Page 1

L7200

MOZART, 12V DISK DRIVE SPINDLE & VCM, POWER &

CONTROL “COMBO”

PRODUCT PREVIEW

GENERAL

■

12V (+/- 10%) OPERATION.

■

REGISTER BASED ARCHITECTURE

■

MINIMUM EXTERNAL COMPONENTS

■

BCD TECHNOLOGY

VCM DRIVER

■

1.7A DRIVE CAPABIL ITY

■

0.75Ω TOTAL BRIDGE IMPEDANCE AT 125°C

■

LINEAR MODE

■

PHASE SHIFT MODULATION (PWM MODE)

■

INSTANTANEOUS, (GLICH FREE) SWITCH

■

BETWEEN THE 2 MODES.

■

CLASS AB OUTPUT DRIVERS

■

ZERO CROSSOVER DISTORSION

■

14 BIT DAC DEFINE OUTPUT CURRENT

■

SELECTABLE TRANSCONDUCTANCE

■

RAMP LOADING & PARKING VOLTAGE

■

FULL INTERNAL VCM CALIBRATION

■

DYNAMIC BRAKE

SPINDLE DRIVER

■

2.5A DRIVE CAPABIL ITY

■

0.75Ω TOTAL BRIDGE IMPEDANCE AT

125°C

■

SMOOTHDRIVE™ ARCHITECTURE

■

SINUSOIDAL DRIVING, VOLTAGE MODE

■

BIPOLAR DRIVING

■

BEMF, INTERNAL OR EXTERNAL,

PROCESSING

■

SENSOR-LES S MOTOR COM MUTA TION

■

PROGRAMMABLE COMMUTATION DELAY

■

FIXED FREQUENCY PW M OPERATION

MODE

■

INTERNAL FREQUENCY LOCKED LOOP

SPEED CONTROL (FLL)

■

PROGRAMMABLE DIGITAL FILTER FOR

SPEED CONTROL LOOP

■

BEMF RECTIFICATION DURING RETRACT

■

BUILT-IN INDUCTIVE SENSING START UP

■

DYNAMIC & REVERSE BRAKE

■

BACK ROTATION DETECTION

MULTIPOWER BCD TECHNOLOGY

TQFP64

ORDERING NUMBER: L7200

OTHER FUNCTIONS

■

12V, 5V , 3.3V AND 2.5V MONITORING WITH

POSSIBLE EXTERNAL SET TRIP POINTS

AND HYSTERESIS

■

POWER UP/DOWN SEQUENCING

■

8V, 3.3V AND 2.5V POSITIVE REGULATORS

■

3.3V LOGIC COMPATIBILITY

■

SHOCK SENSOR DETECTOR

■

INTERNAL POR DELAY TIME AT POWER ON

(80ms)

■

INTERNAL ISOFET FOR BEMF

RECTIFICATION

■

THERMAL SHUTDOWN AND PRETHERMAL

WARNING

DESCRIPTION

The L7200 Mozart integrates into a single chip both

spindle and VCM controllers as well as power stages. The device is designed for 12V disk drive application requiring up to 2.5A of spindle and 1.7A of

VCM peak currents. The device is based on the sinusoidal driving of the spindle motor. This is realized

digitally by the SMOOTHDRIVE™ SYSTEM.

A serial port with up to 40 MHz capability provides

easy interface to the microprocessor. A register controlled Frequency Locked L oop (FLL) allow s flexibili ty

in setting the spindle speed. Integrated BEMF processing, digital filter, digital masking, digital delay,

and sequencing minimize the number of external

components required.

September 1999

This is preliminary information on a new product now in development. Details are subject to change without notice.

1/23

Page 2

L7200

g

g

g

DESCRIPTION

(continued)

Power On Reset (POR) circuitry is included. Upon detection of a low voltage condition, POR is asserted, the

internal registers are reset, and spindle power circuitry is tri-stated. The BEMF is rectified providing power for

actuator retraction followed by dynamic spindle braking. Three Linear regulators and a Shock Sensor circuitry

are also integrated.

The device is built in BCD mixed signal technology allowing dense digital/analog circuitry to be combined with

a high power DMOS output stage.

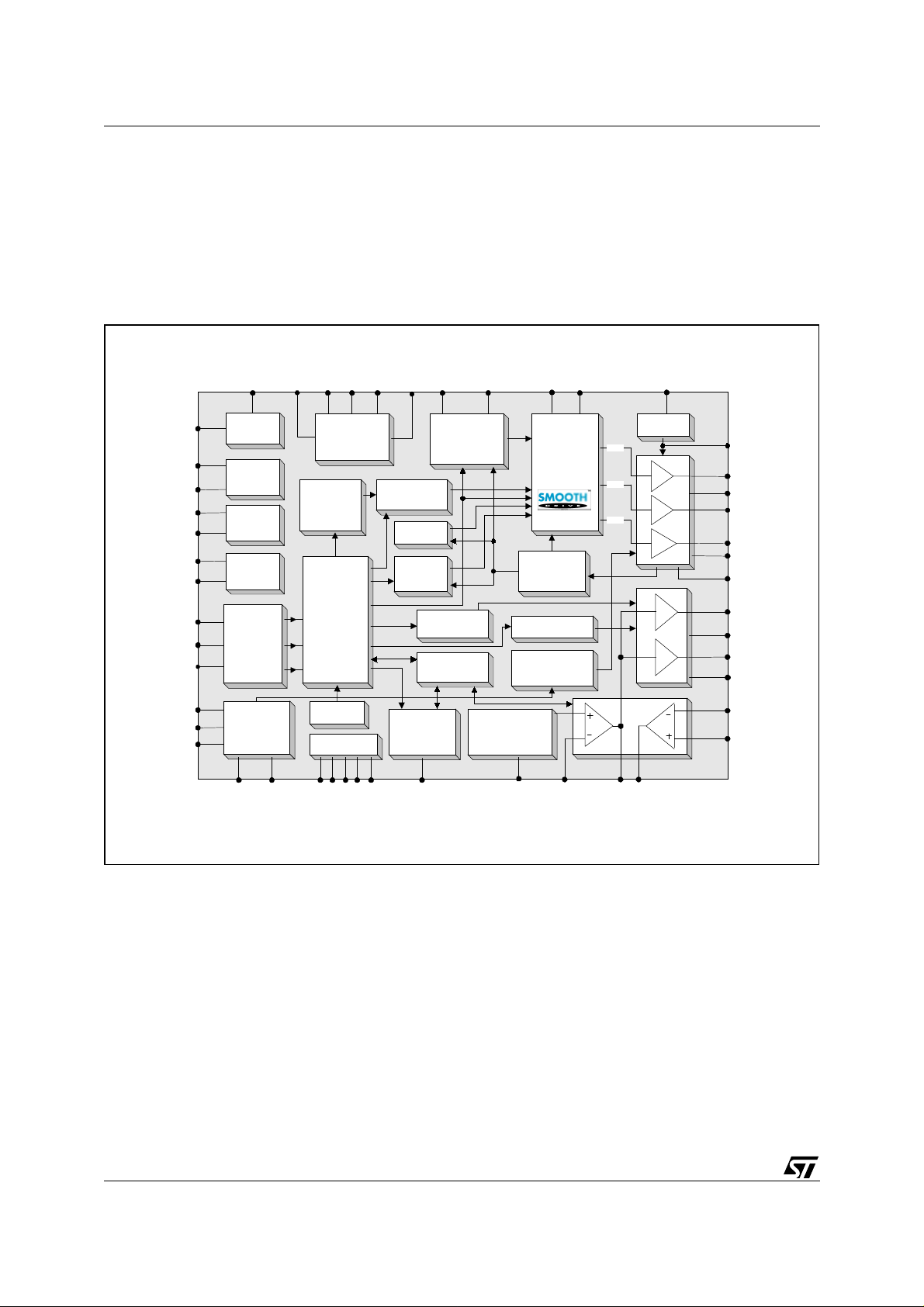

BLOCK DIAGRAM

PUMP

VREG3.3_IN

VREG2.5_IN

VREG8_DRV

VREG8_IN

SDATA

SCLK

SDEN

VBOOST

CHARGE

PUMP

3.3V

Re

ulator

2.5V

Re

ulator

8V

Re

ulator

SERIAL

PORT

SSIN

INDUCTIVE

SENSE

START-UP

REGISTERS

SSFIN

DETECTOR

SSFOUT

SHOCK

SSBUFOUT

SSOUT

BIPOLAR /

TRIPHASE

RE-SYNC

DYNAMIC/

REVERSE

BRAKE

CALIBRATION

RBIAS

FLL &

DIGITAL

FILTER

VCM

PSM/LIN

VCM

SYSCLK

RAMP LOADING

RECTIFICATION

BRAKE

SPINDLE

Architecture

BEMF

DETECTION

BEMF

FCOM

PWM A

PWM B

PWM C

VPS

ISOFET

A B

C

A+ A-

VCC

OUT_A

CTAP

OUT_B

OUT_C

RSENSE

ISENSE

VCM_A+

VCC

VCM_AVCM_GND

TR_12V

TR_5V

TR_3.3V

SUPPLY

FAULT

MONITORS

PORB

TR_2.5V

THERMAL

SUPPLY

VDD

AVCC

DGND

GND

AGND

14 BIT

VCM DAC

DAC_OUT

REFERENCE

VOLTAGE VCC/4

& GAIN SWITCH

GAINRES

A=4

ERROR_IN

ERROR_OUT

SENSE_IN-

SENSE_IN+

SENSE_OUT

2/23

Page 3

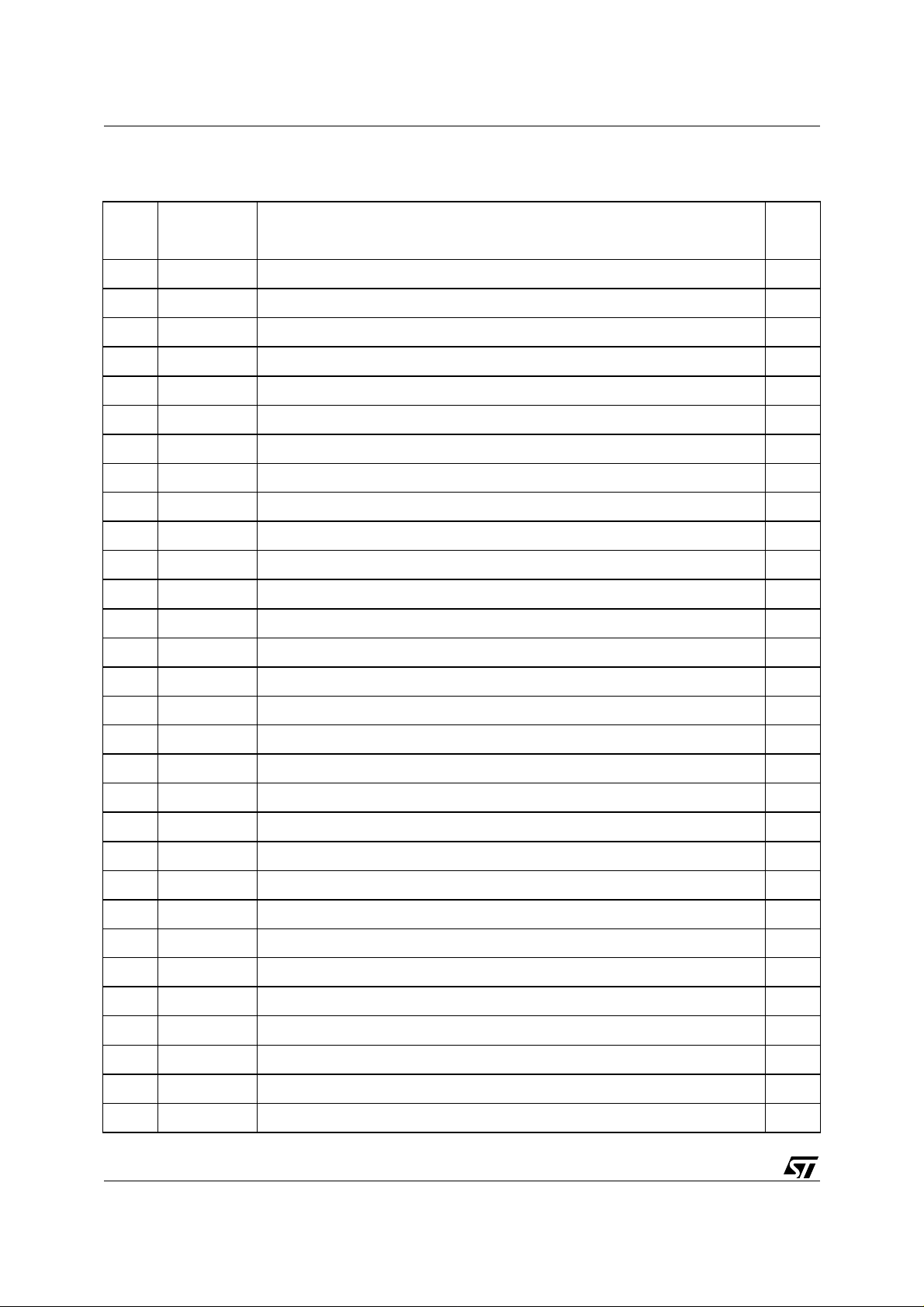

SPINDLE SMOOTHDRIVE™ ARCHITECTU RE, START-UP & FLL

L7200

BIPOLAR /

TRIPHASE

SPIN-UP

INDUCTIVE

SENSE

A/D 7bit

MEMORY AND

MEMORY SCAN

TORQUE

OPTIMIZER

SERIAL PORT

6bit

8bit

FEED

FORWARD

DIGITAL

MULTIPLIER

KFLL

REGISTER

8bit

3x

9bit

10bit

10bit 12bit

d

DIGITAL

FILTER

10bit

FREQUENCY

MULTIPLIER

BYTE TO

PWM

CONVERTER

9bit

Resolution

3x

10bit2x12bit

Z.C.

PWM A

PWM B

PWM C

FLL

BEMF

DETECTION

AB

POWERS

C

PIN CONNECTION (Top view)

VCM_A+

VCM_A+

VCM_GND

VCM_GND

VCM_AVCM_A-

OUT_A

OUT_A

RSENSE

RSENSE

OUT_B

OUT_B

RSENSE

RSENSE

OUT_C

OUT_C SSFIN

SDEN

VPS

VPS

VCC

VCC

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

VPS

VCC

VPS

VCC

SDATA

SCLK

GND

L7200

"MOZART"

FCOM

SYSCLK

VDD

GND

DGND

BRAKE

SENSE_OUT

ERROR_OUT

ERROR_IN

CTAP

ISENSE

GAINRES

VREG8_IN

SENSE_IN-

SENSE_IN+

PUMP

SSOUT

VBOOST

33343536373839404142434445464748

DAC_OUT

32

31

PORB

30

VREG3.3_IN

VREG3.3_DRV

29

28

VREG2.5_IN

27

VREG2.5_DRV

26

RBIAS

25

AVCC

24

AGND

23

TR_12V

22

TR_5V

TR_3.3V

21

TR_2.5V

20

SSIN

19

18

SSBUFOUT

17

SSFOUT VREG8_DRV

3/23

Page 4

L7200

PIN FUNCTION

Pin Types: D = Digital, P = Power, A = Analog

N° Pin Name Description Type

1,2 VCC +12V Power Supply after ISOFET. P

3,4 VPS +12V Power Supply. P

5 GND Power Ground (substrate). P

6 SYSCLK Clock Frequency for system timers and counters D

7 FCOM Output of Spindle zero crossing or Current Sense circuit D

8 VD D Digital +5V Supply D

9 BRAKE Storage capacitor for brake circuit. Typically 5.9V A

10 ISENSE Input to sense the voltage of the SPINDLE Sense Resistor. A

11 CTAP Spindle Center Tap used for Differential BEMF sensing A

12 GAINRES External resistor for VCM switch gain. A

13 VBOOST External main Charge Pump Capacitor (typically VCC+5.8V) A

14 PUMP External Charge Pump A

15 SSOUT Shock Sensor detector Digital Output D

16 SSFOUT Shock Sensor detector filter Output A

17 SSFIN Shock Sensor detector filter Input A

18 SSBUFOUT Shock Sensor detector amplifier Output A

19 SSIN Shock Sensor detector amplifier Input A

20 TR_2.5V Set Point Input for 2.5V Supply monitor A

21 TR_3.3V Set Point Input for 3.3V Supply monitor A

22 TR_5V Set Point Input for 5V Supply monitor A

23 TR_12V Set Point Input for 12V Supply monitor A

24 AGND Analog Ground A

25 AVCC +12V analog Supply (after ISOFET) P

26 RBIAS External resistor for setting accurate bias current A

27 VREG2.5_DR 2.5V positive regulator drive output A

28 VREG2.5_IN 2.5V positive regulator sense input A

VREG3.3_DRV

29

30 VREG3.3_IN 3.3V positive regulator sense input A

3.3V positive regulator drive output A

31 PORB Power On Reset Output A

32 DAC_OUT Output of VCM DAC A

33 VREG8_DRV 8V positive regulator drive output A

4/23

Page 5

L7200

PIN FUNCTION

N° Pin Name Description Type

34 VREG8_IN 8V positive regulator sense input A

35 SENSE_IN- Inverting Input of the Sense Amplifier A

36 SENSE_IN+ Non inverting Input of the Sense Amplifier A

37 SENSE_OUT Output of the Sense Amplifier A

38 ERROR_OUT Output of the Error Amplifier A

39 ERROR_IN Inverting Input of the Error Amplifier A

40 DGND Digital Ground D

41 SDEN Serial Data Enable. Active high input pin for serial port enable D

42 SDATA Serial port Data input/output D

43 SCLK Serial Port Data Clock. Positive edge triggered clock input for serial data D

44 GND Power Ground (substrate). P

45,46 VPS +12V Power Supply. P

47,48 VCC +12V Power Supply after ISOFET. P

49,50 VCM_A+ VCM Power Amplifier positive Output terminal. A

(continued)

51,52 VCM_GND Ground for VCM power section. A

53,54 VCM_A- VCM Power Amplifier negative Output terminal. A

55,56 OUT_A Spindle DMOS half bridge Output and Input A for BEMF sensing. A

57,58 RSENSE Output Connection for the Motor Current Sense Resistor to ground. A

59,60 OUT_B Spindle DMOS half bridge Output and Input B for BEMF sensing. A

61,62 RSENSE Output Connection for the Motor Current Sense Resistor to ground. A

63,64 OUT_C Spindle DMOS half bridge Output and Input C for BEMF sensing. A

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

Vcc Maximum Supply voltage -0.5 to 14 Volts

Vdd Maximum Logic supply -0.5 to 6 Volts

Vin max Maximum digital input voltage Vdd + .3 volts Volts

Vin min Minimum digital input voltage GND - .3 volts Volts

SPINDLE

Ipeak

VCM Ipeak VCM peak sink/source output current 1.8 Amps

Spindle peak sink/source output current 2.6 Amps

5/23

Page 6

L7200

THERMAL DATA

Symbol Parameter Value Unit

θ(jc) Thermal resistance Junction to case ≈11 °C/Watt

θ(ja)* Thermal resistance Junction to ambient ≈40 °C/Watt

Ptot* Maximum Total Power Dissipation ≈2.0 Watt

Tstg,Tj Maximum storage/junction temperature -40 to 150 °C

* In typical application with multi la yer 120x120 m m Printed Circ ui t Board.

RECOMMENDED OPERATING CONDITIONS

Symbol Parameter Value Unit

Vdd Supply Voltage 10.8 to 13.2 V

Vcc Logic Supply Voltage 4.5 to 5.5 V

Tamb Operating Ambient Temperature 0 to 70 °C

Tj Junction Temperature 0 to 125 °C

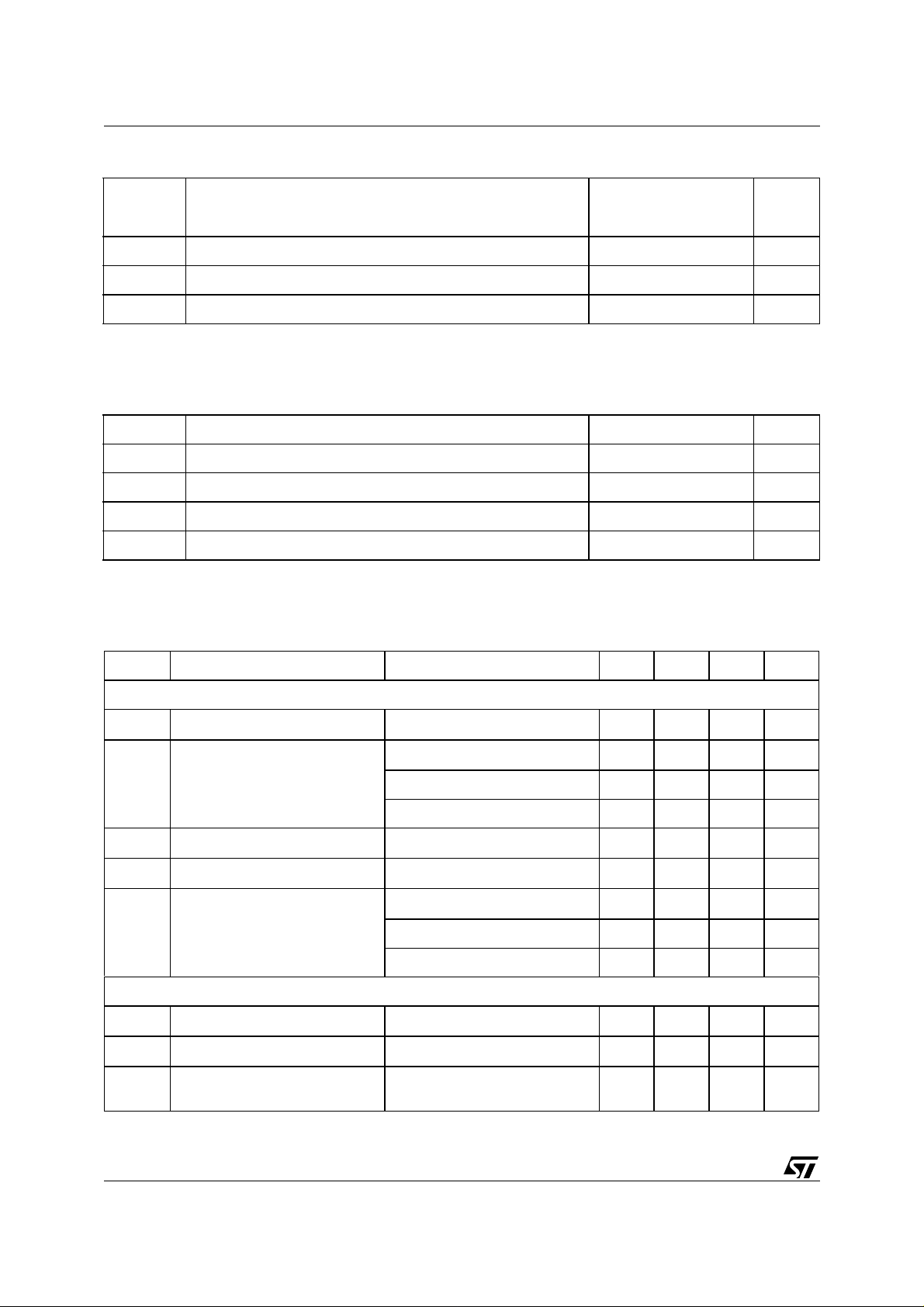

ELECTRICAL CHARACTERISTCS

All specifications are for 0<Tamb<70°C, VCC=12V, VDD=5V, unless otherwise noted.

Symbol Parameter Test Condition Min. Typ. Max. Unit

POWER SUPPLIES

12V supply 10.8 13.2 V

V

CC

I

VCC

V

rectified

V

I

THERMAL SENSING

T

T

Vcc Current SPINDLE + VCM TBD mA

SPINDLE ONLY TBD mA

VCM ONLY TBD mA

Vcc supply rectified 3.5 13.2 V

5V supply 4.5 5.5 V

dd

5V supply SPINDLE + VCM TBD mA

vdd

SPINDLE ONLY TBD mA

VCM ONLY TBD mA

SHUTDOWN TEMPERATURE 150 180 °C

SD

HYSTERESIS 60 °C

HYS

6/23

T

EARLY WARNING TSD-

EW

°C

25

Page 7

L7200

ELECTRICAL CHARACTERISTCS

(continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

SUPPLY MONITOR

V

V

R

on_por

T

PorDly

TRIP POINT 2.5V-3.3V-5V-12V INPUT RISING 1.20 1.25 1.30 V

TR

HYSTERESIS VOLTAGE INPUT FALLING 25 mV

HYS

PORB PULL DOWN Ron Vdd > 2V and sink 1mA 500 W

POR Delay Time 80 mSec

12VTR Minimum Voltage 12V 8.6 V

5VTR Minimum Voltage 5V 4.2 V

3.3VTR Minimum Voltage 3.3V 3.135 V

2.5VTR Minimum Voltage 2.5V 2.375 V

VOLTAGE BOOST

V

BOOST

F

OUTPUT VOLTAGE VCC+5

INTERNAL OSCI LLATOR 200 KHz

OSC

VCC+6.3

SW1 OUTPUT

V

INPUT LOGIC "1" 2.4 V

IH

V

V

V

INPUT LOGIC "0" 0.5 V

IL

OUTPUT LOGIC "1" ISOURCE = 20µAVdd-

OH

V

0.2

V

F

SYSCLK

OUTPUT LOGIC "0" ISOURCE = -400µA 0.4V

OL

SYSTEM CLOCK 20 25 MHz

VCM, DAC

RESOLUTION 14 BITS

DIFFERENTIAL LINEARITY 1 LSB Change

- Tested

- By design

-1

-0.5

1

0.5

INTEGRAL LINEARITY 9 BITS

MIDSCALE OFFSET REFERENCED TO V

CONVERTION TIME 5 µs

T

C

FULL SCALE VOLTAGE REFERENCED TO V

CC/4

CC/4

-5 5 mV

±1 V

FULL SCALE ERROR -6 6 %

VCM, ERROR AMPLIFIER

AVOL OPEN LOOP GAIN DC 80 dB

LSB

VOS INPUT OFFSET VOLTAGE 1 mV

7/23

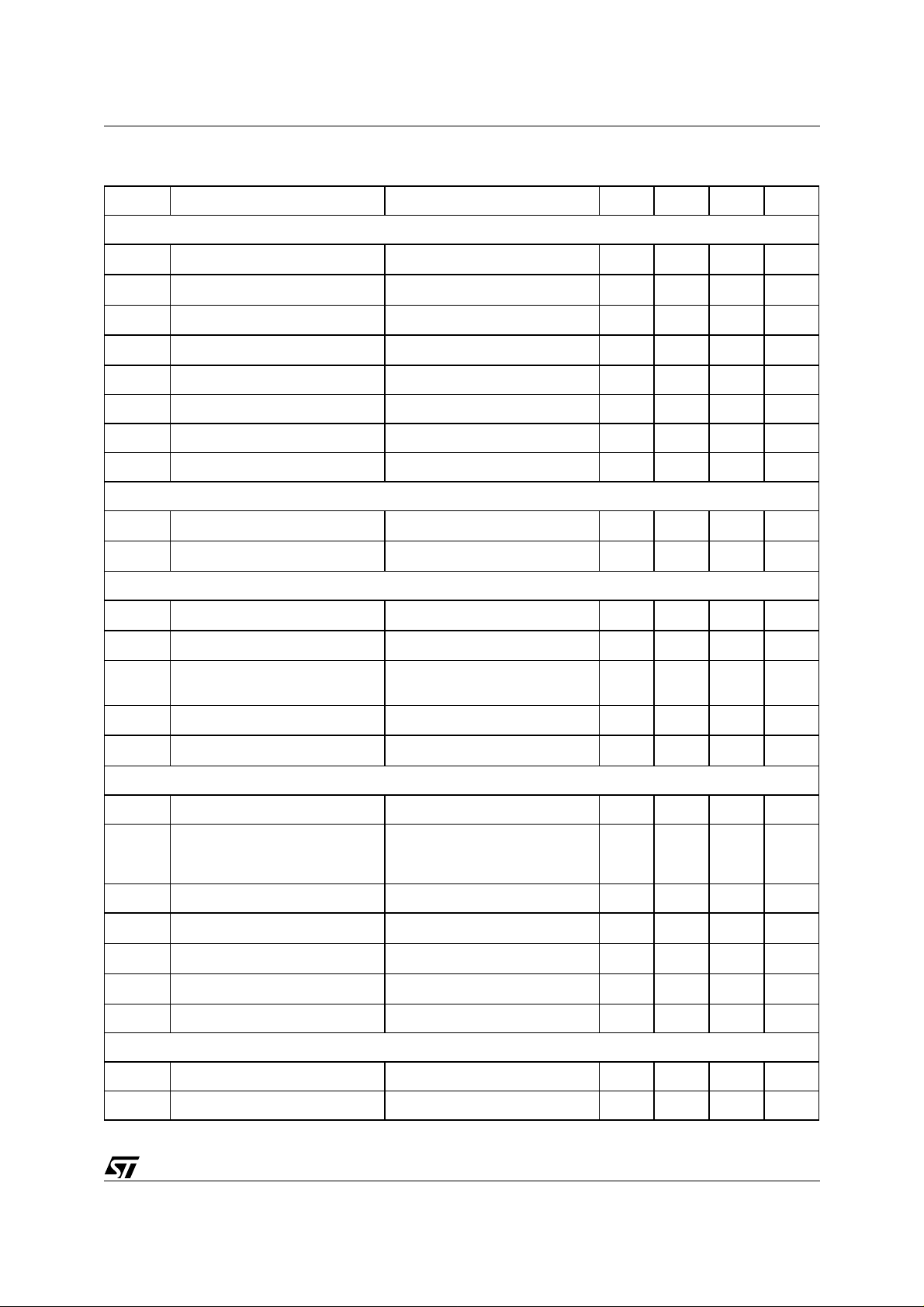

Page 8

L7200

ELECTRICAL CHARACTERISTCS

(continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

VICM INPUT COMMON MODE

RANGE

VCC/4

+/-1.5

FODB UNITY GAIN BANDWIDTH 10 MHz

VCM, POWER STAGE

R

DS(ON)

I

I

O(LEAK)

Output On Resistance (Each

Device)

Operating Current 1.3 A

o

Output Leakage Current Vcc = 14V 1.0 mA

Tj = 25°C

T

= 125°C

j

0.25

0.35 Ω

VCM, CURRENT SENSE AMPLIFIER

A

Voltage Gain 3.88 4 4.12 V/V

V

V

Input Common Mode Range -0.3 Vcc

ICM

+0.3

V

V

F

OCM

Output Common Mode Range -1mA < Io < 1mA 1.5 4.5 V

Output Offset Voltage SENSE_IN(-/+) = Vcc/4 10 mV

OS

3dB Bandwidth 3 MHz

3dB

V

V

CMRR Input Common Mode Rejection

50 dB

Ratio

PSRR Power Supply Rejection Ratio 60 dB

VCM RETRACT

V

T

retract

Retract Voltage PKV=0 & PKV1=0 & PKV2=0

park

PKV=1 & PKV1=0 & PKV2=0

PKV=0 & PKV1=1 & PKV2=0

PKV=1 & PKV1=1 & PKV2=0

PKV=0 & PKV1=0 & PKV2=1

PKV=1 & PKV1=0 & PKV2=1

PKV=0 & PKV1=1 & PKV2=1

PKV=1 & PKV1=1 & PKV2=1

Retract Time

limited by the internal

oscillator 200KHz

RT0 = 0 & RT1 = 0

RT0 = 1 & RT1 = 0

RT0 = 0 & RT1 = 1

RT0 = 1 & RT1 = 1

0.30

0.60

0.90

1.20

1.50

1.80

2.10

2.40

80

160

320

640

SPINDLE, PWM CURRENT SENSE COMPARATOR

T

Delay to Fcom Out 200 500 ns

DLY

SPINDLE, POWER STAGE

R

DS(ON)

Output On Resistance (each

device)

Tj = 25°C

T

= 125°C

j

0.25

0.35

V

ms

Ω

I

O(LEAK)

8/23

Start-up Current 2A

I

o

Output Leakage Current VCC = 14V 1.0 mA

Page 9

L7200

ELECTRICAL CHARACTERISTCS

(continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

BEMF

N

V

HYS

Output Slew Rate (PWM) Reg# 2.2 = 0

Reg# 2.2 = 1

Minimum BEMF Voltage for

MI

Detection

Hysteresis 18 mV

10

20

35 mVp-p

CURRENT SENSE AMPLIFIER

A

Voltage Gain 3.8 4.0 4.2 V/V

v

/dt Output Slew Rate 20 V/µS

dV

o

3.3V LINEAR REGULATOR

V3.3 3.3V Regulation Voltage Iload < 0.6A 3.15 3.3 3.45 V

Av Open Loop Gain 60 dB

Ibase Driving Base Current 20 mA

2.5V LINEAR REGULATOR

V2.5 2.5V Regulation Voltage Iload < 0.6A 2.5 V

Av Open Loop Gain 60 dB

V/µs

Ibase Driving Base Current 20 mA

8V LINEAR REGULATOR

V

A

I

base

8V Regulation Voltage I

8

Open Loop Gain 60 dB

V

Driving Base Current 5 mA

< 0.2A 8 V

load

SHOCK SENSOR - INPUT OPERATIONAL AMPLIFIER A1

Av Open Loop Gain 20 dB

Rin Input Inpedance 10 MΩ

FodB Unity Gain Bandwidth 30 KHz

SHOCK SENSOR - FILTER OPERATIONAL AMPLIFIER A2

Av Open Loop Gain 80 dB

FodB Unity Gain Bandwidth 5 KHz

V

offset

Offset Voltage ±5 V

SHOCK SENSOR - OUTPUT WINDOW COMPARATOR

V

Vth High Referred to Vcc/4 +0.5 V

H

V

Vth Low Referred to Vcc/4 -0.5 V

L

9/23

Page 10

L7200

SERIAL PORT

PARAMETER MIN. TYP. MAX. UNITS

SCLK Period, (T

SCLK low time, (T

SCLK high time, (T

Enable to SCLK (T

SCLK to disable (T

Data set-up time before rising edge SCLK (T

Data hold time (T

Minimum SDEN low time (T

)25ns

SCK

)10ns

CKL

)10ns

CKH

)1015ns

SDENS

) 12.5 ns

SDENH

DS

)5ns

DH

)30ns

SDENL

Figure 1. Serial Port Ti min g In form ation

SDEN

SCLK

SDATA

0A0 A6A1D0 D1

1st Byte 2nd Byte

)5ns

D2 D7

Serial Port Write Timing

SDEN

SCLK

SDATA

1A0 A6A1D0 D1

1st Byte 2nd Byte

Serial Port Read Timing

D7

SERIAL PORT OPERATION

The serial port inter face is a bi-directi onal port for readi ng and writing pr ogramming data fr om/to the internal registers of this device. For data transfers SDEN is brought high, serial data is presented at the SDATA pin, and a

serial clock is applied to the SCLK pin. After the SDEN goes high , the first 16 pulses applied to the SCLK pin

will shift the data presented at the SDATA pin into an internal shift register on the rising edge of each clock. An

internal counter prevents more than 16 bits from being shifted into the register. The data in the shift register is

10/23

Page 11

L7200

latched after the 16th SC LK pulse. If less than 16 clock pulses are provided before SDEN goes low, the data

transfer is aborted.

All transfers are shifted into the serial port LSB first. The first byte of the transfer is for Address and Instruction

information. The first bit is R/W instruction bit, 0 is for WRITE and 1 is for READ. Following 3 bits are for

Combo Data Bank (all set to ‘1’). The last 4 bits are for Register Address.

Figure 2. Serial Port Data Transfer Format

SDEN

SCLK

SDATA

INSTRUCTION (READ/WRITE), 1BIT

ADDRESS, COMBO DATA BANK, 3 BITS

ADDRESS, 4 BITS

DATA, 8 BITS

INTERNAL REGISTERS DEFINITION

Reg: 0

Name: Spindle Spin-Up Register

Type: Write only

Address: 0Eh

BIT LABEL DESCRIPTION

0 START “0” Reset and Brakes the Spindle. “1” Initiates the Spindle Start-Up

procedure.

1 EXTERNAL “0” Spindle BEMF processing in internal mode. “1” External mode.

2 SEQINC In external mode, a “0” to ”1” transition, increments the Spindle

Sequencer.

3 STOP “0” Complete Internal Spindle Start-Up. “1” Stop after Inductive Sense

4 INDSENSE “0” Normal condition. “1” in External mode, initiate the Inductive

Sense

5 SPCOAST “0” Spindle Outputs Enabled. “1” Disabled.

6 SPINUPTIME 0 Spindle Internal Spin Up.

Energization Time. First Bit. 0 0 10mS

7 SPINUPTIME 1 Spindle Internal Spin Up. 0 1 20mS

Energization Time. Second Bit. 1 0 30mS

Bit 7 Bit 6 Time

1 1 40mS

11/23

Page 12

L7200

INTERNAL REGISTERS DEFINITION

(continued)

Reg: 1

Name: Spindle Set-Up 0 Register

Type: Write only

Address: 1Eh

BIT LABEL DESCRIPTION

0 SMOOTH “0” Spindle SMOOTHDRIVE™. “1” Spindle Six step drive.

1 BIPMASK Spindle Mask Time. “0” 15°. “1” 7.5°. (Only in six step drive).

2 MINON 0 Minimum ON time in Current

limit. First Bit. 0 0 6µS

3 MINON 1 Minimum ON time in Current 0 1 3µS

limit. Second Bit. 1 0 9µS

4 BIPDELAY Spindle Commutation Delay. “0” 30°. “1” 15°. (Only in six step drive).

5 MASKSPIN 0 Spindle Mask at acceleration.

First Bit. 0 0 3.2mS

Bit 3 Bit 2 Min TON

11 7.6µS

Bit 6 Bit 5 Mask

6 MASKSPIN 1 Spindle Mask at acceleration. 0 1 1.6mS

Second Bit. 1 0 0.8mS

1 1 6.4mS

7 FREEZE “0” Torque Optimizer Activated. “1” Torque Optimizer Frozen.

Reg: 2

Name: Spindle Set-Up 1 Register

Type: Write only

Address: 2Eh

BIT LABEL DESCRIPTION

0 IL0 Current Limit and Inductive

Sense thresholds. First Bit. 0 0 0.45V

1 IL1 Current Limit and Inductive 0 1 0.50V

Sense thresholds. Second Bit. 1 0 0.55V

2 SSLEW Spindle Chopping Slew Rate. “0” 10V/µS. “1” 20V/µS.

Bit 1 Bit 0 Vlimit

1 1 0.75V

3 FLLEXT Spindle Speed control loop. “0” Internal. “1” External.

12/23

Page 13

L7200

INTERNAL REGISTERS DEFINITION

BIT LABEL DESCRIPTION

4 INDEX External FLL update.

5 EXTK “0” Spindle Speed internal KFLL. “1” All Reg#7 and Lsb of Reg#8 bits are

6 MECH/ELEC Electrical or Mechanical cycle for Spindle FLL control.

7 8_12POLE Spindle Motor Poles. “0” 8 poles. “1” 12 poles.

(continued)

mixed to allow external setting of KFLL.

“0” Mechanical. “1” Electrical.

Reg: 3

Name: Spindle Set-Up 2 Register

Type: Write only

Address: 3Eh

BIT LABEL DESCRIPTION

0 ZCWINDOW Chop cycle for Spindle ZC tristate time. “0” Two. “1” One.

1 REVBRAKE “1” Spindle Reverse Brake. Toggling this bit will define the time before

ending over normal brake. 1 = 10mS. 2 = 20mS. 3 = 40mS.

2 CLKDIV SYSCLK divider. “0” SYSCLK. “1” SYSCLK divide by 2.

3 DIV1.5 SYSCLK divider. “0” SYSCLK. “1” SYSCLK divide by 1.5.

4 FLLCOARSE<0> LSB of Spindle FLL Coarse Counter.

5 FLLCOARSE<1> Bit 1 of Spindle FLL Coarse Counter.

6 FLLCOARSE<2> Bit 2 of Spindle FLL Coarse Counter.

7 FLLCOARSE<3> Bit 3 of Spindle FLL Coarse Counter.

Reg: 4

Name: Spindle FLL Coarse Register

Type: Write only

Address: 4Eh

BIT LABEL DESCRIPTION

0 FLLCOARSE<4> Bit 4 of Spindle FLL Coarse Counter.

1 FLLCOARSE<5> Bit 5 of Spindle FLL Coarse Counter.

2 FLLCOARSE<6> Bit 6 of Spindle FLL Coarse Counter.

3 FLLCOARSE<7> Bit 7 of Spindle FLL Coarse Counter.

4 FLLCOARSE<8> Bit 8 of Spindle FLL Coarse Counter.

5 FLLCOARSE<9> Bit 9 of Spindle FLL Coarse Counter.

13/23

Page 14

L7200

INTERNAL REGISTERS DEFINITION

BIT LABEL DESCRIPTION

6 FLLCOARSE<10> Bit 10 of Spindle FLL Coarse Counter.

7 FLLCOARSE<11> MSB of Spindle FLL Coarse Counter.

(continued)

Reg: 5

Name: Spindle FLL Fine Register

Type: Write only

Address: 5Eh

BIT LABEL DESCRIPTION

0 FLLFINE<0> LSB of Spindle FLL Fine Counter.

1 FLLFINE<1> Bit 1 of Spindle FLL Fine Counter.

2 FLLFINE<2> Bit 2 of Spindle FLL Fine Counter.

3 FLLFINE<3> Bit 3 of Spindle FLL Fine Counter.

4 FLLFINE<4> Bit 4 of Spindle FLL Fine Counter.

5 FLLFINE<5> Bit 5 of Spindle FLL Fine Counter.

6 FLLFINE<6> Bit 6 of Spindle FLL Fine Counter.

7 FLLFINE<7> Bit 7 of Spindle FLL Fine Counter.

Reg: 6

Name: Spindle Set-Up 3 Register

Type: Write only

Address: 6Eh

BIT LABEL DESCRIPTION

0 FLLFINE<8> Bit 8 of Spindle FLL Fine Counter.

1 FLLFINE<9> Bit 9 of Spindle FLL Fine Counter.

2 FLLFINE<10> MSB of Spindle FLL Fine Counter.

3 COEFF_B0<8> MSB of Spindle FLL filter coefficient B0.

4 COEFF_B1<8> MSB of Spindle FLL filter coefficient B1.

5 STUCKSET Spindle Stuck Rotor Time. “0” 400mS. “1” 100mS.

6 CLAMP0 KFLL clamp. First Bit.

7 CLAMP1 KFLL clamp. Second Bit. 0 0 0.50

Bit 7 Bit 6 Clamp

010.55

14/23

100.60

110.65

Page 15

L7200

INTERNAL REGISTERS DEFINITION

(continued)

Reg: 7

Name: Spindle FLL Filter Coefficient A1 Register

Type: Write only

Address: 7Eh

BIT LABEL DESCRIPTION

0 COEFF_A1<0> LSB of Spindle FLL filter coefficient A1.

1 COEFF_A1<1> Bit 1 of Spindle FLL filter coefficient A1.

2 COEFF_A1<2> Bit 2 of Spindle FLL filter coefficient A1.

3 COEFF_A1<3> Bit 3 of Spindle FLL filter coefficient A1.

4 COEFF_A1<4> Bit 4 of Spindle FLL filter coefficient A1.

5 COEFF_A1<5> Bit 5 of Spindle FLL filter coefficient A1.

6 COEFF_A1<6> Bit 6 of Spindle FLL filter coefficient A1.

7 COEFF_A1<7> MSB of Spindle FLL filter coefficient A1.

Reg: 8

Name: Spindle FLL Filter Coefficient B0 Register

Type: Write only

Address: 8Eh

BIT LABEL DESCRIPTION

0 COEFF_B0<0> LSB of Spindle FLL filter coefficient B0.

1 COEFF_B0<1> Bit 1 of Spindle FLL filter coefficient B0.

2 COEFF_B0<2> Bit 2 of Spindle FLL filter coefficient B0.

3 COEFF_B0<3> Bit 3 of Spindle FLL filter coefficient B0.

4 COEFF_B0<4> Bit 4 of Spindle FLL filter coefficient B0.

5 COEFF_B0<5> Bit 5 of Spindle FLL filter coefficient B0.

6 COEFF_B0<6> Bit 6 of Spindle FLL filter coefficient B0.

7 COEFF_B0<7> Bit 7 of Spindle FLL filter coefficient B0.

15/23

Page 16

L7200

INTERNAL REGISTERS DEFINITION

(continued)

Reg: 9

Name: Spindle FLL Filter Coefficient B1 Register

Type: Write only

Address: 9Eh

BIT LABEL DESCRIPTION

0 COEFF_B1<0> LSB of Spindle FLL filter coefficient B1.

1 COEFF_B1<1> Bit 1 of Spindle FLL filter coefficient B1.

2 COEFF_B1<2> Bit 2 of Spindle FLL filter coefficient B1.

3 COEFF_B1<3> Bit 3 of Spindle FLL filter coefficient B1.

4 COEFF_B1<4> Bit 4 of Spindle FLL filter coefficient B1.

5 COEFF_B1<5> Bit 5 of Spindle FLL filter coefficient B1.

6 COEFF_B1<6> Bit 6 of Spindle FLL filter coefficient B1.

7 COEFF_B1<7> Bit 7 of Spindle FLL filter coefficient B1.

Reg: 10

Name: Voice Coil DAC 0 Register

Type: Write only

Address: AEh

BIT LABEL DESCRIPTION

0 VCMDAC<0> LSB of Voice Coil DAC.

1 VCMDAC<1> Bit 1 of Voice Coil DAC.

2 VCMDAC<2> Bit 2 of Voice Coil DAC.

3 VCMDAC<3> Bit 3 of Voice Coil DAC.

4 VCMDAC<4> Bit 4 of Voice Coil DAC.

5 VCMDAC<5> Bit 5 of Voice Coil DAC.

6 VCMDAC<6> Bit 6 of Voice Coil DAC.

7 VCMDAC<7> Bit 7 of Voice Coil DAC.

16/23

Page 17

L7200

INTERNAL REGISTERS DEFINITION

(continued)

Reg: 11

Name: Voice Coil DAC 1 Register

Type: Write only

Address: BEh

BIT LABEL DESCRIPTION

0 VCMDAC<8> Bit 8 of Voice Coil DAC.

1 VCMDAC<9> Bit 9 of Voice Coil DAC.

2 VCMDAC<10> Bit 10 of Voice Coil DAC.

3 VCMDAC<11> Bit 11 of Voice Coil DAC.

4 VCMDAC<12> Bit 12 of Voice Coil DAC.

5 VCMDAC<13> MSB of Voice Coil DAC.

6 PSM/LIN VCM Current control. “0” Linear mode. “1” PSM mode.

7 VCMEN “0” VCM Disabled. “1” VCM Enabled.

Reg: 12

Name: Voice Coil Retract Register

Type: Write only

Address: CEh

BIT LABEL DESCRIPTION

0 PKV0 Retract Voltage. First Bit.

1 PKV1 Retract Voltage. Second Bit. 0 0 0 0.30V

2 PKV2 Retract Voltage. Third Bit. 0 0 1 0.60V

1001.50V

1011.80V

3 RT0 Retract Time. First Bit.

4 RT1 Retract Time. Second Bit. 0 0 80ms

Bit 2 Bit 1 Bit 0 Voltage

0100.90V

0111.20V

1102.10V

1112.40V

Bit 4 Bit 3 Time

0 1 160ms

1 0 320ms

1 1 640ms

17/23

Page 18

L7200

INTERNAL REGISTERS DEFINITION

BIT LABE L DESCRIPTION

5 RETDIR Retract Direction.

6 RETRACT “1” Retracts the Voice Coil arm.

7 RETBRK “1” Brakes the VCM for the first 20mS of the retract time then it reverses

(continued)

“0” VCM- high, VCM+ low. “1” VCM- low, VCM+ high.

the direction of the retract opposite to the RETDIR bit setting for other

20mS, then it finish the normal retract. This total 40mS are

subtructed from the programmed Retract time.

Reg: 13

Name: Voice Coil Set-Up and Ramp Loading Register

Type: Write only

Address: DEh

BIT LABEL DESCRIPTION

0 VCMCAL0 VCM Calibration. First Bit.

1 VCMCAL1 VCM Calibration. Second Bit. 0 0 0 0 None

2 VCMCAL2 VCM Calibration. Third Bit. 0 0 0 1 1.4mV

Bit 3 Bit2 Bit 1 Bit 0 Adj

3 VCMCAL3 VCM Calibration. Fourth Bit. 0 0 1 0 2.8mV

00114.2mV

01005.6mV

01017.0mV

01108.4mV

01119.8mV

100011.2mV

100112.6mV

101014.0mV

101115.4mV

110016.8mV

110118.2mV

111019.6mV

111121.0mV

4 VCMCALDIR VCM Calibration Direction. “0” Positive offset. “1” Negative offset.

5 RAMPLOADING VCM Ramp Loading Setting. “1” Ramp Loading mode.

6 SAMPLE/HOLD VCM Ramp Loading Setting. “0” Hold. “1” Sampling.

7 TRISTATE VCM Ramp Loading Setting. “1” Synchronusly clamps the VCM outputs until

current is less than 100mA, then tristate them.

18/23

Page 19

L7200

INTERNAL REGISTERS DEFINITION

(continued)

Reg: 14

Name: System FunctionSet-Up Register

Type: Write only

Address: EEh

BIT LABEL DESCRIPTION

0 GAINSWITCH VCM current loop Gain Switch. “0” Switch open. “1” Switch close.

1 EXTP VCM external mode VCMP output. “0” VCMP low. “1” VCMP high.

2 EXTN VCM external mode VCMN output. “0” VCMN low. “1” VCMN high.

3 EXTVCM VCM mode. “0” Internal. “1” External.

4 VBDIS Vboost oscillatotor. “0” Enabled. “1” Disabled.

5 SHOCKEN Schock Detector. “0” Disabled. “1” Enabled.

6

7

Reg: 15

Name: Spindle Diagnostic Register

Type: Read only

Address: 0Fh

BIT LABEL DESCRIPTION

0 LOCK “0” Indicates Spindle Speed error (>16µS sample, either mechanical or

electrical).

1 NOTHR “1” Indicates that the Inductive Sense threshold is not reached.

2 PHREADY “1” Indicates that the Phase reading of the motor succeded.

3 STUCKROTOR “1” Indicates that the Spindle BEMF is not detected.

4 PHASE<0> Inductive Sense Phase detected. First Bit.

5 PHASE<1> Inductive Sense Phase detected. Second Bit.

6 PHASE<2> Inductive Sense Phase detected. Third Bit.

7 BACKSPIN “1” Indicateds a Back rotation of the Spindle Motor.

19/23

Page 20

L7200

INTERNAL REGISTERS DEFINITION

(continued)

Reg: 16

Name: System Diagnostic Register

Type: Read only

Address: 1Fh

BIT LABEL DESCRIPTION

0 PHASEFINE<0> Torque Optimizer Phase Shift. First Bit.

1 PHASEFINE<1> Torque Optimizer Phase Shift. Second Bit.

2 PHASEFINE<2> Torque Optimizer Phase Shift. Third Bit.

3 PHASEFINE<3> Torque Optimizer Phase Shift. Fourth Bit.

4 THWARNING Thermal Warning. “1” Indicates that the Device temperature is

approximately 25°C lower than the thermal shutdown’s one.

5 THSHUTDOWN Thermal Shutdown. “1” Indicates that the Device temperature has

exceeded 160°C. The bit will reset (=0) when the temperature drops

below 130°C.

6 VCMCAL Outputs of the Calibration Comparator.

7 RET “1” Indicates that the Voicel Coil is Retracting.

Reg: 17

Name: ID Register

Type: Read only

Address: 2Fh

BIT LABEL DESCRIPTION

0 ID_REV0 Device Minor Revision. First Bit.

1 ID_REV1 Device Minor Revision. Second Bit.

2 ID_REV2 Device Minor Revision. Third Bit.

3 ID_REV3 Device Minor Revision. Fourth Bit.

4 ID_REV4 Device Major Revision. First Bit.

5 ID_REV5 Device Major Revision. Second Bit.

6 ID_REV6 Device Major Revision. Third Bit.

7 ID_REV7 Device Major Revision. Fourth Bit.

20/23

Page 21

APPLICATION CIRCUIT

L7200

VCC

SYSCLK

SDEN

SDATA

SCLK

FCOM

PORB

SENSOR OUT

SENSOR IN

33nF

22uF/25V

Tantalum

330pF

CTAPOUT_COUT_BOUT_A

2.2uF

25

1

2

47

+

48

40

6

41

42

43

7

31

15

10K

19

18

17

5V

63

64

59

60

55

56

5

44

24

8

9

VDD

BRAKE

AVCC

VCC

VCC

VCC

VCC

DGND

SYSCLK

SDEN

SDATA

SCLK

FCOM

PORB

SSOUT

SSIN

SSBUFOUT

SSFIN

SSFOUT

VBOOST

161314515253543536495023222120

GND

GND

AGND

OUT_A

OUT_A

"MOZART"

TQFP64

PUMP

VCM_GND

VCM_GND

VCM_A-

VCM_A-

OUT_B

OUT_B

OUT_C

SENSE_IN-

SENSE_IN+

VCM_A+

OUT_C

VCM_A+

62

11

CTAP

TR_12V

RSENSE

TR_5V

0.3ohm / 1W

57

58

61

RSENSE

RSENSE

RSENSE

ISENSE

VREG8_DRV

VREG8_IN

VREG3.3_DRV

VREG3.3_IN

VREG2.5_DRV

VREG2.5_IN

GAINRES

DAC_OUT

ERROR_IN

ERROR_OUT

SENSE_OUT

TR_3.3V

TR_2.5V

RBIAS

26

VPS

VPS

VPS

VPS

12V

12V

12V

12K

60K

1nF

10K

PNP

10uF

5V

PNP

10uF

5V

PNP

10uF

10

33

34

3

4

29

30

46

45

27

28

12

32

39

62K

38

37

100K

1N4148

1uF

Analog Ground Power Ground VCM Ground Digital Ground

47nF

1N4148

VCC

0.25ohm

1W

VCM_A+VCM_A-

21.5K

21/23

Page 22

L7200

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.60 0.063

A1 0.05 0.15 0.002 0.006

A2 1.35 1.40 1.45 0.053 0.055 0.057

B 0.18 0.23 0.28 0.007 0.009 0.011

C 0.12 0.16 0.20 0.0047 0.0063 0.0079

D 12.00 0.472

D1 10.00 0.394

D3 7.50 0.295

e 0.50 0.0197

E 12.00 0.472

E1 10.00 0.394

E3 7.50 0.295

L 0.40 0.60 0.75 0.0157 0.0236 0.0295

L1 1.00 0.0393

K 0°(min.), 7°(max.)

OUTLINE AND

MECHANICAL DATA

TQFP64

D

D1

TQFP64

3348

32

E3D3E1

17

16

E

L1

L

0.10mm

Seating Plane

K

49

B

64

1

e

A1

B

A

A2

C

22/23

Page 23

L7200

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or p at ent rights of STMicroelectronics. Spec i fications mentioned i n this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri t i cal compone nts in life support device s or systems without express written approval of STMicroel ectronics.

The ST logo is a registered trademark of STMicroelectronics

1999 STMi croelectronics - All Ri ghts Rese rved

Australi a - Brazil - Chin a - Finland - Franc e - Germany - Hong Kong - India - Ita l y - Japan - Malaysi a - Malta - Morocco - Singapore - Spain

STMicroelectronics GROUP OF COMPANIES

- Sweden - Sw itzerlan d - United Kin gdom - U.S.A.

http://www.s t. com

23/23

Loading...

Loading...