Page 1

L6223

DMOS PROGRAMMABLE

HIGH SPEED UNIPOLAR STEPPER MOTOR DRIVER

HIGH EFFICIENCY UNIPOLAR STEPPER

MOTORDRIVER

HIGH SPEED UNIPOLAR STEPPER MOTOR

DRIVER

SUPPLYVOLTAGE UP TO 46V

PHASECURRENT UP TO 1A

UP TO 2A/PHASE IN DUAL CONFIGURA-

TION

PARALLEL CMOSµP INTERFACE FOR

FULL/HALFSTEP MOTOR ROTATION

SERIAL INTERFACE FOR 6 BIT PROGRAM-

MING

CLOSE/OPEN LOOP, 8 PWM CURRENT

LEVELS

DUAL PWM FREQUENCYSELECTION

INPUTBIDIRECTIONALLYPROTECTED

THERMALSHUTDOWN

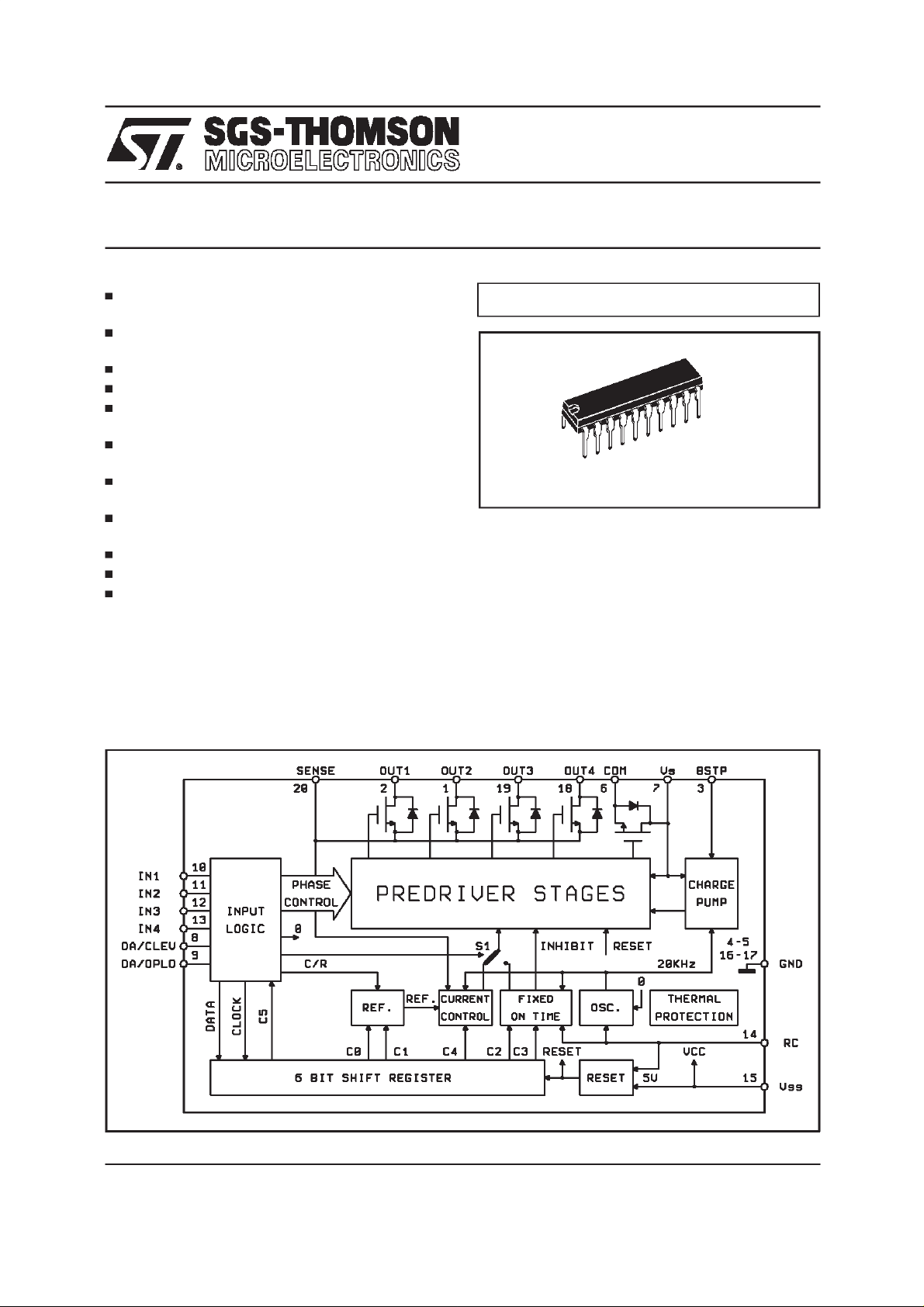

DESCRIPTION

The L6223 is a programmable integrated system

for driving a unipolar stepper motor. It is realized

in Multipower BCD technology. The DMOS output

BLOCKDIAGRAM

MULTIPOWER BCD TECHNOLOGY

POWERDIP

16+2+2

ORDERING NUMBER : L6223

stage, realized by a single upper DMOS switch

and four lower DMOS,can deliverup to 1A/phase

with motor supplyvoltages up to 46V.

All inputsare CMOS and microprocessor compatible. An internal 6-bit shift register allows the device to be programmed to select different duty cycles in open loop mode and different chopping

frequencies in closed loop mode. When the current control is in closed loop mode it is also possible to select a reduced current chopping level to

optimize system efficiency. The L6223 is de-

March 1998

1/33

Page 2

L6223

signed to work with a single sense resistor. During chopping t(OFF) time the current is reduced

by half, improving efficiency.Higher current appli-

The L6223 is mounted in a 20-lead Powerdip

package, (16+2+2). Four ground leads conduct

heat to dedicated heatsinkarea on the PCB.

cations can be achieved by paralleling two L6223.

ABSOLUTEMAXIMUM RATINGS

Symbol Parameter Value Unit

V

SS

V

S

V

I

V

O

V

Opeak

I

pl

I

ph

P

tot

V

sense

T

stg,Tj

( * ) Oscillator running

(**)4cm

2

copper area on PCB, see fig. 34

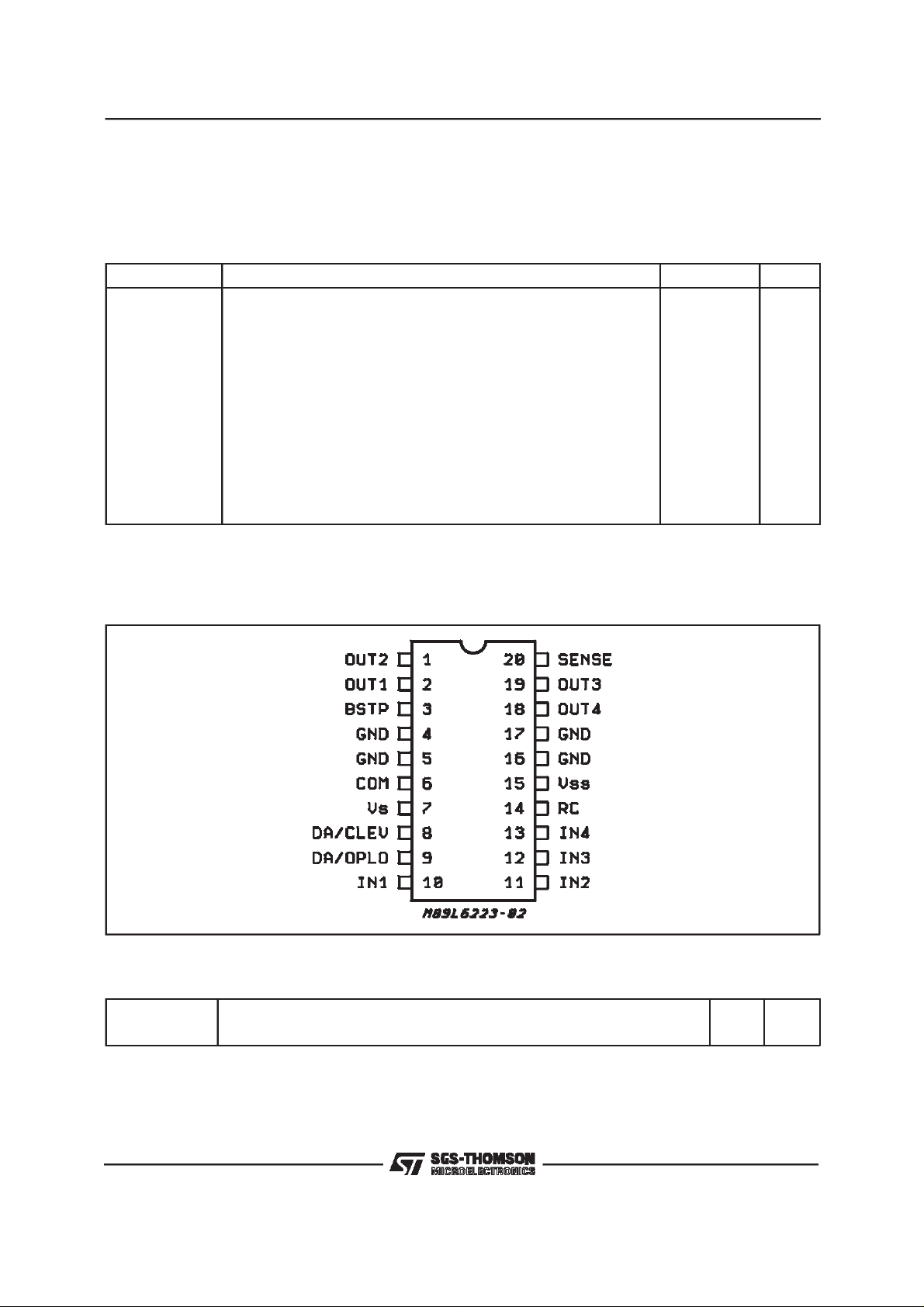

PIN CONNECTION

Logic supply 7 V

Supply voltage 50 V

Logic input voltage (*) – 0.3V to V

Output voltage 100 V

Output peak voltage (tpk = 5µs,10% d.c.) 125 V

Output sink peak current d.c. 10% t(on) = 10µs3A

Output source peak current d.c. 10%,t(on) = 10µs6A

Total power dissipation: T

=90°C 4.3 W

pins

=70°C (**) 2 W

T

amb

Sensing voltage – 1V to V

Storage and junction temperature – 40 to 150 °C

( topwiew )

SS

SS

THERMAL DATA

R

thj-pins

R

thj-amb

2/33

Thermal Resistance Junction-pins Max 14 °C/W

Thermal Resistance Junction-ambient Max 60

C/W

°

Page 3

PIN DESCRIPTION

No. Name Function

L6223

1,2

18,19

OUT2,OUT1

OUT4,OUT3

Outputs for motor windings.

3 BSTP A bootstrap capacitor connected between this pin and COM will

generate the internal overvoltage required for driving the gate of the

upper DMOS.

6 COM Output for common wire of motor.

4,5

GND Common ground. Also provides heatsinking to PCB.

16,17

7V

S

Power supply

8 DA/CLEV Digital input.

1) In PROGRAM MODE,operates in XOR withDA/OPLO to load data

into 6-bit shift register.

2) In OPERATING MODE,works with the otherdigital inputs to reduce

the current level (see Table 2 and Table 3).

9 DA/OPLO Digital input.

1) In PROGRAM MODE, operates in XOR with DA/CLEV to load data

into 6-bit shift register.

2) In OPERATING MODE,selects current control method: open loop(H)

or closed loop (L).

10,11

12,13

IN1,IN2

IN3,IN4

Digital inputs. When all inputs are low level,the device is in

PROGRAMMING MODE.

In OPERATING MODE:

1) FULLMODE - IN1 to IN4 drive the motor phases.

A previous programming is requested.

2) SIMPLIFIEDMODE - IN1 and IN2 drive the phases,IN3 is

ENABLE, IN4 works with DA/CLEV to enable the reduce current

level. Previous programming not needed.

14 RC Input for external RC network. Defines the higher of two possible

chopping frequencies. If this pin is set to ground it will reset the IC.

15 V

SS

Logic supply.

20 SENSE Output for sense resistor.

3/33

Page 4

L6223

ELECTRICAL CHARACTERISTICS (Tj=25°C, VS= 42V,VSS=5V, externalRC network: R =18kΩ,

C = 3.3nF,unlessotherwise specified).

Symbol Parameter Test conditions Min Typ Max Unit

V

S

V

SS

I

S

Power Supply 9 32 46 V

Logic Supply 4.5 5 5.5 V

Power Supply Quiescent

Current

I

SS

Logic Supply Quiescent

Current

I

OL

V

rs

Output Leakage Curr. VO= 100V (Fig. 1) 1 mA

Reset Threshold

Voltage (Pin 14)

T

BOOT

Bootstrap Refresh Pulse C

SINK MOS

R

DS(ON)

ON Resistance (Fig. 2a and Fig. 3) 1.2 Ω

SOURCEMOS

R

DS(ON)

ON Resistance (Fig. 2b and Fig. 3) 0.7 Ω

CURRENT CONTROL SECTION

IN1, IN2, IN3, IN4 = L

24mA

RC = 0V DA/CLEV = L

DA/OPLO = L

IN1, IN2, IN3, IN4 = L

14 20 mA

RC = 0V DA/CLEV = L

DA/OPLO = L

= 10nF 3 5 µs

BOOT

0.9 V

V

ref

f

(OSC)

t

(dis)

R

int

T

W

LOGICLEVELS

V

(IN)L

V

(IN)H

4/33

Internal Reference Volt. DA/CLEV = L; IN4 = H

I

= 100% nominal value

O

0.475 0.5 0.525 V

Oscillator Frequency (Fig. 20) 18 20 22 KHz

RC Network Discharge

Time (t

ON

min)

Internal Discharge Resistor

(Fig. 20) 2.3 3 4.3 µs

1.2 k

Ω

(pin 14)

Sense Filter Time Constant (Fig. 4) 1 1.4 2.3 µs

Input Low Voltage –0.3 0.8 V

Input High Voltage 2.4 V

SS

V

Page 5

ELECTRICAL CHARACTERISTICS (Continued)

Symbol Parameter Test conditions Min Typ Max Unit

SWITCHINGTIMING

L6223

t2, t4 Fall/Rise Time (IN1, 2, 3, 4) R

t1, t3 Input-Output Delay

t

dPWM

(IN1, 2, 3, 4)

Close Loop PWM

Control Delay

=39Ω(Fig. 5)

(load)

Pure Resistive Load to V

R

=39Ω(Fig. 5)

(load)

Pure Resistive Load to V

(Fig. 4) Note 1 1 µs

S

S

250 ns

700 ns

PROGRAMMING TIMING

t1 Loading Time (Fig. 6) 1.7 µs

t2 Protection Time (Fig. 6) Note 2 0.2 µs

t3 Data Set-up (Fig. 6) 0 ns

t4 Data Hold (Fig. 6) 1.6

t5 Setting Time (Fig. 6) 200 ns

Note 1) Upper DMOS turn ON delay when the signal is applied at the input comparator (point A in Fig. 4).

Note 2) Internal clock pulse isgenerated only if IN1...IN4 stay Low for almost 0.2 µs. This delay avoids undesirable programmings.

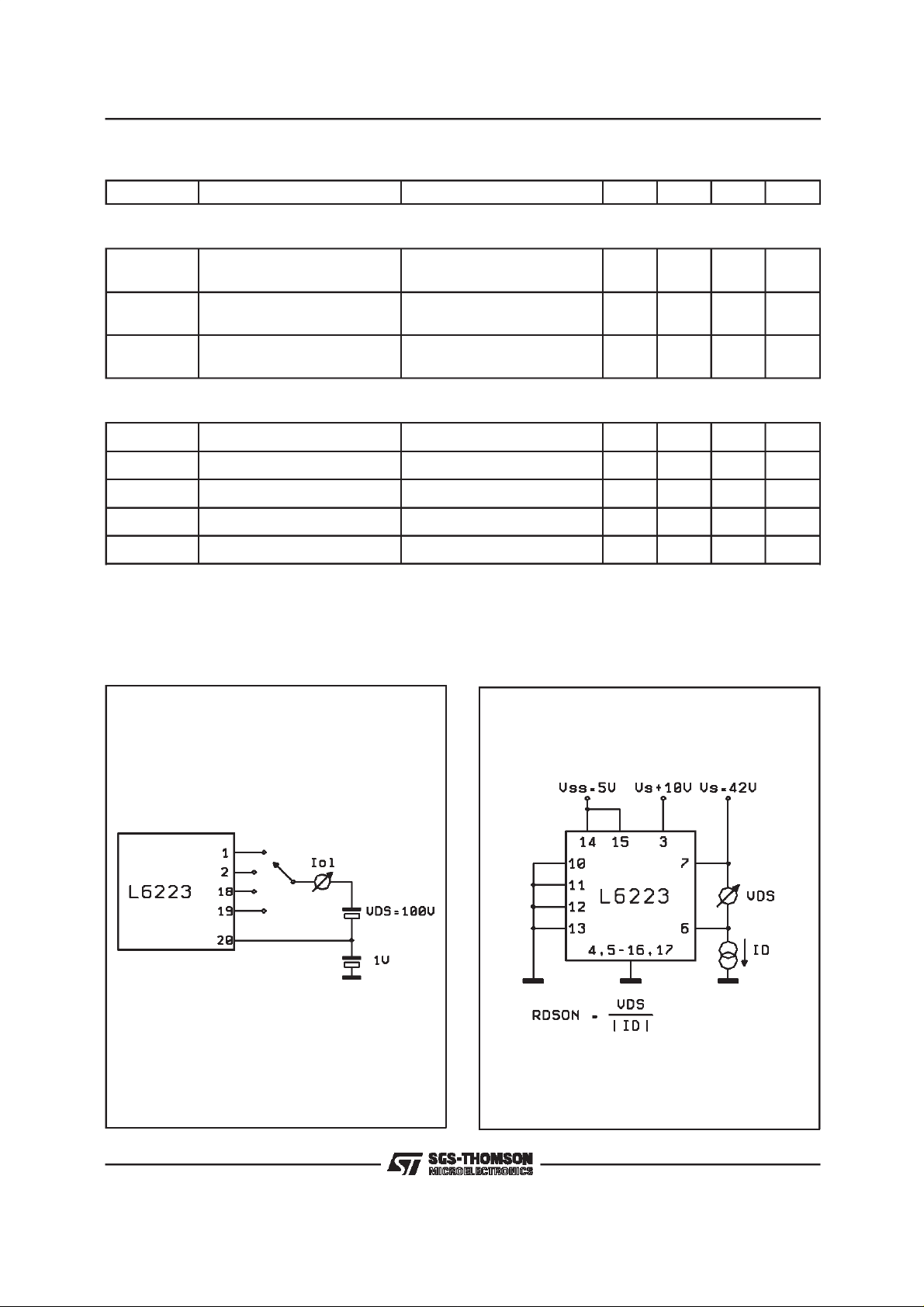

Figure1:

Outputleakage I

Test Circuit

OL

Figure2a:

Source Output DMOS R

DS(ON)

Circuit

µ

Test

s

5/33

Page 6

L6223

Figure2b:

Figure4:

SinkOutput DMOSR

DS(ON)

Test Circuit

SenseFilterRCTimeConstantandPWM

ClosedLoop control Circuit

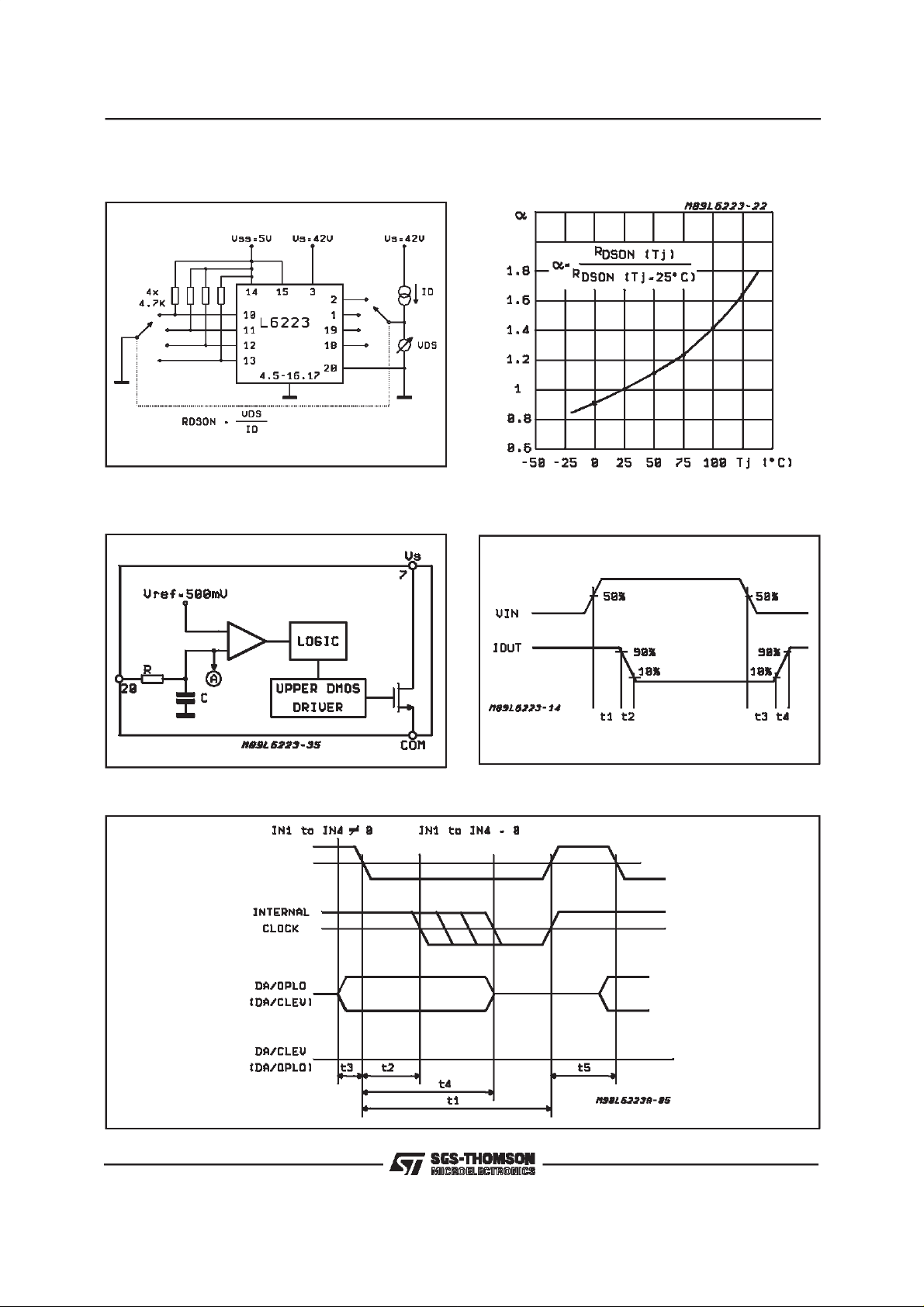

Figure3:

Figure5:

Typical normalized R

DS(ON)

vs. Junction

temperature

OutputSink Current Delay vs Input

Control

Figure6:

6/33

ProgrammingTiming Diagram(see Block Diagram)

Page 7

L6223

BLOCKDIAGRAM DESCRIPTION

InputLogic

Decodes the input signals IN1, IN2, IN3, IN4,

DA/OPLO, and DA/CLEV for programming the

device and driving the motor. The six inputs are

CMOS compatible and can interface directly with

a microprocessor.

PredriverStages

Drive the gates of the five DMOS. They interface

the power section with the logic section. The internal inhibit, when activated, disables the power

section. The reset initializes the shift register and

disables the power section.

6 bit Shift Register

Internal memory which defines the working configuration of the device along with the input signals.

Current Control

When selected with the input DA/OPLO = L

(Closed Loop), it will maintain a constant output

current level by chopping. The value of the reference voltage, which is compared to the sense

voltage, is given by the Ref Block. The chopping

frequencydepends on bit C4.

Ref Block

Defines the current chopping level according to

bits C0 and C1 and the inputsignals.

Fixed on Time

When selected with DA/OPLO = H, it will define

accordingto bits C2 and C3 the chopping duty cycle for the Open Loop mode. The chopping frequencyis fixed.

Oscillator

Provides the clock setting the S/R FLIP-FLOP

that turn ON/OFF the upper DMOS (Fig. 22). The

higher operative chopping frequencyis defined by

the external RC network (typically 20KHz). At the

phase change a syncronous clock pulse is generated

Reset Logic Block

Generates the reset signal for the logic at power

on and disables the outputs. The reset can also

be generated externally by setting the RC pin to

less that 0.9V.

ThermalProtection

Disables the power section in case of over temperaturecondition.

Charge Pump

Along with an external bootstrap capacitor connected between the BSTP and COM pins, this

block generates the internal over voltage required

to drive the upper DMOS on.

PowerOutput

Driven by the Predriver Stages, it supplies the

power for the motor windings.

CIRCUIT OPERATION

The five N DMOS transistors of the output stage

drive the unipolar motor windings, controlling the

current by chopping. In particular, the four Low

side (OUT1, OUT2, OUT3, OUT4) switch the

phase configurations, and the High side DMOS

(COM)is for chopping control.

For this transistor a charge pump circuit provides

its necessarygate drive over voltage.

The microprocessor outputs are interfaced with

the L6223 output stages through the input logic

block. This block also protects the devicefrom microprocessor output errors and failures from the

power section back to the microprocessor outputs. The six digital inputs IN1, IN2, IN3, IN4,

DA/CLEV, DA/OPLO, are decoded for motor control and rotation when in ”Operating mode” and

used for the internal six Bit memory programming

when in ”ProgrammingMode”.

Table 1 shows the condition that selects these

devicestatus. The programmingof the internal six

bit memory setsoperative conditionssuch as:

•PWM CURRENT LEVELS

•CHOPPINGFREQUENCY

•LOGICIN/OUT DECONDING

This memory works like a shift register.Each bit is

introduced serially by decoding the IN1, IN2, IN3,

IN4 low status for the internal clock pulse generation and by the DA/CLEV DA/OPLO, inputs in

exor, as data in.

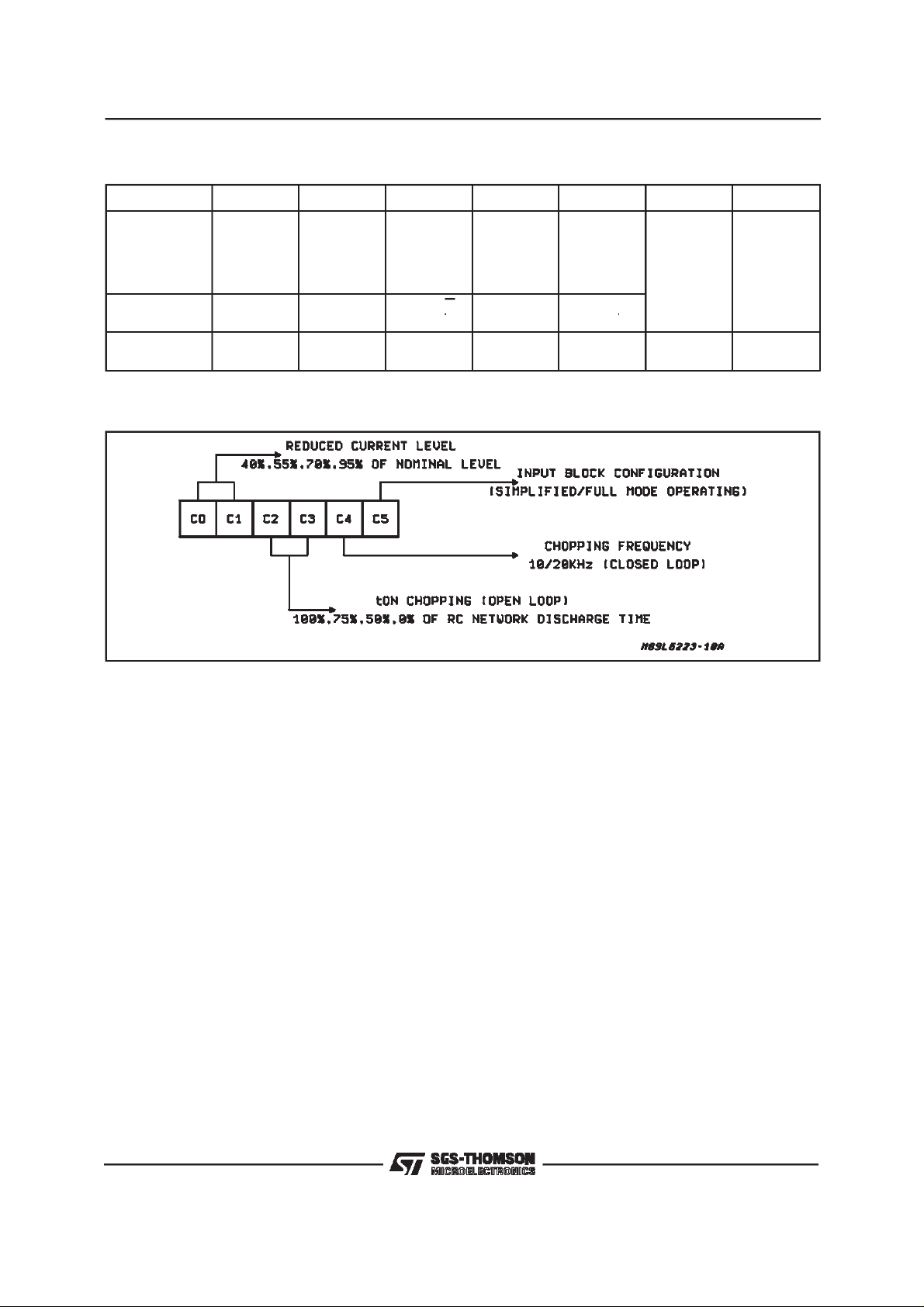

Figure 7 shows the six bit meaning.

In theoperating mode two different input drive are

possible. In SIMPLIFIEDOPERATING MODE the

IC needs few logic wire for the motor rotation, but

only the full step driving sequence can be performed.

7/33

Page 8

L6223

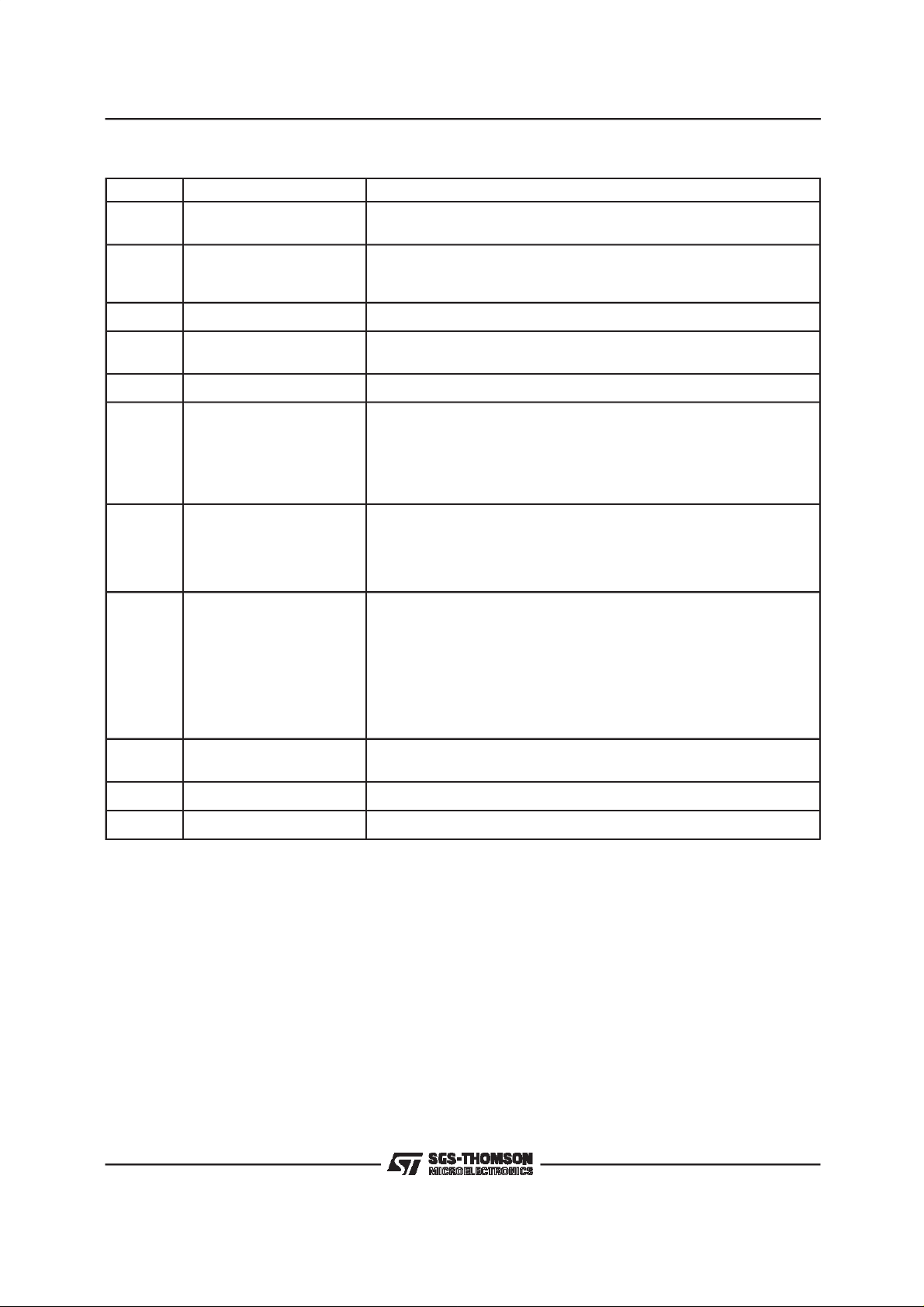

Table 1

Device status Bit C5 IN1 IN2 IN3 IN4 DA/CLEV DA/OPLO

Simplified

mode

operating

Full mode

operating

Programming

mode

Figure7:

L

H

XLLLL

Phase A

Driver

Phase A Phase A

Phase B

Driver

driver

InternalSix-Bit Shift Register Bit Functions

Enable

Phase B

driver

Alternative

Current

Reduction

”LOW”

Phase B

driver

Current

Reductio

Active

”HIGH”

serial

data in

Open/Closed

Loop current

control

serial

data in

CIRCUIT OPERATION

(continued)

The FULL OPERATING MODE permits all the

driving possibilities.The 4 low side DMOS transistors are drived directly by the 4 inputs IN1, IN2,

IN3, IN4 which define directly the phases configuration. The chopping of the motor current can be

in open loop or in close loop. When in open loop

(fixed on-time block) the DA/OPLO pin is High

and the motor current is not controlled but it

mostly depends from the bits C2 nd C3. When in

close loop the DA/OPLO is Low and the output

current is controlled at a constant value defined

by the internal reference and by the sensing resistor value. The internal reference depends by

the programming bits C0, C1, and by the input

configurations.During the power on sequencethe

reset circuitry prevents current spikes disabling

the outputsand by resettingthe memory.

Power Section

The basic concept for the current control is explained by examining the winding pair phase A

(MA) in Figure 24. With Q5 = ON, Q2 = OFF the

current rises until R

equals the comparator

SIP

thresholdvalue. The comparatoroutput resets the

8/33

F/F and Q5 switches off. In this condition the current decay path begins as shown in Figure 25.

The current value becomesI

/2, according to the

p

double number of turns interested. In order to reduce the dissipation, Q2 is also driven on. Q5 remains off (PWM off time) up to a new clock pulse

sets again the F/F.The winding current behaviour

is shown in Figure 26.

Since during PWM off time the current value is

half that of the on time and since in a typical application Toff >>Ton, the device dissipation is further reduced.

The five DMOS transistors are connected to the

”predriver stages” block, that drives the DMOS

gates, and interfaces them to the internal input

logic. The ”charge pump” provides correct voltage

for Q5 UPPER DMOS gate drive by using the external bootstrapcapacitor.

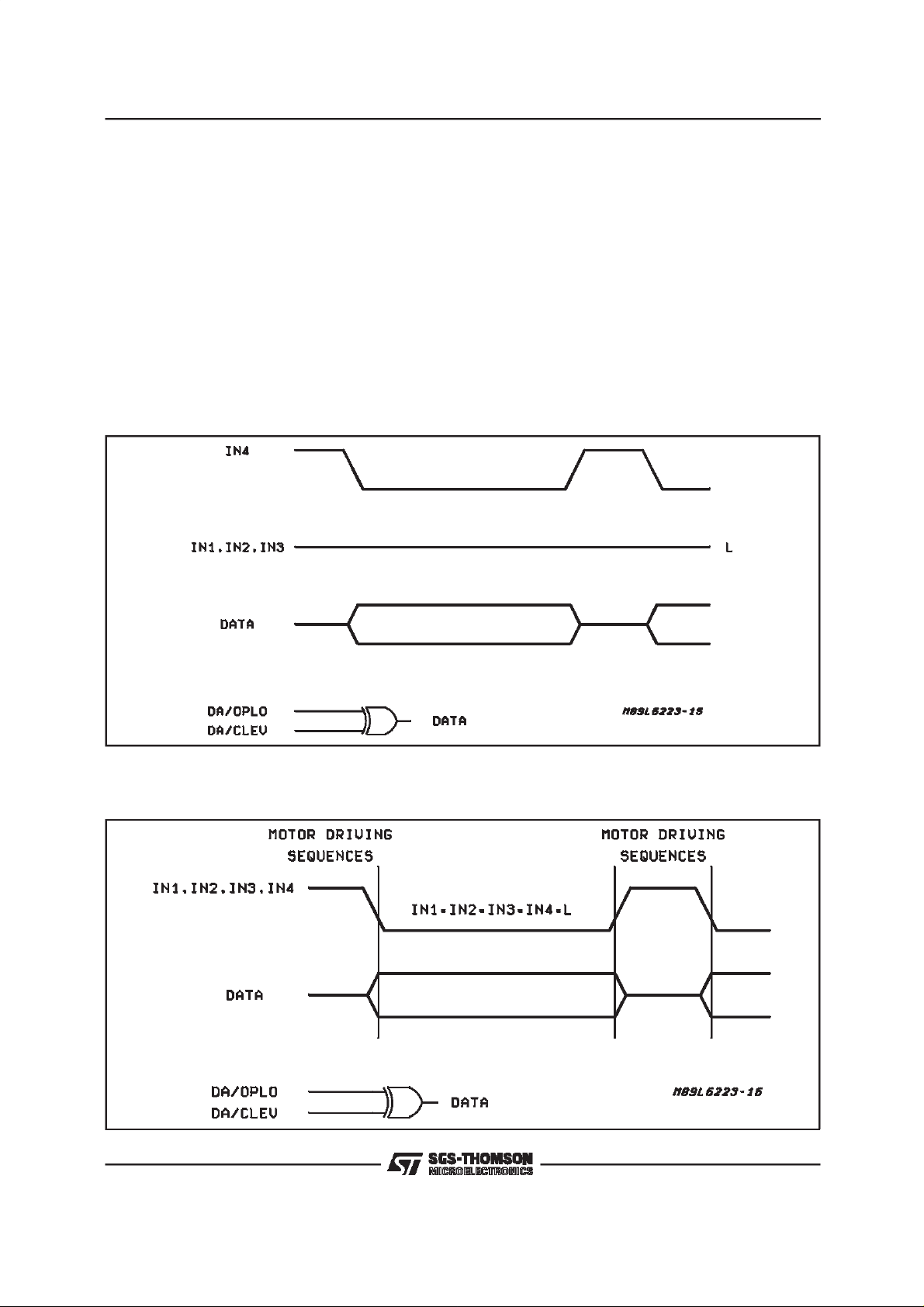

ProgrammingMode

The Programming Mode is defined by the inputs

IN1=IN2=IN3=IN4=Low. When in PROGRAMMING MODE the outputs are disabled. The waveform shown in Fig. 8 represents one possible tim-

Page 9

L6223

ing diagram for programming. When the inputs

IN1...IN4 are together Low a clock pulse is generated internally which clocks a data bit into the

shift register. If the time interval during which all

four inputs are Low is less than 0.2µs, no clocks

pulse in generated thus preventing undesirable

programming. To generateanother clock pulse at

least one of the four inputs must first go High and

then Low again. The first bit isloaded into C0 and

after 6 clock pulse it will be in the C5 posistion.

Two programming technique are suggested. The

first (Fig. 8) uses IN4 in such a way that the

Figure 8:

Wavefor mforprogrammi ng:the outputis disabledduringall theprogram mingduration(seeTable 4).

power section is disabled the total programming

time (the carriage of the 6 programmingbits). Fig.

9 shows another technique:the motor driving signals at the inputsIN1...IN4 are interrupted switching IN1...IN4 Low to carry a single bit. This permits the motor to be enabled for the 50% of total

programming time. During the motor rotation it’s

suggested to program the device immediately after the motor phase change: this make neglectable the motor driving discontinuity due to the device programming.

Figure9: Waveform for programming:theoutput is disabled only whenall four inputs are atthe low level.

9/33

Page 10

L6223

OperatingMode

The bit C5 defines the two available input configurations.

C5 = H: FULL MODE OPERATING

The digital inputshave the following functions:

•

IN1drives OUT1

•

IN2drives OUT2

• IN3drives OUT3

The output DMOS is ON

when the corrisponding input is low

• IN4drives OUT4

• DA/CLEVenablesthe current reduction

(seeTab 2)

•

DA/OPLOselectsthe motor current control

mode(open or closeloop).

Since each input drives one phase of the motor it

is possible to work either in Half Step or in Full

Step mode. DA/OPLO defines the current control

modeas follow:

– DA/OPLO = H open loop

– DA/OPLO = L closedloop

The reduced currentlevel is enabledby the inputs

IN1, IN2, IN3, IN4 or by DA/CLEV (Tab. 2). The

reduced current value dependsfrom the bits C0,

C1 (TAB. 5). The outputs are disabled when the

inputs are in a prohibited state (Tab. 4).

C5 = L, SIMPLIFIED MODEOPERATING

When in SIMPLIFIEDMODE OPERATINGthe in-

puts assumethe following functions:

•IN1 drivesPhase A

•IN2 drivesPhase B

•

IN3 ENABLE input (activeHigh)

•

IN4 enables the reduced current(Tab. 3)

•DA/CLEVenables the reduced current (Tab. 3)

• DA/OPLO selects the motor current control

mode

The SIMPLIFIED MODE OPERATING configura-

tion does not allow the drive of a unipolar motor in

Half step.

The signal DA/OPLO functions as in FULL Mode

Operation. When the current control is implemented in closed loop, the reduced current level

is enabled by the inputs IN4, DA/CLEV (Tab. 3).

The current reduction depends from the bits C0,

C1 (Tab. 5).

Open/ClosedLoopMotor Current Control

The logic input DA/OPLO selects the current control mode as previously seen. When in open loop,

the chopping frequency is that one as defined by

the external RC network. In open loop are available three different t(ON), dependingfrom the bits

C2, C3 (Tab. 6), as a percentage of the RC dischargetime t

(dis)

.

When in closed loop two different chopping frequencies are selectable by means of the bit C4

(Tab. 7). The higher is defined by the external RC

network. The other one is exactely the half. In

closed loop 5 different current levels are available: the nominal current level and four reduced

current levels (Tab. 5). The nominal current level

is set by an internal reference voltage of 0.5V.

The configuration of bits C0, C1 sets the reference voltage to a pecentageof the nominal value.

TRUTH TABLES

(L = Low; H = High; X = don’t

care)

Table 2

IN1 IN2 IN3 IN4 DA/CLEV C/R*

HHXX X H

XXHH X H

HHHH X H

XXXX H H

*) C/R = H,reduced current

Table 3

IN4 DA/CLEV C/R

LXH*

XHH*

H L L**

*) Reducedcurrent **) Nominal current

Table 4

IN1 IN2 IN3 IN4 Output Stage

L L X X DISABLED

X X L L DISABLED

Table 5

C0 C1 Reduced Current Level (*)

L L 40%

L H 50%

H L 70%

H H 85%

*) Nominal level percentage

10/33

Page 11

L6223

Table 6

C2 C3 t

LL75

LH50

H L 100

H H Output Disabled

(ON)/t(OSC)

*

Table 7

C4 Chopping Frequency

L 20kHz

H 10kHz

*) RC discharge time percentage

L6223 Operating Configuration vs. 6bits Shift Register Programming

(External RC network: R =

18kΩ C = 3,3nF)

SHIFT REGISTER bITS

Nr C5 C4 C3 C2 C1 C0

0 0 0 0 0 0 0 S 20 75 40%

1 0 0 0 0 0 1 S 20 75 70%

2 0 0 0 0 1 0 S 20 75 55%

3 0 0 0 0 1 1 S 20 75 85%

4 0 0 0 1 0 0 S 20 100 40%

5 0 0 0 1 0 1 S 20 100 70%

6 0 0 0 1 1 0 S 20 100 55%

7 0 0 0 1 1 1 S 20 100 85%

8 0 0 1 0 0 0 S 20 50 40%

9 0 0 1 0 0 1 S 20 50 70%

10 0 0 1 0 1 0 S 20 50 55%

11 0 0 1 0 1 1 S 20 50 85%

12 0 0 1 1 0 0 S 20 DISABLED 40%

13 0 0 1 1 0 1 S 20 DISABLED 70%

14 0 0 1 1 1 0 S 20 DISABLED 55%

15 0 0 1 1 1 1 S 20 DISABLED 85%

16 0 1 0 0 0 0 S 10 75 40%

17 0 1 0 0 0 1 S 10 75 70%

18 0 1 0 0 1 0 S 10 75 55%

19 0 1 0 0 1 1 S 10 75 85%

20 0 1 0 1 0 0 S 10 100 40%

21 0 1 0 1 0 1 S 10 100 70%

22 0 1 0 1 1 0 S 10 100 55%

23 0 1 0 1 1 1 S 10 100 85%

24 0 1 1 0 0 0 S 10 50 40%

25 0 1 1 0 0 1 S 10 50 70%

26 0 1 1 0 1 0 S 10 50 55%

27 0 1 1 0 1 1 S 10 50 85%

28 0 1 1 1 0 0 S 10 DISABLED 40%

29 0 1 1 1 0 1 S 10 DISABLED 70%

30 0 1 1 1 1 0 S 10 DISABLED 55%

31 0 1 1 1 1 1 S 10 DISABLED 85%

32 1 0 0 0 0 0 F 20 75 40%

33 1 0 0 0 0 1 F 20 75 70%

34 1 0 0 0 1 0 F 20 75 55%

35 1 0 0 0 1 1 F 20 75 85%

36 1 0 0 1 0 0 F 20 100 40%

37 1 0 0 1 0 1 F 20 100 70%

38 1 0 0 1 1 0 F 20 100 55%

Full/Simpl.

Operation

Mode

Close Loop

Frequency

(kHz)

Open Loop

t

[%]

(ON)

Close Loop

Current

Level [%]

11/33

Page 12

L6223

L6223 OperatingConfiguration vs. 6bits Shift Register Programming

SHIFT REGISTER bITS

Nr C5 C4 C3 C2 C1 C0

39 1 0 0 1 1 1 F 20 100 85%

40 1 0 1 0 0 0 F 20 50 40%

41 1 0 1 0 0 1 F 20 50 70%

42 1 0 1 0 1 0 F 20 50 55%

43 1 0 1 0 1 1 F 20 50 85%

44 1 0 1 1 0 0 F 20 DISABLED 40%

45 1 0 1 1 0 1 F 20 DISABLED 70%

46 1 0 1 1 1 0 F 20 DISABLED 55%

47 1 0 1 1 1 1 F 20 DISABLED 85%

48 1 1 0 0 0 0 F 10 75 40%

49 1 1 0 0 0 1 F 10 75 70%

50 1 1 0 0 1 0 F 10 75 55%

51 1 1 0 0 1 1 F 10 75 85%

52 1 1 0 1 0 0 F 10 100 40%

53 1 1 0 1 0 1 F 10 100 70%

54 1 1 0 1 1 0 F 10 100 55%

55 1 1 0 1 1 1 F 10 100 85%

56 1 1 1 0 0 0 F 10 50 40%

57 1 1 1 0 0 1 F 10 50 70%

58 1 1 1 0 1 0 F 10 50 55%

59 1 1 1 0 1 1 F 10 50 85%

60 1 1 1 1 0 0 F 10 DISABLED 40%

61 1 1 1 1 0 1 F 10 DISABLED 70%

62 1 1 1 1 1 0 F 10 DISABLED 55%

63 1 1 1 1 1 1 F 10 DISABLED 85%

Full/Simpl.

Operation

Mode

Close Loop

Frequency

(kHz)

(Continued)

Open Loop

t

[%]

(ON)

Close Loop

Current

Level [%]

APPLICATION INFORMATION

SingleDevice Application

Figure 10 shows a typical Single Device Application. With the shown external RC network, the

higher choppingfrequencyis 20 kHz.

In the figure 11, 12 and 13 are shown the waveforms required to drive the motor in Half/Full Step

in FULL MODE OPERATING (FMO) and SIMPLIFIED MODE OPERATING (SMO). The sense resistor defines the total motor current. This means

that when two phases are ON, the sense current

is two times the phase current. In this case the

sense resistor value is R

S

=(V

ref

/2Ip), where V

ref

is the reference voltage and IPthe phase current.

We have supposed that the phase current is of

the same intensity in the two phases. When only

one phase in ON, the current flowing in the sensing resistor is the phase current: this occurs in

half step driving mode. The Figures 14 and 15

show the envelope of the sensing voltage in full

and half step respectively.

When current imbalance is not considered, this

12/33

envelope represents the current level 2I

control-

p

led by the chopping when L6223 is working at

100% of current; in full step this level is constant

while in half step two different levels are present

(Figure 15). Actually, in full step two phases are

alwaysON, and the chopping current levelcan be

changed only by the controller. In half step when

two phases are ON and L6223 is working at

nominal current level (2I

), but when only one

p

phase is ON, L6223 selects automatically the reduced current. This level depends upon the programming bits. In Figure 15 the higher level represents the chopping at nominal value (two

phases ON), the lower level the chopping at the

reduced current (one phase ON). The negative

peak shown in the figures represents the fast current recirculationat the phase change.

Fig. 15 shows also what happens when the reduced current level selected is at 70% of the

nominalvalue. The motor torque is proportionalto

the vectorial sum of the phase currents: it can be

seen that the unipolar stepper motor control actuated by L6223 in half step is at constant torque

but not at constat current.

Page 13

L6223

Figure10:

TypicalApplicationCircuitusing a singledevice:the max peakcurrent capabilityis of 1A/phase

=0.25Ω)

(R

S

Figure11:

Inputsfor Half Stepdrive, single device

FMO.

Figure13: Inputsfor Full Step drive singledevice SMO.

Figure12:

Inputsfor Full Step drive, single device

FMO.

13/33

Page 14

L6223

Figure14:

Peakcurrent 2I

crossingthe sense resistorRSin Full step drive. The phase sequenceCCW

p

is: AB →BA →AB → BA (4 Full Steps, 2 phase ON)

Figure15: Peakcurrent(2I

resistorR

S

/2phaseON)andreducedpeakcurrent(1.4Ip/1phaseON)crossingthesense

p

in Halfstep drive. The phasesequence is: A→AB

→ B →

BA→A→AB→B→BA

(8 Half Steps,1 phaseON and 2 phasesON alternatively)

Figure 16: Typical Application Circuit using 2 devices (Paralleled configuration): the max peak current

capabilityis of 2A/phase(R

= 0.25Ω)

S

14/33

Page 15

L6223

Dual Device Application

Fig. 16 shows how to drive one unipolar stepper

motor by means of two L6223 Each device drives

one phase of the motor. This permits doubling of

the phase current. Since in this configuration

each sense resistor controls the phasecurrent (in

Single only one sense resistor controls the total

=(V

motor current), we have: R

S

/Ip) where V

ref

ref

is the voltage reference and Ip the phase current

in the Dual that is coincident with the chopping

Figure17: Inputsfor Half Step drivedual device SMO.

current. The configuration in the figure shows the

only possible way to parallel two L6223. The use

of another configuration can cause serious demage to the IC during the programming. The

waveforms required to drive the motor in half/full

step are shown in Fig. 17 and 18: as it can be

seen, the two L6223 are in SIMPLIFIED MODE

OPERATING configuration. The half step drive

can be achieved by driving the inputs IN3 which

are ENABLEinputs.

Figure18:

Inputsfor Full Step drive singledevice SMO.

Dot Matrix Printer MotorDriver

Fig. 19 shows how to drive the paper feed and

the carriage motors by means of 3 L6223 using a

very low wire number. The carriage motor is

driven by two paralleled L6223, the paper feed

motor, which requires a lower current, uses one

L6223. The three ICs are working in SIMPLIFIED

MODE OPERATING. The inputs IN1-IN2, IN3 are

driven as previously seen (Single and Dual Device configuration). The inputs IN4 and DA/CLEV

are grounded so that the ICs work in reducedcurrent levels. This means L6223 can select seven

current levels through programming: four in

closed loop and three in open loop. The input

DA/OPLO is used to load the programming data;

only the device in PROGRAMMING MODE is programmed. The two paralleled L6223 can deliver

up to 2A/phasewhilethe single L6223, 1A/phase.

15/33

Page 16

L6223

Figure19:

Dot MatrixPrinter Motor Driver schematicdiagram (See also fig. 10, 16).

ExternalRC Network (pin 14)

The external RC network provides the higher of

the two possible chopping frequencies. The discharge time of the capacitor represents the minimum t

is possible to select a smallert

available in closed loop. In open loop it

(ON)

, (see Fig. 20).

(ON)

The t

min defines the min current the IC can

(ON)

supply to the motor, as well as the protection

”window”. This window is necessary to mask the

spike generated at the beginning of each chopping period (see Fig. 21a).

Figure20: Oscillator waveformand timing.

The window must be large enough to mask this

spike, without penalizing excessively the min current control. The capacitor C mainly defines the

value of the window. The mathematical formulas

to calculatethe approximatevaluesare:

f

= 1/(0.84 • RC) for R > 10kΩ

(osc)

t

ON(min)=t(window)

for R

where R

= 1.2kΩ

in

is the resistor internal to the IC for the

in

= 0.84 • C •R • Rin/(R+Rin)

capacitordischarging.

16/33

Page 17

L6223

Figure21a:Relati ons hi pbetweencapacitordischar ge

oftheoscillator ,windowandsensingvoltage

Figure21b: Oscillatorbehaviourof the L6223 and

of theL6223 (simplifiedwaveforms).

The behaviour of the oscillator at each phase

change allows the L6223 to drive high speed

unipolarstepper motors.

This is the main functionaldifference between the

L6223 and the L6223 (see fig. 21b).

In the latter, the phase change starts only when

the clock pulse sets the F-F (Fig. 22) that is when

the capacitor voltage reaches the discharge

threshold.

As a result, a variable delay between the leading

edge of the input signal and the beginning of the

currentdecay to zero can be expected.

Because of that, driving high speedy stepper motors is produced a noisy beating between chopping frequencyand phase change rate.

In the L6223 as soon as the phase change is

driven by the inputs, the oscillator voltage Jumps

to its top level, a new discharge period is generated and the chopping transistor is switched ON

(Q5 in fig. 22). The advantages are a motor

phase change synchronous to the driving signal

and no beating for whatever rotation speed. By

setting pin 14 at a voltage equal or less than Vrs

= 0.9V, when the IC is normally supplied and the

oscillator is running, the 6 bit shift register is

quickly reset and the power outputs are disabled:

a delay of 700nsec max mustbe expected.

The use of this behaviour to reset the device at

the turn-on is not allowed; however the reset is

automatically provided by the Logic Supply Voltage crossing the threshold of 3.5V (typ.) both at

the turn-ONand at the turn-OFF.

Protection

The protection zeners on the outputs protect the

IC from overvoltage during chopping and phase

change. Actually, at the phase change, the outputs rise to a voltage equal to V

where V

is the power supply and Vmthe product

S

=2VS+Vm,

O

of the motor resistance Rm with the peak phase

current Ip. Vs is doubled because in the unipolar

motor we have two coupled phases connected in

series(phase A and A, B and B) for each of the

two windings of the motor (MA, MB see Fig. 22).

The leakageinductance,seen from the outputs of

the L6223, can generate an overvoltage higher

than V

. To protect the IC, the zeners must be

O

able to sustain a power of 400W for 1 microsec

and must be able to conduct at a voltage V

higher than V0=2V

s(max)+Vm

. It’s importantthat

during the transition, at the max operating ambient temperature, the zener conduction is guaranteed for a voltage lower than 125V (see Absolute

Max Ratings). The ST-BZWO4-85 satisfies this

requirement. The diode connected to the common protects this input from the undergounds due

to the leakage inductances and/or the imbalancing between the phase currents.

z

17/33

Page 18

L6223

Figure22:

Poveroutput configuration.

Use of the ProgrammingMode

A typical application of the L6223 requires driving

the motoraccording to Fig. 23a andFig. 23b.

Starting from t

tor is kept in stand-by;at time t

eration period that is completed at time t

and continuinguntil t1themo-

0=t5

beginsan accel-

1

. The

3

motor then is driven at a contant speed until t

when the speed is decelerated and is stopped at

t

for a new standbyperiod.

5=t0

During these events the L6223 can be programmed several times for different working

modes. The most important parameter is the current through the windings of the stepper: at the

time t

0;t1;t2;t3

and t4the current can be modified, for example, as it is shown in Fig. 23b. This

behaviour allows the best motion control and, at

the same time, optimizes efficency of the power

output block of the I. C.

But this is not the best in terms of performances

by programming:in fact, betweent

and t5thede-

1

vice can be programmed to work in Closed Loop

and to chop at half of the RC oscillator frequency

during the time t

to t4. In the stand-by condition

3

the I. C. can be programmed to work in Open

Loop mode where the current can be fixed by the

reduction of the minimum T

time (75% or 50%)

ON

defined by the dischargetime of the RC oscillator.

Of course in this way the current can be modified

by Supply Voltage changes; the same is not possible in Closed Loop operation where the device,

in order to keep the windings current constant,

modifies the T

at high V

. This is the reason why when the motor

S

is driven at a constant speed (t

time: wide at low VSand narrow

ON

to t4) with small

3

current and high Supply Voltage, it could become

necessary to program the lower chopping fre-

quency to allow a suitable T

width otherwise

ON

the current of the windings would go out of control.

The motion profile, shown in Fig. 23a can be obtained when preferred, with only two program

changes actuated while the motor is in stand-by.

The current becomes as shown in Fig. 23c. The

device can be programmed at t

55% (stand-by) and at t

1

for I

0=t5

= 70%: for both

motor

the actuations,the DA/CLEVis kept high to allow

the program change, while, by keeping it to zero

during t

and t4-t5, the current is automat-

1-t3

ically select as 100% (Fig. 23d). During t

current is reduced according to the percentage

programmedat the time t

.

1

Power dissipation (Simplified method of calculation).

Here below the Full Step Operating Mode is considered; in addition, the following working conditions have been taken up:

1) Constant speed rotation of the driven unipolar

stepperMotor.

Figure23: a,b) Speed profileand motorcurrent

controlchange for the best efficencyof the I.C.

c,d) Current control change by using DA/CLEV

input only, duringthe stand-byperiod.

,

4

for I

3-t4

motor

=

the

a

b

c

d

18/33

Page 19

L6223

2) Back EMF (BEMF) equal to 80% of its peak

during the phase change and equal to 50% of its

peak during the choppingperiod.

3) Constant slope of the current during t

ON,tOFF

and for power calculation during the phase

change (See t

in Fig. 27).

1

4) Current imbalancesupposed to be zero.

5) Current ripple during the chopping neglegible.

As was previously stated, the current chopping is

obtained by means of one PWM Loop that controls the charge time t

of the inductance of the

ON

windings, A and B for example in fig.22.

This time starts each clock pulse and stops when

Q5 is switched OFF becauseof thecondition:

=2RSIp.

V

ref

A factor 2 is required because the single sensing

resistor R

is crossedby the peak current Ipflow-

S

ing through each of the two energized windings

(A of MA; B of MB).

This configuration can produce an imbalance between the two peak currents because at the

phase change the BEMF of one winding (MA) can

be out of phase with respect to the BEMF of the

other one (MB); in addition, an imbalance may

also occur at the phase change when the Power

Supply Voltage selected is too low and/or when

one motor is drivenwith too large Lm/Rm ratio.

Neverthelessin most of the applications the dissipated power is not increased and there is no significant change in torque.

During t

phase A (seg. Fig. 24), is defined by V

VON≅ VS-R

where R

the current Ip, flowing through the

ON

Ip - BEMF

tot

tot=RS+Rm+RDSON tot

ON

in which Rmis the winding resistance of the

phase A and R

Q1 and Q5: R

DSON tot

m

is the sum of the R

DSON

of

and BEMF are not shown on the

Figure 24.

At the end of t

and jumps to I

ductance becomes four times L

, the current starts its slow decay

ON

/2 (see Fig. 25) since the total in-

p

(perfect cou-

m

pling) that is the inductanceof the phase A alone.

The recirculationtime t

V

≅ 2BEMF+ IP(Rm+R

OFF

since R

DSONQ1=RDSONOQ2

is defined by:

OFF

DSONQ1

.

)

The current through Q1 is shown in Fig. 26: the

current ripple is on lp and I

/2 during tONand t

P

OFF

respectively.It can be obtained the Duty Cycle:

DC = V

since 2V

/ (2VON+V

OFF

ONtON=VOFFtOFF

OFF

)

The slow decay allows a small current ripple as

earlier It is considered equal to zero. The current

through the phases A and B can be seen in Fig.

27 where the InA and InB signals (see Fig. 22)

are shown as well.

These two signals are 90° out of phase with each

other and they are 180° out of phase with the corresponding inputs of the IC. In A and In B are not

shownin the Figure.

During the time Tp the motor goes through four

steps and the rotation speed V

(step/sec) can

rot

be given by:

V

= 4/Tp.

rot

By consideringwhat was stated above, the following can be applied:

1) Dissipated power by the 4 sink power DMOS

(Q1to Q4).

PdL ≅

4R

DSONQ1

T

P

2

I

p

T

T

1

+

3

2

1 +

p

+

T

1

DC

2

2) Dissipated power by Q5 (PdH).

PdH ≅ 4R

DSONQ5

2

DC

I

p

T

4

1

+

− 4DC

T

3

p

wherethe phase change duration is:

log

−

1

e

Vs− 1.6 BEMF + R

2R

totIp

L

m

= −

T

1

R

tot

tot

I

P

The chopping produces little power dissipation.

It’s value can be approximatedby:

-3

3) Pdch ≅ 8 ⋅ 10

VsI

p

The sum of 1) + 2) + 3) gives the dissipated

power of the output stage. To obtain the total

amount of dissipated power it’s necessary to include the power dissipation produced by the quiescent currents I

(from the power stage) and I

S

SS

(fromthe Logicalcircuits):

P

do=VSIS+VSSISS

consideringI

P

= PdL+ PdH + Pdch+ Pdo

tot

S

,

constatversusVS. Finally:

Example

SupplyVoltage V

Logic Voltage V

Peak current (per phase)I

Motorresistance R

Motorinductance L

Rotationspeed V

=36V

S

=5V

SS

= 0.7A

p

=9Ω

m

=6mH atT

m

= 500step/sec(const)

rot

amb

=50°C

Peak of the BEMF BEMF = 1 Vp

Max ambient temperature T

Max junction temperature T

=50°C

amb

=125°C

j

Fromthe ElectricalCharacteristicsof the L6223

(Typicalvalue):

InternalReference VoltageV

SinkDMOS R

DSON

SourceDMOSR

R

DSON

DSONRDSON

PowerSupply Current I

Logic Supply Current I

= 0.5V

ref

L = 1.2Ω at

H = 0.7Ω Tj= 25°C

= 4 mA Worst

S

= 20 mA Case

SS

FromFig. 3 (see pag. 6) the following is obtained:

≅

1.65 at Tj = 125°C.

α

TheDMOS ON-Resistancesbecome(worst case):

19/33

Page 20

L6223

R

R

R

R

V

V

DC= 15.6%

T

T

PdL = 1.1W

PdH = 0.4W

Pdch = 0.20W

Pdo = 0.24W

At last:

P

The neededthermalresistance betweenjunction

and ambient mustbe equal to:

L=α1.2= 2Ω

DSON

H=α0.7 = 1.15Ω

DSON

= 0.36Ω

S

= 12.5Ω

tot

= 26.24V (During the chopping)

ON

= 9.7 (Duringthe chopping)

OFF

=8 msec

p

=250µs (During the phase change)

1

= 1.94W

tot

T

thj−amb

=

P

tot

R

The worst case here considered requires an

jmasc−Tambmasc

≅

39°C/W

heatsink of 25°C/W. The calculation of the power

dissipation by considering the current imbalance

and by simulating a typical motion needed to

carry the head of a printer for example, becomes

full of difficulties. The use of the Personal Computer is helpful in such a case: few examples are

shownfromFig. 28ab untilFig. 31 ab.

Each figure shows the Application Datas and one

diagram where the Total Dissipated Power versus

the peak of themotor current is plotted.

A max Ambient temperature of 70°C and a max

junction temperature of 150°C have been considered for a few applications using one single device and a dual device configuration to drive one

Figure24: Motor current Ip during t

Figure25:

Slow decay of the motor currentI

(phaseMA; Q5 and RSsre common whit the phase MB).

ON

/2 during t

p

(phaseMA).

off

20/33

Page 21

L6223

steppermotor in the Full Step Mode.

The calculations consider three different conditions of heatsinking: the package with minimum

dissipating copper area on the p.c.b. (R

thj-amb

55°C); the copper side of 6 cm

40°C/W - See Fig. 34) and the additional heatsink

(R

thj-amb

=30°C/W).

=

Figure26: Phase current waveformduring chopping: the current decayduring t

OFF

is halved.

2

(R

thj-amb

Figure 27: Simplifiedwaveformsof the currentthrough the phase A (winding MA) and through the phase

B (winding MB). See also fig.22.

=

21/33

Page 22

L6223

Figure28a:

Single L6223 slow speed, ApplicationData.

Figure 28b: Total Power Dissipation. The vertical indicator tells us the max value of the current we can

supplyto the windings (Ip = 0.8A).The peakcurrentcorrespondingto the flat side ofeach of

the three shown trends is not allowed

22/33

Page 23

L6223

Figure29a:

Single L6223 high speed, ApplicationData.

Figure 29b: Total Power Dissipation.

23/33

Page 24

L6223

Figure30a: DualL6223 slow speed, Application Data.

Figure 30b:

Total Power Dissipation.

24/33

Page 25

Figure31a: DualL6223 high speed, Application Data.

L6223

Figure 31b:

Total Power Dissipation.

25/33

Page 26

L6223

Matchingthe L6223 with the motor.

For the correct design of the application the followingnotes must be considered.

* For low motor resistance and high supply volt-

age the L6223 minimum duty cycle may limit

the minimum current at a value higher than requested.

In this case we suggest to reduce the window

protection time changing the RC oscillator network. (See Fig. 21a and External RC Network).

* Only in single device application, for very low

motor resistance, a large current imbalance

may affect the correct motor rotation. Motor resistance value higher than 7 Ohm are generally

recommendedfor 35V PowerSupply.

* The correct motor winding execution is very im-

portant for the motor and the L6223 efficiency.

A simple test is the measurement of the stray

inductance between the central tap and the

ends shorted together of each winding. Theoretically the inductance would be zero; values

higherthan 50µH may show poor motor quality.

Computer Aided Development Board

An improvement in the application development

and in system debugging can be obtained by

meansof the PersonalComputer.

Interfacing the appliction with the PC, the motor

can be driven directly by this in real time operation. This permits the testing in very short time

and a lot of different motion configurations,during

application debugging and optimization. Moreover, by paralleling more application boards, an

efficientreliability test can be implemented.

The development board designed to drive L6223

in Single and Dual Device configuration is shown

in Fig. 32a-b. Fig. 33 is the corresponding electrical circuit. On the board are mounted three

L6223: two for the Dual Device configuration and

one for the Single Device. The three connectors

J1, J2, J3 allow the application board to be interfaced with the PC and to be paralleled with another one. The remaining connectors provide the

interface with the motor and the power and logic

supply. The ground area has been sized to act as

heatsink (35 micron thickness). When the copper

area is not sufficient to dissipate the heat an external heatsinkis required.

26/33

Page 27

Figure32a: L6223p.c.b. (componentsside).

L6223

27/33

Page 28

L6223

Figure32b:

L6223 p.c.b. (backside).

28/33

Page 29

L6223

Figure33:

L6223 Development Board schematicdiagram.

29/33

Page 30

L6223

Figure 34:

with two ”on board”square heatsink vs. side I.

R

th

Figure35: Transient thermal resistance for single pulses

Thermalcharacteristics.

The p.c.b. copper size needed for a definedthermal resistance between junction and ambient is

estimate the typical thermal resistance junction to

ambient for a single pulse of peak power and for

a repetetivepeak respectively.

shownin Fig. 34. Fig. 35 and Fig. 36 are useful to

30/33

Page 31

Figure 36: PeaktransientRth pulsewidth and DutyCycl e.

L6223

Notes on the p.c.b. design.

We recommend to observe the following layout

rules to avoid application problems associated

with ground loops and anomalous recirculation

currents. The by-pass capacitors for the power

and logic supply must to be kept as close to the

IC as possible.

It’s important to separate on the PCB board the

logic and the power grounds avoiding that

grounds traces of the logic signals cross the

ground traces of the power signals. The starpoint

grounding, the point of the board in which the

logic ground meets the power ground, should be

kept far enough away from where the power

ground traces terminate to ground (sense resistors and protection zener diodes traces). This

avoids interference with the logic signals. Be-

cause the IC uses the board as a heatsink the

dissipating copper area must be sized in accordance with the requiredvalue of R

thj-amb

. It’s important to provide a good filter for the logic supply,

especially for the resistor of the oscillator network. In addition, the capacitor ground of the RC

network must be as clean as possible. When the

ground is used also to heatsink, it is helpful to

use either a polistyrin capacitor or one with a low

temperature coefficient. The value of the bootstrap capacitor is not a critical parameter, nevertheless the use of a capacitor of 10nF±20% is

recommended. A non-inductive resistor is the

best way to implementthe sensing, but when that

is not possible, more metalfilm resistors of the

same value canbe paralleled.

31/33

Page 32

L6223

POWERDIP20 PACKAGEMECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.51 0.020

B 0.85 1.40 0.033 0.055

b 0.50 0.020

b1 0.38 0.50 0.015 0.020

D 24.80 0.976

E 8.80 0.346

e 2.54 0.100

e3 22.86 0.900

F 7.10 0.280

I 5.10 0.201

L 3.30 0.130

Z 1.27 0.050

mm inch

32/33

Page 33

L6223

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specification mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied. SGSTHOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems without express

written approval of SGS-THOMSON Microelectronics.

1998 SGS-THOMSON Microelectronics – Printed in Italy – All Rights Reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China- France - Germany - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

33/33

Loading...

Loading...