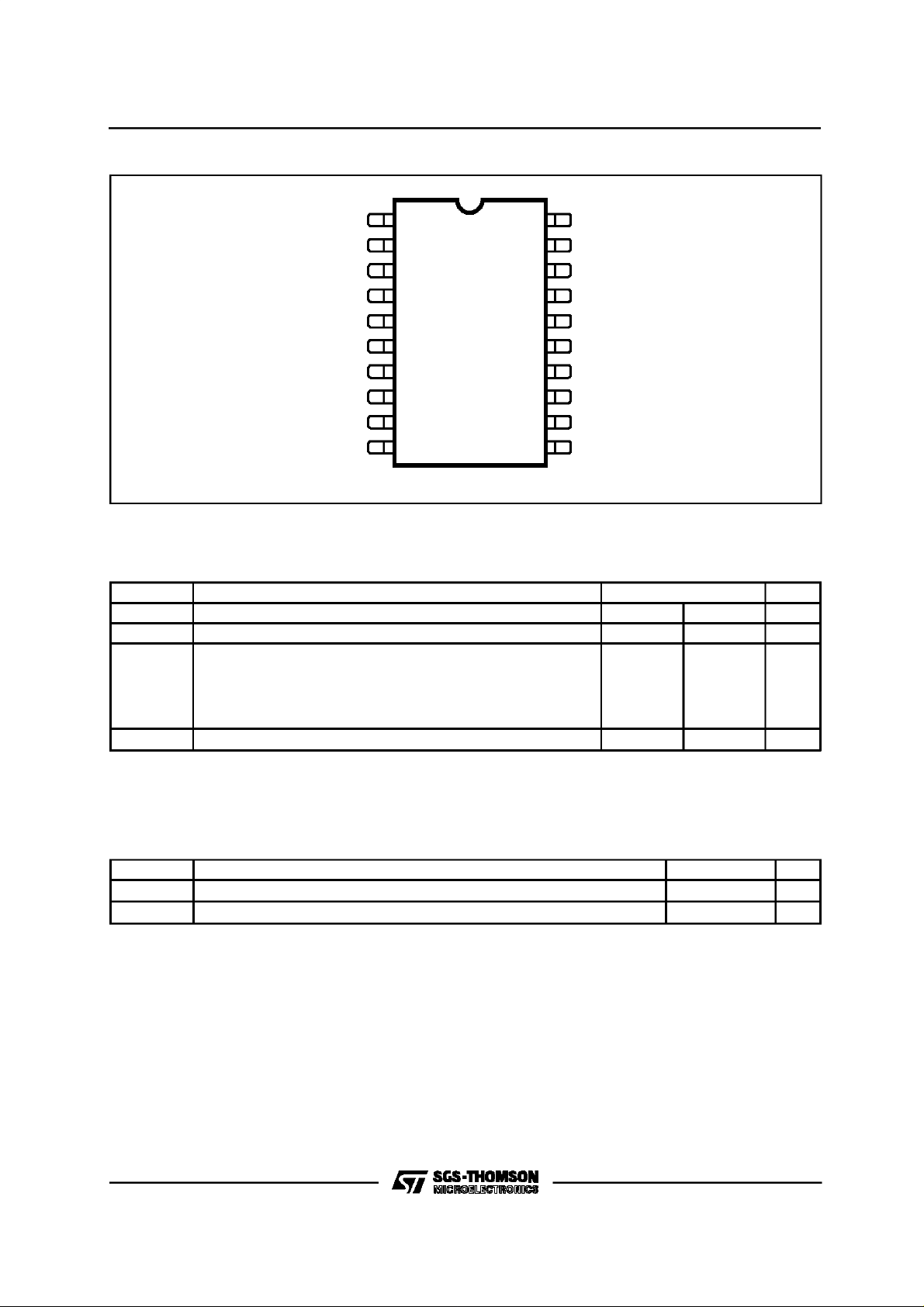

PIN CONNECTIONS

(topview)

RESET

GND

2

3

V

SO

CC

4

OUT7

OUT6

OUT5

OUT4

N.C. N.C.

GND GND

5

6

7

8

9

10

D94AT119A

20

19

18

17

16

15

14

13

12

11

GND1

SI

SCLK

CE

OUT0

OUT1

OUT2

OUT3

ABSOLUTEMAXIMUM RATINGS

Symbol Parameter Value Unit

DC Logic Supply – 0.7 7 V

Output Voltage – 0.7 40 V

Input Transient Current

(CE, SI, SCLK, RESET, SO) :

Duration Time t = 1s,

<0

V

I

V

I>VCC

Junction and Storage Temperature Range – 40 150

stg

–25

+25

T

j

V

CC

V

O

I

I

,T

mA

mA

°

C

THERMAL DATA

Symbol Parameter Value Unit

Thermal Resistance Junction-Case Max. 1.5

Thermal Resistance Junction-Ambient Max. 60

2/9

R

th j-case

R

th j-amb

C/W

°

C/W

°

Page 3

PIN DESCRIPTION

L9822N

V

CC

Logicsupplyvoltage - nominally 5V

GROUND

DeviceGround.Thisgroundappliesforthelogiccircuitsas well as the poweroutputstages.

RESET

Asynchronousresetfortheoutputstages,theparal-

lellatchand the shiftregisterinsidetheL9822NSP.

Thispin isactivelowandit mustnotbe left floating.

Apoweronclearfunctionmaybe implementedconnectingthis pin to V

withan externalresistorand

CC

to groundwith an externalcapacitor.

CE

ChipEnable. Datais transferredfromthe shift registerstotheoutputson the risingedgeof thissignal.

Thefalling edgeof this signalsets the shiftregister

with the outputvoltagesensebits coming from the

output stages.The output driver for the SO pin is

enabledwhen this pinis low.

SO

SerialOutput.This pin is theserialoutputfrom the

shift register andit is tri-stated when CE is high.A

highfor a data biton thispin indicatesthat the par-

ticularoutput is high. A low on thispin for adatabit

indicatesthat the outputis low.

Comparing the serial output bits with the previous

serial input bits the external microcontroller implementsthediagnosticdata supplied by theL9822.

SI

SerialInput.Thispin is theserialdata input.A high

onthispinwillprogramaparticularoutputtobeOFF,

whilea lowwill turn itON.

SCLK

SerialClock.This pin clocksthe shift register.New

SO data will appearon every rising edgeof thispin

andnewSIdatawillbe latchedoneverySCLK’sfallingedgeinto theshiftregister.

OUTPUTS00-07

Poweroutputpins.The inputandoutputbitscorres-

pondingto07 aresentandreceivedfirstviatheSPI

bus and 00is thelast.

The outputs are provided with current limiting and

voltagesensefunctionsfor fault indicationand protection.The nominal load current for theseoutputs

is 500mA. Theoutputsalsohave on boardclamps

set at about 36V for recirculation of inductiveload

current.

ELECTRICALCHARACTERISTICS (V

Symbol Parameter Test Conditions Min. Typ. Max. Unit

Output Clamping Volt. IO= 0.5A, Output Programmed OFF 30 35 40 V

Out. Clamping Energy IO= 0.5A, When ON 20 mJ

Out. Leakage Current VO= 24V, Output Progr. OFF 1 mA

On Resistance Output Progr. ON

Turn-on Delay IO= 500mA

Turn-off Delay IO= 500mA

Fault Refer. Voltage Output Progr. OFF

Fault Reset Delay

(after CE L to H

transition)

Output OFF Voltage Output Pin Floating.cOutput Progr. OFF, 1.0 V

R

V

V

V

OC

E

OC

I

OFF

DSon

t

PHL

t

P

OREF

t

UD

OFF

=5V±5%.Tj=– 40to 125°C ; unlessotherwise speciifed)

CC

= 0.5A

I

O

= 0.75A

I

O

=1A

I

O

With Fault Reset Disabled

No Reactive Load

No Reactive Load

1.6 2 V

Fault detected if V

See fig. 3 75 250

O>VOREF

0.53

0.53

0.53

1

1

1

10

10

Ω

Ω

Ω

s

µ

s

µ

s

µ

3/9

Page 4

L9822N

ELECTRICALCHARACTERISTICS (Continued)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

INPUTBUFFER(SI, CE, SCLKand RESETpins)

V

T–

Threshold Voltage at

Falling Edge

V

T+

Threshold Voltage at

Rising Edge

V

C

H

I

I

Hysteresis Voltage VT+–V

T–

Input Current VCC= 5.25V, 0 < VI<V

Input Capacitance 0 < VI<V

I

CC

CC

OUTPUT BUFFER(SOpin)

V

SOL

V

SOH

I

SOtl

C

SO

I

CC

Output LOW Voltage IO= 1.6mA 0.4 V

Output HIGH Voltage IO= 0.8mA V

Output Tristate Leakage

Current

Output Capacitance 0 < VO<V

0<VO<VCC, CE Pin Held High,

V

= 5.25V

CC

CC

CE Pin Held High

Quiescent Supply

Current at V

CC

Pin

All Outputs Progr. ON. I

O

per Output Simultaneously

= 0.5A

SERIALPERIPHERAL INTERFACE (see fig.2, timingdiagram)

f

op

t

lead

t

lag

t

wSCKH

t

wSCKL

t

su

t

H

t

EN

t

DIS

t

t

rSO

t

fSO

t

rSI

t

fSI

t

ho

V

Operating Frequency D.C. 2 MHz

Enable Lead Time 250 ns

Enable Lag Time 250 ns

Clock HIGH Time 200 ns

Clock LOW Time 200 ns

Data Setup Time 75 ns

Data Hold Time 75 ns

Enable Time 250 ns

Disable Time 250 ns

Data Valid Time 100 ns

Rise Time (SO output) VCC= 20 to 70% CL= 200pF 50 ns

Fall Time (SO output) VCC= 70 to 20% CL= 200pF 50 ns

Rise Time SPI

VCC= 20 to 70% CL= 200pF 200 ns

Inputs (SCK, SI, CE)

Fall Time SPI

VCC= 70 to 20% CL= 200pF 200 ns

Inputs (SCLK, SI, CE)

Output Data Hold Time 0 ns

0.2V

CC

0.7V

1.45 V

–10 +10

CC

– 1.3V

–10 10

V

V

CC

µ

20 pF

V

µA

20 pF

10 mA

A

4/9

Page 5

FUNCTIONALDESCRIPTION

TheL9822NDMOSoutputis a low operatingpower

device featu-ring, eight 1Ω R

DMOS drivers

DSON

with transient protection circuits in output stages.

Eachchannelis independentlycontrolledbyan outputlatchanda commonRESETlinewhichdisables

all eightoutputs.The driver has low saturationand

shortcircuitprotectionandcandriveinductiveandresistive loads such as solenoids, lamps and relais.

DataistransmittedtothedeviceseriallyusingtheSerialPeripheralInterface(SPI)protocol.Thecircuitreceives8 bit serialdata by meansof the serial input

(SI)which is storedin an internal register to control

theoutputdrivers.Theserialoutput(SO)provides 8

bit ofdiagnosticdata representingthe voltage level

at thedriver output.Thisallows themicroprocessor

to diagnosetheconditionof theoutputdrivers.

The output saturation voltage is monitored by a

comparatorfor an outof saturationconditionandis

abletounlatchtheparticulardriverthroughthefault

resetline. Thiscircuitis also cascadablewith another octal driver in orderto jam 8 bit multiple data.

The device is selected when the chip enable (CE)

lineis low.

Additionallythe (SO) is placed in a tri-state mode

when the deviceis deselected.The negativeedge

of the(CE) transfersthe voltagelevelof thedrivers

tothe shiftregisterand thepositiveedgeofthe(CE)

latchesthenewdatafromtheshiftregistertothedrivers. WhenCE is Low, data bit containedinto the

shift register is transferred to SO output at every

SCLKpositivetransitionwhiledatabitpresentat SI

inputis latchedintotheshiftregisteroneverySCLK

negativetransition.

InternalBlocks Description

The internalarchitectureof the deviceis based on

the threeinternalmajorblocks: the octalshiftregisterfortalkingto the SPIbus,the octallatchfor holdingcontrolbits writtenintothe deviceandthe octal

load driverarray.

L9822N

Individualregisters in the latch may be clearedby

fault conditions in order to protectthe overloaded

outputstages.The entire latchmay also becleared

by theRESET signal.

OutputStages

Theoutputstagesprovidean activelowdrivesignal

suitable for 0.75A continuous loads. The outputs

haveinternalzeners set to 36voltsto clampinductive transients at turn-off. Each output also has a

voltagecomparatorobservingtheoutputnode.Ifthe

voltageexceeds1.8V on an ON outputpin, a fault

conditionis assumedand thelatchdriving thisparticularstageis reset,turningthe outputOFFtoprotect it. The timing of this actionis describedbelow.

These comparators also provide diagnostic feedbackdatatothe shiftregister.Additionally,thecomparatorscontainan internalpulldowncurrentwhich

will cause the cell to indicatea lowoutputvoltageif

the outputis programmed OFF and the output pin

is open circuited.

TIMINGDATA TRANSFER

Figure#2 showsthe overall timing diagramfrom a

byte transfer to and fromthe L9822NSPusing the

SPIbus.

CE Highto LowTransition

Theactionbeginswhenthe ChipEnable(CE)pinis

pulledlow.Thetri-stateSerialOutput(SO)pin driver

willbeenabledentire timethatCE islow.Atthefallingedge of theCEpin,thediagnosticdata fromthe

voltagecomparatorsin theoutputstageswillbelatched into the shift register.If a particularoutput is

high, a logic one will be jammedinto that bit in the

shiftregister.Iftheoutputis low,a logiczerowillbe

loadedthere.Themostsignificantbit(07)shouldbe

presentedat theSerialInput(SI) pin. A zeroat this

pin will programan outputON,whilea one will programthe outputOFF.

Shift Register

The shiftregisterhas bothserialandparallelinputs

and serial and parallel outputs.Theserial input acceptsdatafromthe SPIbusandtheserialoutputsimultaneously sends data into the SPI bus. The

paralleloutputsarelatchedintotheparallellatchinside the L9822N at the end of a datatransfer.The

parallelinputs jam diagnosticdata intothe shift registerat thebeginningof a datatransfercycle.

ParallelLatch

The parallellatchholdstheinputdatafromtheshift

register.This data then actuatestheoutputstages.

SCLK Transitions

The Serial Clock(SCLK) pin shouldthenbe pulled

high.Atthispointthediagnosticbit fromthe mostsignificantoutput(07)willappearattheSOpin.Ahigh

here indicates that the 07 pin is higher than 1.8V.

TheSCLKpinshouldthenbe toggledlowthenhigh.

NewSOdatawillappearfollowingeveryrisingedge

of SCLK and new SI data will be latched into the

L9822Nshift register on the falling edges.An unlimitedamountofdatamaybeshiftedthroughthedeviceshiftregister(intotheSIpinandouttheSOpin),

allowingthe otherSPI devicesto be cascadedin a

daisychainwiththe L9822N.

5/9

Page 6

L9822N

CELow to HighTransition

Once the last data bit has been shifted into the

L9822NSP,theCE pin shouldbe pulled high.

Attherisingedgeof CE the shiftregisterdataislatchedintotheparallellatchandtheoutputstageswill

beactuatedbythe newdata.An internal160µsdelaytimerwillalso be startedat thisrisingedge (see

). During the 160µs period, the outputs will be

t

UD

protectedonlyby the analogcurrentlimiting circuits

since the resetting of the parallel latches by faults

conditionswillbeinhibitedduringthisperiod.Thisallowsthe part toovercomeany highinrushcurrents

that may flow immediately after turn on. Once the

delay period has elapsed, the outputvoltages are

sensedbythe comparatorsand anyoutputwithvoltageshigherthan1.8VarelatchedOFF.Itshouldbe

notedthat the SCLK pin shouldbe low at both transitionsof the CE pin to avoidany false clocking of

theshiftregister.TheSCLKinputis gatedbytheCE

Figure 1 : ByteTiming withAsynchronousReset.

pin, so that the SCLK pin is ignored whenever the

CE pinis high.

FAULTCONDITIONSCHECK

Checkingforfaultconditionsmaybe donein thefol-

lowing way. Clock in a new controlbyte. Wait 160

microseconds or so to allow the outputsto settle.

Clockinthesamecontrolbyteandobservethediagnosticdata that comes outof the device.The diagnostic bits should beidentical to the bits that were

firstclockedin. Anydifferenceswouldpointtoa fault

onthatoutput.IftheoutputwasprogrammedONby

clockingina zero,anda one camebackas the diagnosticbitforthatoutput,theoutputpinwasstillhigh

anda shortcircuit oroverloadconditionexists.Ifthe

output was programmedOFF by clocking in a one,

and a zerocameback as thediagnosticbit for that

output,nothinghad pulledtheoutputpin highandit

must befloating,so an open circuitconditionexists

for that output.

6/9

Page 7

L9822N

Figure 2

: TimingDiagram.

Figure 3 : TypicalApplication Circuit.

N

7/9

Page 8

L9822N

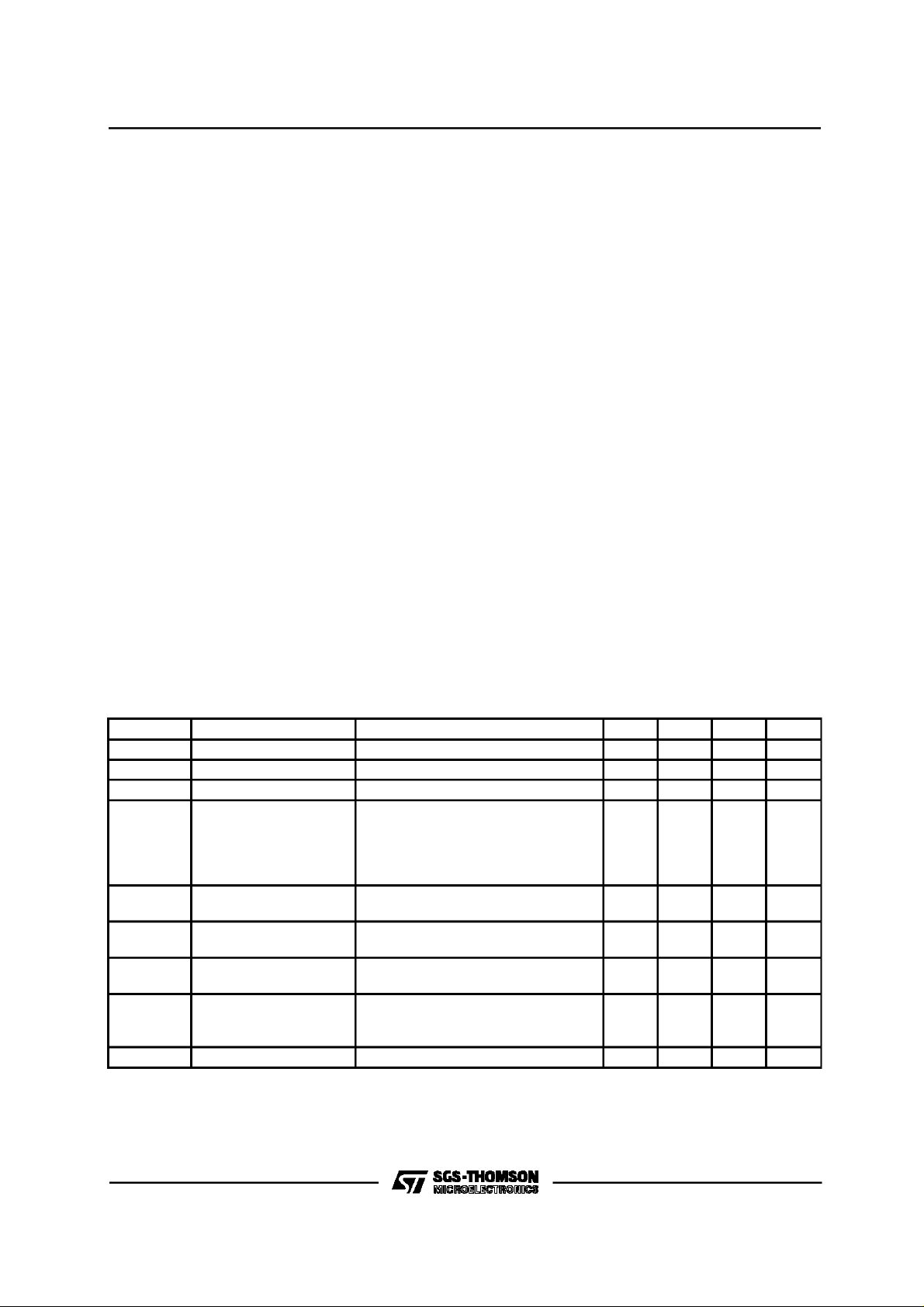

PowerSO20 PACKAGE MECHANICAL DATA

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 3.60 0.1417

a1 0.10 0.30 0.0039 0.0118

a2 3.30 0.1299

a3 0 0.10 0 0.0039

b 0.40 0.53 0.0157 0.0209

c 0.23 0.32 0.009 0.0126

D (1) 15.80 16.00 0.6220 0.6299

E 13.90 14.50 0.5472 0.570

e 1.27 0.050

e3 11.43 0.450

E1 (1) 10.90 11.10 0.4291 0.437

E2 2.90 0.1141

G 0 0.10 0 0.0039

h 1.10

L 0.80 1.10 0.0314 0.0433

N

S

10°(max.)

8° (max.)

T 10.0 0.3937

(1) ”D and E1” do not include mold flash or protrusions

- Mold flash or protrusions shall not exceed 0.15mm (0.006”)

E2

hx45°

NN

a2

A

b

DETAILA

e3

e

R

DETAILB

D

1120

E1

T

110

PSO20MEC

lead

a3

Gage Plane

E

DETAILB

0.35

S

a1

L

c

DETAIL A

slug

-C-

SEATING PLANE

GC

(COPLANARITY)

8/9

Page 9

L9822N

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for

the consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its

use. No license is granted by implicationor otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specification

mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously

supplied. SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems

withoutexpress written approval of SGS-THOMSON Microelectronics.

Australia - Brazil - Canada - China - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco -

The Netherlands - Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

1997 SGS-THOMSON Microelectronics – Printed in Italy– AllRights Reserved

PowerSO-20 is a Trademark of SGS-THOMSON Microelectronics

SGS-THOMSON Microelectronics GROUP OF COMPANIES

9/9

Loading...

Loading...