Page 1

L4969

SYSTEM VOLTAGE REGULATOR

WITH FAULT TOLERANT LOW SPEED CAN-TRANSCEIVER

PRELIMINARY DATA

■ OPERATING SU PPLY VOLTAGE 6V TO 28V,

TRANSIENT UP TO 40V

■ LOW QUIESCENT CURRENT CONSUMP-

TION, LESS THA N 40

■ TWO VERY LOW DROP VOLTAGE

REGULATORS 5V / 200mA

AND 5V/200mA

■ SEPARATE VOLTAGE REGULATOR FOR

CAN-TRANSCEIVER SUPPLY WITH LOW

POWER SLEEP MODE

■ EFFICIENT UC SUPERVISION AND RESET

LOGIC

■ 24 BIT SERIAL INTERF AC E

■ AN UNPOWERED OR INSUFFI C IENTLY

SUPPLIED NODE DOES NOT DIST U RB THE

BUS LINES

■ VS VOLTAGE SENSE COMPARATOR

■ SUPPORTS TRANSMISSION WITH

GROUNDSHIFT:

SINGLE WIRE: 1.5V, DIFFERENTIAL: 3V

µA IN SLEEP MODE

SO20 PowerSO20

ORDERING NUMBERS: L4969MD (SO20)

L4969 (PowerSO20)

DESCRIPTION

The L4969 is an integrated circuit containing 3 independent Voltage Regulators and a standard fault tolerant low speed CAN line interface in multipower

BCD3S process.

It integrat es all mai n l ocal functions for automot iv e body

electronic applications conn ected to a CAN bus.

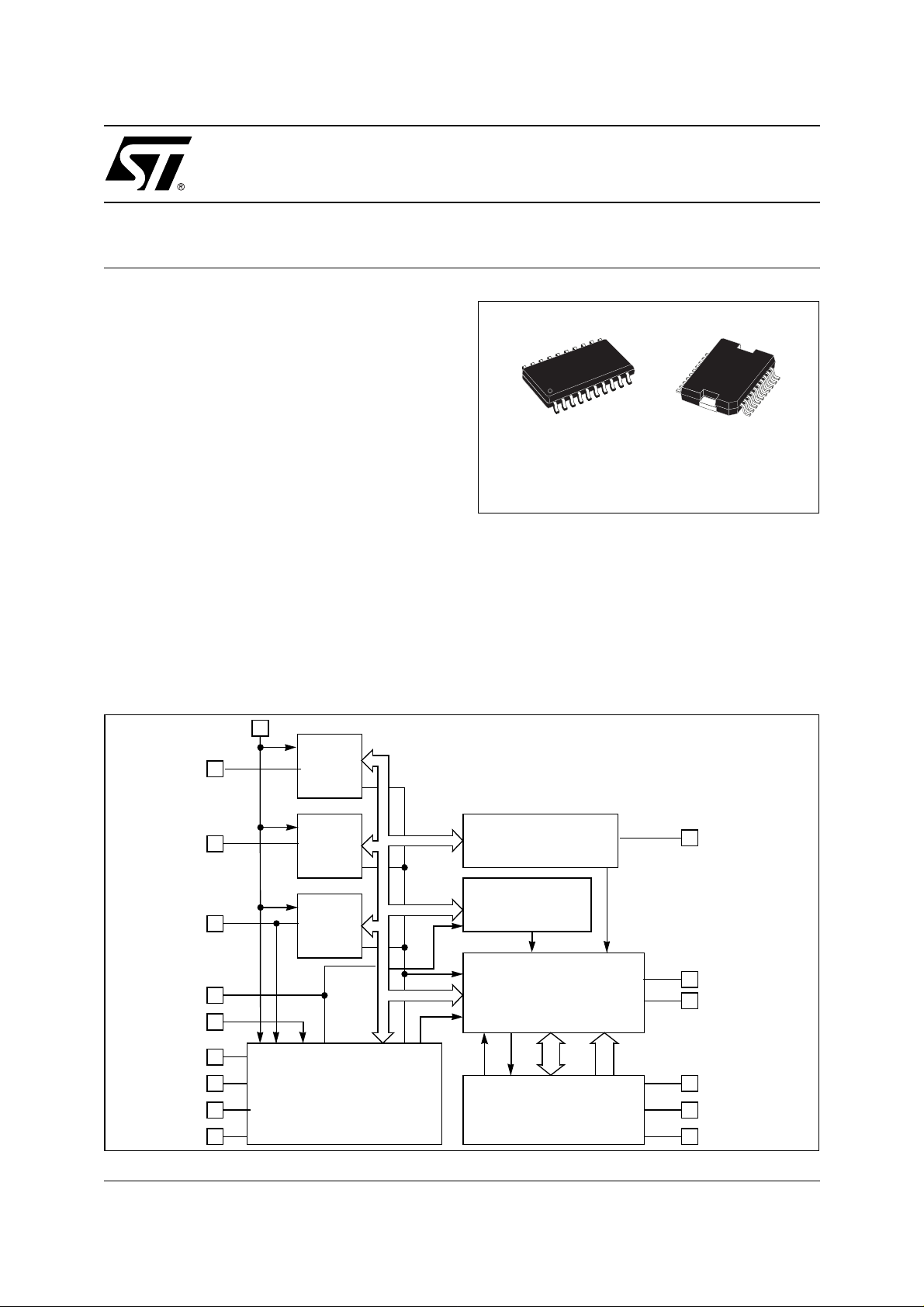

Figure 1. Block Diagram

VS

V1

V2

V3

RX

TX

CANH

RTH

CANL

RTL

VREG 1

VREG 2

VREG 3

Fault tole ran t

low speed

CAN-transceiver

Watchdo g and

adjustable RC-O s cillator

Iden tifier Filter

Control and Status Memory

24 Bit SPI

NRESET

WAKE

NINT

SCLK

SIN

SOUT

August 2003

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

1/35

Page 2

L4969

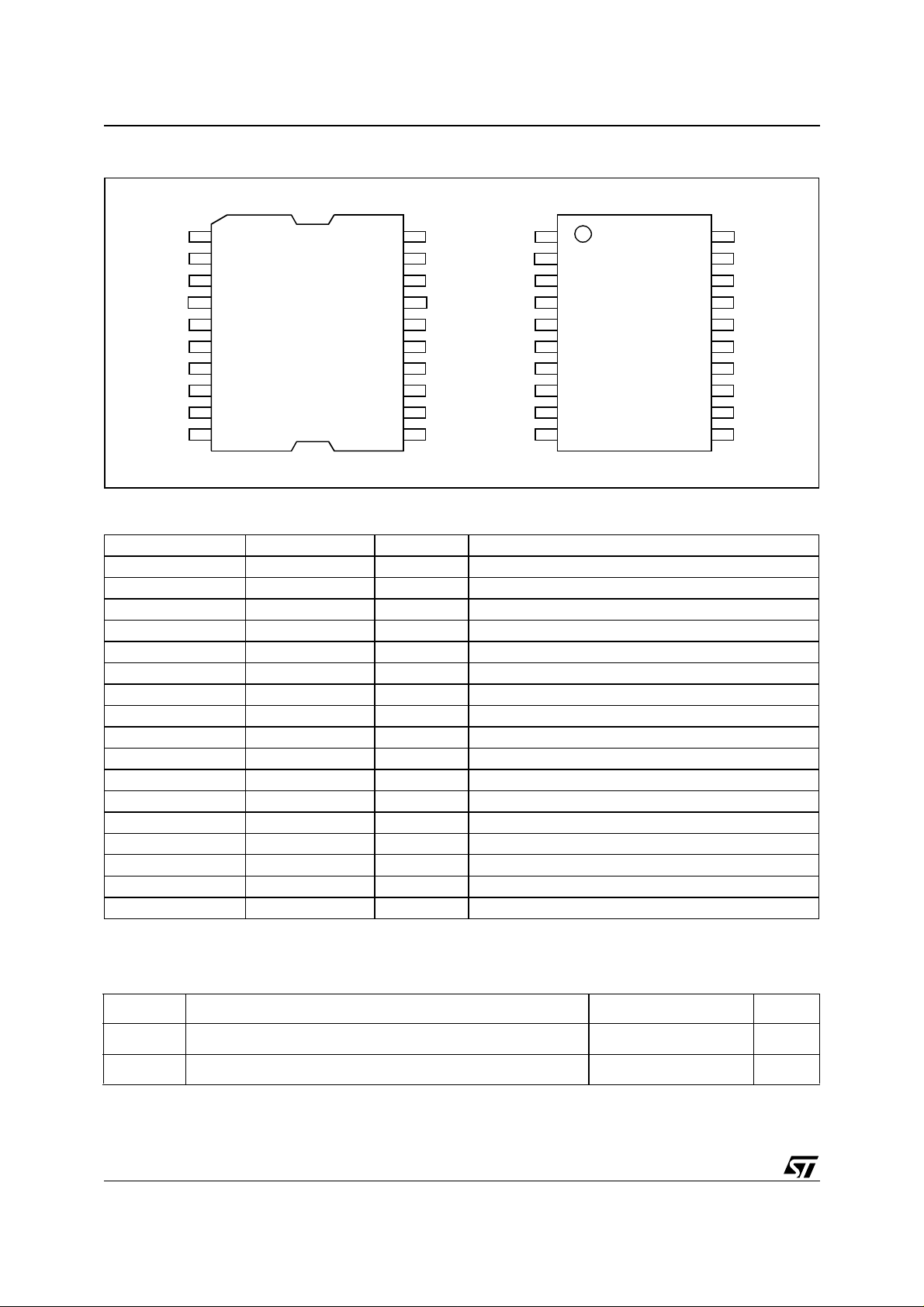

Figure 2. Pin Connection

GND

V1

V2

V3

VS

CANH

RTL

CANL

RTH

GND

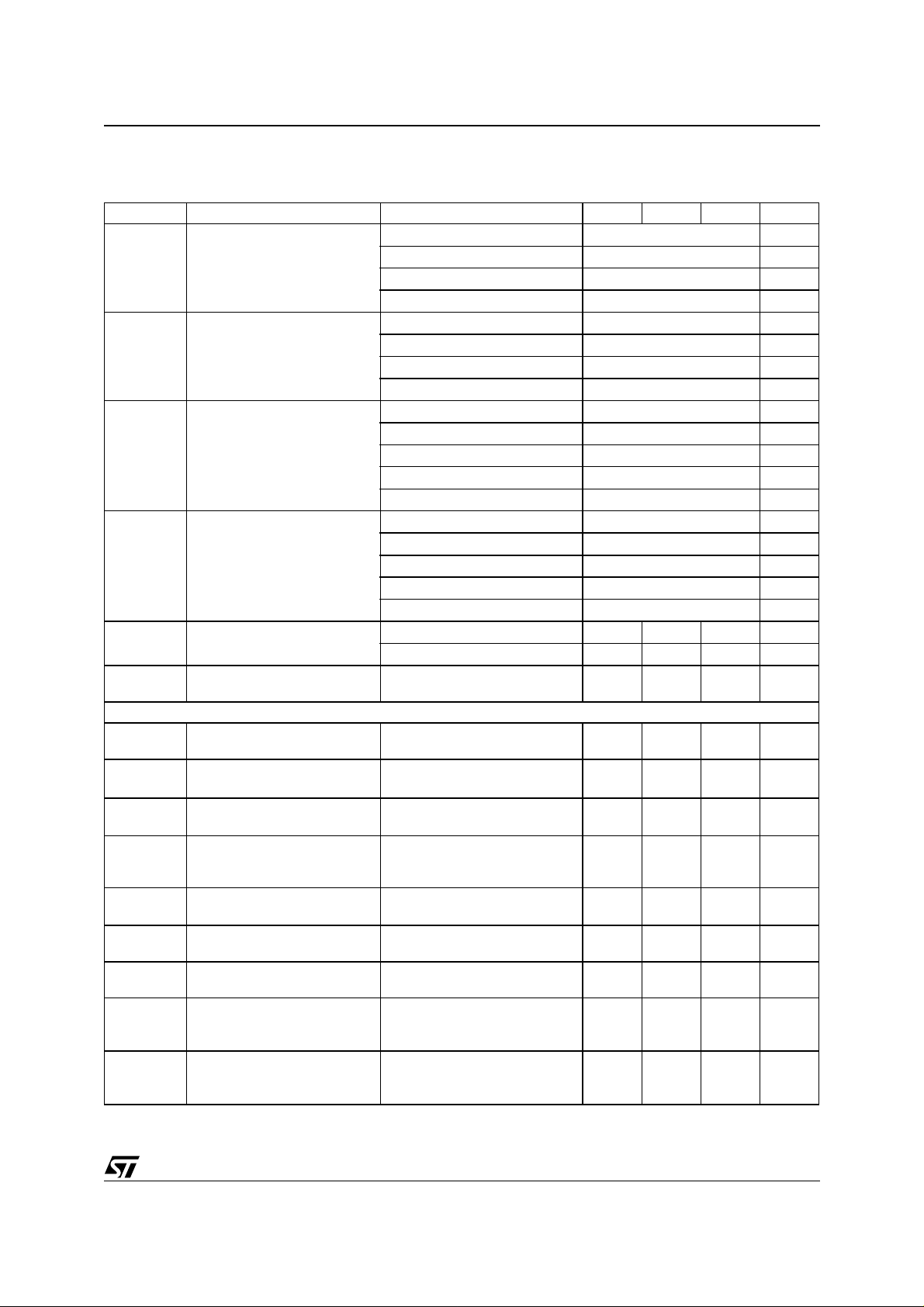

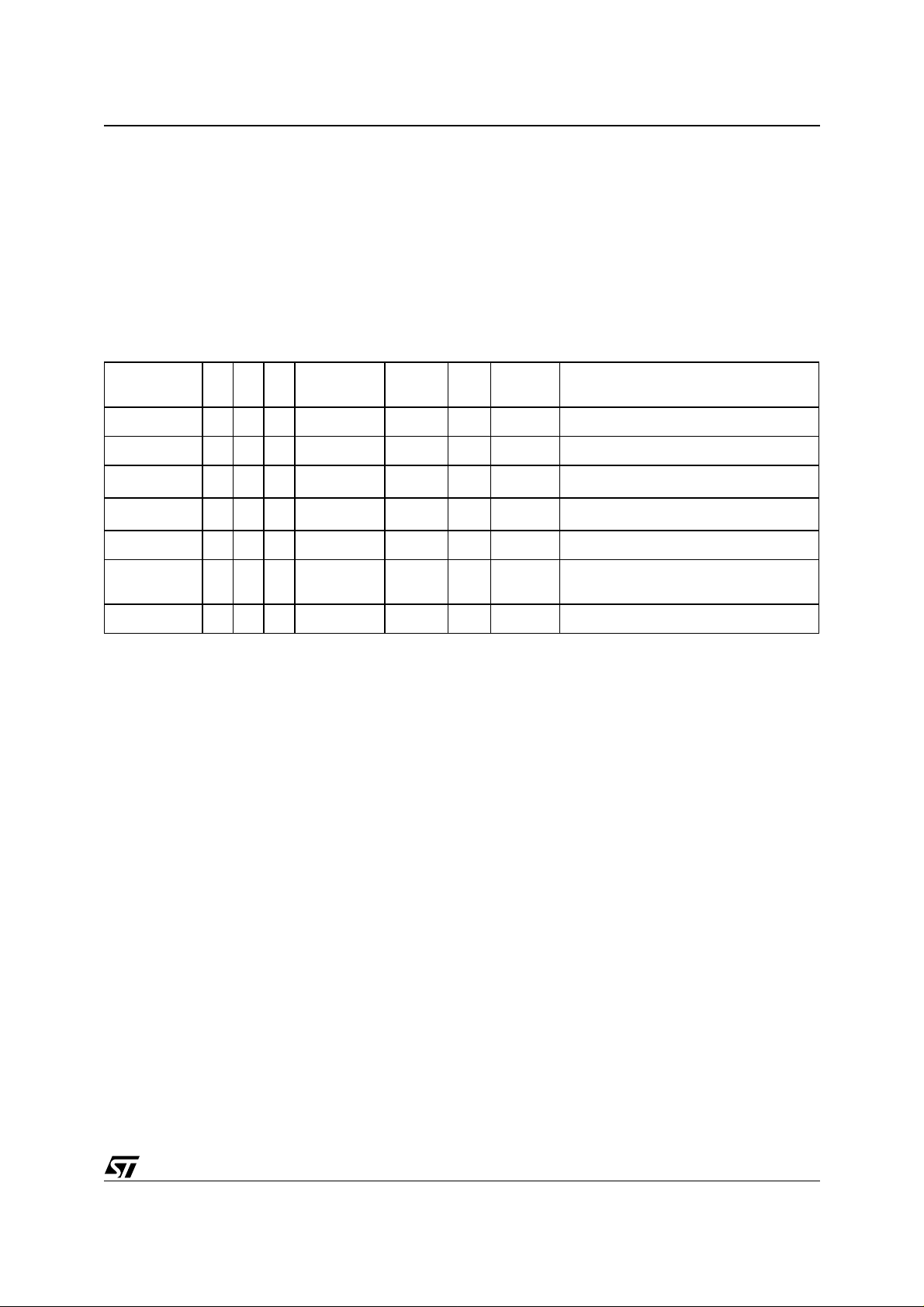

Table 1.

Pin Functions

Pin No. (PSO20) Pin No. (SO20) Pin Name Function

1, 10, 11, 20 5,6, 15, 16 GND Power Ground

2 7 V1 Microcontroller Supply Voltage

3 8 V2 Peripheral Supply Voltage

4 9 V3 Internal CAN Supply

5 10 VS Power Supply

6 11 CANH CANH Line Driver Output

7 12 RTL CANL Termination Source

8 13 CANL CANL Line Driver Output

9 14 RTH CANH Termination Source

12 17 RXD Act. Low CAN Receive Dominant Data Output

13 18 TXD Act. Low CAN Transmit Dominant Data Input

14 19 SOUT Serial Data Output

15 20 SIN Serial Data Input

16 1 SCLK Serial Clock

17 2 NRES Act. Low Reset Output

18 3 NINT Act. Low Interrupt Request

19 4 WAKE Dual Edge Triggerable Wakeup Input

PSO20

GND

WAKE

NINT

NRES

SCLK

SIN

SOUT

TXD

RXD

GND

SCLK

NRES

NINT

WAKE

GND

GND

V1

V2

V3

VS

SO20

SIN

SOUT

TX

RX

GND

GND

RTH

CANL

RTL

CANH

Table 2. Thermal Data

Symbol Parameter Value Unit

R

thj-amb

R

thj-case

Note: 1. Typical value soldered on a PC board wit h 8 cm2 copper ground plane (35µm thick).

2/35

Thermal resistance junction-ambient

Thermal resistance junction-case 3 °C/W

40

1)

°C/W

Page 3

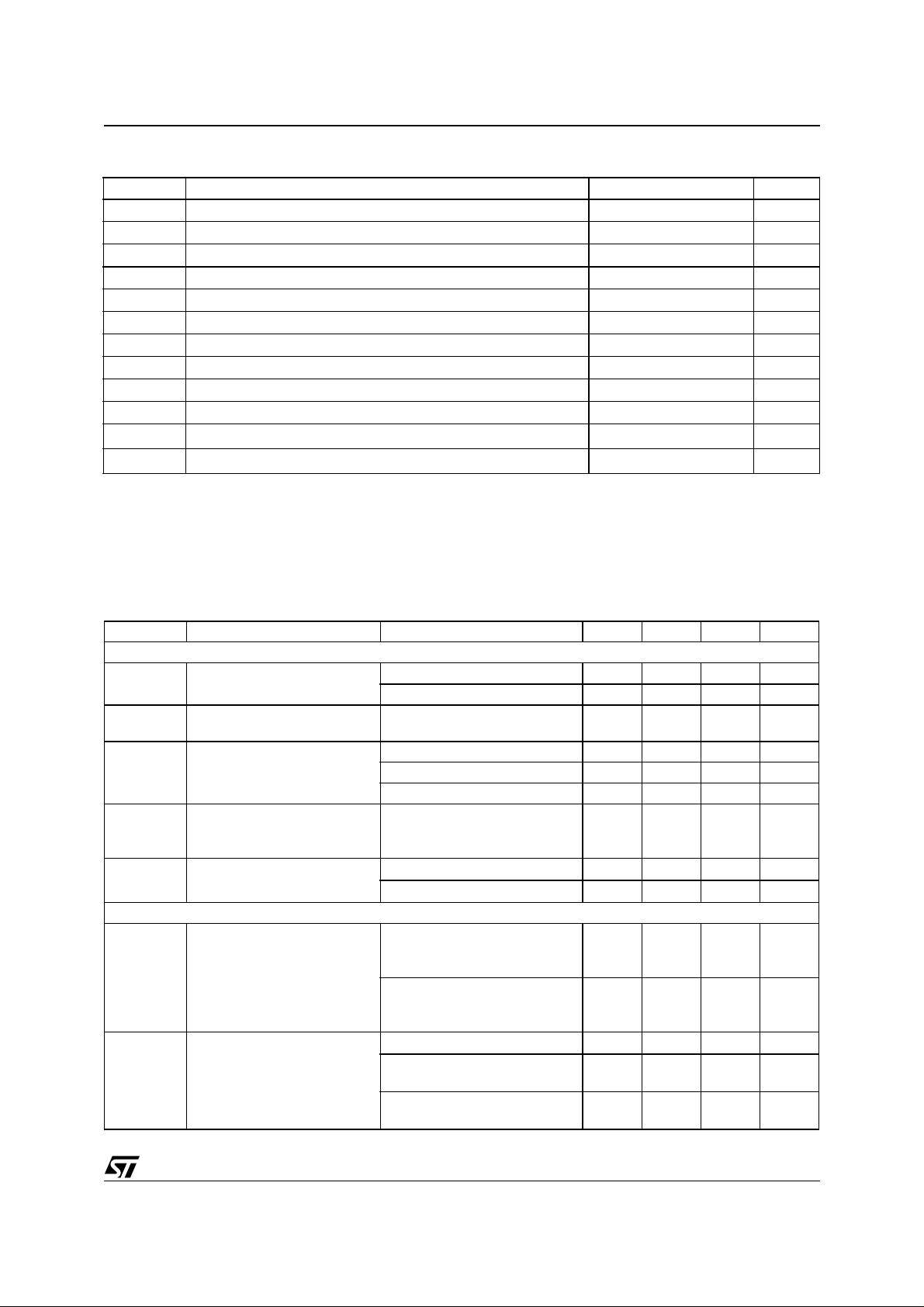

Table 3. Absolute Maximum Ratings

Symbol Parameter Value Unit

V

VSDC

V

VSTR

I

VOUT1...3

T

STG

T

V

OUT1

V

OUT2

V

OUT3

V

inli

V

inliW

V

canh

V

canl

Notes: 1. All pins of the IC are protect ed against ESD. The verifi cation is perf ormed according to MIL 883C,

2. Voltage forced means voltage limited to the specified values whil e the current is not limited.

3. ESD Pulses on CAN-Pins up to 4K V HBM vs GND with all other P i ns grounded.

DC operating supply voltage -0.3 ... +28 V

Transient operating supply voltage (T < 400ms) -0.3 ... +40 V

Output currents Internally limited

Storage temperature -65 ... +150 T

Operating junction temperature -40 ... +150 T

J

Externally forced output voltage OUT1 -0.3 ... VS+0.3, max +6.3 V

Externally forced output voltage OUT2 -0.3 ... VS+0.3 V

Externally forced output voltage OUT3 -0.3 ... VS+0.3, max +6.3 V

Input voltage Logic inputs: SIN, SCLK, NRES -0.3 ... +7 V

Input voltage WAKE -0.3 ... VS+0.3 V

Voltage CANH line

Voltage CANL line

human body model with R = 1.5kW, C = 100pF and dischar ge voltage 200 0V,

corresponding to a maximum disch arge energy of 0.2mJ..

3

3

-28 ... +40 V

-28 ... +40 V

L4969

VSDC

VSTR

I

VOUT1...3

STG

J

OUT1

OUT2

OUT3

inli

inliW

canh

canl

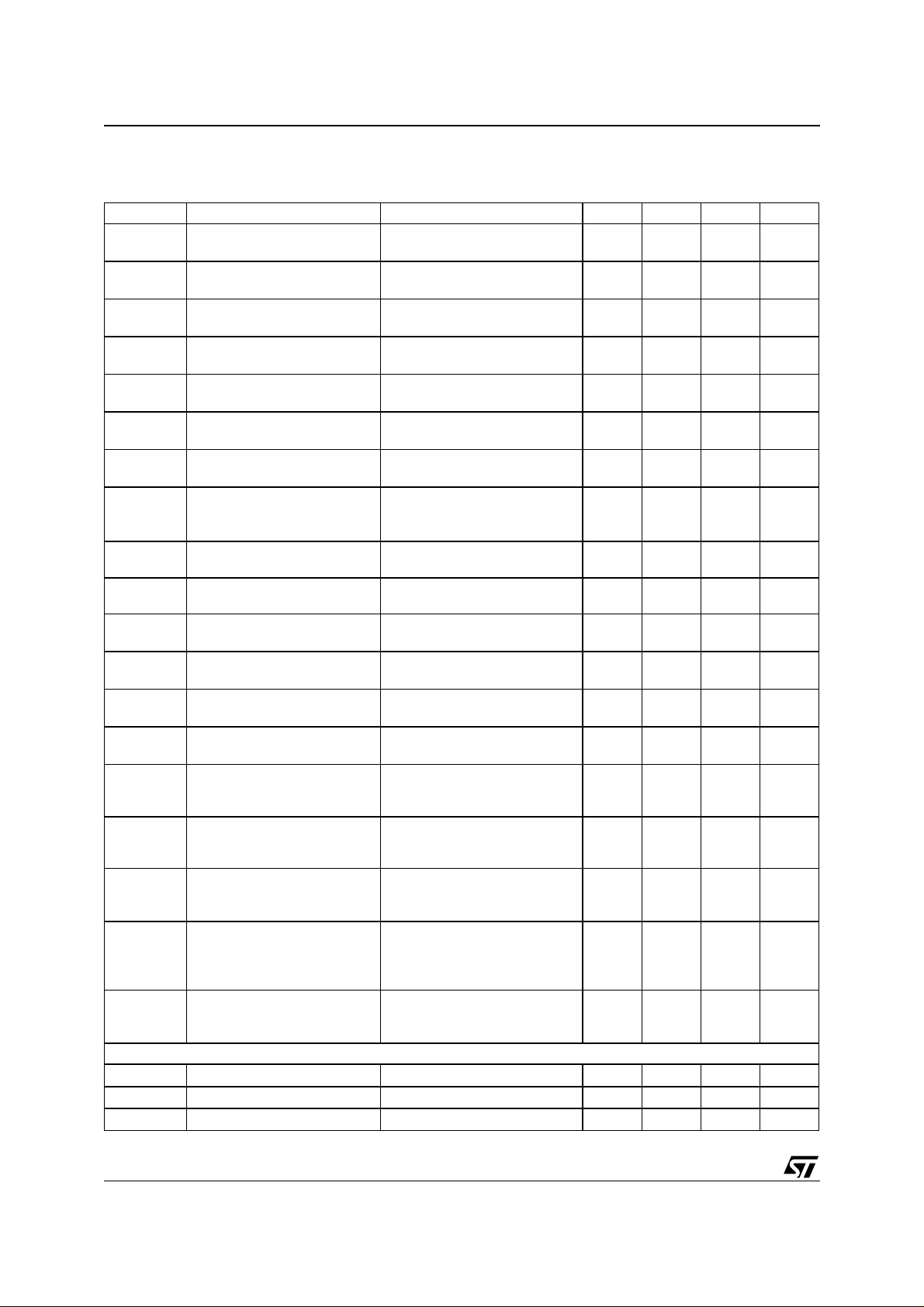

Table 4. Electrical Characteristics

V

= 14V, Tj=-40°C to 150°C unless otherwise specified.

S

Symbol Parameter Test Conditions Min. Typ. Max. Unit

Supply Current

I

SSL

All Regulators off

(CANH Standby

I

SSLWK

V1 off, V2 off, V3 on

(CAN RX only)

I

SSB

I

S

V1 only (CAN Standby) Timer off (Standby #1) 150 250 µA

All Regulators on,

(CAN active, TX high)

I

SCP

Additional Oscillator- and

Chargepumpcurrent at low VS

Voltage Regulator 1

V

01

V

DP1

V1 output voltage 6V < VS < 28V

Dropout voltage 1@ VS=4.8V I

Timer off (Sleep #1) 30 40 60 µA

Timer on (Sleep #2) 70 90 135 µA

RXonly 4 6 mA

Timer on (Standby #2) 200 300 µA

Default (Standby #3) 440 600 µA

I

OUT1

I

OUT2

= -100mA

= -10mA

120 150 mA

No CAN load.

VS = 6V; Timer Off 55 80 100 µA

= 6V; Timer On 10 30 50 µA

V

S

4.9 5 5.1 V

IO >-100mA

SO20 Package

6V < V

I

>-150mA

O

< 28V

S

4.9 5 5.1 V

PSO20 Package

= -10mA 0.0 0.025 0.06 V

OUT1

I

OUT1

= -100mA

0.0 0.25 0.6 V

SO20 Package

I

OUT1

= -150mA

0.0 0.4 0.9 V

PSO20 Package

3/35

Page 4

L4969

Table 4. Electrical Characteristics (continued)

V

= 14V, Tj=-40°C to 150°C unless otherwise specified.

S

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

OL01

I

LIM1

V

OLI1

T

OVT1

T

OTKL1

V

res

Voltage Regulator 2 and 3

V

O

V

DP

V

OLO

I

LIM

V

OLI

T

OVT

T

OTKL

Vtrc V2 tracking offset 6V < VS < 28V, I

Reset and Watchdog

t

OSC

t

WDC

t

RDnom

t

WDstart

Load regulation 1 IO =-1mA to-100mA

01040mV

SO20 Package

=-1mA to -150mA

I

O

01040mV

PSO20 Package

Current limit 1 0.8V < V

< 4.5V, VS=6V,

O1

-180 -400 -800 mA

SO20 Package

0.8V < V

O1

< 4.5V

-180 -400 -800 mA

VS=14V,

PSO20 Package

Line regulation 1 6V < VS < 28V

I

= -1mA

O1

0530mV

Overtemp flag 1 6V < VS < 28V 130 140 150 °C

Thermal shutdown 1 6V < VS < 28V 175 185 205 °C

Min V1 reset threshold voltage RTC0 = 0 4.15 4.5 4.7 V

RTC0 = 1 3.7 4.0 4.2 V

Output voltage 6V < VS < 28V

4.8 5 5.2 V

IO >-100mA

SO20 Package

6V < V

I

>-150mA

O

< 28V

S

4.8 5 5.2 V

PSO20 Package

Dropout voltage VS = 4.8V

= 100mA

I

O UT

0.0 0.25 0.6 V

SO20 Package

I

O UT

= 150mA

0.0 0.4 0.9 V

PSO20 Package

Load regulation IO =-1mA to -100mA

01040mV

SO20 Package

=-1mA to -150mA

I

O

01040mV

PSO20 Package

Current limit 0.8V < V

< 4.5V, VS=6V,

O1

-180 -400 -800 mA

SO20 Package

0.8V < V

O1

< 4.5V

-180 -400 -800 mA

PSO20 Package

Line regulation 6V < VS < 28V

I

= -5mA

OUT

0530mV

Overtemp flag 6V < VS < 28V 130 140 150 °C

Thermal shutdown 6V < VS < 28V 150 165 180 °C

= 0 -90 0 +90 mV

O2

OnChip RC-Timebase RC-Adjustment = 0 0.95 1.1 1.35 us

Watchdog timebase (2.5ms) 2498 t

Reset pulse duration (1ms) 1024 t

Reset pulse pause (320ms)

128 t

(startup watchdog)

OSC

OSC

WDC

4/35

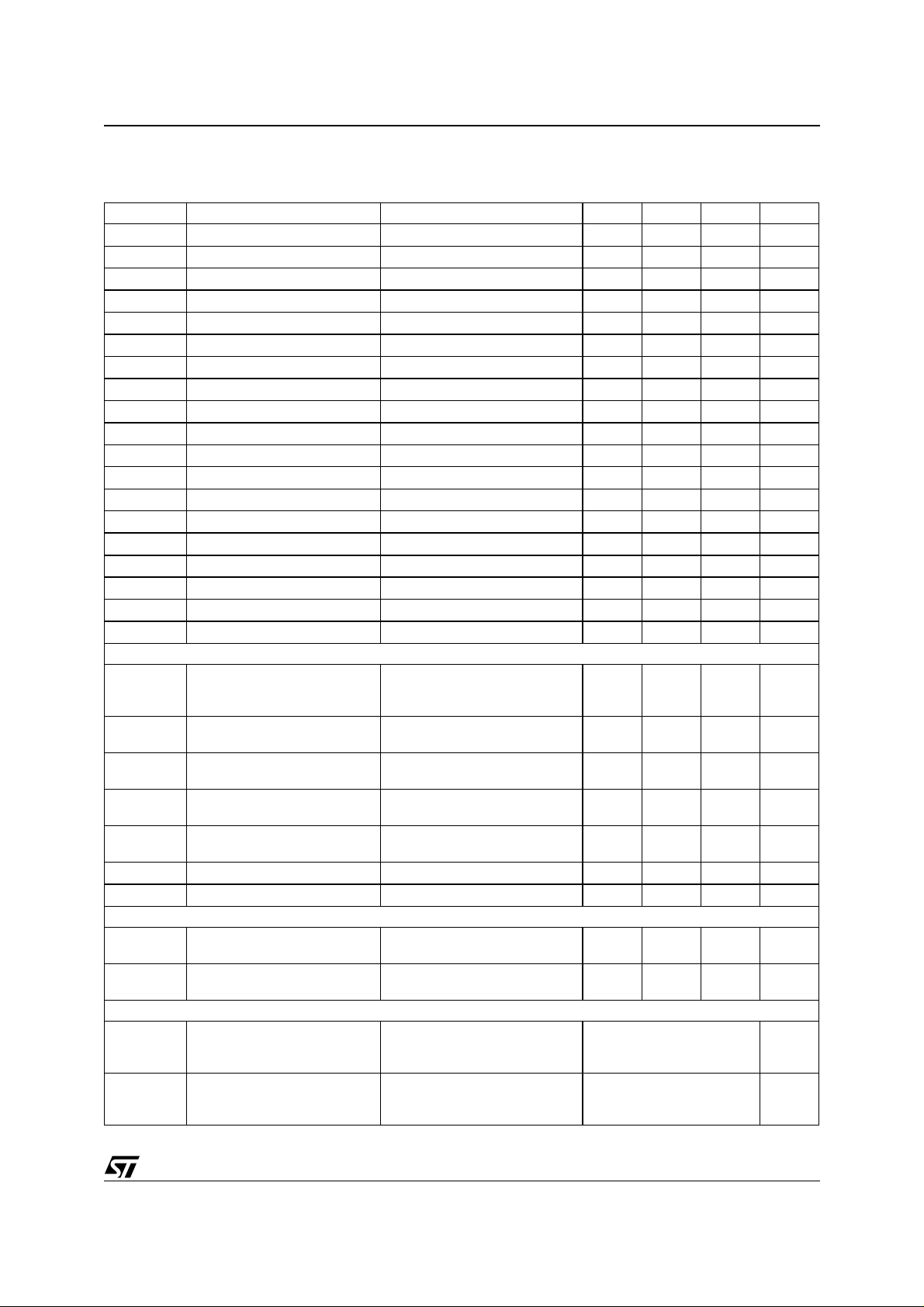

Page 5

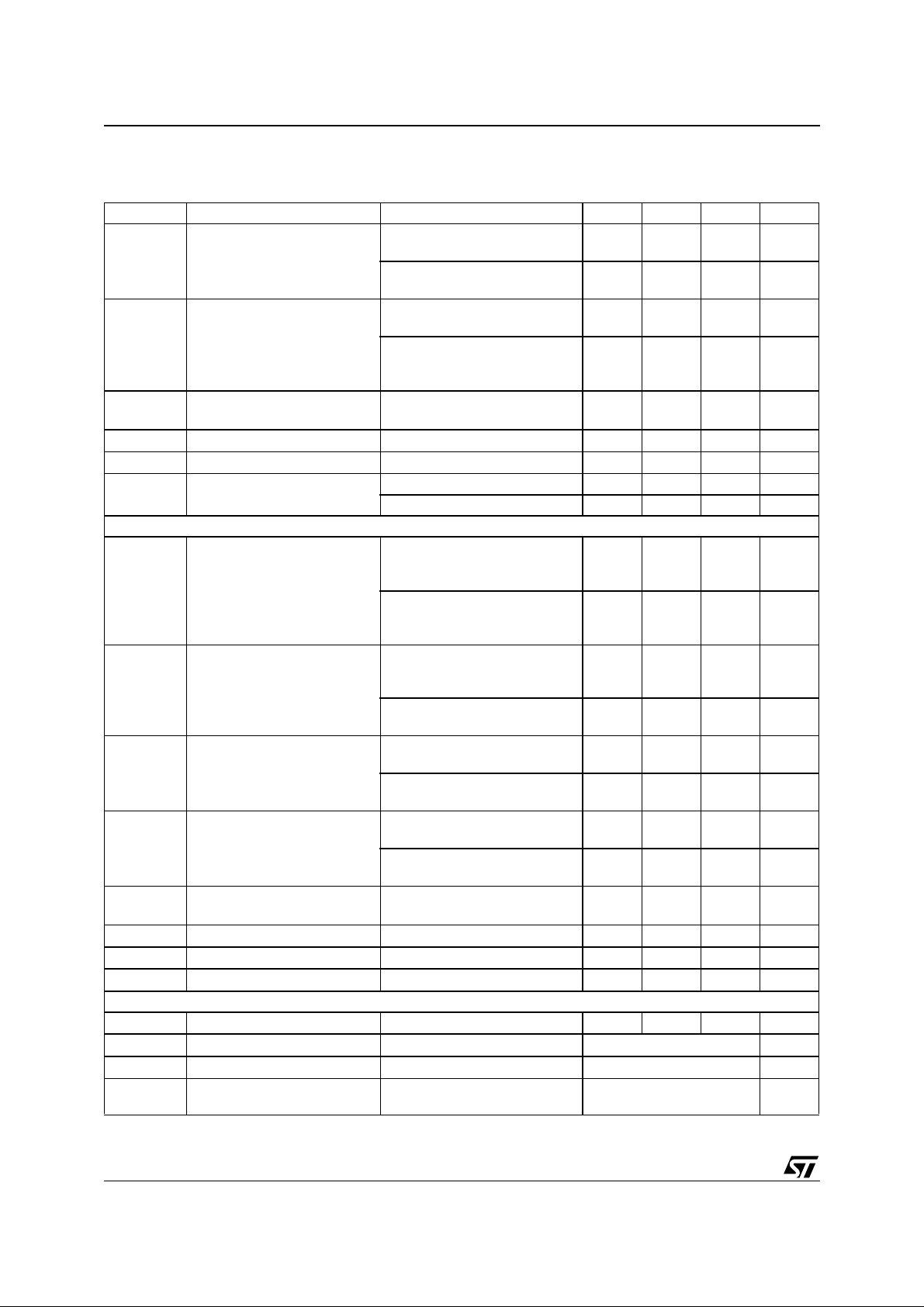

Table 4. Electrical Characteristics (continued)

V

= 14V, Tj=-40°C to 150°C unless otherwise specified.

S

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

WDswS

t

WDswE

t

WD1C

t

WD2C

V

RESL

R

PURES

CAN Line Interface

t

drd

t

ddr

S

RD

, R

R

RTH

V

CCFS

VH

RXD

VL

RXD

Vd_r Differential receiver

Vr_d Differential receiver

Watchdog window start

(Software window Watchdog)

SWT = 0 (2.5ms) 1 t

SWT = 1 (5ms) 2 t

SWT = 2 (10ms) 4 t

SWT = 3 (20ms) 8 t

Watchdog window end

(Software window watchdog)

SWT = 0 (5ms) 2 t

SWT = 1 (10ms) 4 t

SWT = 2 (20ms) 8 t

SWT = 3 (40ms) 16 t

System Watchdog 1 WDT = 0 (80ms) 32 t

WDT = 1 (160ms) 64 t

WDT = 2 (320ms) 128 t

WDT = 3 (640ms) 256 t

WDT = 4 (800ms) 320 t

System Watchdog 2 WDT = 8 (1s) 400 t

WDT = 9 (2s) 784 t

WDT = 10 (4s) 1600 t

WDT = 11 (8s) 3200 t

WDT = 12 (45min) 1081344 t

Reset output LOW voltage I

Internal Reset Pull-Up

= 500u, V1 = 2.5V 0 0.3 0.4 V

RES

= 500u, V1 = 1.5V 0 0.85 1.4 V

I

RES

80 120 280 KΩ

Resistance

Propagation delay

C

= 3.3n 0.4 1.0 1.5

load

(rec to dom state)

Propagation delay

(dom to rez state)

Bus output slew rate (r -> d) 10% ... 90%

external Termination

RTL

C

load

R

TERM

C

Load

= 3.3n,

=100

= 3.3n

0.4 1.0 2.0

458V/µs

0.5 16

resistance

(application limit)

Force Standby mode (fail

safe)

High level output voltage on

min VS to turn off CAN-IF and

V3

2.20 4.0 V

V1 - 0.9 V1 V

RXD

Low level output voltage on

0 0.9 V

RXD

No bus failures -3.85 -2.50 V

dom to rec threshold

- V

V

CANH

CANL

No bus failures -3.50 -2.20 V

rez to dom threshold

- V

V

CANH

CANL

L4969

WDC

WDC

WDC

WDC

WDC

WDC

WDC

WDC

WDC

WDC

WDC

WDC

WDC

WDC

WDC

WDC

WDC

WDC

µs

µs

Ω

K

5/35

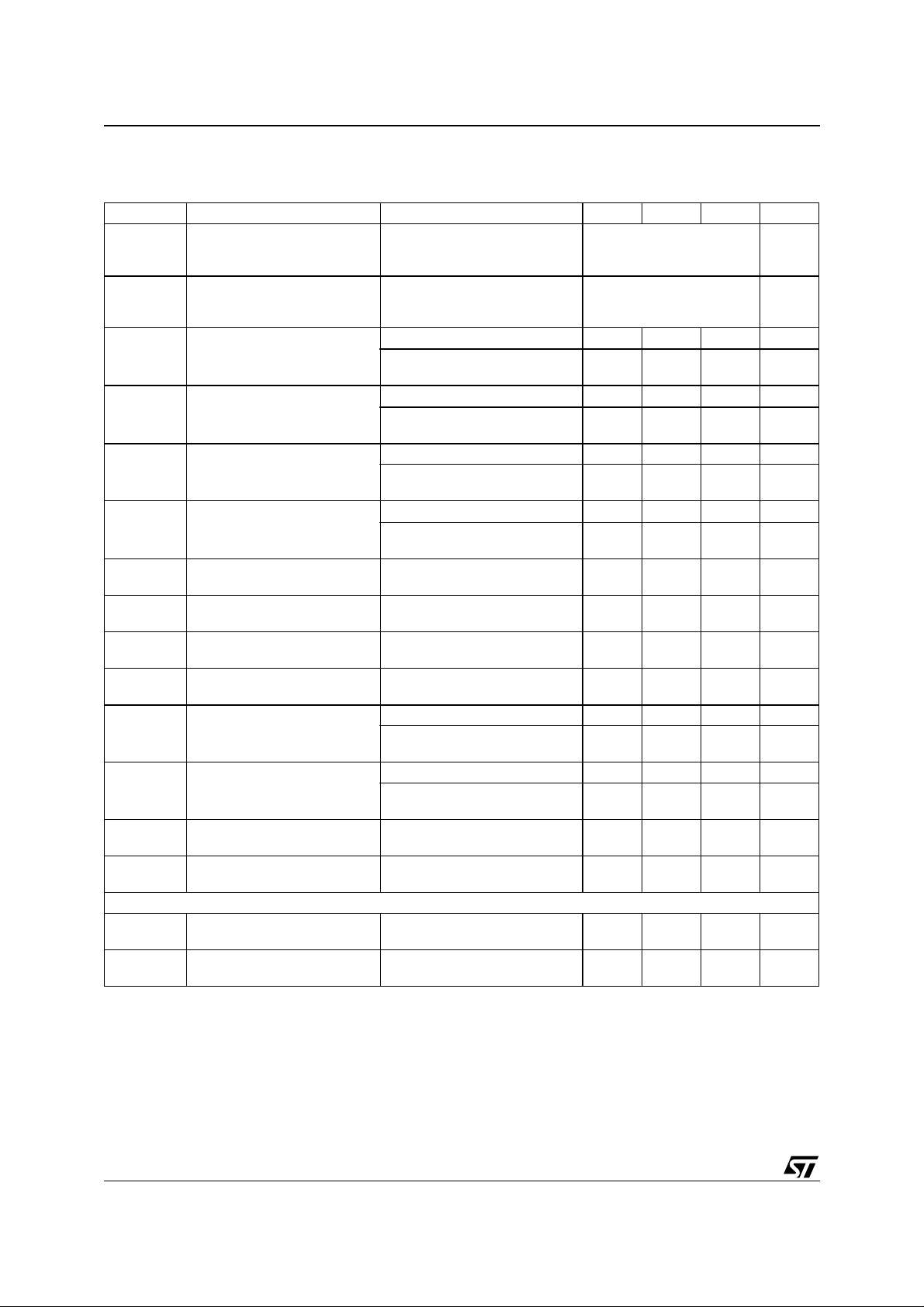

Page 6

L4969

Table 4. Electrical Characteristics (continued)

V

= 14V, Tj=-40°C to 150°C unless otherwise specified.

S

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

CANHr

V

CANHd

V

CANLr

V

CANLd

I

CANH

I

CANL

I

LCANH

I

LCANL

V

WakeH

V

WakeL

V

canhs

V

canls

V

OVH

V

OVL

RT

RTH

IT

RTHF

RT

RTL

IT

RTLF

RT

RTLS

Digital I/O

V

SINL

V

SINH

V

SCLKL

CANH recessive output

voltage

CANH dominant output

voltage

CANL recessive output

voltage

CANL dominant output

voltage

CANH dominant output

current

CANL dominant output

current

CANH Sleep mode

leakage current

CANL Sleep mode

leakage current

CANH wakeup voltage Sleep/

TXD = V1

< 4K

R

RTH

TXD = 0

= 40mA

I

CANH

TXD = V1

< 4K

R

RTL

TXD = 0

= -40mA

I

CANL

TXD = 0

= 0V

V

CANH

TXD = 0

= 14V

V

CANL

Sleep mode. Tj=150°C

= 0V

V

CANH

Sleep mode. Tj=150°C

= 0V

V

CANL

V

= 12V

S

V3 -

1.4V

V3 -

0.2V

70 100 160 mA

-70 -100 -160 mA

0

0

1.2 1.9 2.7 V

standby mode

CANL wakeup voltage Sleep/

2.4 3.1 3.8 V

standby mode

CANH single ended

receiver threshold

CANL single ended

receiver threshold

CANH overvoltage

detection threshold

CANL overvoltage

detection threshold

internal RTH to GND

Normal mode.

-5V < CANL < V

S

Normal mode.

-5V < CANH< V

S

Normal mode.

-5V < CANL < V

S

Normal mode.

-5V < CANH < V

= 1V 30 45 80 W

V

RTH

S

1.5 1.82 2.15 V

2.7 3.1 3.4 V

6.5 7.2 8.0 V

6.5 7.2 8.0 V

termination resistance

Normal mode, No failures.

internal RTH to GND

V

=V3 - 1V 55 75 100

RTH

termination current

Normal mode, Failure EIII

internal RTL to VCC

V

=V3 - 1V 30 45 85 W

RT L

termination resistance

Normal mode, no failures.

internal RTL to VCC

V

=V3 - 1V -6 -40 -70

RTL

termination current

Normal mode.

(failure EIV, EVI, EVII)

internal RTL to VS

termination resistance

Standby/sleep mode.

=1V, 4V

V

RTL

8 13.0 26

No failures.

Low level input voltage 0 0.9 V

High level input voltage V1 - 0.9 V1 V

Low level input voltage 0 0.9 V

0.35 V

1.4 V

µA

µA

µA

µA

K

V

V

Ω

6/35

Page 7

Table 4. Electrical Characteristics (continued)

V

= 14V, Tj=-40°C to 150°C unless otherwise specified.

S

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

SCLKH

V

TXL

V

TXH

V

WakeL

V

WakeH

V

SoutH

V

SoutL

V

RXDH

V

RXDL

Ioh

RXD

Iol

RXD

Ioh

SOUT

Iol

SOUT

Ioh

Iol

INT

Ioh

Reset

Iol

Reset

Ioh

Wake

Iol

Wake

Serial Data Interface

t

Start

t

Setup

t

Hold

t

D

t

CKmax

t

GAP

f

SCLK

Diagnostic Functions

VS

min

GS

CANH

CAN Error Detection

N

EdgeH

N

EdgeHR

High level input voltage V1 - 0.9 V1 V

Low level input voltage 0 0.9 V

High level input voltage V1 - 0.9 V1 V

Low level input voltage 0 0.9 V

High level input voltage 4.1 5.0 V

High level output voltage V1 - 0.9 V1 V

Low level output voltage 0 0.9 V

High level output voltage V1 - 0.9 V1 V

Low level output voltage 0 0.9 V

High level output current RXD = 0 -1.2 -1.8 -2.5 mA

Low level output current RXD = 5V 1.1 1.6 2.2 mA

High level output current SOUT = 0 -9.0 -14.0 -18.0 mA

Low level output current SOUT = 5V 18.0 24,0 30.0 mA

High level output current INT = 0 -10.0 -15.0 -20.0 mA

INT

Low level output current INT = 5V 18,0 24,0 30,0 mA

High level output current RESET = 0 -6,0 -15,0 -25.0

Low level output current RESET = 5V 5.0 6.5 8.0 mA

High level output current V

Low level output current V

SIN low to SCLK low setup

= 5V 0 0 0.5

Wake

= 0V -2.2 -3.4 -4.5

Wake

100 ns

time

(frame start)

SIN to SCLK setup time

100 ns

(write)

SIN to SCLK hold time

100 ns

(write)

SCLK to SOUT delay time

(read)

SCLK maximum cycle time

1 1.5 3.0 ms

(timeout)

Interframe Gap 5 µs

SCLK frequency range 0.25 0.5 1 MHz

Sense comparator

6.0 7.2 8.0 V

detection threshold

CANH groundshift

-1.5 -1 -0.6 V

detection threshold

Nr of dom to rec edges on

Operating mode (EI_V) 3 Ed ges

CANL to detect permanent

rez CANH

Nr of dom to rec edges to

Operating mode (EI_V) 3 Ed ges

detect

recovery of CANH

500 ns

L4969

µA

µA

µA

7/35

Page 8

L4969

Table 4. Electrical Characteristics (continued)

V

= 14V, Tj=-40°C to 150°C unless otherwise specified.

S

Symbol Parameter Test Conditions Min. Typ. Max. Unit

N

EdgeL

N

EdgeLR

t

EIII

t

EIIIR

t

EIV

t

EIVR

t

EVI

t

EVIR

t

EVII

t

EVIIR

t

EVIII

t

EVIIIR

t

FailTX

t

FailTXR

Wakeup

t

wuCAN

t

wuWK

Nr of dom to rec edges on

CANH to detect permanent

rez CANL

Nr of dom to rec edges to

detect

recovery of CANL

CANH to VS short circuit

detection time

CANH to VS short circuit

recovery time

CANL to GND short circuit

detection time

CANL to GND short circuit

recovery time

CANL to VS short circuit

detection time

CANL to VS short circuit

recovery time

CANL to CANH short circuit

detection time

CANL to CANH short circuit

recovery time

CANH to VDD short circuit

detection time

CANH to VDD short circuit

recovery time

TX permanent dominant

detection time (Fail safe)

TX permanent dominant

recovery time (Fail safe)

Minimum dominant time for

wake-up via CANH or CANL

Minimum pulse time for wakeup via WAKE

Operating mode (EII_IX) 3 Edges

Operating mode (EII_IX) 3 Edges

Operating mode (EIII) 1 .6 2 3.6 ms

Sleep/

1.6 2 3.6 ms

standby mode (EIII)

Operating mode (EIII) 0 .4 0.9 1.6

Sleep/

0.4 0.9 1.6

standby mode (EIII)

Operating mode (EIV) 0.4 0.9 1.6 ms

Sleep/

0.4 0.9 1.6 ms

standby mode (EIV)

Operating mode (EIV) 10 30 50

Sleep/

0.4 0.9 1.6

standby mode (EIV)

Operating mode (EVI) 0.4 0.9 1.6

Operating mode (EVI) 200 500 750

Operating mode (EVII) 0.4 0.9 1.6 ms

Operating mode (EVII) 10 30 50

Operating mode (EVIII) 1.6 1.8 3.6 ms

Sleep/

1.6 1.8 3.6 ms

standby mode (EVIII)

Operating mode (EVIII) 0.4 0.9 1.6 ms

Sleep/

0.4 0.9 1.6

standby mode (EVIII)

Operating mode (EX) 0.4 0.9 1.6 ms

Operating mode (EX) 1 4 8

sleep/standby 8 22 38

sleep/standby 8 22 38

ms

ms

µs

ms

ms

µs

µs

ms

µs

µs

µs

8/35

Page 9

L4969

1 FUNCTIONAL DESCRIPTION

1.1 General Features

The L4969 is a monolithic integrated circuit which provides all main functions for an automotive body

CAN network.

It features two independent regulated v oltage supplies V1 and V2, an inter rupt and reset logic with internal cloc k

generator, Serial Interface and a low speed CAN-bus transceiver which is supplied by a separate third voltage

regulator (V3).

The device guarantees a clearly defined behavior in case of failure, to avoid permanent CAN bus errors.

The device operates in four basic modes, with additional programming for V1 Standbymodes in CTCR:

LP1, LP0

Mode V1 V2 V3 Timer/WDC CAN-IF

Sleep #1 Off Off Off Off Standby 40u x,x No Timer based wakeup

I

typ

(CTCR)

Remarks

Sleep #2 Off Off Off

(*1)

Standby #1

Standby #2

Standby #3 On Off Off On (1MHz) Standby 440u 0,0 Watchdog or timer activ, POR default

RXOnly Off Off On On (1MHz) RX-Only 4mA x,x Active during Busactivity to filter ID, auto-

Normal On On On On (1MHz) Normal 5mA x,x No Currents from CAN or Regulators

(*1) Note, that in order to enter either Standby #1 or Standby #2 the Startup-Watchdog has to be acknowledged (see Chapter 1.2), in Standby

#1, the Window Watchdog has to be disabled as described in Chapter 2.5, to allow the decativation of the internal oscillator.

On Off Off Off Standby 170u 1,1 No Watchdog or Timer

(*1)

On Off Off

On (250KHz)

On (250KHz)

Standby 80u x,x Timer active

Standby 210u 1,0 Watchdog or timer active

matic fall back to Sleep when Bus idle

1.1.1 V1 Output Voltage

The V1 regulator uses a DMOS transistor as an output stage. With this structure very low dropout voltage is

obtained. The dropout operation of the standby regulator is maintained down to 4V input supply voltage. The

output voltage is regulated up to the transient input supply voltage of 40V. With this feature no functional interruption due to overvoltage pulses is generated. The output 1 regulator is switched off in sleep mode.

1.1.2 V2 Output Voltage

The V2 regulator uses the same output structure as the output 1 regulator except to being short circuit proof to

VS, and to be rated for the output current of 200mA. The V2 output can be switched on and off through a dedicated enable bit in the control register. In addition a tracking option can be enabled to allow V2 follow V1 with

constant offset. This feature allows c onsistent A /D conver sion insi de the

µ

C (supplied by V 1) when the converted signals are referenced to V2. The maximum voltage that can be applied to V2 is VS + 0.3V up to a max VS

of 40V.

1.1.3 V3 Output Voltage

The third voltage regulator of the device generates the supply voltage for the internal logic and the CAN-transceiver. In operating mode it is capable of supplyi ng up to 200mA in order to guarantee the required short ci rcuit

current for the CAN_H driver. The sleep and operating modes are switched through a dedicated enable bit.

1.1.4 Internal Supply Voltage

A low power sleep mode regulator supplies the internal logic in sleep mode.

9/35

Page 10

L4969

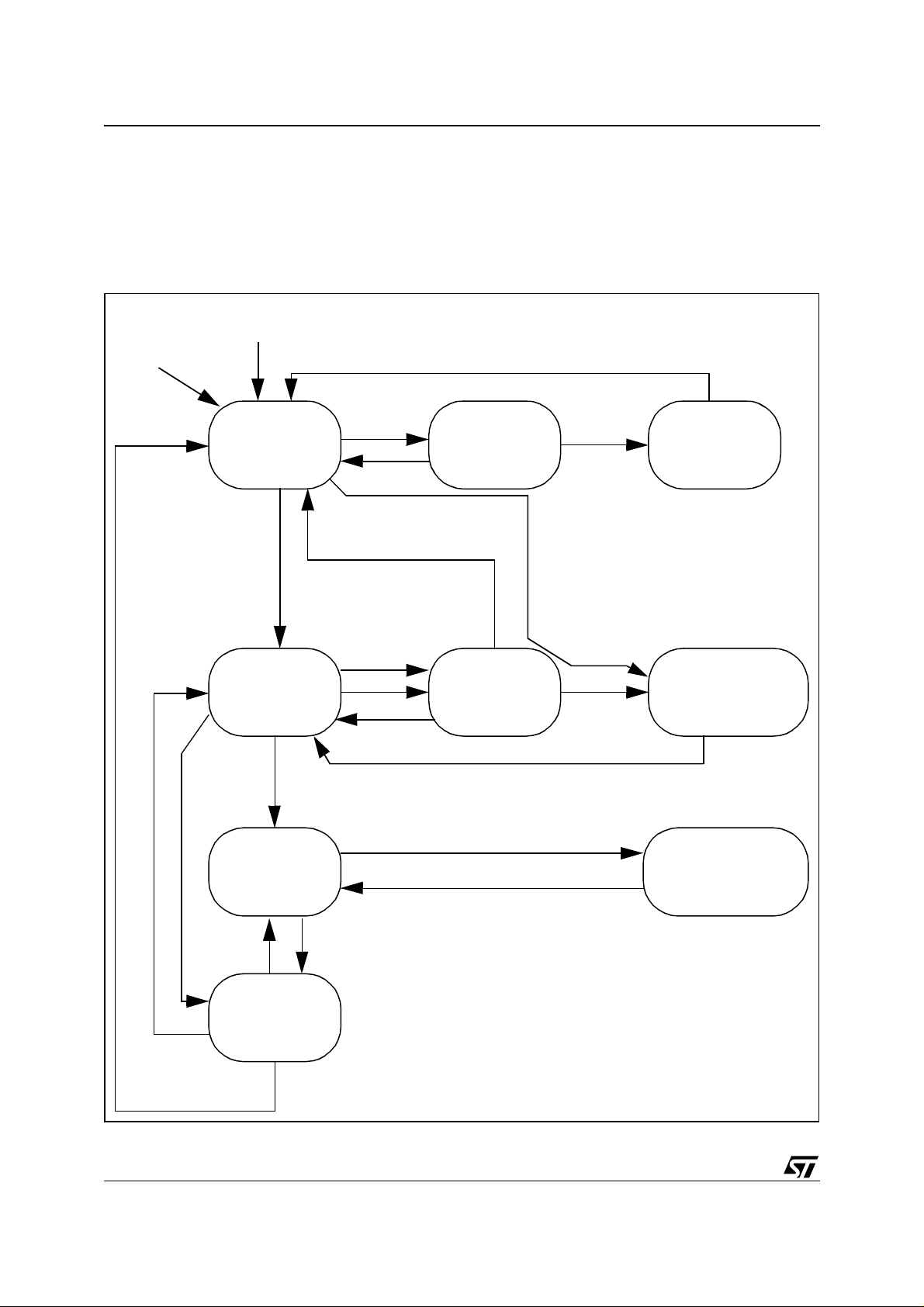

1.2 Power-Up, Initialization and Sleep mod e transitions

The following state-diagram illustrates the possible mode transitions inside the device.

As a prerequisite, a SPI-connection to the uC with the correct CRC-algorythms is required.

During the debug phase the NRES line can be forced high externally (connect to V1) to deactivate the startup

failure mechanis keeping V1 will alive.

Figure 3.

After POR, V1 up or externally forced reset

through low NRES, the STARTUP STATE is

entered

V1 Low

NRES Low

WAKEUP

STARTUP

V1 active

V2, V3, CAN off

WDC-ACK

Dependi g on th e value f rom the last

WDC-ACK, another one has to be

Writing to the WDCregister (WDC-ACK)

the NORMAL STATE is

entered.

written within the spec ified time frame

(SWDC[1:0]). A failure will activate

the STARTUP STATE

NORMAL MODE

WINDOW WDC

ACTIVE

WND SET

DISAR

SET

If during the last WDC-ACK WND has been set (after releasing

write lock , see d escription of Watc hdog Cont rol Register) th e Window wa tch do g is de act ivat e d, an d no uC sup erv ision is active.

NORMAL MODE

WINDOW WDC

DISABLED

The forced sleep mode is left upon wakeup through either CAN or edge on

WAKE. Appl ying a per manent wakeup ( i. e. bot h CAN-l ines domin ant) pr events V1 from being turned off (can be used during System debugging)

WAKEUP

Forcing NRES high externally, fail will not be incremented (Emulation)

STARTUP

t=320ms

FAILURE

fail = 7

RESET low

t=1ms

A missing ACK within 320ms will

initiate a STARTUP FAILURE

phase (RESET low).

WDC-FAIL

(fail ++)

If no WDC-ACK is recei ved within

seven retrials the voltage regulator

WDC-ACK

&

WDEN SET

The Window supervision can temporarily be deactivated for the time programmed during the

last WDC-ACK (WDT[3:0]). Upon rewriting

(WDC -AC K) or e xpiry of the time r, the NO R MAL

STATE is reentered.

V1 will be turned off by entering the

FORCED SLEEP state.

WDC-ACK

t=t

WIN2

WDC-OK

WINDOW

WATCHDOG

REFRESH

TIMEOUT | WDC-ACK

WDEN SET

TIMEOUT | WDC-ACK

FORCED SLEEP

V1 off

No Reset

TIMER

ACTIVEWDEN SET

(restart by double

WDC-ACK & WDEN)

Here the t imer ca n b e used to

generate time events (i.e.

wakeup uC from stop)

TIMER

ACTIVE

(restart by double

WDC-ACK & WDEN)

WAKEUP

&V1_UV

WAKEUP&V1_UV

10/35

WAKEUP

Programmed

SLEEP

V1 OFF

No Reset

DISAR

SET

Setti ng DI SAR ( see V ol t age Reg ul a t or Con t r ol R egi s te r ) Vol t ag e r e gu la t or V1 i s

turned off, and the output voltage is decreasing depending on the external load

and blocking capa citor .

Note, that during this transition no Reset will be generated (due to Debugmode).

Upon wakeup howewer NRES wil l be pulled low, if V1was below the programmable reset threshold (V1_UV).

Page 11

L4969

1.3 CAN Transceiver

– Supports double wire unshielded busses

– Baud rate up to 125KBaud

– Short circuit protection (battery, ground, wires shorted)

– Single wire operation possible (automatic switching to single wire upon bus failures)

– Bus not loaded in case of unpowered transceiver

The CAN transceiver stage is able to transfer serial data on two independent communication wires either deferentially (n ormal operation) or in case of a single wi re fault on the remaining li ne. The physical bitcoding is done

using dominant (transmitter active) and overwritable recessive states. Too long dominant phases are detected

internally and further transmission is automatically disabled (malfunction of protocol unit does not affect communication on the bus, "fail-sa fe" - mechanism). For low current consu mption during bus inactiv ity a sleep mode

is available. The operating mode can be entered from the sleep mode either by local wake up (

tection of a dominant bit on the CAN-bus (external wake up).

Ten different errors on the physical buslines can be distinguished:

1.3.1 Detectable Physical Busline Failures

N Type of Errors Conditions

Errors caused by damage of the datalines or isolation

µ

C) or upon de-

I CANH wire interrupted (tied to Ground or termination) Edgecount difference > 3

II CANL wire interrupted (floating or tied termination) Edgecount difference > 3

III CANH short circuit to V

IV CANL short circuit to GND (permanently dominant) V(CANL) < 3.1V & V(CANH)-V(CANL)

V CANH short circuit to GND (permanently recessive) Edgecount difference > 3

VI CANL short circuit to V

VII CANL shorted to CANH V(CANH) - V(CANL) < -3.25V after

Errors caused by misbehavior of transceiver stage

VIII CANH short circuit to VDD (permanently dominant) V(CANH) > 1.8V & V(CANH) -

IX CANL short circuit to VDD (permanently recessive) Edgecount difference > 3

Errors caused by defective protocol unit

X CANH, CANL driven dominant for more than 1.3ms

(overvoltage condition) V(CANH) > 7.2V after 32us

BAT

< -3.25V after 1.3ms

(overvoltage condition) V(CANL) > 7.2V after 32us

BAT

1.3ms

V(CANL) < -3.25V after 2.5ms

Not all of the 10 different errors lead to a breakdown of the whole communication.

So the errors can be categorized into 'negligible', 'problematic' and 'severe':

11/35

Page 12

L4969

1.3.2 Neg ligible Errors

1.3.2.1

Error I and II (CANH or CANL interrupted but still tied to termination)

Error IV and VIII (CANH or CANL permanently dominant by short circuit)

Transmitter

In all cases above data can still be transmitted in differential mode.

1.3.2.2

Error I and II (CANH or CANL interrupted but still tied to termination)

Error V and IX (CANH or CANL permanently recessive by short circuit)

Receiver

In all cases above data can still be received in differential mode.

1.3.3 Problematic Errors

1.3.3.1

Error III and VI (CANH or CANL show overvoltage condition by short circuit)

Transmitter

Data is transmitted using the remaining dataline (single wire)

1.3.3.2

Error III and VI (CANH or CANL show overvoltage condition by short circuit)

Receiver

Data is received using the remaining dataline (single wire)

1.3.4 Severe Errors

1.3.4.1

Error V and IX (CANH or CANL permanently recessive by short circuit)

Transmitter

Data is transmitted on the remaining dataline after short circuit detection

Error VII (CANH is shorted to CANL)

Data is transmitted on CANH or CANL after overcurrent was detected

Error X (attempt to transmit more than 10 successive dominant bits (at lowest bitrate specified)

Transmission is terminated (fail safe)

1.3.4.2

Error VII (CANH is shorted to CANL)

Receiver

Data is received on CANH or CANL after detection of permanent dominant state

Error IV and VIII (CANH or CANL permanently dominant by short circuit)

Data is received on CANH or CANL after short circuit was detected

Error X (reception of a sequence of dominant bits, violating the protocol rules)

Data is received normally, error is detected by protocol-unit

The error conditions is signaled issuing an error flag inside a dedicated register which is readable by the µC

through the serial interface. The information of the error type (I through X) is also stored into this register.

12/35

Page 13

L4969

1.4 Oscillator

A low power oscillator provides an internal clock. In sleep mode (Watchdog active) the output frequency is

250kHz, if the Watchdog function is not requested, the internal Oscillator is switched off.

In standby and operating mode the os cill ator is r unning at 1MHz, and can be c alibrated i n a r ange from -16% to

+16% using the

1.5 WatchdL4969og

A triple function programmable watchdog is integrated to perform the following tasks:

– Wakeup Watchdog:

When in sleep or standby mode the watchdog can generate a wakeup condition after a programmable period of time ranging from 80ms up to 45 minutes

– Startup Watchdog:

Upon V1 power-up or

ated periodically every 320ms for 2.5ms until activity of the

knowledge is received within 7 cycles (2.2sec). In this condition the device is forced into Sleep mode

until a Wakeup is detected and a startup cycle is reinitialized.

– Window Watchdog:

After passing the startup sequence, this watchdog request an ac knowledge by the

within a programmable timing fr ame, ranging from 2.5 ... 5ms up to 20 . .. 40ms. Upon a m issing or

misplaced acknowledge the Startup Watchdog is initialized.

µ

C-XTAL as a reference.

µC failure during SPI supervision (see SW-Wat chdog) a res et pulse is gener-

µC is detected (SPI sequence) or no ac-

µC via the SPI

1.6 Reset

1.6.1 Powe r- on Re set

Upon Power-on (VS > 3.5V), the internal reset forces the device into a predefined power-on state (see 1.1):

Standby #3:V1 on V2 off V3 off,CAN-Standby mode, ID-Filter disabled, Startup Watchdog active

With VS below 5V the regulator V1 will follow VS with minimum drop. The

µ

C retrieves a reset if V1 is dropping

below a programmable voltage level of either 4.5V (default) or 4.0V. The programmed state of the L4969 remains unchanged. The act. low Resetpulse duration is fixed internally by an open-drain output stage to 1ms.

However, this time can be externally extended by an additional capacitance connect between NRESET and

GROUND which is then charged by the internal pull-up of typ. 120K. Depending on the Reset-Input-Threshold

of the uC (U

C

= -tD / (120E3 ln(1-UTR/V1))).

EXT

To obtain a reset-pulse duration of t

), the reqired Capacitance for a typical tD can be calculated as follows:

TR

= 50ms with UTR/V1 = 0.5, a Capacitance of C

D

= -50E-3 / (120E3 ln

EXT

0.5) = 600nF is required.

Figure 4.

V1

120K

NRES

C

EXT

to Reset Input of uC

1.6.2 Un der volt age Rese t

Upon detection of a V1 voltage level below a programmable voltage level of either 4.5V (default) or 4.0V,the

NRES-pin is pulled low. Since this undervoltage detection is additionally sampled periodically every ms, the

NRES low time will be extended by up to 1 ms if V1 was low (V1

) at the sampling point (see below).

UV

13/35

Page 14

L4969

Figure 5.

1ms sampling

V1

UV

NRES

1.6.3 Reset signalling during Sleepmode

When entering the sleep mode by writing 1 to DISAR in the VRCR register, the Voltageregulators and their references will be deactivated to allow minimum current consumption. By removing the V1 reference, the outputvoltage is no longer supervised and thus NO reset will be generated.

Now two scenarios are possible (see statediagram in chapter 1.2):

1) Wakeup with V1 still above reset threshold: V1 will be reactivated and Normal mode is resumed

2) Wakeup with V1 below reset threshold: V1 will be activated, NRES will go low and remain low until V1 is

above reset threshold and Startup mode is entered.

The scenario 2 is the most critical when used with uC that do not have their own POR circuitry.

In this case V1 will ramp down with an unknown application state.

To guarantee a proper shut off of an uC without an internal POR circuitry the following mechanism can be utilized: The L4969 uses a bidirectional Reset to detect a possible Watchdog failure of the uC. If this failure condition is detected, NRES will be forced low for 1 ms (with activated timer) or until a wakeup condition occurs

(WDEN bit in WDC register reset, thus RC-oscillator will be switched off during sleep).

Two methods can be used to allow a proper sleep transition:

- With Timer (WDEN=1): immediately after setting DISAR the uC has to program its WDC to generate a failure

causing the L496 9 to detect a low level on NRES foll owed by an automatic 1m s pulse ex tension. If V1 is ramping

down slow, Cext has to be defined in a way, that NRES will stay below the input threshold of the uC until V1 is

in a safe level.

- Without timer (WDEN=0): same proc edure as above, bu t uC has to generate a R eset within 1 ms after WDEN

has been cleared. NRES will then stay low, until a wakeup condition occurs.

Figure 6.

.

DISAR

REF REG

R1

V1

R2

NRES

WDC

1ms

RC-Osc

C

EXT

uC

L4969

1.7 Identifier Fil ter

A 12-Bit CAN-ID-filter is implemented allowing wakeup via specific CAN-messages thus aiding the implementation of low power partial communication networks like standby diagnostics without the need to power-up the

whole network.

To guarantee the detection of the programmed Identifiers, the local RC-oscillator can be calibrated to allow the

programmable Bittime logic to extract the incoming stream with a maximum of tolerance over temperature deviation.

1.8 Groun d Shift Detection

14/35

Page 15

L4969

In case of single wire communication via CANH the signal to noise ratio is low. Detecting the local ground shift

can be used as an additional indicator on the current signal quality. The information of the integrated ground

shift detector will be refreshed upon every falling edge on TX and can be read from the CAN Transceiver Status

Register (CTSR).

It will be set, if V(CANH) < -1V, reset if V(CANH > -1V) at the falling edge of TX.

1.9 Thermal Protection

The device features three independent thermal warning circuits which moni tor the temperature of the V1 output,

the V2 output and the CAN_H and CAN_L drivers together with voltage regulator V3. Each circuit sets a separate overtemperature flag in a register which is read and writable by the serial interface. The overtemperature

flags cause an interrupt to the

enable registers. To enhance system security following strategy is chosen for thermal warning and shutdown:

– 3 independent warning flags are set at 140°C for V1, V2 and V3/CAN-Transceiver

– at 170°C V2 and V3 switched off

– at 200°C V1 is switched off

– V2 and V3 can be switched on again through the

– V1 can be switched on again at wake-up (Watchdog wake-up, CAN wake-up, external wake-up)

Note, that if no wakeup source is set for V1 a 1sec watchdog timeout will be established to enable a proper retry

cycle.

µ

C. The µC is able to switch V1, V2 and CAN drivers on and off through dedicated

µC

1.10 Serial Interface (SPI)

A standard serial p eripheral interfac e (SPI) is implemented to allow access to the internal register s of the L4969.

A total of 12 Registers with differen t datalengths ca n be directly read fr om or w ritten to, providi ng the req uested

address at the beginning of a dataframe. Upon every access to this interface, the content of the register currently

accessed is shifted out via SOUT. All operations are performed on the rising edge of SCLK.

If a frame is not completed, the interface is automatically reset after 1.5ms of SCLK idle time (auto timeout detection). If a message is corrupted ( additional or missi ng SCLK pulses), the appli cation softw are can detect thi s

by evaluating the returned value of the crc and force a communication gap of min 1.5ms to allow communicvation recovery. A corruption c an be caused during star tup of the uC and S PI initializ ation. The appli cation s hould

then wait at least 1.5ms after SPI init prior to starting the communication.

The dataframe format used described on the next page:

15/35

Page 16

L4969

1.10.1General Dataframe Format:

Figure 7.

SIN

7

SOUT ADR/CMD Datafield 1 (R) Datafield 2/CRC (R)

SCLK

99AT0015

ADR/CMD

Datafield 1 (W/R)

0

15

0715

8823

Datafield 2/CRC (W/R)

23

15

15

Data is sampled on the rising edge of the clock and SOUT will change upon SCLK falling. SOUT will show a

copy of SIN for the Address/ C ommand field for initial data path checks. Independent of the command state,

SOUT will show the content of the register addressed. SIN contains either data to be written or arbitrary data

for all other operations. The transaction will be terminated with four bit of data followed by a 4-Bit wide CRC

(Cyclic Redundancy Check) as a result of either SIN related data or calculated automatically on data returned

via SOUT. Here the

µ

C has to provide the cor rect sequenc e in order to get the write command acti vated ins ide.

A CRC-failure is signall ed v ia N INT. For r eturned data the C RC c an als o be used to verify a succ essful tr ansfer.

1.10.2 Address/Command Field

Figure 8.

70

C0

Frame start sequence

always has to be

transmitted as 0 1

ADR310

ADR2 ADR1

Addressfield specifying

the Control/Status word

to be accessed

ADR0 C1

SPI command:

00: Read register

01: C le a r IFR

10: illegal command

11: Write register

The Address/Command field starts with a 2-Bit start sequence consisting of ‘01’. Any other sequence will lead

to a protocol error signalled via the NINT. The addressfield is specifying the register to be accessed. The SPI

command flags all ow in additi on to the normal r ead/write operation to clear the Interrupt flag regis ter after read.

16/35

Page 17

1.10.3 Datafield #1

Figure 9.

L4969

D7

D6

D5

D4 D3

D2

D1 D0

Lower 8 Bit of 12 Bit data

SIN: Data to write

99AT0017

SOUT: Data currently in selected register

Datafield #1 contains either the lower 8 bits of a 12-Bit frame or the complete byte of an 8-Bit transfer.

Note, that SOUT is always show ing the content of the register cur rently acc essed a nd not a c opy of SIN as during the Address/Command field.

1.10.4 Datafield #2/CRC

Figure 10.

D11

D10 D9 D8

CRC3 CRC2 CRC1 CRC0

Upper 4 Bit of 12 Bit data (Zero if 8 Bit data)

CRC Check sequence

to be appended to tranferred data

Note that upon CRC check failure

no write operation will be performed

SIN: Data to write

SOUT: Data currently in selected register

99AT0018

SIN: CRC of SIN sequence

SOUT: CRC of SOUT sequence

Datafield #2 contains either the upper four bits of a 12-Bit frame or zeros in case of an 8-Bit transfer. This field

is followed by a four bit CRC sequence that is calculated based upon the polynom 0x11h (17 decimal). This

sequence is simply the remainder of a polynomial division performed on the data previously transferred. If the

CRC appended to the SIN sequence fails, any writing will be disabled and an error is signalled via NINT. Another

remainder is cal culated on the SOUT stream and appended accor ding ly t o all ow the appli cation software to validate the correctness of incoming data. To aid evaluation, the CRC checking can be turned off by writing arbitrary data with a valid CRC to address 15. CRC-checking will be reenabled upon another operation of this kind

(Toggled information).

17/35

Page 18

L4969

1.11 Memory Map

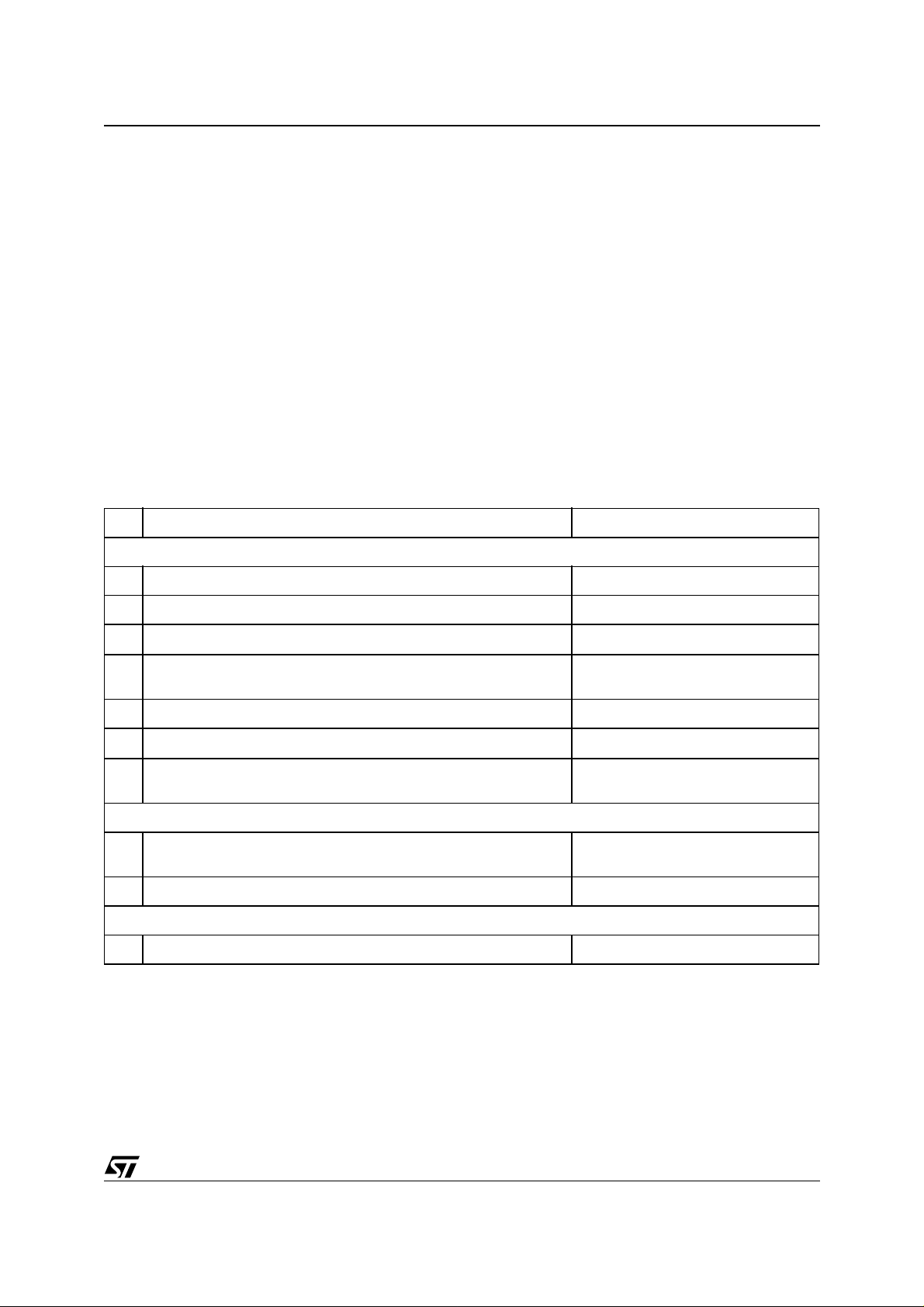

Table 5. L4969 Memory Map

ADR Group MSB D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

0 VRCR

1CTCR

2GPTR

3 RCADJ

4WDC

5GIEN

6IFR

7CTSR

8ID01

9ID23

10 BTL

11 NAV

12 NAV

13 NAV

14 TEST

15 SYS

Undefined

Register Memory

ESPI ISET IRES UV23 UVVS OVT3 OVT2 OVT1 WKE WKC WKW WKIF

RES RES RES GSH EX EVIII EVII EVI EIV EIII EII EI

A11 A10 A01 A00 B11 B10 B01 B00 C11 C10 C01 C00

D11 D10 D01 D00 E11 E10 E01 E00 F11 F10 F01 F00

PS23 PS22 PS21 PS20 PS13 PS12 PS11 PS10 TD3 TD2 TD1 TD0

T11 T10 T09 T08 T07 T06 T05 T04 T03 T02 T01 T00

Undefined Register Memory NCRC STAT WNDF STF OTF UCF WAKE NPOR

EUV3 EUV2 RTC0 TRC RES ENV3 ENV2 DISAR

ACT TXEN RES RES RES LP2 LP1 LP0

RES RES RES RES TM1 TM0 TMUX TEN

CG1 CG0 PGEN SIGN ADJ3 ADJ2 ADJ1 ADJ0

WDEN WND SWT1 SWT0 WDT3 WDT2 WDT1 WDT0

ISET IRES EUV EOVT EEW ECW EWW EIFW

Undefined

Register Memory

The memory space is divided up into 16 different registers each being directly accessible using the SPI.

Each register contains specific information of a functional group.

In general al reserved bitpositions (‘RES’) have to be written with ‘0’.

Undefined bits are read as ‘0’ and cannot be overwritten.

In addition there is one register (CTSR) being read only, thus any write attempt will leave the register content

unchanged.

Certain interlock mechanism exist to prevent unwanted overwriting of important functions i.e. voltage regulators

or oscillator adjustments. These mechanisms are described with the functions of these registers.

*1) “shorted to ...”

18/35

Page 19

L4969

2 CONTROL AND STATUS REGISTERS

The functionality of the device can be observed and controlled through a set of registers which are read and

writable by the serial interface.

2.1 ADR 0: VRCR Voltage Regulator Control Register

Figure 11.

D7 D0

EUV2EUV3 ENV3 ENV2 DISAR

RTC0

TRC

RES

Has to be

Enable undervoltage

written as ‘0 ’.

detection on

Regulator #2 and #3

(see note below)

Set reset threshold value to 4.0V

Default value is ‘0’ (4.5V)

Enable Regulator #2 tracking option

to have V2 following V1 with constant offset

Default value is ‘0’ (disabled)

Enable Regulator #3 .

V3 will be activated by either setting ENV3 or

upon enabling of the CAN Lineinterface

Default value is ‘0’ (dis a ble d)

This bit will be automatically reset upon

Overtemperature from CANIF or Regulator #3

Disable all Regulators (Go to Sleep)

Note, that at least one Wakeup Source

without a pending wakeup is required

to enable access.

This bit will be automatically set upon

the system failures Overtemperature V1

or watchdog startup failure.

Note, that no reset will be generated

from low V1 during Sleep mode transition

The Reset line has to be forced low

externally, or through a window failure

DISAR will be cleared upon a valid

wakeup signal which is either defined

in GIEN or is forced to WAKE or CAN

after a system fail ure

Enable Regulator #2.

Default value is ‘0’ (disabled)

This bit will be automatically reset upon

Overtemperature at Regulator #2.

Note, that due to the large initial charging current of the output capacitors,

the activation of V2 AND V3 within the same command is not recommended

also leaving ENV2 or ENV3 set when setting DISAR can therefor not be

recommended (after wakeup V1 AND V2 or V3 would be turned on)

TRC

DISAR

REF

V1 V3

Note, that when using the Undervoltage-detecti on, EUV2 and EUV3 have to be activated

DISAR

& ENV2

(DISAR

ACT) & T SDV3

V2

V3 will be activated upon VRCR.ENV3 or

CCTR.ACT without pending thermal shutdown

AFTER

& ENV3 |

V2 or V3 have

been turned on and settled (t > 1ms). Otherwise unwanted undervoltage can be detectected dur ing turn on of

the corresponding voltage regulator.

19/35

Page 20

L4969

2.2 ADR 1: CTCR CAN-Transceiver Control Register

Figure 12.

D7 D0

RESTXENACT

RES RES

LP2

LP1 LP0

Standby-m ode control (V1 only, see 1.1)

CAN-Trans ceiver application control

0X : Standby / Sleep

reduce Osc-fr equency to 250KHz

enabl e Auto-Osc-Off

10 : Receive only mode A (Readback TX, if not EX)

11 : Normal Operat ion

Note, that TXEN is automatically reset upon

occurence of EX (TX permanent dominant)

and has to be reprogrammed after problem

correction to enter normal mode.

Reserved bits (‘RES’) have to be written as ‘0’.

Three basic operating modes are available using different logic combinations on ACT and TXEN. Each of these

modes in conjunction with other inputs has its unique combination of parameters inside the specification:

Table 6. Operating Modes of the CAN Lineinterface

Input Signals Output Signals

ACT TXEN TX CANH CANL V3 Mode RTL RTH CANH CANL RX

0 X X RTH RTL ON Standby V

1 0 1/0 RTH RTL ON RXonly V

1 0 1 RTL ON RXonly V

1 0 1 RTH ON RXonly V

1 1 1 RTH RTL ON Normal V

1 1 0 RTH RTL ON Normal V

1 1 1 RTL ON Normal V

1 1 1 RTH ON Normal V

*1

11

0

1X1

1X1

RTH RTL ON Error X V

VDD

VS

*1

*1

RTL ON Error

VII, VIII

RTL ON Error

EIII, VII, VIII

1 X 1 GND x 3 ON Error

EI_V

1X1 x 3VDDON Error

EII_IX

1X1RTH

1X1RTH

1X1

CANL

*1

VS

GND

CANH

*1

*1

*1

ON Error

EVI

ON Error

EVII, EIV

ON Error

EVII

ISRC GND ON OFF CANH

ISRC GND ON OFF CANH

ISRC GND ON OFF CANH

V

V

V

V

GND OFF OFF 1

BAT

GND OFF OFF TX

DD

GND OFF OFF

DD

GND OFF OFF

DD

GND ON ON 1

DD

GND VDD GND 0

DD

GND ON ON

DD

GND ON ON

DD

GND OFF OFF 1

DD

ISRC OFF ON CANL

DD

ISRC OFF ON CANL

DD

GND ON ON

DD

GND ON ON

DD

20/35

Page 21

2.3 ADR 2: GPTR Global Parameter and Test Register

Figure 13.

D7 D0

L4969

RES

This register is to be used for testpurpose only, all bits have to remain ‘zero’

2.4 ADR 3: RCADJ RC-Oscillator Adjust register

Figure 14.

RES RES

RES

TM1 TM0 TMUX TEN

D7

CG1 CG0 PGEN ADJ4 ADJ3 ADJ2 ADJ1 ADJ0

0: 0%

1: +16%

0: 0%

1: -8%

0: 0%

1: -4%

0: 0%

1: -2%

Program enable (read only)

Bit will be set after 'Finish cycle measurement',

and reset after register write

D0

0: 0%

1: -1%

RC Oscillator

Frequency Adjust

default value 10000

Note, that programming

is only enabled with PGEN set

Test cycle request

A low pulse on NINT

for a fixed period

of time can be requested

for XTAL synchronization

99AT0022

During normal operation the µC can set CG1 and CG0 to ‘01’ to force a 200Hz rectangular waveform on NINT

with 50% duty cycle. Note, that all other pending interrupts have to be cleared before.

After the XTAL driven timer of the

CG1 and CG0 have to be set to ‘10’ to disable the adjustment cycle on NINT. From the deviation calculated by

the

µ

C, the correction factor of the RC-oscillator -15% to + 16% can be reprogrammed with CG1 and CG0 set

to ‘00’ or ‘11’. (‘11’ can be used to indicate that calibration has already been performed).

Note, that overwriting this register is only valid, if the cycle measurement was started and terminated properly.

This can be tested by evaluating PGEN either prior to or during correction (Read back via SOUT).

Note also, that any write to the W DC register w ill reset the timer a nd thus reset the phase of the testcycle. Therefore a cyclic access to the window watchdog during the pulsewidth measurement has to be avoided and the

timer watchdog to be used instead (i.e. 1sec)

µ

C calculated the relative cycle time and the corresponding deviation,

00: No request (Adjustment disabled)

01: 2.5ms low cycle on NINT (repetitive)

10: Finish cycle measurement

11: No request (Adjustment disabled)

21/35

Page 22

L4969

Figure 15.

State transition during oscillator calibration

CG=01

“No Request”

Watchdog and Interrupt

has to be disabled

“2.5ms cycle

on NINT”

Start time measurement

at rising edge

CG=10 CG=00

2.5 ADR4: WDC Watchdog Control Register

Figure 16.

D7 D0

SWT0 WDT3SWT1WNDWDEN WDT2 WDT1 WDT0

Disable

Window Watchdog,

only allowed with

PGEN set, see

previous table

for Osc adjust

Enable Wakeup Watchdog,

Window Watchdog will be

automatically deactivated

until wakeup watchdog expires

Reserved bits (‘RES’) have to be written as ‘0’.

Software Window Watchdog

timing configuration

00 : 2.5 - 5ms

01 : 5 - 10ms

10 : 10 - 20ms

11 : 20 - 40ms

“Finish Cycle” “Update ADJ”

CG=11

Calculate

Offset

Watchdog and Interrupt can be enabled

Write offset

Wakeup Watc hdog

timing configuration

0000 : 80ms

0001 : 160ms

0010 : 320ms

0011 : 640ms

0100 : 800ms

1000 : 1sec

1001 : 2sec

1010 : 4sec

1011 : 8sec

1100 : 45min

The Startup Watchdog is not programmable and will always generate a 1.0ms low cycle on NRESET followed

by a 320ms high cycle until an Acknowledgment will occur. If no Acknowldege is received after the 7th cycle,

the device will automatically be forced into Sleep mode.

Acknowledgment and Reset of Startup and Window Watchdog is automatically performed by overwriting

(or rewriting) this register.

Note, that with WDEN set, a cyclic setting of IFR.WKW after the programmed Wakeup time will occur.

2.5.1 Watchdog configuration:

22/35

Page 23

L4969

Figure 17.

POR

NRESET

forced low

externally

Wakeup

Prog

Sleep

Ack

Note: WR, writing to this address, will restart the timer

After power-on-reset of VS and V1 or wakeup from Sleep or NRESET being forced low externally, the Startup

Watchdog is active, supervising the proper startup of the V1 supplied uC. Upon missing SPI write operation to

the WDC register after 7 reset cycles (1ms active, 320ms high) the Sleep mode is entered.

Leaving the forced Sleep mode will be automatically performed upon wakeup via CAN, an edge on WAKE or

upon device powerup.

After successful startup, the W indow Watchdog supervision is activated, meaning, that the uC has to send an

acknowledge within a predefined, programmable w i ndow.

Upon failure, a reset is generated and the Startup Watchdog is reactivated.

If the Timer func tion is requ ested, t he window watchdog is deactivated until expiry o f the wakeup tim e, or rewriting of this register. Note, that any write to this register will reset the timer.

Ack

ExtWake

Startup

Wd

Window

Wd

CAN-Wake

missing Ack

(after 350ms)

missing

Ack

Timeout

WR

WR & WDEN

Forced

Sleep

Wakeup

Timer

2.5.2 Startup

Figure 18.

V1

1ms

NRESET

Startup Acknowledgement via SPI within 320ms

NRESET

Startup Acknowledgemen t via SPI within 640ms

NRESET

No Startup Acknowledgement via SPI within 2.3s (De vice will enter Sleep mode)

After powerup, the L4969 is expec ting the uC to send an ac knowledgement w ithin a predefined segmented timing frame of 7 x 320ms. A missing acknowledgement until after the 2.3s will force the device into sleep mode

until either external or CAN wakeup or POR cause a restart of the sequence above.

2.5.3 Window Watchdog

23/35

Page 24

L4969

Figure 19.

2,5 .. 20ms

50%

Early (late) Acknowlede supervision

5 .. 40ms

Early (late) Acknowlede supervision

Acknow ledge is restarting Window

After successful acknowledgement of the Startup sequence, the Window watchdog is automatically activated

and controlling proper uC activity by super vising an incoming acknowledge to ly within a predefined programmable window. Upon every acknowledge the watchdog is restarting the window.

24/35

Page 25

2.5.4 Wakeup Watchdog

Figure 20.

Window Wd Window WdTimer (80ms .. 45min)

L4969

restart tim e r

at any time

writing WDC twice

Timeout and resume Window Wd

NINT

Ack Window &

Start Timer

Interrupt active upon timeout (via GIEN)

If the Timer is activated during N ormal mode by setting WDEN in WDC, an “acknowledge-free” sequence is

started for a predefied programmable time. Window Watchdog activity is resumed after expiry of the timer.

To be able to detect the timeout, the corresponding interrupt enable must be set in GIEN.

This mode can also be used to allow a bootstrap loader mode with longer execution times than the maximum

specified window. Correct s tartup of this load er i s safely detected upon mi ssing r esponse following the timeout.

The timer can always be restarted by rewriting WDEN twice in WDC with a new timing.

25/35

Page 26

L4969

2.6 ADR5: GIEN Global Interrupt Enable Register

Figure 21.

D7 D0

EOVT EEWEUVIRESISET ECW EWW EIFW

Enable Interrupt

upon CAN error

detection

Enable CAN

wakeup / Interrupt

Enable Interrupt

upon CAN error

recov ery

Enable

Interrupt

upon VS / VREG

Undervoltage

Enable Interrupt

upon Overtemp.

Warning

Enable Wakeup / Interrupt

via edge on WAKE

Enable Identifier

based wakeup / Interrupt

Enable Wakeup,/ Interrupt

via Watchdog

2.7 ADR6: IFR Interrupt Flag Register

Figure 22.

D11 D0

ESPI ISET IRES UV23

CAN Linefailure

detected (ISET)

remov e d (IRE S )

CRC- / Format

Error or SCL KTimeout detected

by SPI (non maskable)

UVVS

VS < 7.2V

detected

V2 or V3

Undervoltage

OVT1 : T(V1) > 140degC

OVT2 : T(V2) > 140degC

OVT3 : T(V3) > 140degC

OVT3

Overtemperature

Warning level reached

OVT2

OVT1

WKE

Signal edge

on W AKE

dete cte d

W ak eup condition

via CAN detected

Watchdog timeout

detected

WKWWKC

Identifier passed

CAN ID-Filter

WKIF

Reserved bit (‘RES’) has to be written as ‘0’.

Except ESPI all bits in this register are maskable in GIEN. Any mask ed bit will force NINT low until the register

content is reset (either explicitly or by SPI ‘clear register).

26/35

Page 27

2.8 ADR7: CTSR CAN Transceiver Status Register

Figure 23.

D11 D0

RES RES RES GSH EI_VEII_IXEIIIEIVEVIII EV II EVIEX

L4969

CANH < -1V

at falling edge TX

TX permanent

dominant detected

(TXD = ‘0’, t > 1.3ms)

CANH permanen t

dominant detected

(CANH > 1.8V, t > 1.3ms)

CANL short

circuit to VS

detected

(CANL > 7.2V ,

t > 32us)

CANL permanent

dominan t de tec t ed

(CANL < 3.1V,

t > 1.3ms)

Short circuit CANH to CANL detected

(CANH - CANL > -3.25V, t > 1.3ms)

CANH short

circuit to VS

detected

(CANH > 7.2V,

t > 32us)

Reserved bit s (‘RE S ’) are al w ays read as ‘0’

Note, that this register i s read only and only provides the unlatched i nformation on current bus errors.

Single wire

communication

detected

(edge co unt

difference > 3)

EI_V : CANH off

EII_IX : CANL off

27/35

Page 28

L4969

2.9 ADR 8 and 9: ID01, ID23 Identifier Filter Sequence Select Register

Figure 24.

SEGA SEGB SEGC SEGD SEGE SEGF

00

A00

A01

A10

A11

SOF

ID10 ID9 ID8

4/2

Demux

11

ID7

ID6 ID5

ID4

ID3

ID2 ID1

00

F00

F01

F10

F11

ID0

Demux

RTR

4/2

11

99AT0028

PASS

Identifier of CAN Frame can be divided up into 6 segments numbered from ‘A’ to ‘F’.

For each segment a filter regis t er is im plemented, enabl ing different pass func tions on ever y two bit w ide block.

Segments A through C (ID01) are located at ADR 8 with MSB ‘C11’

Segments D through F (ID23) are located at ADR 9 with MSB ‘F11’

Note, that clearing a complete segment disables the whole filter.

SEGE

SEGF

01 01 01

01 11 01

Valid sequence

for each segment

SEGA: A10, A00

SEGB: B01

SEGC: C01, C00

SEGD: D10, D01

ID bits to be set

0101

0010 ID01: 0011 0010 0101

0011

0110

Examples:

Identifiers to pass:

SEGD

10 01 00

10 01 01

00 01 01 10 00 10

SEGE: E11, E01, E00 1011 ID01: 0110 1011 0110

SEGA

SEGC

SEGF: F10, F01

0011

SEGB

28/35

Page 29

2.10 ADR 10: BTL Identifier Filter Bittimelogic Control Reg ister

Figure 25.

D11 D0

L4969

PS23 PS22 PS21 PS2 PS13 PS12 PS11 PS10

Phasesegment 2

length configuration

t

= 1us * PSEG2 t

PSEG2

Phasesegment 1

length configuration

= 1us * (1 + PSEG1)

PSEG1

Bittime synchronization mechanism

t

PSEG1

TD3

TD2 TD1

Dominant to Rezessive

bitlength difference control

td = t

t

PSEG2

dom

- t

TD0

rez

t = 1u

Sample Point

99AT0030

The total bitlength equals the sum of 1 + PSEG1 + PSEG2 in units of µs.

The location of the sampling point is determined by the length of PSEG1.

At the start of frame (initial recessive to dominant edge) the bitlength counter is reset.

Upon every signal edge the counter will be lengthened or shortened according to location of the transition wi thin

the programmed boundaries of PSEG1 or PSEG2. If the edge lies within PSEG1 additional cycles are inserted

in order to shift the sampling point to a safe location after the settling of the input signal. If the signal transition

is located within PSEG2, this segment will be shortened accordingly with the goal of the next edge to lie at the

beginning of PSEG1.

The amount of cycles one segment is lengthened or shortened is determined by the type of edge (rec -> dom

or dom -> rec) and the programming of TD: The resynchronization jump width will be either set to ‘1’ (dom ->

rec edge) or to 1 + TD (rec -> dom edge).

Note, that the length of one timequanta depends on the offset of the on chip RC-oscillator and therefore on the

accuracy of calibration (see register RCADJ (ADR 3) for details on frequency correction)

29/35

Page 30

L4969

2.11 ADR 15: SYS System Status Register

Figure 26.

D7 D0

STF

CRC-Checking

disabled

OTFWNDFSTATNCRC UCF W AKE NPOR

Cold Start

after low VS

Reserved

status flag

(test only)

Warm start

Warm start

after V 1

Overtemp failure

Warm start

after leaving

prog. Sleep mode

after failure of

Window watchdog

Warm start

after 7 m i ss i n g

Ack during Startup

Warm start

after < 7 missing

Ack during Startup

The lower 6 bit of this register can be used to analyze the reason of startup (after NRESET low). This information

is valid until the first Watchdog-Acknowldge, and will then be reinitialized to 000001.

30/35

Page 31

3 INTERRUPT MANAGEMENT

Figure 27.

L4969

D11 D0

ESPI ISET IRES UV23

IFR

WKIFWKWWKCWKEOVT3 OVT2 OVT1UVVS

EUVIRESISET ECW EWW EIFW

EOVT

EEW

D7 D0

GIEN

NINT

All Interrupt flags (in IFR) except ESPI can be masked in the global interrupt enable register (GIEN).

An Interrupt will be signalled by NINT going low until either the corresponding ma sk or the flag itself will be reset

by the applicati on software. A n auto reset functi on is avai lable for IFR, allow ing to remove all i nter rupt flags after

reading their state (see SPI).

31/35

Page 32

L4969

4 REMARKS FOR APPLICATION

Figure 28. General circuit connection diagram

Thermal

VS

Supervision

*

10u

47n

Standby Supply

& Adjustable

RC-Oscillator

V2

V1

*

47n

Peripheral

Supply

10u

33u

*

47p

*

47n

Programmable

Timer

Wakeup & Interrupt

Detection

WAKE

V3

RTH

CANH

CANL

CAN

Transceiver

Groundshift

Detection

SPI

120K

NRES

NINT

SCLK

SOUT

SIN

RX

TX

*

47n

10u

opt

µC

*

47p

99AT0032

C* ceramic C close to pin recommended for EMI

32/35

RTL

ID-Filter

GND

Page 33

L4969

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 2.35 2.65 0.093 0.104

A1 0.1 0.3 0.004 0.012

B 0.33 0.51 0.013 0.020

C 0.23 0.32 0.009 0.013

D 12.6 13 0.496 0.512

E 7.4 7.6 0.291 0.299

e 1.27 0.050

H 10 10.65 0.394 0.419

h 0.25 0.75 0.010 0.030

L 0.4 1.27 0.016 0.050

K 0˚ (min.)8˚ (max.)

mm inch

OUTLINE AND

MECHANICAL DATA

SO20

B

e

D

1120

110

L

h x 45˚

A

K

A1

C

H

E

SO20MEC

33/35

Page 34

L4969

DIM.

MIN. TYP . MAX. MIN. TYP . MAX.

mm inch

A 3.6 0.142

a1 0.1 0.3 0.004 0.012

a2 3.3 0.130

a3 0 0.1 0.000 0.004

b 0.4 0.53 0.016 0.021

c 0.23 0.32 0.009 0.013

D (1) 15.8 16 0.622 0.630

D1 9.4 9.8 0.370 0.386

E 13.9 14.5 0.547 0.570

e 1.27 0.050

e3 11.43 0.450

E1 (1) 10.9 11.1 0.429 0.437

E2 2.9 0.114

E3 5.8 6.2 0.228 0.244

G 0 0.1 0.000 0.004

H 15.5 15.9 0.610 0.626

h 1.1 0.043

L 0.8 1.1 0.031 0.043

N 8˚ (typ.)

S 8˚ (max.)

T 10 0.394

(1) “D and E1” do not include mold flash or protusions.

- Mold flash or protusions shall not exceed 0.15mm (0.00 6”)

- Critical dimensions: “E”, “G” and “a3”.

OUTLINE AND

MECHANICAL DATA

Weight:

1.9gr

JEDEC MO-166

PowerSO20

E2

NN

a2

b

h x 45

DETAIL A

e3

H

D

T

110

e

1120

E1

A

DETAIL B

PSO20MEC

R

lead

a3

Gage Plane

BOTTOM VIEW

E

DETAIL B

0.35

S

D1

L

c

a1

DETAIL A

slug

- C -

SEATING PLANE

GC

(COPLANARITY)

E3

0056635

34/35

Page 35

L4969

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or oth erwise unde r any patent or patent r i ghts of STMi croelectroni cs. Speci fications me ntioned in this publicat ion are subj ect

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as crit i cal components in life support devices or sy st em s without express writt en approval of STMi croelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2003 STMic roelectronic s - All Rights Reserved

Austra lia - Brazil - Canada - China - F i nl and - France - G erm any - Hong Kong - India - Israel - Italy - Japan -M alaysia - Ma l ta - Morocco -

Singap ore - Spain - Sw eden - Switzerl and - United Ki ngdom - Unit ed S tates.

STMicroelectronics GROUP OF COMPANIES

http://www.s t. com

35/35

Loading...

Loading...