Page 1

Adjustable step-down controller with synchronous rectification

Features

■ Input voltage range from 1.8 V to 14 V

■ Supply voltage range from 4.5 V to 14 V

■ Adjustable output voltage down to 0.6 V with

±0.8% accuracy over line voltage and

temperature (0°C~125°C)

■ Fixed frequency voltage mode control

■ t

■ 0% to 100% duty cycle

■ Selectable 0.6 V or 1.2 V internal voltage

■ External input voltage reference

■ Soft-start and inhibit

■ High current embedded drivers

■ Predictive anti-cross conduction control

■ Selectable uvlo threshold (5 V or 12 V BUS)

■ Programmable high-side and low-side R

■ Switching frequency programmable

■ Master/slave synchronization with 180° phase

■ Pre-bias start up capability (L6730)

■ Selectable source/sink or source only

■ Selectable constant current or hiccup mode

■ Power Good output with programmable delay

■ Overvoltage protection with selectable

■ Thermal shut-down

■ Package: HTSSOP20

lower than 100 ns

ON

reference

sense overcurrent protection

DS(on)

from 100 kHz to 1 MHz

shift

capability after soft-start (L6730)

overcurrent protection after soft-start (L6730B)

latched/not-latched mode

HTSSOP20

Applications

■ High performance / high density DC-DC

modules

■ Low voltage distributed DC-DC

■ niPOL converters

■ DDR memory supply

■ DDR memory bus termination supply

Table 1. Device summary

Order codes Package Packing

L6730 HTSSOP20 Tube

L6730TR HTSSOP20 Tape and reel

L6730B HTSSOP20 Tube

L6730BTR HTSSOP20 Tape and reel

L6730

L6730B

December 2009 Doc ID 11938 Rev 3 1/52

www.st.com

52

Page 2

Contents L6730 - L6730B

Contents

1 Summary description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

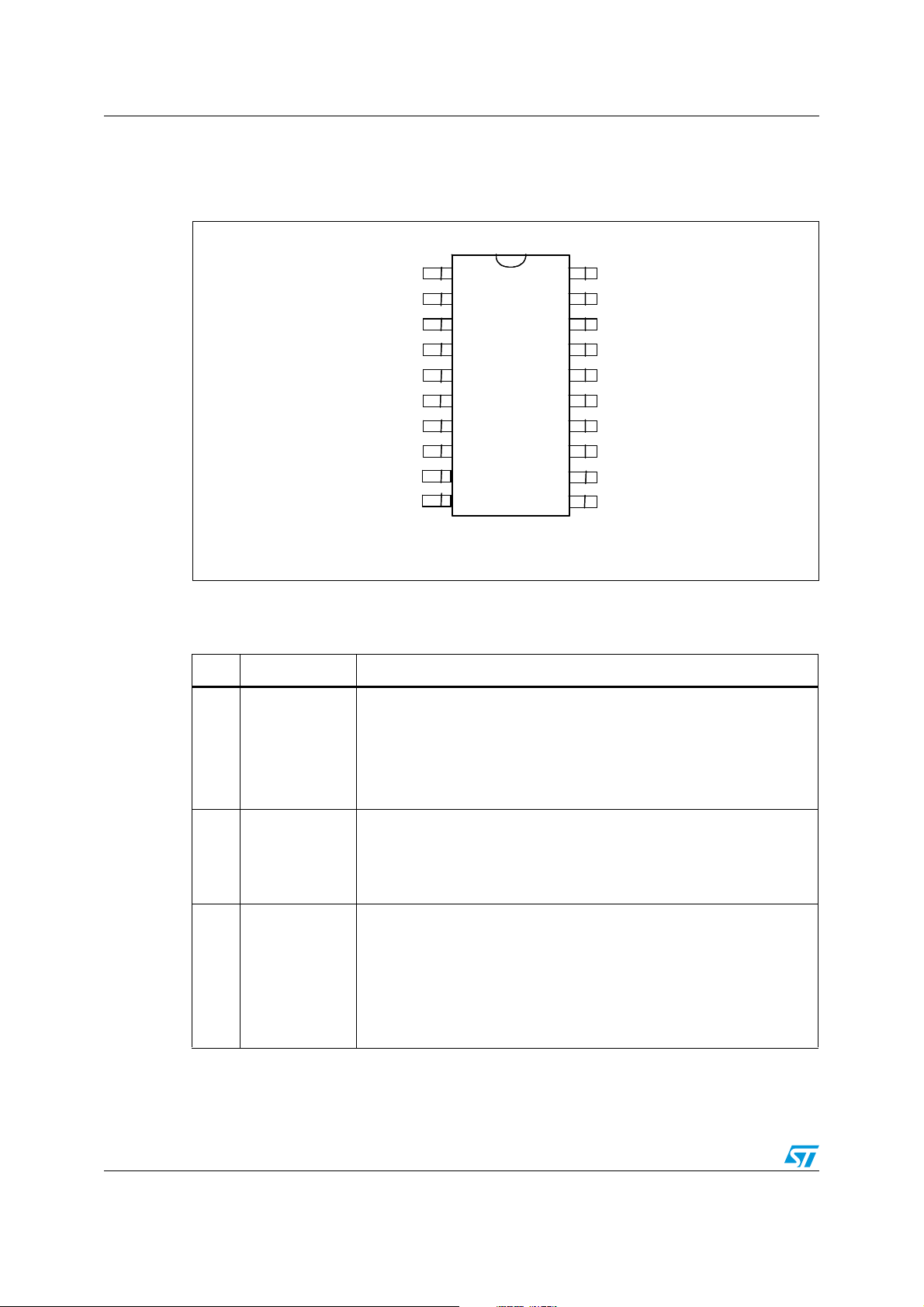

3 Pin connections and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Internal LDO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Bypassing the LDO to avoid the voltage drop with low Vcc . . . . . . . . . . . 15

5.4 Internal and external references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.5 Error amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.6 Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7 Driver section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.8 Monitoring and protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.9 Adjustable masking time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.10 Multifunction pin (S/O/U L6730) (CC/O/U L6730B) . . . . . . . . . . . . . . . . . 27

5.11 Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.12 Thermal shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.13 Minimum ON-time TON(MIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.14 Bootstrap anti-discharging system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.14.1 Fan power supply failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.14.2 No-sink at zero current operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6 Application details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1 Inductor design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2/52 Doc ID 11938 Rev 3

Page 3

L6730 - L6730B Contents

6.2 Output capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3 Input capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4 Compensation network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.5 Two quadrant or one quadrant operation mode (L6730) . . . . . . . . . . . . . 37

7 L6730 demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.2 PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8 I/O Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9 Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10 POL demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

12 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Doc ID 11938 Rev 3 3/52

Page 4

Summary description L6730 - L6730B

1 Summary description

The controller is an integrated circuit designed using BiCMOS-DMOS, v5 (BCD5)

technology that provides complete control logic and protection for high performance, stepdown DC/DC and niPOL converters.

It is designed to drive N-Channel MOSFETs in a synchronous rectified buck converter

topology. The output voltage of the converter can be precisely regulated down to 600 mV,

with a maximum tolerance of ±0.8%, or to 1.2 V, when one of the internal references is used.

It is also possible to use an external reference from 0 V to 2.5 V.

The input voltage can range from 1.8 V to 14 V, while the supply voltage can range from 4.5

V to 14 V. High peak current gate drivers provide for fast switching to the external power

section and the output current can be in excess of 20 A, depending on the number of the

external MOSFETs used. The PWM duty cycle can range from 0% to 100% with a minimum

on-time (T

very high switching frequency possible.

The device provides voltage-mode control. It includes a 400 kHz free-running oscillator that

is adjustable from 100 kHz to 1 MHz. The error amplifier features a 10 MHz gain-bandwidthproduct and 5 V/µs slew-rate that permits to realize high converter bandwidth for fast

transient response. The device monitors the current by using the R

side and low-side MOSFET(s), eliminating the need for a current sensing resistor and

guaranteeing an effective over current-protection in all the application conditions. When

necessary, two different current limit protections can be externally set through two external

resistors. A leading edge adjustable blanking time is also available to avoid false overcurrent-protection (OCP) intervention in every application condition.

ON(MIN)

) lower than 100 ns, making conversions with a very low duty cycle and

of both the high-

DS(ON)

It is possible to select the HICCUP mode or the constant current protection (L6730B) after

the soft-start phase.

During this phase constant current protection is provided. It is possible to select the sinksource or the source-only mode capability (before the device powers on) by acting on a

multifunction pin (L6730). The L6730 disables the sink mode capability during the soft-start

in order to allow a proper start-up also in pre-biased output voltage conditions. The L6730B

can always sink current and, so it can be used to supply the DDR memory BUS termination.

Other features include Master-Slave synchronization (with 180° phase shift), Power-Good

with adjustable delay, over voltage-protection, feed back disconnection, selectable UVLO

threshold (5 V and 12 V Bus), and thermal shutdown. The HTSSOP20 package allows the

realization for very compact DC/DC converters.

4/52 Doc ID 11938 Rev 3

Page 5

L6730 - L6730B Summary description

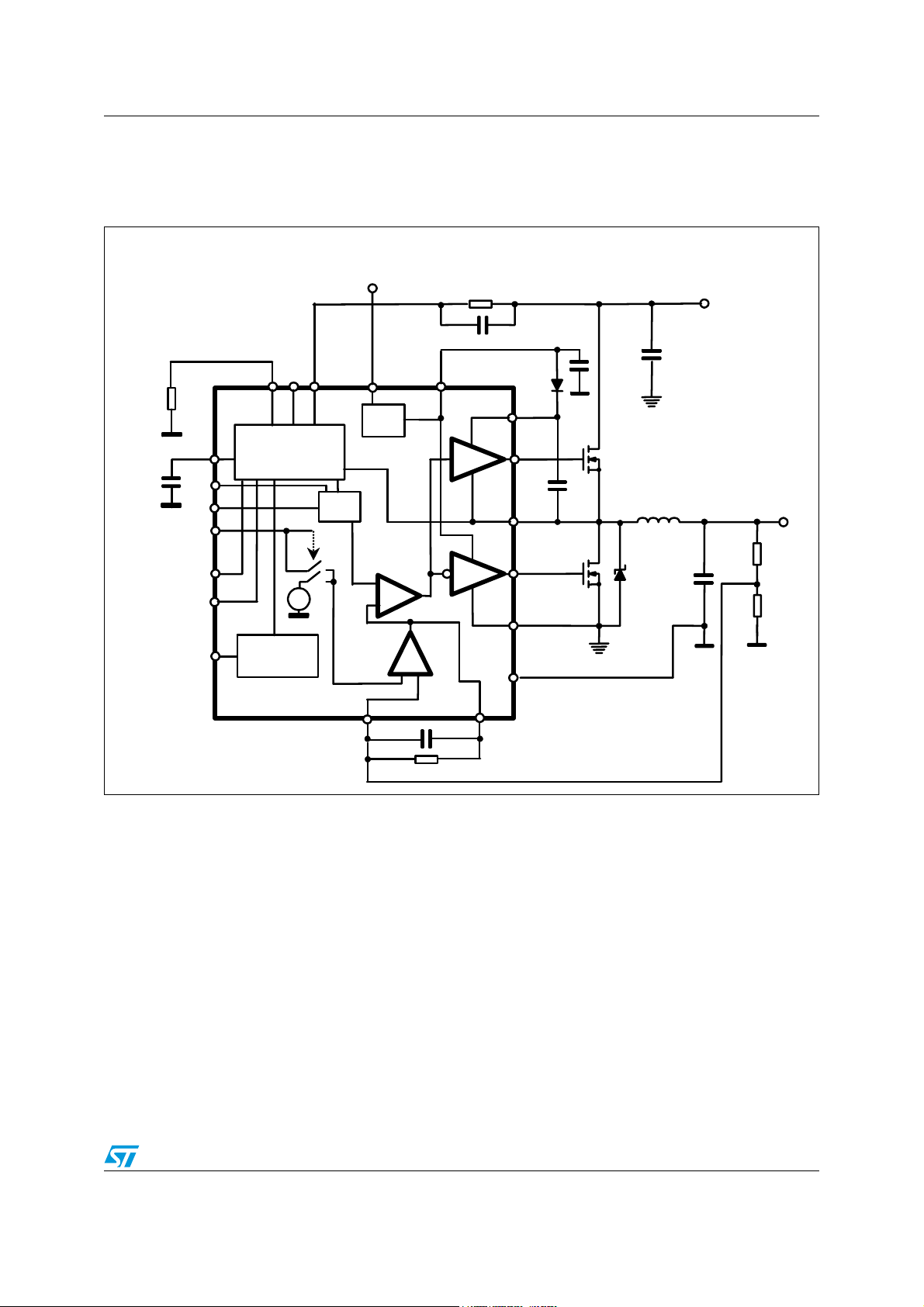

1.1 Functional description

Figure 1. Block diagram

VCC=4.5V to14V

V

=1.8V to14V

in

OCL

PGOOD

OCH

LDO

VCCDR

BOOT

Monitor

SS/INH

SYNCH

OSC

EAREF

PGOOD

SINK/OVP/UVLO*

TMASK

Protection

and Ref

+

-

MASKING TIME

ADJUSTMENT

OSC

L6730/B

0.6V

1.2V

-

+

PWM

E/A

+

-

FB

HGATE

PHASE

LGATE

PGND

GND

COMP

Note: In the L6730B the multifunction pin is: CC/OVP/UVLO.

Vo

Doc ID 11938 Rev 3 5/52

Page 6

Summary description L6730 - L6730B

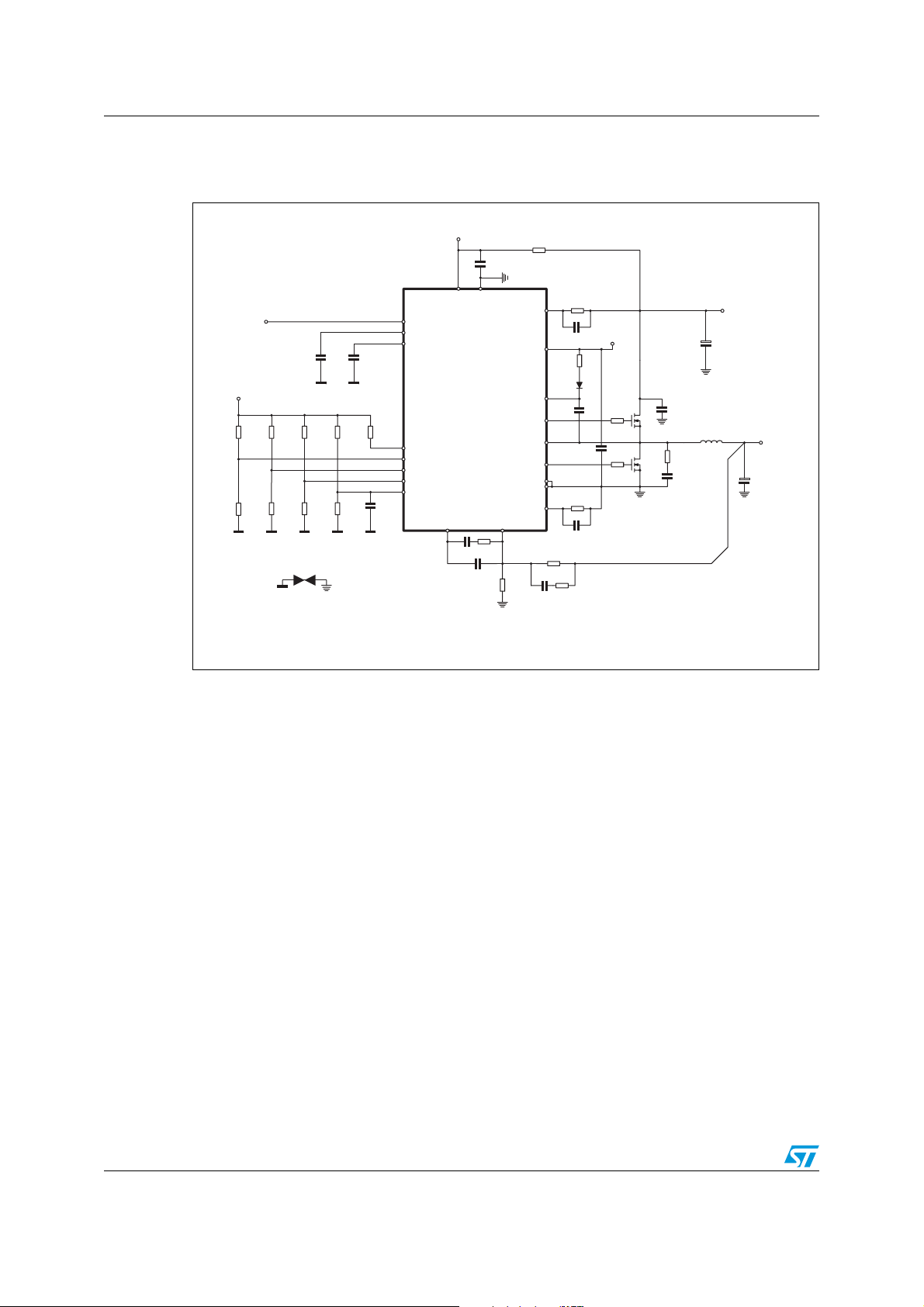

1.2 Application circuit

Figure 2. Application circuit

VCC = 4.5V to 14V

DEC

THERMAL PAD

FB

R

OS

OCH

VCCDR

BOOT

HGATE

PHASE

LGATE

PGND

OCL

R

FILT

R

OCH

C

OCH

R

BOOT

C

BOOT

C

VCCDR

R

OCL

C

OCL

R

FB

RSC

S

VCCDR

R

R

SYNCH

R

H_SOU

H_OSC

L_OSCRL_SOU

SHORT PIN

R

R

H_MASK

L_MASK

1

C

VCC

GND

SYNCH

SS/INH

PGOOD DELAY

C

C

PGdelay

SS

L6730

R

PG

R

R

H_EAREF

L_EAREF

PGOOD

OSC

SOU/COU

TMASK

EAREF

C

EAREF

COMP

RFC

F

C

P

NOTE 1: In module application it is recommended to place the short pin on the module where device is mounted.

VCCDR

VIN = 1.8V to 14V

C

IN_BULK

C

R

HS

IN_HF

HS

LVout

R

LS

R

SN

LS

C

SN

C

OUT

6/52 Doc ID 11938 Rev 3

Page 7

L6730 - L6730B Electrical data

2 Electrical data

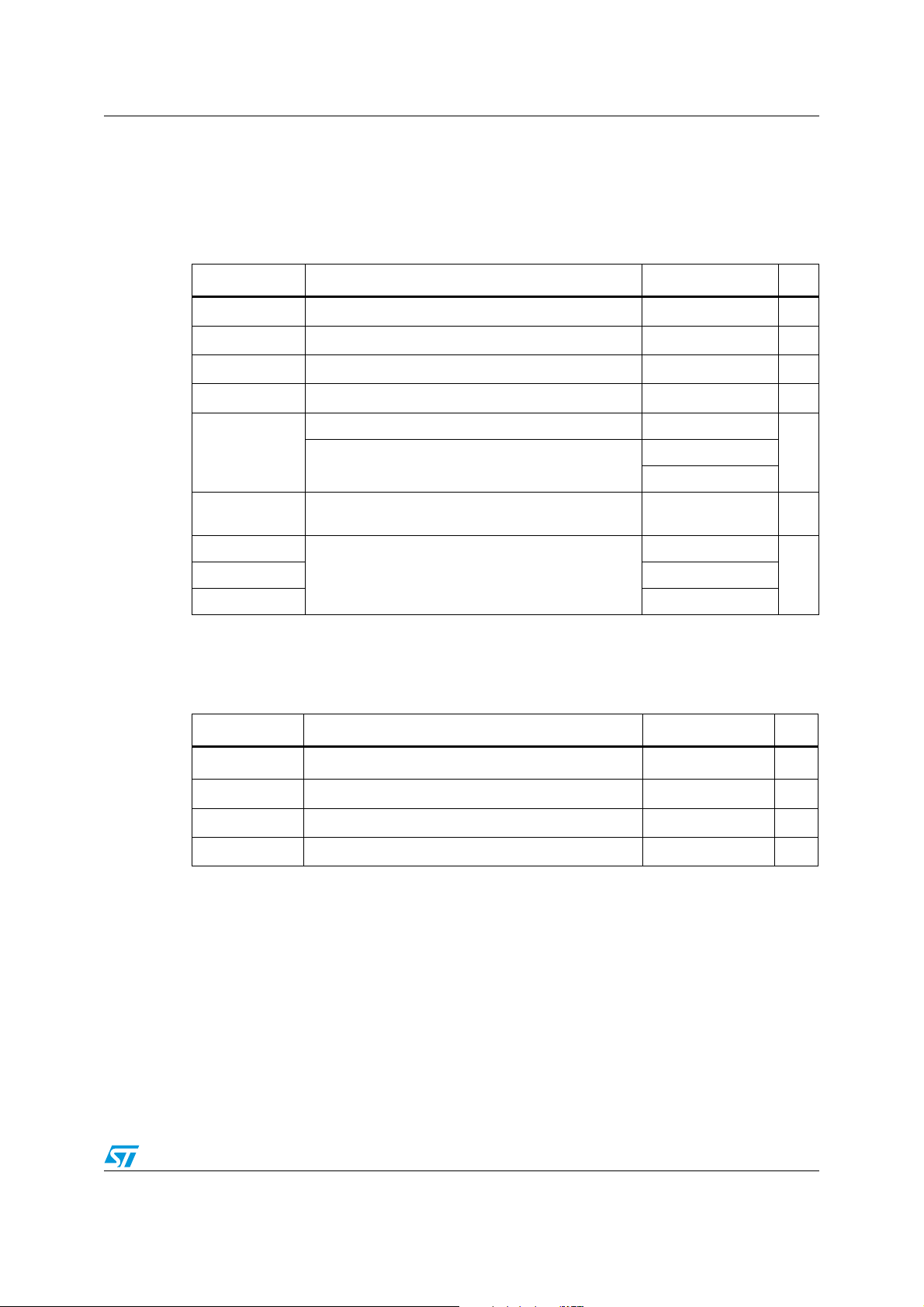

2.1 Maximum rating

Table 2. Absolute maximum ratings

Symbol Parameter Value Unit

V

VCC to GND and PGND, OCH, PGOOD

CC

V

BOOT - VPHASE

V

HGATE - VPHASE

V

BOOT

V

PHASE

Boot voltage 0 to 6 V

BOOT -0.3 to 24 V

PHASE -1 to 18

PHASE spike, transient < 50ns (F

= 500kHz)

SW

-0.3 to 18 V

0 to V

BOOT

- V

-3

+24

PHASE

V

V

SS, FB, EAREF, SYNC, OSC, OCL, LGATE, COMP,

S/O/U, TMASK, PGOODELAY, V

OCH Pin

Maximum withstanding voltage range

test condition: CDF-AEC-Q100-002 “human body

OTHER PINS ±2000

model” acceptance criteria: “normal performance”

2.2 Thermal data

Table 3. Thermal data

Symbol Description Value Unit

(1)

R

thJA

T

STG

T

J

T

A

1. Package mounted on demonstration board

Max. thermal resistance junction to ambient 50 °C/W

Storage temperature range -40 to +150 °C

Junction operating temperature range -40 to +125 °C

Ambient operating temperature range -40 to +85 °C

CCDR

-0.3 to 6 V

±1500

VPGOOD Pin ±1000

Doc ID 11938 Rev 3 7/52

Page 8

Pin connections and functions L6730 - L6730B

(

⋅

=

3 Pin connections and functions

Figure 3. Pins connection (top view)

PGOOD DELAY

PGOOD DELAY

SYNCH

SYNCH

SINK/OVP/UVLO

TMASK

TMASK

GND

GND

FB

FB

COMP

COMP

SS/INH

SS/INH

EAREF

EAREF

OSC

OSC

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

HTSSOP20

HTSSOP20

20

20

19

19

18

18

17

17

16

16

15

15

14

14

13

13

12

12

11

11

Note: In the L6730B the multifunction pin is: CC/OVP/UVLO.

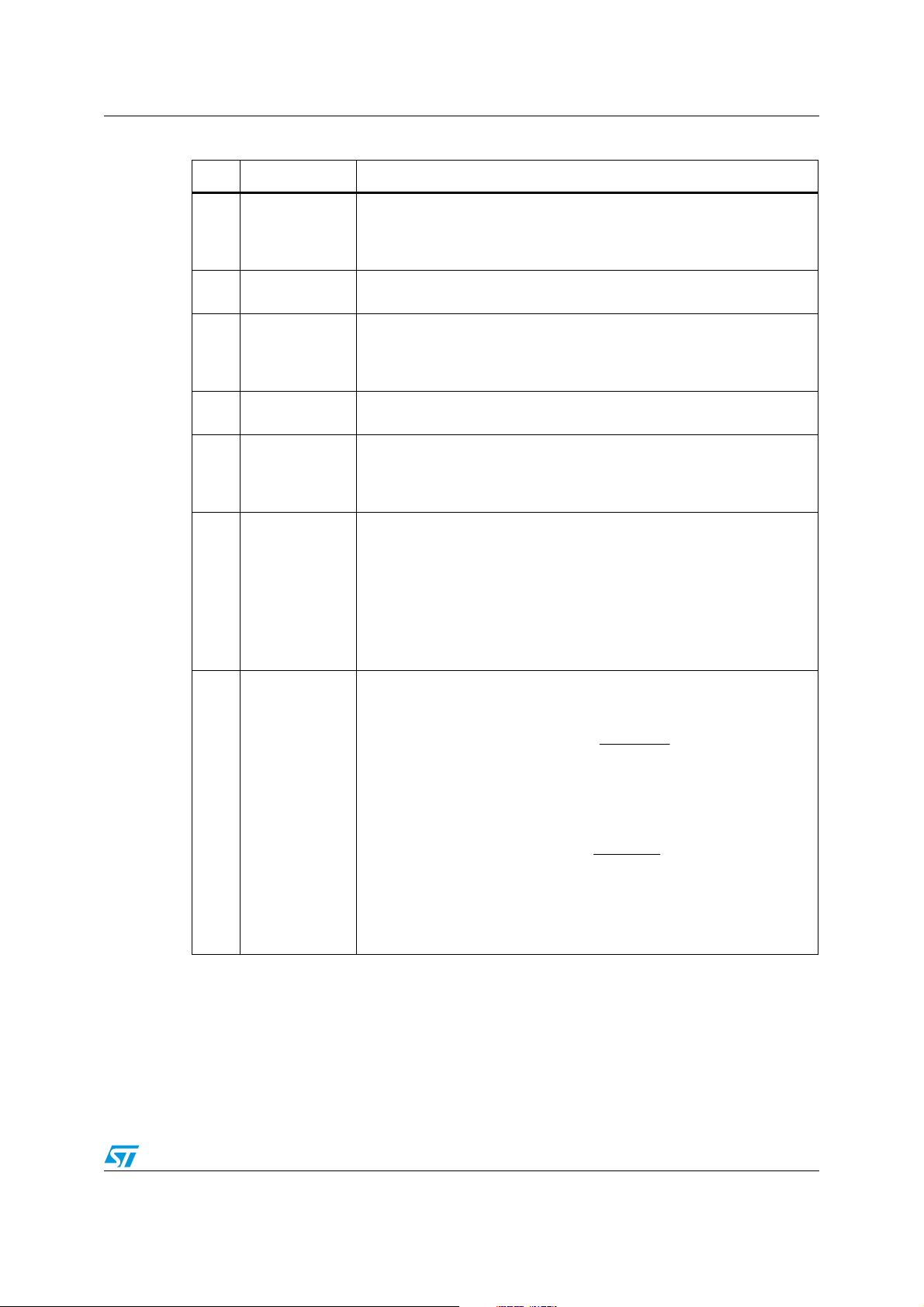

Table 4. Pin connection

Pin n. Name Description

A capacitor connected between this pin and GND introduces a delay

between the internal PGOOD comparator trigger and the external signal

1 PGOOD DELAY

rising edge. No delay can be introduced on the falling edge of the

PGOOD signal. The delay can be calculated with the following formula:

PGOOD

PGOOD

VCC

VCC

VCCDR

VCCDR

LGATE

LGATE

PGND

PGND

BOOT

BOOT

HGATE

HGATE

PHASE

PHASE

OCH

OCH

OCL

OCL

Two or more devices can be synchronized by connecting the SYNCH pins

together. The device operating with the highest F

2 SYNCH

device. The Slave devices will operate at 180° phase shift from the

Master. The best way to synchronize devices is to set their FSW at the

same value. If it is not used, the SYNCH pin can be left floating.

With this pin it is possible:

SINK/OVP/UVLO

L6730

3

CC/OVP/UVLO

L6730B

To enable-disable the sink mode current capability after SS (L6730);

To enable-disable the constant current OCP after SS (L6730B);

To enable-disable the latch mode for the OVP;

To set the UVLO threshold for the 5 V BUS and 12 V BUS.

The device captures the analog value present at this pin at the start-up

when V

meets the UVLO threshold.

CC

8/52 Doc ID 11938 Rev 3

[μ

s]

)

pFCPGDelay

5.0

SW will be the Master

Page 9

L6730 - L6730B Pin connections and functions

Table 4. Pin connection (continued)

Pin n. Name Description

The user can select two different values for the leading edge blanking

4

T

MASK

time on the peak overcurrent protection by connecting this pin to V

GND. The device captures the analog value present at this pin at the

start-up when VCC meets the UVLO threshold.

CCDR or

5GND

All the internal references are referenced to this pin. Connect to the PCB

signal ground.

This pin is connected to the error amplifier inverting input. Connect it to

6FB

Vout through the compensation network. This pin is also used to sense

the output voltage in order to manage the over voltage conditions and the

PGood signal.

7COMP

This pin is connected to the error amplifier output and used to

compensate the voltage control loop.

The soft-start time is programmed connecting an external capacitor from

8 SS/INH

this pin and GND. The internal current generator forces a current of 10mA

through the capacitor. This pin is also used to inhibit the device: when the

voltage at this pin is lower than 0.5V the device is disabled.

It is possible to set two internal references 0.6V / 1.2V or provide an

external reference from 0V to 2.5V:

V

9 EAREF

V

V

An internal clamp limits the maximum V

captures the analog value present at this pin at the start-up when VCC

meets the UVLO threshold.

Connecting an external resistor from this pin to GND, the external

frequency can be increased according with the following equation:

from 0% to 80% of V

EAREF

from 80% to 95% of V

EAREF

from 95% to 100% of V

EAREF

-> external reference

CCDR

-> V

CCDR

-> V

CCDR

400

+=KRKHzFsw

=1.2V

REF

=0.6V

REF

at 2.5V (typ.). The device

EAREF

6

1088.9

⋅

)(

Ω

OSC

10 OSC

Connecting a resistor from this pin to V

(5V), the switching frequency

CCDR

can be lowered according with the following equation:

7

1001.3

400

⋅

−=KRKHzFsw

OSC

)(

Ω

If the pin is left open, the switching frequency is 400 KHz. Normally this

pin is at a voltage of 1.2V. In OVP the pin is pulled up to 4.5V (only in

latched mode). Don’t connect a capacitor from this pin to GND.

Doc ID 11938 Rev 3 9/52

Page 10

Pin connections and functions L6730 - L6730B

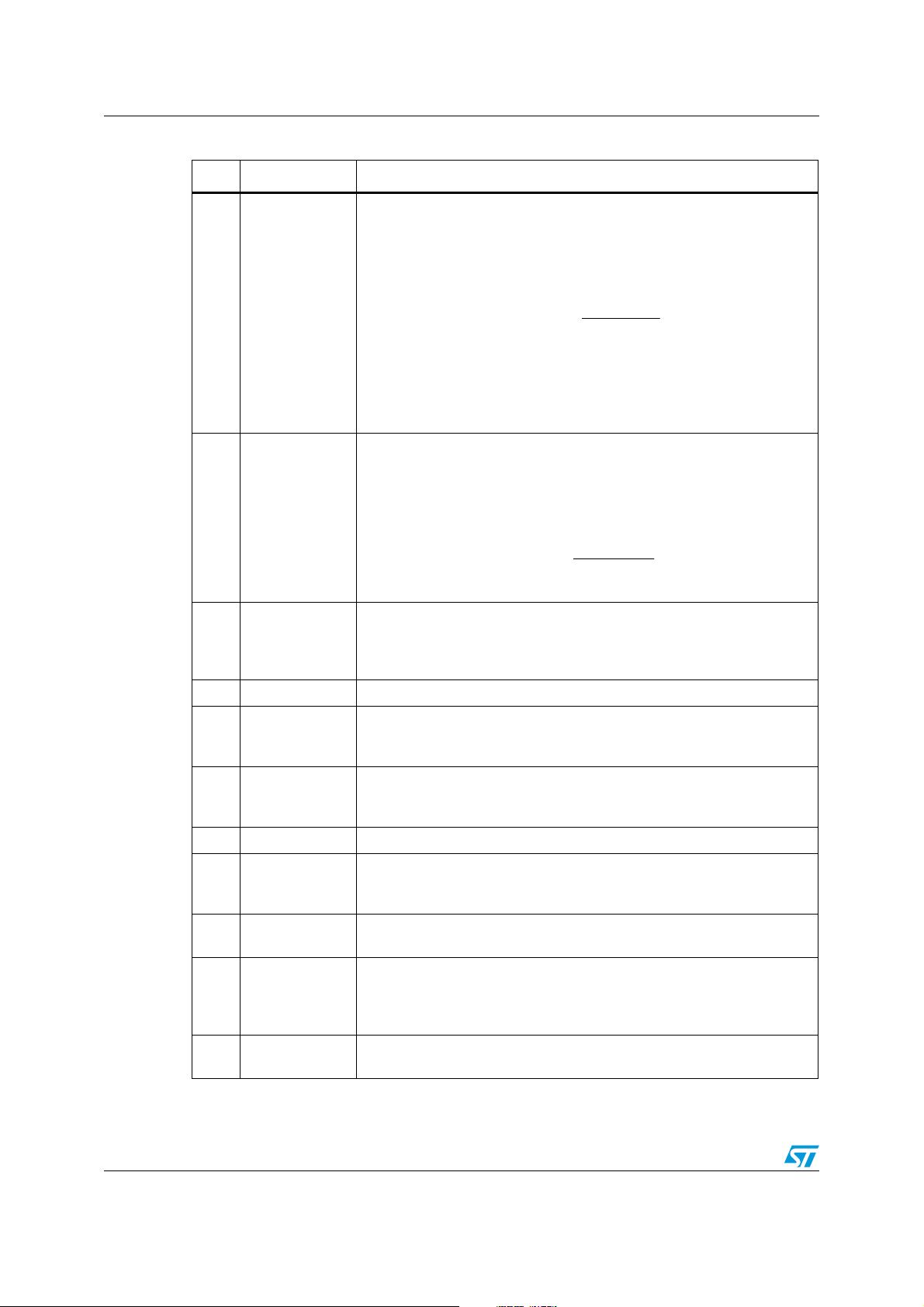

Table 4. Pin connection (continued)

Pin n. Name Description

A resistor connected from this pin to ground sets the valley- current-limit.

The valley current is sensed through the low-side MOSFET(s). The

11 OCL

12 OCH

internal current generator sources a current of 100μA (I

to ground through the external resistor (R

). The over-current threshold

OCL

is given by the following equation:

R

I

⋅

OCL

I

VALLEY

OCL

=

R2

⋅

DSonLS

Connecting a capacitor from this pin to GND helps in reducing the noise

injected from V

to the device, but can be a low impedance path for the

CC

high-frequency noise related to the GND. Connect a capacitor only to a

“clean” GND.

A resistor connected from this pin and the high-side MOSFET(s) drain

sets the peak-current-limit. The peak current is sensed through the highside MOSFET(s). The internal 100μA current generator (I

current from the drain through the external resistor (R

current threshold is given by the following equation:

R

I

⋅

I

PEAK

OCH

=

R

DSonHS

OCH

) from this pin

OCL

OCH

). The over-

OCH

) sinks a

This pin is connected to the source of the high-side MOSFET(s) and

13 PHASE

provides the return path for the high-side driver. This pin monitors the

drop across both the upper and lower MOSFET(s) for the current limit

together with OCH and OCL.

14 HGATE This pin is connected to the high-side MOSFET(s) gate.

The high-side driver is supplied through this pin. Connect a capacitor from

15 BOOT

this pin to the PHASE pin, and a diode from V

CCDR to this pin (cathode

versus BOOT).

This pin has to be connected closely to the low-side MOSFET(s) source

16 PGND

in order to reduce the noise injection into the device. Connect to the PCB

power ground plane.

17 LGATE This pin is connected to the low-side MOSFET(s) gate.

5V internally regulated voltage. It is used to supply the internal drivers

18

V

CCDR

and as a voltage reference. Filter it to GND with at least a 1µF ceramic

cap.

19

V

CC

Supply voltage pin. The operative supply voltage range is from 4.5V to

14V.

This pin is an open collector output and it is pulled low if the output

20 PGOOD

voltage is not within the specified thresholds (90%-110%). If not used it

may be left floating. Pull up this pin to V

with a 10K resistor to obtain

CCDR

a logical signal.

- Thermal PAD

Thermal Pad connects the silicon substrate and makes good thermal

contact with the PCB. Connect to the PCB power ground plane.

10/52 Doc ID 11938 Rev 3

Page 11

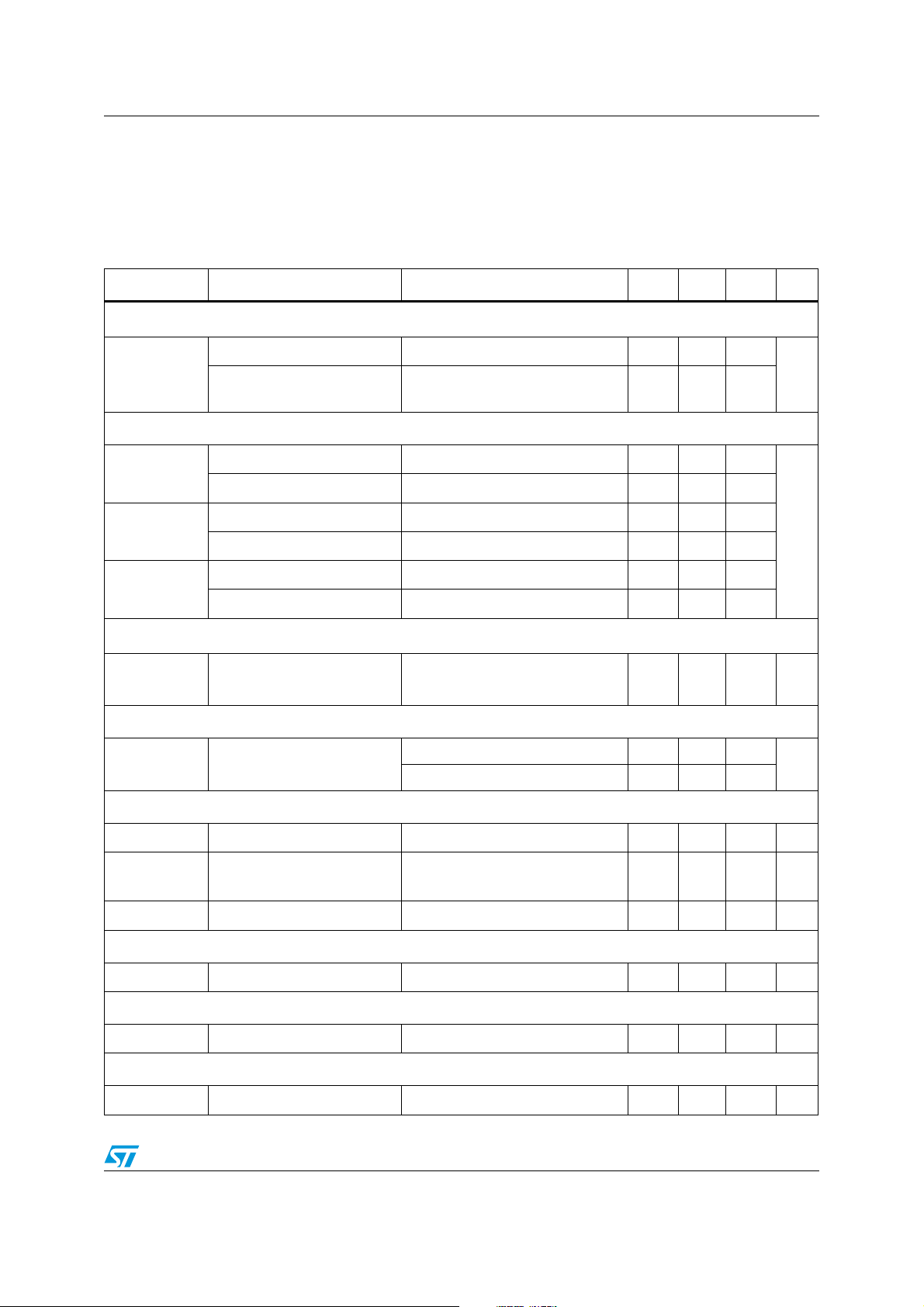

L6730 - L6730B Electrical characteristics

4 Electrical characteristics

V

= 12 V, TA = 25°C unless otherwise specified

CC

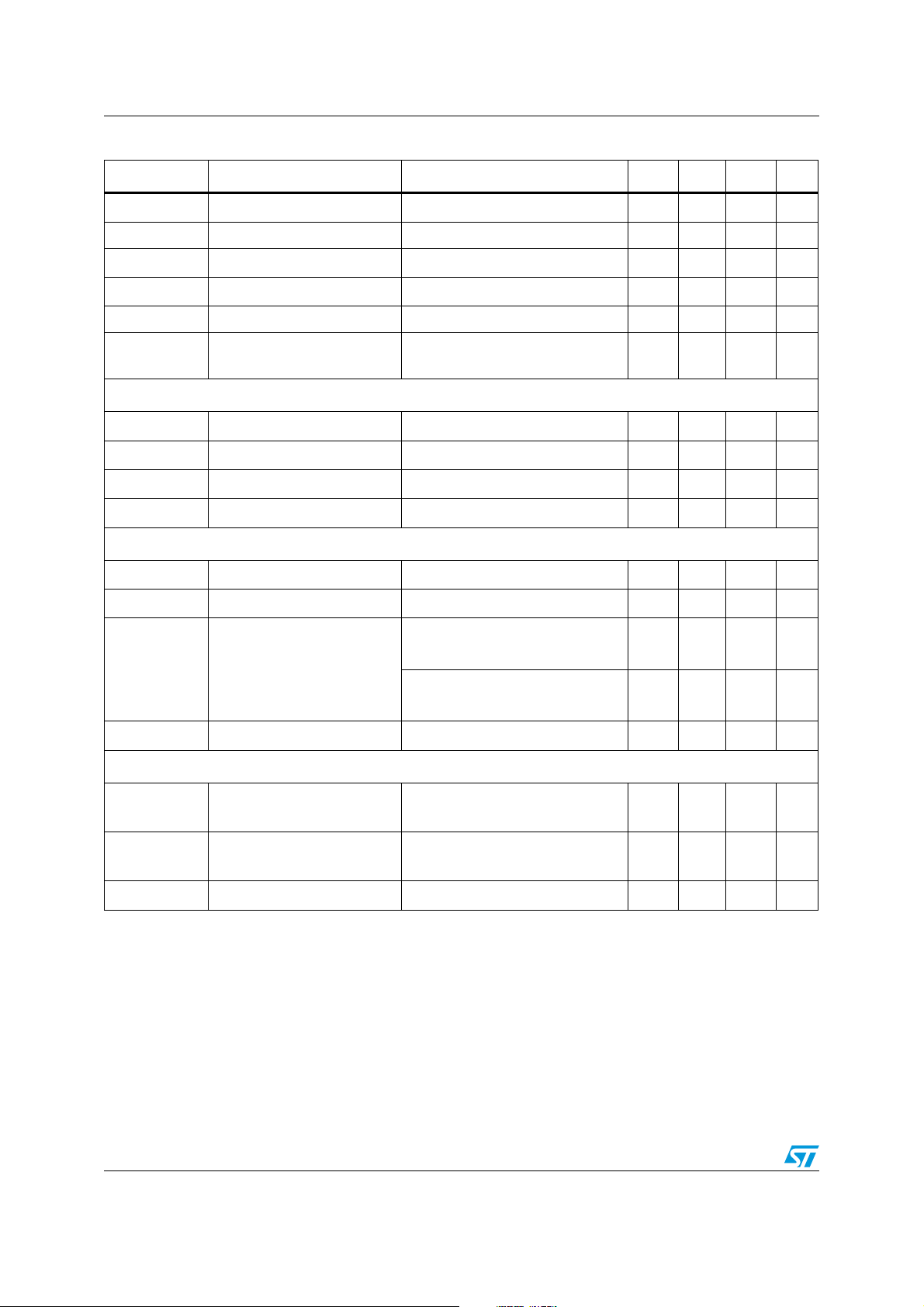

Table 5. Electrical characteristics

Symbol Parameter Test condition Min. Typ. Max. Unit

V

supply current

CC

VCC stand by current

I

CC

V

CC

Power-ON

Tu r n -O N V

5V BUS

Tu r n -O F F V

Tu r n -O N V

12V BUS

Tu r n -O F F V

Tu r n -O N V

V

V

CCDR

IN OK

regulation

Tu r n -O F F V

V

CCDR

Soft start and inhibit

I

SS

Soft start current

quiescent current

threshold V

CC

threshold V

CC

threshold V

CC

threshold V

CC

threshold

OCH

threshold

OCH

voltage

OSC = open; SS to GND 7 9

OSC= open;

HG = open, LG = open, PH=open

= 1.7V

OCH

= 1.7V

OCH

= 1.7V

OCH

= 1.7V

OCH

4.0 4.2 4.4

3.6 3.8 4.0

8.3 8.6 8.9

7.4 7.7 8.0

8.5 10

1.1 1.25 1.47

0.9 1.05 1.27

=5.5V to 14V

V

CC

= 1mA to 100mA

I

DR

4.5 5 5.5 V

SS = 2V 7 10 13

SS = 0 to 0.5V 20 30 45

mA

V

µA

Oscillator

f

OSC

f

OSC,RT

ΔV

OSC

Initial accuracy OSC = OPEN 380 400 420 kHz

Total accuracy

Ramp amplitude 2.1 V

Output voltage (1.2V MODE)

V

FB

Output voltage 1.190 1.2 1.208 V

Output voltage (0.6 MODE)

V

FB

Output voltage 0.597 0.6 0.603 V

Error amplifier

R

EAREF

EAREF input resistance Vs. GND 70 100 150 kΩ

RT = 390KΩ to V

RT = 18KΩ to GND

CCDR

-15 15 %

Doc ID 11938 Rev 3 11/52

Page 12

Electrical characteristics L6730 - L6730B

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

I

FB

I.I. bias current

= 0V

V

FB

0.290 0.5 μA

Ext Ref Clamp 2.3 V

V

OFFSET

G

V

Error amplifier offset Vref = 0.6V -5 +5 mV

Open loop voltage gain Guaranteed by design 100 dB

GBWP Gain-bandwidth product Guaranteed by design 10 MHz

SR Slew-rate

COMP = 10pF

Guaranteed by design

5V/μs

Gate drivers

R

HGATE_ON

R

HGATE_OFF

R

LGATE_ON

R

LGATE_OFF

High side source resistance

High side sink resistance

Low side source resistance

Low side sink resistance

V

BOOT

V

BOOT

V

CCDR

V

CCDR

- V

- V

= 5V

= 5V

PHASE

PHASE

= 5V

= 5V

1.7 Ω

1.12 Ω

1.15 Ω

0.6 Ω

Protections

I

OCH

I

OCL

OVP

I

OSC

OCH current source

OCL current source 90 100 110 μA

Over voltage trip

(V

FB

/ V

EAREF

)

OSC sourcing current

= 1.7V

V

OCH

V

rising

FB

V

V

V

V

= 0.6V

EAREF

falling

FB

= 0.6V

EAREF

> OVP Trip V

FB

OSC

= 3V

90 100 110 μA

120 %

117 %

30 mA

Power Good

V

PGOOD

Upper threshold

(V

FB

/ V

EAREF

)

Lower threshold

(VFB / V

EAREF

)

PGOOD voltage low

V

rising

FB

V

falling

FB

I

PGOOD

= -5mA

12/52 Doc ID 11938 Rev 3

108 110 112 %

88 90 92 %

0.5 V

Page 13

L6730 - L6730B Electrical characteristics

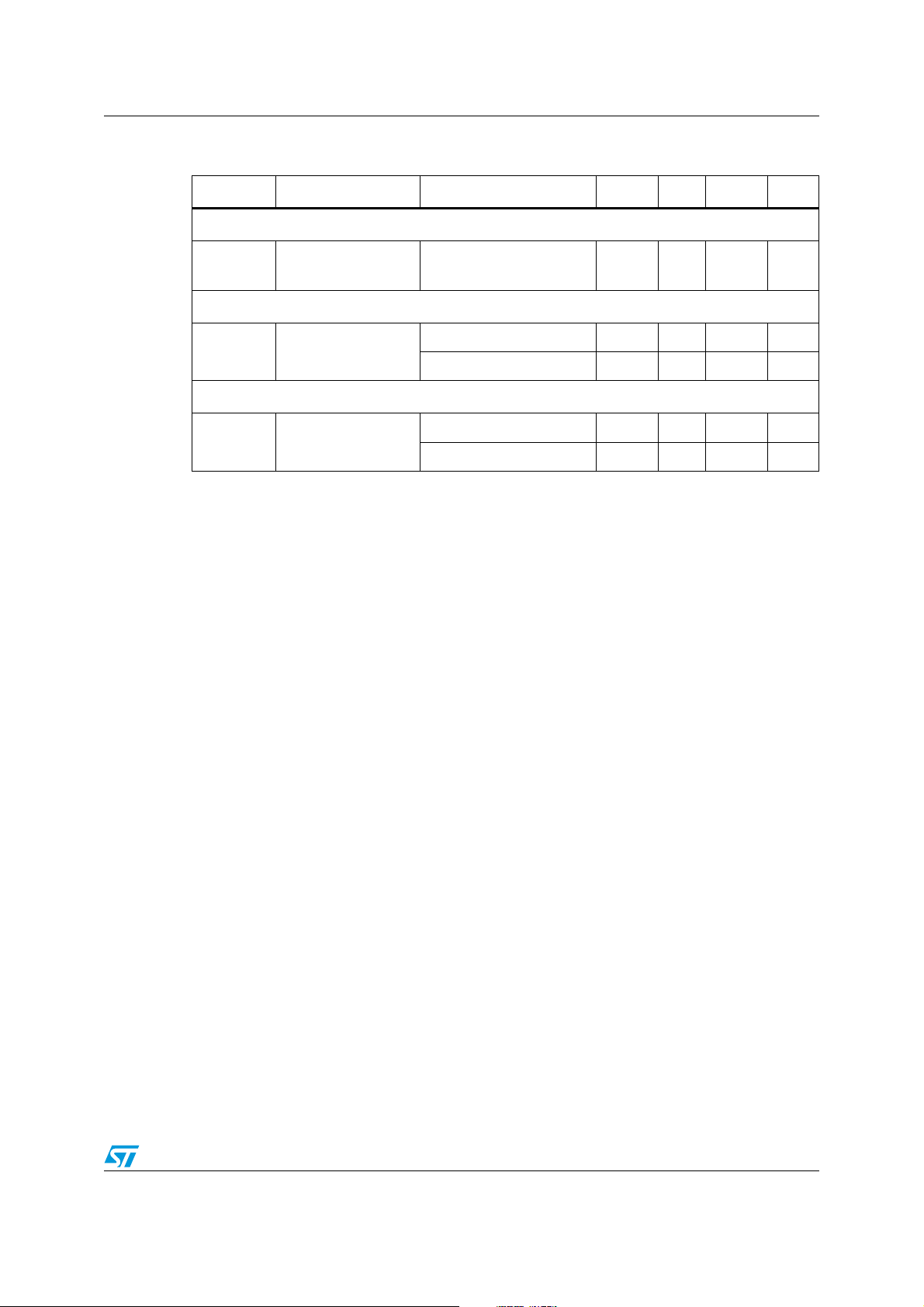

Table 6. Thermal characterizations (V

CC

= 12 V)

Symbol Parameter Test condition Min Typ Max Unit

Oscillator

f

OSC

Initial accuracy

OSC = OPEN;

= 0°C~ 125°C

T

J

376 400 424 kHz

Output voltage (1.2V MODE)

T

= 0°C~ 125°C

V

FB

Output voltage

J

= -40°C~ 125°C

T

J

1.188 1.2 1.212 V

1.185 1.2 1.212 V

Output voltage (0.6V MODE)

T

= 0°C~ 125°C

V

FB

Output voltage

J

T

= -40°C~ 125°C

J

0.596 0.6 0.605 V

0.593 0.6 0.605 V

Doc ID 11938 Rev 3 13/52

Page 14

Device description L6730 - L6730B

5 Device description

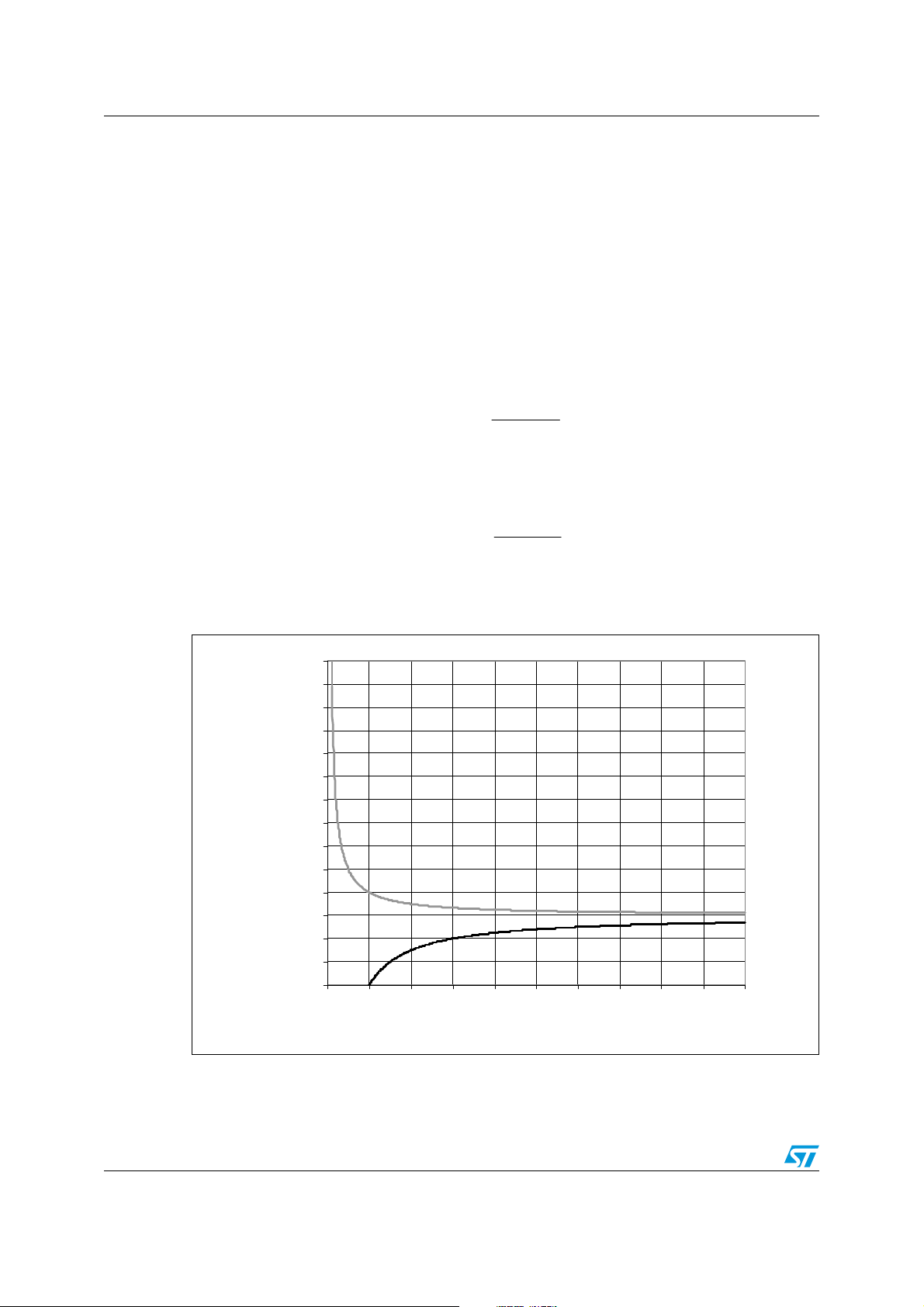

5.1 Oscillator

The switching frequency is internally fixed to 400 kHz. The internal oscillator generates the

triangular waveform for the PWM charging and discharging an internal capacitor (F

kHz). This current can be varied using an external resistor (R

and GND or V

in order to change the switching frequency. Since the OSC pin is

CCDR

) connected between OSC pin

T

maintained at fixed voltage (typ. 1.2 V), the frequency is increased (or decreased)

proportionally to the current sunk (sourced) from (into) the pin. In particular by connecting

R

versus GND the frequency is increased (current is sunk from the pin), according to the

T

following relationship:

6

1088.9

400

+=KRKHzFsw

⋅

OSC

Ω

(1)

)(

SW

= 400

Connecting R

to V

T

reduces the frequency (current is sourced into the pin), according

CCDR

to the following relationship:

7

1001.3

400

Switching frequency variation vs. R

Figure 4. Switching frequency variation versus RT

1500

1400

1300

1200

1100

1000

900

800

700

Fsw (KHz)

600

500

400

300

200

100

Rosc connected to GND

0 100 200 300 400 500 600 700 800 900 1000

is shown in Figure 4.

T

⋅

−=KRKHzFsw

OSC

)(

Ω

Rosc connected to Vccdr

Rosc (KOHM)

(2)

14/52 Doc ID 11938 Rev 3

Page 15

L6730 - L6730B Device description

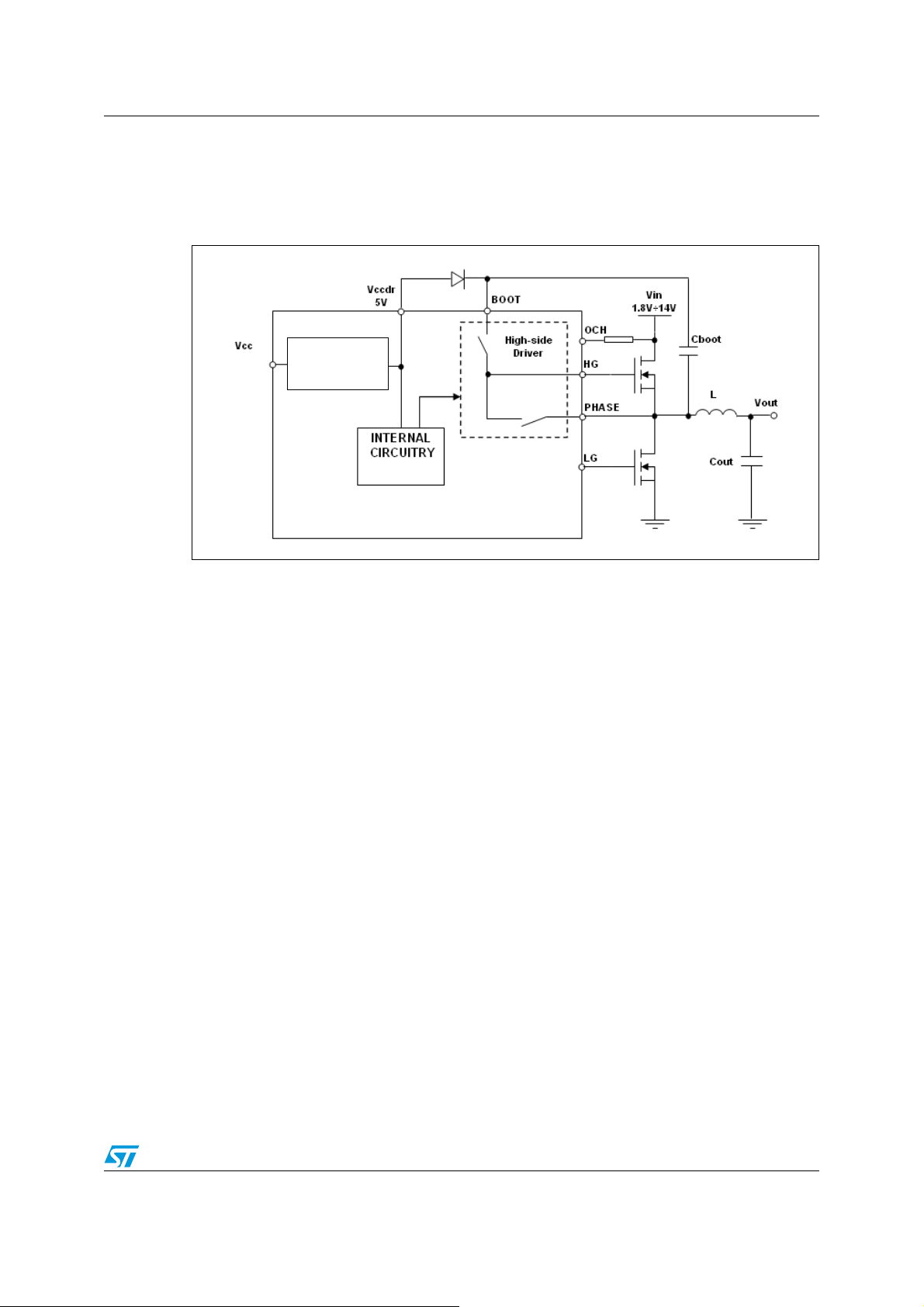

5.2 Internal LDO

An internal LDO supplies the internal circuitry of the device. The input of this stage is the

V

pin and the output (5 V) is the V

CC

Figure 5. LDO block diagram

pin (see Figure 5).

CCDR

4.5V÷14V

LDO

5.3 Bypassing the LDO to avoid the voltage drop with low Vcc

The LDO can be by passed by providing 5 V voltage directly to V

V

pins must be shorted together as shown in Figure 6. V

CCDR

CCDR

at least 1 μF capacitor to sustain the internal LDO during the recharge of the bootstrap

capacitor. V

also represents a voltage reference for Tmask pin, S/O/U pin (L6730) or

CCDR

CC/O/U pin (L6730B) and PGOOD pin (see Table 4: Pin connection).

If Vcc

≈ 5 V the internal LDO works in dropout with an output resistance of about 1 Ω.

The maximum LDO output current is about 100 mA, and so the output voltage drop can be

100 mV. The LDO can be bypassed to avoid this.

. In this case Vcc and

CCDR

pin must be filtered with

Doc ID 11938 Rev 3 15/52

Page 16

Device description L6730 - L6730B

Figure 6. Bypassing the LDO

5.4 Internal and external references

It is possible to set two internal references, 0.6 V and 1.2 V, or provide an external reference

from 0 V to 2.5 V. The maximum value of the external reference depends on the V

V

= 4 V the clamp operates at about 2 V (typ.), while with VCC greater than 5 V the

CC

CC

: with

maximum external reference is 2.5 V (typ).

● V

● V

● V

from 0% to 80% of V

EAREF

from 80% to 95% of V

EAREF

from 95% to 100% of V

EAREF

−> External reference

CCDR

−> V

CCDR

CCDR

−> V

REF

REF

= 1.2 V

= 0.6 V

Providing an external reference from 0V to 450 mV the output voltage will be regulated but

some restrictions must be considered:

● The minimum OVP threshold is set at 300 mV.

● The under-voltage-protection doesn’t work.

● The PGOOD signal remains low.

To set the resistor divider it must be considered that a 100 kΩ pull-down resistor is

integrated into the device (see Figure 7.). Finally it must be taken into account that the

voltage at the EAREF pin is captured by the device at the start-up when Vcc is about 4 V.

16/52 Doc ID 11938 Rev 3

Page 17

L6730 - L6730B Device description

V

V

CC

V

V

V

V

V

5.5 Error amplifier

Figure 7. Error amplifier reference

DR

0.6

5.6 Soft-start

When both VCC and VIN are above their turn-on thresholds (VIN is monitored by the OCH

pin) the start-up phase takes place. Otherwise the SS pin is internally shorted to GND. At

start-up, a ramp is generated charging the external capacitor C

generator. The initial value for this current is 35 µA and charges the capacitor up to 0.5 V.

After that it becomes 10 µA until the final charge value of approximately 4 V (see Figure 5).

Figure 8. Device start-up: voltage at the SS pin

EAREF

100K

1.2

EXT

2.5

Error Amplifier Ref.

with an internal current

SS

cc

Vcc

in

Vin

4.2V

4.2V or 8.6V

1.25V

1.25V

t

Vss

ss

0.5V

0.5V

0.5V

4V

4V

t

Doc ID 11938 Rev 3 17/52

Page 18

Device description L6730 - L6730B

The output of the error amplifier is clamped with this voltage (Vss) until it reaches the

programmed value. No switching activity is observable if V

is lower than 0.5 V and both

SS

MOSFETs are off. When Vss is between 0.5 V and 1.1 V the low-side MOSFET is turned on

because the output of the error amplifier is lower than the valley of the triangular wave and

so the duty-cycle is 0%. As V

reaches 1.1 V (i.e. the oscillator triangular wave inferior

SS

limit) even the high-side MOSFET begins to switch and the output voltage starts to increase.

The L6730 - L6730B can only source current during the soft-start phase in order to manage

the pre-bias start-up applications. This means that when the startup occurs with output

voltage greater than 0V (pre-bias startup), even when Vss is between 0.5 V and 1.1 V the

low-side MOSFET is kept OFF (see Figure 9 and Figure 10).

Figure 9. Start-up without pre-bias

LGate

V

OUT

I

L

V

SS

Figure 10. Start-up with pre-bias

LGate

V

OUT

I

L

V

SS

The L6730B can always sink current and so it can be used to supply the DDR memory

termination BUS. If overcurrent is detected during the soft-start phase, the device provides

constant current-protection. In case there is short soft-start time and/or small inductor value

and/or high output capacitors value and thus, in case of high ripple current during the softstart, the converter can start-up in anyway and limit the current (Chapter 5.8: Monitoring and

18/52 Doc ID 11938 Rev 3

Page 19

L6730 - L6730B Device description

protection on page 21) but not enter into HICCUP mode. The soft-start phase ends when

V

reaches 3.5 V. After that the over current-protection triggers the HICCUP mode

SS

(L6730). With the L6730B there is the possibility to set the HICCUP mode or the constant

current mode after the soft-start acting on the multifunction pin CC/O/U. With the L6730 the

low-side MOSFET(s) management after soft-start phase depends on the S/O/U pin state

(see related section). If the sink mode is enabled the converter can sink current after softstart (see Figure 11) while, if the sink mode is disabled the converter never sinks current

(see Figure 12).

Figure 11. Sink mode enabled: Inductor current during and after soft-start (L6730)

V

OUT

V

SS

V

CC

I

L

During normal operation, if any under voltage is detected on one of the two supplies (V

V

), the SS pin is internally shorted to GND by an internal switch so the SS capacitor is

IN

CC

rapidly discharged. Two different turn-on UVLO thresholds can be set: 4.2 V for 5 V BUS

and 8.6 V for 12 V BUS.

Doc ID 11938 Rev 3 19/52

,

Page 20

Device description L6730 - L6730B

Figure 12. Sink mode disabled: Inductor current during and after soft-start (L6730)

Vout

Vss

Vcc

I

L

5.7 Driver section

The high-side and low-side drivers allow for the use of different types of power MOSFETs

(also multiple MOSFETs to reduce the R

low-side driver is supplied by V

A predictive dead time control avoids MOSFETs cross-conduction maintaining very short

dead time duration (see Figure 13.).

The control monitors the phase node in order to sense the low-side body diode recirculation.

If the phase node voltage is less than a certain threshold (–350 mV typ.) during the dead

time, it will be reduced in the next PWM cycle. The predictive dead time control does not

work when the high-side body diode is conducting because the phase node does not go

), maintaining fast switching transitions. The

DSON

while the high-side driver is supplied by the BOOT pin.

CCDR

20/52 Doc ID 11938 Rev 3

Page 21

L6730 - L6730B Device description

(

⋅

=

negative. This situation happens when the converter is sinking current for example and, in

this case, an adaptive dead time control operates.

Figure 13. Dead times

5.8 Monitoring and protection

The output voltage is monitored by the FB pin. If it is not within ±10% (typ.) of the

programmed value, the Power-Good (PGOOD) output is forced low. The PGOOD signal can

be delayed by adding an external capacitor on PGDelay pin (see Table 4: Pin connection

and Figure 14.); this can be useful to perform cascade sequencing. The delay can be

calculated with the following formula:

The device provides over voltage protection: when the voltage sensed on FB pin reaches a

value 20% (typ) greater than the reference, the low-side driver is turned on. If the OVP notlatched mode has been set the low-side MOSFET is kept on as long as the overvoltage is

detected (see Figure 15.).The OVP latched-mode has been set the low-side MOSFET is

)

pFCPGDelay

5.0

Doc ID 11938 Rev 3 21/52

Page 22

Device description L6730 - L6730B

turned on until VCC is toggled (see Figure 16). In case of latched-mode OVP the OSC pin is

forced high (4.5 V typ) if an over voltage is detected.

Figure 14. PGOOD signal

FB

PGOOD

2ms/Div.

Figure 15. OVP not latched

LGate

FB

OSC

22/52 Doc ID 11938 Rev 3

Page 23

L6730 - L6730B Device description

Figure 16. OVP latched

LGate

OSC

FB

There is an electrical network between the output terminal and the FB pin and therefore the

voltage at this pin is not a perfect replica of the output voltage. If the converter can sink

current, in the most of cases the low-side will be turned on before the output voltage

exceeds the over-voltage threshold because the error amplifier will throw off balance in

advance.

Even if the device does not report an overvoltage event, the behavior is the same because

the low-side is turned on immediately. Instead, if the sink mode is disabled, the low-side will

be turned on only when the overvoltage protection (OVP) operates and not before because

the current can not be reversed. In this case, a delay between the output voltage rising and

FB voltage rising can appear and the OVP can turn on late. Figure 17 and Figure 18 show

an overvoltage event in the cases of the sink being enabled or disabled. The output voltage

rises with a slope of 100 mVµs, emulating the breaking of the high-side MOSFET as an

overvoltage occurs.

Doc ID 11938 Rev 3 23/52

Page 24

Device description L6730 - L6730B

Figure 17. OVP with sink enabled: the low-side MOSFET is turned-on in advance

V

OUT

109%

FB

V

LGate

Figure 18. OVP with sink disabled: delay on the OVP operation

126%

V

OUT

V

FB

LGate

The L6730B can always sink current and so the OVP will operate always in advance. The

device realizes the over-current-protection (OCP) sensing the current both on the high-side

MOSFET(s) and the low-side MOSFET(s) and so 2 current limit thresholds can be set (see

OCH pin and OCL pin in Table 4: Pin connection):

● Peak current limit

● Valley current limit

The peak current protection is active when the high-side MOSFET(s) is turned on, after an

adjustable masking time (see Chapter 5.10 on page 27). The valley-current-protection is

enabled when the low-side MOSFET(s) is turned on after a fix masking time of about 400

ns. If, when the soft-start phase is completed, an over current event occurs during the on

time (peak-current-protection) or during the off time (valley-current-protection) the device

24/52 Doc ID 11938 Rev 3

Page 25

L6730 - L6730B Device description

−

enters in HICCUP mode (L6730): the high-side and low-side MOSFET(s) are turned off, the

soft-start capacitor is discharged with a constant current of 10 µA and when the voltage at

the SS pin reaches 0.5 V the soft-start phase restarts. During the soft-start phase the OCP

provides a constant-current-protection. If during the T

the OCH comparator triggers an

ON

over current the high-side MOSFET(s) is immediately turned-off (after the masking time and

the internal delay) and returned-on at the next pwm cycle. The limit of this protection is that

the Ton can’t be less than masking time plus propagation delay (see Chapter 5.9: Adjustable

masking time on page 27) because during the masking time the peak-current-protection is

disabled. In case of very hard short circuit, even with this short T

, the current could

ON

escalate. The valley-current-protection is very helpful in this case to limit the current. If

during the off-time the OCL comparator triggers an over current, the high-side MOSFET(s)

is not turned-on until the current is over the valley-current-limit. This implies that, if it is

necessary, some pulses of the high-side MOSFET(s) will be skipped, guaranteeing a

maximum current due to the following formula:

VoutVin

II

+=

T

⋅

L

(4)

MINONVALLEYMAX

,

In constant current protection a current control loop limits the value of the error amplifier’s

output (comp), in order to avoid its saturation and thus recover faster when the output

returns in regulation. Figure 19 shows the behaviour of the device during an over current

condition that persists also in the soft-start phase.

Figure 19. Constant current and hiccup mode during an OCP (L6730)

VSS

VCOMP

I

L

Using the L6730B there is the possibility to set the constant-current-protection also after the

soft-start. The following figures show the behaviour of the L6730B during an overcurrent

event.

Figure 20 shows the intervention of the peak OCP: the high-side MOSFET(s) is turned-off

when the current exceeds the OCP threshold. In this way the duty-cycle is reduced, the

V

is reduced and so the maximum current can be fixed even if the output current is

OUT

escalating. Figure 21 shows the limit of this protection: the on-time can be reduced only to

the masking time and, if the output current continues to increase, the maximum current can

increase too. Notice how the Vout remains constant even if the output current increases

because the on-time cannot be reduced anymore.

Doc ID 11938 Rev 3 25/52

Page 26

Device description L6730 - L6730B

Figure 20. Peak overcurrent-protection in constant-current-protection (L6730B)

V

OUT

Peak th

T

I

L

Figure 21. Peak OCP in case of heavy overcurrent (L6730B)

I

OUT

ON

V

OUT

I

L

I

OUT

If the current is higher than the valley OCP threshold during the off-time, the high-side

MOSFET(s) will not be turned ON. In this way the maximum current can be limited

(Figure 22).

During the constant-current-protection if the Vout becomes lower than 80% of the

programmed value an UV (under-voltage) is detected and the device enters in HICCUP

mode. The under-voltage-lock-out (UVLO) is adjustable by the multifunction pin (see

Chapter 5.10 on page 27). It’s possible to set two different thresholds:

● 4.2 V for 5 V bus

● 8.6 V for 12 V bus

26/52 Doc ID 11938 Rev 3

Page 27

L6730 - L6730B Device description

Working with a 12 V BUS, setting the UVLO at 8.6 V can be very helpful to limit the input

current in case of BUS fall.

Figure 22. Valley OCP (L6730B)

V

OUT

Valley th

I

L

T

OFF

T

OFF

5.9 Adjustable masking time

By connecting the masking time pin to V

values for the peak current protection leading edge blanking time. This is useful to avoid any

false OCP trigger due to spikes and oscillations generated at the turn-on of the high-side

MOSFET(s). The amount of this noise depends very much on the layout, MOSFETs, freewheeling diode, switched current, and input voltage.

When good layout and medium current are used, the minimum masking time can be

chosen, while in case of higher noise, it is better to select the maximum masking time. By

connecting the t

MASK

pin to V

the masking time is about 400 ns, while connecting it to

CCDR

GND results in about 260 ns masking time.

or GND it is possible to select two different

CCDR

5.10 Multifunction pin (S/O/U L6730) (CC/O/U L6730B)

With this pin it is possible:

● To enable disable the sink mode current capability (L6730) or the constant current

protection (L6730B) at the end of the soft-start

● To enable or disable the latch-mode for the OVP

● To set the UVLO threshold for 5 V BUS and 12 V busses

Doc ID 11938 Rev 3 27/52

Page 28

Device description L6730 - L6730B

⋅≤≤

Ta bl e 7 shows how to set the different options through an external resistor divider:

Figure 23. External resistor

R1

R2

VCCDR

S/O/U

CC/O/U

L6730/B

Table 7. S/O/U and CC/O/U pin

R1 R2

N.C 0Ω 0 5V BUS Not latched Not

11KΩ 2.7KΩ 0.2 5V BUS Not latched Yes

6.2KΩ 2.7KΩ 0.3 5V BUS Latched Not

4.3KΩ 2.7KΩ 0.4 5V BUS Latched Yes

2.7KΩ 2.7KΩ 0.5 12V BUS Not latched Not

1.8KΩ 2.7KΩ 0.6 12V BUS Not latched Yes

1.2KΩ 2.7KΩ 0.7 12V BUS Latched Not

0Ω N.C 1 12V BUS Latched Yes

5.11 Synchronization

The presence of many converters on the same board can generate beating frequency noise.

To avoid this it is important to make them operate at the same switching frequency.

Moreover, a phase shift between different modules helps to minimize the RMS current on

the common input capacitors. Figure 24 shows the results of two modules in

synchronization. Two or more devices can be synchronized simply connecting together the

SYNCH pins. The device with the higher switching frequency will be the Master while the

other one will be the slave. The slave controller will increase its switching frequency

reducing the ramp amplitude proportionally and then the modulator gain will be increased.

V

SOU/VCCDR

UVLO OVP SINK CC

To avoid a huge variation of the modulator gain, the best way to synchronize two or more

devices is to make them work at the same switching frequency and, in any case, the

switching frequencies can differ for a maximum of 50% of the lowest one. If, during

synchronization between two (or more) L6730, it’s important to know in advance which the

master is, it’s timely to set its switching frequency at least 15% higher than the slave. Using

an external clock signal (f

different switching frequency (f

28/52 Doc ID 11938 Rev 3

) to synchronize one or more devices that are working at a

EXT

) it is recommended to follow the below formula:

SW

fff

3,1

SWEXTSW

Page 29

L6730 - L6730B Device description

The phase shift between master and slaves is approximately done 180°.

Figure 24. Synchronization

PWM SIGNALS

INDUCTOR CURRENTS

5.12 Thermal shutdown

When the junction temperature reaches 150°C ±10°C, the device enters in thermal

shutdown.

Both MOSFETs are turned OFF and the soft-start capacitor is rapidly discharged with an

internal switch. The device does not restart until the junction temperature goes down to

120°C and, in any case, until the voltage at the soft-start pin reaches 500 mV.

5.13 Minimum ON-time T

The device can manage minimum ON times lower than 100 ns. This feature comes from the

control topology as well as from the particular L6730/B overcurrent protection system. In a

voltage mode controller, the current does not have to be sensed to perform regulation and,

in the case of L6730/B, it does not have to be sensed for the overcurrent protection either

because valley current protection can operate during the OFF time. The first advantage

related of this feature is the achievement of extremely low conversion ratios. Figure 25

shows a conversion from 14 V to 0.5 V at 820 kHz with a t

limited by the MOSFET turn-on and turn-off times.

ON(MIN)

ON of about 50 ns. The ON time is

Doc ID 11938 Rev 3 29/52

Page 30

Device description L6730 - L6730B

Figure 25. 14 V -> 0.5 V@820 kHz, 5 A

50ns

5.14 Bootstrap anti-discharging system

This built-in anti-discharging system keeps the voltage going across the bootstrap capacitor

from going below 3.3 V. An internal comparator senses the voltage across the external

bootstrap capacitor and helps to keep it charged, eventually turning on the low-side

MOSFET for approximately 200 ns. If the bootstrap capacitor is not charged up enough, the

high-side MOSFET cannot be effectively turned on and it will present a higher R

some cases, the OCP can be also triggered. There are up to two conditions during which

the bootstrap capacitor can be discharged:

● fan power supply failure, and

● no sink at zero current operation.

DS(on)

. In

30/52 Doc ID 11938 Rev 3

Page 31

L6730 - L6730B Device description

5.14.1 Fan power supply failure

In many applications the fan is driven by a DC motor that uses a DC/DC converter. Often

only the speed of the motor is controlled by varying the voltage applied to the input terminal

and there is no control on the torque because the current is not directly controlled. The

current has to be limited in case of overload or short-circuit, but without stopping the motor.

With the L6730B, the current can be limited without shutting down the system because

constant current protection is provided. In order to vary the motor speed, the output voltage

of the converter must be varied. Both L6730 and L6730B have a dedicated EAREF pin (see

Figure 4) which provides an external reference to the non-inverting input of the error-

amplifier.

In these applications the duty cycle depends on the motor’s speed and sometimes a 100%

duty cycle setting has to be used to attain the maximum speed. In these conditions, the

bootstrap capacitor can not be recharged and the system cannot work properly. Some PWM

controllers limit the maximum duty cycle to 80 or 90% in order to keep the bootstrap

capacitor charged, but this makes performance during the load transient worse. The

“bootstrap anti-discharging system” allows the L6730x to work at 100% without any

problem.

Figure 26.: 100% duty cycle operation on page 31 shows the following picture illustrates the

device behavior when the input voltage is 5 V and a 100% duty cycle is set by an external

reference.

Figure 26. 100% duty cycle operation

TOFF≈200ns

5.14.2 No-sink at zero current operation

The L6730 can work in no-sink mode. If output current is zero the converter skip some

pulses and works with a lower switching frequency. Between two pulses can pass a

relatively long time (say 200-300 µs) during which there’s no switching activity and the

current into the inductor is zero. In this condition the phase node is at the output voltage and

in some cases this is not enough to keep the bootstrap cap charged. For example, if Vout is

3.3 V the voltage across the bootstrap cap is only 1.7 V. The high-side MOSFET cannot be

Vout=5V

Vin=5V

LGate

≈

Fsw?6.3KHz

Doc ID 11938 Rev 3 31/52

Page 32

Device description L6730 - L6730B

effectively turned-on and the regulation can be lost. Thanks to the “bootstrap antidischarging system” the bootstrap cap is always kept charged. The following picture shows

the behaviour of the device in the following conditions: 12 V -> 3.3 V@0 A.

It can be observed that between two pulses trains the low-side is turned-on in order to keep

the bootstrap cap charged.

Figure 27. 12 V -> 3.3 V@0 A in no-sink

I

L

V

BOOT

Pulse trainMinimum Bootstrap Voltage V

PHASE

32/52 Doc ID 11938 Rev 3

Page 33

L6730 - L6730B Application details

−

V

H

V

V

V

6 Application details

6.1 Inductor design

The inductance value is defined by a compromise between the transient response time, the

efficiency, the cost and the size. The inductor has to be calculated to maintain the ripple

current (ΔI

can be calculated with the following relationship:

) between 20% and 30% of the maximum output current. The inductance value

L

Vout

VoutVin

≅

L

⋅

Δ⋅

IFsw

L

(6)

Vin

Where F

is the switching frequency, VIN is the input voltage and V

SW

is the output

OUT

voltage. Figure 28 shows the ripple current vs. the output voltage for different values of the

inductor, with V

= 5 V and VIN = 12 V at a switching frequency of 400 kHz.

IN

Increasing the value of the inductance reduces the current ripple but, at the same time,

increases the converter response time to a load transient. If the compensation network is

well designed, during a load transient the device is able to set the duty cycle to 100% or to

0%. When one of these conditions is reached, the response time is limited by the time

required to change the inductor current. During this time the output current is supplied by

the output capacitors. Minimizing the response time can minimize the output capacitor size.

Figure 28. Inductor current ripple

8

7

6

5

4

3

2

1

INDUCTOR CURRENT RIPPL

0

01234

OUTPUT VOLTAGE (V)

in=12V, L=1uH

in=12V, L=2uH

in=5V, L=500n

in=5V, L=1.5uH

Doc ID 11938 Rev 3 33/52

Page 34

Application details L6730 - L6730B

⋅Δ=

Δ

6.2 Output capacitors

The output capacitors are basic components for the fast transient response of the power

supply. They depend on the output voltage ripple requirements, as well as any output

voltage deviation requirement during a load transient. During a load transient, the output

capacitors supply the current to the load or absorb the current stored into the inductor until

the converter reacts. In fact, even if the controller recognizes immediately the load transient

and sets the duty cycle at 100% or 0%, the current slope is limited by the inductor value. The

output voltage has a first drop due to the current variation inside the capacitor (neglecting

the effect of the ESL):

(7)

ESR

Moreover, there is an additional drop due to the effective capacitor discharge or charge that

is given by the following formulas:

Vout

COUT

=Δ

Vout

COUT

=Δ

2

ESRIoutVout

2

LIout

⋅Δ

VoutDVinCout

−⋅⋅⋅

2

LIout

⋅Δ

VoutCout

⋅⋅

(9)

(8)

)maxmin,(2

Formula (8) is valid in case of positive load transient while the formula (9) is valid in case of

negative load transient. D

For a given inductor value, minimum input voltage, output voltage and maximum load

transient, a maximum ESR, and a minimum C

values also affect the static output voltage ripple. In the worst case the output voltage ripple

can be calculated with the following formula:

Usually the voltage drop due to the ESR is the biggest one while the drop due to the

capacitor discharge is almost negligible.

6.3 Input capacitors

The input capacitors have to sustain the RMS current flowing through them, that is:

Where D is the duty cycle. The equation reaches its maximum value, I

The losses in worst case are:

is the maximum duty cycle value that in the L6730/B is 100%.

MAX

value can be set. The ESR and C

OUT

+⋅Δ=Δ

(

ESRIVout

L

1

8

)

(12)

(10)

/2 with D = 0.5.

OUT

⋅⋅

FswCout

(11)

)1( DDIoutIrms −⋅⋅=

2

)5.0( IoutESRP ⋅⋅=

OUT

34/52 Doc ID 11938 Rev 3

Page 35

L6730 - L6730B Application details

6.4 Compensation network

The loop is based on a voltage mode control (Figure 29). The output voltage is regulated to

the internal/external reference voltage and scaled by the external resistor divider. The error

amplifier output V

pulse-width modulated (PWM) with an amplitude of V

is filtered by the output filter. The modulator transfer function is the small signal transfer

function of V

OUT/VCOMP

L-Cout resonance and a zero at F

Gain of the modulator is simply the input voltage V

voltage: V

OSC

.

Figure 29. Compensation network

is then compared with the oscillator triangular wave to provide a

COMP

at the PHASE node. This waveform

IN

. This function has a double pole at frequency FLC depending on the

depending on the output capacitor’s ESR. The DC

ESR

divided by the peak-to-peak oscillator

IN

Z

FB

Z

IN

The compensation network consists in the internal error amplifier, the impedance networks

Z

(R3, R4 and C20) and Z

IN

(R5, C18 and C19). The compensation network has to

FB

provide a closed loop transfer function with the highest 0dB crossing frequency to have

fastest transient response (but always lower than fsw/10) and the highest gain in DC

conditions to minimize the load regulation error. A stable control loop has a gain crossing the

Doc ID 11938 Rev 3 35/52

Page 36

Application details L6730 - L6730B

0 dB axis with -20 dB/decade slope and a phase margin greater than 45°. To locate poles

and zeroes of the compensation networks, the following suggestions may be used:

● Modulator singularity frequencies:

ω

● Compensation network singularity frequencies:

=

ω

P

1

ω

Z

● Compensation network design:

– Put the gain R

–Place

–Place

–Place

–Place

ω

before the output filter resonance ωLC;

Z1

ω

at the output filter resonance ωLC;

Z2

ω

at the output capacitor ESR zero ω

P1

ω

at one half of the switching frequency;

P2

1

=

CoutLLC⋅

1

⎛

⎜

⋅

R

5

⎜

⎝

1

=

1

⋅

CR

in order to obtain the desired converter bandwidth

5/R3

(13)

⎞

⋅

CC

1918

⎟

⎟

+

CC

1918

⎠

(17)

195

R

5

⋅=

R

3

(15)

Vin

Δ

Vosc

ω

ESR

ω

P

2

=

ω

2

Z

ϖϖ

⋅

LCC

1

=

=

CoutESR

⋅

1

⋅

(16)

CR

204

1

()

+⋅

RRC

4320

(18)

;

ESR

– Check the loop gain considering the error amplifier open loop gain.

(14)

(18)

Figure 30. Asymptotic bode plot of converter's open loop gain

36/52 Doc ID 11938 Rev 3

Page 37

L6730 - L6730B Application details

6.5 Two quadrant or one quadrant operation mode (L6730)

After the soft-start phase the L6730 can work in source only (one quadrant operation mode)

or in sink/source (two quadrant operation mode), depending on the setting of the

multifunction pin (see Chapter 5.10 on page 27). The choice of one or two quadrant

operation mode is related to the application. One quadrant operation mode permits to have

a higher efficiency at light load, because the converter works in discontinuous mode (see

Figure 31). Nevertheless in some cases, in order to maintain a constant switching

frequency, it’s preferable to work in two quadrants, even at light load. In this way the

reduction of the switching frequency due to the pulse skipping is avoided. To parallel two or

more modules is requested the one quadrant operation in order not to have current sinking

between different converters. Finally the two quadrant operation allows faster recovers after

negative load transient. For example, let’s consider that the load current falls down from I

to 0A with a slew rate sufficiently greater than L/V

(where L is the inductor value). Even

OUT

considering that the converter reacts instantaneously setting to 0% the duty-cycle, the

energy ½*L*I

2

stored in the inductor will be transferred to the output capacitors,

OUT

increasing the output voltage. If the converter can sink current this overvoltage can be faster

eliminated.

Figure 31. Efficiency in discontinuous-current-mode and continuous-current-mode

EFFICIENCY: DCM vs. CCM

OUT

0.7

0.6

0.5

0.4

EFF. (%

0.3

0.2

0.1

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

OUTPUT CURRENT (A)

EFFICIENCY DCM

EFFICIENCY CCM

Doc ID 11938 Rev 3 37/52

Page 38

L6730 demonstration board L6730 - L6730B

7 L6730 demonstration board

7.1 Description

L6730 demonstration board realizes in a four layer PCB a step-down DC/DC converter and

shows the operation of the device in a general purpose application. The input voltage can

range from 4.5 V to 14 V and the output voltage is at 3.3 V. The module can deliver an

output current in excess of 30 A. The switching frequency is set at 400 kHz (controller freerunning F

the UVLO threshold (5 V or 12 V bus), the OVP intervention mode and the sink-mode

current capability.

Figure 32. Demonstration board picture

) but it can be increased up to 1 MHz. A 7 positions dip-switch allows to select

SW

Top Side Bottom Side

38/52 Doc ID 11938 Rev 3

Page 39

L6730 - L6730B L6730 demonstration board

7.2 PCB layout

Figure 33. Top layer Figure 34. Power ground layer

Figure 35. Signal ground layer Figure 36. Bottom layer

Doc ID 11938 Rev 3 39/52

Page 40

L6730 demonstration board L6730 - L6730B

Figure 37. Demonstration board schematic

Table 8. Demonstration board part list

Reference Value Manufacturer Package Supplier

R1 820Ω Neohm SMD 0603 IFARCAD

R2 0Ω Neohm SMD 0603 IFARCAD

R3 N.C.

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

10Ω 1% 100mW

11K 1% 100mW

6K2 1% 100mW

4K3 1% 100mW

2K7 1% 100mW

1K8 1% 100mW

1K2 1% 100mW

2K7 1% 100mW

1K

2K7 1% 100mW

40/52 Doc ID 11938 Rev 3

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Page 41

L6730 - L6730B L6730 demonstration board

Table 8. Demonstration board part list (continued)

Reference Value Manufacturer Package Supplier

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

C1

C3-C7-C9-C15-C21

C2

C4-C6

C8

C10

C11

C12

C13

C14

C18-C19

C20

L1

D1

D2

Q1-Q2

Q4-Q5

U1

1K 1% 100mW

1K 1% 100mW

4K7 1% 100mW

N.C.

2.2Ω

2.2Ω

10K 1% 100mW

N.C.

N.C.

0Ω

220nF

100nF

1nF.

100uF 20V

4.7uF 20V

10nF

N.C.

47nF

1.5nF

4.7nF

330uF 6.3V

N.C.

1.8uH

1N4148

STS1L30M

STS12NH3LL

STSJ100NH3LL

L6730

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Kemet SMD 0603 IFARCAD

Kemet SMD 0603 IFARCAD

Kemet SMD 0603 IFARCAD

OSCON 20SA100M RADIAL 10X10.5 SANYO

AVX SMA6032 IFARCAD

Kemet SMD 0603 IFARCAD

Kemet SMD 0603 IFARCAD

Kemet SMD 0603 IFARCAD

Kemet SMD 0603 IFARCAD

POSCAP 6TPB330M SMD SANYO

Panasonic SMD ST

ST SOT23 IFARCAD

ST DO216AA ST

ST SO8 ST

ST SO8 ST

ST HTSSOP20 ST

SWITCH DIP SWITCH 7 POS. ST

Doc ID 11938 Rev 3 41/52

Page 42

L6730 demonstration board L6730 - L6730B

Table 9. Other inductor manufacturer

Manufacturer Series Inductor value (µH) Saturation current (A)

WURTH ELEKTRONIC 744318180 1.8 20

SUMIDA CDEP134-2R7MC-H 2.7 15

EPCOS HPI_13 T640 1.4 22

TDK SPM12550T-1R0M220 1 22

TOKO FDA1254 2.2 14

COILTRONICS

HCF1305-1R0 1.15 22

HC5-1R0 1.3 27

Table 10. Other capacitor manufacturer

Manufacturer Series Capacitor value (µF) Rated voltage (V)

TDK

NIPPON CHEMI-CON 25PS100MJ12 100 25

PANASONIC ECJ4YB0J107M 100 6.3

C4532X5R1E156M 15 25

C3225X5R0J107M 100 6.3

42/52 Doc ID 11938 Rev 3

Page 43

L6730 - L6730B I/O Description

8 I/O Description

Figure 38. Demonstration board

Table 11. I/O functions

Symbol Function

The input voltage can range from 1.8V to 14V. If the input voltage is between

Input (Vin-Gin)

Output (V

V

CC

OUT-GOUT

-GND

V

CCDR

TP1

CC

4.5V and 14V it can supply also the device (through the V

case the pin 1 and 2 of the jumper G1 must be connected together.

The output voltage is fixed at 3.3V but it can be changed by replacing the

resistor R14 of the output resistor divider:

)

The over-current-protection limit is set at 15A but it can be changed by

replacing the resistors R1 and R12 (see OCL and OCH pin in Ta bl e 4 : P in

connection).

Using the input voltage to supply the controller no power is required at this

input. However the controller can be supplied separately from the power stage

through the V

input (4.5-14V) and, in this case, jumper G1 must be left

CC

open.

An internal LDO provides the power into the device. The input of this stage is

the VCC pin and the output (5V) is the V

providing directly a 5V voltage from V

and 3 of the jumper G1 must be shorted.

This pin can be used as an input or as a test point. If all the jumper G2 pins are

shorted, TP1 can be used as a test point of the voltage at the EAREF pin. If

the pins 2 and 3 of G2 are connected together, TP1 can be used as an input to

provide an external reference for the internal error amplifier (see section 4.3.

Internal and external references).

pin) and in this

CC

R

VVo

REF

16

)1(

+⋅=

R

14

pin. The LDO can be bypassed,

CCDR

and Gndcc. In this case the pins 1

CCDR

Doc ID 11938 Rev 3 43/52

Page 44

I/O Description L6730 - L6730B

Table 11. I/O functions (continued)

Symbol Function

TP2 This test point is connected to the Tmask pin (see Table 4: Pin connection).

TP3 This test point is connected to the S/O/U pin (see Chapter 5.10 on page 27).

SYNCH

PWRGD This pin is connected to the PGOOD pin of the controller.

DIP SWITCH

This pin is connected to the synch pin of the controller (see Chapter 5.11 on

page 28).

Different positions of the dip switch correspond to different settings of the

multifunction pin (S/O/U) (CC/O/U).

Table 12. Dip switch

UVLO OVP SINK CC

5V Not latched Not 0 S7 A

5V Not latched Yes 0.2 S1-S7 B

5V Latched Not 0.3 S2-S7 C

5V Latched Yes 0.4 S3-S7 D

12V Not latched Not 0.5 S4-S7 E

12V Not latched Yes 0.6 S5-S7 F

12V Latched Not 0.7 S6-S7 G

12V Latched Yes 1 S1 H

Vsou/V

CCDR

DIP switch State

44/52 Doc ID 11938 Rev 3

Page 45

L6730 - L6730B Efficiency

Y

Y

9 Efficiency

The following figures show the demo board efficiency versus load current for different values

of input voltage and switching frequency:

Figure 39. Demonstration board efficiency 400 kHz

Fsw=400KHz

95.00%

VO = 3.3V

90.00%

85.00%

EFFICIENC

80.00%

75.00%

V

VIN = 5V

IN = 5VVIN = 5V

VIN = 12V

13579111315

Iout (A)

Figure 40. Demonstration board efficiency 645 kHz

Fsw=645KHz

95.00%

90.00%

85.00%

80.00%

EFFICIENC

75.00%

VIN = 5V

VIN = 12V

V

O

= 3.3V

70.00%

13579111315

Iout (A)

Doc ID 11938 Rev 3 45/52

Page 46

Efficiency L6730 - L6730B

Y

Figure 41. Demonstration board efficiency 1 MHz

Fsw=1MHz

VO = 3.3V

95.00%

90.00%

85.00%

VIN = 5V

80.00%

75.00%

EFFICIENC

70.00%

65.00%

60.00%

13579111315

Iout (A)

Figure 42. Efficiency with 2xSTS12NH3LL+2XSTSJ100NH3LL

12V-->3.3V

0.96

0.95

0.94

0.93

0.92

0.91

0.9

EFFICIENCY (%)

0.89

0.88

0.87

3 5 7 9 11 13 15 17 19

VIN = 12V

400KHz

700KHz

1MHz

OUTPUT CURRENT (A)

46/52 Doc ID 11938 Rev 3

Page 47

L6730 - L6730B POL demonstration board

10 POL demonstration board

10.1 Description

A compact demonstration board has been designed to manage currents in the range of 1015 A. Figure 39 shows the schematic and Tab l e 10 the part list. Multi-layer-ceramiccapacitors (MLCCs) have been used on the input and the output in order to reduce the

overall size.

Figure 43. Pol demonstration board schematic

Table 13. Pol demonstration board part list

Reference Value Manufacturer Package Supplier

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

1K8Ω

10KΩ

N.C.

10Ω

11K 1% 100mW

2K7 1% 100mW

N.C.

0Ω

3K 1% 100mW

4K7 1% 100mW

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Doc ID 11938 Rev 3 47/52

Page 48

POL demonstration board L6730 - L6730B

Y

Table 13. Pol demonstration board part list (continued)

Reference Value Manufacturer Package Supplier

R11

R12

R13

R14

R15

C1-C7

C6- C19-C20-C9

C2

C11

C12

C13

C8

C14

C3-C4-C5

C15-C16-C17-C18

L1

D1

Q1

Q2

U1

15Ω 1% 100mW

4K7 1% 100mW

1K 1% 100mW

2.2Ω

2.2Ω

220nF

100nF

1nF

N.C.

68nF

220pF

4.7uF 20V

6.8nF

15uF

100uF

1.8uH

STS1L30M

STS12NH3LL

STSJ100NH3LL

L6730

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Neohm SMD 0603 IFARCAD

Kemet SMD 0603 IFARCAD

Kemet SMD 0603 IFARCAD

Kemet SMD 0603 IFARCAD

Kemet SMD 0603 IFARCAD

Kemet SMD0603 IFARCAD

AVX SMA6032 IFARCAD

Kemet SMD 0603 IFARCAD

TDK MLC

C4532X5R1E156M

PANASONIC MLC

P/N ECJ4YBOJ107M

SMD1812 IFARCAD

SMD 1210 IFARCAD

Panasonic SMD ST

ST DO216AA ST

ST POWER SO8 ST

ST POWER SO8 ST

ST HTSSOP20 ST

Figure 44. Pol demonstration board efficiency

12V-->3.3V@400KHz

0.94

0.92

0.9

0.88

0.86

EFFICIENC

0.84

0.82

1357911

OUTP UT CURRENT (A)

48/52 Doc ID 11938 Rev 3

Page 49

L6730 - L6730B Package mechanical data

11 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK is an ST trademark.

Table 14. HTSSOP20 mechanical data

mm inch

Dim.

Min. Typ. Max. Min. Typ. Max.

A 1.200 0.047

A1 0.150 0.006

A2 0.800 1.000 1.050 0.031 0.039 0.041

b 0.190 0.300 0.007 0.012

c 0.090 0.200 0.003 0.008

(1)

D

(3)

D1

2.200 0.087

E 6.200 6.400 6.600 0.244 0.252 0.260

(2)

E1

(3)

E2

e 0.650 0.025

6.400 6.500 6.600 0.252 0.256 0.260

4.300 4.400 4.500 0.170 0.173 0.177

1.500 0.059

L 0.450 0.600 0.750 0.018 0.024 0.030

L1 1.000 0.039

k 0° min., 8° max.

aaa 0.100 0.004

1. Dimension “D” does not include mold flash, protrusions or gate burrs. Mold flash, protrusions or gate burrs

shall not exceed 0.15mm per side.

2. Dimension “E1” does not include interlead flash or protrusions. Intelead flash or protrusions shall not

exceed 0.25mm per side.

3. The size of exposed pad is variable depending of leadframe design pad size. End user should verify “D1”

and “E2” dimensions for each device application.

Doc ID 11938 Rev 3 49/52

Page 50

Package mechanical data L6730 - L6730B

Figure 45. Package dimensions

50/52 Doc ID 11938 Rev 3

Page 51

L6730 - L6730B Revision history

12 Revision history

Table 15. Document revision history

Date Revision Changes

21-Dec-2005 1 Initial release

29-May-2006 2 New template, thermal data updated

07-Dec-2009 3 Updated Table 4 on page 8 and added Section 1.2 on page 6

Doc ID 11938 Rev 3 51/52

Page 52

L6730 - L6730B

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

52/52 Doc ID 11938 Rev 3

Loading...

Loading...