Page 1

®

L9377

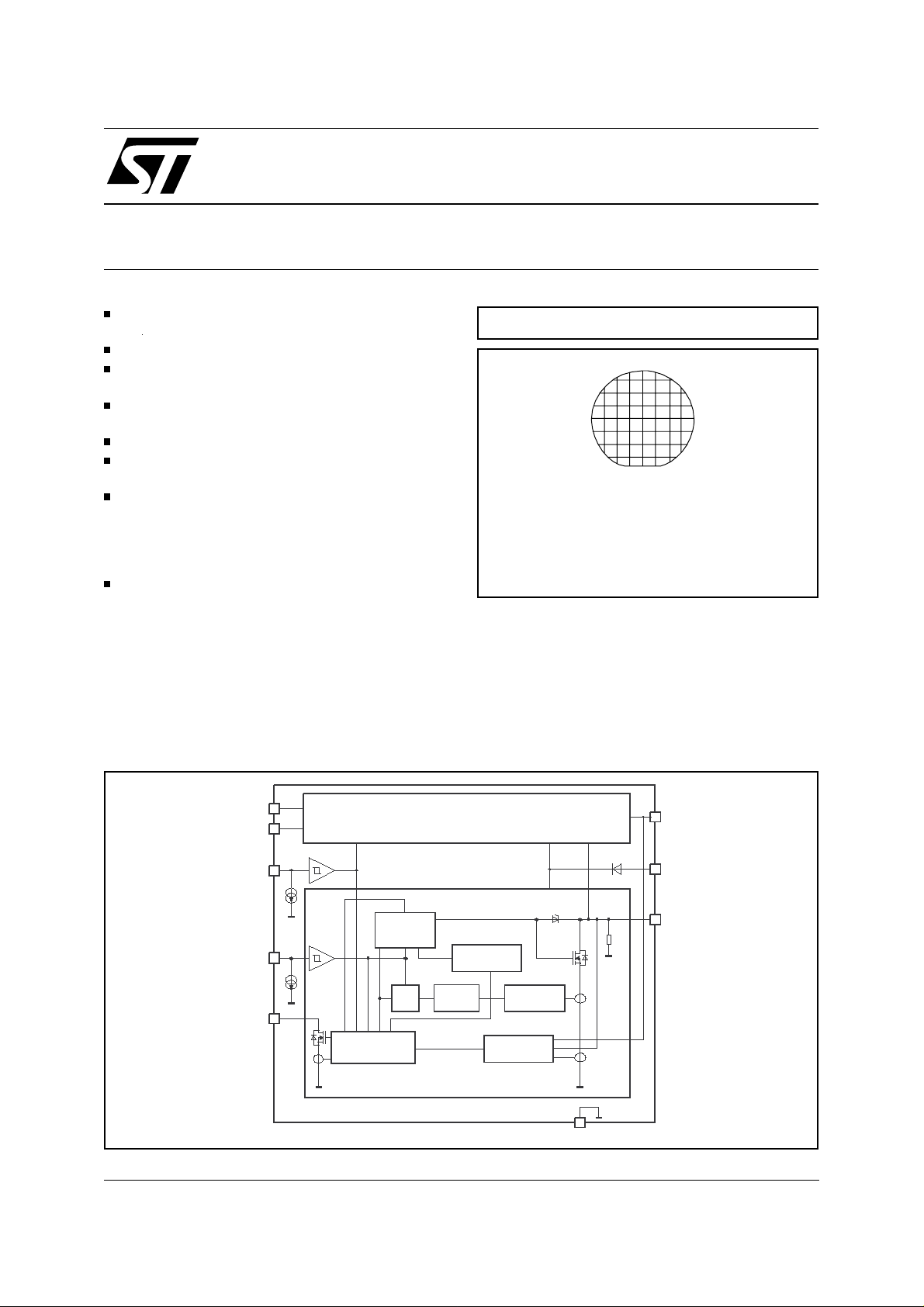

DUAL INTELLIGENT POWE R LOW SIDE SWITCH

DUAL POWER LOW SIDE DRIVER WITH 2 x

5A

LOW R

TYPICALLY 200mΩ @ TJ = 25°C

DSON

INTERNAL OUTPUT CLAMPING DIODES

V

=50V FOR INDUCTIVE RECIRCULATION

FB

LIMITED OUTPUT VOLTAGE SLEW RATE

FOR LOW EMI

P COMPA TIBLE ENAB L E AND INPUT

µ

WIDE OPERATING SUPPLY VOLTAGE

RANGE 4.5V TO 45V

REAL TIME DIAGNOSTIC FUNCTIONS:

- OUTPUT SHORTED TO GND

- OUTPUT SHORTED TO VSS

- OPEN LO AD

- LOAD BYPA SS

DEVICE PROTECTION FUNCTIONS:

- OVERLO AD D I SA BL E

- REVERSE BATTERY UP TO -16V @ V

S

- THERMAL SH UTDOW N

DESCRIPTION

The L9377 is a monolithic integrated dual low

side driver realized in an advanced Multipower-

BLOCK DIAGRAM

MULTIPOWER BCD TECHNOLOGY

DIE

ORDERING NUMBER:

L9377DIE1

BCD mixed technology. It is especially intended

to drive valves in automotive environment. Its inputs are µP compatible for easy driving. Particular

care has been taken to protect the device

against failures, to avoid electro-magnetic interferences and to offer extensive real time diagnostic.

July 2000

IN1

DIAG1

EN

IN2

DIAG2

Diagnostic

Control

Output

Control

R

QS

Channel 2

Channel 1

Overtemp

Delay

Timer

Overload

Openload

GND

OUT1

VS

OUT2

R

O

1/9

Page 2

L9377

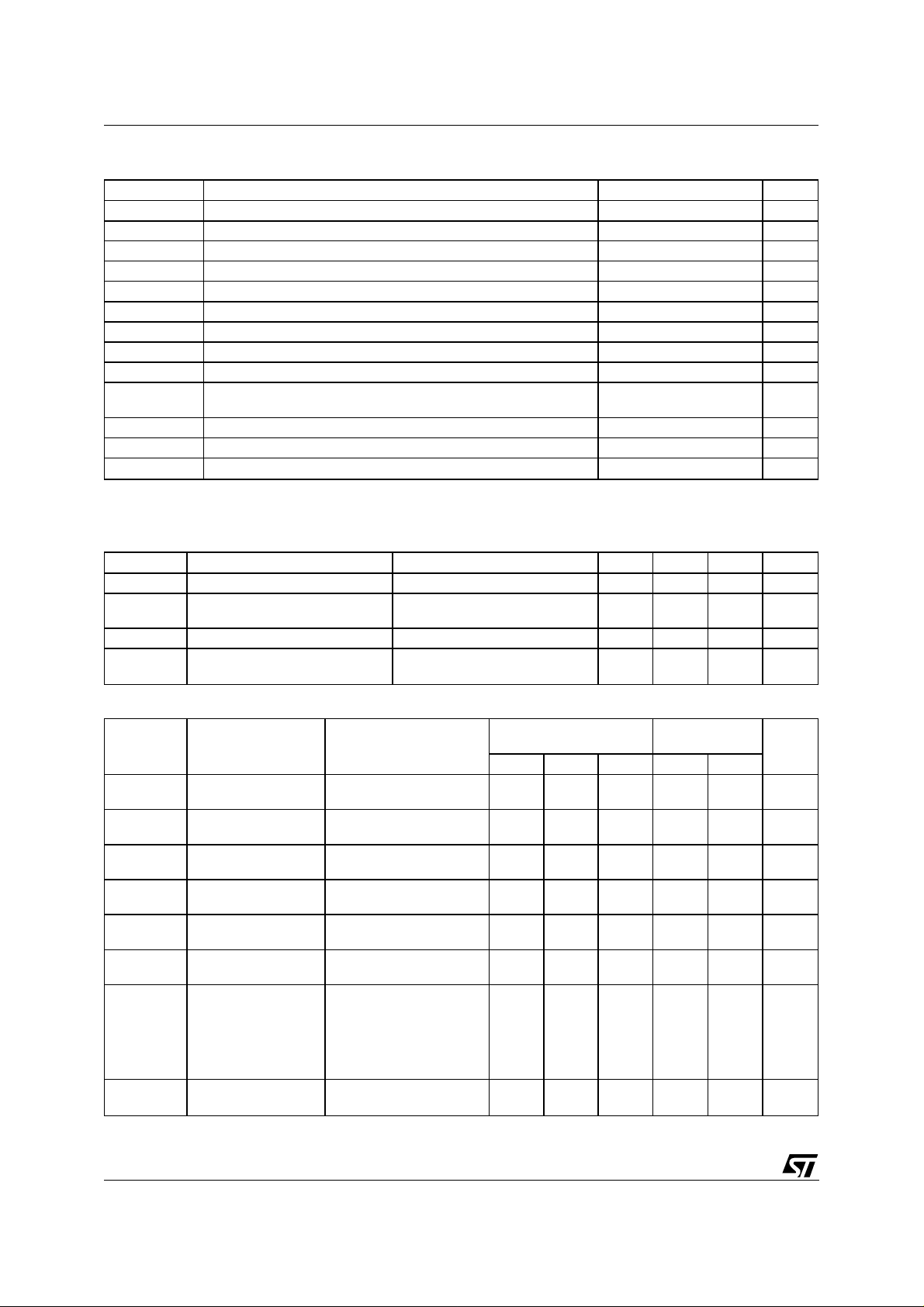

ABSOLUTE MAXIMUM RATINGS

(no damage or latch)

Symbol Parameter Value Unit

VS

DC

VS

TR

V

IN,EN

VD

DC

VO

DC

VO

TR

I

O

I

OR

DC supply voltage -16 to 45 V

Transient supply voltage ( t ≤ 500ms ) 60 V

Input voltage ( | ≤ | 10mA | ) -1.5 to 6 V

Diagnostic DC output voltage ( | ≤ | 50mA | ) -0.3 to 16 V

DC output voltage 45 V

Transient output voltage ( RL ≥ 4Ω )60V

Output load current internal limited

Reverse output current limited by load -4 A

EO Switch-off energy for inductive loads (tEO = 250µs, T = 5ms) 50 mJ

T

jEO

T

j

T

a

T

jDIS

ELECTRICAL CHARACTERISTICS

Junction temperature during switch-off ∑t ≤ 30min

∑t ≤ 15min

175

190

Junction temperature -40 to +150 °C

Storage temperature -55 to +150 °C

Thermal disable junction temp, threshold 180 to 210 °C

(Operating Range) - The electrical characteristics are valid within

the below defined operative range, unless otherwise specified.

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

S

V

D

T

j1

T

j2

*) Parameter will be guaranted by correlation

Board supply voltage 4.5 12 32 V

Stabilized diagnostic output

-0.3 5 16 V

voltage

Junction Temperature -40 150 °C

Junction temperature

150 210 °C

∑t ≤ 15min *)

°C

°C

Symbol Parameter Test Condition

IS

SB

Static standby

supply current

b)

c) V

EN

= L, VO ≥ VO

IS DC supply current b)

c) V

= VIN = H

EN

VD

ID

LE

ID Diagnostic output

VO

UV

Diagnostic ouput

L

low voltage

Diagnostic output

leakage current

current capability

Open load voltage

b) ID = 2mA

c) I

= 1mA

D

VS = 0V or VS = open;

VD = 5.5V T

VD ≤ 16V

DIAG = L

VEN = X, VIN = L 0.51

threshold

∆VO

UV1,2

Open load

difference voltage

threshold

b) VEN = X, VIN1,2 = L

16V ≥ VO

≥ VO

C

VOC = output voltage of

other channel

c)

IO

UC

Open load current

threshold

a) VEN = VIN = H

c)

2/9

≤ 125°C

j

UV

UV

Value

T

j1

Value

T

j2

Unit

Min. Typ. Max. Min. Max.

0.73 1.5

15

1.3 5

15

mA

mA

mA

mA

0.35 0.5 0.7 V

0.1 2 20 µA

2630 mA

x VS

VO

0.9V

VO

0.7V

100

20

0.55

x VS

VO

-

C

1.25V

VO

-

C

1.25V

320 480 580 mA

0.59

x VS

VO

-

C

0.5

x VS

0.8 1.7 V

-

C

0.65

x VS

V

1)

1.6V

VO

-

C

-

C

V

1.8V

mA

Page 3

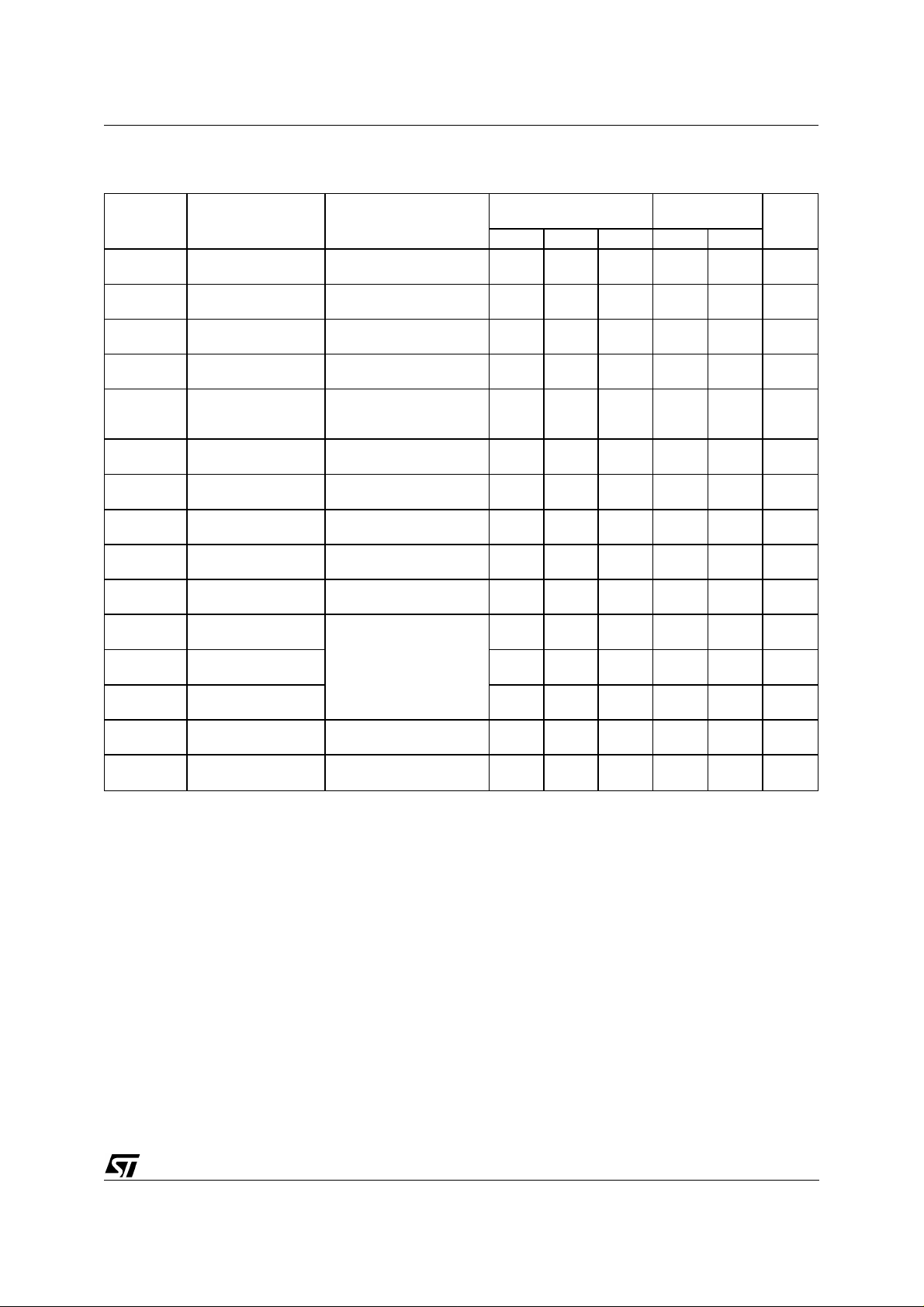

L9377

ELECTRICAL CHARACTERISTICS

(continued)

Symbol Parameter Test Condition

IO

OC

Over load current

b) 5 7 4 A

threshold

VO

CL

Output voltage

IOCL ≥ 100mA 455260 V

during clamping

S

ON,OFF

Output (fall, rise)

a) Fig. 2 200 1500 3200 200 3500 V/rms

slew rate

R

IO

Internal output pull

VEN = L 102040 50KΩ

down resistor

R

DSON

V

(EN,IN)L

Output on resistance VS > 9.5V IO = 2A

T

= 25°C;

j

T

= 150°C

j

Logic input low

|I

| ≤ 10mA -1.5 1 0.8 V

EN, IN

voltage

V

(EN,IN)H

Logic input high

voltage

V

(EN,IN)hys

Logic input

hysteresis

I

EN

Enable input sink

1V ≤ VEN ≤ 5.5V 10 30 60 80 µA

current

I

IN

Logic input sink

1V ≤ VIN ≤ 5.5V 40 95 180 240 µA

current

t

D ON

Output delay ON

Fig. 2 4 25 µs

time

t

D OFF

Output delay OFF

time

t

D H-L, Diag.

Diag. delay output

OFF time

t

D IOu

Diagnostic open

Fig. 4 8 50 µs

load delay time

t

DOL

Diagnostic overload

Fig. 1 50 160 300 µs

delay switch-off time

Value

T

j1

Value

T

j2

Unit

Min. Typ. Max. Min. Max.

200 300

500

mΩ

mΩ

2 5.5 V

0.2 0.4 0.8 V

51530 µs

56590µs

a) 9V ≤ VS ≤ 16V (Nominal operating range)

≤ 6Ω,

R

L

≤ IO

I

O

b) 6.5V ≤ VS ≤ 16V (Diagnostic operation range)

c) 4.5V ≤ V

1) Limit under evaluation.

OC

< 6.5V and 16V < VS ≤ 32V (Extended operation range)

S

3/9

Page 4

L9377

DIAGNOSTIC TABLE

(Operating range: 4.5V ≤ V

≤ 32V)

S

Conditions EN IN Out Diag.

Normal function L

GND short VO

Load bypass VO

Open load IO

≥ 175°C

T

j typ

< 0.55V L X off H

typ

≥ 1.25V H L off H

1,2

< 320mA H H on (*) L

typ

Overtemperature (**)

Latched Over load IO

> 5A X H off L

min

H

H

X

X

X

L

H

L

H

off

off

on (*)

off

off

L

L

H

H

L

Reset over load latch X D.C. D.C.

(*) for 4.5V ≤ VS < 6.5V, IO ≤ 2A diag. table is valid.

(**) If one diag. status shows the overtemp. recognition, in parallel this output will be switched OFF internally. The corresponding channel should

be switched OFF additional by its Input or ENABLE signal, otherwise the overload latch will be set after t

be related to the overdrop sensing which will be used as over load recognition.

Figure 1:

Diagnostic overload delay time

UI

5V

is passed. This behaviour will

DOL

IO

IO

IO

SC

5A

UC

UD

5V

t

td

OL

t

t

4/9

Page 5

L9377

Figure 2:

V

V

U

0.85VO

VS-VO

0.85VS

VO

0.15VS

Output slope.

U

IN

5V

(IN)H

(IN)L

OUT

VO

C

C

VS

CC

UV

td

on

td

off

S

off

S

on

t

t

V

DIAG

0.5V

V

D

D

t

D

H-L

Diag

t

5/9

Page 6

L9377

Figure 3:

Block diagram - Open load voltage detection.

L1 L2

OUT1 OUT2

IN

1

VS

55%

R

IO

-

V

Batt.

IN

R

IO

+

+

-

2

Enable

& &

R

S

Latch

Q

Latch

S

Q

& &

VO

UV1

VO

R

UV2

6/9

Page 7

L9377

Figure 4:

Logic diagram.

open load

voltage

normal

operation

OFF

ON

latch reset

open load voltage

open load current

off

td

normal

operation

u

on

td

IO

td

latched over.

load diagnostic

OL

td

over load

current

open load

current

normal

operation

u

on

td

IO

td

open load current

normal

operation

OFF ON

EN

V

IN

V

u

VO

o

IO

IO

u

D

V

7/9

Page 8

L9377

CIRCUIT DESCRIPTION

The L9377 is a dual low side driver for inductive

loads like valves in automotive environment. The

device is enabled by a common CMOS compatible ENABLE high signal. The internal pull down

current sources at the ENABLE and INPUT pins

protect the device in open input conditions

against malfunctions. An output slope limitation

for du/dt is implemented to reduce the EMI. An integrated active flyback voltage limitation clamps

the output voltage during the flyback phase to

50V.

Each driver is protected against short cir cuit and

thermal overload. In short circuit condition the

output will be disabled after a short delay time

to suppress spikes. This disable is latched

t

DOL

until a negative slope occure at the correspondent

input pin. The thermal disable for T

> 175°C of

J

the output will be reseted if the junction t emperature decreases about 20°C below the disable

threshold temperature.

For the r eal time error diagnosis t he voltage and

the current of the out puts are compared with internal fixed values VO

conditions to recognize open load (R

for OFF and IOUC for ON

UV

≥ 20KΩ, R

L

> 38Ω) in ON and OFF conditions. The diagnostic

operates also in the extended supply voltage

range of 4.5V ≤ VS ≤ 32V.

Also the output voltages VO

are compared

1,2

against each other in OFF condition with a fixed

offset of ∆VO

to recognize GND bypasses.

UV 1,2

To suppress mail ∆VO diagnoses during the flyback phases of the compared output, the ∆VO diagnostic includes a latch function. Reaching the

flyback clamping voltage VO

the diagnostic sig-

C

nal is reseted by a latch. To activate again this

kind of diagnostic a low signal at the correspondent INPUT or the ENABLE pin must occur (see

also Fig.3).

The diagnostic output level in connection with different ENABLE and INPUT conditions allows to

recognize different fail states, lik e ov er temp, short

to VSS, short to GND, bypass to GND and disconnected load (see also page 7 diagnostic table).

The diagnostic output is also protected against

short to UD

threshold IO

. Oversteping the over load current

max

, the output current will be limited in-

o

ternally during the diagnostic overload delay

switch-off time t

L

DOL

.

Figure 5:

+5V

µ P

Controller

Application circuit diagram.

IN1

DIAG1

EN

IN2

DIAG2

Output

Control

Diagnostic

Control

R

QS

Channel 2

Channel 1

Overtemp

Delay

Timer

Overload

Openload

Z

VALVE

OUT1

VS

R

OUT2

O

Z

VALVE

V

Batt

8/9

GND

Page 9

L9377

Information furnishe d is beli eved to be accu rate and reliable. However, STMicroelec tronics assumes no res ponsibility for the consequences

of use of such i nformation nor for any i nfringement of patents or ot her rights of third par ties which may result from its use. No license i s

granted by impli cation or otherwis e under any patent or patent righ ts of STMicroelect ronics. Specifica tion mentioned in this publication are

subject to change without notic e. This public ation supers edes and replaces all information prev iously supplied. STMic roelec tronic s products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelect roni cs

© 2000 STMicroelectronics – Printed in Italy – All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

9/9

Loading...

Loading...