Page 1

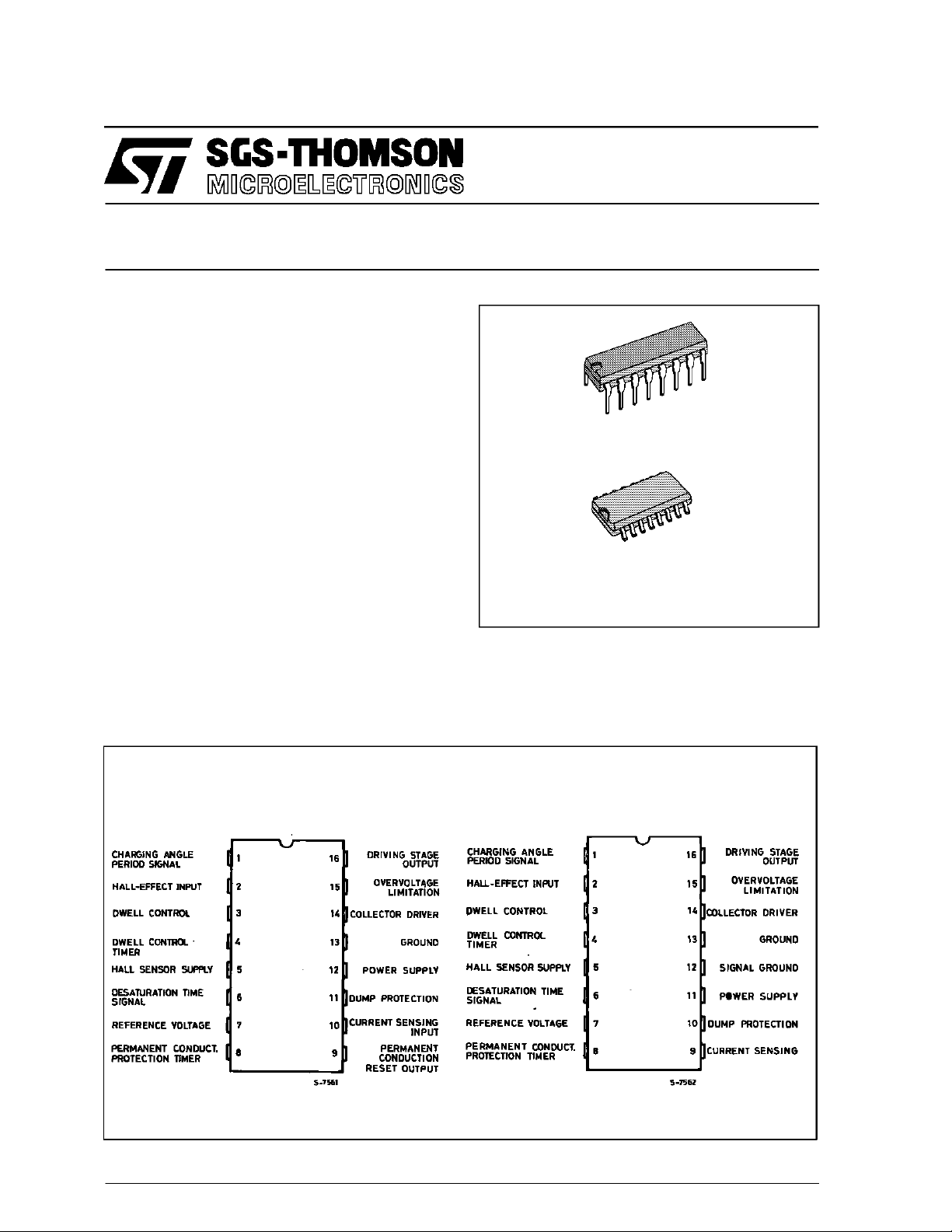

HALL–EFFECT PICKUP IGNITION CONTROLLER

.DIRECT DRIVING OF THE EXTERNAL PO-

WERDARLINGTON

.COILCURRENT CHARGING ANGLE(DWELL)

CONTROL

.COILCURRENT PEAK VALUELIMITATION

.CONTINUOUSCOILCURRENTPROTECTION

.CONDUCTION AND DESATURATION TIME

OUTPUT SIGNALS

.PERMANENT CONDUCTION PROTECTION

RESETOUTPUTSIGNAL

.OVERVOLTAGE PROTECTION FOR EXTER-

NALDARLINGTON

.LOADDUMP PROTECTION

L482

DIP16

DESCRIP T IO N

The L482 is an integratedcircuit designed foruse

with an NPN darlington in breakerlessignition systemswithhall-effectpickupsensorsandhighenergy ignitioncoils.

It controls the energy stored in the ignition coil and

the desaturation time of the external darlingtonto

limit the power dissipation.

PI N CONNECTI ONS (top views)

DIP16

SO16

ORDERING NUMBERS : L482 (DIP16)

L482D1(SO16)

The L482isalsoparticularlysuitableforuseasignition controland driving stage in more sophisticated

car electronicsystems which employmicroprocessor cir cuits.

SO16

November 1991

1/11

Page 2

L482

ABSOLUTEMAXIMUM RATINGS

Symbol Parameter Value Unit

V

R

V

D

P

tot

T

j,Tstg

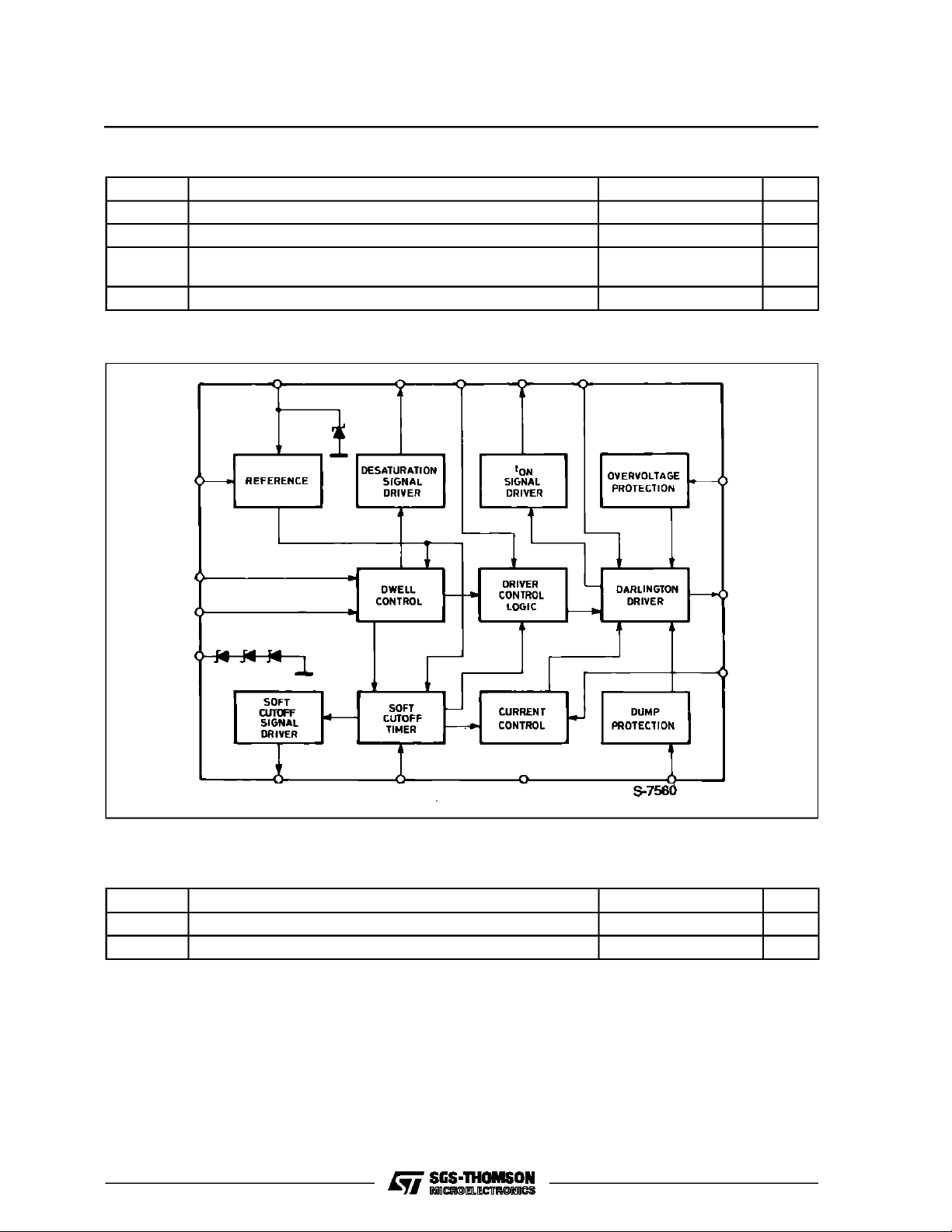

BLOCK DIAGRAM

Reverse Battery Voltage – 14 V

Dump Voltage 100 V

Power Dissipation at T

=90°C SO16

amb

DIP

1.2

0.65

Junction and Storage Temperature Range – 55 to 150 °C

W

W

THERMALDATA

Symbol Parameter Value Unit

R

th j-amb

R

th j-al

(*)Thermalresistance junction-aluminia with thedevice soldered onthe middle of an aluminiasupporting substrate measuring 15 x 20mm;

0.65mm thickness with infiniteheatsink.

2/11

Thermal Resistance Junction-ambient (DIP16) Max 90 °C/W

Thermal Resistance Junction-alumina (SO16) Max 50 °C/W

Page 3

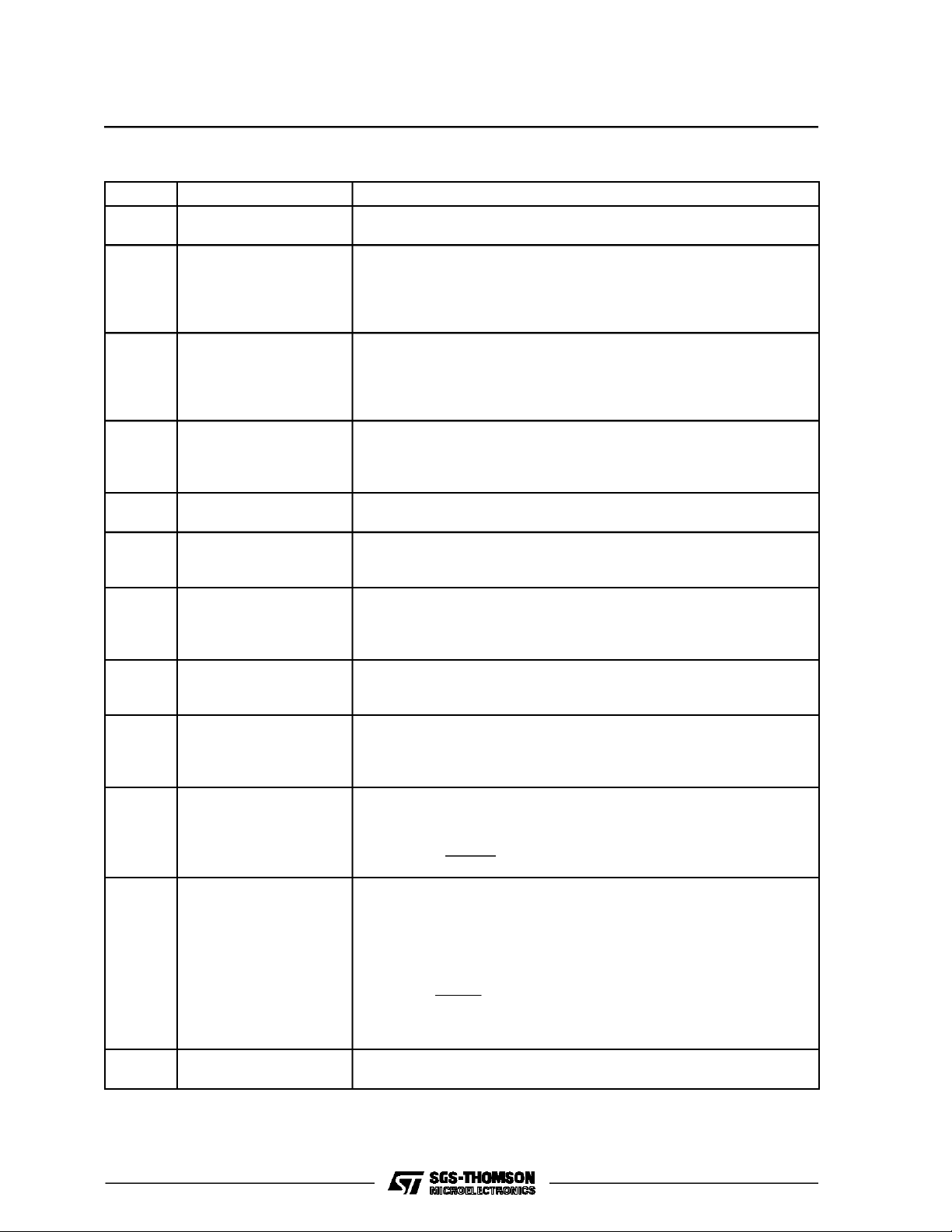

PINFUNCTIONS (refer to fig. 3 for DIP16 package)

N° Name Function

1 CONDUCTION TIME

SIGNAL

2 HALL-EFFECT INPUT Hall-effect Pickup Input. A high level on this pin enables the current driving

3 DWELL CONTROL The average voltage on the capacitor C

4 DWELL CONTROL TIMER The capacitor C5 connected between this pin and ground is charged when

5 HALL SENSOR SUPPLY This pin can be used to project the Hall-effect pickup against the voltage

6 DESATURATION TIME

SIGNAL

7 REFERENCE VOLTAGE A resistor R11 connected between this pin and ground sets the internal

8 PERMANENT CONDUCT.

PROTECTION TIMER

9 PERMANENT CONDUCT.

RESET OUTPUT

(no available in

Micropackage) (*)

10 CURRENT SENSING

INPUT (*)

11 DUMP PROTECTION

(*)

A low level on this output signal indicates when the external darlington is in

the ON condition i.e. when the current flows through the coil (ton in fig.1)

into the coil. The effective coil charge will be a function of the dwell control

logic. A High to Low transition from the Hall-effect pickup is the signal for

ignition actuation. The input signal, supplied by the open collector output

stage of the Hall-effect sensor, has a duty cycle typically about 70%.

connected between this pin and

2

ground depends on the motor speed and the voltage supply. The

comparison between V

and VC5voltages determines the timing for the

C2

dwell control. The recommended value is 100nF using a 100KΩ resistor at

pin 7. For the optimized operation of the device, C2 = C5.

the Hall-effect output is high and is discharged at the High to Low transition

of the Hall-effect signal. The recommended value is 100nF using a 100KΩ

resistor at pin 7.

transients, The resistor R

limits the current into the internal zener.

a

Open Collector Output Signal. This output is high when the external

darlington is in desaturation condition (current limitation), see t

d

1.

current used to drive the external capacitors of the dwell control (C

) and permanent conduction protection (C1). The recommended value is

C

5

100KΩ.

A capacitor C1 connected between this pin and ground determines the

intervention delay of the permanent conduction protection, t

With a 1µF capacitor and 100KΩ resistorR

at pin 7 the typical delay is 1s.

11

of the figure 2.

pc

A low pulse on this output detects the intervention of the permanent

conduction protection, as shown in figure 2. Typically the duration of the

time t

is more than 100µs.

r

Connection for Coil Current Limitation. The current is measured on the

sense resistor R

and divided on R1/R2. The current limitation value is

S

given by :

I

SENS

= V

SENS

R1 + R2

⋅ R2

R

S

The device is protected against the load dump. In load dump condition an

internal circuit, based on a zener diode and a darlington transistor,

switches off the external darlington and short circuits the supply.

By means of the external divider R8/R9 the protection threshold can be

changed and is given as first approximation by:

L482

pulse in fig.

and

2

R8+ R

= 8.5 ⋅

V

Dth

9

R

9

+ 5 ⋅ 10

−4

⋅ R

8

(the resistor R9 value must be higher than 4KΩ).

12 POWER SUPPLY (*) Supply Voltage Input. A 7V (typ) zener is present at the input. The external

resistor R

limits the current through the Zener for high supply voltages.

7

3/11

Page 4

L482

PINFUNCTIONS (continued)

N° Name Function

13 GROUND This pin must be connected to ground.

14 DRIVER COLLECTOR The collector current for the internal driver which drives the external

15 OVERVOLTAGE

LIMITATION

darlington is supplied through this pin. The external resistor R

dissipation in the IC. The value of the resistor depends is a function of the

darlington used and on the limiting current in the coil.

The external is protected against overvoltage by means of an internal

zener available at this pin. The external divider R

defines the limitation

5/R6

value, given as first approximation by:

30

=

R

5

+ 5 ⋅ 10

V

ovp

−3

⋅ R6+ 30

10

limits the

16 DRIVING STAGE

OUTPUT

Current Driver for the External Darlington. To ensure stability and precision

of Tdesat C

and R3must be used. Recommended value for R3 is 2KΩ in

3

order not to change the open loop gain of the system.

may be added to C3to obtain greater flexibility in various application

R

C

situations.

and RC values ranges are 1 to 100nF and 5 to 30KΩ depending on the

C

3

external darlington type.

(*)These pins referonly tothe DIP package type.

For the SO16 version the permanent conduction reset output signal is not availableand the pin 9 becomes the current sensing input. Pin 10

replacesthe pin 11 function, pin 11 becomes thepower supply inputand pin 12 is usedas thesignal ground.

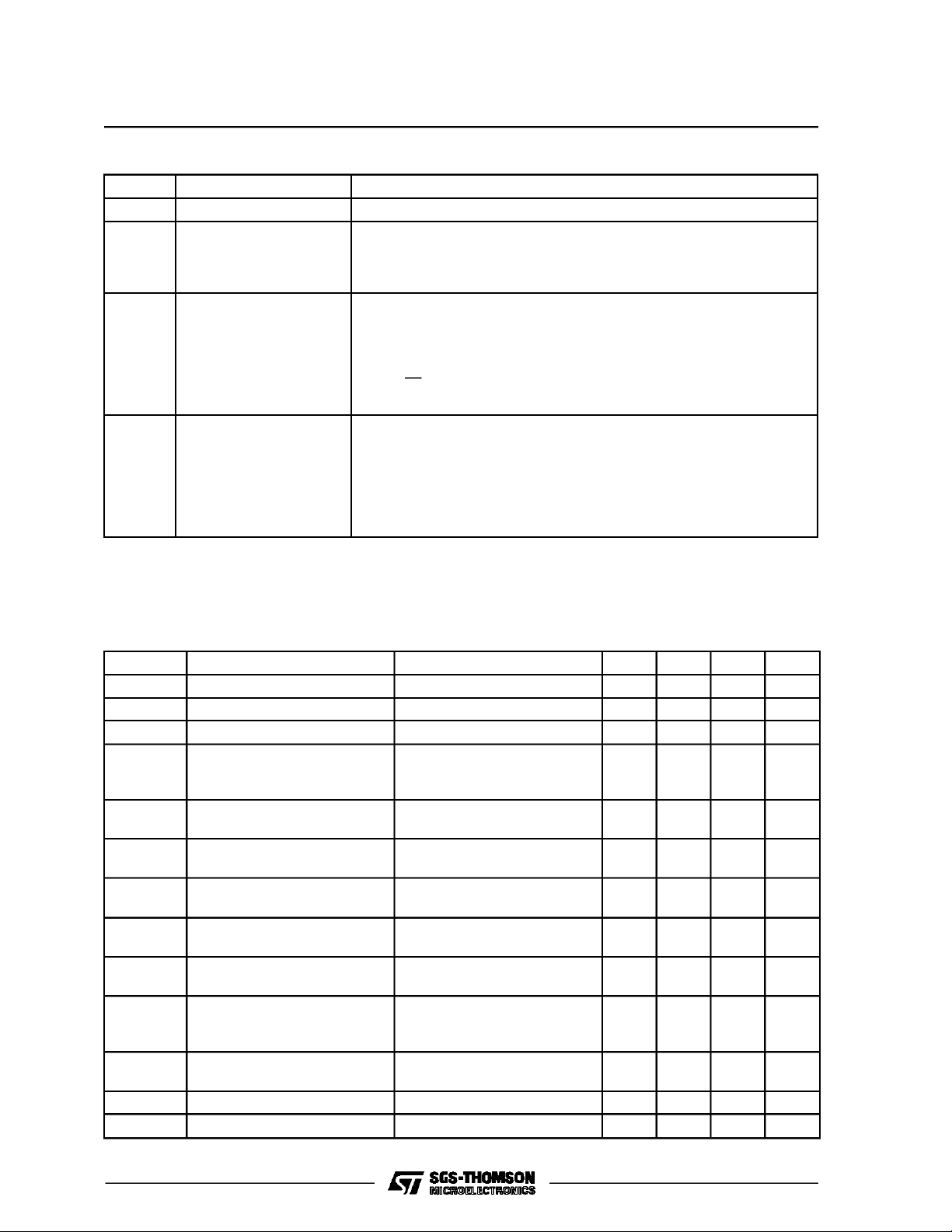

ELECTRICAL CHARACTERISTICS (VS=14V, –40°C≤Tj≤125°C referred to application circuit of

figure 3 regarding DIP-16 package version)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

S

I

S

V

Z

V

I

I

I

V

Hz

I

HZ

V

CE sat

(V14–V16)

V

SENS

I

3D

I

3C

I3C/I

3D

V

OVZ

V

7

t

d

Operating Supply Voltage 6 28 V

Supply Current V12= 4.5V 25 mA

Zener Voltage (pin 12) IZ= 80mA 6.5 8.8 V

Sensor Input (pin 2)

LOW Voltage

HIGH 2.5

Sensor Input Current (pin 2) VI= LOW

= 6 to 16V

V

S

Hall-cell Supply Zener Voltage

IHz= 10mA 19 22 25 V

–12 –1 mA

0.5 V

V

(pin5)

Hall-cell Supply Zener Current

(pin5)

Series Darlington Driver Sat.

Voltage

Current Limit. Sensing Voltage

t = 10ms

=25°C

T

AMB

I

= 70mA

o

= 150mA 0.4

I

o

VS= 6 to 16V 200 400 mV

100 mA

0.6

1.0

V

V

(pin10)

C2 Discharge Current

C2 Charge Current

External Darlington Overvoltage

Protection Zener Voltage

VS= 6 to 16V

(*) Note 1

I

= 5mA to 15mA

OVZ

=25°C

T

AMB

0.2

5

6

3.4

20

35

25 30 35 V

µA

µA

Reference Voltage 2.5 3.5 V

Desaturation Time f = 40Hz VS= 14V 0.6 1.2 1.57 ms

4/11

Page 5

ELECTRICAL CHARACTERISTICS (Continued)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

PC

V

1

V

6

I

6L

I

9L

Permanent Conduction

Protection Time (pin 8) (see fig.

2)

Charging Angle Output Voltage

LOW

HIGH

Desat. Time Output Low

Voltage

Desat. Time Leakage Current

(pin6)

Permanent Conduction Reset

Leakage Current (pin9)

VI=H

=1µF

C

I

=0

I

SINK

I

= 1mA

SINK

I

I

I

= 1.5mA

SOURCE

= 2.5mA

SOURCE

= 0.5mA 0.7 V

6 (sink)

V6= 5V 10.5 µA

V9= 5V 10.5 µA

135s

0.5

1.2

3

5

L482

V

V

V

V

APP LICATION INFO RMATION

Figure 1 : Main Wa v ef o rms.

5/11

Page 6

L482

Figure 2 : Low Frequency Condition an d Permanent Conduction Protection.

Figure 3 : Application circuit (DIP–16).

6/11

Page 7

Figure 4 : App lic a tion Circuit (SO –16 ).

L482

CIRCUIT OP ERA TI ON

TheL482controltheconductiontime(dwell)andthe

peakvalueof theprimarycurrentin thecoiloverthe

full rangeof operatingconditions.

The coil current is limited to a predeterminedlevel

by meansof a negativefeedbackcircuitincludinga

current sensing resistor, a comparator, the driver

stageand the powerswitch.

The dwell controlcircuit maintainstheoutputstage

in itsactiveregionduringcurrentlimitation.Thetime

the outputstageisintheactiveregion(desaturation

time) is sufficient to compensatefor possiblevariationsin the nergy storeddue to the accelerationof

the motor; moreoverthistimeislimitedtoavoidexcessivepower dissipation.

CONTROL OF THE DWELLANGLE (fig.1 and 4)

The dwell angle control circuit calculates the con-

ductiontime Dfor the outputtransistorin relation to

the speedof rotation,to the supply voltageand to

the characteristicof thecoil.

On the negativeedgeof the Hall-effect inputsignal

the capacitorC

currentI

3D

beginsdischargingwitha constant

2

. When theset peakvalue of thecoilcurrent is reached,this capacitorcharges with a constant current I

=13.3 x I3Dand the coil current is

3C

kept constantby desaturatingthe driverstage and

the externaldarlington.

The capacitor C

starts charging on the positive

5

edgeof the Hall-effect input signal with a constant

currentI

4C

.

Thedwellangle,andconsequentlythestartingpoint

ofthecoilcurrentproduction,isdecidedby thecomparisonbetweenV

andVC5. A positivehysteresis

C2

isaddedto the dwell comparatorto avoid spurious

effectsand C

israpidlydischargedon the negative

5

edgeof Hall-effectsinput signal.

In this way the averagevoltage on C

increases if

2

the motorspeed decreasesand viceversain order

to maintainconstanttheratiotdatany motorspeed.

T

td is kept constant (andnot d = cost) to control the

power dissipation and to have sufficient time to

avoidlow energy sparksduring acceleration.

The chargingtime D – td dependson the coil and

the voltagesupply.

DESATURATION TIMES IN STATIC CONDITIONS.Instaticconditions,if C

2=C5

asrecommendedand if the valuesof the applicationcircuitof fig.

3, 4 are used.

td 1

=

T1+I

3C/I3D

7/11

Page 8

L482

DESATURATIONTIMESINLOWANDHIGHFREQUENCYOPERATION.Duetotheupperlimitofthe

voltagerangeof pin3,if thecomponentsof fig.3, 4

areused, below10Hz(300RPMfor a4 cylinder engine) the OFF time reaches its maximum value

(about50ms)andthenthecircuitgraduallylosesthe

controlof the dwellangle becauseD = T – 50ms

Over200Hz (6000RPMfora 4 cylinderengine)the

availabletimefortheconductionislessthan3.5ms.

If theused coil is6mH, 6A,the OFFtime isreduced

to zero andthe circuitlosesthe dwellanglecontrol.

TRANSIENT RESPONSE. The ignition system

must deliverconstant energy even during the conditionof accelerationand decelerationof the motor

below 80Hz/s. These conditions can be simulated

by means of a signal generator with a linearly modulated frequency between 1Hz and 200Hz (this

correspondstoachangebetween30and6000RPM

for a 4 cylindersengine.

CURRENT LIMIT.The currentin thecoil is monitored by measuring the I

sensingresistorR

lington.I

WhenthevoltagedropacrossRsreachesthe internalcomparatorthresholdvaluethefeedbackloopis

activatedand I

externaldarlingtonin theactive region. In this condition:

WhenaprecisepeakcoilcurrentisrequiredR5must

be trimmedor an auxiliaryresistor divider (R

added :

Icpeak(A) = ( + 1)

sense

ontheemitteroftheexternaldar-

s

is givenby :

I

sense=Icoil+I16

keptconstant(fig. 1)forcingthe

sense

I

sense=Icoil

V

SENS

R

S

current flowing in the

sense

R

1

R

2

1,R2

DARLINGTONOVERVOLTAGELIMITATION

The darlingtonis protectedagainst overvoltageby

meansof an externaldividerR

internalzener.Thiszenerdrives theexternaldarlingtonin orderto limit the collectorvoltage.

REVERSEBATTERY PRTOTECTION. Due to the

presenceof externalimpedanceatpin5, 10,11,14,

15, L482 is protectedagainstreverse battery voltage.

DUMPPROTECTION.

The load dump protection withstands up to 100V

with a decaytime ≤ 300ms. The interventionthresholdforloaddumpisfixedbymeansof anexternal

divider connected to pin 11 (DIP-16 package version)or to pin 10 using a Micropackagetype.

NEGATIVESPIKEPROTECTION.If correctoperationis requestedalso duringshort negativespikes,

thediode DS and capacitorC

USEOF THE IC ELECTRONICADVANCE SYSTEM

When the device is digitally controlled the control

unit transmits a suitable input signal to the power

module, receivingin turninformationthat allowsthe

controlof thedwell and theontime of thefinaltransistor.

ForthisreasonL482providesthefollowingoutputs:

(pin15) and an

5/R6

mustbe used.

s

.a time signal equal to the time in which the final

)

Darlingtonis intheactiveregioni.e.whenthecoil

current islimited (V

signalmust be TTL compatible.

) as shown in figure1.This

ds

PROT ECT IO N CIRCUIT

PERMANENTCONDUCTION PROTECTION

The batteryvoltageis applied to ignitionmoduleby

meansof theignitionkey. In these conditions, with

the motor stopped, it is necessarythat there is no

permanentconductionin the ignitioncoil irrespective of the polarity of the input signal.

The L482incorporatesa timing circuitto implement

thisprotection; thedurationoftheinterventionisset

by means of a capacitor C

=100kΩ, whenthe inputsignalis highfor more

R

11

than1 s, the coilcurrent graduallydecreasesdown

to zero to avoid spurious sparks (seefig. 2).

This timing allows normal operation of the module

above30RPM.

8/11

at pin 8 = 1µF, and

1

.a TTL compatibleoutput from the timing circuit

in figure2). Thispulse,availableonly using

(V

rs

the DIP-16packageversion is present after the

protectionagainstcranking transients.

.a time signal equal to the time in which the final

Darlington,is in”on” condition(V

current flows throughthe coil, see fig. 1.

OTHER APPLICATIONINFORMATION

Ifthe supplyvoltageisdisconnected- or thebattery

wireis broken- whilethe current is flowing through

thecoil,the externaldiodeD

fromrecirculating into the device : in this way both

deviceanddarlington are protected.

keepsthe coilcurrent

1

)i.e.whenthe

on

Page 9

DIP16 PACKAGE MECHANICAL DATA

L482

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.51 0.020

B 0.77 1.65 0.030 0.065

b 0.5 0.020

b1 0.25 0.010

D 20 0.787

E 8.5 0.335

e 2.54 0.100

e3 17.78 0.700

F 7.1 0.280

I 5.1 0.201

L 3.3 0.130

Z 1.27 0.050

mm inch

9/11

Page 10

L482

SO16 PACKAGE MECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.75 0.069

a1 0.1 0.2 0.004 0.008

a2 1.6 0.063

b 0.35 0.46 0.014 0.018

b1 0.19 0.25 0.007 0.010

C 0.5 0.020

c1 45° (typ.)

D 9.8 10 0.386 0.394

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 8.89 0.350

F 3.8 4.0 0.150 0.157

L 0.5 1.27 0.020 0.050

M 0.62 0.024

S8°(max.)

mm inch

10/11

Page 11

L482

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for

the consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its

use. No license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied. SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or

systems without express written approval of SGS-THOMSON Microelectronics.

1994 SGS-THOMSON Microelectronics - All Rights Reserved

Australia - Brazil - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands - Singapore-

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Spain - Sweden - Switzerland - Taiwan - Thaliand - United Kingdom - U.S.A.

11/11

Loading...

Loading...