Page 1

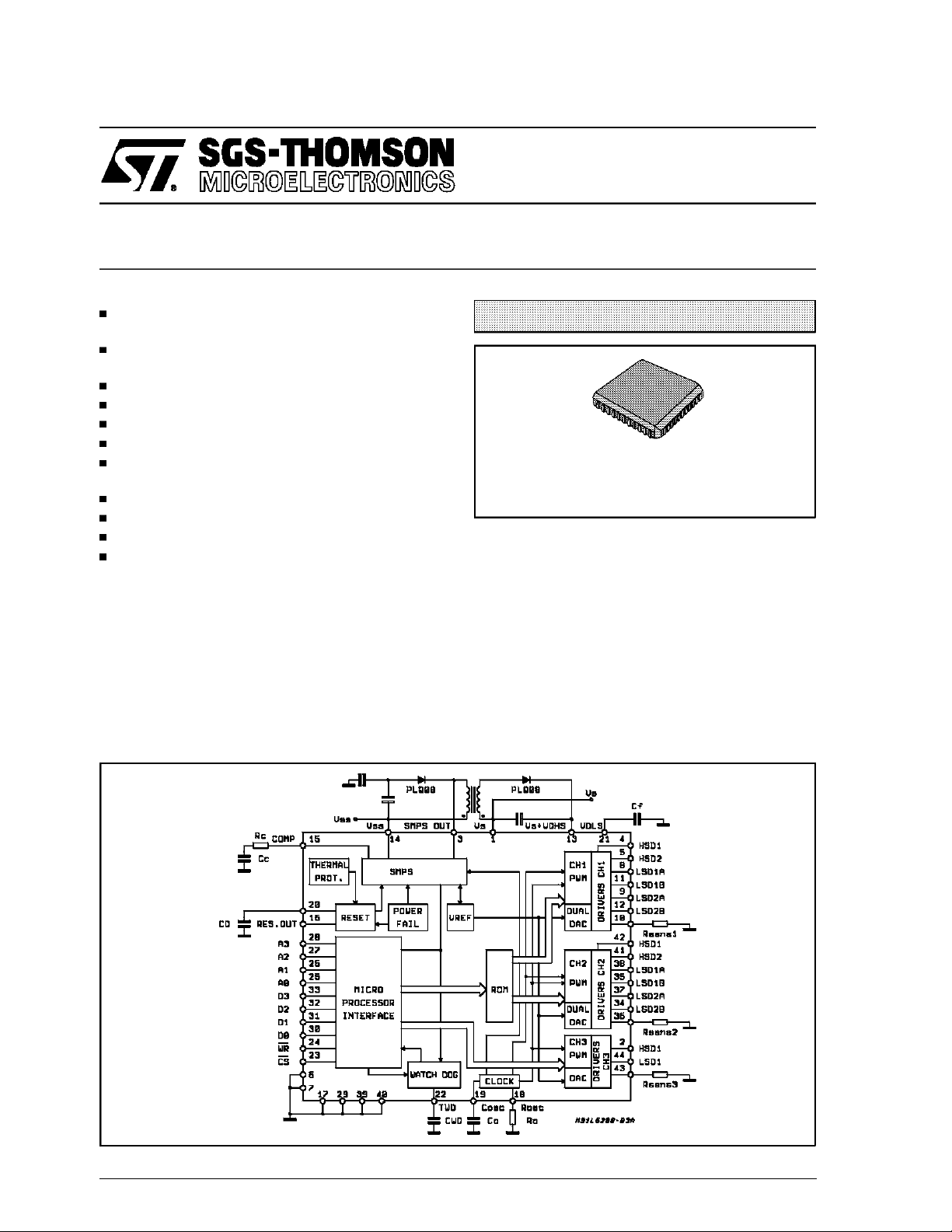

L6280

THREE CHANNELS MULTIPOWER DRIVER SYSTEM

ADVANCE DATA

PROGRAMMABLE CONFIGURATION

(CHANNELS1 AND2)

OUTPUT CURRENT UP TO 1A (CHANNELS

1AND2)

1 SENSEPER CHANNEL

OUTPUTCURRENT CHANNEL 3 UP TO 3A

DIRECT INT ERFACE TO MICROP ROCESSOR

C-MOSCOMPATIBLE INPUT

INTERNAL DC-DC CONVERTER FOR LOGIC

SUPPLY(+5V)

POWER FAIL

WATCHDOG MANAGEMENT

THERMAL PROTECTION

VERY LOW DISSIPATED POWER (SUIT-

ABLE FOR USE IN BATTERY SUPPLIED APPLICATIONS)

DESCRIPTION

TheL6280 is a multipowerdriver system for motor

and solenoid control applicatios that connects directly to a microprocessor bus. Realized in MultipowerBCD technology-- which combinesisolated

DMOS transistors, CMOS & bipolar circuits on the

BLOCK DIAGRAM

MULTIPOWERBCD TECHNOLOGY

PLCC44

ORDERING NUMBER: L6280

same chip -- it integrates two 1A motor drivers

(channels1 & 2) a 3A solenoid driver (channel 3)

and a 5V switchmode power supply.

All of the drivers in the L6280 are controlled by a

microprocessor which loads commands and

reads diagnostic information, treating the device

as a peripheral. Channels 1 and 2 feature a programmable output DMOS transistor configuration

that can be set during the initialization phase.

Thanksto very low dissipation of its DMOS power

stagesthe L6280 needs no heatsink and is packagedin a 44-leadPLCC package.

January1992

This is advanced information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

1/26

Page 2

L6280

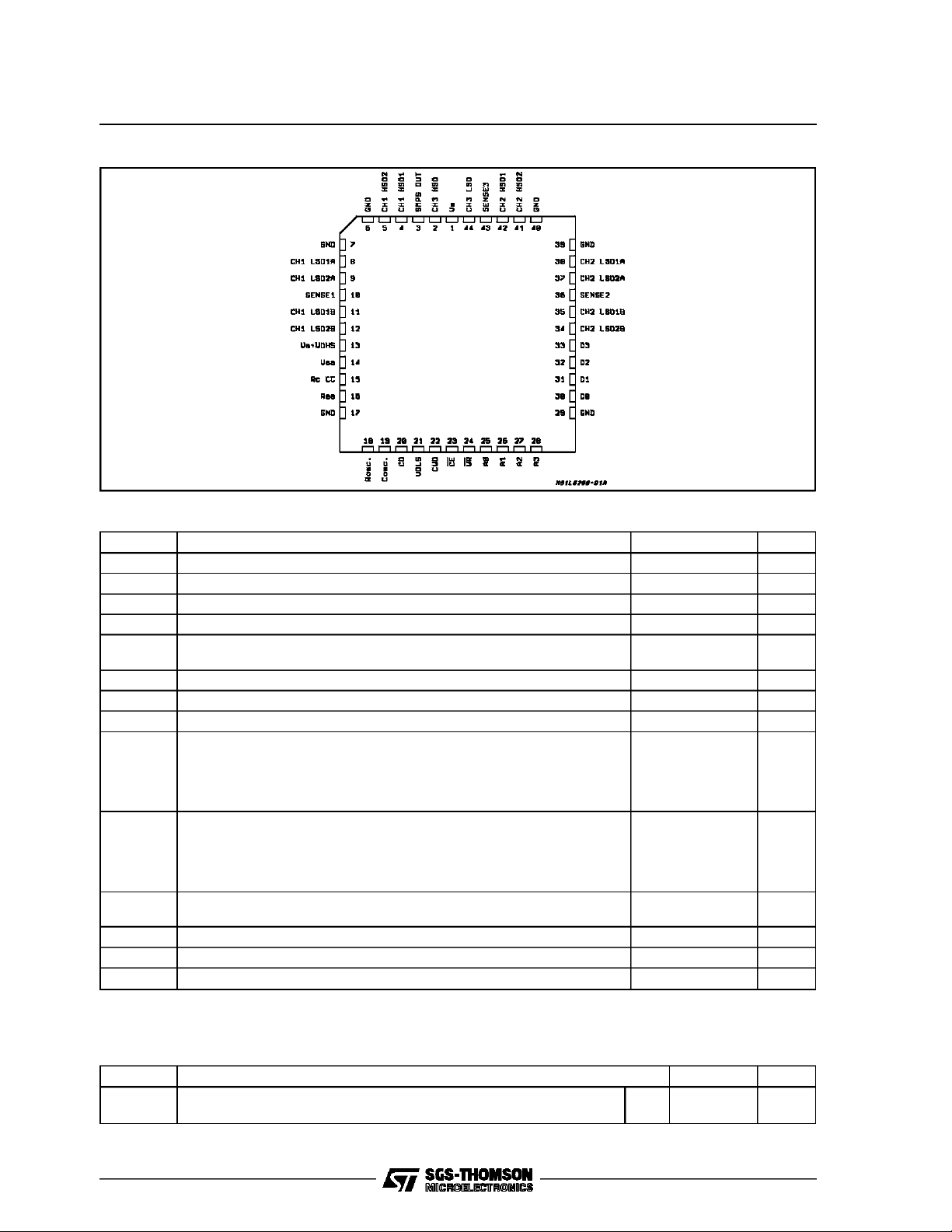

PIN CONNECTION (top view)

ABSOLUTE MAXIMUMRATINGS

Symbol Parameter Value Unit

V

V

SS

V13 Pin 13 InputVoltage (Note B) 60 V

V

DHS

V

V

OD

V

sense

V

I

LSD

I

HSD

I

SSOUT

I

RES

P

tot

T

stg;Tj

Notes: A) D0 =D1 = D2 = D3 =0; B) V13 = VS+V

D) D0 = 1; D1 = D2 = D3 = 0; E) D1 = 1; D0 =X; D2 =D3 = 0; F) The pulse width must be< 5ms and the Duty Cycle must be < 10%

G) The pulse widthmust be <5ms and the Duty Cyclemust be< 6%; H) mounted on board with minimized dissipatingcopper area.

THERMAL DATA

Power Supply Voltage (Note A) 35 V

S

Logic Supply Voltage 7 V

High Side Out Transistor Driving Voltage (NoteB,C) 18 V

Output Voltage. CH1; CH2: Unipolar Motor Drive (Note D)

O

CH3

60

60

Differential Output Voltage CH1; CH2; FullBridge Configuration (Note E) 60 V

Sensing Voltage -1 to 2 V

Logic Input Voltage -0.3to VSS+0.3 V

I

Low Side DriverInput Current

CH1; CH2 DC Operation

Peak (Note F)

CH3 DC Operation

Peak (Note G)

0.7

2

3

4.4

High Side Driver Onput Current

CH1; CH2 DC Operation

Peak (Note F)

CH3 DC Operation

Peak (Note G)

SMPS Output Current (Continuous)

(Peak; TON< 5ms)

1

2

3

4.4

1

2

Reset Output Open Drain Input Current 16 mA

Total Power Dissipation atTamb = 70°C (Note H) 1.6 W

Storage an Junction TemperatureRange -40 to 150 °C

; C) At 20V > V

DHS

> 17V the input current at pin 13 mustbe < 30mA;

DHS

V

V

A

A

A

A

A

A

A

A

A

A

Symbol Description Value Unit

R

th j-pins

R

th j-amb

(*) Mounted on board with minimized dissipating copper area.

Thermal Resistance Junction-pins

Thermal Resistance Junction-ambient (*)

Max.

Max.

12

50

2/26

°C/W

°C/W

Page 3

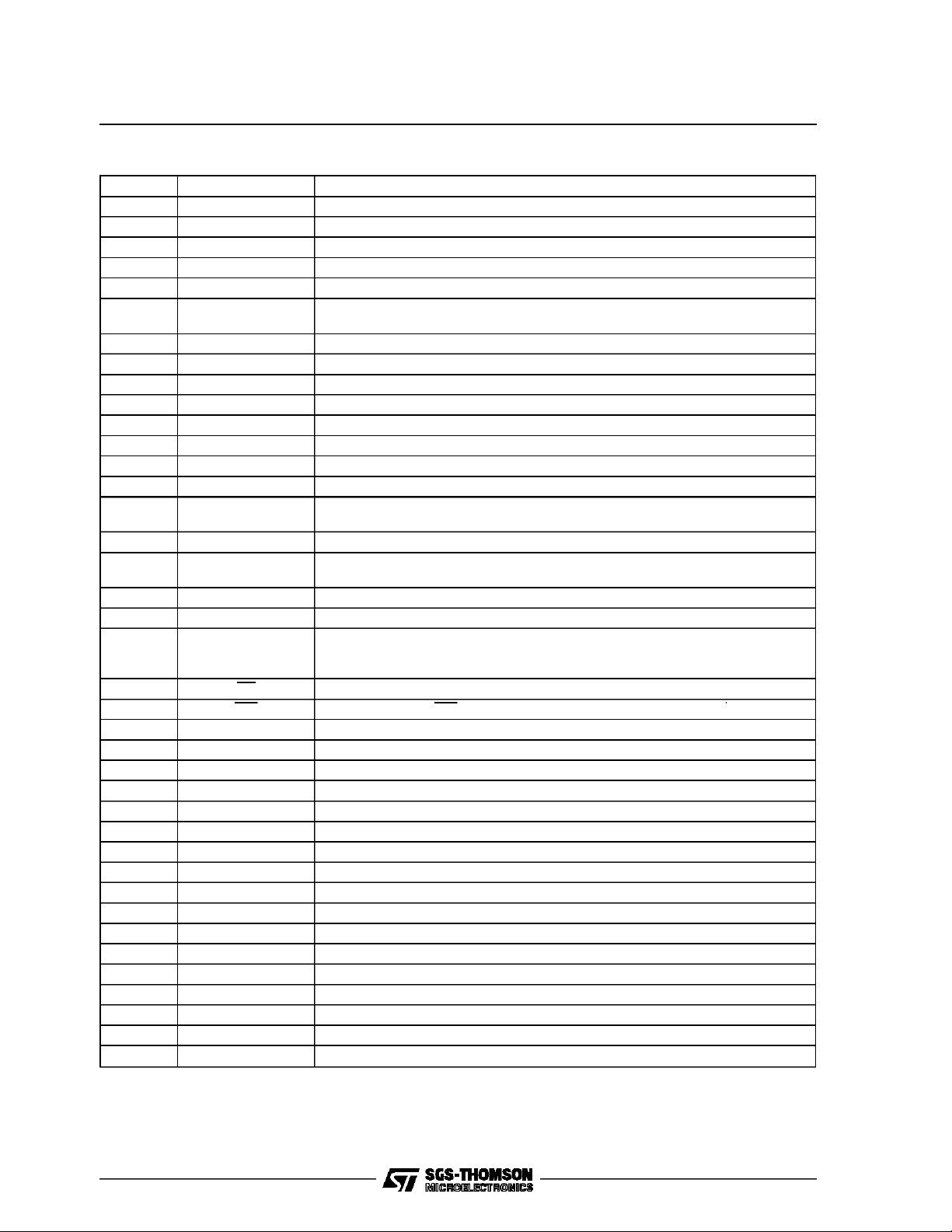

PIN DESCRIPTION

PINS NAME FUNCTIONS

1V

S

2 HSD 1 High Side CH 3 Power Output

3 SMPS OUT Output of Switchmode Power Supply

4 HSD 1 High Side CH 1 Power Output

5 HSD 2 High Side CH 1 Power Output

6, 7,17,29,

GND Common GroundedTerminal

39, 40

8 LSD 1A Low Side CH 1 Power Output

9 LSD 2A Low Side CH 1 Power Output

10 SENSE 1 A Resistor Rsense, connected to this pinallows loadcurrent control for CH 1

11 LSD 1B Low Side CH 1 Power Output

12 LSD 2B Low Side CH 1 Power Output

13 V

14 V

S+VDHS

SS

15 Comp. An RC series network allows the compensation of the SMPS regulation loop

16 RES OUT The reset opendrain output can be used to warnthe microprocessor about V

18 R

19 C

20 C

21 V

22 t

OSC

OSC

D

DLS

WD

23 CS Enable Input(active when low)

24 WR Write Input. WhenWR is low the data is loaded into the µP interface

25 A0 Operation Selection (see programming sequence).

26 A1 Operation Selection (see programming sequence).

27 A2 Channel Selection (see programming sequence).

28 A3 Channel Selection (see programming sequence).

30 D0 Data (see programming sequence).

31 D1 Data (see programming sequence).

32 D2 Data (see programming sequence).

33 D3 Data (see programming sequence).

34 LSD 2B Low Side CH 2 Power Output

35 LSD 1B Low Side CH 2 Power Output

36 SENSE 2 A Resistor R

37 LSD 2A Low Side CH 2 Power Output

38 LSD 1A Low Side CH 2 Power Output

41 HSD 2 High Side CH 2 Power Output

42 HSD 1 High Side CH 2 Power Output

43 SENSE 3 A Resistor R

44 LSD 1 Low Side CH 3 Power Output

Power Supply Voltage Input

Input Voltage for the HSD Gates Drive

Logic Supply Voltage Input

and VSSstatus

Together with C

Together with C

, sets the cycle time ofthe SMPS t = 1.1 ROC

OSC

, sets the cycle time ofthe SMPS t = 1.1 ROCOand sets the

OSC

minimum ON time in the PWM current control loop

The value of this capacitor sets the reset delay tD=7 x104C

D

By-pass Capacitorof the LSD Gates Voltage drive

ThevalueofthisCWDsetsthedurationofthewatchdogmonostable tWD=3x 104CWD.

If no watchdog signal is generatedinto the TWD timethe device is automatically

switched off.

, connected to this pin allows load current control forCH 2

sense

, connected to this pin allows load current control forCH 3

sense

L6280

S

O

3/26

Page 4

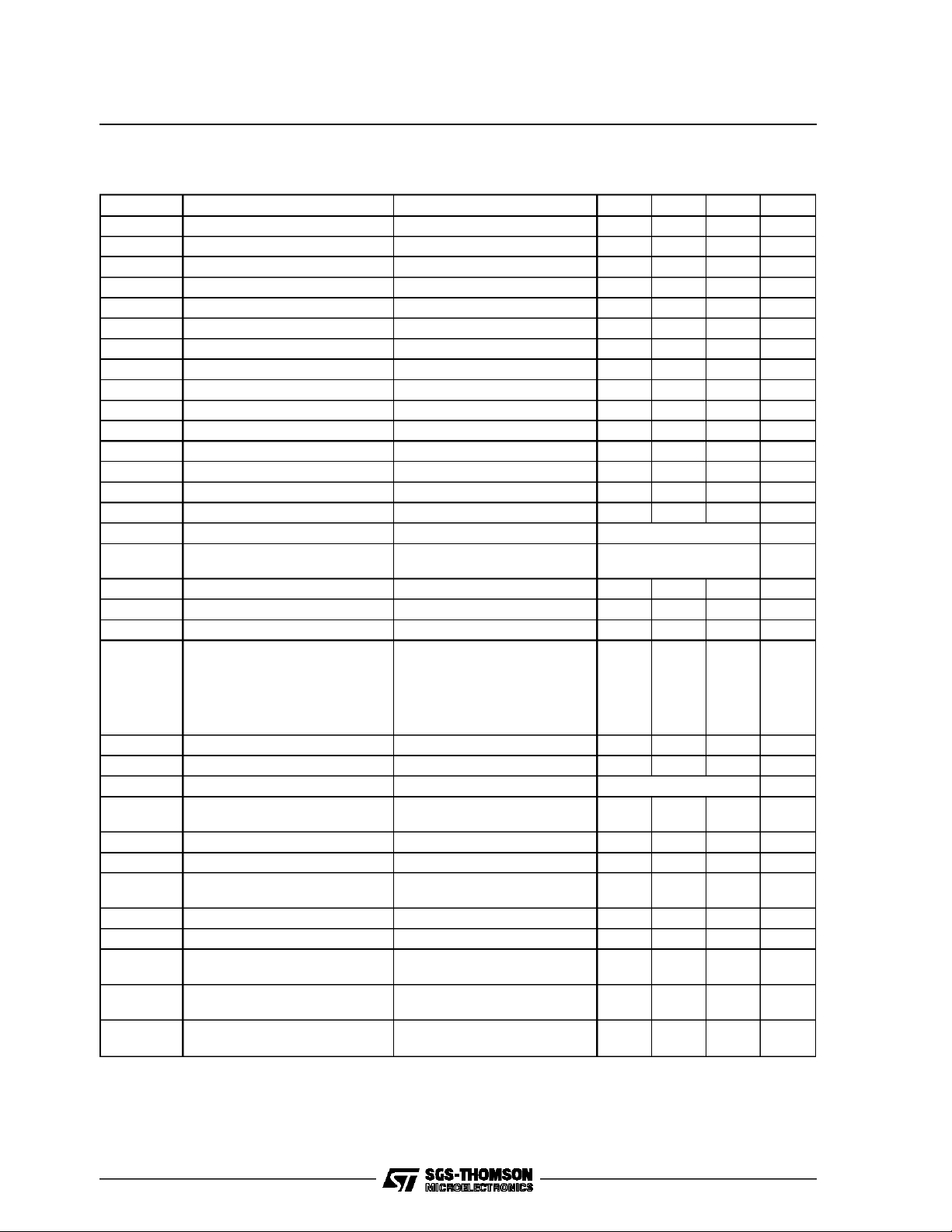

L6280

ELECTRICALCHARACTERISTICS (VS= 20V; Tj=25°C; VSS =5V; V

C

=680pF; unlessotherwise specified)

O

=15V; RO=165KΩ;

DHS

Symbol Parameter Test Condition Min. Typ. Max. Unit

I

DSS

V

s

V

INL

I

INL

V

INH

I

INH

V

ROUT

V

PF

I

S

V

SS

I

SS(IN)

I

SS(OUT)

f

osc

f

1

f

1max

f

2

f

3

Leakage Current Fig. 1 VDS = 60V 2 mA

Power Supply Voltage Note 1,2 >V

PF

48 V

Low Level InputVoltage -0.3 1.35 V

Low Level InputCurrent -10 µA

High Level InputVoltage 3.15 VSS V

High Level Input Current 10 µA

Low Level Reset Out I16 = 1.5mA 0.8 V

Power Supply Fail Voltage (Fig. 2) 13 V

Quiescent Supply Current VS = 12V 4.5 6 7.5 mA

Logic Supply Voltage 4.75 5 5.25 V

Logic Supply Current 4.5 6 7.5 mA

SMPS Out Current Range Note 3 800 mA

Oscillator Frequency 64 80 96 KHz

SMPS and CH3 Frequency f

osc

Max SMPSSwitching Frequency 120 KHz

PWM Frequency fosc/2 KHz

High Side Driver Switching

fosc/4 KHz

Frequency

TSD Thermal Shutdown 125 150 °C

t

WD

t

D

R

ON

Monostable Watchdog Time CWD = 0.22µF (Note 4) 6.6 ms

Reset Delay Time CD= 0.22µF; Fig.2 (Note 5) 15.4 ms

ON State DrainResistance

Transistor LSD CH1 - CH2

HSD CH1 - CH2

LSD CH3

HSD CH3

SMPS

Fig 3; 4ab

2

1.1

0.5

0.5

1

2.4

1.4

0.8

0.8

1.2

SENSE Internal Sense LOW-Pass Filter 300 500 ns

V

ref

DAC Reference Voltage D0=D1=D2 =1 (Table 1) 1 V

DAC DAC Resolution (3 Bit) (See Table 1) Vref/8 V

t

C

Discarge Time of Cosc

(Note 6) 0.4 µs

Capacitor (Minimum TON)

V

DHS

I

DHS

I

SS (OUT) max

HSD Gates Voltage Drive 13 15 17 V

Pin 13 OverageInput Current 3 mA

SMPS Overload Protection

1.2 A

Current

V

DLS

V

SSF

V

FHSD (1;2)

Pin 21 OverageInput Voltage 12 V

Logic VSS FailThreshold Voltage (Fig. 2) 2.6 4.1 V

Internal Clamp Diode Forward

@IDS = 0.4A (Fig. 5) 1.2 V

Voltage CH1/CH2

V

FLSD

(1AB;2AB)

V

FHSD

Internal Clamp Diode Forward

Voltage CH1/CH2

Internal Clamp Diode Forward

@IDS = 0.4A (Fig. 5) 1.4 V

@IDS= 1A (Fig. 5) 1.1 V

Voltage CH3

KHz

Ω

Ω

Ω

Ω

Ω

4/26

Page 5

ELECTRICALCHARACTERISTICS (continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

FLSD

Internal Clamp Diode Forward

Volt. CH3

t

CW

t

WPW

t

SU

t

DH

t

WC

Notes:

1) When driving a unipolar stepper motor the Power Supply Voltage must be lower than24V.

2) A lower Supply Voltage than the Power Fail thresholddisables the Step Down Power Supply (see Fig.2)

3) The minimumoutput current equals the half of the peak-to-peak current ripple

4) t

WD ≅ CWD

5) t

x 3.5 /50 x 10

D ≅ CD

6) t

C≅ COSC

Chip Seletion to End of Write (Fig. 6) 700 ns

Write Pulse Width (Fig. 6) 700 ns

Data Set-up Time (Fig. 6) 700 ns

Data Hold-up Time (Fig. 6) 0 ns

Write Cycle Time (Fig. 6) 2.7 ms

x 1.5 /50 x 10

x R

(sec); R

int.

-6

(sec)

-6

(sec)

= 600Ω ± 30%

int.

@IDS= 1A (Fig. 5) 1.1 V

L6280

Figure1: DrainLekage Current Equivalent Test

Circuit. The Gate-to-Source Voltage

VGS is below theSwitch-Off

Threshold.

Figure3: TypicalNormalized R

JunctionTemperature

DS(ON)

vs.

5/26

Page 6

L6280

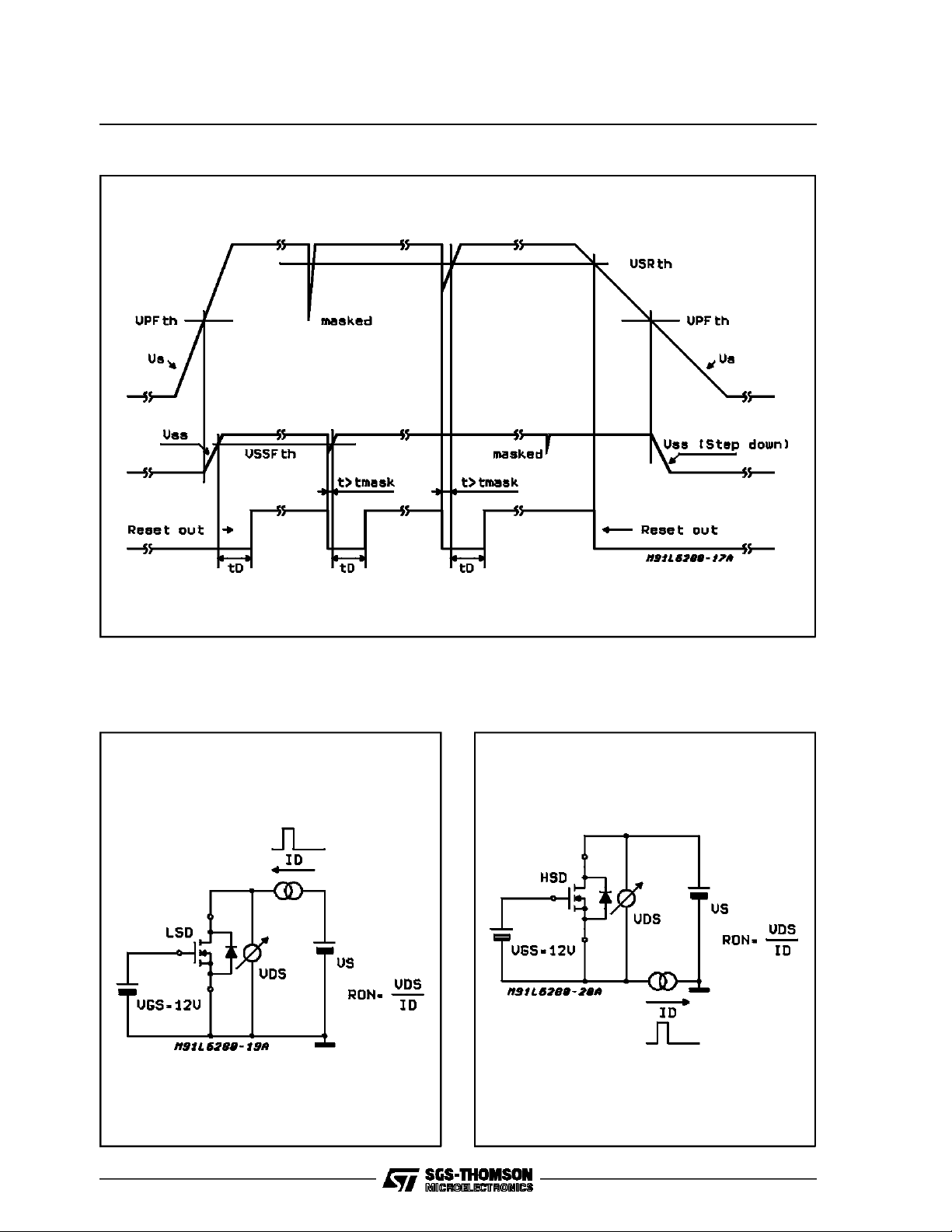

Figure2: Reset Output Behaviour versusPower Supply Voltage V

and/orLogic SupplyVoltage VSS.

S

Figure4a:Sink Output DMOSRONEquivalent

Test Circuit

Figure4b:Source OutputDMOS R

Test Circuit

Equivalent

ON

6/26

Page 7

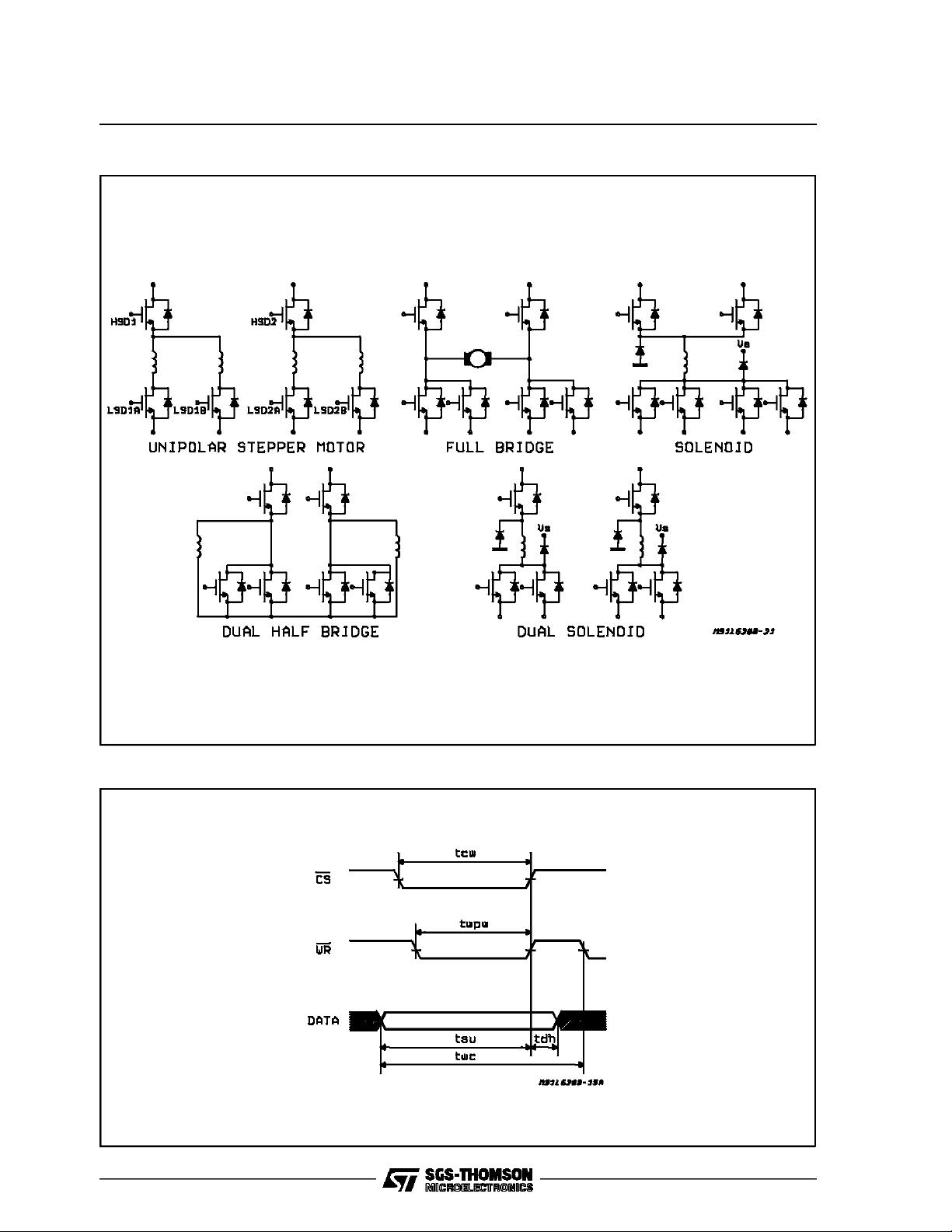

Figure5: Possible HardwareConfigurationsof PowerStage (CH1and CH2)

L6280

Figure6: Write Cycle

7/26

Page 8

L6280

SYSTEM DESCRIPTION (Refer to the Block Dia-

gram)

The L6280 is a single chip power microsystem

which includes drives for three differentloads, the

associated control logic and a Switched Mode

PowerSupply(SMPS) at V

=5V± 5%.

SS

The IC can be directly connected to a standard

microprocessor because of its common I/O interface architecture. The L6280 can exchange information regarding the load driver and the control

methodvia a 8 bit data bus. The blocknamed microprocessor interface decodes the first four bits

(A0....A3),which, depending on the content of the

remainingfour(D0.......D3)are used to enable the

power DMOS, to activate the PWM loop, and finally to set the D/A output value.

The power stage can be divided into 3 channels.

Channels1 and 2 have 6 DMOS transistors each

one (2high side drivers with R

drivers with R

=2Ω). Depending on the appli-

dson

=1Ω, 4 low side

dson

cation load, these driver transistors can be connected in different ways. The microprocessor, via

software, must activate the proper control loop to

optimize operation of different loads and output

stage configurations. Because of this programmability in the control of the output configurations,

a large variety of different loads can be driven by

the same integrated circuit (see possible configuration for power stage on Figure 5) giving the

greater system flexibility. Current levels up to 1A

are possible from CH1 and CH2, limited primarily

by the power dissipation of the IC.

The third channel has a fixed configuration intended to drive a solenoid. DMOS transistorswith

0.5Ω R

are used to provide 4A max load ca-

dson

pability.

All three channels have 3 bit current D/A resolution. Some auxiliary blocks of diagnostic and protection(e.g.: Thepower Fail/Reset andthe watchdog) are provided to protect the system from

microprocessorfailure or powerfail.

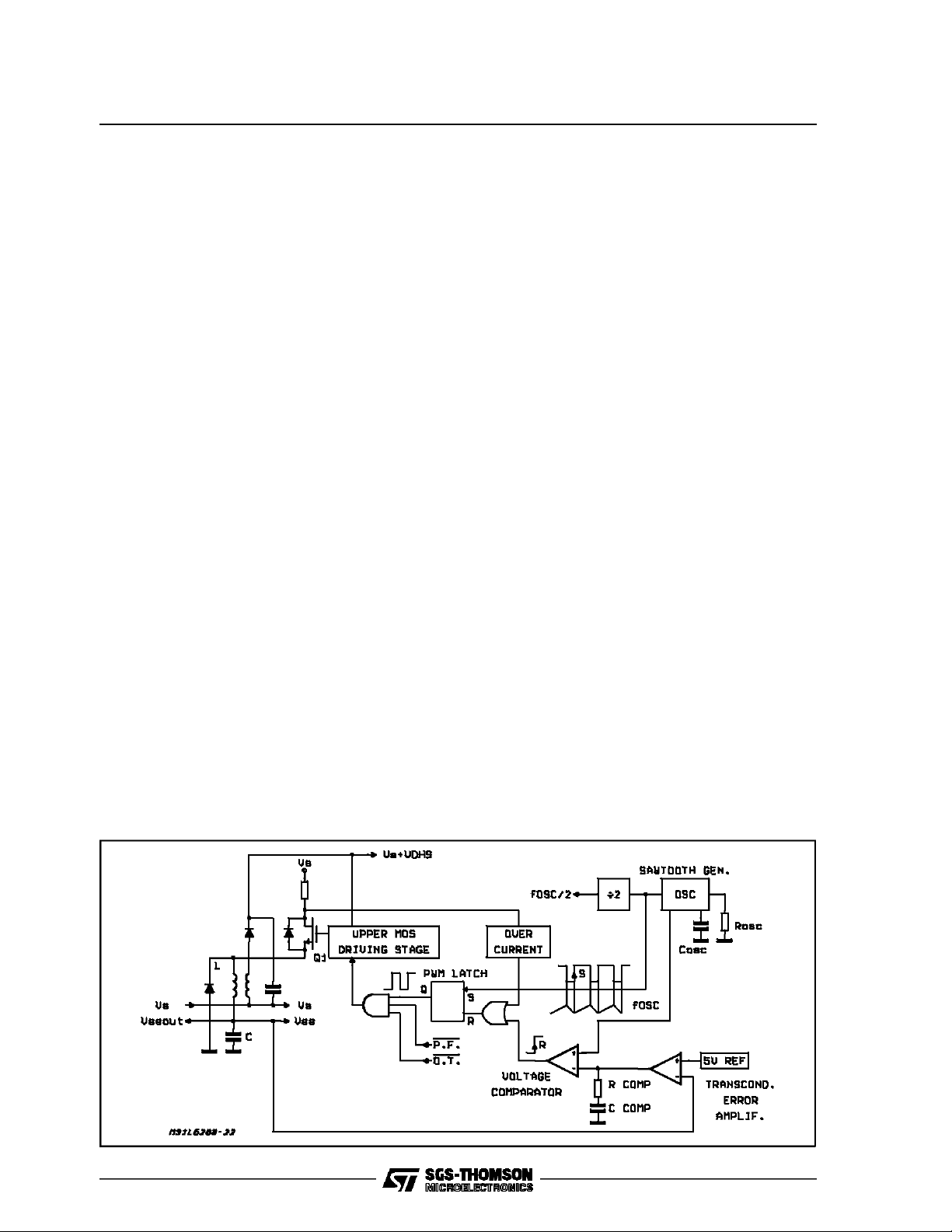

Figure7: SMPSBlock Diagram

Step Down Switchmode Power Supply (See

Figure7).

The step down switchmode power supply con-

tains a DMOS power stage with 1Ω R

dson

(Q1),

control circuitry, diagnostics and protection circuits; a regulated voltage (V

is used to drive

SSout)

some of the internal circuit blocks and the external microprocessor and memories. Thanks to the

DMOS output stage this regulator can deliver a

continuousoutput power of 4W (5V; 0.8A) with an

efficiency betler than 90% at a typical frequency

of80kHz.

The regulation loop uses a classical pulse width

modulation circuit that includes a sawtooth generator,an erroramplifier,a voltagecomparatoranda

PWM latch. A precision 5V referenceis generated

and trimmed on chip to guaranteea 5% tolerance.

This referenceis used as voltage referencefor the

SMPSand the reference for the DACs.

The IC also provides an extra voltage (V

S+VDHS

for the correct driving of the high side drivers.

These transistors require a gate voltage higher

than the supply voltageVs to obtainthe minimum

ON resistance. Because of the v ery low current

needed to drive DMOS transistors, this auxiliary

voltage is easily obtainedfrom a second winding

on the inductor of the LC output network (see ApplicationInformation).

An overcurrent protection circuit is included to

turn OFF the power transistor when a current

levelof 1.2A isexceeded.

The SMPS block also includes a voltage sensing

circuitto generate a powerON reset signal for the

microprocessor. This Power Fail circuit senses

the input supply voltage and the output regulated

voltage and sets the Reset-out pin to the high

voltage only when both the sensed voltages are

correct.

Finally, the SMPS block is able to deliver f

OSC/2

used in the actuation stage for the PWM control

of the current(CH1; CH2 and CH3).

)

8/26

Page 9

L6280

PwmCurrentControl Loop

The current control is achieved big a cycle of

charge (T

) and discharge (T

ON

) of the energy

OFF

stored in each couple of windings of the driven

motor (MA and MB). Fig. 8 shows the windings

MA of an unipolar stepper motor during T

ON

. FF1

is setted by the clock pulse and the transistor Q

is ON. At the moment Q1is ON the current exponentiallyincreases until R

A reset pulse is produced, Q

and Q

netic flux 0

is switched ON (Fig. 9). Since the mag-

2

=NAIPcannot suddenly change

MA

IPequalsV

x

S

A

.

REF

is switched OFF

and since the coil tourus number in the discharge

loop is doubled, the peak current I

self into I

/2. The OFF time is characteryzedby a

P

slow recirculation of the current I

creases until a new clock pulse sets a new T

modifies it

P

/2 that de-

P

ON

configuration. To control the current in two separate windings MA and MB with just one sense resistor RS and one comparator, a special PWM

control loop based on a ”time sharing” technique

(Patented)is used(Fig. 10).

In this configuration the chopping frequency, that

defines the T

ON+TOFF

period of each phase, is

halved by FF3 that drives ON G1 and G2 alternately. During T

MA (and Q

A

of one winding, for instance

OFF

is OFF), its current does not flow

throught the sensing resistor that can be used to

monitor the current that flows through the second

windingMB, allowed by the ON-statusof Q

.

B

Fig. 11 shows a simplified timing before and during the phase change from AB to AB (CCW, full

step). It can be seen that before the time t

and IBare alternatelycontrolled in a choppingperiod Tch1 of 4 oscillatorperiods or two clock periods. The time sharing is 50% - 50% and the

chopping frequency is typically of 20KHz (f

80KHz).

Afther the time t

A

ferent time sharing is generated. In fact since a

, as soon as IAis sensed, a dif-

1

Reset pulse is last after one clock pulse, FF2 can

drive FF3 to change for I

chopping only at the

B

next clock pulse (Fig 10; Fig 11).

Thismeans that the choppingtime becomesTch2

= 6 oscillator pulses, the frequency decreases to

16.6KHz (f

= 80 KHz) and the time sharing be-

osc

comesof67% - 33%.

At the end of the phase change period tphc the

time sharing comes back to 50% - 50% again. It

can be noted that this behaviour allows a faster

phase change and then a higher speed of the

motor. The cost of that, is the increase of the

of the unchangedphase B and then a small

T

OFF

increase of the ripple of the current I

<∆IB2in Fig. 11).

This time sharing current control method is also

used when two indipendent load are driven by

one single channel. when only one load is present,such as a DCmotor could be, the timesharing is automatically switched OFF and the PWM

frequency becomes f

/4 = 20KHz. Table 1

osc

showshow the referencevoltage can be modified

with a three bits DAC to allow microstepping operations(see below).

(see ∆I

B

1,IA

osc

=

B1

Figure8 - T

Configuration:Motor Windings

ON

MA (A;A).

Figure9 - T

Configuration:Motor Windings

OFF

MA (A:A).

9/26

Page 10

L6280

Figure10 - PWM CurrentControl Loop. Time Sharing Technique.

Figure11: Chopping Characteristics(simplified)

10/26

Page 11

L6280

Digital/AnalogConverters(DACs)

The output current levels are programmed by

5DACseach with 3 bit resolution. Channels1 and

2 each have 2 DACs, one for the left part of the

output stage and the other for the right part.

When the output stage is used to drive only one

load (as with DC motors), the L6280 uses only

the right register. Channel3 has only 1DAC.

Microstepping operation is easily performed with

channels1 and 2. The value of each DAC can be

changedin two ways:

a) the new value can be directly generated by

the microprocessor and then loaded into the

specifiedDAC;

b) the value of a DAC can be incremented or

decrementedby 1; in this case the microprocessor during acceleration or deceleration has

only to indicate the DAC on which operate

and the type of the operation, reducing the

CPU’sburden.

The correspondence between the DAC value and

the Vref level is shown in table 1.

Table 1

D2 D1 D0 V

1111 V

1 1 0 0.875 V

1 0 1 0.75 V

1 0 0 0.625 V

0 1 1 0.5 V

0 1 0 0.375 V

0 0 1 0.25 V

0 0 0 0.125 V

ref

UNIT

Iload = 0 is obtained bydisabling all low-sidedrivers.

Turn ON/OFF Characteristicsand Program Sequence

During power-on the Switchmode Power Supply

output stage is turned OFF till V

reaches V

S

PFth

The pin Reset Out is held low and remains low till

is < V

V

SS

(the powerstages and the logic of

SSFth

the L6280 aredisabled.

Not correct signals coming from the microproces-

sor are then ignored; the microprocessor on the

other hand, receives a low state signal from the

Reset Out pin. When the V

during a delay t

set by the CDcapacitor, the pin

D

output is stabilized

SS

Reset Out goes to the high level; the microprocessor is enabled to work while the L6280 is in

stand-by waiting for a keyword and initialization

sequence.Every command that arrives beforethe

keyword is ignored. At this time the programming

sequence can start accordingto the flow diagram

(Fig.12).

At first the Keyword (00111010) has to be sent to

the L6280 to activate the watch - dog function

that begins to control the microprocessor functionality. From this moment the microprocessor

must send periodically the Watch-dog word

(00110101) otherwise its absence is interpreted

as a microprocessor failure: to prevent any damage both in the load and in the IC, the L6280itself

disablesthe power stages. No reset signal is generated towards the CPU; the system must restart

the sequencefrom Power-ON.

The next step is to set the configuration of channel 1 and channel 2 output stages by the initialization word. The configuration can be chosen to

fit in the load characteristics.To do thisthe microprocessor generates a word with A0, A1 = 0 and

where A2, A3 choose the channel to be configured, D0 to D3 choose the type of configuration

(unipolar, dual half bridge or full bridge; see Data

and Address decoding). Every input configuration

different from the allowed initialization word is ignored.

Whenthe initializationarrives, the L6280 sets the

configuration of the output stage of the chosen

channel. The initialization word has to be repeated for the other channel (CH1 or CH2 only). If

two initializations arrive for the same channel,the

L6280 disables the output stages while pin Reset

Out goes low for a time Td to advise the mocroprocessorabout the uncorrectcondition.The program sequence must restart from the Keyword

step. After the initialization step is succesfully

completed the L6280 begins to accept commands. If a command is sent before the relative

channel has been configured, the command is

neglected.

Commandcan be of three type:

a - selectionof currentlevel loading a DAC;

b - increment or decrement of aDAC;

c - selection of the driving strategy of a channel

(e.g. half/fullstep, fast/slowdecay and so on).

To select the current level is necessary to load a

value into the appropriateDAC. The microprocessor must select the channel via A2, A3 and (only

for channel 1 and2) left or right DAC via D3; the

.

value of D0,....D2 are loaded in the chosen DAC.

There are two possibilities of changing the value

of a DAC; the first one is to load directly the new

value,the second one is to causean incrementor

a decrement in a DAC, in this way the burden of

the microprocessor can be partially decreased

generating inc/dec command without calculating

the value.

To incrementod decrement a DACthe microprocessor must select the channel via A2,A3, left or

right DAC and the operationvia D0 to D3 according to truth table in Datas and Address Decoding

(see below). The increment or decrement is done

immediately after the arrive of the command. For

every configuration of the output stages are possible different type of driving strategy explained in

Datasand Address Decoding.

11/26

Page 12

L6280

Figure12: ProgramSequence

Dataand Address Decoding

SPECIALWORDS

A3 A2 A1 A0 D3 D2 D1 D0

00111010

KEYWORD

This word is used during the start-up procedure to

enable operations; all settings arrived before the

keywordare reset.

A3 A2 A1 A0 D3 D2 D1 D0

00110101

WATCHDOG

The microprocessor must periodically generate

this word; the value of the maximum period is set

by the capacitor C

. The absence of the Watch-

D

dog is interpreted by L6280 as a microprocessor

failure.The maximumperiodis:

T

WD=CD

1.5 / ( 50 x 10E-6)

x

Except for special words (keyword and watchdog), the input words are organized like the following:

A0 A1 Operation selection

A2 A3 Channel selection

D0 D1 D2 D3 Datas

A0,A1DECODING(OPERATIONSELECTION)

A0,A1selectthe type ofoperation (channel initiali-

zation,commands, DACs loading, DAC increment/decrement).

A0A1

0 0 This configurationis usedto send the infor-

mationabout the configurationof the

vchannelspecifiedby A3 and A2; D0 to D3

are used to specify the configuration of the

channel(full bridge, dual half bridge,unipolar motor).

A0A1

1 0 This configuration is usedto changedriv-

ing strategyof the output stagesof the

channelspecifiedby A3 and A2 (full/half

step, slow/fastdecay and so on). The driving strategyis codedin D0 to D3, and dependsfrom the configurationof the output

stage.

A0A1

0 1 This configurationis usedto load the value

of a DAC of the channel selected by A3

and A2. D3indicates rightand left DAC

just for channel1 and 2.

12/26

Page 13

L6280

A0 A1

1 1 Thisconfigurationis used to cause an incre-

ment or a decrement of a DAC. Right or

left DAC and inc/dec are selected by

D0 toD3 value.

D0 to D3 DECODING(Datas)

The meaning of D0, D3 changes according to

the value of A0, A1

A0A1

0 0 When A0,A1 are in this configuration,and

A2, A3 DECODING (Channel Selection)

Every time a command or a initializationis sent to

the L6280, a channel must be selected. This is

done via A2 and A3 accordingto the table.

A2 A3

0 1 Select channel 2

1 0 Select channel 1

1 1 Select channel 3

0 0 Used only with keyword and watchdog

D3 D2 D1 D0

0 0 0 0 Null (power disabled)

a 0 0 0 1 Unipolarmotor

b 0 0 1 0 Full Bridge

c 0 0 1 1 Dual Half Bridge

b) Full Bridge Configuration

a) Unipolar Motor Configuration

In this configurationD0 to D3 directlydrive the low side drives:

D3 D2 D1 D0

0000

0001

0010

0100

0101

0110

1000

1001

1010

Low side drivers 1,2,3,4 OFF

Low side drivers 2,3,4 OFF Low side driver 1 ON

Low side drivers 1,3,4 OFF Low side driver 2 ON

Low side drivers 1,2,4 OFF Low side driver 3 ON

Low side drivers 2,4 OFF Low side drivers 1,3 ON

Low side drivers 1,4 OFF Low side drivers 2,3 ON

Low side drivers 1,2,3 OFF Low side driver 4 ON

Low side drivers 2,3 OFF Low side drivers 1,4 ON

Low side drivers 1,3 OFF Low side driver 2,4 ON

Configurations

channel1 or 2 is selected, the data appearing in D0 to D3 set the outputpower stage

configurationto fit the chosedload according to the allowed Truth Table. There is no

need to configure channel 3.

Possible configurations for

channels 1 and2

The following configurations are not allowed: the microprocessor does not to generate them otherwise

they can cause faulty operations.

D3 D2 D1 D0

0011

0111

1011

1100

1101

1110

1111

Alwaysnot allowed

This configurationis not allowed when drivinga unipolar motorand it is

permittedonly to drive a high currentsolenoid.

13/26

Page 14

L6280

In full bridge configuration D0 to D3 set the driving strategy of the bridge:

D0 D1 D2 D3

X 0 0 0 Tristate leftand right

X 0 0 1 Chopper left, brake right

X 0 1 0 Chopper right, brake left

X 0 1 1 Brake left, brake right

X 1 0 0 Tristate leftand right

X 1 0 1 Diagonalchopper

X 1 1 0 Inverted diagonal chopper

X 1 1 1 Tristate leftand right

c) Dual Half Bridge Configuration

D0 D1 D2 D3

X 0 0 0 Tristate leftand right

X 0 0 1 Brake right, chopper left

X 0 1 0 Brake right, chopper right

X 0 1 1 Brake left, brake right

X 1 0 0 Chopper left, chopper right

X 1 0 1 Tristate left, chopper right

X 1 1 0 Tristate right, chopper left

X 1 1 1 Tristate leftand right

CHANNEL 3

For channel 3 only D0 has a meaning: it directly

drives the low side driver DMOS. When D0 = 0

the low side driver DMOS is switched OFF and

the current flows through external recirculation diodes.

(only for channel 1 and 2)

D3

0 LeftchannelDAC

1 Rightchannel DAC

For channel 3, D0 to D2 are loaded into the

uniqueDAC.

A1A0

1 1 WhenA0, A1 are in this configuration, the

value of D0 to D3 causesan incrementor

a decrement of the content of left/right

DACof a channel. The inc/dec operation

and the DAC register selection(rightor

left) are selectedaccording to the following

truth table:

D3 D2 D1 D0

dec LEFT inc LEFT dec RIGHT inc RIGHT

The change in DAC registersis done immediately

after receiving the data.The configurationsD3, D2

= 11 and D1, D0 =11 are not allowed. (Them can

cause faulty operations) Channel 3 has only one

DAC; the change in its value is doneaccording to

D0,D1value.

D1 D0

dec DAC inc DAC

D1, D0 = 11 is not allowed (they can cause faulty

operations).

OutputOperation

In full bridge and dual half bridge configurations,

the output stages will operate according to D1,

D2,D3 values.

A0 A1

1 0 When A0, A1 are in this configuration,D0

to D3are used to set the strategyof the

output power stages according to the output stageconfiguration previouslyselected.

A1 A0

1 0 When A0, A1 are in this configuration,

D0 toD2 are loaded into left or rightwinding D/A converter,accordingto D3 value

14/26

FULL BRIDGE CONFIGURATION (CH1 and

CH2)

In full bridge configuration the cennection between the output of the high side drivers and the

corresponding low side drivers has to be made

with external jumpers. The output stage diagram

here below (Fig. 13) must be substituted inside

the blank boxes in the following block diagrams.

Page 15

L6280

Figure13

D0 D1 D2 D3

X 0 0 0 Tristate left and right

All output DMOSs of the channel are OFF (Fig.

14)

Figure14

Figure15

D0 D1 D2 D3

X010

hopper right side, fixed

left side (one phase

chopping)

As above but with the two channel exchanged

each to other(Fig. 16).

Figure16

D0 D1 D2 D3

X001

Chopper left side; fixed

right side (one phase

chopping)

The left side of the bridge is controlled by the

PWM loop while HSD2 is held OFF and LSD2A

and 2B are held ON. During ON time (Q low) the

current flows thrugh HSD1, motor winding and

LSD2A and 2B. During OFF time the current can

recirculate through LSD1A, 1B, 2A and 2B (Fig.

15)

D0 D1 D2 D3

X011

Fixed both leftand right

(brake action)

All High side drivers are held OFF while all low

side drivers are held ON. The motor winding is

short circuited through the low side drivers; the

motor’s back EMF acts as a brake voltage (Fig.

17).

15/26

Page 16

L6280

Figure17

D0 D1 D2 D3

X100

D0 D1 D2 D3 INVERTED DIAGONAL CHOPPER

(Twophase chopping)

During ON time (Q = LOW) the current flows

through HSD2, motor winding and LSD1A and

1B. During OFF time (Q = HIGH) the current can

recirculate through LSD2A and 2B motor windind

and HSD1 (Fig.19).

Figure19

Three state left and right

(see X000 configuration)

D0 D1 D2 D3

X101

Diagonal chopper (Two

phase chopping)

During

During On time (Q=LOW) the current flows

through HSD1, motor winding and LSD2A and

2B. During OFF time (Q = HIGH) the current can

recirculate through LSD1A and 1B motor winding

and HSD2 (Fig. 18).

Figure18

D0 D1 D2 D3

X111

Tristate left and right (see X000

configuration)

16/26

Page 17

L6280

DUAL HALF BRIDGE CONFIGURATION (CH1

and CH2)

In dual half bridge configuration the connection

between the output of the high side drivers and

the corresponding low side drivers has to be

made with external jumpers. The output stage

block diagram shown in figure 20 must be substituted in side the blank boxes in the following

block diagrams. In dual half bridge configuration,

the time sharingstrategy is always used.

Figure20

Figure21

D0 D1 D2 D3

X 1 0 1 Tristate left, chopper right

During ON time (Q = LOW) the current flows

through high side driver HSD2, right winding and

sense resistor. During OFF time the current recirculate through winding and side drivers LSD2A

and LSD2B (Fig. 22).

D0 D1 D2 D3

X 0 0 0 Tristate leftand right

X 0 0 1 Chopper left, fixed righ

X 0 1 0 Chopper right, fixedleft

Fixed left and right. For these

X011

D0 D1 D2 D3

X 1 0 0 Chopper left chopper right

configurations, see the

corresponding shown in Full

Bridge Configuration paragraph

(Page 14/24).

As foreseen when in unipolar motor configuration(see Figure 5), the time sharing strategy is

used (see Figure 10), so when the current in left

winding is controlled, the current in right winding

recirculate trough the low side drivers and not

throughthe sense resistor(Fig. 21).

Figure22

D0 D1 D2 D3

X 1 1 0 Tristateright, chopper left

During ON time (Q = LOW) the current flows

through high side driver HSD1, left winding and

sense resistor. During OFF time the current recirculate through the winding and low side drivers

LSD1Aand LSD2A(Fig 23).

17/26

Page 18

L6280

Figure23

D0 D1 D2 D3

X111

Tristate left and right (see

X000 configuration of full

bridge).

APPLICATIONINFORMATION

An application circuit useful to test the performance of the L6280 can be formed as shown on

Figure 24: CH1 drives one unipolar stepper motor, CH2 drives a DC motor, CH3 drivesone solenoid and theSMPS can supply continuously0.5A.

If the Watch Dog and the Chip Select functions

are not of interest, pins 22 and 23 must be

grounded. Each sensing resistor would be obtained by the parallelof two or more metal film resistor of the same value to minimize their series

equivalentinductance.

Generally, optimum stability of the SMPS voltage

control loop, is achieved by a series network

made by 1nF and 39 KΩ (seepin 15) and by using an output capacitor of 100µF having an

equivalent series resistance of 100 mΩ (see pin

14):the mostofthe unexpensivealuminium electrolithiccapacitors can be right.

The snubber network at the secondary windingof

the step-down inductor can be saved by accepting a not regulated voltage at the Charge Pump

input pin 13. This condition is not recommended

when the supply voltage and/or the SMPS output

current changes too much (for instance respectively20V + 30%and/or 100 to 800 mA).

Theinductance value of the primary winding of T1

defines the peak-to peak current ripple that flows

throught itself, that is the minimum output current

that allows the correct behaviour in continuous

mode of the SMPS; nevertheless, the device is

not demaged if it is obliged to work in discontinuousmode at a low current level.

Figure 25 shows the characteristics of the transformer T1 suitable to be used on the Application

of Figure 24:

The maximum output current is of 500 mA continuous but current peaks of 800 mA can be

sinked out without the risk of the core saturation.

To avoid the discontinuous mode, the minimum

SMPSoutput current must be of 70mA. The rectified voltage trend for the high side gate drive at

pin 13 is as shown on Figure26.

Not equally cheap, the choice of a toroidal core

for T1 canoptimize theapplication.

Instead of this, another solution can be as in Figure 27a it is shown. This is a full wave rectifier of

the voltage at pin 3; Z1and R1 clamp the positive

peak while the forward characteristicof the Zener

rectifies the negative peak and charges C1. The

recommendedZener voltage is of 12V.

Could happen that the V

output voltage is not

SS

requestedbecause already available:in this case

and only if at least one unipolar stepper motor is

continuously driven, the solution shown in Figure

27b can be implemented. The step down output

componentscan be left out.

Theconnectionof the network is as follows:

A: to pin 4 (or pin 5) when the unipolar motor is

drivenvia CH1;

to pin 41 (or pin 42) when the unipolar motor

is drivenvia CH2;

B: to pin 1

C: topin13

TheSMPS switching frequency is the sameof the

oscillator frequency that can be typically defined

by:

f

osc

Referringto Fig. 24 it iscalculated f

9

=

RC

= 82KHz.

osc

CH3 is chopped at the same frequency. The output diodes must be chosen according to the solenoid working current (50ns of reverse recovery

time or better): for a current less than 1 A, the

PLQ08is a goodchoice.

Drivingone unipolar stepper motor, output protection diodes (Transil) are recommended: CH1 in

Fig 24 uses four BZW04 - 48 diodes; when a low

current motor is driven or a Vs less than 20V is

supplied, four fast diodes and only one Zener diode can be used as a protection of the outpus

(see Figure 28). The driving of DC motor needs

the connection as shown for CH2 (full bridge configuration).

The drive of one bipolar stepper motor by using

CH1 and CH2 both in full bridge configurationallows the use of a higher supply voltage level that

however cannot exceed the Absolute Maximum

18/26

Page 19

L6280

Ratings of 35V:a max value of 33V is reccommended.

In this case, at each couple of outputs for the bipolar windings, a snubber network must be connected. This network is doneby the series of a resistorand of onecapacitor:

R

snub=VS

C

snub

max/Imotorpeak;

= Imotor peak/ (dv/dt)

One dv/dt of 200V/µsec is generally a correct

choice.

Of course, care must be taken in the Printed Circuit Board design regarding the ground paths and

Figure24: ApplicationTest Circuitof the L6280

the high current loops.

An example of P.C.B. layout is shown in Figure

29ab; Figure 30 shows the SchematicDiagram of

the circuit of the L6280 S.P.D. S.AB.

The driving signals useful for this board can be

easily generated by using an additional board

(EMUKIT 512) not describedhere.

On Figure 29a itcan be observedthe copper area

near the I.C. is used to sink out the heat from the

device. Useful thermal characteristics of the

L6280are shown in Figure 31 and 32.

19/26

Page 20

L6280

Figure25: Characteristicsof the TransformerT1.

N1: 118 tourns, copperwire ∅ 0.35mm

N2: 88 tourns, copperwire ∅ 0.2mm

TYPICALPARAMETERS

L

= 560µH

N1

N2

1

= 680mΩ

R

1

= 300µH

L

2

= 1.5Ω

R

2

@ 1KHz

@ 1KHz

Figure26: Charge Pump Voltage vs. Supply Voltageby using the transformershown on Figure25

20/26

Page 21

Figure27a : OtherCharge PumpSolution Figure 27b : OtherChargePump Solution

Figure28 : Unexpensive Output Protection Net-

work for theUnipolar MotorDriving

L6280

21/26

Page 22

L6280

Figure29a: L6280 PCB Components Side (1st metallization)

22/26

Page 23

Figure29b: P.C.B. Back Side (2nd metallization)

L6280

Figure30: SchematicDiagram of the CircuitAssembledon the L6280-AB(Figure 29)

23/26

Page 24

L6280

Figure31; TypicalTransientThermal Resistance

vs. Single Pulse Width.

Figure32; Typical ThermalResistance vs.

HeatsinkingCopper Area.

24/26

Page 25

PLCC44PACKAGE MECHANICAL DATA

L6280

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 17.4 17.65 0.685 0.695

B 16.51 16.65 0.650 0.656

C 3.65 3.7 0.144 0.146

D 4.2 4.57 0.165 0.180

d1 2.59 2.74 0.102 0.108

d2 0.68 0.027

E 14.99 16 0.590 0.630

e 1.27 0.050

e3 12.7 0.500

F 0.46 0.018

F1 0.71 0.028

G 0.101 0.004

M 1.16 0.046

M1 1.14 0.045

mm inch

25/26

Page 26

L6280

Information furnished is believed to be accurateand reliable. However,SGS-THOMSON Microelectronics assumes no responsibilityfor the

consequences of use of such information nor for any infringement ofpatents or other rightsof third parties which may result from its use. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are not authorized for use as critical components in lifesupport devices or systems without express writtenapproval of SGS-THOMSON Microelectronics.

1994 SGS-THOMSON Microelectronics - All Rights Reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil- France -Germany - Hong Kong - Italy - Japan - Korea -Malaysia - Malta - Morocco - The Netherlands - Singapore -

Spain - Sweden - Switzerland - Taiwan - Thaliand - United Kingdom - U.S.A.

26/26

Loading...

Loading...