Page 1

5V & 12V SPINDLE AND VCM MOTORS DRIVER

■

12V & 5V (±10%) OPERATION

■

REGISTER BASED ARCHITECTURE

■

3 WIRE SERIAL COMMUNICATION

INTERFACE UP TO 33 MHZ

■

BCD TECHNOLOGY

L7250

PRODUCT PREVIEW

Spindle Motor Controller

■

INTERNAL POWER DEVICE 0.9 OHM MAX

VALUE @ 125°C (SINK+SOURCE)

■

2.5A PEAK CURRENT CAPABILITY

■

ST SMOOTHDRIVE SINUSOIDAL PWM

COMMUTATION

■

DEDICATED ADC FOR POWER SUPPLY

VOLTAGE COMPENSAT IO N

■

SPINDLE CURRENT LIMITING VIA FIXED

FREQUENCY PWM OF SPINDLE POWER

OUTPUTS AT THE SMOOTHDRIVE PWM

RATE

■

SYNCHRONOUS RECTIFICATION DURING

PWM TO REDUCE POWER DISSIPATION

■

CURRENT SENSING VIA EXTERNAL

CURRENT SENSE RESISTOR

■

INDUCTIVE SENSE POSITION START UP

DRIVEN BY µPROCESSOR

■

SPINDLE BRAKING DURING POWER DOWN

CONDITION

Voice Coil Motor Driver with Ramp Load/Unload

■

INTERNAL POWER DEVICE 0.9 OHM MAX

VALUE @ 125°C (SINK+SOURCE)

■

2A PEAK CURRENT CAPABILITY

■

15 BIT LINEAR DAC FOR CURRENT

COMMAND, WITH INTERNAL REFERENCE

VOLTAGE

■

SENSE AMPLIFIER GAIN SWITCH

■

CLASS AB OUTPUT STAGE WITH ZERO

DEAD-BAND AND MINIMAL CROSSOVER

DISTORTION

■

RAMP LOAD AND UNLOAD CAPABILITY AS

WELL AS CONSTANT VOLTAGE RETRACT

■

EXTERNAL CURRENT SENSE RESISTOR IN

SERIES WITH MOTO R .

■

HIGH CMRR (>70DB) AND PSRR (>60DB)

SENSE AMP

■

EXTERNAL CURRENT CONTROL LOOP

COMPENSATION

■

HIGH BANDWIDTH VCM CURRENT

CONTROL LOOP CAPABI L ITY

■

HIGH PSRR, LOW OFFSET, LOW DRIFT GM

LOOP

ORDERING NUMBER: L7250

■

VCM VOLTAGE MODE, CONTROLLED BY

TQFP64

VCM DAC

■

GM LOOP OFFSET CALIBRATION SCHEME

INCLUDES A COMPAR ATOR ON THE

ERROR AMP

Auxiliary Functions

■

3.3V AND 1.8V LINEAR REGULATOR

CONTROLLER

■

NEGATIVE VOLTAG E REGUL ATOR

■

INTERNAL ISOFET 0.1 OHM @125C

■

POWER MONITOR OF 12V, 5V, 3.3V AND

1.8V

■

SHOCK SENSOR CIRCUIT TAKES INPUTS

FROM PIEZO OR CHARGING ELEMENT

■

10 BIT ADC WITH 4 MUXED INPUTS

■

THERMAL SENSE CIRCUIT AND OVER

TEMPERATURE SHUT DOWN

■

CHARGE PUMP BOOST VOLTAGE

GENERATOR FOR HIGH SIDE GATE DRIVE

■

ANALOG PINS AVAILABL E TO ENTER

SIGNALS TO BE CONVERTED BY THE

INTERNAL ADC

DESCRIPTION

L7250 is a power IC for driving the SPINDLE and

VCM motors, suitable for 5V & 12V application. The

spindle system includes integrated power FETs

which are driven using ST's Smoothdrive pseudo-sinusoidal commutation technology. The voice coi l motor (VCM) system includes integrated power FETs,

as well as ramp load and unload capability. Linear

3.3V and1.8V volt age regulators ar e include d, as wel l

as a negative regulator.

Power monitoring of VCC5, VCC12, and of the two

positive voltage regulators is also included.L7250

uses a 3 wire serial interface: S_DATA, S_CLK and

S_ENABLE

July 2001

This is preliminary information on a new product now in development. Details are subject to change without notice.

1/46

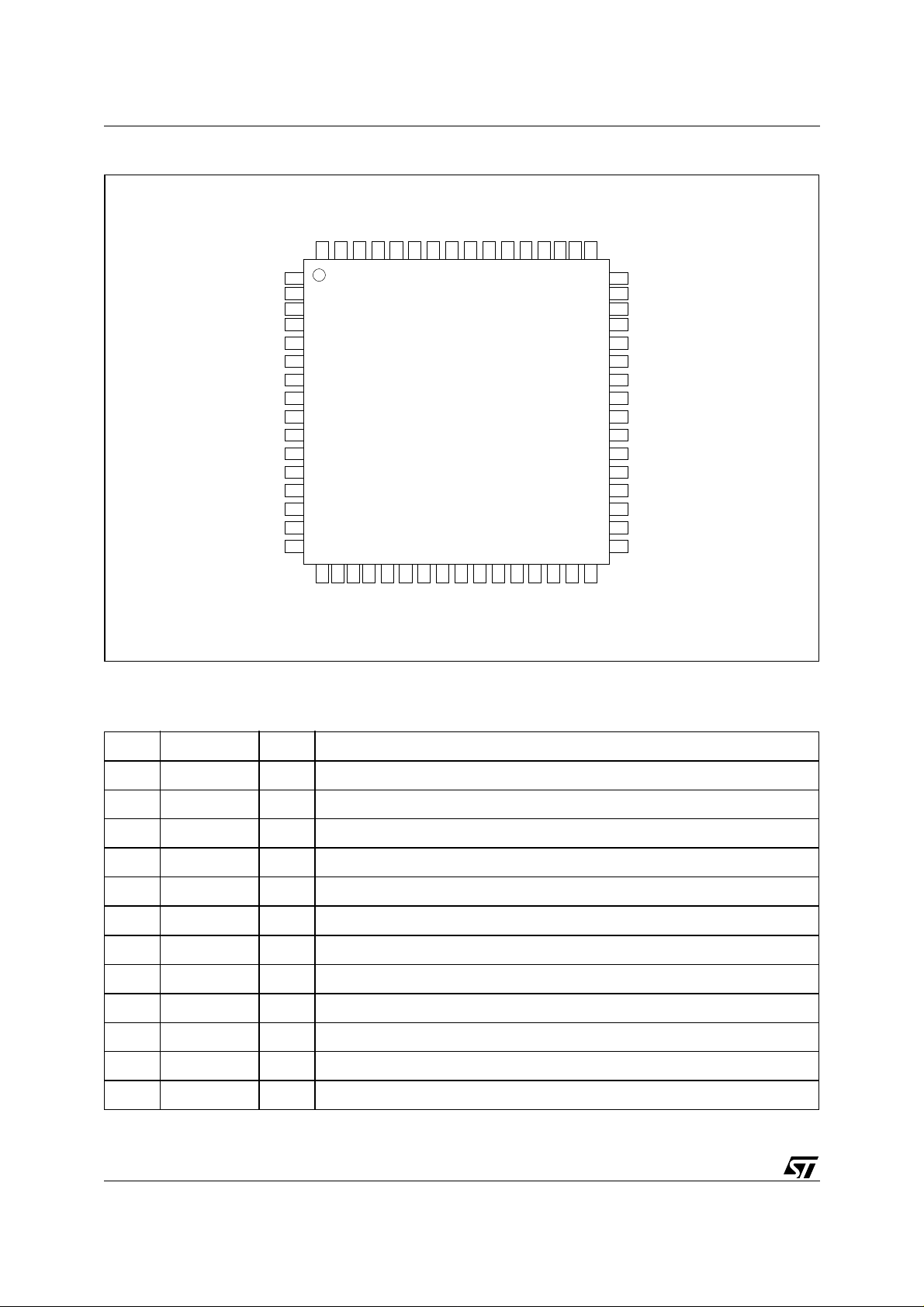

Page 2

L7250

PIN CONNECTION

(Top view)

VCV1

VCV2

VCMP1

VCMP2

VCMGND1

VCMGND2

CPOSC

VCC5

DIG_GND

N_DRV

N_FEED

N_COMP

25_BASE

25_FEED

33_BASE

33_FEED

CT

OUTU1

RSEN4

VBOOST

64

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

OUTU2

CPOSCH

61

62

63

20212223242526272829303132

191718

RSEN3

60

59

58

VCV3

OUTV1

OUTV2

55

56

57

VCV4

VM1

VM2

53

54

Rsense

OUTW2

OUTW1

514950

52

RSEN2

48

RSEN1

47

VCMN2

46

VCMN1

45

VCMGND4

44

VCMGND3

43

SNS_N

42

SNS_P

41

SNS_OUT

40

ERR_OUT

39

ERR_IN

38

DAC_OUT

37

SCLK

36

SYSClk

35

SDATA

34

33

SEN

ZC

Skin

SkFin

CPOR

CBRAKE

VREF25

AGND

NPOR

Skout

SkFout

Timer1

SkDout

CalCoarse

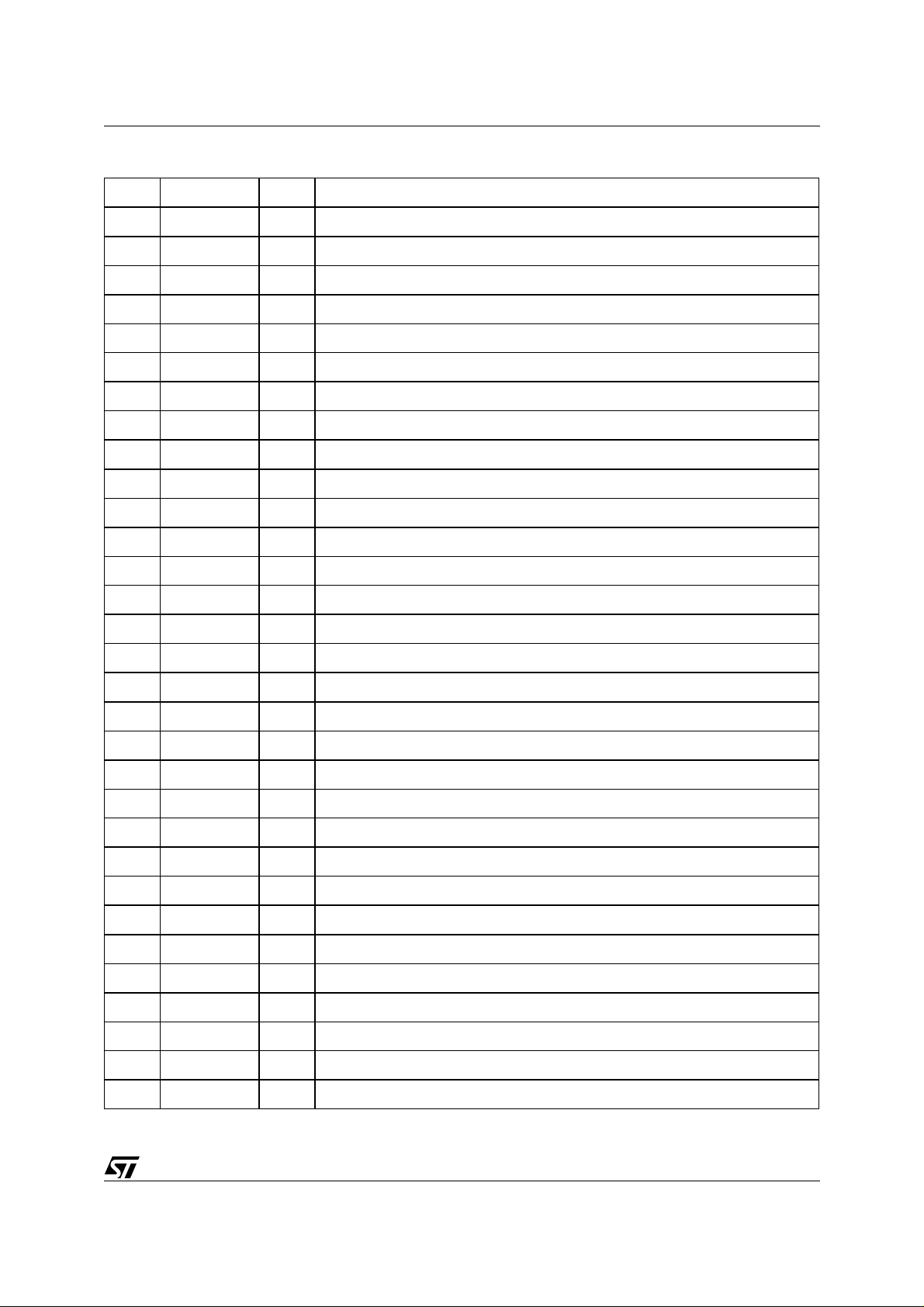

PIN DESCRIPTI ON

N° Pin V Description

1 VCV1 S12 12V power supply

2 VCV2 S12 12V power supply and POR sensing threshold

3 VCMP1 O12 VCM positive output

4 VCMP2 O12 VCM positive output

5 VCMGND1 gnd VCM power ground

6 VCMGND2 gnd VCM power ground

7 CPOSC O12 Charge pump oscillator

8 VCC5 S5 5V power supply

9 DIG_GND gnd Digital & Switching regulator ground

10 N_DRV O5 Neg Reg ext FET gate driver

11 N_FEED I5 Neg Reg feedback

Test

ADaux

VCMBEMF

12 N_COMP IO5 Neg Reg error output

2/46

Page 3

L7250

PIN DESCRIPTI ON

N° Pin V Description

13 25_BASE O5 Reg 1.8V ext NPN base

14 25_FEED I5 Reg 1.8V feedback

15 33_BASE O5 Reg 3.3V ext NPN base

16 33_FEED IO5 Reg 3.3 V feedback

17 CPOR IO5 POR delay capacitor

18 NPOR O5 POR output signal

19 CBRAKE IO5 Spindle brake capacitor

20 AGND gnd analog gnd

21 VREF25 IO5 2.5V reference

22 ZC O5 Spindle zero crossing

23 Skin I5 Shock sensor input

24 Skout O5 Shock sensor 1st opamp output

25 SkFin I5 Shock sensor filter input

26 SkFout O5 Shock sensor filter output

(continued)

27 SkDout O5 Shock sensor output

28 Timer1 IO5 Timer 1 for unload procedure

29 CalCoarse I5 VCM BEMF coarse calibration

30 ADaux I5 auxiliary input for the ADC

31 VCMBEMF O5 VCM BEMF processor output

32 Test IO5 used for testing porpouse (*)

33 SEN I5 Serial enable

34 SDATA IO5 Serial data

35 SYSClk I5 System clock

36 SCLK I5 Serial clock

37 DAC_OUT O5 VCM DAC output

38 ERR_IN I5 VCM error opamp input

39 ERR_OUT O5 VCM error opamp output

40 SNS_OUT O5 VCM sense opamp output

41 SNS_P I12 VCM sense opamp positive input

42 SNS_N I12 VCM sense opamp negative input

43 VCMGND3 gnd VCM power ground

3/46

Page 4

L7250

PIN DESCRIPTI ON

N° Pin V Description

44 VCMGND4 gnd VCM power ground

45 VCMN1 O12 VCM negative output

46 VCMN2 O12 VCM negative output

47 RSEN1 O12 Spindle power sensing resitor

48 RSEN2 O12 Spindle power sensing resitor

49 Rsense I5 Spindle sensing resistor input

50 OUTW1 O12 Spindle phase C output

51 OUTW2 O12 Spindle phase C output

52 VM1 IO12 Vmotor

53 VM2 IO12 Vmotor

54 VCV4 S12 12V power supply

55 VCV3 S12 12V power supply

56 OUTV1 O12 Spindle phase B output

57 OUTV2 O12 Spindle phase B output

(continued)

58 RSEN3 O12 Spindle power sensing resitor

59 RSEN4 O12 Spindle power sensing resitor

60 OUTU1 O12 Spindle phase A output

61 OUTU2 O12 Spindle phase A output

62 CT I12 Spindle central tap

63 CPOSCH IO20 Charge pump diodes connection

64 VBOOST IO20 Charge Pump voltage

(*) used al so to set the IC power supply applicati on. If this pin is pull-up exter nal l y the L7250 be came a 5V appl i cation

S = Supply ; IO = Input/Output ; I = Input ; O = Output ; gnd = Ground.

4/46

Page 5

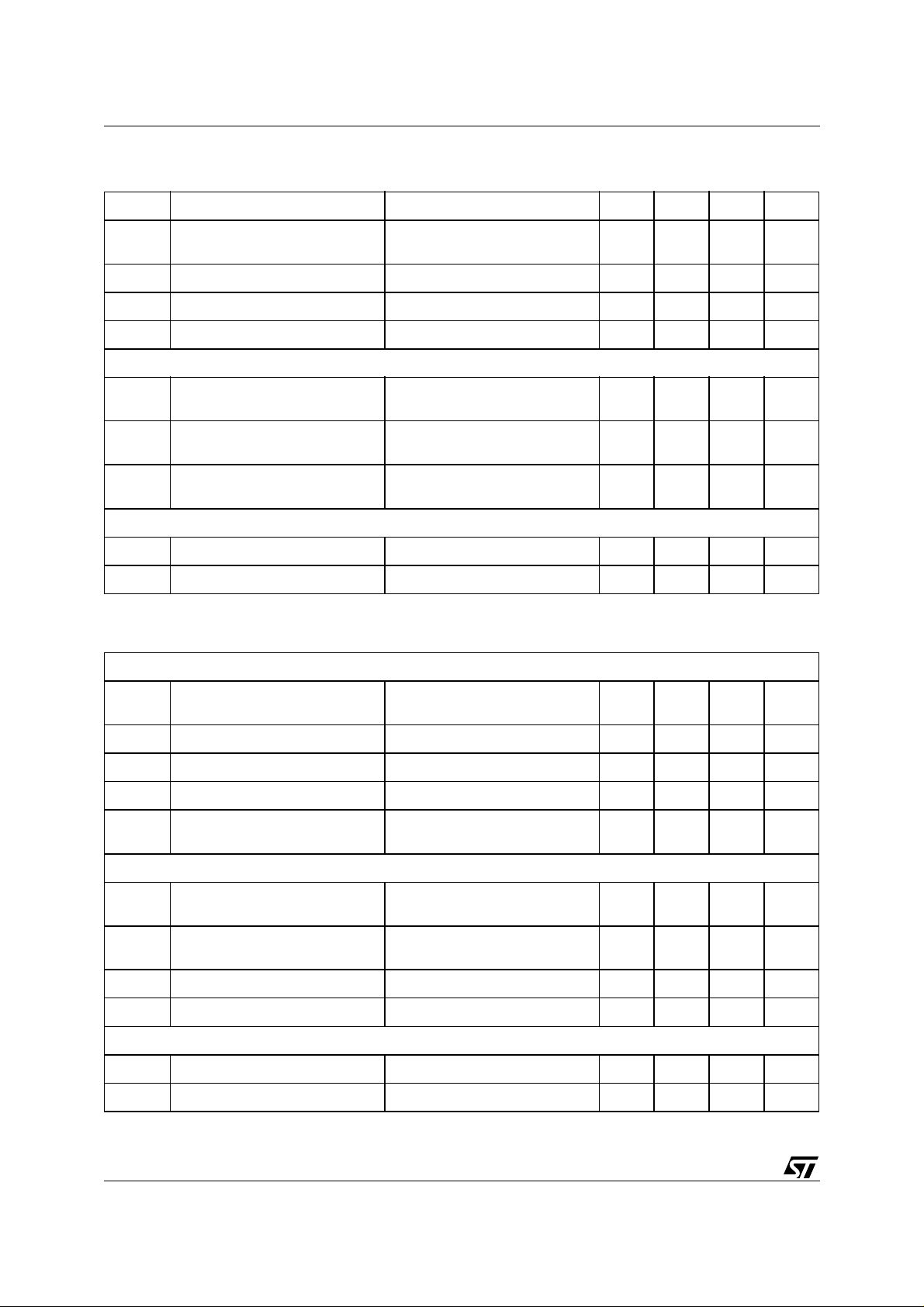

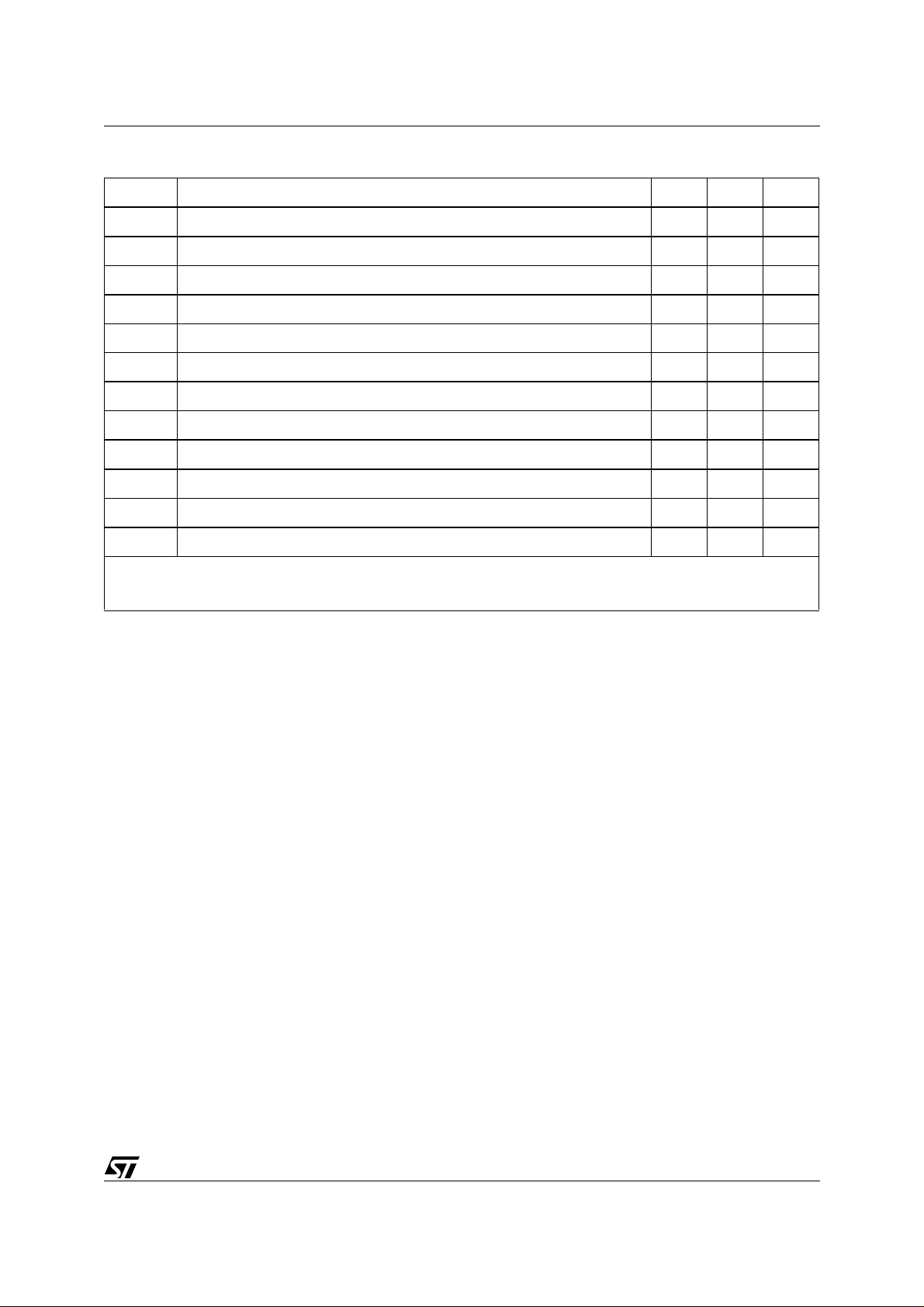

ELECTRICAL CHARACTERISTCS

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

VCV1,VCV2,VCV3,VCV4 14 V

VCC5 maximum voltage 6 V

L7250

OUTU1,OUTU2,OUTV1,OUTV2,OUTW1,OUTW2

VCMP1,VCMP2,VCMN1,VCMN2

VM1,VM2

Digital Input Voltage -0.3 to VCC5 V

Operating free-air temperature 0 to 70 °C

Storage Temperature -55 to 150 °C

-1V to 16 V

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

Symbol Parameter Test Condition Min. Typ. Max. Unit

POWER MONITOR, SUPPLY CURRENTS, ETC.

Icc5 VCC5 Operating current Spindle and VCM enabled, no

load

Ivcv VCV + VRET Operating current Spindle and VCM enabled, no

load

CHARGE PUMP VOLTAGE BOOSTER

VBOOSTCharge pump output voltage VCV = 12V

Iload = 5mA

= 25°C (unless otherwise specified)

amb

9mA

44 mA

18.5 V

VBOOS

Tfreq

POWER MONITOR

vt5 VCC5 threshold 4.0 4.175 4.35 V

vt12 VCC12 threshold 9 9.5 10 V

hv5 VCC5 hysteresis 40 100 160 mV

hv12 VCC12 hysteresis 100 200 300 mV

vt33 V33 Threshold 2.7 2.8 2.9 V

hv33 V33 Hysteresis 20 40 60 mV

vt18 V18 Threshold (at pin 25_FEED) 1.07 1.12 1.17 V

hv18 V18Hysteresis 25 50 75 mV

NPOR

Switching frequency 1 MHz

NPOR low level output voltage VCV > 4.5V Iol = 5mA 0.75 V

low

5/46

Page 6

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

(continued)

= 25°C (unless otherwise specified)

amb

Symbol Parameter Test Condition Min. Typ. Max. Unit

NPOR

NPOR internal pull_up resistor to

pull

6Kohm

V33

CPOR

CPOR

CPOR charging current Vout = 0V 5 uA

Ic

CPOR low level output voltage VCV > 4.5V Iol = 1mA 50 mV

low

Vref25 2.5V reference voltage -5% 2.5 +5% V

THERMAL WARNING AND THERMAL SHUTDOWN

T

warn

Thermal warming temperature Characterized, tested by

130 140 150 °C

correlation.

Tsoff Thermal Shutdown temperature Characterized, tested by

150 165 180 °C

correlation

Thys Thermal Hysteresis valid for both temperature

20 25 30 °C

thresholds

VM ISOLATION FET

IsoR Rds ON @ 125°C , I=2.5A 0.1 Ohm

IsoI Continuous current 2.5 A

SPINDLE DRIVER SECTION

POWER STAGE

Rds(on) Total output ON resistance

@ 125°C, I=2.5A 0.9 Ω

(Source + Sink)

Idsx Output leakage current -200 -500 µA

CTlkg Centarl tap leakage 1 µA

DiodeFw Clamp diode forward voltage If = 2.5A 0.6 1.2 V

Slew Output slew rate OUTx 10% to 90%

40 V/µS

Reg04H ‘b7b6b5’ = 011

BACK EMF COMPARATOR

Vie Common mode input voltage

Guaranteed by design 0 VM V

range.

Vr Input voltage range where output

Guaranteed by design -1 VM+1 V

shall not invert.

BEMFoff BEMF input offset CT = 6V -15 +15 mV

BEMFhy BEMF hysteresys CT = 6V 50 mV

SPINDLE CURRENT LIMITING

Iin RSENSE Input bias current. 0 < Vin < 3.3V 1 µA

CURoff Comparator offset -15 +15 mV

6/46

Page 7

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

(continued)

= 25°C (unless otherwise specified)

amb

Symbol Parameter Test Condition Min. Typ. Max. Unit

CURdacr

CUR

CUR

CUR

DAC resolution 3 bit

DAC output Reg04H ‘b4b3b2’ = 000 250 mV

dac_L

DAC output Reg04H ‘b4b3b2’ = 111 600 mV

dac_H

DAC linearity -10 +10 mV

lin

Cbrake

Icbrake VCbrake leakage VCbrake=5V 1 µA

VCM SECTION

CURRENT SENSE AMPLIFIER

Vts Common mode input voltage

GBD - not tested -0.6 VM+1 V

range.

Sns _vof

Sns_gai n0

f Input offset voltage -12 12 mV

Differential Voltage GAIN0 Reg09H ‘b7’ = 0 -5% 4.5 +5%

Sns _gain1

Sns_low

Sns_high

sns_slew

Sns_band

sns _cmrr

sns _svrr

Differential Voltage GAIN1 Reg09H ‘b7’ = 1 -5% 16 +5%

VSENSE output saturation

voltage

Iload=+/-1mA

Vin_diff=+/- 500m V

4.75

250 mV

V

Output slew rate Cload=50pF 1 V/µs

-3dB Bandwidth Guaranteed by design 200 400 kHz

Common mode rejection ratio f < 10 KHz, tested at DC only

CMRR=A

V DIFF/AV CM

70 dB

supply voltage rejection ratio VCV f < 10 KHz, tested at DC only 60 dB

ERROR SUMMING AMPLIFIER

err _gain Voltage gain no load 60 dB

err _band

Unity gain bandwidth Guaranteed by design 4 MHz

err _slew Output Slew Rate Cload=50pF 1.5 V/µS

err _ibias

Input bias current 1 µA

err _off Input offset voltage -10 0 10 mV

err_svrr supply voltage rejection ratio f < 10 KHz, tested at DC only 60 dB

err _clamp

Low output (clamp) voltage Isink = 1 mA, referred to Vref25 TBD V

low

7/46

Page 8

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

Symbol Parameter Test Condition Min. Typ. Max. Unit

err _clamp

high

VCM OUTPUT DRIVERS

PWR_Gain

Rds(on) Total output ON resistance

PWR_Lkg

DiodeFw Clamp diode forward voltage If = 2A 0.6 1.2 V

THD Total Harmonic Distortion characterized no tested 1 %

PWR_Slew

PWR_B

and

Icross Static Shoot-through current Guaranteed by design 0 mA

VCM CURRENT CONTROL LOOP STATIC AND DYNAMIC CHARACTERISTICS

IVCMoff Total offset current Rs=0.2 -75 75 mA

High output (clamp) voltage Isource = 1mA, referred to Vref25 TBD V

Power amplifier differential gain. Io = ±1A, Rload = 8Ω 14 15 16 V/V

(Source + Sink)

Output leakage current 600 uA

VCMN or VCMP slew rate RL = 8 ohms 1 V/us

Power Amp -3dB Bandwidth Driving ERROUT = VDACREF,

(continued)

@ 125°C, I=2A .9 Ω

Guaranteed by design

= 25°C (unless otherwise specified)

amb

250 500 kHz

DIVCMoff

Gm_psrr Gm loop VSRR of VCV -1 1 mA/V

VCM LINEAR DAC

DAC_res Resolution 15 bit

DAC_out Full Scale Output Voltage wrt VDACREF 0.96 1 1.04 V

DAC_off Mid-Scale Error wrt VDACREF -12 12 mV

DAC_DNL

DAC_INL

DAC_Co

nvT

VCM LOAD/UNLOAD

ADC

ADC_res

ADC_DNL

ADC_INL

Total offset current drift

temperature coefficient

Differential Non linearity Guaranteed Monotonicity ±1 LSB

Integral Non Linearity ±64 LSB

Conversion time 90% from 3FFFh to 0020h 3 µs

resolution 10 bit

Differential Non Linearity 1 LSB

Integral Non Linearity 3 LSB

Guaranteed by design .2

mA/oC

ADC_Co

nvT

8/46

Conversion time 40 ADC

Clock

cycles

Page 9

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

Symbol Parameter Test Condition Min. Typ. Max. Unit

ADC AUXILIARY INPUT

AUX_ran

ge0

AUX_ran

ge1

AUX_Ibias

VCM VOLTAGE AMPLIFIER

V olt_gain

Volt_off Input offset -15 +15 mV

Vo lt

_cmrr

Volt

_svrr

BEMF processor amplifier

CalCoar

seIn

Input range 0 Reg06H ‘b3’ = 0

Input range 1 Reg06H ‘b3’ = 1

Input bias -100 100 µA

Voltage gain 0.165 V/V

Common mode rejection ratio f < 10 KHz, tested at DC only

supply voltage rejection ratio f < 10 KHz, tested at DC only 60 dB

Calcoarse voltage input range 0.5 2 V

(continued)

Referred to Vref25

Referred to Vref25

CMRR=A

V DIFF/AV CM

= 25°C (unless otherwise specified)

amb

±1 V

±2.25 V

46 dB

Gain1 First stage gain Vcontrol = 1.25 V 1.91 V/V

Gain2 Second stage gain 16 V/V

Offset Residual input offset after

calibration

Rout BEMF amp output resistance (pin

31)

ULOAD @ POR

Timer1_V

Timer1_I Timer1 Discharging Current 2 µA

Timer1_T

VOLTAGE REGULATORS

1.8 AND 3.3 LINEAR REGULATOR

V18 feed 1.8V feedback Voltage -5% 1.25 +5% V

V33 OUT

Timer1 Charging Voltage 2.5 V

Timer1 Low threshold 0.2 V

3.3V Output Voltage -5% 3.3 +5% V

Vcontrol = 1.25V

(Measured between VCMN and

SNS_P pins)

-3 +3 mV

500 ohm

9/46

Page 10

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

Symbol Parameter Test Condition Min. Typ. Max. Unit

V18

IDRIVE

V33

IDRIVE

NEGATIVE REGULATOR

FREQ0 Oscillator frequency Default configuration 500 KHz

FREQ1 Oscillator frequency TestRegister = ‘00001001’

VoutH High level output voltage TBD V

VoutL Low level output voltage TBD V

VNEerr

OFFS

VNEGerr

BIAS

Vneg_err

_cmrr

Vneg_err

_svrr

Output base current drive

Feedback input offset -10 10 mV

Feedback input bias 0 1 µA

Common mode rejection ratio f < 10 KHz, tested at DC only

supply voltage rejection ratio VCV f < 10 KHz, tested at DC only 60 dB

(continued)

or = ‘00101001’

CMRR=A

V DIFF/AV CM

= 25°C (unless otherwise specified)

amb

1 MHz

46 dB

15 mA

SHOCK SENSOR

SkIgain0 Input OPAMP gain0 Reg02H ‘b7’ = 0 10 V/V

SkIgain1 Input OPAMP gain1 Reg02H ‘b7’ = 1 80 dB

SkIoff Input OPAMP offset -15 +15 mV

SkIinput Input OPAMP input impedance Reg02H ‘b7’ = 0 10 Mohm

SkFgain Filter OPAMP open loop gain 80 DB

SkFband Filter OPAMP unity gain

bandwidth

SkFoff Filter OPAMP offset voltage -10 +10 MV

SkOThH0

SkOThH1

SkOThL0

SkOThL1

Output window comparator

VthHigh

Output window comparator

VthHigh

Output window comparator

VthLow

Output window comparator

VthLow

Guaranteed by design 5 Mhz

Referred to Vref25 ;

Reg02H ‘b6’ = 0

Referred to Vref25 ;

Reg02H ‘b6’ = 1

Referred to Vref25;

Reg02H ‘b6’ = 0

Referred to Vref25;

Reg02H ‘b6’ = 1

200 mV

500 mV

200 mV

500 mV

10/46

Page 11

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

Symbol Parameter Test Condition Min. Typ. Max. Unit

SERIAL PORT

Voh Logic Output voltage high Ioh=1mA 2.7 V

Vol Logic Output voltage low Iol=1mA 0.5 V

Vih L ogic input high Iih=1uA 2.2 V

Vil Logic input low Iil=-1uA 0.5 V

Iih Logic high input current Internal Pulldown Resistor

Iil Logic low input current -1.00 µA

(continued)

Vin = 3.3V

= 25°C (unless otherwise specified)

amb

33 µA

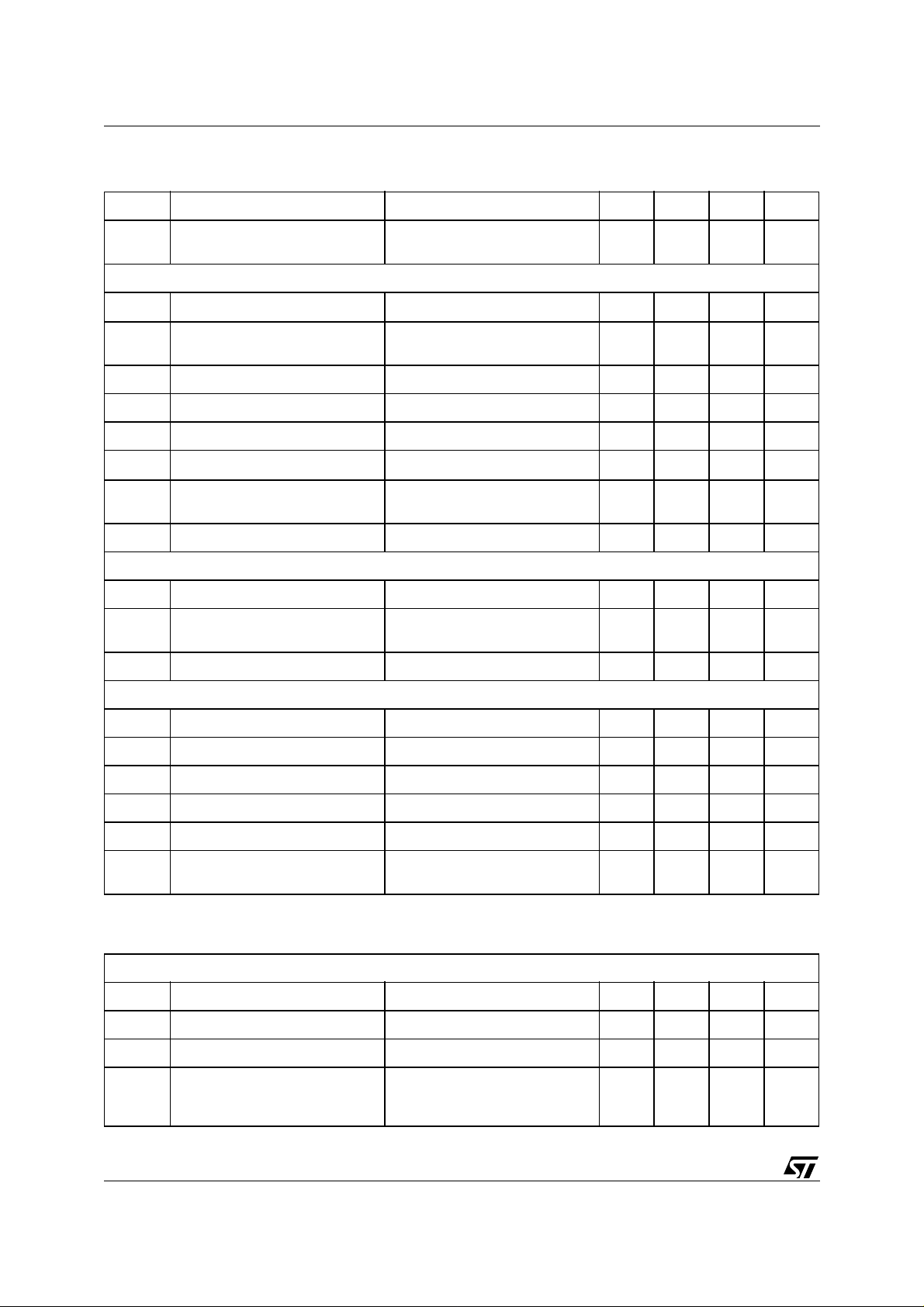

1 SERIAL PORT

The serial port is a bidirectional three pi n interface, using SDATA, SCLK and SE N to addr ess and communi cate

with sixteen 8 bit registers in the L7250. These registers include the status register, Spindle control registers,

VCM control registers, sinewave drive registers, and test mode register. These registers are cleared to zero at

power up.

1.1 Default comunication modes setting (bit 7, Reg05H ) = 0

After the SEN falling edge, the internal state machine is waiting for the first SCLK falling edge. This means that

if the SCLK line starts from an high level the first falling edge, respecting the setup time Tefcf, is considered,

and is used to read the R/W bit. During a writing process the internal state machine must see 16 SCLK falling

edges to validate the operation. The write mode is started if the R/W bit is low on the first falling edge of SCLK.

The read mode is started if the R/W bit is high on the first falling edge of SCLK. The ID, Address, and Data are

all then subsequently read by the L7250 on the falling edges of SCLK. (See Figure 1)

The microcontroller has to read the data on the falling edge of the SCLK signal. After the hold time (Tedh) the

data line switches to the next data without a tri-state phase.During a read mode the last address bit is read by

L7250 on the eighth falling edge of SCLK. The internal state machine then turns the SDATA bit around for the

L7250 to assume control at the next SCLK rising edge (the first rising edge after the 8th SCLK falling edge).

11/46

Page 12

L7250

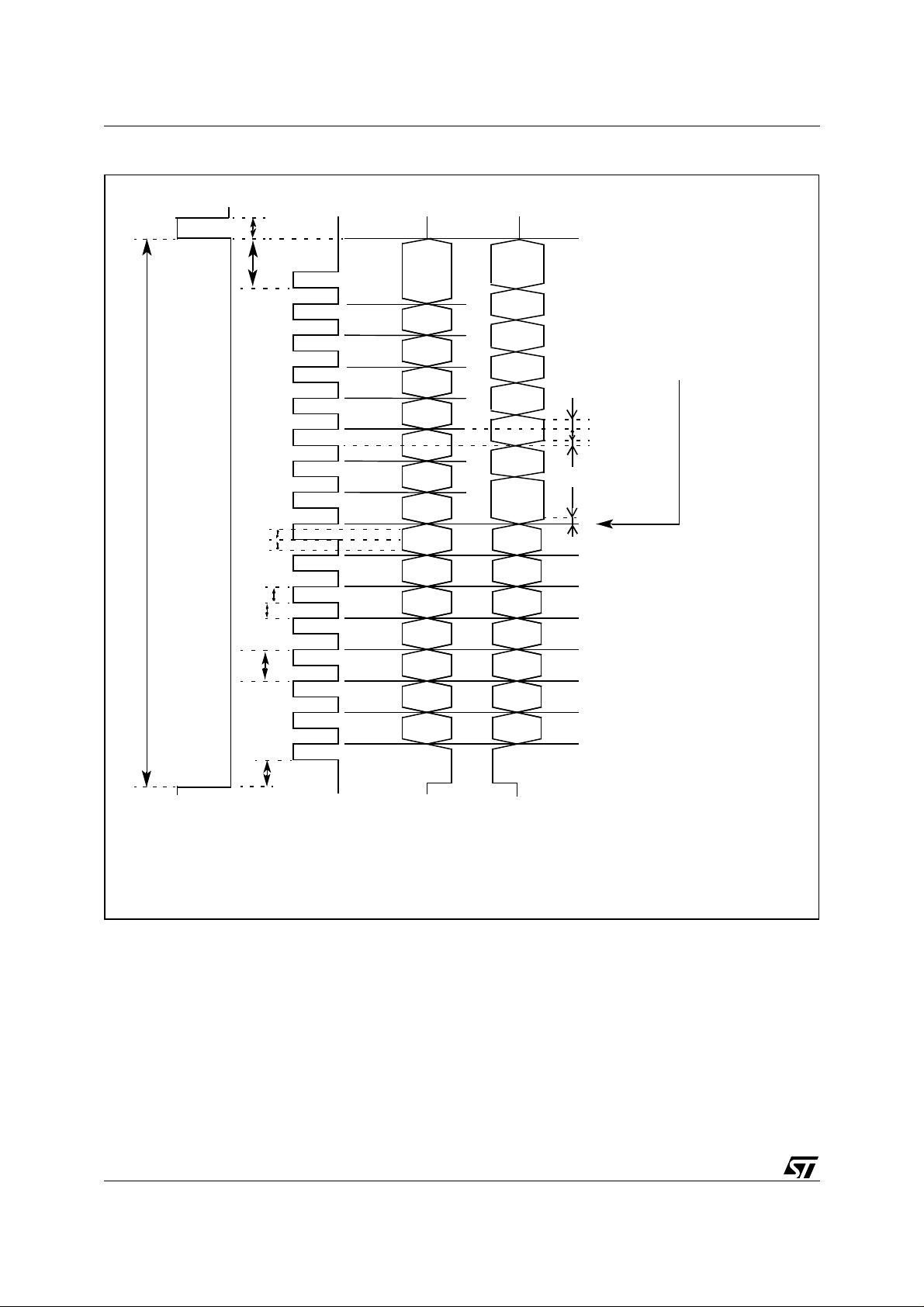

Figure 1. Default serial port timing diagram (bit 7, Reg05H = 0)

Teh

Tcfer

Tcrer

D1 D0

D2

D0

Tedh

D5 D4 D3

D6

D6 D5 D4 D3 D2 D1

D7

Tdly

Tcdd

L 7250 takes bus control

Tcds Tcdh

A1 A0 D7

A2

A1 A0

A2

Tcc Tch Tcl

ID2 ID2 A2

ID2 ID2 A2

ID 2

Tefcf

SEN

Note1: During writing process L7250 latches the data on the SC LK falling edge (the ASI C is writing on the SCLK

rising edge)

Note2: During reading process L7250 takes the bus control on the next SCLK rising edge after the 8th SCLK

falling edge

The L7250 write the data on the SCLK falling edge respecting the data hold time (Tedh)

Note3: The ID number for the L7250 is ID1=ID2=ID3=1

12/46

SCLK

W

SDATA

(w rite)

ID 2

R

SDATA

(read)

Page 13

1.2 Default serial port timing Table

Symbol Parameter Min Max Unit

Tcc Serial clock period 30 ns

Tch Serial clock high time 13 ns

Tcl Serial clock low time 13 ns

Tcds Serial data setup time to clock falling edge (write mode) 5 ns

Tcdh Serial clock falling edge to serial data hold time (write mode) 4 ns

Tedh Serial clock falling edge to serial data hold time (read mode) 5 ns

Tcdd Serial data setup time to clock falling edge (read mode) 5 ns

Tel Serial Enable low time 490 ns

Teh Serial Enable high time 30 ns

Tefcf Serial Enable falling edge to serial clock falling edge 17 ns

Tcfer Serial clock falling edge to Serial enable rising edge 17 ns

Tdly SDATA turn around delay time 0 ns

L7250

Note 1: All specifications with respect to 50% of signal switching thresholds

Note 2: Reading mode tested at M ax 20Mhz

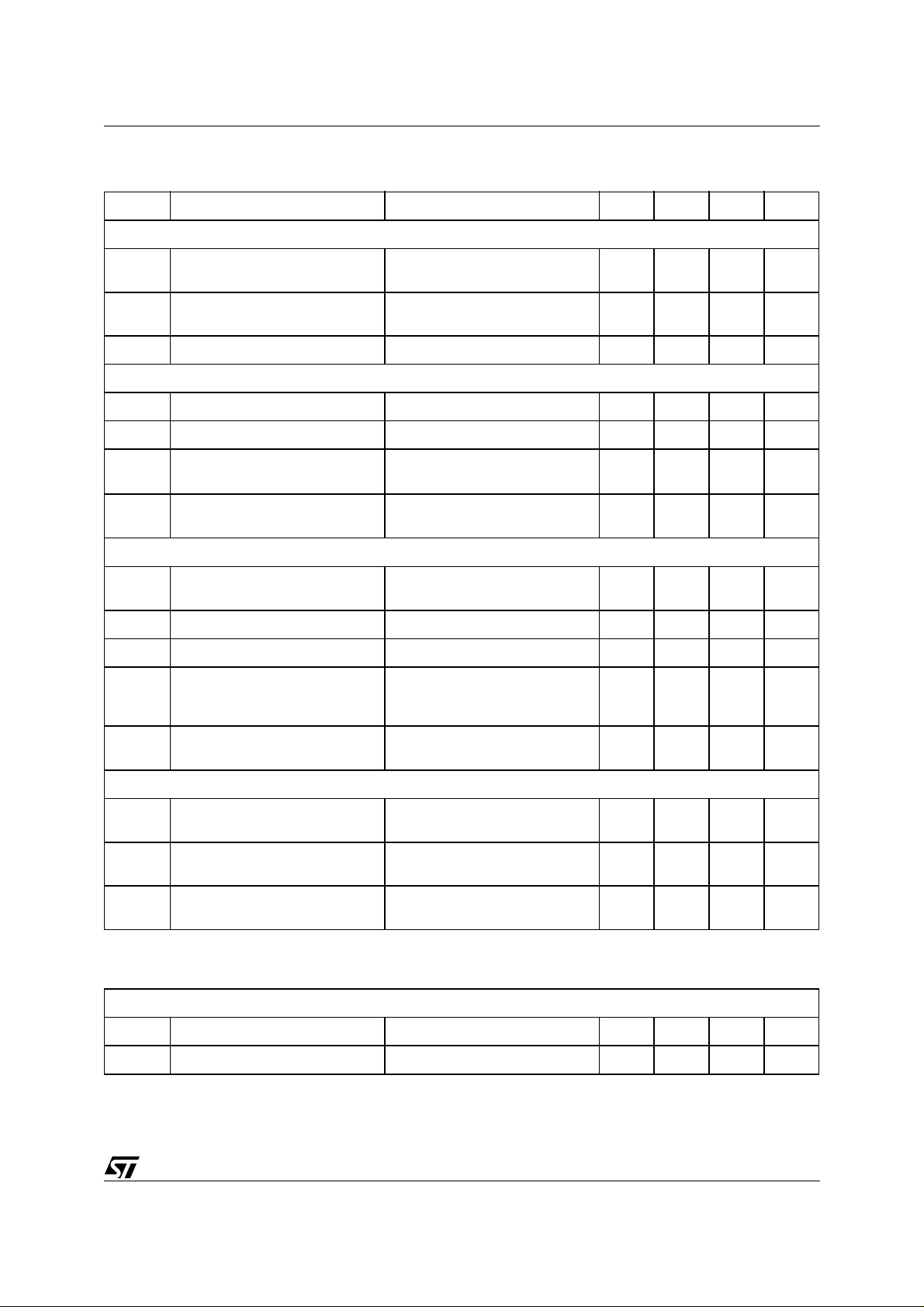

1.3 Inverted clock comunication modes (bit 7, Reg05H) = 1

To set the bit7, Reg05H to 1, entering this different comunication mode, a writing process using the default comunication protocol (see the above paragraph) must be used.

After the SEN falling edge, the internal state machine is waiting for the first SCLK rising edge. This means that

if the SCLK line starts from a low level the first rising edge, respecting the setup time Tefcr, is considered, and

is used to read the R/W bit. The internal state machine must see 16 SCLK rising edges to validate the write

operation. The write mode is started if the R/W bit is low on the first rising edge of SCLK. The read mode is

started if the R/W bit is h igh on the first rising ed ge of SCLK. The ID, Address, and Data are a ll then subsequently read by the L7250 on the rising edges of SCLK (See Figure 2).

The microcontroller has to r ead (l atch) the data on the falli ng edge of the SCLK signal. L7250 pr esents the data

on the SCLK rising edge. During a read mode the last address bit is latched by the L7250 on the eighth rising

edge of SCLK. The internal state machine then turns the SDATA bit around for the L7250 to ass ume control at

the next SCLK falling edge (the first falling edge after the 8th SCLK rising edge).

13/46

Page 14

L7250

Figure 2. Inverted clock serial port timing diagram (bit 7, Reg05H = 1)

Teh

Tcrer

D1 D0

D2

D0

Tedh

D5 D4 D3

D6

Tel

D6 D5 D4 D3 D2 D1

D7

Tdly

Tvld

L7250 takes bus control

Tcdh

Tcds

A1 A0 D 7

A1 A0

Tcl

A2

A2

Tch

Tcc

ID 2 ID2 A2

ID 2 ID2 A2

ID 2

Tefcr

SEN

Note1: During writi ng proc ess L7250 l atches the data on the SCLK ris ing ed ge ( the ASIC is w riting on the S CLK

falling edge)

Note2: During reading proces s L7250 takes the bus c ontrol on the next SCLK falling edge after the 8th SCLKrising edge

The L7250 write the data on the SCLK rising edge and it is expec ting the ASIC to latches the data on the SCLK

falling edge

Note3: The ID number for the L7250 is ID1=ID2=ID3=1

14/46

SCLK

W

SDATA

(w rite)

R

SDATA

ID 2

(read)

Page 15

1.4 Inverted clock serial port timing Table

Symbol Parameter Min Max Unit

Tcc Serial clock period 30 ns

Tch Serial clock high time 13 ns

Tcl Serial clock low time 13 ns

Tcds Serial data setup time to clock falling edge (write mode) 5 ns

Tcdh Serial clock falling edge to serial data hold time (write mode) 4 ns

Tedh Serial clock falling edge to serial data hold time (read mode) 5 ns

Tvld Serial clock rising edge to SDATA stable time (read mode)

Cload=5pF (see Note2)

Cload=50pF (see Note2) 11

15

Tel Serial Enable low time 490 ns

Teh Serial Enable high time 30 ns

Tefcr Serial Enable falling edge to serial clock rising edge 17 ns

Tcrer Serial clock rising edge to Serial enable rising edge 17 ns

L7250

ns

ns

Tdly SDATA turn around delay time 0 ns

Note 1: All specifications with respect to 50% of signal switching thresholds

Note 2: In reading mode the clock frequency is li m i ted by this pa ram eter;

in fact the min ‘serial clock high time’ is defined by (Tvld+Tasu)

where Tasu = min ASIC setup time

15/46

Page 16

L7250

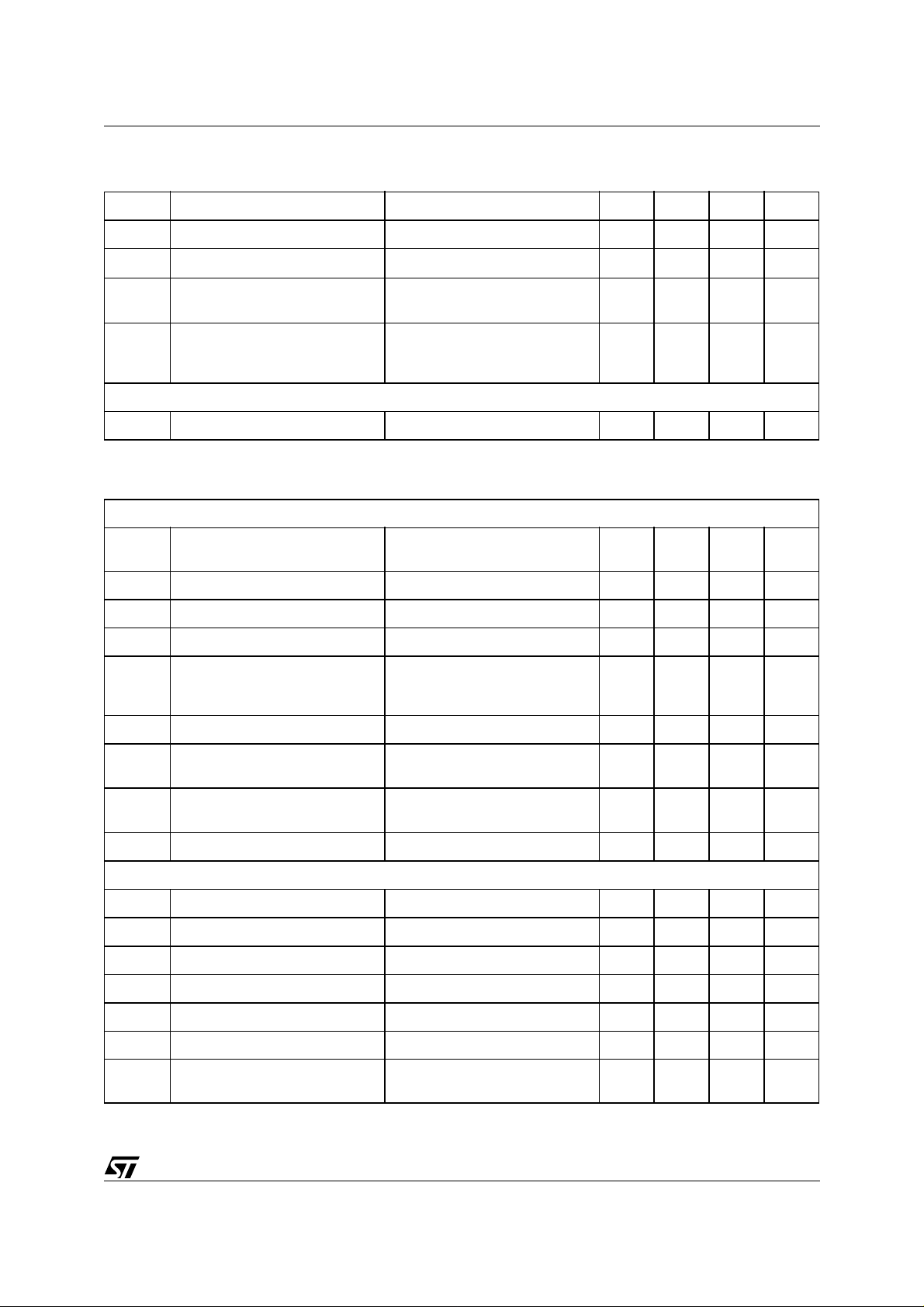

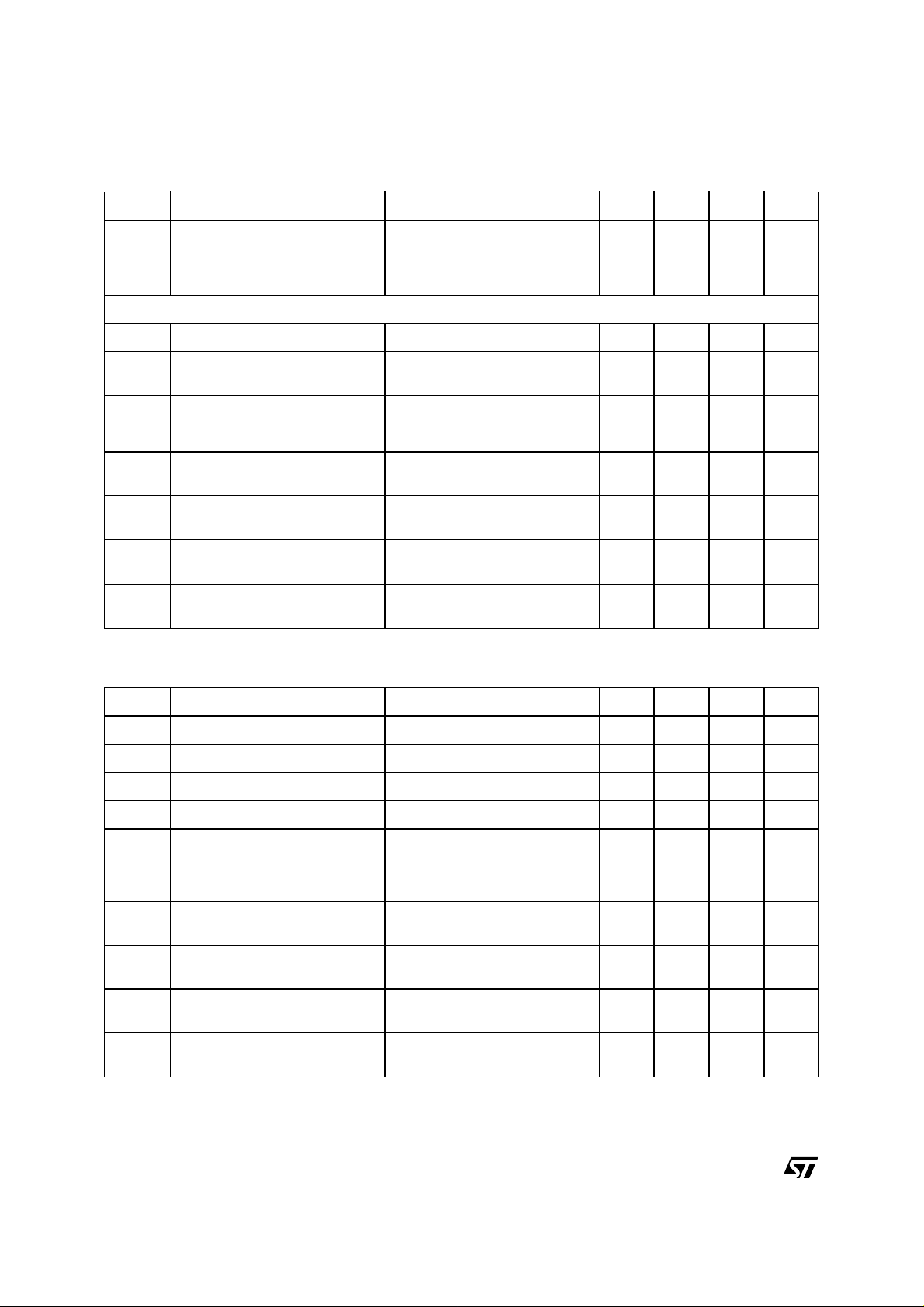

Table 1. Register Map

addr b7 b6 b5 b4 b3 b2 b1 b0 name

00H SPNCurrSignVCMcalOut ZCBad

ThShutdown

ThWarn rev2 rev1 rev0 SR status readonly

mnemoni

c

attributes

01H RLvoltage1

02H ShockConf ShockTh[0]

03H BemfOffCal VCMState2 VCMState1 VCMSt ate0 SP state3 SPstate2 SPstate1 SPstate0 CTR1 SP&VCMst

04H SPslew2 SPslew1 SPslew0 Cu rdac2 Curdac1 Curdac0

05H SPIprot m3 m2 m1 m0 TSDen VnegEn Sken CTR3 control read/write

06Hw4w3w2w1w0

07H LoadCP Adv a nc e FFWEn TO4 TO3 TO2 TO1 TO0 CTR5 control read/write

08H Kv7 Kv6 Kv5 Kv4 Kv3 Kv2 Kv1 Kv0 KVR Kv a l read/write

09H GainSwitch dac14 dac13 dac12 dac1 1 dac10 dac9 dac8 DAR1 DAC reg 1 read/write

0AH dac7 dac6 dac5 dac4 dac3 dac2 dac1 dac0 DAR2 DAC reg 2 read/write

0BH ADC_DATA

0CH ADC_DAT A

0DH reserved reserved reserved reserved reserved reserved reserved reserved read/write

0EH reserved reserved reserved reserved reserved reserved reserved reserved read/write

0FH test7 test6 test5 test4 test3 test2 test1 test0 TEST test read/write

RLvo ltage1

[1]

ADC_DATA

(9)

ADC_DATA

(1)

RLvo ltage2

[0]

RL ToffBrake

ADC_DATA

(8)

ADC_RES

(0)

_ADDR(1)

RLvoltage2

[1]

RL ToffBrake

[1]

ADC_DATA

(7)

ADC_RES

_ADDR(0)

Rltimer[2] Rltimer[1] Rltimer[0] NoBrake VCM1 VCM RLreg read/write

[0]

Rlcalib[3] Rlcal ib[2] Rlcalib[ 1] Rlcalib[0] VCM2 VCMR L reg read/write

[0]

ADC_DATA

(6)

ADCRange ADC_CH_

PREADC(1) PREADC(0)

ADC_DATA

(5)

ADDR(1)

PWMmask 1 PWMmask0

ADC_DATA

(4)

ADC_CH_

ADDR(0)

PREsm o CTR4 control read/write

ADC_DATA

(3)

(2)

ADC_START

CTR2 control read/write

ADR ADC reg readonly

ADR ADC reg read/write

read/write

ate

16/46

Page 17

L7250

Table 2. Register map content description

Bit SPI field name Content

REGISTER SR, ADDRESS: 00H

[2:0] Rev[2:0] Revision number of the device, set internally

[3] ThWarn Thermal warning

[4] ThShutdown Thermal shutdown

[5] ZCbad Signals a problem with spindle speed loop synchronism

[6] VCMcalOut VCM error output in calibration mode

[7] SPNCurrSign Spindle current sign to implement adaptive torque optimizer

REGISTER VCM1, ADDRESS: 01H

[0] NoBrake 0=VCM active brake phase enabled

[3:1] Rltimer[2:0] 000 = only Unload1 is enabled

(continued)

control

1= VCM active brake phase disabled

001 = threshold set to 0.4V

010 = threshold set to 0.8V

011 = threshold set to 1.2V

100 = threshold set to 1.6V

101 = threshold set to 2V

110 = threshold set to 2.4V

111 = only Unload2 is enabled

[5:4] Rlvoltage2[1:0] Selects between 4 values of unload voltage in Unload2 phase:

00 = 1V

01 = 1.125V

10 = 1.250V

11 = 1.375V

[7:6] Rlvoltage1[1:0] Selects between 4 values of unload voltage in Unload1 phase:

REGISTER VCM2, ADDRESS: 02H

[3:0] Rlcalib[3:0] 0111 = 29.4%

00 = 0.375V

01 = 0.5V

10 = 0.625V

11 = 0.75V

0110 = 25.2%

0101 = 21%

0100 = 16.8%

0011 = 12.6%

0010 = 8.4%

0001 = 4.2%

0000 = 0%

1111 = -4.2%

1110 = -8.4%

1101 = -12.6%

1100 = -16.8%

1011 = -21%

1010 = -25.2%

1001 = -29.4%

1000 = -33.6%

17/46

Page 18

L7250

Table 2. Register map content description

Bit SPI field name Content

[5:4] RLToffBrake[1:0] Selects the duration of Toff (Ton) active brake phase:

[7] SkockConf Selects the Shock Sensor application

[6] SkockTh[0] Selects the Shock Sensor threshold

REGISTER CTR1, ADDRESS: 03H

[3:0] Spstate[3:0] 0000 = CLCOAST

[6:4] VCMstate[2:0] Possible states for the VCM:

(continued)

00 = 300usec

01 = 400usec

10 = 500usec

11 = 600usec

0 = piezo element

1 = charging element

0 = Vref +/- 200mV

1 = Vref +/- 500mV

0001 = OLCOAST

0010 = OLSIX

0011 = OLSIN

0100 = OLBRAKE

0101 = INDSENSE

0110 = CLSIX

0111 = CLSIN

1000 = CLBRAKE

000 = Unload/Retract

001 = tri-state

010 = brake

011 = enable current mode

100 = enable voltage mode

101 = offset calibration

110 = confirm the previous state

111 = confirm the previous state

[7] BemfOffCal VCM BEMF processor offset calibration

REGISTER CTR2, ADDRESS: 04H

[1:0] PWMmask[1:0] Selects the length of the mask over PWM rising edge:

[4:2] Currdac[2:0] Selects the voltage threshold for the spindle current limiter:

18/46

00 = 2 us

01 = 4 us

10 = 6 us

11 = 8 us

000 = 250mV

001 = 300mV

010 = 350mV

011 = 400mV

100 = 450mV

101 = 500mV

110 = 550mV

111 = 600mV

Page 19

L7250

Table 2. Register map content description

Bit SPI field name Content

[7:5] Spslew[2:0] 000 = 10 V/us

REGISTER CTR3, ADDRESS: 05H

[0] Sken 0 = shock sensor output no latched

[1] Vnegen 0 = negative regulator disabled

[2] TSDen 0 = thermal shutdown disabled

[6:3] M[3:0] masking while sensing ZC, expressed in terms of half samples

[7] SPIprot 0 = default protocol

(continued)

001 = 20 V/us

010 = 30 V/us

011 = 40 V/us

100 = 50 V/us

101 = 60 V/us

110 = 70 V/us

111 = 80 V/us

1 = shock sensor output latched (to clear the latched information

a transition 1 -> 0 -> 1 is necessary)

1 = negative regulator enabled

1 = thermal shutdown enabled

after window opening

In terms of electrical degrees the single mask step is 3.75.

1 = inverted SCLK protocol

REGISTER CTR4, ADDRESS: 06H

[0] PREsmo 0 = spindle clock is system clock divided by two (FFWDADC clock

is system clock divided by 8)

1 = spindle clock is system clock (FFWDADC clock is system

clock divided by 4)

[2:1] PREADC[1:0] 00 = sleep mode

01 = ADC clock is system clock divide by 4

10 = ADC clock is system clock divide by 2

11 = ADC clock is system clock

[7:3] W[4:0] Windowing while sensing ZC, expressed in terms of half samples

before TO value

In terms of electrical degrees the single window step is 3.75.

REGISTER CTR5, ADDRESS: 07H

[4:0] TO[4:0] Coarse and fine section of phase shift, applied for torque

[5] FFWEn 0 = power supply compensation for spindle disabled

[6] Advance 0->1 increments by one the current sample position

[7] LoadCP 0->1 enables load of TO value as the current sample position

REGISTER KVR, ADDRESS: 08H

optimization.

In terms of electrical degrees the Torque Optimizer single step is

0.937 electrical degrees.

1 = power supply compensation for spindle enabled

[7:0] Kv[7:0] KVAL factor for speed loop control

19/46

Page 20

L7250

Table 2. Register map content description

Bit SPI field name Content

REGISTER DAR1, ADDRESS: 09H

[6:0] Dac[14:8] 7 MSB for VCM dac

[7] GainSwitch 0 = gain voltage of the VCM sense amplifier equal to 4.5 V/V

REGISTER DAR2, ADDRESS: 0AH

[7:0] Dac[7:0] 8 LSB for VCM dac

REGISTER ADR, ADDRESS: 0BH

[7:0] ADC_DATA[9:2] 8 MSB output data from ADC conversion

REGISTER ADR, ADDRESS: 0CH

[0] ADCSTART 0-> 1 starts a new ADC conversion

[2:1] ADC_CH_ADDR[1:0] Channel whose conversion is required

[3] ADCrange 0 = the 4 signals enter directly (maintaining the proper dynamic

(continued)

1 = gain voltage of the VCM sense amplifier equal to 16 V/V

00 = VCM current sense amplifier output

01 = VCM voltage amplifier output

10 = VCM BEMF

11 = Auxiliary Channel (external pin)

range) the ADC block

1 = the 4 signals are scaled down to the ADC dynamic range

[5:4] ADC_RES_ADDR[1:0] Channel whose result conversion is currently present in

REGISTER ADR, ADDRESS: 0DH

0DH [7:0] reserved

REGISTER ADR, ADDRESS: 0EH

0EH [7:0] reserved

REGISTER ADR, ADDRESS: 0FH

0FH [7:0] Test[7:0] Test register

ADC_DATA

20/46

Page 21

2 SPINDLE MOTOR CONTROLLER

(

)

Figure 3.

REGISTER

KVAL

MULTIPLIER

ZERO

CROSSING

PERIOD

COUNTER

16+4 BIT

KVAL

DIGI TAL

6 State

or

Sine

Mode

COARSE

PHASE

ADVANCE

BITS

LOADCP

BIT

OLSIX/O L SIN

OR CLSIX/CLSIN

ADVANCE

BIT

FINE

PHASE

ADVANCE

BITS

SMOOTHDRIVE

RAW

DUTY CYCLE

SMOOTHDRIVE

PROFILE

MEMORY/

LOGIC

MEMORY

ADDRESS

COUNTER

N=48

FSCAN

FSCAN

COUNTERZCTc

SYSCLK

16.5MHZ

SMOOTHDRIVE

MODULATED

DUTY CYCLE

START-OF-COUNT

WINDOW

TRISTATE

CMD

WINDOW

MASK

PWM MASK

MASK

REGISTERS

COMPENSATION

COUNTER

&

COM PA R ATOR S

CURRENT

COMP.

SUPPLY

VOLTAGE

ADC

BEMF

COMP.

LIMIT

VM

TIME DOMAIN

DUTY CYCLE

SIGNALS

FET

GATE

DRIV E

FET

GATE

DRIV E

FET

GATE

DRIV E

CUR DAC

L7250

VM

HGU

MOTU

LGU

VM

HGV

MOTV

LGV

VM

HGW

MOTW

LGW

CTAP

xx

SPSENH

xx

SPINDLE

MOTOR

2.1 Spindle Sm oothdrive Functionality

L7250 utilizes ST's proprietary Smoothdrive commutation algorithm. Smoothdrive is a voltage mode pseudosinusoidal spindle drive scheme where the duty cycles of the three windings are modulated to form sinusoidal

voltages across each winding. The system determines the shape and amplitude of the driving voltages in a

completely digital manner.

2.2 SYSCLK

The Smoothdrive system clock comes through the SYSCLK pin.

The system expects eit her 33MH z or 16.5M Hz on t his pi n, and needs 16.5MH z internally. A SYSCLK divide by

two can be enabled by a SPI register bit PRESMO to accomodate a 33MHz external clock.

2.3 Smoothdrive Wave shape

The basic Smooth drive wave shape is stored in digital memory. A voltage profile designed to reduce switching

losses and increase th e voltage headr oom has been im plemented. Essenti ally, two phas es are PWM' ed, while

the low side driver of the third phase is on at 100% duty cycle. The PWM duty cycles are modulated in such a

way as to result in sinusoidal cur rents on all 3 motor phases. Driv ing in this manne r, as opposed to dri ving true

sinusoids on all three phases, results in improved headroom and effici ency, appr oachi ng that of conventional 6

state commutation.

The system is phase locked to the motor by sensing one BEMF zero crossi ng on one winding, once per electrical

21/46

Page 22

L7250

cycle. A window is opened up in that winding, and it is tri-stated to allow sensing of the zero crossing. The width

of the window opening is programmable, and can be made very small in steady stat e. A frequency lock ed loop

keeps the wave shape in sync with the motor speed. The system is entirely digital, requiring no external components.

The Smoothdrive wave shape is sync with the motor. It divides the electrical period, from one zero crossing to

the next, into 48 evenly spaced sample periods. For each sample period, the driving duty cycle is defined for

each motor phase by a table in the Smoothdrive logic. The Memory Address Counter sequences the samples

through the cycle, and is clocked N times per cycle. The following describes how the frequency locked loop

system works:

There are N sine wave samples per electrical rev. N=48 for this design.

Each electrical period (from one ZC to the next) is measured by a timer with an effective frequency of Fsysclk/

48, resulting in a measured zero crossing period Tc. The timer does not actually run at Fsysclk/48 - the resolution is more like Fsysclk/3.

The FSCAN Counter is a down counter preloaded with Tc, and running at Fsysclk. The FSCAN Counter puts

out a pulse each time it hits zero, then it resets to Tc and counts down again. This cycle occurs N (48) times

per electrical cyc le. Thus, t he FSCAN Counter divides the el ectr ical cycl e into N ev enly spaced s amples based

on the previous Tc. The pulse signal out of this block, that occurs 48 times per electrical period, is called FSCAN.

The Memory Address Counter counts FSCAN pulses, and tells the Profile Logic which full scale duty cycle values to use for each Smoothdrive sample period.

2.4 PWM rate

The PWM rate is unrelated to the Smoothdrive sample rate. The minimum PWM rate is 32.2kHz with 16.5MHz

spindle system cl ock, defined by (Fsys /512). The spin sy stem clock is SYSCLK or SYSCLK/2, chosen via s erial

port (SYSCLK/2 is the default at power up). 9 bits of resolution define the duty cycle at each sample period.

The PWM counter is reset at the beginning of each electrical cycle (at the ZC).

The PWM duty cycle is defined for each of the two chopping phases by comparing the appropriate duty cycle

values to the counter. The duty cycle values are the result of multiplying values in the Smoothdrive waveform

table by the amplitude value KVAL coming from SPI.

2.5 Supply Voltage Compensation via ADC

The Smoothdrive system is a voltage mode drive scheme. Without compensation, the spindle drive amplitude

would be a proportion of the motor supply voltage. L7250 implements a supply voltage compensation scheme

whereby the drive amplitude is indipendent on motor supply voltage.

An internal 6 bit ADC reads the motor supply voltage variation (+/-10%), and the applied duty cycle is modified

to keep the applied voltage constant. A side effect is that the PWM frequency will be changed as well as the

duty cycle.

The ADC runs on a 4MHz clock derived from the SYSCLK (it is divided by 8 if the PRESMO bit is set to zero

else it is divided by 4). The conversion resul ts affects the PWM counter onc e per PWM cycle, nominally 32 kH z.

2.6 BEMF comparator Hysteresis

Since only one polarity ZC is detected, the BEMF comparator hysteresis no longer needs to contribute a time

offset. The hysteresis is zero on the significant edge, and is engaged on the other edge. Thus, larger values of

hysteresis can be used to provide noise immunity at low speed while coasting, without affecting ZC timing.

Hysteresis of 50mV provides adeguate sensitivity for detecting motion startup, while improving noise immunity

when the motor is moving very slow or is stationary.

2.7 Startup Algorithm Description

L7250's spindle motor startup is controlled by firmware, and consists of four distinct phases: Inductive Position

22/46

Page 23

L7250

Sense, to determine rotor position, Open Loop Commutation, which accelerates the motor to build up BEMF,

Synchronization , to measure motor speed and position, initializing the Smoothdrive system, and Closed Loop

Smoothdrive Commutation, the normal synchronous commutation mode to accelerate and run at speed.

2.7.1 Inductive Position Sense

Inductive position sen sing is achieved throug h a firmware routine that measur es the current rise time in each of

the six possible states (six steps profile), and uses this information to determine the rotor position.

The six steps profile still comes from the Profile Memory that contains 48 samples, but in this case there are

only six different configuration, each of them r epeated eight times; the line ar scansion of the memor y one sample at a time gives a new six step configuration every eight increments.

Before any operation can be done, the firmware routi ne must set the KVAL v alue present in S PI to the maximum

value (*1) , to saturate the PWM signals given to the motor, and put the Memory Address Counter in a known

position (*3); this is done keeping the motor in OLCOAST (*2) state and asserting a LoadCP command (*4) to

load the content of the torque optimizer related SPI register into the Memory Address Counter.

At this point, the present six steps configuration can be energized through the INDSENSE state (*5) , w aiting

for the current to reach the thre shold programmable vi a SPI (*6); the current lim iting comparator will be trigger ed

by this condition, and it's output will be visible at ZC pad. The current rise time will be measured and stored from

the ASIC (*7) .

The device automatically limits the PWM si gnals for the three phases to limit the cur rent, but the cur rents in the

windings must be recirculated from firmware putting the motor in OLCOAST (*8) state.

A burst of eight ADVANCE signals (*9) must be asserted from SPI to reach the next configuration in the profile

memory, then the procedure can be r epeated. Each w inding can be e xcited mor e than one ti me, to av erage the

measurements, and at the end of the sensing sequence the ASIC decides the rotor position.

Figure 4. Inductive Sense Routine

START

Inductive Sense Routine

Nadv=0 , Nph=0

(*2)

(*1)

(*3)

(*4)

(*5)

(*6)

ZC=0

Set OLCOAST

Write Reg.03 H

Spstate[3:0] = 0001

Set KVAL

Write Reg.08 H

Kv[7:0] = 11111111

Set Torque Optimizer

Write Reg.07 H

TO[4:0] = 00000

Set Load Coarse Phase

Write Reg.07 H

LoadCP = 1

Set INDUCTIVE SENSE

Write Reg.03 H

Spstate[3:0] = 0101

Measure Current

Rise Time

By reading the

ZC

(pin 22)

ZC=1

Nph = 48

Nadv=0

YESNO

YES

Nadv=8

Inc Nadv

Inc Nph

Set ADVANCE

Write Reg.07 H

Advance = 1

Wait for

Current Decay

Set OLCOAST

Write Reg.03 H

Spstate[3:0] = 0001

Store the measured

Current Rise Time

& Nph associated

NO

(*9)

(*8)

(*7)

Compare the Six

Measured Rise Time

to define the

ROTOR POSITION

EXIT

Inductive Sense

Routine

23/46

Page 24

L7250

2.7.2 Open Loop Commutation

After position sense is complete, the microcontroller commutates the motor following a constant acceleration

profile until sufficient BEMF is developed to reliably measure it.

The starting position of the open loop commutation, determined by the position sense routine, is set up by first

initializing the Memory Address Counter using LOADCP (*1), then clocking ADVANCE (*2) the appropriate

number of times (8 pulses pe r 6 s tate position). The spindle state wil l be OLCOAST whi le setting the initial state.

Then, drivers ar e enabled in ei ther OL_SIX or O L_SIN modes (*3 ) , dependi ng on whether 6 state or sine mode

open loop commutation is desired. Once the motor is accelerated up to an appropriate speed (*4) , the motor

is tri-stated by transitioning to the OLCOAST (*5) and then CLCOAST states, as described below, to synchronize the Smoothdrive system to the motor.

Figure 5. Open Loop Commut ation

Note1: Spstate[3:0] condition has

been set in OLCOAST

by the Inductive Sense

Routine

Open Loop Commutation

Nadv=0 , i=0

Set Load Coarse Phase

(*1)

Write Reg.07H

LoadCP = 1

START

(*5)

EXIT

Open Loop

Commutation

Set OLCOAST

Write Reg.03H

Spstate[3:0]=0001

(*2)

Note2: Nalign is received from

the Inductive Sense routine

Indicating the rotor position

alignement

(*3)

Set ADVANCE

Write Reg.07H

Advance = 1

Nadv=Nalign

Accelerate in

Sine or Six

Inc Nadv

SIX

SINE

Set Open Loop SIX

Write Reg.03H

Spstate[3:0] =0010

Set Open Loop SINE

Write Reg.03H

Spstate[3:0] =0011

(*4)

i = RAMP_Steps

Inc i

Wait the End of

RAMP_DELAY[ i ]

Set ADVANCE

Write Reg.07H

Advance = 1

2.7.3 Synchronization to Smoothdrive Commutation

When the open loop commutati on is complete, the dr ivers are put i n OLC OAST mode, and after a delay for setting the Bemf sampling period, CLCOAST is asserted, so that a ZC Period (Tc, the time between two BEMF

zero crossings) can be detected and measured.

The BEMF sampling period is set in OLCOAST (*1) and after a delay (30 usec ) a Load CP ( *2) is asserted.

After a delay of time Tc0 (300usec suggested) another Load CP is asserted (*3); this initializes the electrical

period for BEMF sampling. Once pregrammed the transition to CLCOAST (*4) , the BEMF is sampled at the

rate of Tc0 to look for two consecutive LOW readings (in anticipation of the LOW->HI zero crossing transition

(*5) ).

After the first ZC rising edge, the BEMF sampling period is refreshed to Tc0 value.

If two consecutive ZC edges are detected (*6), then after the last rising edge the Smoothdrive commutation is

synchronized with the motor rotor position and it is ready to be programmed in closed loop commutation .

At least two ZCs must be observed before transitioning to closed loop spinup (CLSIX or CLSIN) (*7a or *7b) .

This ensures that the Smoothdrive circuitry is synchronized to the spindle motor.

24/46

Page 25

Figure 6. Synchronization to Smooth Drive Commutation

L7250

ZC_SamplingRoutine

Set OLCOAST

(*1)

Write Reg.03H

Spstate[3:0]=0001

Wait Loop

(30 usec)

Set Load Coarse Phase

(*2)

Write Reg.07H

LoadCP = 1

Wait Loop

(300 usec)

Set Load Coarse Phase

(*3)

Write Reg.07H

LoadCP = 1

Set CLCOAST

(*4)

Write Reg.03H

Spstate[3:0]=0000

ZC_SamplingRoutine

BEGIN

END

NO

Time Out

Control

YES

START UP

FAILURE

Exit

ZC_SamplingTime

Reset Time Out

Wait Rising Edge

of ZC (pin 22)

(*6)

YES

START

i=0

CALL

Routine

i = 2

(*5)

YES

NO

Sync. To SmoothDrive Commutation

NO

Set Closed Loop SIX

Write Reg.03H

Spstate[3:0] =0110

Inc i

Drive Commutation

SIX

CALL

ZC_SamplingTime

Routine

Reset Time Out

EXIT

Sync. To Smooth

(*7a)

(*7b)

Motor Running in

Sine or Six

Set Closed Loop SINE

Write Reg.03H

Spstate[3:0] =0111

SINE

2.7.4 Closed Loop Commutation

During closed loop commutation, the motor is driven following the smooth driver wave shape (or the traditional

six step profile). To keep sync, each electrical cycle a winding of the spindle motor (phase U) is tri-stated, for a

programmable (via SPI) window (W), to sense for the ZC occurrence; to mask the current flyback time a masking time is applied starting from the opened window for a certain number M of samples (settable via SPI). Due

to the fact that the moto r windi ng is driven i n voltag e mode a control of the phase shift betw een the applied voltage and the Bemf is required in order to optimize the system efficiency (the loss in efficiency is related to the

cosine of the angle between Bemf and current). Via the SPI it is possible to set an appr opriate Torque Optimizer

(TO) value based on the application characteristics (Rm, Lm, Speed).

When a ZC is detected the circuit starts scanning the s tored smooth drive wave shape (or the traditional six step

profile) from the number of sam ple poi nted by the TO r egister; the tri- s tated window is opened a cer tain number

of samples before.

In the following table the relation between the TO register contents and the window and masking time position

and duration:

start stop

window TO-W At ZC detection

mask TO-W TO-W+M

25/46

Page 26

L7250

2.8 Spindle PWM Current Limiting

Peak motor current is limited with a fixed frequency PWM scheme that works in conjunction with the Smoothdrive PWM rate. When the current limit threshold is reached the motor is put in brake condition, and it is reenabled at the beginning of the next PWM cycle if the current limiting condition is false.

Spindle current is sensed via an external resistor connected from the low side driver sources to ground. This

sense voltage is compared to an internal programmable voltage reference (Reg04H Currdac[2:0]).

There is a built in digital filter, generating a SYSCLK derived delay (20 * SYSCLK period) from the over current

event. This delay appears on both edges of the current limiting comparator.

2.9 Slew Rate Control

Closed loop Voltage Slew rate control is provided on both edges for the high and low side drivers. The slew rate

value can be set with three bits in the serial port (Reg04H Spslew[2:0]). Slew rates up to 80V/us and down to

10V/us will be controllable.

2.10Synchronous rectificat ion

The appropriate low-side driv er is enabl ed during the off-time phase to conduct recirculation curr ent with a lower

voltage drop than the low side driver body diode, reducing power losses. Crossover current protection is provided to prevent shoot-through currents.

2.11Open loop and closed loop brake

Spindle braking may be done while keeping the Smoothdrive system in sync with the motor, or not.

Closed Loop Braking means ZC's are sti ll being detected in the same way as when normally commutating. S o,

all 3 motor phases are dr iv en low, but when the window is normal ly opened to l ook for a ZC, MOTU is tri- stated.

When the ZC occurs, MOTU is driven low as the other motor phases, until the next window comes up. A motionless motor will wait for a ZC, keeping MOTU tri-stated and the other two phases low. Open loop braking

means that all 3 motor phases are driven low, and ZC's are not detected. Braking caused by a power fault is

always open loop braking.

CBRK provides control voltage for br ake ci rcuitry after power fail s. An external cap on this pin is charged to 5V ,

so that the cap stays charged after a power failure.

26/46

Page 27

L7250

3 VOICE COIL MOTOR DRIVER

The VCM driver is configured as a transconductance amp, with an n-channel DMOS H-bridge power output,

current sense amp, error amp, and 15 bit linear DAC for command input. The power stage is a class AB voltage

amp. The error amp closes the transconductance loop around the power amp, using feedback from the current

sense amp. The VCM block is shown below.

Figure 7. VCM Driver Block Diagram

VCV

1/2/54/55

POR

39

DACREF

38

37

40

S1

Tristate

DAC 15

ErrorAmp

S2

DACREF

AGND

DACREF

DACREF

VM/2

Gpow

VM/2

Gpow

SenseAmp

DACREF

Rc

Cc

Ri

Rf

43/44

VM

VM

52/53

VCMN

45/46

VCM

GND

VCMP

VCM GND

Gs

Rs

Rm

Lm

3/4

5/6

42

41

Tristate

The current flowing into the voice coil is equal to:

R

------

–

Where G

I

coil

is the sensing opamp gain (programmable via serial port

s

Considering a typical application where Rf = 5.6k, Ri = 2.5k, Rs = 0.25

R

ƒ

⋅⋅=

i

1

---------------- R

⋅

sGs

V

in

Ω

and Gs = 4.5V/V we obtain a maximum

current equal to about 2A for 1V DAC output (Vin). The sense amplifier input range is about 0.55V. The power

stages assure this current requirement and they have a differential gain of 16.

The loop is compensated through the RC network Rc and Cc that cancels out the motor pole Lm/Rm.

This graphic shows the theoretic Gloop Bode diagram and put in evidence the second pole of the loop that is

strictly related to the error amplifier bandwidth.

Figure 8. Gloop

A02G

-------------------------------------------------

⋅⋅⋅

powRsGs

+

R

sRm

A

⋅

0

R

-----------------

⋅

RiRf+

R

i

----------------RiRf+

i

R

c

-----R

f

Gloop

2G

--------------------------------------

⋅⋅

powRsGs

R

+

R

s

m

----------------

⋅

RfC

1

⋅

c

Fdt erro r

closed loop

ω

⋅

t

R

i

----------------RiRf+

1

---------------- R

⋅

cCc

1

---------------R

⋅

fCc

---------------------------------

ω

⋅

t

R

c

RfR

⋅

RfRi+()⋅

i

27/46

Page 28

L7250

Considering a typical application with Rs = 0.25Ω, Lm = 0.75mH, Rm = 7.5Ω, Gs = 4.5 Gpow = 8, Rf = 5.6K, Cc =

3.3nF, Rc = 33k we will obtain a bandwidth about 20kHz. To increase the bandwidth a differen t values of the external

components could be calculated following the above relation and taking in account the limitation introduced by the

second pole due to the error amplifier bandwidth (

3.1 VCM Operating Modes and Control

At power-on-reset the VCM register is cleared and the VCM is in Unload/Retract mode.

Via serial port is possible to command the following modes: Unload/Retract, Tri-state (disable), Brake, Enable

Current Mode, Enable Voltage Mode, Offset Calibration

3.2 VCM Power Driver H-Bridge

The VCM driver is capable of high performance linear, class-AB, H-bridge operation with all power devices internal. The power amp st age is configured as a voltage amp with gain of 16. The H -bridge c onsists of 4 N -channel DMOS power transistors. Power is supplied to the H-bridge through the internal ISO-FET ( at pins VM

52,53), and ground returned via four VCMGND pins (5,6,43,44). Boosted gate drive for the high side drivers is

provided by the charge pump circuitry, with the boosted voltage at the VCP pin.

3.3 VCM Current Command 15 bit DAC

The VCM current command is defined by an internal linear, 2's complement, 15 bit DAC. The mid scale reference for the DAC, VREF25, is defined by an on-chip reference at 2.5V. VREF25 is the reference for the sense

amp and error amp in the VCM loop. Level shifting from VREF25 to VM/2 will be done in the power stage.

0x3FFF Max current flowing from VCMN to VCMP (current mode operation)

0x---0x0001

0x0000 zero current

0xFFFF

0x---0x4000 Max current flowing from VCMP to VCMN (current mode operation)

To write the 15 bit DAC the two register REG09H [14:8] and REG0AH [7:0] have to be referred.

At any time the MSB register is entered, to apply the modification also the LSB register must be write. Instead

writing only the LSB register its content will be immediatly visible on the DAC structure.

Then a double write sequence its necessary if the [14:8] bit have to be modified while it is possible to move the

DAC in a fine way (write of the [7:0] bit) with only one write sequence.

ω

t). This one has a ty pical value about 4MHz.

3.4 VCM Current Sense Amp

VCM current is sensed by a diff amp that amplifies and level shifts the voltage drop across an external resistor

in series with the VCM coil. The sense amp has a nominal differential voltage gain programmable through the

serial port bit Reg09H bit 7, and the output, VSENSE, is relat ive to V REF25 (pin 21). The am p has been des ign

to have high common mode rejection (over 70dB at DC), Power supply rejection over 60dB, and as low an input

offset as possible.

3.5 VCM Curre nt Loop Erro r Amplifier

The VCM error amp gains up the difference between the current command voltage DAC_OUT and the current

sense voltage VSENSE. VCM current loop compensation is implemented externally with an RC network connected across ERR_IN and ERR_OUT. The error amp output is referred to VREF25.

3.6 Error Am p Ou tput Clamp

The error amp output swing is clamped in both directions (Vref25+/-3Vbe) to prevent wind-up of the integrating

compensation components around the error amp in the event of saturation.

28/46

Page 29

L7250

3.6.1 Voltage Mode

In Voltage Mode, the VCM power outputs will apply a voltage to the VCM motor commanded by the VCM DAC.

This is implemented by tristating the sense amp and error amp outputs, and connecting DAC_OUT to

ERR_OUT with an internal switch (switch S2). Skipping the err_out amplifier the DAC command will enter the

power section without any inve rsion, then the DAC codifi cation must be consi dered in opposite dir ection respect

to the current mode operation.

3.7 VCM Loop Offset Calibration Mode

The VCM Loop Calibration mode can be implemented following two different approach:

1)

The VCM loop is enabled (sense amp, error amp, DAC), but the VCM power stage is tri-stated. Thus,

the sense amp is guaranteed to be monitoring a zero current condition.

To implement offset c alibration, the current command is swept through zero by the controller ASIC.

Since the Gm loop is open, the error amp output will be saturated in one direction or the other depending

on the current comman d (to configura te the error op amp as a comparat or the external compensation

network will be disconnected opening the switch S1). As the command sweeps through the zero current

command point, the error amp output will swing to the other extreme. The comparator senses the output swing of the error amp, and through the serial port (Re g. 00H -> b6) interrupts the A SIC. The appropriate DAC value corresponding to the trip point interrupt is the loop zero current offset.

Figure 9. VCM Current Loop Of fset Calibration 1

START

VCM Current Loop

Offset Calibrat ion R out ine

Set SenseAmpl.Gain

Write Reg.09H

GainSW bit = 0

DAC_VAL = DAC_VAL +1

Set VCM Offset Calibration

Write Reg.03H

VCMState[2:0] = 101

DAC_VAL = 0

Flag1 = 0 , Flag2 = 0

4.5 V/V 16 V/V

Flag1 = 1

NO

Flag2 =1 Flag1 = 1

YES

NO YES

Select

Sense Amplifier

Gain

UPDATE 15 Bit DAC

Write Reg.09H

dac[14:0]= DAC_VAL

Read Error Ampl Output

Read Reg.00H

VCMcalOut bit va lue

VCMcalOut = 0

* DAC_VAL is in 2 complement format

Flag2 = 1

DAC_VAL = DAC_VAL -1

NO

YES

Set SenseAmpl.Gain

Write Reg.09H

GainSW bit = 1

Store the DAC_ VAL

as the zero loop offset

EXIT

VCM Current Loop

Offset Calibrat ion R out ine

29/46

Page 30

L7250

g

g

g

g

g

g

g

g

g

g

g

g

2)

A second approach is considering to have the VCM in stop position; to enable it in current mode configuration driving current in the right direction in order to be sure to mantain the stop position; to decrement the 15bit DAC value to reach the zero current condition using the 10bit ADC to measure the

current value.

In the following diagram a detailed flow chart is presented.

Figure 10. VCM Current Loop Offset Cal ib rat io n 2

START

Current Mode “Zero Iout”

Calibration Routine

Flag_A=0

DACvalue=1200 ( 0x4B0 )

Note 1

Set VCM in Tristate

Write Re

VCMState[2:0] = 001

IoutDigitalVal Routine

Iout_Offset = ADC_DATA[9:0]

Set 15BitDAC to have VCM Current

Write Re

Dac[14:0] = DACvalue

Set the GainSw to High or Low

Set VCM in En.Current Mode

VCMState[2:0] = 011

Note 1 : once the VCM will be enabled in current mode with the DAC value at 1200 the current will keep the motor against the crash stop posit ion

Note 2 : with the VCM in tristate, the result of the digital conversion of the Iout Channel has to be used as ZERO current offset value

.03H

Call

Note 2

with no motion

.09H & Reg.0Ah

Write Re

.03H

Wait 20 msec

Flag_A=1

DACvalue-=1

DACvalue<-1200

Update the 15BitDAC

Write Re

.09H & Reg.0Ah

Dac[14:0] =DACvalue

Call

IoutDigitalVal

Routine

No

No

Iout Yes

Polarity check

ADC_DATA[9] = 0

Yes

ADC_DATA[9:0] -= Iout_offset

( Subtract the offset )

Flag_A=0

No

Store DACvalue

As reference for

ZERO Iout

EXIT with Error 2

Calibration not performed

Ne

ative offset to bi

Yes

Calibration not performed

START

IoutDi

Routine

START 10Bit ADC Conversion

of the Iout Channel

Write Re

ADC_CH_ADDR[1:0] =00

ADC_START=1

Read 10Bit ADC

Read Re

ADC_DATA[9:2]

Read Re

ADC_DATA[1:0]

EXIT

IoutDi

Routine

EXIT with Error 1

Positive offset to bi

EXIT

Current Mode “Zero Iout”

Calibration Routine

italVal

.0CH

Wait End of

Conversion

.0BH

.0CH

italVal

YES

NO

30/46

Page 31

3.8 VCM Ramp Load / Unload System

Figure 11.

L7250

VCM

Predriver

+A

VCMP

VCM

Rs

VCMN

-A

_

VGA

+

Offset

calibration

Gain

Calibration

Procedure

_

+

_

+

+

_

(Sense Ampl)

Bemf

Voltage

Current

5 MSB from

ADC

CalCoarse

Fine calibration

bit from

Serial Port

ADC

10 bit

Sel&start

Vcontrol

29

to

Serial Port

The Ramp Load system is designed to allow a microcontrolled assisted constant velocity for ramp loading and

unloading.

VCM Current-Voltage-Bemf monitor circuitry is integrated for the loading or unloading operation. VCM CurrentVoltage-Bemf are converted in digital by a 10 bit AD converter and can be read through the serial port.

3.8.1 Load/Unload operatio n at pow er good

When both the 12V and 5V are present, the Load/Unload operation can be as sisted b y the microc ontr oller. The

power stage can be driven in both current and voltage mode and the velocity of the Load/Unload operation is

controlled by reading the internal registers that give information regarding the VCM current, voltage and the

Bemf generated by the VCM motion.

The VCM current measurements is done by sending to the AD converter the output of the VCM Current Sense

Ampl.

The VCM voltage is measured by connecting an operational amplifier, with a scaling factor, to the VCMP and

VCMN of the power stage.

The VCM Bemf detection is done using a first amplifier, having a controlled gain, followed by a second operational amplifier implementing the transfer function necessary to BEMF reconstruction. The programmable gain

of the first operational amplifier it is necessary to consider various coil resistance values related to different application.

The BEMF information is carry out on pin VCMBEMF (31) for filtering pourpose (the output impedance is typically set to 500ohm).

The conversion in digital of these parameters is used by the microcontroller as a feedback to close the velocity

control loop during the ramp loading or unloading operation, and to perform calibrations.

All these signals can enter directly the ADC block (ADCrange bit = 0) or can be scaled to adjust the dynamic

range to the ADC one (ADCRange bit = 1).

The scaling factor is set equal to 2.25 for the ‘Current’, ‘Voltage’, ‘Auxiliary’ input channels, while is set to 1.25

for the ‘Bemf’ input channel.

31/46

Page 32

L7250

3.8.2 Gain Calibration Procedure

The Bemf detector circuitry must be calibrated right before the beginning of any Load/Unload operation.

Because the coil resistance can vary up to 30% due to thermal effects, it is necessary to calibrate the gain of

the first stage depending on the ratio between the operating coi l resistance value and the sense resistance value.

The output of the Bemf detector circuiry is:

Bemf = OutP - OutM - Rs*Ivcm ( 1+ Rm/Rs)

where: Rm = motor resistance

Rs = sensing resistance

If the Gain of the first stage is matching the ratio between the coil resistance at operating temperature and the

sense resistor, the Bemf measured is right the value generated by the VCM motion.

The gain trimming is done with the VCM in a stop position (no Bemf must be generated) with a certain amount

of current flowing into the coil; in this con dition the gain must be adj usted in order to have zero voltage from the

Bemf circuitry.

The gain adjusting is splitted i n two phases. A coarse calibr ation is obtained setti ng the external resistor divider

at the CalCoarse pin (29) following the relation:

Vcontrol = [0.21 + (Rm/Rs) / 28.8]

Vcontrol max. range = Vbg ±0.75V

Where: Vbg = bandgap voltage (typ = 1.25)

A fine calibration is obtained by writing the internal register 02H -> b[3:0]. The fine calibration is used to com-

pensate the variation of the VCM coil resistance according with operating temperature condition.

The calibration is implemented moving the Vcontrol voltage by a percentage indicated on the RLcal table at

pag.17.

3.8.3 VCM Bemf offset trimming

Due to the high gain necessary to implement the BEMF reconstruction, the inpact of the offset on the output

value is very high. For this reason dedicated ci rcuitry, usin g the 5 MSB of the AD converter, has been integrated

in order to compensate this offset.

The flow chart below reported are describing the method to implement the offset calibration.

32/46

Page 33

Figure 12. VCM Bemf Offset Calibration CLEAR Routine

L7250

OPTIONAL

VCM Bemf offset calibration

START

CLEAR Routine

Set VCM in Tristate

Write Reg.03H

VCMState[2:0] = 001

Reset Rm/Rs FINE Calibration

Write Reg.02H

Rlcalib[3:0] = 0000

Set PREAD C in Sleep

Write Reg.06H

PREADC [1:0] = 00

Read 10Bit ADC

Read Reg.0BH

ADC_DATA[9:2] = 00000000 (reset value)

Read Reg.0CH

ADC_DATA[1:0] =00XXXXXX (reset value)

Latch Offset Compensation

Write Reg.03H

BemfOffCal = 1

then

BemfOffCal = 0

Set ADC Clock

Write Reg.06H

PREADC [1:0] = 01

EXIT

VCM Bemf offset calibration

CLEAR Routine

33/46

Page 34

L7250

g

g

g

g

g

Figure 13. VCM Bemf Offset CALIBRATION Routine

START

VCM Bemf offset calibration

Routine

OPTIONAL

Set VCM in Tristate

VC MState[2: 0 ] = 001

PR EADC[1:0] = 01

START 10Bit ADC Conversion

of the BEMF Channel

ADC_CH_ADDR[1:0] =10

Read 10 Bi t ADC

ADC_DATA[9:2]

Latch Offset Compensation

VCM Bemf offset calibration

.03H

Write Re

Set ADC Clo ck

.06H

Write Re

Write Re

.0CH

ADC_START=1

Read Re

.0BH

Read Re

.0CH

ADC_DATA[1:0]

Write Reg.03H

BemfOffCal = 1

then

BemfOffCal = 0

EXIT

W ait End of

Conversion

YES

To r es tart th is routin e is mandato ry to sta r t

Fir s t t h e clea r routine (see F ig. 10 )

NO

At the end of the calibration routine the analog value measured at pin 31 is rapresenting the VCM BEMF value

at the zero motion (BEMF zero va lue) . With the ADC it i s poss ible to operate a new c onvertion i n or der to memorize this value and to take in account of it during the load/unload procedure.

3.8.4 Power Off Unload - Active brake and constant voltage unload operation

In case of power shut down, an unload procedure start automatically in order to take the heads over the ramp

in the parking positio n ( the s ame proc edur e can be al so e nabled, w hen the power is on, via serial por t programming the unload/retract status of the VCM -> reg. 03H. In this case at the end of the unload phase the spindle

motor is driven in tri-state condition).

The unload procedure doesn’t start at power off if the V CM status bit are set to 000 because the syste m is considering the heads already in park position. No entering the unload procedure also the spindle brake is not activated.

The unload procedure is done in two step:

- active brake

- constant voltage unload operation

The unload procedure take place only if the VCM status bit have moved from the 000 configuration. Otherwise

the unload procedure doesn't star t and in case of power shut down the s pindle motor enter the brake condi tion.

Active Brake : it is used to have a fast recovery of the VCM velocity down to the unload programmed velocity.

If just before a power shut down a fast seek was commanded, it is necessary to recover the VCM velocity in

34/46

Page 35

L7250

order to avoid to rise the ramp or to meet the ID crash stop at high speed.

The over velocity det ector circui t consist in a window compara tor; in case of power fai lure the VCM power stage is tri-

stated (for a fix ed time about 200

If the VCM Bemf is out of the window of the over velocity detector (this means that the heads are travelling at

high speed versus the inner or outer position), the active brake routine is invoked.

The voltage threshold ( = motor electrical constant * motor angular velocity), setting the over velocity detector

window, is set internally to 1.1V (to 0.4V if 5V application is considered).

At the contrary, if the VCM speed is inside the window (the heads where on track or moving slowly) the active

brake is skipped and the constant unload operation is commanded.

The active brake routine consist in a procedure that drive the VCM alternately with two steps:

- first activating the diagonal of the power stage in order to drive current in the right direction to slow down the

speed of the VCM for a time (RLTonBrake) that is half of the programmed RLToffBrake.

- then activating both the low side drivers of the power st age putting the VCM in short br ake conditi on for a programmable time (RLToffBrake).

With the VCM in short brake the current into the coil is forced by the Bemf generated by the motion of the motor

and the sense amplifier output is sensed in order to detect indirectly the VCM speed.

The switch bet ween the acti ve brake rou tine and th e constant vo ltage unl oad operati on is done when t he VCM current,

measured at the sense amplifier outpu t dur ing the short brake conditi on, fall down to zero (VCM is stopped).

The RLToffBrake (and so the RLTonBrake) time can be programmed by writing the Reg. 02H.

The active brake procedure can enabled/disabled by writing the Reg. 01H. In case the active brake procedure

is disabled, at power off the constant unload operation start immediately.

µ

s) in order to detect the amplitude of the Bemf generated by the VCM motion.

Constant Voltage Unload operation : a constant voltage (with a sink and source capability) is applied to the

VCM in order to drive the heads over the ramp in the parking position.

According with the contents of the registers REG. 01H it is possible to perform the unload operation in one or

two steps and for each steps to select the voltage level applied to the VCM.

The capacitor connected at the Timer1 (pin 28) define the total time of the unload operation ; during the unload

operation this capacitor is discharged by un internal constant current generator.

Programming the bit ‘b3b2b1’ of the REG. 01H it is possible to select different unload procedures:

With these bit set to 000 the unload is done in one step with the voltage selected by the two bit RLvoltage1 of

REG. 01H.

With these bit set to 111 the unload is done in one step with the voltage selected by the two bit RLvoltage2 of

REG. 01H.

The spindle motor is tristated during the unload operation

The other combinations of the bit ‘b3b2b1’ defines different threshold for the comparison with the discharging

voltage of the capacitor at pin 21 .

The timing for the first step is with the capacitor voltage greater then the programmed threshold, the timing for

the second step start when the capacitor voltage is below the threshold and end when the capacitor is discharged under the 'end unload threshold' (0.2V typ) .

In all the cases, when the capacitor at pin 21 is discharged under the 'end unload threshold' the spindle motor

is driven inbrake condition.

The typical value of the retract procedure timing can be extimated using the following expression:

T = Tstep1 + Tstep2 = 1.15 * C

ext

Where:

Cext = External capacitor at pin ‘Timer1’ (28) measured in uF

35/46

Page 36

L7250

g

g

g

g

g

Figure 14. Costant voltage retract operation at power do wn

Constant Voltage

R etra c t O p e ra tion

Get Rltim er[2:0]

Read Re

Rltimer[2:0] = “000”

Start ONLY U nload1

with the selected

Rlvolta

e1

Disabled Enabled

.01H

No

Rltimer[2:0] = “111”

Yes

Start ONLY U nload2

with the selected

Rlvolta

High

Check NPOR

Status

Set Spindle P owers

in TRISTATE

Check VCM

Active Brake Proc.

.01H -bit[0]

Re

No

Start Unload1 + Unload2

e2

Rlvolta

Low

with the selected

e1 & Rlvoltage2

Start the VCM

Active Brake

Procedure

(*)

Wait END

of Rltimer

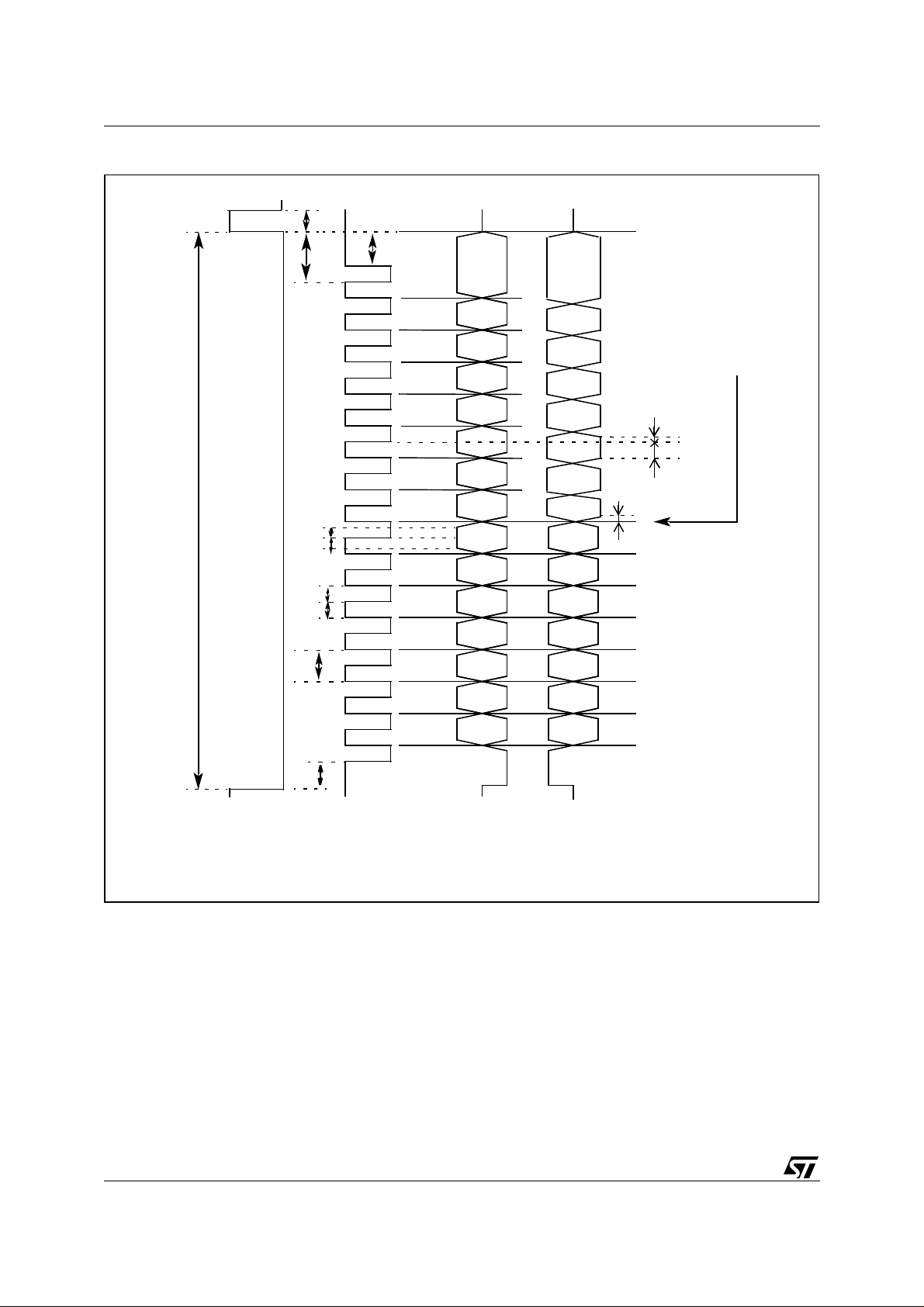

Figure 15. Two step unload temporization

Voltage

Capacitor

pin 21

POR

Programming

Threshold

End Unload

Threshold

Step 1 Step 2

36/46

Set Spindle P owers

in BR AKE

END

Time

Page 37

L7250

3.8.5 Constant Voltage Unload operation at POWER ON

The same costant voltage retract operation can be activated via software (during a power on phase). In that

case no actions are implemented to the spindle motor; the spindle motor will continue to mantain its running

status.

Again in power on condition if the bit ‘ b3b2b1’ of the REG. 01 H are set to 000 or 111 only one step cost ant voltage retract is activated as in power off condition with the difference that when the ‘End unload threshold’ is

reached the retract voltage is manta ined appli ed to the motor until a di fferent pr ogrammation i s as sert ed via serial port by the microcontroller.

In all the others ‘b3b2b1’ combination as the timer1 is elapsed the VCM is put in tristate condition.