Page 1

Inverter Interface and Digital Deadtime Generator

for 3-Phase PWM Controls

Type Package Configuration Temp. Range

IXDP630 PI 18-Pin Plastic DIP RC Oscillator -40°C to +85°C

IXDP631 PI 18-Pin Plastic DIP Crystal Oscillator -40°C to +85°C

This 5 V HCMOS integrated circuit is

intended primarily for application in

three-phase, sinusoidally commutated

brushless motor, induction motor, AC

servomotor or UPS PWM modulator

control systems. It injects the required

deadtime to convert a single phase leg

PWM command into the two separate

logic signals required to drive the upper

and lower semiconductor switches in a

PWM inverter. It also provides facilities

for output disable and fast overcurrent

and fault condition shutdown.

In the IXDP630, deadtime programming

is achieved by an internal RC oscillator.

In the IXDP631, programming is

achieved by use of a crystal oscillator.

An alternative for both the IXDP630/

631 is with an external clock signal.

Because of its flexibility, the IXDP630/

631 is easily utilized in a variety of

brushed DC, trapezoidally commutated

brushless DC, hybrid and variable

reluctance step and other more exotic

PWM motor drive power and control

circuit designs.

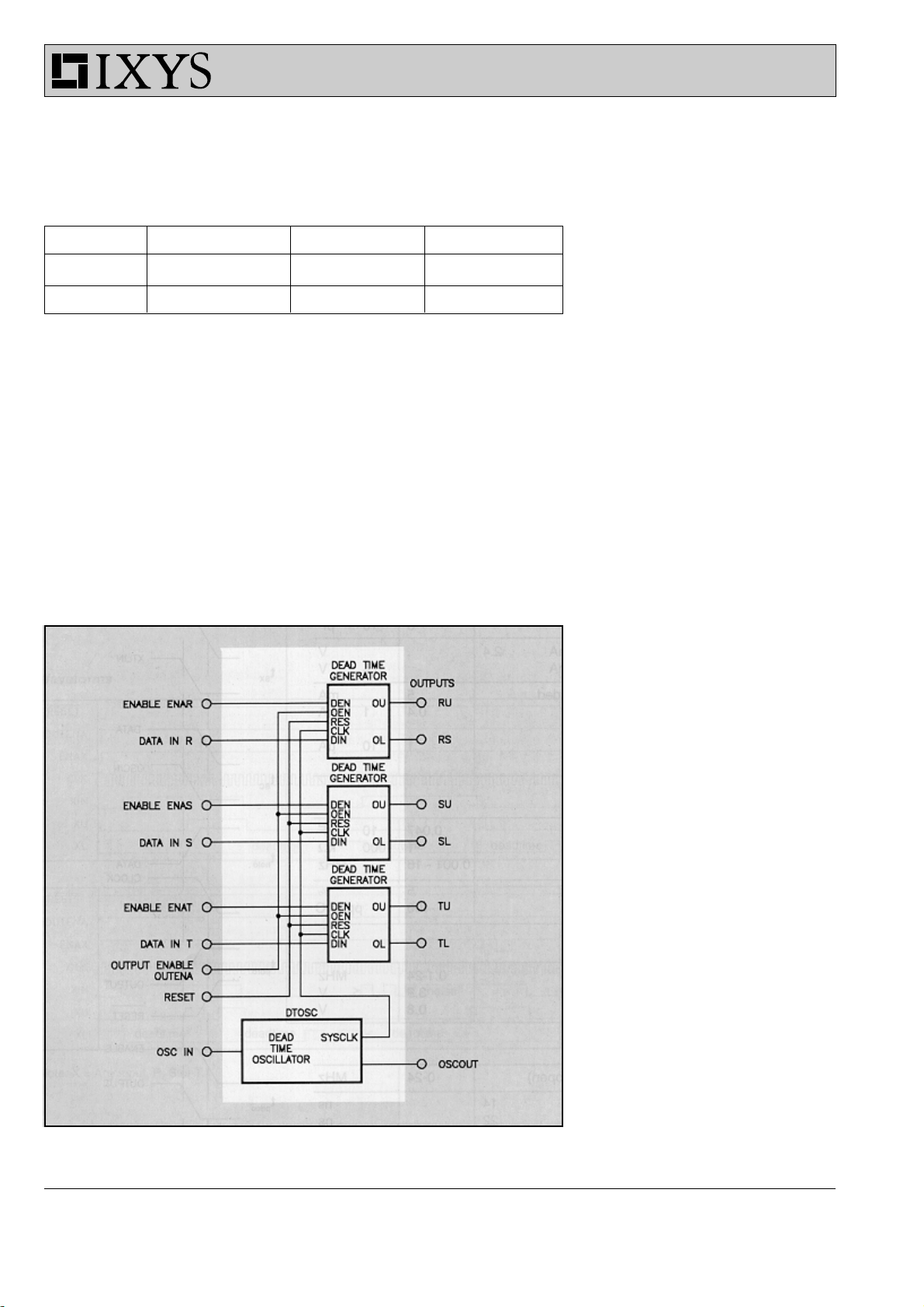

Block Diagram IXDP 630/IXDP 631

Features

l 5 V HCMOS logic implementation

maintains low power at high speed

l Schmitt trigger inputs and CMOS

logic levels improve noise immunity

l Simultaneously injects equal dead-

time in up to three output phases

l Replaces 10-12 standard SSI/MSI

logic devices

l Allows a wide range of PWM

modulation strategies

l Directly drives high speed

optocouplers

Applications

l 1- and 3- Phase Motion Controls

l 1- and 3- Phase UPS Systems

l General Power Conversion Circuits

l Pulse Timing and Waveform

Generation

l General Purpose Delay and Filter

l General Purpose Three Channel

"One Shot"

IXYS reserves the right to change limits, test conditions and dimensions.

I - 14

© 1998 IXYS All rights reserved

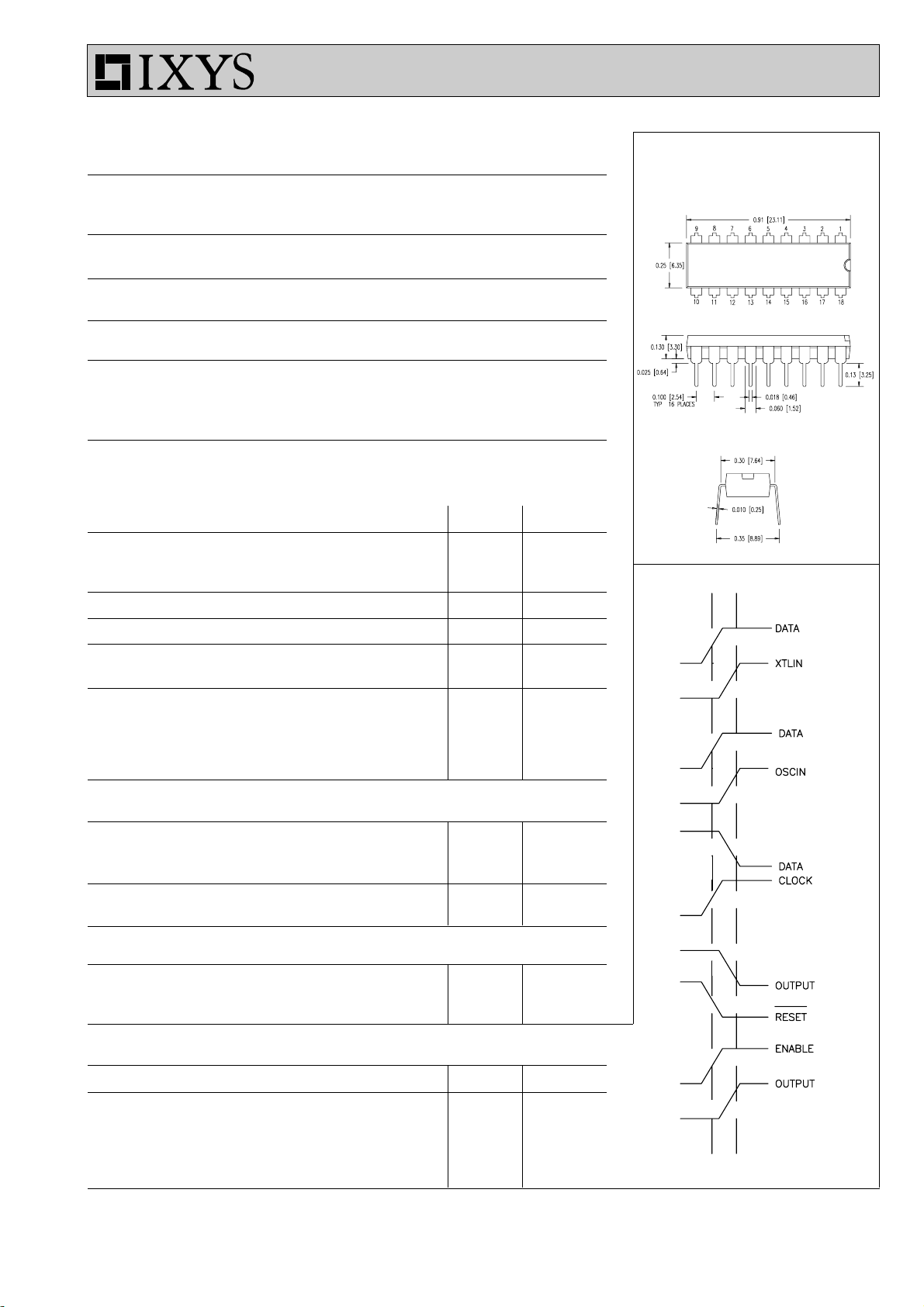

Page 2

IXDP630

IXDP631

Symbol Definition Maximum Ratings

min. max.

V

CC

V

IN

I

IN

V

0

I

0

T

stg

T

L

Supply Voltage -0.5 7 V

DC Input Voltage -0.5 VCC + 0.5 V

DC Input Current -1 1 mA

DC Output Voltage 0.5 VCC + 0.5 V

DC Output Current -25 25 mA

Storage Temperature -55 150 °C

Lead Soldering (max. 10 s) 300 °C

Recommended Operating Conditions

V

T

l

f

CC

J

0

OSC

Supply Voltage 4.5 5.5 V

Operating Temperature -40 85 °C

Output Current -8 8 mA

Oscillator Frequency 0.001 16/24 MHz

Symbol Definition/Condition Characteristic Values

min. typ. max.

V

V

V

I

C

V

V

I

I

I

t+

t-

HYS

in

in

oh

ol

CC

CCQ

CCQ

Input Hi Threshold 3.6 2.7 V

Input Lo Threshold 1.6 0.8 V

Hysteresis 1.1 V

Input Leakage Current -10 10 µA

Input Capacitance 5 10 pF

Output High Voltage lo = -8 mA 2.4 V

Output Low Voltage lo = 8 mA 0.4 V

Supply Current Outputs Unloaded 5 mA

Quiescent Current Outputs 0.4 1 mA

Unloaded IXDP630

Quiescent Current Outputs 1 10 µA

Unloaded IXDP631

DP630 Oscillator Section

Dimensions in inch (1" = 25.4 mm)

16-Pin Plastic DIP

t

SX

t

SC

C

R

f

OSC

OSC

OSC

Capacitor (RCIN to GND) 0.047 10 nF

Resistor (OSCOUT to RCIN) 1 1000 kΩ

Frequency Range 0.001 - 16 MHz

Initial Tolerance (f

Temperature Coefficient -400 ppm/°C

DP631 Oscillator Section

f

V

V

OSC

INH

INL

Frequency Range 0.1-24 MHz

Oscillator Thresholds (IXTLIN) 3.9 V

External Oscillator

f

t

t

t

t

t

IN

SX

SC

hold

pdro

pdeo

Frequency Range (ODCOUT open) 0-24 MHz

Set Up Time DATA-to-XTLIN 14 nS

Set Up Time DATA-to-OSCIN 22 ns

Hold Time CLOCK-Data 0 ns

Propagation Delay RESET-to-OUTPUT 15 20 ns

Propagation Delay ENABLE-to-OUTPUT 8 16 ns

© 1998 IXYS All rights reserved

≤ 1MHz) 5 %

OSC

0.8 V

t

t

t

hold

pdro

pdeo

I - 15

Page 3

IXDP630

IXDP631

Pin Description IXDP630

Pin Description IXDP631

Sym. Pin Description

R 1 R, S and T are the three single S 3 phase inputs. Each input is

T 5 expanded into two outputs to

generate non-overlapping drive

signals, RU/RL, SU/SL, and TU/

TL. The delay from the falling

edge of one line to the rising

edge of the other is a function of

the clock.

ENAR 2 High logic input will enable the

ENAS 4 outputs, as set by the proper

ENAT 6 input phase. The ENA (R,S,T)

signals control the drive output

lines. A low logic input will force

both controlled outputs to a low

logic level

OUT 7 High logic level will enable all

ENA outputs to their related phase.

The OUTENA simultaneously

controls all outputs. Low input

logic level will inhibit all outputs

(low).

RESET 8 The RESET signal is active low.

When a logic low RESET is

applied, all outputs will go low.

After releasing the RESET

command within the generated

delay, the outputs will align with

the phase input level after the

programmed delay internal.

Sym. Pin Description

GND 9 CIRCUIT GROUND - 0 Volts

RCIN 10 The first node of the clock

or network. For the IXDP630, the

XTLIN RC input is applied to RCIN. For

OSC 11 This is the output node of the

OUT oscillator. It is connected indi-

TL 12 After the appropriate delay, the

TU 13 external drive outputs (R,S, T) U

SL 14 are in phase with their corres SU 15 ponding inputs; (R,S, T) L are

RL 16 the complementary outputs.

RU 17

V

CC

the IXDP 631, the crystal oscillator is applied to XTLIN. If an

external clock is to be supplied

to the chip it should be connected to this pin.

rectly to the RCIN or XTLIN pins

when using the internal oscillator

as described in the applications

information. It is not recommended for external use.

18 Voltage Supply +5 V ± 10 %

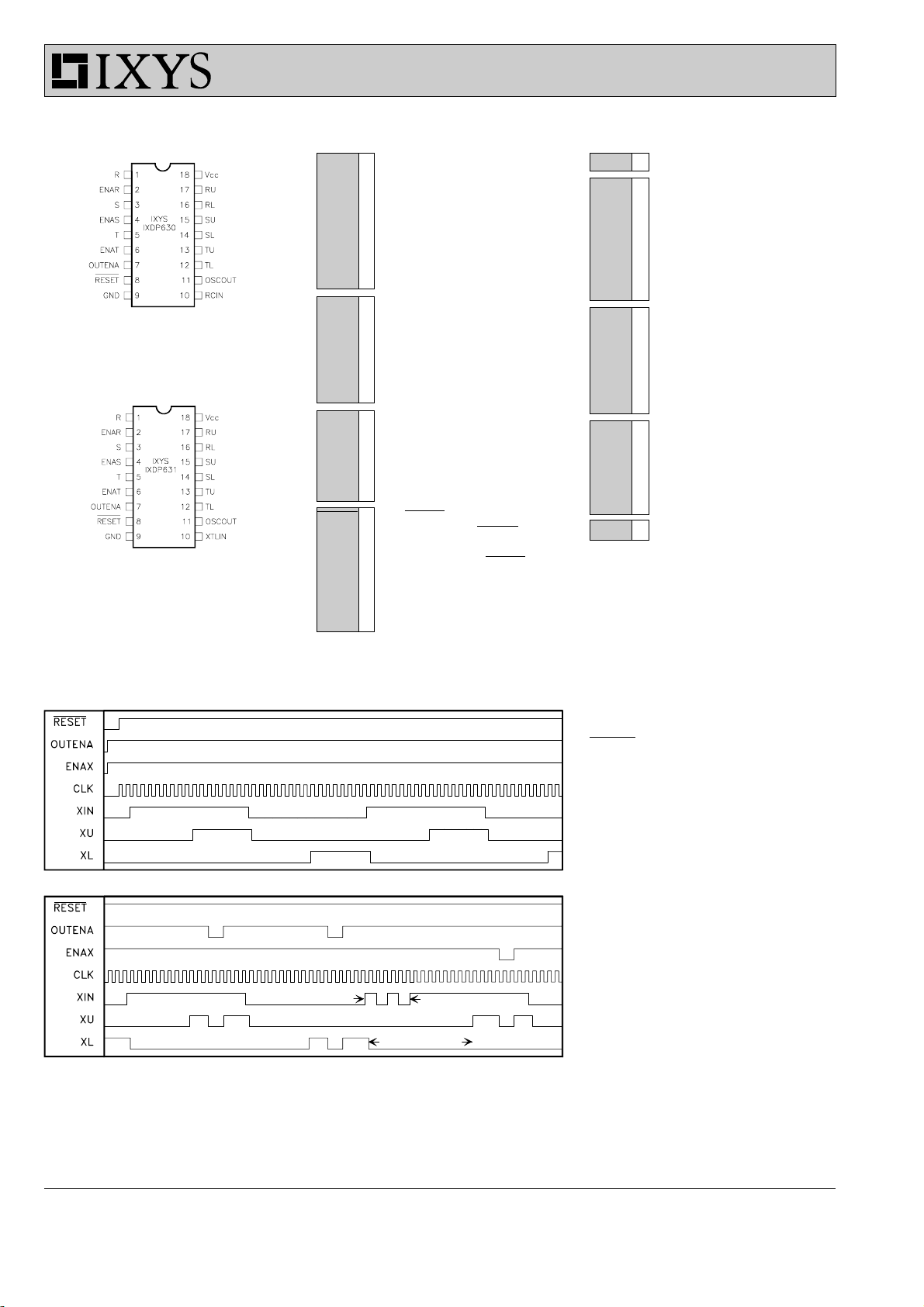

Waveforms

Note: X = Any input, R, S or T.

deadtime

deadtimedeadtime

deadtime deadtime

noise

deadtime

This diagram shows the normal

operation of the IXDP630/631 after the

RESET input is released. The

DEADTIME is the 8 Clock periods

between XU and XL when both XU and

XL are a "0". The length of the

DEADTIME is fixed at 8 times the

period of CLK.

The diagram shows OUTENA and ENAX

asynchronously forcing the XU Output

and the XL Output to the off state.

OUTENA will force all three channels to

the off state. ENAX (where X is one of

the three channels) will only force the

XU and XL Outputs of that channel to

the off state. Note that because ENAX

is asynchronous with respect to the

internal clock and deadtime counters,

when ENAX goes HI whatever state the

deadtime counter was in immediately

propagates to the output. This figure

also shows that noise at the XIN input

will be filtered before the XU Output or

XL Output will become active, which

may extend the deadtime.

I - 16

© 1998 IXYS All rights reserved

Page 4

IXDP630

IXDP631

Application Information

Basic Operation

The IXDP630/631 Deadtime Generators are intended to simplify the

implementation of a single- or threephase digitally controlled power

conversion circuit. It replaces one to

three digital event counters (timer/

counters) in a microcontroller or DSP

implementation of a motor control, UPS

or other power system. In most cases

these timers are at a premium. They

must be used to calculate pulse width

on one to three independent modula-

set interrupt service times, generate

tors,

a real-time clock, handle communications timing functions, etc.

The input command on the R, S and T

inputs is first synchronized with the

internal oscillator. When an input

changes state, the on output is

switched off, and after a deadtime of

exactly 8 clock periods, the complimentary output is switched on. For example, if input R is hi, output RU is hi. At

the first rising edge of CLK out after

input R is brought low, the RU output

goes low. After exactly 8 more clock

periods the RL output goes high. This

injected delay is the deadtime.

This method of synchronizing is utilized

to guarantee that the deadtime is

always exactly the same (to the accuracy of the CLK frequency). This can be

very important in certain applications.

Unbalanced deadtime creates an offset

in the PWM output stage transfer function, and can cause saturation of the

induction machine control or the driven

transformer if not corrected within a few

cycles.

Fig. 1: Totem Pole configuration of

transistor switches; reason for deadtime requirements

Deadtime in power circuits

Why is deadtime required?

Fig. 1 is typical of a switching power

conversion equipment output stage. It

has two (or typically more) switches. A

simple logic error - turning a transistor

on at the wrong instant - can cause

catastrophic failure in the right (or

wrong) circumstances.

In normal operation, when the state of

the output totem pole must change, the

conducting transistor is turned off.

Then, after a delay (usually called the

deadtime), the other transistor is turned

on. The delay is added to ensure that

there is no possibility of both transistors

conducting at the same time (this would

cause a short circuit of the DC link - a

"shoot through" - and would likely fail

both transistors in a few microseconds).

When the control logic commands a

switch to change to the off state,

several parasitics may delay/modify this

command. The propagation delay of

the control logic and gate drive buffer,

td (off) of the power transistor, storage

time (for bipolars) or tail time (for

IGBTs), voltage rise and current fall

times, etc., may be significant.

Problems Caused by Excessive

Deadtime

If a little is good, a lot should be better except with deadtime. Unfortunately,

deadband in the switching output stage

causes a nonlinearity in the power

circuit transfer function that may be

difficult for the control loop to remove.

Fig. 2 illustrates the problem. The

switching period T is:

+ t2 + DT

T = t

1

is the time Q1 is commanded on, t2 is

t

1

the time Q2 is commanded on, and DT

is the deadtime. Assuming continuous

condition, and with current in the

direction of IL1:

= t1 + DT

t

hi

tlo = t

2

With current in the direction of IL2:

= t1 + DT

t

hi

tlo = t2 + DT.

The change in "apparent duty cycle" is

then twice the deadtime (2DT). If

deadtime is 5% of the cycle period, the

duty cycle, as load current crosses

zero, instantly changes by 10 %. This is

a significant nonlinearity that causes

zero crossing distortions in load current

and voltage that must be removed by

the feedback loop around the PWM

stage. If these nonlinearities get large

enough, the loop may not have the gain

or the speed to remove them. This may

cause problems in the behavior of the

end product that are unacceptable.

Zero crossing distortion in the current of

a microstepped step motor, for example, causes very serious position errors,

velocity ripple, and audible noise in

operation - all undesirable.

I

L1

I

L2

Fig. 2: Problems caused by excessive

deadtime.

Calculating Appropriate Deadtime

Values

The designer must determine, under

worst case conditions, the absolute

maximum delay between the logic off

command and the actual cessation of

transistor conduction. This includes all

appropriate stages of logic, transistor

storage and delay times, etc. It is very

important to include special effects due

to the switch technology chosen.

Storage time of a bipolar transistor with

constant base drive can vary 10:1 as

collector current varies (storage time

increases dramatically at low collector

current, such as at light load). These

effects must be considered when

determining "worst case" delay time

requirements. A power circuit must not

only work at full rated load, but must

not fail under light or no load conditions.

A delay of at least this time (plus a

guardband) must be injected in the

command to the series transistor so as

to absolutely prohibit its turn-on during

this interval.

© 1998 IXYS All rights reserved

I - 17

Page 5

IXDP630

IXDP631

Selecting Components for a Specific

Requirement

Deadtime in the IXDP630/631 is exactly

8 clock periods: DT= 8/fclk. Once the

worst case (minimum) deadtime has

been determined (from Power switching

component manufacturer data sheets,

drive circuit analysis, breadboard

measurements, etc.) the clock

frequency is calculated: fclk(max) =

8/ DT(min).

This is the highest allowable clock

frequency, including the effects of initial

accuracy, tolerance, temperature coefficient, etc. When choosing oscillator

components, special attention to

resistor and capacitor construction is

mandatory.

Oscillator Design

There are two versions of the deadtime

generator. They have distinctly different

internal oscillator designs to serve

different application. In either case,

however, the internal oscillator can be

disabled by simply leaving its external

components off. An HCMOS compatible

clock up to 24 MHz can be fed directly

into the RCIN or XTLIN pin.

IXDP630 RC Oscillator Design

The IXDP630 uses a Schmitt trigger

inverter oscillator (Fig. 3). Two external

R

components,

the clock frequency and consequently

OSC

and C

, determine

OSC

the deadtime. This design allows a

significant cost reduction over a

standard crystal oscillator, but entails a

trade-off in frequency accuracy. The

initial accuracy and drift are a function

of the external component tolerance

and temperature coefficients, supply

voltage, and IXDP630 internal parameters. At frequencies under 1 MHz,

assuming the external components

were perfect, the IXDP630 would

introduce an initial accuracy error of

5 %, and a temperature dependence of

-400 ppm. The shift in frequency over

the VCC range 4.5 V to 5.5 V is typically

less than 5 %.

At higher frequencies and with resistor

values below 1 kΩ, the IXDP630

internal parameters become more

influential factors. This results in

greater frequency variation from one

device to another, as well as with

temperature and supply voltage

variations. If high accuracy is a

requirement, the IXDP631 with a crystal

oscillator would be the better choice.

Oscillator frequency vs. Rosc and Cosc

is shown in Fig. 4. For an analytical

method of setting the oscillator, the

design equation is for operation below

1 MHz approximately:

0.95

≈

f

OSC

Cosc Rosc

For operation above 1 MHz,

0.95

f

≈

OSC

Cosc (Rosc+30) + 3 10

-

8

IXDP631 Precision Crystal Oscillator

Design

The IXDP631 uses a more common

standard internal crystal oscillator

design. For proper operation the crystal must be of the parallel resonant

type, resonating at the crystal's fundamental frequency. Fig. 5 illustrates the

recommended oscillator configuration.

Note the external components required.

The capacitors are needed to achieve

the calibrated crystal frequency (their

value is determined by the crystal

manufacturer), and the resistor is

necessary to assure that the circuit

starts in every case. While the circuit

will usually operate without these extra

parts, this is not recommended.

The crystal oscillator in the IXDP631 is

significantly more accurate than the RC

oscillator in the IXDP630. The total

tolerance (including effects of initial

accuracy, temperature, supply voltage,

drift, etc.) is better than ±100 ppm. This

improves the accuracy and repeatability

of the desired deadtime, but at the

added expense of a crystal.

Which version is appropriate for your

application? That depends on how you

are willing to trade off component cost

for deadtime accuracy.

C

= 470 pF

OSC

C

= 270 pF

OSC

C

= 100 pF

OSC

C

= 47 pF

OSC

Fig. 3: IXDP630 internal Schmitt Trigger

inverter oscillator (R

external)

OSC

, C

OSC

are

I - 18

C

= 1 nF

OSC

C

= 2.2 nF

OSC

C

= 4.7 nF

OSC

C

= 10 nF

OSC

0.1 1 10 100 1000 10 000

Oscillator - kHz

Fig. 4. Oscillator frequency component selection for IXDP630.

© 1998 IXYS All rights reserved

Page 6

IXDP630

IXDP631

IXDP630 RC Oscillator Component

Details

The IXDP630 oscillator has only two

external components. Rosc should be

a precision, high frequency resistor.

The material used in carbon composition resistors is hydroscopic (it

absorbs water), causing resistors

above 100 kΩ to 1 MΩ to change value

with relative humidity. This is on top of

initial tolerance and temperature

coefficient deviations, and so is not

recommended. Instead, precision

metal film or carbon film resistor

construction is preferred, with initial

tolerances of 1 % and better with

temperature coefficients of ±100 ppm.

The construction of Cosc is also critical

to circuit operation. Cosc should be a

good quality monolithic ceramic (single

or multilayer) or a metallized polypropylene timing capacitor. If ceramic technology is chosen, be sure to consider

temperature coefficient and tolerance. It

is the minimum capacitor value that is

critical, not the part number rated

capacitance. A Z5U ceramic has an

initial tolerance of +80/-20 %, and a

temperature variation of +30/-80 %

over temperature. An X7R is ±10 %

initial tolerance, ±10 % over

temperature. An NPO is ±5 % initial

tolerance, ±5 % over temperature

(although tighter selections are readily

available in NPO).

If film technology is chosen, polypropylene is one of the best choices.

Tolerances down to 1 % and 2 % are

standard and temperature coefficient is

±100 ppm.

The layout of the external components

is also critical. The components should

be as close to the device as possible,

minimizing stray capacitance and

inductance.

Fig. 5. Recommended Crystal

Oscillator Components

IXDP631 Crystal Oscillator

Component Details

The IXDP631 oscillator requires three

external passive components, in

addition to the crystal. The crystal is

chosen with a frequency below fclk

(min). The capacitors and resistor

(illustrated earlier in Fig. 5) follow rules

similar to the RC oscillator option. The

resistor should be metal or carbon film,

although its accuracy and stability do

not significantly affect oscillator

frequency accuracy. The capacitors

should be monolithic ceramic

construction (CK05, or similar) with

X7R or better characteristics.

Grounding, Interfacing and Noise

Immunity

Due to the very high level of currents

that are switched at high speed in a

typical motor control power circuit,

voltage transients (V = L di/dt) can

cause serious problems. Fast digital

circuits respond to transients instead of

legitimate inputs, disturbing inverter

operation or causing outright failure.

Bypassing and Decoupling

As with any high speed logic component, the IXDP630/631 should be

bypassed with a good quality (monolithic ceramic or

film) capacitor designed

specifically for bypass application.

Decoupling is normally not required.

The IXDP630 does not generate

sufficient supply line current ripple to be

a significant noise source when

properly bypassed, and it is capable of

rejecting normal supply line noise.

Logic Levels

All inputs to the IXDP630 and IXDP631

(except XTLIN on the IXDP631) are

HCMOS Schmitt Trigger compatible.

On the IXDP631, the XTLIN pin is

different because the crystal oscillator

circuit cannot tolerate a Schmitt input.

The hysteresis inherent in Schmitt

Trigger inputs greatly improves the

reliability of digital communications. It

can reject ground bounce of up to 2 V,

and induced voltages in digital signal

traces of 1 V.

Power Circuit Noise Generation

In a typical transistor inverter, the

output MOSFET may switch on or off

with di/dt ≥ 500A/µs. Referring to Fig. 6,

and assuming that the MOSFET

Source Terminal has a 1 inch path on

the PCB to system ground, a voltage as

high as 13.5 V can be developed:

V = 27 nH

500A/µs = 13.5 V

If the MOSFET switches 25 A, the

transient will last as long as (25/500) µs

or 50 ns, which is much more than the

typical 6 or 7 ns propagation delay of a

74 HC series gate.

Caution: If one set of digital circuits is

tied to system ground, and one to local

ground, it is clear that such a transient

would cause spurious outputs. In an

inverter, the consequences of such an

error could be catastrophic. Turning a

transistor on at the wrong time could

easily cause it to explode, with the

potential for equipment damage and

operator injury -- clearly undesirable.

Fig. 6. Power circuit noise generation

Methods of Correcting these

Problems

The first step is to use a logic family

with inherent noise immunity. Standard

TTL (or any of its derivatives, including

74HCT CMOS) is a poor choice

because of the logic levels these families employ. In particular, V

close to ground to reject the levels of

OL, VIL

are too

ground noise common to power circuits.

74HC logic is significantly superior, and

the older 4000 series CMOS is even

better. Unfortunately, in modern motor

controls, especially those that employ

microprocessors, the speeds of the

4000 series CMOS are no longer

adequate. In most cases 74HC logic is

the only viable alternative.

Layout

The second, and most important step is

the printed circuit board (PCB) layout.

The PCB is a very important component in any power circuit, and there is a

© 1998 IXYS All rights reserved

I - 19

Page 7

IXDP630

IXDP631

tendency to leave it off the schematic.

During the layout process, the engineer

must consider each and every connection from the standpoint of its contribution to system operation. How sensitive

is it? What noise producing lines are

routed near it? What transients can

occur between circuits tied to each end

of this trace...? With few exceptions,

modern autorouters cannot deal with

these requirements. If autorouters are

used, they produce layouts that will not

function.

Remember that the IXDP630/631 is the

interface between the control circuits

and the power circuits. Nowhere else

on the PCB are these problems more

likely to occur. Nowhere else will one

need to pay more attention. Fig. 7

illustrates an example layout problem.

The power circuit consists of three

the MOSFET is 6 V), the di/dt at turn-on

will be regulated by the driver/MOSFET/

L

loop to about 200 A/µs - quite a

S1

surprise when your circuit requires

500 A/µs to operate correctly.

It is possible to make use of this behavior to create a turn-on or turn-off di/dt

limiter (perhaps to snub the upper

freewheeling diode reverse recovery).

While possible, this is normally not

desirable or practical where two or

more transistors are controlled.

Equalizing the parasitic impedances of

three traces while positioning the

transistors next to their heat sink and

meeting UL/VDE voltage spacings is

just too difficult.

Grounding the gate drive buffer as in

option (a) solves the MOSFET turn on

problem by eliminating LS1 from the

Fig. 7. Potential layout problems that create functional problems.

power transistors (MOSFETs in this

example) controlled by a common

digital IC (the IXDP630). With the gate

drive amplifier (a discrete circuit or

possibly an IC driver like the

IXBD4410) grounded as in option (b),

the communication path from the

IXDP630 will operate without errors.

The PC trace induced voltages are not

common with the digital path so the

input of the gate drive buffer will not

see or respond to them. Unfortunately,

the MOSFET will not operate properly.

The voltage induced across L

Q1 is turned on, acts as source dege-

when

S1

neration, modifying the turn-on behavior

of the MOSFET. If L

is 12 V (assuming the gate plateau of

= 27 nH, and V

S1

Source feedback loop. Now, unfortunately, the gate driver will oscillate every

time you turn it on or off. As the

IXDP630 output goes high, the gate

driver output follows (after its propagation delay) and the MOSFET starts to

conduct. The voltage transient induced

across LS1 (V = Ls1/di/dt) raises the

local ground (point a) until it exceeds

Voh (630)-Vil (gate buffer) and the buffer

(after its prop. delay) turns the MOSFET

off. Now the MOSFET current falls,

V(Ls1) drops, point (a) drops to (or

slightly below) system ground, and the

buffer detects a "1" at its input. After its

propagation delay, it again turns the

MOSFET on, continuing the oscillation

CC

for one more cycle.

To eliminate this problem, a ground

level transformation circuit must be

added that rejects this common mode

transient. The simplest is a decoupling

circuit, also illustrated in Fig. 7. The

capacitor voltage (on Cd) remains

constant while the transient voltage is

dropped across Rd and the buffer

detects no input transition, eliminating

the oscillation. This circuit does add

significantly to turn-on and turn-off

delay time, and cannot be used if the

transient lasts as long as these delays

are allowed to extend. Delay times

must be considered in selection of

system deadtime.

It is also important to consider the

layout of the bypass capacitor as well

as the oscillator components in order to

keep these as close to the device as

possible.

Isolation

The most complex (and most effective)

method of eliminating the effects of

transients between grounds is isolation.

Optocouplers and pulse transformers

are the most commonly used isolation

techniques, and work very well in this

case. The IXDP630/631 has been

specifically designed to directly drive a

high speed optocoupler like the Hewlett

Packard HCPL22XX family or the

General Instrument 740L60XX

optologic family. These optos are

especially well suited to motor control

and power conversion equipment due

to their very high common-mode dv/dt

rejection capabilities.

The major problem associated with

using an optocoupler in a power circuit

is its common-mode dv/dt capability.

When a lower transistor is turned on, its

Collector (or Drain) is pulled to ground

very quickly. The optocoupler that

drives the upper transistor has its local

output stage referenced to the Emitter

(Source) of this upper device, which is

tied to the Collector of the lower device.

As this node moves, the dv/dt between

here and input circuit common is impressed across the upper optocoupler.

This causes displacement currents to

flow in sensitive nodes in the optical

receiver circuitry, and may cause false

triggering of the output. Always pay

strict attention to the manufacturer's

recommended dv/dt ratings - exceeding

them could be disastrous.

I - 20

© 1998 IXYS All rights reserved

Loading...

Loading...