Page 1

®

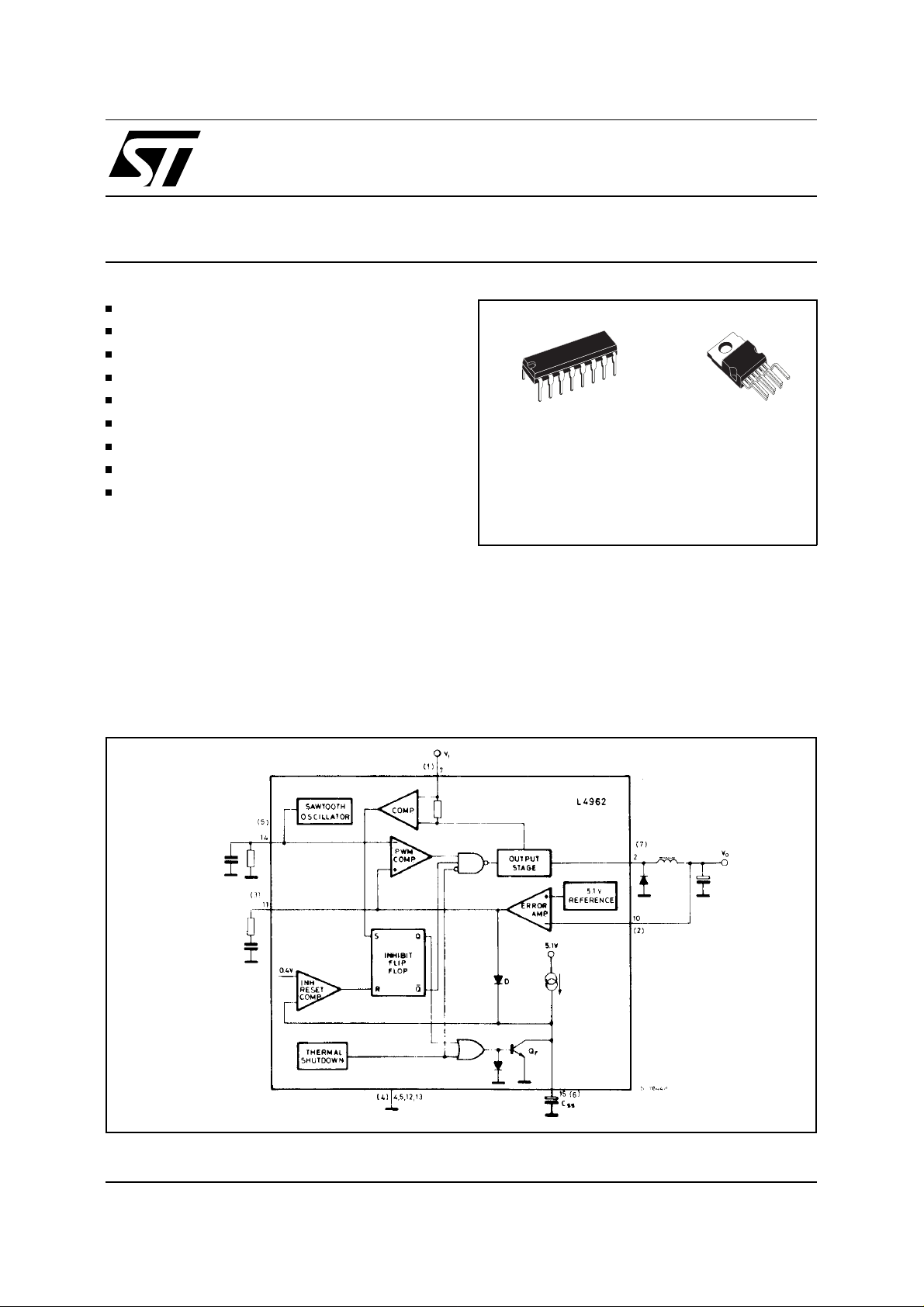

1.5A POWER SWITCHING REGULATOR

1.5A OUTPUT CURRENT

5.1V TO 40V OUTPUT VOLTAG E RANG E

PRECISE (± 2%) ON-CHIP REFERENCE

HIGH SWITCHING FREQUENCY

VERY HIGH EFFICIENCY (UP TO 90%)

VERY FEW EXTERNAL COMPONENTS

SOFT START

INTERNAL LIMITING CURRENT

THERMAL SHUTDOWN

DESCRIPTION

The L4962 is a monolithic power switching regulator delivering 1.5A at a voltage variable from 5V to

40V in step down configuration.

Features of the device include current limiting, soft

start, thermal protection and 0 to 100% duty cycle

for continuous operating mode.

L4962

POWERDIP

(12 + 2 + 2)

ORDERING NUMBERS

: L4962/A (1 2 + 2 + 2 P ower di p)

L4962E/A (Heptawatt

Vertical)

L4962EH/A (Horizontal

Heptawatt)

The L4962 is mounted in a 16-lead Powerdip plastic

package and Heptawatt package and requires very

few external components.

Efficient operation at switching frequencies up to

150KHz allows a reduction in the size and cost of

external filter components.

HEPTAWATT

BLOCK DIAGRAM

June 2000

Pin X = Powerdip

Pin (X) = Heptawatt

1/16

Page 2

L4962

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Val ue Unit

V

Input voltage 50 V

7

V7 - V2Input to output voltage difference 50 V

V

Negative output DC voltage -1 V

2

Output peak voltage at t = 0.1µs; f = 100KHz -5 V

V11, V15Voltage at pin 11, 15 5.5 V

V

I

I

P

, T

T

j

PIN CONNECTION

Voltage at pin 10 7 V

10

Pin 11 sink current 1 mA

11

Pin 14 source current 20 mA

14

Power dissipation at T

tot

T

Junction and storage temperature -40 to 150

stg

≤ 90°C (Powerdip)

pins

≤ 90°C (Heptawatt)

case

(Top view)

4.3

15

W

W

C

°

THERMAL DATA

Symbol Parameter Heptawatt Powerdip

R

th j-case

R

th j-pins

R

th j-amb

* Obtained with the GND pins soldered to printed circuit with minimized copper area.

Thermal resistance junction-case max 4°C/W Thermal resistance junction-pins max - 14°C/W

Thermal resistance junction-ambient max 50°C/W 80°C/W*

PIN FUNCTIONS

HEPTAWATT POWERDIP NAME

1 7 SUPPL Y VOLTAGE Unregulated voltage input. An in ternal re gulator po wers

the internal logic.

2 10 FEEDBACK INPUT The feedback terminal of the regulation loop. The output

is connected directly to this terminal for 5.1V operation;

it is connected via a divider for higher voltages.

3 11 FREQUENCY

COMPENSATION

A series R C network connected between this terminal

and ground determines the regulation loop gain

characteristics.

2/16

FUNCTION

Page 3

L4962

PIN FUNCTIONS

HEPTAWATT POWERDIP NAME

(cont’d)

FUNCTION

4 4, 5, 12, 13 GROUND Common ground terminal.

5 14 OSCILLATOR A parallel RC network connected to this terminal

determines the switching frequency. This pin must be

connected to pin 7 input when the internal oscillator is

used.

6 15 SOFT STAR T Soft start time constant. A capacitor is connected

between this terminal and ground to define the soft start

time constant. This capacitor also determines the

average short circuit output current.

7 2 OUTPUT Regulator output.

1, 3, 6,

N.C.

8, 9, 16

ELECTRICAL CHARACTERISTICS

(Refer to the test circuit, T

= 25 °C, Vi = 35V, unless otherwise

j

specified)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

DYNAMIC CHARACTERISTICS

V

Output voltage range Vi = 46V Io = 1A V

o

Input voltage range Vo = V

V

i

Line regulation Vi = 10V to 40V Vo = V

V

∆

o

Load regulation Vo = V

V

∆

o

V

∆

∆

I

I

I

V

V

I

Internal reference voltage

ref

Vi = 9V to 46V Io = 1A 5 5.1 5.2 V

(pin 10)

ref

Average temperature

coefficient of refer. voltage

T

Dropout voltage Io = 1.5A 1.5 2 V

d

Maximum operating load

om

current

Current limiting threshold

2L

(pin 2)

Input average current Vi = 46V; output short-circuit 15 30 mA

SH

Efficiency f = 100KHz V

η

Tj = 0°C to 125°C

= 1A

I

o

Vi = 9V to 46V

= V

V

o

Vi = 9V to 46V

= V

V

o

= 1A Vo = 12V 80 %

o

ref

to 36V Io = 1.5A 9 46 V

ref

Io = 1A 15 50 mV

ref

ref

Io = 0.5A to 1.5A 8 20 mV

1.5

to 36V

ref

to 36V

ref

= V

o

ref

2

70 %

40 V

0.4

3.3 A

mV/°C

A

SVR Supply voltage ripple

rejection

V

∆

fripple

V

o

= V

= 2V

i

rms

= 100Hz

ref

Io = 1A

50 56

dB

3/16

Page 4

L4962

ELECTRICAL CHARACTERISTICS

(continued)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

DYNAMIC CHARACTE RISTICS

(cont’d)

f Switching frequency 85 100 115 KHz

f

∆

Voltage stability of

switching frequency

V

∆

i

f

∆

Temperature stability of

switching frequency

T

∆

j

f

Maximum operating

max

Vi = 9V to 46V 0.5 %

Tj = 0°C to 125°C1%

Vo = V

ref

Io = 1A 120 150 KHz

switching frequency

T

Thermal shutdown

sd

150

junction temperature

DC CHARACTERISTICS

I

Quiescent drain current 100% duty cycle

7Q

pins 2 and 14 open

V

= 46V

i

0% duty cycle 15 20 mA

30 40 mA

C

°

-I

Output leakage current 0% duty cycle 1 mA

2L

SOFT START

I

15SO

I

Source current 100 140 180

Sink current 50 70 120

15SI

ERROR AMPLIFIER

V

V

I

-I

High level output voltage V10 = 4.7V I11 = 100µA 3.5 V

11H

Low level output voltage V10 = 5.3V I11 = 100µA 0.5V

11L

Sink output current V10 = 5.3V 100 150

11SI

Source output current V

11SO

I

Input bias current V10 = 5.2V 2 10

10

DC open loop gain V11 = 1V to 3V 46 55 dB

G

v

OSCILLATOR

-I

Oscillator source current 5 mA

14

= 4.7V 100 150

10

A

µ

A

µ

A

µ

A

µ

A

µ

4/16

Page 5

L4962

CIRCUIT OPERA TION

(refer to the block diagram)

The L4962 is a monolithic stepdown switching regulator providing output voltages from 5.1V to 40V and

delivering 1.5A.

The regulation loop consists of a sawtooth oscillator, error amplifier, comparator and the output

stage. An error signal is produced by comparing the

output voltage with a precise 5.1V on-chip r eference (zener zap trimmed to ± 2%).

This error signal is then compared with the sawtooth

signal to generate the fixed frequency pulse width

modulated pulses which drive the output stage.

The gain and frequency stability of the loop can be

adjusted by an external RC network connected to

pin 11. Closing the loop directly gives an output

voltage of 5.1V. Higher voltages are obtained by

inserting a voltage divider.

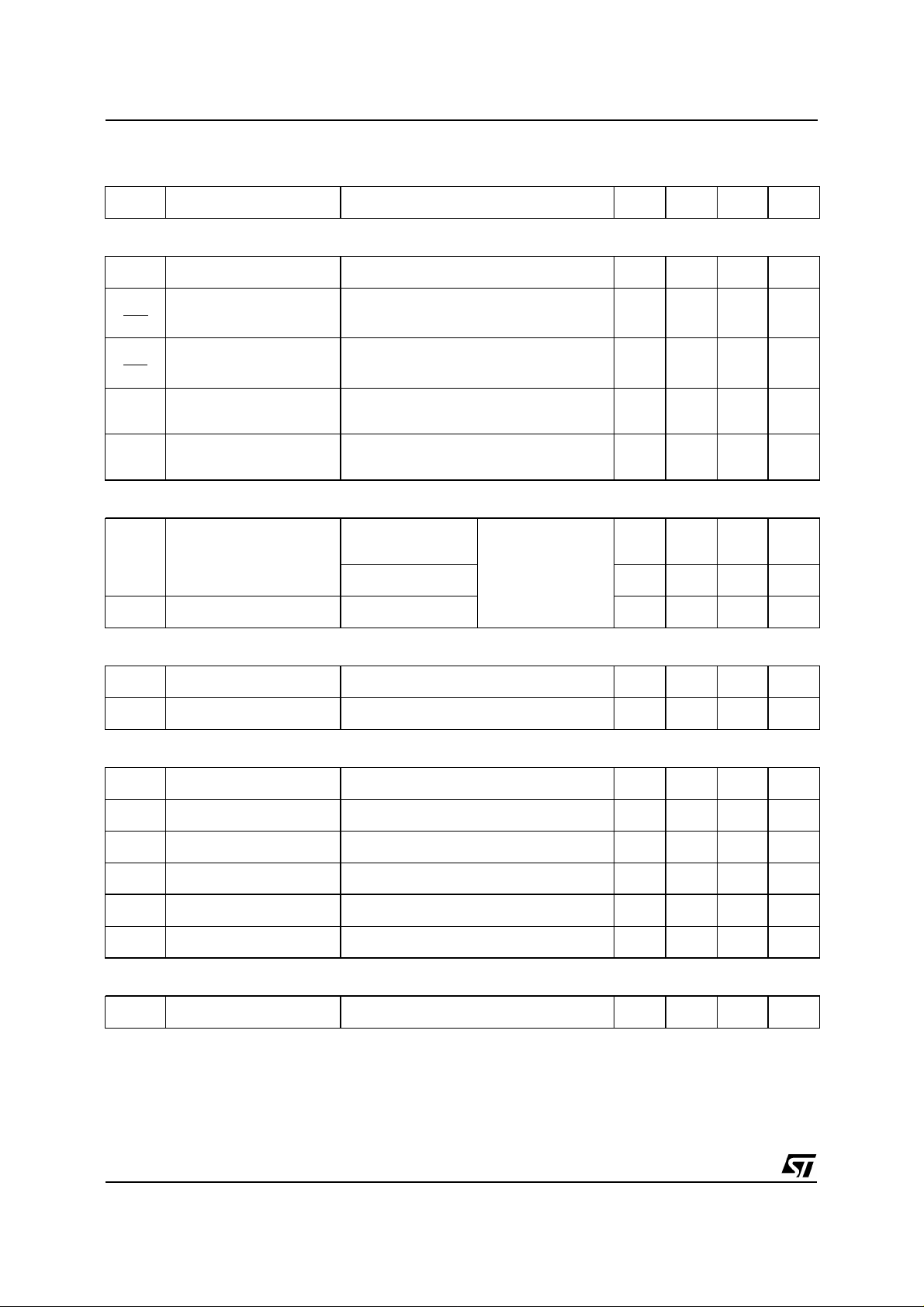

Output overcurrents at switch on are prevented by

the soft start function. The error amplifier output is

initially clamped by the ext ernal capacit or C

ss

and

Figure 1. Soft start waveforms

allowed to rise, linearly, as this capacitor is charged

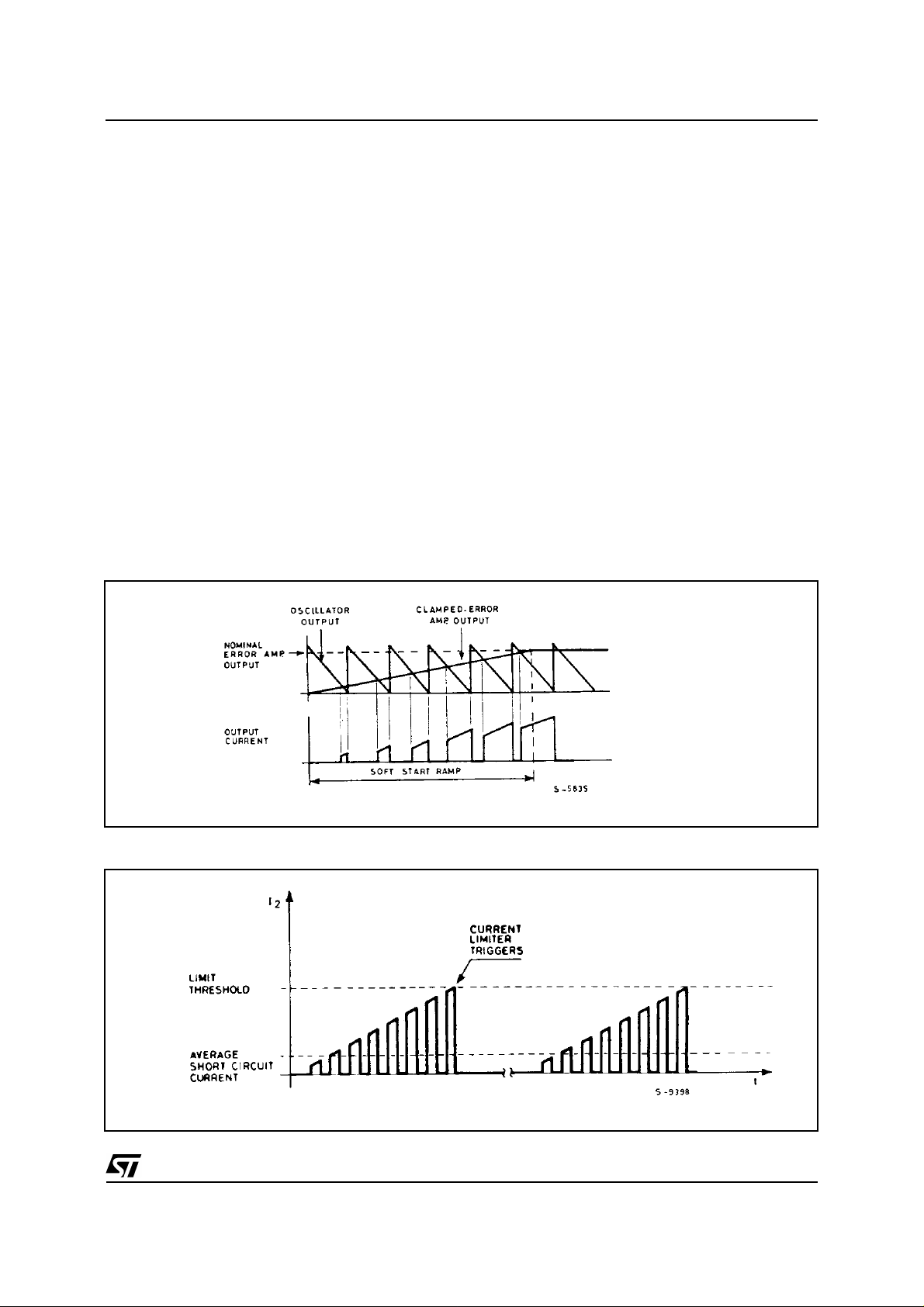

by a constant current source. Output overload protection is provided in the form of a current limiter.

The load current is sensed by an internal metal

resistor connected to a comparator. When the load

current exceeds a preset threshold this comparator

sets a flip flop which disables the output stage and

discharges the soft start capacitor. A second comparator resets the flip flop when the voltage across

the soft start capacitor has fallen to 0.4V.

The output stage is thus re-enabled and the out put

voltage rises under control of the soft start network.

If the overload condition is still present the limiter

will trigger again when the threshold current is

reached. The average short circuit current is lim ited

to a safe value by the dead time introduced by the

soft start network. The thermal overload circuit disables circuit operation when the junction temperature reaches about 150°C and has hysteresis to

prevent unstable conditions.

Figure 2. Current limiter waveforms

5/16

Page 6

L4962

Figure 3. Test and application circuit (Powerdip)

1) D1: BYW98 or 3A Schottky diode, 45V of VRRM;

: CORE TYPE - MAGNETICS 58120 - A2 MPP

2) L

1

N° TURNS 45, WIRE GAUGE: 0.8mm (20 AWG)

, C7: ROE, EKR 220µF 40V

3) C

6

Figure 4. Quiescent drain

current vs. supply voltage (0%

duty cycle)

6/16

Figure 5. Quiescent drain

current vs. supply voltage

(100% duty cycle)

Figure 6. Quiescent drain

current vs. junction temperature (0% duty cycle)

Page 7

L4962

Figure 7. Quiescent drain

current vs. junction temperature (100% duty c ycle)

Figure 10. Open loop frequency and phase re- sponse

of error amplifier

Figure 8. Reference voltage

(pin 10) vs. V

rdip) vs. V

i

i

Figure 11. Switching frequency vs. input voltage

Figure 9. Reference voltage

(pin 10 ) vs. junction temperature

Figure 12. Switching frequency vs. junction temperature

Figure 13. Switching frequency vs. R2 (see test circuit)

Figure 14. Line transient

response

Figure 15. Load transient

response

7/16

Page 8

L4962

Figure 16. Supply voltage

ripple rejection vs. frequency

Figure 19. Efficiency vs.

output current

Figure 17. Dropout voltage

between pin 7 and pin 2 vs.

current at pin 2

Figure 20. Efficiency vs.

output current

Figure 18. Dropout voltage

between pin 7 and 2 vs.

junction temperature

Figure 21. Efficiency vs.

output current

Figure 22. Efficiency vs.

output volta ge

8/16

Figure 23. Efficiency vs.

output voltage

Figure 24. Maximum allowable power dissipation vs. ambient temperature (Powerdip)

Page 9

APPLICATION INFORMATION

Figure 25. Typical application circuit

C1, C6, C7: EKR (ROE)

: BYW98 OR VISK340 (SCHOTTKY)

D

1

SUGGESTED INDUCTORS: (L

COGEMA 946043

OR U15, GUP15, 60 TURNS 1mm, AIR GAP 0.8mm (20 AWG) - COGEMA 969051.

) = MAGNETICS 58120 - A2MPP - 45 TURNS - WIRE GAUGE 0.8mm (20AWG)

1

L4962

Figure 26. P.C. board and component layout of the circuit of Fig. 25 (1 : 1 scale)

Resistor values for

standard output 7 voltages

V

12V

15V

18V

24V

o

R3 R4

4.7K

Ω

4.7K

Ω

4.7K

Ω

4.7K

Ω

6.2K

9.1K

12K

18K

Ω

Ω

Ω

Ω

9/16

Page 10

L4962

APPLICATION INFORMATION

(continued)

Figure 27. - A minimal 5.1V fixed regulator; Very few component are required

* COGEMA 946043 (TOROID CORE)

969051 (U15 CORE)

** EKR (ROE)

Figure 28. Programmable power supply

Vo = 5.1V to 15V

= 1.5A max

I

o

Load regulation (0.5A to 1.5A) = 10mV (V

Line regulation (220V ± 15% and to I

= 5.1V)

o

= 1A) = 15mV (Vo = 5.1V)

o

10/16

Page 11

L4962

APPLICATION INFORMATION

(continued)

Figure 29. DC-DC converter 5.1V/4A, ± 12V/1A. A suggestion how to synchronize a negative output

L1, L3 = COGEMA 946043 (969051)

L2 = COGEMA 946044 (946045)

Figure 30. In multiple supplies several

L4962s can be synchronized as shown

Figure 31. Preregulator for distributed supplies

* L2 and C2 are necessary to reduce the switching frequency spikes

when linear regulators are remote from L4962

11/16

Page 12

L4962

MOUNTING INSTRUCTION

The Rth-j-amb of the L4962 can be reduced by

soldering the GND pins to a suitable copper area of

the printed circuit board (Fig. 32).

The diagram of figure 33 shows the R

function of the side "l" of two equal square copper

areas having the thickness of 35µ (1.4 mils). During

th-j-a mb

as a

soldering the pins temperature must not exceed

260°C and the soldering time must not be longer

than 12 seconds.

The external heatsink or printed circuit copper are

must be connected to electrical ground.

Figure 32. Example of P .C. board copper area which is used

as heatsink

Figure 33. Maximum dissipable

power and junction to ambient

thermal resistance vs. side "l"

12/16

Page 13

L4962

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.51 0.020

B 0.85 1.40 0.033 0.055

b 0.50 0.020

b1 0.38 0 .50 0.015 0.020

D 20.0 0.787

E 8.80 0.346

e 2.54 0.100

e3 17.78 0.700

F 7.10 0.280

I 5.10 0.201

L 3.30 0.130

Z 1.27 0.050

mm inch

OUTLINE AND

MECHANICAL DATA

Powerdip 16

13/16

Page 14

L4962

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 4.8 0.189

C 1.37 0.054

D 2.4 2.8 0.094 0.110

D1 1.2 1.35 0.047 0.053

E 0.35 0.55 0.014 0.022

E1 0.7 0.97 0.028 0.038

F 0.6 0.8 0.024 0.031

F1 0.9 0.035

G 2.34 2.54 2.74 0.095 0.100 0.105

G1 4.88 5.08 5.28 0.193 0.200 0.205

G2 7.42 7.62 7.82 0.295 0.300 0.307

H2 10.4 0.409

H3 10.05 10.4 0.396 0.409

L 16.7 16.9 17.1 0.657 0.668 0.673

L1 14.92 0.587

L2 21.24 21.54 21.84 0.386 0.848 0.860

L3 22.27 22.52 22.77 0.877 0.891 0.896

L4 1.29 0.051

L5 2.6 2.8 3 0.102 0.110 0.118

L6 15.1 15.5 15.8 0.594 0.610 0.622

L7 6 6.35 6.6 0.236 0.250 0.260

L9 0.2 0.008

M 2.55 2.8 3.05 0.100 0.110 0.120

M1 4.83 5.08 5.33 0.190 0.200 0.210

V4 40˚ (typ.)

Dia 3.65 3.85 0.144 0.152

mm inch

OUTLINE AND

MECHANICAL DATA

Heptawatt V

H3

L

VV

E

L1

M1

A

C

D

M

D1

H2

V4

L9

H1

L5

L2

L3

F

E1

E

GG1G2

Dia.

F

L7

L6

L4

F1H2

HEPTAMEC

14/16

Page 15

L4962

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 4.8 0.189

C 1.37 0.054

D 2.4 2.8 0.094 0.110

D1 1.2 1.35 0.047 0.053

E 0.35 0.55 0.014 0.022

F 0.6 0.8 0.024 0.031

F1 0.9 0.035

G 2.41 2.54 2.67 0.095 0.100 0.105

G1 4.91 5.08 5.21 0.193 0.200 0.205

G2 7.49 7.62 7.8 0.295 0.300 0.307

H2 10.4 0.409

H3 10.05 10.4 0.396 0.409

L 14.2 0.559

L1 4.4 0.173

L2 15.8 0.622

L3 5.1 0.201

L5 2.6 3 0.102 0.118

L6 15.1 15.8 0.594 0.622

L7 6 6.6 0.236 0.260

L9 4.44 0.175

Dia 3.65 3.85 0.144 0.152

mm inch

OUTLINE AND

MECHANICAL DATA

Heptawatt H

15/16

Page 16

L4962

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences of

use of such informat io n nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mention ed i n this publication are subject to

change without notic e. This publication s upersedes and replace s all information previou sly supplied. STMi croelectronics produc ts are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2000 STMicroelectronics – Printed in Italy – All Rights Reserved

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

16/16

Loading...

Loading...