®

ISL6237

Data Sheet March 18, 2008

High-Efficiency, Quad-Output, Main Power

Supply Controllers for Notebook

Computers

The ISL6237 dual step-down, switch-mode power-supply

(SMPS) controller generates logic-supply voltages in

battery-powered systems. The ISL6237 includes two

pulse-width modulation (PWM) controllers, 5V/3.3V and

1.5V/1.05V. The output of SMPS1 can also be adjusted from

0.7V to 5.5V . The SMPS2 o utput can be adjusted from 0.5V to

2.5V by setting REFIN2 voltage. This device features a linear

regulator providing 3.3V/5V, or adjustable from 0.7V to 4.5V

output via LDOREFIN. The linear regulator provides up to

100mA output current with automatic linear-regulator

bootstrapping to the BYP input. When in switchover, the LDO

output can source up to 200mA. The ISL6237 includes

on-board power-up sequencing, power-good (POK_) output s,

digital soft-start, and internal so f t-stop output di scharge that

prevents negative voltages on shutdown .

Constant on-time PWM control scheme operates without

sense resistors and provides 100ns response to load

transients while maintaining a relatively constant switching

frequency . The unique ul trasonic pul se-ski pping mode

maintains the switching frequency above 25kHz, which

eliminates noise in audio applications. Other features include

pulse skipping, which maximizes efficiency in light-load

applications, and fixed-frequency PWM mode, which reduces

RF interference in sensitive applications.

Ordering Information

PART

NUMBER

(Note)

ISL6237IRZ ISL6237 IRZ -40 to +100 32 Ld 5x5 QFN L32.5x5B

ISL6237IRZ-T* ISL6237 IRZ -40 to +100 32 Ld 5x5 QFN

*Please refer to TB347 for details on reel specifications.

NOTE: These Intersil Pb-free plastic packaged products employ

special Pb-free material sets; molding compounds/die attach materials

and 100% matte tin plate PLUS ANNEAL - e3 termination finish, which

is RoHS compliant and compatible with both SnPb and Pb-free

soldering operations. Intersil Pb-free products are MSL classified at

Pb-free peak reflow temperatures that meet or exceed the Pb-free

requirements of IPC/JEDEC J STD-020.

PART

MARKING

TEMP.

RANGE

(°C)

PACKAGE

(Pb-free)

Tape and Reel

PKG.

DWG. #

L32.5x5B

FN6418.4

Features

• Wide Input Voltage Range 5.5V to 25V

• Dual Fixed 1.05V/3.3V and 1.5V/5.0V Outputs or

Adjustable 0.7V to 5.5V (SMPS1) and 0.5V to 2.5V

(SMPS2), ±1.5% Accuracy

• 1.7ms Digital Soft-Start and Independent Shutdown

• Fixed 3.3V/5.0V, or Adjustable Output 0.7V to 4.5V,

±1.5% (LDO): 200mA

• 2.0V Reference Voltage

• Constant ON-TIME Control with 100ns Load-Step

Response

• Selectable Switching Frequency

•r

Current Sensing

DS(ON)

• Programmable Current Limit with Foldback Capability

• Selectable PWM, Skip or Ultrasonic Mode

• BOOT Voltage Monitor with Automatic Refresh

• Independent POK1 and POK2 Comparators

• Soft-Start with Pre-Biased Output and Soft-Stop

• Independent ENABLE

• High Efficiency - Up to 97%

• Very High Light Load Efficiency (Skip Mode)

• 5mW Quiescent Power Dissipation

• Thermal Shutdown

• Extremely Low Components Count

• Pb-Free (RoHS Compliant)

Applications

• Notebook and Sub-Notebook Computers

• PDAs and Mobile Communication Devices

• 3-Cell and 4-Cell Li+ Battery-Powered Devices

• DDR1, DDR2, and DDR3 Power Supplies

• Graphic Cards

• Game Consoles

• Telecommunication

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2007, 2008. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

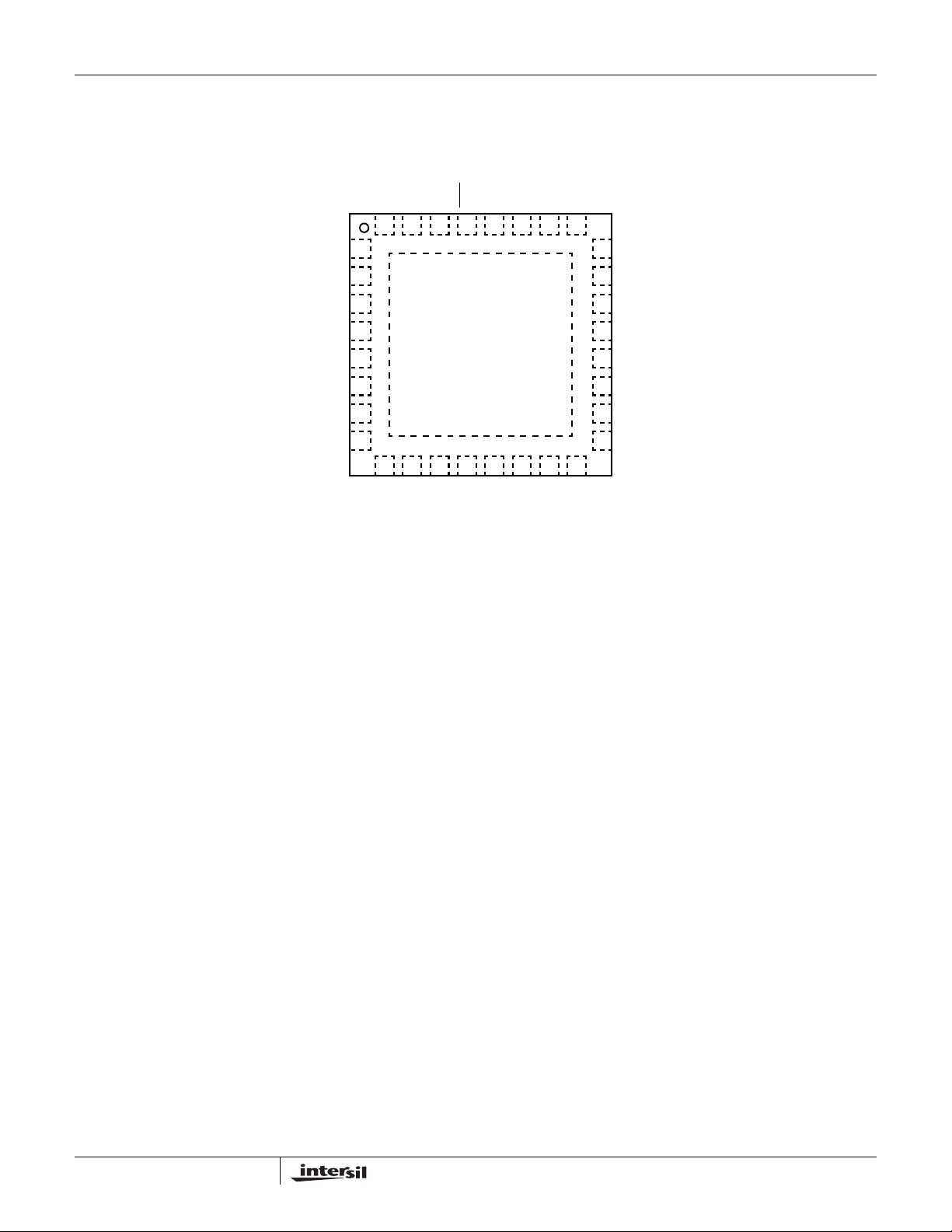

Pinout

REF

ISL6237

ISL6237

(32 LD 5x5 QFN)

TOP VIEW

REFIN2

ILIM2

OUT2

SKIP

POK2

32 31 30 29 28 27 26 25

1

EN2

UGATE2

PHASE2

24

BOOT2

TON

VCC

EN_LDO

NC

VIN

LDO

LDOREFIN

2

3

4

5

6

7

8

9 10111213141516

BYP

FB1

OUT1

ILIM1

POK1

EN1

LGATE2

23

PGND

22

GND

21

NC

20

PVCC

19

LGATE1

18

BOOT1

17

UGATE1

PHASE1

2

FN6418.4

March 18, 2008

ISL6237

Absolute Voltage Ratings

VIN, EN_LDO to GND . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +27V

BOOT_ to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +33V

BOOT_ to PHASE_ . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +6V

VCC, EN_, SKIP

PVCC, POK_ to GND . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +6V

LDO, FB1, REFIN2, LDOREFIN to GND . . . -0.3V to (VCC + 0.3V)

OUT_, REF to GND . . . . . . . . . . . . . . . . . . . .-0.3V to (VCC + 0.3V

, TON,

Thermal Information

Thermal Resistance (Typical) θJA (°C/W) θJC (°CW)

32 Ld QFN (Notes 1, 2) . . . . . . . . . . . . 32 3.0

Operating Temperature Range . . . . . . . . . . . . . . . .-40°C to +100°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+150°C

Storage Temperature Range . . . . . . . . . . . . . . . . . .-65°C to +150°C

Pb-free reflow profile . . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

UGATE_ to PHASE_ . . . . . . . . . . . . . . . . . . -0.3V to (PVCC + 0.3V)

ILIM_ to GND. . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to (VCC + 0.3V)

LGATE_, BYP to GND. . . . . . . . . . . . . . . . . -0.3V to (PVCC + 0.3V)

PGND to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to + 0.3V

LDO, REF Short Circuit to GND . . . . . . . . . . . . . . . . . . .Continuous

VCC Short Circuit to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1s

LDO Current (Internal Regulator) Continuous . . . . . . . . . . . . 100mA

LDO Current (Switched Over to OUT1) Continuous . . . . . . +200mA

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

NOTES:

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See

1. θ

JA

Tech Brief TB379.

2. For θ

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

3. Limits established by characterization and are not production tested.

4. Parts are 100% tested at +25°C. Temperature limits established by characterization and are not production tested.

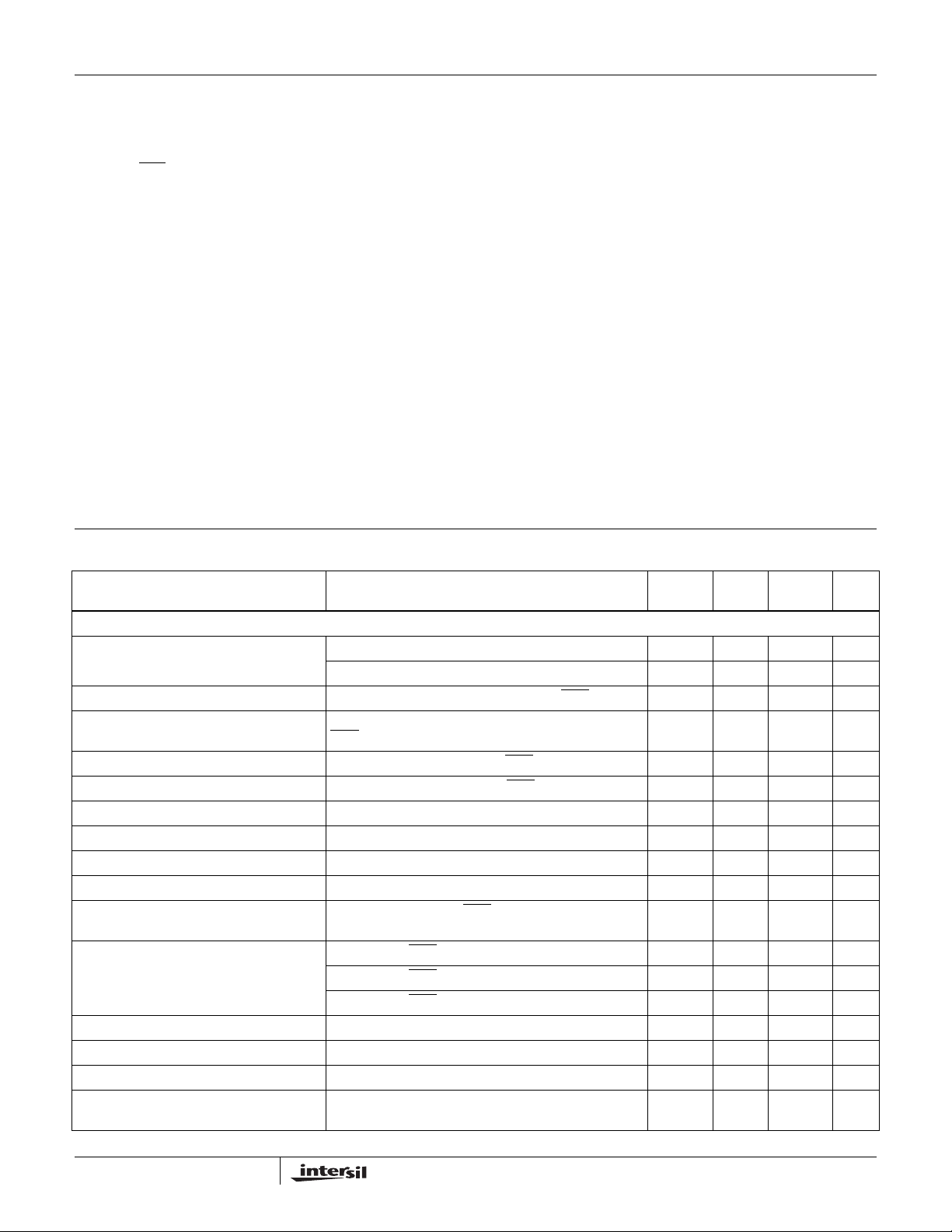

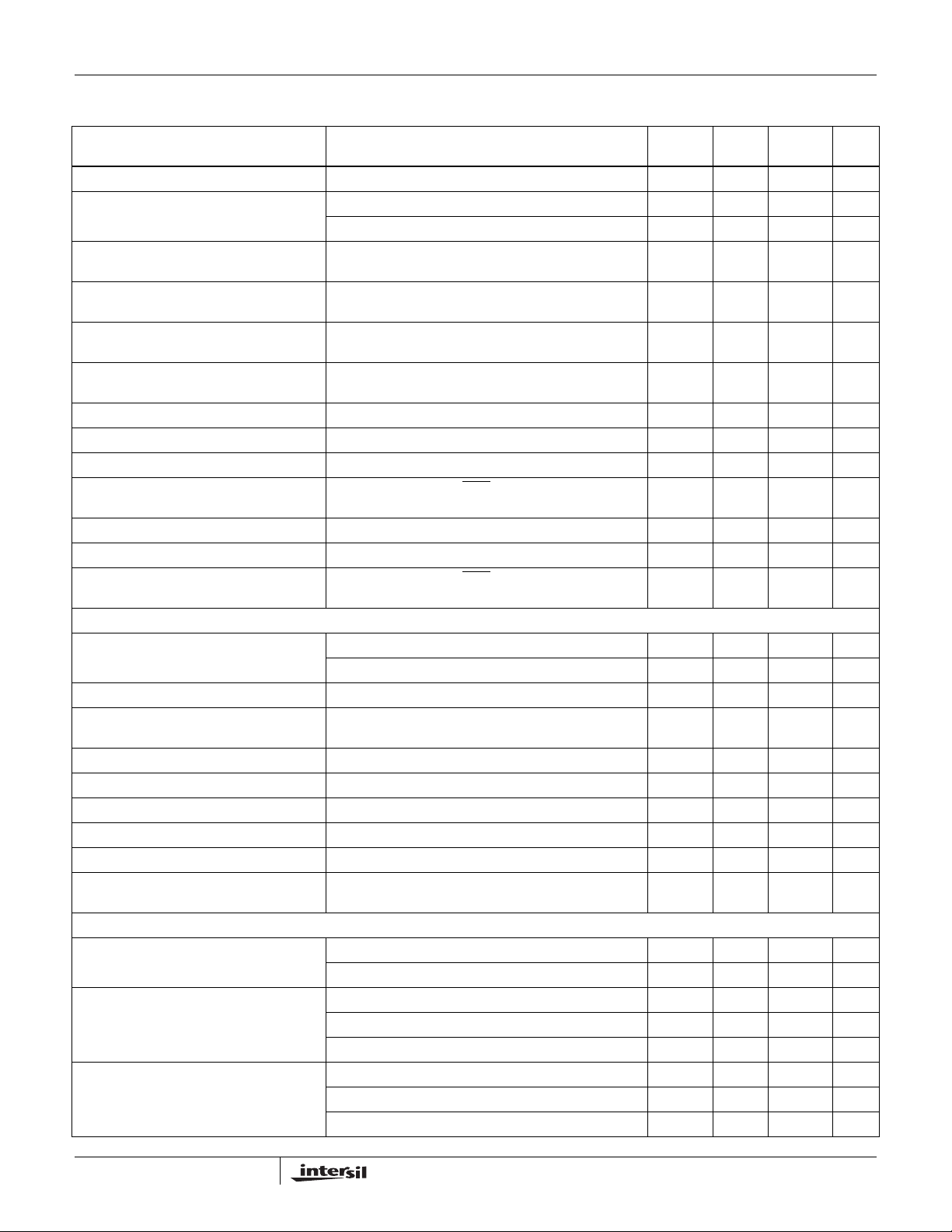

Electrical Specifications No load on LDO, OUT1, OUT2, and REF, V

V

EN_LDO

PARAMETER CONDITIONS

=5V, TA= -40°C to +100°C, unless otherwise noted. Typical values are at TA = +25°C.

= 12V, EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V,

IN

MIN

(Note 4) TYP

MAX

(Note 4) UNITS

MAIN SMPS CONTROLLERS

VIN Input Voltage Range LDO in regulation 5.5 25 V

= LDO, V

V

IN

< 4.43V 4.5 5.5 V

OUT1

3.3V Output Voltage in Fixed Mode VIN = 5.5V to 25V, REFIN2 > (VCC - 1V), SKIP = 5V 3.285 3.330 3.375 V

1.05V Output Voltage in Fixed Mode V

1.5V Output Voltage in Fixed Mode V

5V Output Voltage in Fixed Mode V

FB1 in Output Adjustable Mode V

= 5.5V to 25V, 3.0 < REFIN2 < (VCC - 1.1V),

IN

SKIP

=5V

= 5.5V to 25V, FB1 = VCC, SKIP = 5V 1.482 1.500 1.518 V

IN

= 5.5V to 25V, FB1 = GND, SKIP = 5V 4.975 5.050 5.125 V

IN

= 5.5V to 25V 0.693 0.700 0.707 V

IN

1.038 1.05 1.062 V

REFIN2 in Output Adjustable Mode VIN = 5.5V to 25V 0.7 2.50 V

SMPS1 Output Voltage Adjust Range SMPS1 0.70 5.50 V

SMPS2 Output Voltage Adjust Range SMPS2 0.50 2.50 V

SMPS2 Output Voltage Accuracy

REFIN2 = 0.7V to 2.5V, SKIP

=VCC -1.0 1.0 %

(Referred for REFIN2)

DC Load Regulation Either SMPS, SKIP

Either SMPS, SKIP

Either SMPS, SKIP

Line Regulation Either SMPS, 6V < V

= VCC, 0 to 5A -0.1 %

= REF, 0 to 5A -1.7 %

= GND, 0 to 5A -1.5 %

< 24V 0.005 %/V

IN

Current-Limit Current Source Temperature = +25°C 4.75 5 5.25 µA

ILIM_ Adjustment Range 0.2 2 V

Current-Limit Threshold (Positive, Default) ILIM_ = VCC, GND - PHASE_

93 100 107 mV

(No temperature compensation)

3

FN6418.4

March 18, 2008

ISL6237

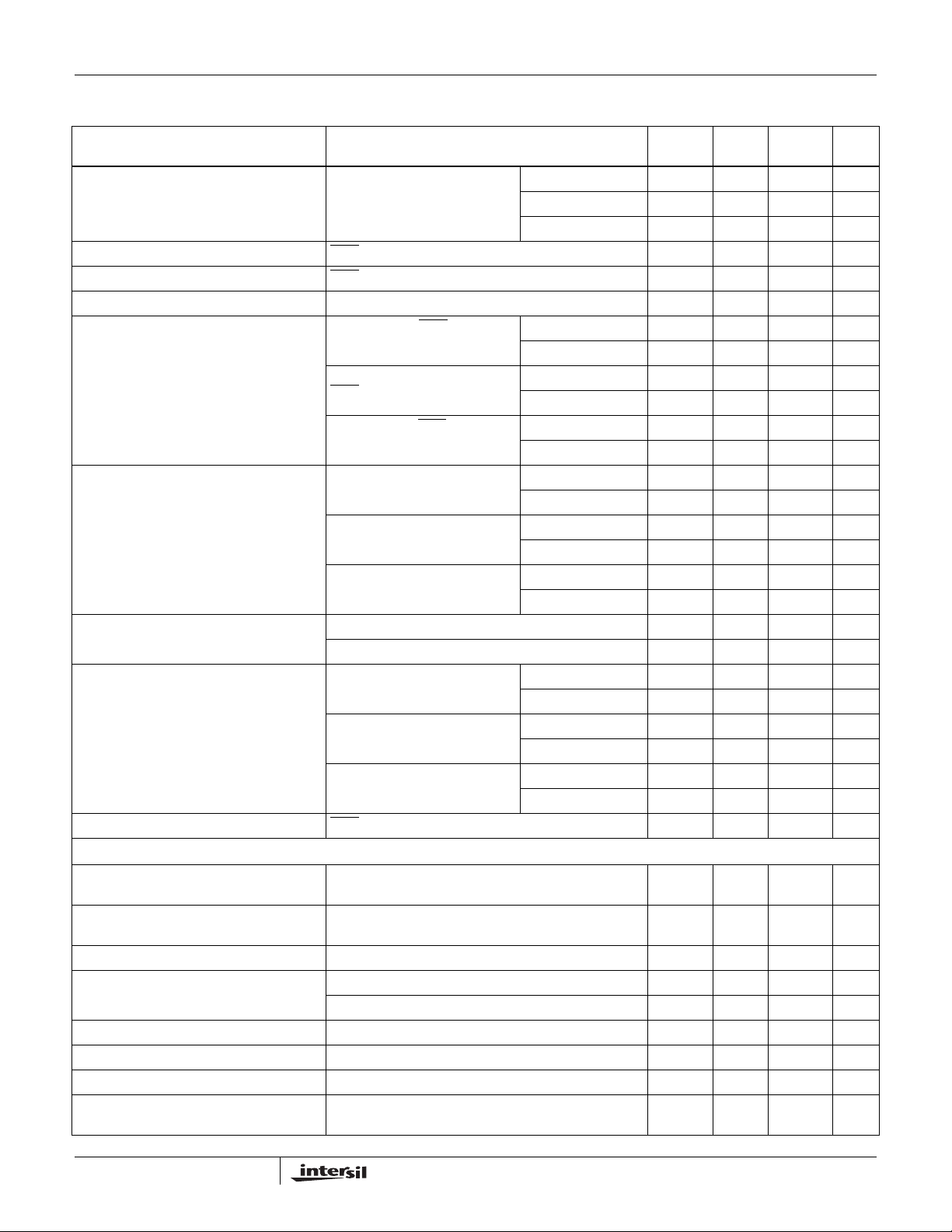

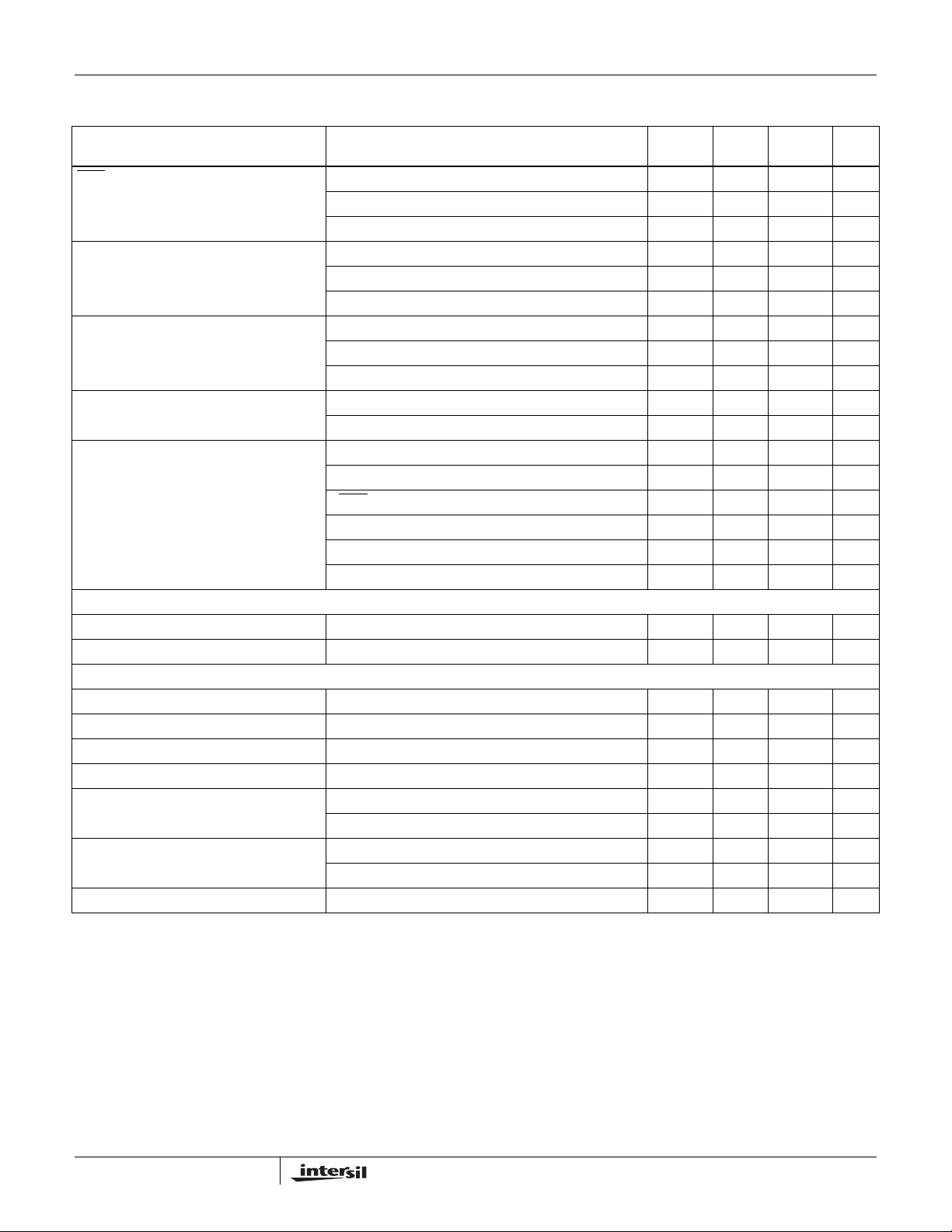

Electrical Specifications No load on LDO, OUT1, OUT2, and REF, V

PARAMETER CONDITIONS

Current-Limit Threshold

(Positive, Adjustable)

V

EN_LDO

=5V, TA= -40°C to +100°C, unless otherwise noted. Typical values are at TA = +25°C. (Continued)

GND - PHASE_ V

= 12V, EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V,

IN

MIN

(Note 4) TYP

= 0.5V 40 50 60 mV

ILIM_

V

= 1V 93 100 107 mV

ILIM_

V

= 2V 185 200 215 mV

ILIM_

MAX

(Note 4) UNITS

Zero-Current Threshold SKIP = GND, REF, or OPEN, GND - PHASE_ 3 mV

Current-Limit Threshold (Negative, Default) SKIP

= VCC, GND - PHASE_ -120 mV

Soft-Start Ramp Time Zero to full limit 1.7 ms

Operating Frequency (V

= GND), SKIP = VCC SMPS 1 400 kHz

tON

SMPS 2 500 kHz

(V

= REF or OPEN),

tON

SKIP

= VCC

= VCC), SKIP = VCC SMPS 1 200 kHz

(V

tON

SMPS 1 400 kHz

SMPS 2 300 kHz

SMPS 2 300 kHz

On-Time Pulse Width V

Minimum Off-Time T

= GND (400kHz/500kHz) V

tON

V

= REF or OPEN

tON

(400kHz/300kHz)

V

= VCC (200kHz/300kHz) V

tON

= -40°C to +100°C 200 300 425 ns

A

= 5.00V 0.895 1.052 1.209 µs

OUT1

V

= 3.33V 0.475 0.555 0.635 µs

OUT2

V

= 5.05V 0.895 1.052 1.209 µs

OUT1

V

= 3.33V 0.833 0.925 1.017 µs

OUT2

= 5.05V 1.895 2.105 2.315 µs

OUT1

V

= 3.33V 0.833 0.925 1.017 µs

OUT2

TA = -40°C to +85°C 200 300 410 ns

Maximum Duty Cycle V

Ultrasonic SKIP Operating Frequency SKIP

= GND V

tON

V

= REF or OPEN V

tON

V

= VCC V

tON

= 5.05V 88 %

OUT1

V

= 3.33V 85 %

OUT2

= 5.05V 88 %

OUT1

V

= 3.33V 91 %

OUT2

= 5.05V 94 %

OUT1

= 3.33V 91 %

V

OUT2

= REF or OPEN 25 37 kHz

INTERNAL REGULATOR AND REFERENCE

LDO Output Voltage BYP = GND, 5.5V < V

0 < ILDO < 100mA

LDO Output Voltage BYP = GND, 5.5V < V

0 < ILDO < 100mA

LDO Output in Adjustable Mode V

LDO Output Accuracy in Adjustable Mode V

LDOREFIN Input Range V

LDO Output Current BYP = GND, V

LDO Output Current During Switchover BYP = 5V, V

LDO Output Current During Switchover to

3.3V

= 5.5V to 25V, V

IN

= 5.5V to 25V, V

IN

V

= 5.5V to 25V, V

IN

=2xV

LDO

BYP = 3.3V, V

LDOREFIN

= 5.5V to 25V (Note 3) 100 mA

IN

= 5.5V to 25V, LDOREFIN < 0.3V 200 mA

IN

= 5.5V to 25V, LDOREFIN > (VCC - 1V) 100 mA

IN

4

< 25V, LDOREFIN < 0.3V,

IN

< 25V , LDOREFIN> (VCC - 1V),

IN

=2xV

LDO

LDOREFIN

LDOREFIN

LDOREFIN

= 0.35V to 0.5V ±2.5 %

= 0.5V to 2.25V ±1.5 %

4.925 5.000 5.075 V

3.250 3.300 3.350 V

0.7 4.5 V

0.35 2.25 V

FN6418.4

March 18, 2008

ISL6237

Electrical Specifications No load on LDO, OUT1, OUT2, and REF, V

V

EN_LDO

PARAMETER CONDITIONS

=5V, TA= -40°C to +100°C, unless otherwise noted. Typical values are at TA = +25°C. (Continued)

= 12V, EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V,

IN

MIN

(Note 4) TYP

MAX

(Note 4) UNITS

LDO Short-Circuit Current LDO = GND, BYP = GND 200 400 mA

Undervoltage-Lockout Fault Threshold Rising edge of PVCC 4.35 4.5 V

Falling edge of PVCC 3.9 4.05 V

LDO 5V Bootstrap Switch Threshold to BYP Rising edge at BYP regulation point

4.53 4.68 4.83 V

LDOREFIN = GND

LDO 3.3V Bootstrap Switch Threshold to

BYP

LDO 5V Bootstrap Switch Equivalent

Rising edge at BYP regulation point

3.0 3.1 3.2 V

LDOREFIN = VCC

LDO to BYP , BYP = 5V, LDOREFIN > (VCC - 1V) (Note 3) 0.7 1.5 Ω

Resistance

LDO 3.3V Bootstrap Switch Equivalent

LDO to BYP, BYP = 3.3V, LDOREFIN < 0.3V (Note 3) 1.5 3.0 Ω

Resistance

REF Output Voltage No external load 1.980 2.000 2.020 V

REF Load Regulation 0 < I

< 50µA 10 mV

LOAD

REF Sink Current REF in regulation 10 µA

VIN Operating Supply Current Both SMPSs on, FB1 = SKIP

V

= BYP = 5.3V, V

OUT1

VIN Standby Supply Current V

VIN Shutdown Supply Current V

= 5.5V to 25V, both SMPSs off, EN_LDO = VCC 180 250 µA

IN

= 4.5V to 25V, EN1 = EN2 = EN_LDO = 0V 20 30 µA

IN

Quiescent Power Consumption Both SMPSs on, FB1 = SKIP

V

= BYP = 5.3V, V

OUT1

= GND, REFIN2 = VCC

= 3.5V

OUT2

= GND, REFIN2 = VCC,

= 3.5V

OUT2

25 50 µA

57mW

FAULT DETECTION

Overvoltage Trip Threshold FB1 with respect to nominal regulation point +8 +11 +14 %

REFIN2 with respect to nominal regulation point +12 +16 +20 %

Overvoltage Fault Propagation Delay FB1 or REFIN2 delay with 50mV overdrive 10 µs

POK_ Threshold FB1 or REFIN2 with respect to nominal output, falling

-12 -9 -6 %

edge, typical hysteresis = 1%

POK_ Propagation Delay Falling edge, 50mV overdrive 10 µs

POK_ Output Low Voltage I

= 4mA 0.2 V

SINK

POK_ Leakage Current High state, forced to 5.5V 1 µA

Thermal-Shutdown Threshold +150 °C

Output Undervoltage Shutdown Threshold FB1 or REFIN2 with respect to nominal output voltage 65 70 75 %

Output Undervoltage Shutdown Blanking

From EN_ signal 10 20 30 ms

Time

INPUTS AND OUTPUTS

FB1 Input Voltage Low level 0.3 V

High level VCC - 1.0 V

REFIN2 Input Voltage OUT2 Dynamic Range, V

OUT2=VREFIN2

0.5 2.50 V

Fixed OUT2 = 1.05V 3.0 VCC - 1.1 V

Fixed OUT2 = 3.3V VCC - 1.0 V

LDOREFIN Input Voltage Fixed LDO = 5V 0.30 V

LDO Dynamic Range, V

LDO

=2xV

LDOREFIN

0.35 2.25 V

Fixed LDO = 3.3V VCC - 1.0 V

5

FN6418.4

March 18, 2008

ISL6237

Electrical Specifications No load on LDO, OUT1, OUT2, and REF, V

V

EN_LDO

PARAMETER CONDITIONS

=5V, TA= -40°C to +100°C, unless otherwise noted. Typical values are at TA = +25°C. (Continued)

= 12V, EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V,

IN

MIN

(Note 4) TYP

MAX

(Note 4) UNITS

SKIP Input Voltage Low level (SKIP) 0.8 V

Float level (ULTRASONIC SKIP) 1.7 2.3 V

High level (PWM) 2.4 V

TON Input Voltage Low level 0.8 V

Float level 1.7 2.3 V

High level 2.4 V

EN1, EN2 Input Voltage Clear fault level/SMPS off level 0.8 V

Delay start level 1.7 2.3 V

SMPS on level 2.4 V

EN_LDO Input Voltage Rising edge 1.2 1.6 2.0 V

Falling edge 0.94 1.00 1.06 V

Input Leakage Current V

= 0 or 5V -1 +1 µA

tON

V

EN_=VEN_LDO

VSKIP

= 0V or 5V -1 +1 µA

V

= 0V or 5V -0.2 +0.2 µA

FB1

V

= 0V or 2.5V -0.2 +0.2 µA

REFIN

V

LDOREFIN

= 0V or 5V -0.1 +0.1 µA

= 0V or 2.75V -0.2 +0.2 µA

INTERNAL BOOT DIODE

V

Forward Voltage PVCC - V

D

I

BOOT_LEAKAGE

Leakage Current V

BOOT

, IF= 10mA 0.65 0.8 V

BOOT

= 30V, PHASE = 25V, PVCC = 5V 500 nA

MOSFET DRIVERS

UGATE_ Gate-Driver Sink/Source Current UGATE1, UGATE2 forced to 2V 2 A

LGATE_ Gate-Driver Source Current LGATE1 (source), LGATE2 (source), forced to 2V 1.7 A

LGATE_ Gate-Driver Sink Current LGATE1 (sink), LGATE2 (sink), forced to 2V 3.3 A

UGATE_ Gate-Driver ON-resistance BST_ - PHASE_ forced to 5V (Note 3) 1.5 4.0 Ω

LGATE_ Gate-Driver ON-resistance LGATE_, high state (pull-up) (Note 3) 2.2 5.0 Ω

LGATE_, low state (pull-down) (Note 3) 0.6 1.5 Ω

Dead Time LGATE_ Rising 15 20 35 ns

UGATE_ Rising 20 30 50 ns

OUT1, OUT2 Discharge ON-resistance 25 40 Ω

6

FN6418.4

March 18, 2008

ISL6237

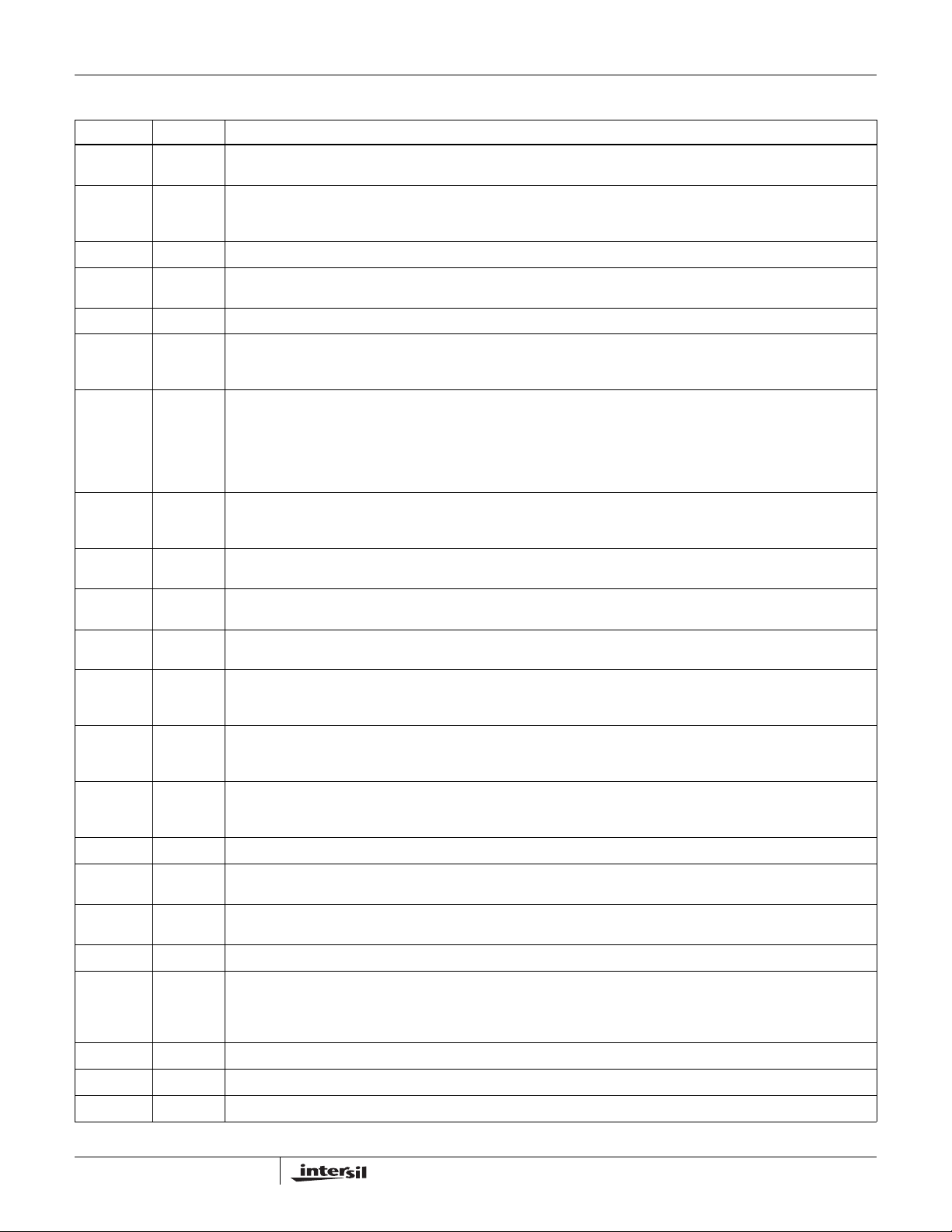

Pin Descriptions

PIN NAME FUNCTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

REF 2V Reference Output. Bypass to GND with a 0.1µF (min) capacitor. REF can source up to 50µA for external loads.

Loading REF degrades FB and output accuracy according to the REF load-regulation error.

TON Frequency Select Input. Connect to GND for 400kHz/500kHz operation. Connect to REF (or leave OPEN) for

400kHz/300kHz operation. Connect to VCC for 200kHz/300kHz operation (5V/3.3V SMPS switching frequencies,

respectively.)

VCC Analog Supply Voltage Input for PWM Core. Bypass to GND with a 1µF ceramic capacitor.

EN_LDO LDO Enable Input. The LDO is enabled if EN_LDO is within logic high level and disabled if EN_LDO is less than the

logic low level.

NC No connect.

VIN Power-Supply Input. VIN is used for the constant-on-time PWM on-time one-shot circuits. VIN is also used to power

the linear regulators. The linear regulators are powered by SMPS1 if OUT1 is set greater than 4.78V and BYP is tied

to OUT1. Connect VIN to the battery input and bypass with a 1µF capacitor.

LDO Linear-Regulator Output. LDO can provide a total of 100mA external loads. The LDO regulate at 5V If LDOREFIN is

connected to GND. When the LDO is set at 5V and BYP is within 5V switchover threshold, the internal regulator shuts

down and the LDO output pin connects to BYP through a 0.7Ω switch. The LDO regulate at 3.3V if LDOREFIN is

connected to VCC. When the LDO is set at 3.3V and BYP is within 3.3V switchover threshold, the internal regulator

shuts down and the LDO output pin connects to BYP through a 1.5Ω switch. Bypass LDO output with a minimum of

4.7µF ceramic.

LDOREFIN LDO Reference Input. Connect LDOREFIN to GND for fixed 5V operation. Connect LDOREFIN to VCC for fixed 3.3V

operation. LDOREFIN can be used to program LDO output voltage from 0.7V to 4.5V. LDO output is two times the

voltage of LDOREFIN. There is no switchover in adjustable mode.

BYP BYP is the switchover source voltage for the LDO when LDOREFIN connected to GND or VCC. Connect BYP to 5V if

LDOREFIN is tied GND. Connect BYP to 3.3V if LDOREFIN is tied to VCC.

OUT1 SMPS1 Output Voltage-Sense Input. Connect to the SMPS1 output. OUT1 is an input to the Constant on-time-PWM

on-time one-shot circuit. It also serves as the SMPS1 feedback input in fixed-voltage mode.

FB1 SMPS1 Feedback Input. Connect FB1 to GND for fixed 5V operation. Connect FB1 to VCC for fixed 1.5V operation

Connect FB1 to a resistive voltage-divider from OUT1 to GND to adjust the output from 0.7V to 5.5V.

ILIM1 SMPS1 Current-Limit Adjustment. The GND-PHASE1 current-limit threshold is 1/10th the voltage seen at ILIM1 over

a 0.2V to 2V range. There is an internal 5µA current source from VCC to ILIM1. Connect ILIM1 to REF for a fixed

200mV threshold. The logic current limit threshold is default to 100mV value if ILIM1 is higher than VCC - 1V.

POK1 SMPS1 Power-Good Open-Drain Output. POK1 is low when the SMPS1 output voltage is more than 10% below the

normal regulation point or during soft-start. POK1 is high impedance when the output is in regulation and the soft-start

circuit has terminated. POK1 is low in shutdown.

EN1 SMPS1 Enable Input. The SMPS1 is enabled if EN1 is greater than the logic high level and disabled if EN1 is less than

the logic low level. If EN1 is connected to REF, the SMPS1 starts after the SMPS2 reaches regulation (delay start).

Drive EN1 below 0.8V to clear fault level and reset the fault latches.

UGATE1 High-Side MOSFET Floating Gate-Driver Output for SMPS1. UGATE1 swings between PHASE1 and BOOT1.

PHASE1 Inductor Connection for SMPS1. PHASE1 is the internal lower supply rail for the UGATE1 high-side gate driver.

PHASE1 is the current-sense input for the SMPS1.

BOOT1 Boost Flying Capacitor Connection for SMPS1. Connect to an external capacitor according to the “Typical Application

Circuits” starting on page 21 (Figures 62, 63 and 64). See “MOSFET Gate Drivers (UGATE_, LGATE_)” on page 28.

LGATE1 SMPS1 Synchronous-Rectifier Gate-Drive Output. LGATE1 swings between GND and PVCC.

PVCC PVCC is the supply voltage for the low-side MOSFET driver LGATE. Connect a 5V power source to the PVCC pin and

bypass to PGND with a 1µF MLCC ceramic capacitor. Refer to Figure 65 - A switch connects PVCC to VCC with 10

when in normal operation and is disconnected when in shutdown mode. An external 10Ω resistor from PVCC to VCC

is prohibited as it will create a leakage path from VIN to GND in shutdown mode.

NC No connect.

GND Analog Ground for both SMPS_ and LDO. Connect externally to the underside of the exposed pad.

PGND Power Ground for SMPS_ controller. Connect PGND externally to the underside of the exposed pad.

Ω

7

FN6418.4

March 18, 2008

ISL6237

Pin Descriptions (Continued)

PIN NAME FUNCTION

23

24

25

26

27

28

29

30

31

32

LGATE2 SMPS2 Synchronous-Rectifier Gate-Drive Output. LGATE2 swings between GND and PVCC.

BOOT2 Boost Flying Capacitor Connection for SMPS2. Connect to an external capacitor according to the “Typical Application

Circuits” starting on page 21 (Figures 62, 63 and 64) See “MOSFET Gate Drivers (UGATE_, LGATE_)” on page 28.

PHASE2 Inductor Connection for SMPS2. PHASE2 is the internal lower supply rail for the UGATE2 high-side gate driver.

PHASE2 is the current-sense input for the SMPS2.

UGATE2 High-Side MOSFET Floating Gate-Driver Output for SMPS2. UGATE1 swings between PHASE2 and BOOT2.

EN2 SMPS2 Enable Input. The SMPS2 is enabled if EN2 is greater than the logic high level and disabled if EN2 is less than

the logic low level. If EN2 is connected to REF, the SMPS2 starts after the SMPS1 reaches regulation (delay start).

Drive EN2 below 0.8V to clear fault level and reset the fault latches.

POK2 SMP2 Power-Good Open-Drain Output. POK2 is low when the SMPS2 output voltage is more than 10% below the

normal regulation point or during soft-start. POK2 is high impedance when the output is in regulation and the soft-start

circuit has terminated. POK2 is low in shutdown.

SKIP

Low-Noise Mode Control. Connect SKIP to GND for normal Idle-Mode (pulse-skipping) operation or to VCC for PWM

mode (fixed frequency). Connect to REF or leave floating for ultrasonic skip mode operation.

OUT2 SMPS2 Output Voltage-Sense Input. Connect to the SMPS2 output. OUT2 is an input to the Constant on-time-PWM

on-time one-shot circuit. It also serves as the SMPS2 feedback input in fixed-voltage mode.

ILIM2 SMPS2 Current-Limit Adjustment. The GND-PHASE1 current-limit threshold is 1/10th the voltage seen at ILIM2 over

a 0.2V to 2V range. There is an internal 5µA current source from VCC to ILIM2. Connect ILIM2 to REF for a fixed

200mV. The logic current limit threshold is default to 100mV value if ILIM2 is higher than VCC - 1V.

REFIN2 Output volt age control for SMPS2. Connect REFIN2 to VCC for fixed 3.3V. Connect REFIN2 to a 3.3V supply for fixed

1.05V. REFIN2 can be used to program SMPS2 output voltage from 0.5V to 2.50V. SMPS2 output voltage is 0V if

REFIN2 < 0.5V.

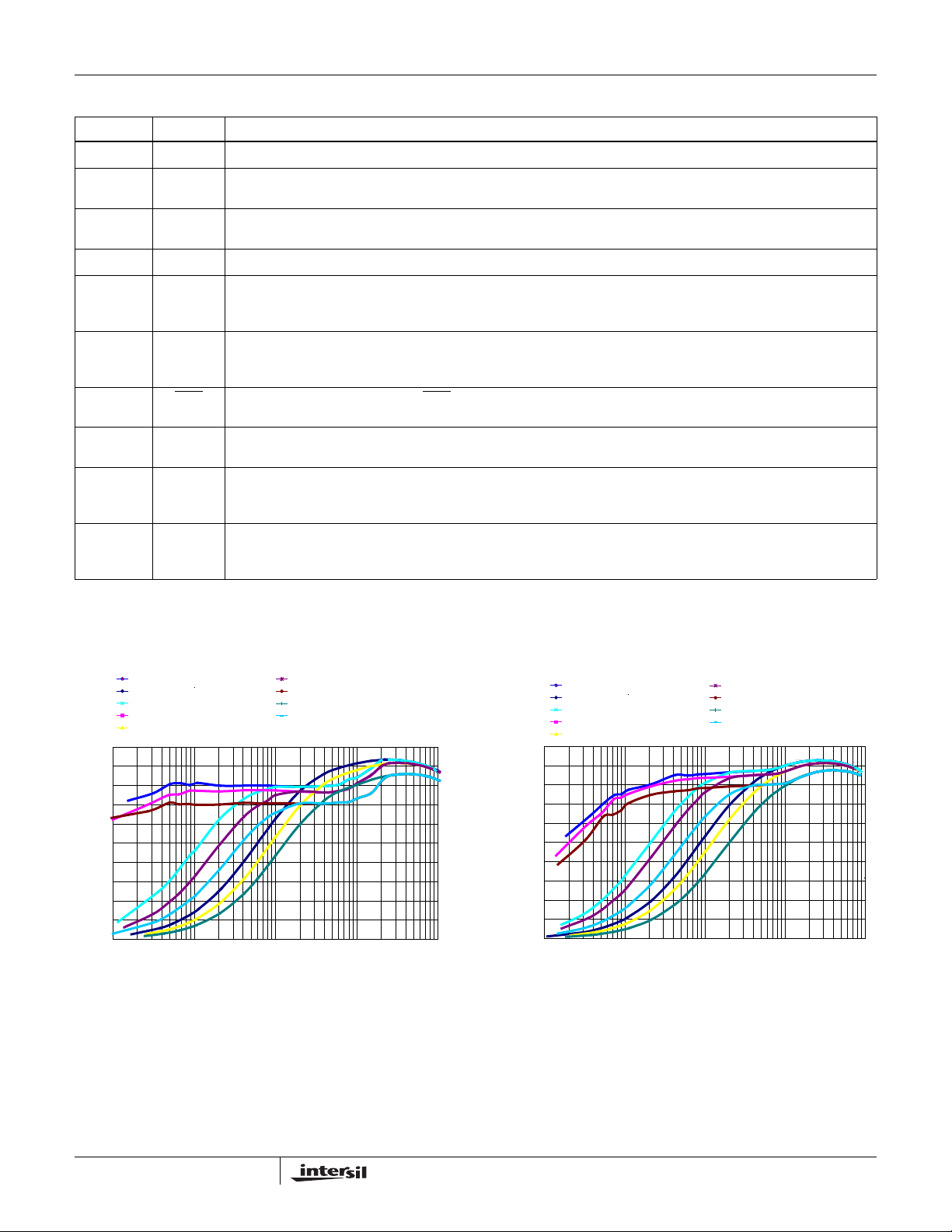

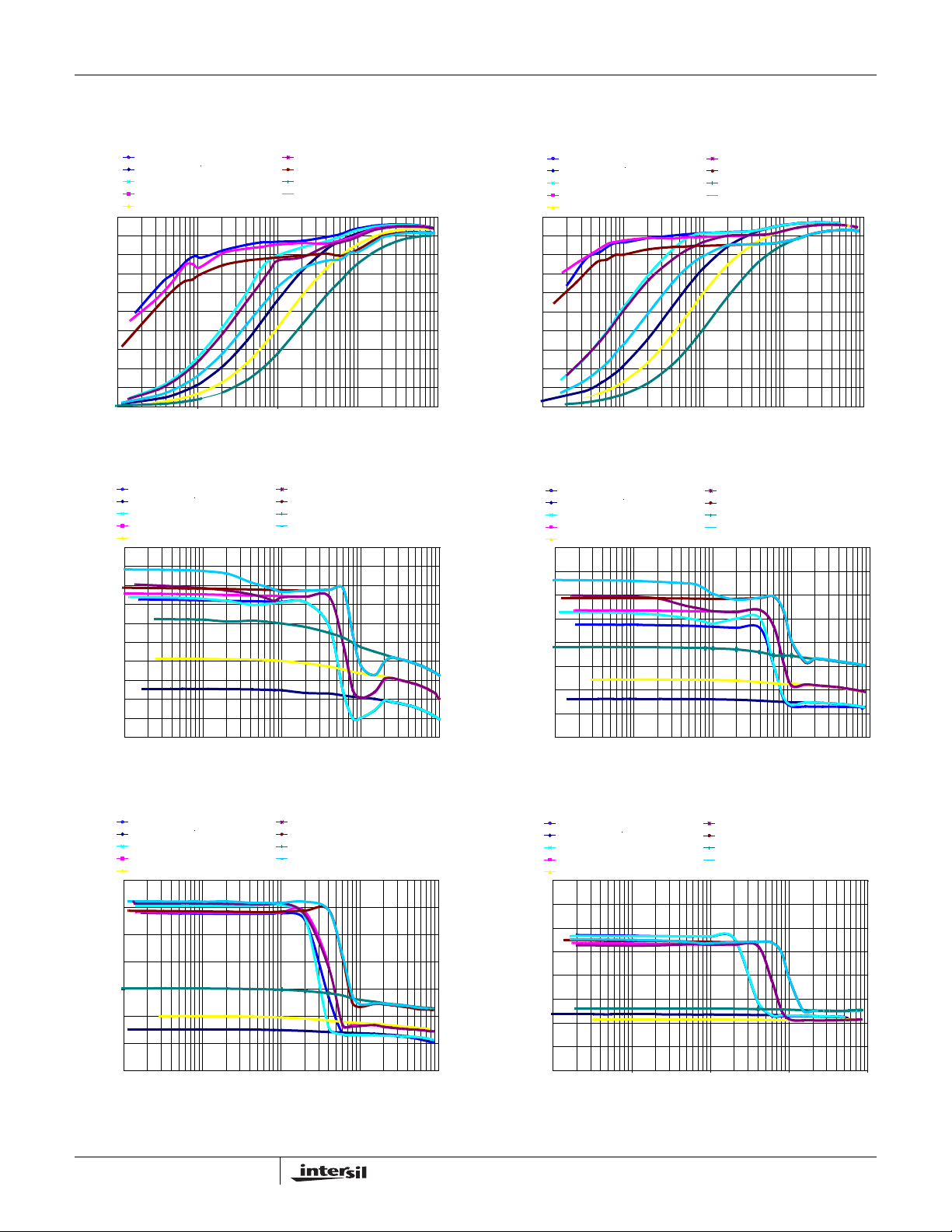

Typical Performance Curves Circuit of Figures 62, 63 and 64, no load on LDO, OUT1, OUT2, and REF, V

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULTRA SKIP MODE

12 VIN SKIP MODE

12 V

PWM MODE

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.001 0.010 0.100

FIGURE 1. V

IN

OUTPUT LOAD (A)

= 1.05V EFFICIENCY vs LOAD (300kHz) FIGURE 2. V

OUT2

EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V, V

otherwise noted. Typical values are at T

12 V

ULTRA SKIP MODE

IN

25 VIN SKIP MODE

25 VIN PWM MODE

ULTRA SKIP MODE

25 V

IN

1.000

10.000

EN_LDO

= +25°C.

A

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULTRA SKIP MODE

12 VIN SKIP MODE

PWM MODE

12 V

100

90

80

70

60

50

40

30

EFFICIENCY (%)

20

10

0

0.001

IN

OUT1

=5V, TA= -40°C to +100°C, unless

12 V

IN

25 VIN SKIP MODE

25 VIN PWM MODE

25 V

IN

0.010 0.100 1.000 10.000

OUTPUT LOAD (A)

= 1.5V EFFICIENCY vs LOAD (200kHz)

=12V,

IN

ULTRA SKIP MODE

ULTRA SKIP MODE

8

FN6418.4

March 18, 2008

ISL6237

Typical Performance Curves Circuit of Figures 62, 63 and 64, no load on LDO, OUT1, OUT2, and REF, V

EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V, V

otherwise noted. Typical values are at T

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULTRA SKIP MODE

12 VIN SKIP MODE

PWM MODE

12 V

100

90

80

70

60

50

40

30

EFFICIENCY (%)

20

10

0

0.001 0.010 0.100 1.000 10.000

FIGURE 3. V

1.070

1.068

1.066

1.064

1.062

1.060

1.058

1.056

OUTPUT VOLTAGE (V)

1.054

1.052

1.050

FIGURE 5. V

IN

OUTPUT LOAD (A)

= 3.3V EFFICIENCY vs LOAD (500kHz) FIGURE 4.

OUT2

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULTRA SKIP MODE

12 VIN SKIP MODE

12 V

PWM MODE

IN

0.001 0.010 0.100 1.000 10.000

OUTPUT LOAD (A)

= 1.05V REGULATION vs LOAD (300kHz) FIGURE 6. V

OUT2

12 V

ULTRA SKIP MODE

IN

25 VIN SKIP MODE

25 VIN PWM MODE

25 V

ULTRA SKIP MODE

IN

12 V

ULTRA SKIP MODE

IN

25 VIN SKIP MODE

25 VIN PWM MODE

ULTRA SKIP MODE

25 V

IN

EN_LDO

= +25°C. (Continued)

A

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULTRA SKIP MODE

12 VIN SKIP MODE

12 V

PWM MODE

100

90

80

70

60

50

EFFICIENCY (%)

40

30

20

10

0

0.001 0.010 0.100 1.000 10.000

IN

VOUT1

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULT RA SKIP MODE

12 VIN SKIP MODE

12 V

PWM MODE

IN

0.001 0.010 0.100 1.000

OUTPUT VOLTAGE (V)

1.540

1.535

1.530

1.525

1.520

1.515

1.510

1.505

1.500

OUT1

=5V, TA= -40°C to +100°C, unless

12 V

IN

25 VIN SKIP MODE

25 VIN PWM MODE

25 V

IN

OUTPUT LOAD (A)

= 5V EFFICIENCY vs LOAD (400kHz)

12 V

IN

25 VIN SKIP MODE

25 VIN PWM MODE

25 V

IN

OUTPUT LOAD (A)

= 1.5V REGULATION vs LOAD (200kHz)

=12V,

IN

ULTRA SKIP MODE

ULTRA SKIP MODE

ULTRA SKIP MODE

ULTRA SKIP MODE

10.000

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULTRA SKIP MODE

12 VIN SKIP MODE

12 V

PWM MODE

3.38

3.37

3.36

3.35

3.34

3.33

OUTPUT VOLTAGE (V)

3.32

3.31

FIGURE 7. V

IN

0.001 0.010 0.100 1.000 10.000

OUT2

OUTPUT LOAD (A)

= 3.3V REGULATION vs LOAD (500kHz) FIGURE 8. V

12 V

ULTRA SKIP MODE

IN

25 VIN SKIP MODE

25 VIN PWM MODE

ULTRA SKIP MODE

25 V

IN

9

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULTRA SKIP MODE

12 VIN SKIP MODE

PWM MODE

12 V

5.16

5.14

5.12

5.10

5.08

5.06

5.04

OUTPUT VOLTAGE (V)

5.02

5.00

IN

0.001 0.010 0.100 1.000 10.000

OUT1

OUTPUT LOAD (A)

= 5V REGULATION vs LOAD (400kHz)

12 V

ULTRA SKIP MODE

IN

25 VIN SKIP MODE

25 VIN PWM MODE

ULTRA SKIP MODE

25 V

IN

FN6418.4

March 18, 2008

ISL6237

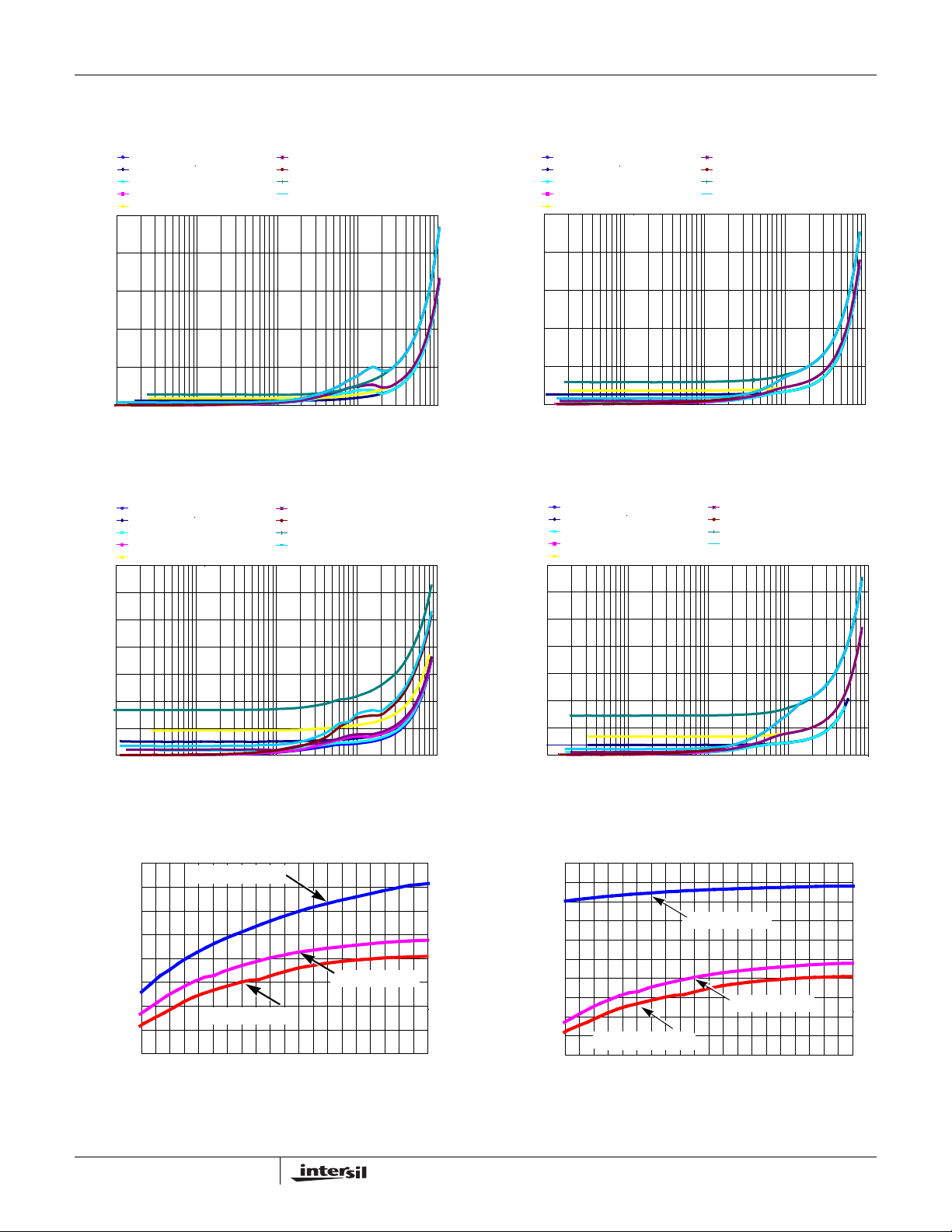

Typical Performance Curves Circuit of Figures 62, 63 and 64, no load on LDO, OUT1, OUT2, and REF, V

EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V, V

otherwise noted. Typical values are at T

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULTRA SKIP MODE

12 VIN SKIP MODE

PWM MODE

12 V

2.5

2.0

1.5

1.0

0.5

POWER DISSIPATION (W)

0

0.001 0.010 0.100 1.000 10.000

FIGURE 9. V

3.5

IN

OUTPUT LOAD (A)

= 1.05V POWER DISSIPATION vs LOAD

OUT2

(300kHz)

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULTRA SKIP MODE

12 VIN SKIP MODE

PWM MODE

12 V

IN

12 V

ULTRA SKIP MODE

IN

25 VIN SKIP MODE

25 VIN PWM MODE

25 V

ULTRA SKIP MODE

IN

12 V

ULTRA SKIP MODE

IN

25 VIN SKIP MODE

25 VIN PWM MODE

25 V

ULTRA SKIP MODE

IN

EN_LDO

= +25°C. (Continued)

A

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULTRA SKIP MODE

12 VIN SKIP MODE

PWM MODE

12 V

2.5

2.0

1.5

1.0

0.5

POWER DISSIPATION (W)

FIGURE 10. V

3.5

IN

0

0.001 0.010 0.100 1.000 10.000

OUT1

(200kHz)

7 VIN SKIP MODE

7 VIN PWM MODE

7 VIN ULTRA SKIP MODE

12 VIN SKIP MODE

PWM MODE

12 V

IN

=5V, TA= -40°C to +100°C, unless

12 V

IN

25 VIN SKIP MODE

25 VIN PWM MODE

25 V

IN

OUTPUT LOAD (A)

= 1.5V POWER DISSIPA TION vs LOAD

12 V

IN

25 VIN SKIP MODE

25 VIN PWM MODE

25 V

IN

=12V,

IN

ULTRA SKIP MODE

ULTRA SKIP MODE

ULTRA SKIP MODE

ULTRA SKIP MODE

3.0

2.5

2.0

1.5

1.0

POWER DISSIPATION (W)

0.5

0

0.001 0.010 0.100 1.000 10.000

FIGURE 11. V

1.064

1.062

1.060

1.058

1.056

1.054

1.052

OUTPUT VOLTAGE (V)

1.050

1.048

FIGURE 13. V

OUT2

(500kHz)

5791113151719212325

OUT2

vs V

OUTPUT LOAD (A)

= 3.3V POWER DISSIPATION vs LOAD

NO LOAD PWM

MID LOAD PWM

MAX LOAD PWM

INPUT VOLTAGE (V)

= 1.05V OUTPUT VOLTAGE REGULATION

(PWM MODE)

IN

3.0

2.5

2.0

1.5

1.0

POWER DISSIPATION (W)

0.5

0

0.001 0.010 0.100 1.000 10.000

FIGURE 12. V

1.068

1.066

1.064

1.062

1.060

1.058

1.056

1.054

OUTPUT VOLTAGE (V)

1.052

1.050

1.048

FIGURE 14. V

OUT1

(400kHz)

MAX LOAD PWM

MAX LOAD PWM

5791113151719212325

OUT2

vs V

IN

OUTPUT LOAD (A)

= 5V POWER DISSIPA TION vs LOAD

NO LOAD PWM

MID LOAD PWM

INPUT VOLTAGE (V)

= 1.05V OUTPUT VOLT AGE REGULA TION

(SKIP MODE)

10

FN6418.4

March 18, 2008

ISL6237

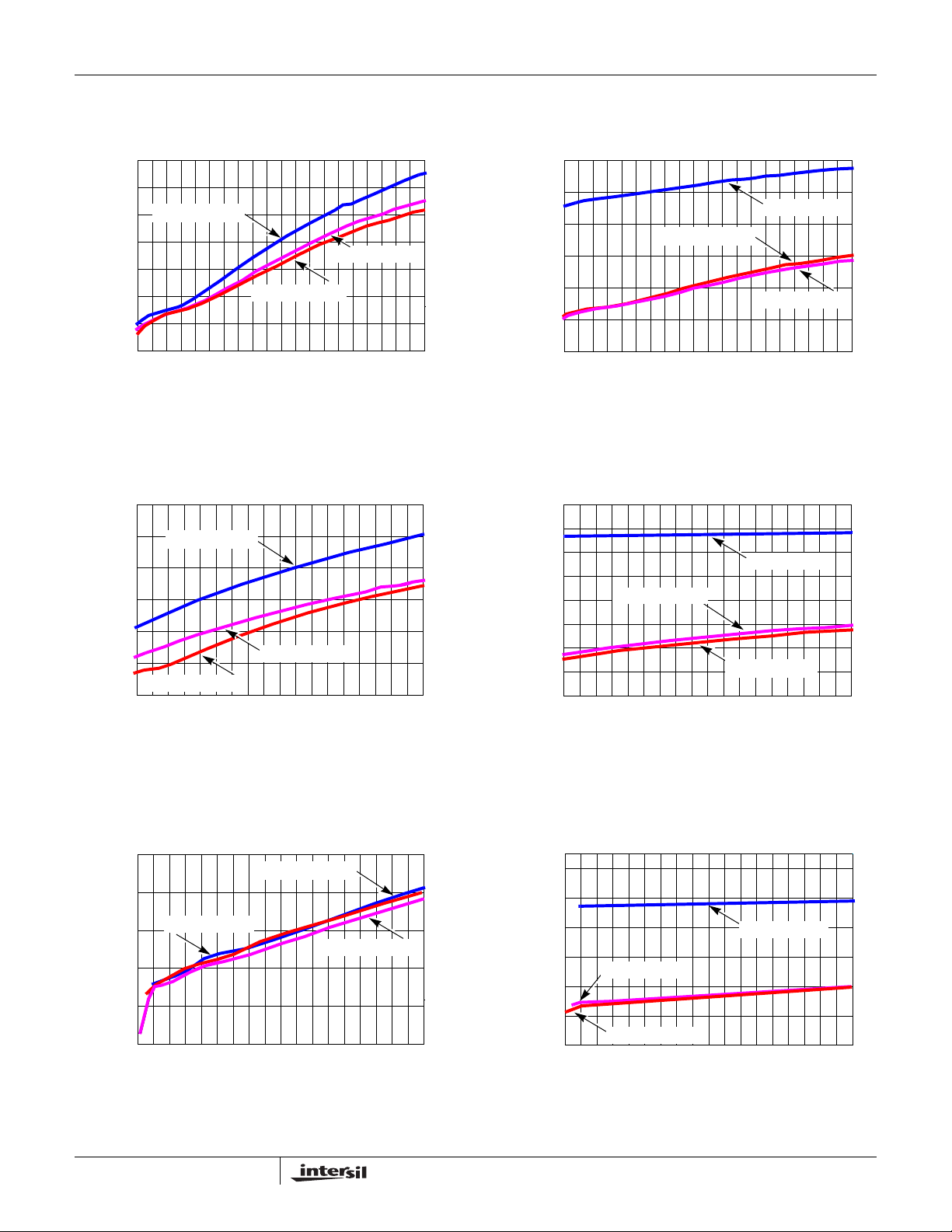

Typical Performance Curves Circuit of Figures 62, 63 and 64, no load on LDO, OUT1, OUT2, and REF, V

1.518

1.516

1.514

1.512

1.510

1.508

OUTPUT VOLTAGE (V)

1.506

1.504

5791113151719212325

FIGURE 15. V

3.340

3.335

3.330

3.325

3.320

OUTPUT VOLTAGE (V)

3.315

3.310

MAX LOAD PWM

7 9 11 13 15 17 19 21 23 25

FIGURE 17. V

EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V, V

otherwise noted. Typical values are at T

NO LOAD PWM

MID LOAD PWM

MAX LOAD PWM

INPUT VOLTAGE (V)

= 1.5V OUTPUT VOLTAGE REGULA TION

OUT1

vs V

(PWM MODE)

IN

NO LOAD PWM

MID LOAD PWM

INPUT VOLTAGE (V)

= 3.3V OUTPUT VOLTAGE REGULA TION

OUT2

vs V

(PWM MODE)

IN

= +25°C. (Continued)

A

1.530

1.525

1.520

1.515

1.510

OUTPUT VOLTAGE (V)

1.505

1.500

5791113151719212325

FIGURE 16. V

3.38

3.37

3.36

3.35

3.34

3.33

3.32

OUTPUT VOLTAGE (V)

3.31

3.30

7 9 11 13 15 17 19 21 23 25

FIGURE 18. V

EN_LDO

OUT1

vs V

OUT2

vs V

=5V, TA= -40°C to +100°C, unless

MID LOAD PWM

INPUT VOLTAGE (V)

= 1.5V OUTPUT VOLT AGE REGULA TION

(SKIP MODE)

IN

NO LOAD PWM

MAX LOAD PWM

MID LOAD PWM

INPUT VOLTAGE (V)

= 3.3V OUTPUT VOLTAGE REGULA TION

(SKIP MODE)

IN

=12V,

IN

NO LOAD PWM

MAX LOAD PWM

5.065

5.060

5.055

5.050

OUTPUT VOLTAGE (V)

5.045

5.040

7 9 11 13 15 17 19 21 23 25

FIGURE 19. V

NO LOAD PWM

MAX LOAD PWM

MID LOAD PWM

INPUT VOLTAGE (V)

= 5V OUTPUT VOLT AGE REGULA TION vs

OUT1

V

(PWM MODE)

IN

11

5.14

5.12

5.10

5.08

5.06

OUTPUT VOLTAGE (V)

5.04

5.02

7 9 11 13 15 17 19 21 23 25

FIGURE 20. V

NO LOAD PWM

MID LOAD PWM

MAX LOAD PWM

INPUT VOLTAGE (V)

= 5V OUTPUT VOLT AGE REGULA TION vs

OUT1

V

(SKIP MODE)

IN

FN6418.4

March 18, 2008

ISL6237

Typical Performance Curves Circuit of Figures 62, 63 and 64, no load on LDO, OUT1, OUT2, and REF, V

EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V, V

otherwise noted. Typical values are at T

300

250

200

150

100

FREQUENCY (kHz)

50

FIGURE 21. V

250

200

150

100

FREQUENCY (kHz)

50

0

ULTRA-SKIP

0

0.001 0.010 0.100 1.000 10.000

OUTPUT LOAD (A)

= 1.05V FREQUENCY vs LOAD FIGURE 22. V

OUT2

PWM

ULTRA-SKIP

SKIP

0.001 0.010 0.100 1.000 10.000

OUTPUT LOAD (A)

PWM

SKIP

EN_LDO

= +25°C. (Continued)

A

50

45

40

35

30

25

20

RIPPLE (mV)

15

10

5

0

0.001 0.010 0.100 1.000 10.000

50

45

40

35

30

25

ULTRA-SKIP

20

RIPPLE (mV)

15

10

5

0

0.001 0.010 0.100 1.000 10.000

=5V, TA= -40°C to +100°C, unless

PWM

OUTPUT LOAD (A)

= 1.05V RIPPLE vs LOAD

OUT2

SKIP

OUTPUT LOAD (A)

=12V,

IN

ULTRA-SKIP

SKIP

PWM

FIGURE 23. V

600

500

400

300

200

FREQUENCY (kHz)

100

SKIP

0

0.001 0.010 0.100 1.000 10.000

FIGURE 25. V

= 1.5V FREQUENCY vs LOAD FIGURE 24. V

OUT1

PWM

ULTRA-SKIP

OUTPUT LOAD (A)

= 3.3V FREQUENCY vs LOAD FIGURE 26. V

OUT2

12

= 1.5V RIPPLE vs LOAD

OUT1

14

12

10

8

6

RIPPLE (mV)

4

2

0

0.001 0.010 0.100 1.000 10.000

PWM

ULTRA-SKIP

OUTPUT LOAD (A)

= 3.3V RIPPLE vs LOAD

OUT2

SKIP

March 18, 2008

FN6418.4

ISL6237

Typical Performance Curves Circuit of Figures 62, 63 and 64, no load on LDO, OUT1, OUT2, and REF, V

450

400

350

300

250

200

150

FREQUENCY (kHz)

100

50

ULTRA-SKIP

0

0.001 1.000

0.010 0.100

FIGURE 27. V

5.04

5.02

5.00

4.98

4.96

4.94

4.92

4.90

4.88

OUTPUT VOLTAGE (V)

4.86

4.84

0 50 100 150 200

PWM

SKIP

OUTPUT LOAD (A)

= 5V FREQUENCY vs LOAD FIGURE 28. V

OUT1

BYP = 0V

BYP = 5V

OUTPUT LOAD (mA)

EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V, V

otherwise noted. Typical values are at T

RIPPLE (mV)

10.000

= +25°C. (Continued)

A

40

35

30

ULTRA-SKIP

25

20

15

10

5

0

0.001 0.010 0.100 1.000 10.000

3.35

3.30

3.25

3.20

3.15

3.10

OUTPUT VOLTAGE (V)

3.05

3.00

0 50 100 150 200

EN_LDO

=5V, TA= -40°C to +100°C, unless

PWM

SKIP

OUTPUT LOAD (A)

= 5V RIPPLE vs LOAD

OUT1

BYP = 0V

BYP = 3.3V

OUTPUT LOAD (mA)

IN

=12V,

FIGURE 29. LDO OUTPUT 5V vs LOAD FIGURE 30. LDO OUTPUT 3.3V vs LOAD

50

45

40

35

30

INPUT CURRENT (mA)

25

20

7 9 11 13 15 17 19 21 23 25

INPUT VOLTAGE (V)

FIGURE 31. PWM NO LOAD INPUT CURRENT vs V

(EN = EN2 = EN_LDO = VCC)

13

IN

1400

1200

1000

800

600

400

INPUT CURRENT (µA)

200

0.0

7 9 11 13 15 17 19 21 23 25

INPUT VOLTAGE (V)

FIGURE 32. SKIP NO LOAD INPUT CURRENT vs V

(EN1 = EN2 = EN_LDO = VCC)

IN

FN6418.4

March 18, 2008

ISL6237

Typical Performance Curves Circuit of Figures 62, 63 and 64, no load on LDO, OUT1, OUT2, and REF, V

177.5

177.0

176.5

176.0

175.5

175.0

174.5

174.0

INPUT CURRENT (µA)

173.5

173.0

7 9 11 13 15 17 19 21 23 25

INPUT VOLTAGE (V)

FIGURE 33. STANDBY INPUT CURRENT vs V

(EN = EN2 = 0, EN_LDO = VCC)

EN1 5V/DIV

EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V, V

otherwise noted. Typical values are at T

IN

V

OUT1

FIGURE 34. SHUTDOWN INPUT CURRENT vs V

2V/DIV

= +25°C. (Continued)

A

26.5

26.0

25.5

25.0

24.5

24.0

23.5

23.0

INPUT CURRENT (µA)

22.5

22.0

7 9 11 13 15 17 19 21 23 25

(EN = EN2 = EN_LDO = 0)

EN_LDO

=5V, TA= -40°C to +100°C, unless

INPUT VOLTAGE (V)

IN

=12V,

IN

IL1 2A/DIV

POK1 2V/DIV

EN1 5V/DIV

V

OUT1

IL1 2A/DIV

POK1 2V/DIV

FIGURE 35. START-UP V

2V/DIV

= 5V (NO LOAD, SKIP MODE)

OUT1

IL1 5A/DIV

POK1 2V/DIV

EN1 5V/DIV

V

OUT1

2V/DIV

FIGURE 36. START-UP V

= 5V (NO LOAD, PWM MODE) FIGURE 37. START-UP V

OUT1

14

= 5V (FULL LOAD, PWM MODE)

OUT1

FN6418.4

March 18, 2008

ISL6237

Typical Performance Curves Circuit of Figures 62, 63 and 64, no load on LDO, OUT1, OUT2, and REF, V

EN2 5V/DIV

V

OUT2

IL2 2A/DIV

FIGURE 38. START-UP V

EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V, V

otherwise noted. Typical values are at T

2V/DIV

POK2 2V/DIV

= 3.3V (NO LOAD, SKIP MODE) FIGURE 39. START-UP V

OUT2

= +25°C. (Continued)

A

EN_LDO

EN2 5V/DIV

=5V, TA= -40°C to +100°C, unless

V

2V/DIV

OUT2

IL2 2A/DIV

= 3.3V (NO LOAD, PWM MODE)

OUT1

=12V,

IN

POK2 2V/DIV

EN2 5V/DIV

V

2V/DIV

OUT2

IL2 5A/DIV

POK2 2V/DIV

FIGURE 40. START - UP V

PWM MODE)

EN1 5V/DIV

POK1 5V/DIV

V

= 3.3V (FULL LOAD,

OUT1

2V/DIV

OUT2

V

OUT1

2V/DIV

EN2 5V/DIV

V

2V/DIV

OUT2

2V/DIV

V

OUT1

POK2 5V/DIV

POK1 5V/DIV

FIGURE 41. DELAYED ST ART -UP (V

EN1 = REF)

EN1 5V/DIV

V

2V/DIV

OUT2

V

2V/DIV

OUT1

OUT1

=5V, V

OUT2

=3.3V,

POK2 5V/DIV

FIGURE 42. DELAYED ST ART -UP (V

EN2 = REF)

15

OUT1

=5V, V

OUT2

=3.3V,

POK1 OR POK2 5V/DIV

FIGURE 43. SHUTDOWN (V

EN2 = REF)

OUT1

=5V, V

OUT2

=3.3V,

March 18, 2008

FN6418.4

ISL6237

Typical Performance Curves Circuit of Figures 62, 63 and 64, no load on LDO, OUT1, OUT2, and REF, V

LGATE1 5V/DIV

RIPPLE 50mV/DIV

V

OUT1

IL1 5A/DIV

V

RIPPLE 50mV/DIV

OUT2

FIGURE 44. LOAD TRANSIENT V

LGATE1 5V/DIV

EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V, V

otherwise noted. Typical values are at T

= 5V FIGURE 45. LOAD TRANSIENT V

OUT1

EN_LDO

= +25°C. (Continued)

A

=5V, TA= -40°C to +100°C, unless

LGATE1 5V/DIV

V

RIPPLE 100mV/DIV

OUT1

IL1 5A/DIV

V

RIPPLE 50mV/DIV

OUT2

OUT1

LGATE2 5V/DIV

=12V,

IN

= 5V (SKIP)

V

RIPPLE 20mV/DIV

OUT1

IL2 5A/DIV

V

RIPPLE 50mV/DIV

OUT2

FIGURE 46. LOAD TRANSIENT V

V

RIPPLE 20mV/DIV

OUT

LDO 1V/DIV

LDOREFIN 0.5V/DIV

IL2 5A/DIV

V

RIPPLE 50mV/DIV

OUT2

= 3.3V (PWM) FIGURE 47. LOAD TRANSIENT V

OUT1

EN1 5V/DIV

0.5V/DIV

V

OUT1

V

RIPPLE 20mV/DIV

OUT1

= 3.3V (SKIP)

OUT1

IL1 2A/DIV

V

RIPPLE 50mV/DIV

OUT2

POK1 2V/DIV

FIGURE 48. LDO TRACKING TO LDOREFIN FIGURE 49. START-UP V

16

= 1.5V (NO LOAD, SKIP MODE)

OUT1

FN6418.4

March 18, 2008

ISL6237

Typical Performance Curves Circuit of Figures 62, 63 and 64, no load on LDO, OUT1, OUT2, and REF, V

EN1 5V/DIV

V

0.5V/DIV

OUT1

IL1 2A/DIV

POK1 2V/DIV

FIGURE 50. START-UP V

EN2 5V/DIV

EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V, V

otherwise noted. Typical values are at T

= 1.5V (NO LOAD, PWM MODE)S

OUT1

EN_LDO

= +25°C. (Continued)

A

EN1 5V/DIV

POK1 2V/DIV

FIGURE 51. START-UP V

PWM MODE)

EN2 5V/DIV

=5V, TA= -40°C to +100°C, unless

V

0.5V/DIV

OUT1

IL1 5A/DIV

= 1.5V (FULL LOAD,

OUT1

IN

=12V,

V

0.5V/DIV

OUT2

IL2 2A/DIV

POK2 2V/DIV

FIGURE 52. START - UP V

SKIP MODE)

EN2 5V/DIV

IL2 2A/DIV

= 1.05V (NO LOAD,

OUT2

V

OUT2

0.5V/DIV

V

0.5V/DIV

OUT2

IL2 2A/DIV

POK2 2V/DIV

FIGURE 53. START-UP V

PWM MODE)

EN2 5V/DIV

V

0.5V/DIV

OUT2

V

2V/DIV

OUT1

POK2 5V/DIV

= 1.05V (NO LOAD,

OUT1

POK2 2V/DIV

FIGURE 54. START - UP V

PWM MODE)

= 1.05V (FULL LOAD,

OUT1

17

POK1 5V/DIV

FIGURE 55. DELAYED ST ART -UP (V

V

= 1.05V, EN1 = REF)

OUT2

OUT1

=1.5V,

FN6418.4

March 18, 2008

ISL6237

Typical Performance Curves Circuit of Figures 62, 63 and 64, no load on LDO, OUT1, OUT2, and REF, V

V

2V/DIV

OUT1

EN1 500mV/DIV

V

500mV/DIV

OUT2

POK1 5V/DIV

POK2 5V/DIV

FIGURE 56. DELA YED START -UP (V

V

= 1.05V, EN2 = REF)

OUT2

LGATE1 5V/DIV

OUT1

EN2 = EN1 = VCC, VBYP = 5V, PVCC = 5V, V

otherwise noted. Typical values are at T

V

OUT1

=1.5V,

FIGURE 57. SHUTDOWN (V

EN_LDO

= +25°C. (Continued)

A

V

2V/DIV

POK1 OR POK2 5V/DIV

EN2 = REF)

=5V, TA= -40°C to +100°C, unless

EN1 5V/DIV

2V/DIV

OUT2

=1.5V, V

OUT1

LGATE1 5V/DIV

IN

OUT2

=12V,

= 1.05V,

V

RIPPLE 50mV/DIV

OUT1

IL1 5A/DIV

V

RIPPLE 20mV/DIV

OUT2

FIGURE 58. LOAD TRANSIENT V

LGATE2 5V/DIV

V

RIPPLE 20mV/DIV

OUT1

IL1 5A/DIV

V

RIPPLE 50mV/DIV

OUT1

IL1 5A/DIV

= 1.5V (PWM) FIGURE 59. LOAD TRANSIENT V

OUT1

LGATE2 5V/DIV

V

RIPPLE 20mV/DIV

OUT1

V

RIPPLE 20mV/DIV

OUT2

V

RIPPLE 20mV/DIV

OUT2

= 1.5V (SKIP)

OUT1

IL2 5A/DIV

V

RIPPLE 20mV/DIV

OUT2

FIGURE 60. LOAD TRANSIENT V

18

= 1.05V (PWM) FIGURE 61. LOAD TRANSIENT V

OUT1

= 1.05V (SKIP)

OUT1

FN6418.4

March 18, 2008

ISL6237

Typical Application Circuits

The typical application circuits (Figures 62, 63 and 64)

generate the typical 5V/7A, 3.3V/11A, 1.25V/5A, static

voltage/10A, 1.5V/5A, and 1.05V/5A supplies found in a

notebook computer. The input supply range is 5.5V to 25V.

Detailed Description

The ISL6237 dual-buck, BiCMOS, switch-mode powersupply controller generates logic supply voltages for

notebook computers. The ISL6237 is designed primarily for

battery-powered applications where high efficiency and lowquiescent supply current are critical. The ISL6237 provides a

pin-selectable switching frequency, allowing operation for

200kHz/300kHz, 400kHz/300kHz, or 400kHz/500kHz on the

SMPSs.

Light-load efficiency is enhanced by automatic Idle-Mode

operation, a variable-frequency pulse-skipping mode that

reduces transition and gate-charge losses. Each step-down,

power-switching circuit consists of two N-Channel

MOSFETs, a rectifier, and an LC output filter. The output

voltage is the average AC voltage at the switching node,

which is regulated by changing the duty cycle of the

MOSFET switches. The gate-drive signal to the N-Channel

high-side MOSFET must exceed the battery voltage, and is

provided by a flying-capacitor boost circuit that uses a 100nF

capacitor connected to BOOT_.

Both SMPS1 and SMPS2 PWM controllers consist of a triplemode feedback network and multiplexer, a multi-in put PWM

comparator, high -side and low -side gate drivers and lo gic. In

addition, SMPS2 can also use REFIN2 to track its output from

0.5V to 2.5V. The ISL6237 contains fault-protection circuits

that monitor the main PWM outputs for undervoltage and

overvoltage conditions. A power-on sequence block controls

the power-up timing of the main PWMs and monitors the

outputs for undervoltage faults . The ISL6237 in cludes an

adjustable low drop-out linear regulator. The bias generator

blocks include the linear regulator , a 2V precision reference

and automatic bootstrap switchover circuit.

The synchronous-switch gate drivers are directly powered

from PVCC, while the high-side switch gate drivers are

indirectly powered from PVCC through an external capacitor

and an internal Schottky diode boost circuit.

An automatic bootstrap circuit turns off the LDO linear

regulator and powers the device from BYP if LDOREFIN is

set to GND or VCC. See Table 1.

TABLE 1. LDO OUTPUT VOLTAGE TABLE

LDO VOLTAGE CONDITIONS COMMENT

VOLTAGE at BYP LDOREFIN < 0.3V,

BYP > 4.63V

VOLTAGE at BYP LDOREFIN > VCC - 1V,

BYP > 3V

5V LDOREFIN < 0.3V,

BYP < 4.63V

Internal LDO is

disabled.

Internal LDO is

disabled.

Internal LDO is

active.

TABLE 1. LDO OUTPUT VOLTAGE TABLE (Continued)

LDO VOLTAGE CONDITIONS COMMENT

3.3V LDOREFIN > VCC - 1V,

BYP < 3V

2 x LDOREFIN 0.35V < LDOREFIN < 2.25V Internal LDO is

Internal LDO is

active.

active.

FREE-RUNNING, CONSTANT ON-TIME PWM

CONTROLLER WITH INPUT FEED-FORWARD

The constant on-time PWM control architecture is a

pseudo-fixed-frequency, constant on-time, current-mode

type with voltage feed forward. The constant on-time PWM

control architecture relies on the output ripple voltage to

provide the PWM ramp signal; thus the output filter

capacitor's ESR acts as a current-feedback resistor. The

high-side switch on-time is determined by a one-shot whose

period is inversely proportional to input voltage and directly

proportional to output voltage. Another one-shot sets a

minimum off-time (300ns typ). The on-time one-shot triggers

when the following conditions are met: the error comp ara to r' s

output is high, the synchronous rectifier current is below the

current-limit threshold, and the minimum off time one-shot

has timed out. The controller utilizes the valley point of the

output ripple to regulate and determine the off time.

On-Time One-Shot (t

ON

)

Each PWM core includes a one-shot that sets the high-side

switch on-time for each controller. Each fast, low-jitter,

adjustable one-shot includes circuitry that varies the on-time

in response to battery and output voltage. The high-side

switch on-time is inversely proportional to the battery voltage

as measured by the VIN input and proportional to the output

voltage. This algorithm results in a nearly constant switching

frequency despite the lack of a fixed-frequency clock

generator. The benefit of a constant switching frequency is

that the frequency can be selected to avoid noise-sensitive

frequency regions:

KV

OUTILOADrDSON LOWERQ()

------------------------------------------------------------------------------------------------------

t

=

ON

⋅+()

V

IN

(EQ. 1)

See Table 2 for approximate K- factors. Switching frequency

increases as a function of load current due to the increasing

drop across the synchronous rectifier, which causes a faster

inductor-current discharge ramp. On-times translate only

roughly to switching frequencies. The on-times established in

the “Electrical Specifications” table o n p age4 are influenced

by switching delays in the external high-side power MOSFET.

Also, the dead-time effect increases the effective on-time,

reducing the switching frequency . It occurs only in PWM mode

(SKIP

= VCC) and during dynamic output voltage transitions

when the inductor current reverses at light or negative load

currents. With reversed inductor current, the inductor's EMF

causes PHASE to go high earlier than normal, extending the

on-time by a period equal to the UGA TE-rising dead time.

19

FN6418.4

March 18, 2008

ISL6237

.

TABLE 2. APPROXIMATE K-FACTOR ERRORS

SMPS

(t

= GND, REF,

ON

or OPEN), VOUT1

(t

= GND),

ON

VOUT2

(t

= VCC),

ON

VOUT1

= VCC, REF,

(t

ON

or OPEN), VOUT2

SWITCHING

FREQUENCY

(kHz)

400 2.5 ±10

500 2.0 ±10

200 5.0 ±10

300 3.3 ±10

K-FACTOR

(µs)

APPROXIMATE

K-FACTOR

ERROR (%)

For loads above the critical conduction point, the actual

switching frequency is:

+

V

OUTVDROP1

-------------------------------------------------------

f

=

t

ONVINVDROP2

+()

(EQ. 2)

where:

•V

is the sum of the parasitic voltage drops in the

DROP1

inductor discharge path, including synchronous rectifier,

inductor, and PC board resistances

•V

DROP2

is the sum of the parasitic voltage drops in the

charging path, including high-side switch, inductor, and PC

board resistances

•t

is the on-time calculated by the ISL6237

ON

20

FN6418.4

March 18, 2008

OUT1 – PCI-e

1.25V/5A

C

C

11

330µF

9mΩ

6.3V

VIN: 5.5V TO 25V

C

10

10µF

SI4816BDY

L1: 3.3µH

R1

7.87kΩ

R

10kΩ

Q3a

Q3b

FB1 TIED TO GND = 5V

FB1 TIED TO VCC = 1.5V

2

VCC

C

0.1µF

5V

C

1µF

9

R

3

200kΩ

ISL6237

5V

8

PVCC

VIN

BOOT1

UGATE1

PHASE1

LGATE1

OUT1

EN1

BYP

FB1

AGND

ILIM1

SKIP

EN_LDO

C

5

1µF

VCC

ISL6237

LDO

LDOREFIN

BOOT2

UGATE2

PHASE2

LGATE2

PGND

OUT2

EN2

REFIN2

ILIM2

REF

R

5

200kΩ

NC

GND

C

4

0.22µF

VCC

C

7

0.1µF

C1

C1

10

10µF

Q

1

IRF7821

L2: 2.2µH

Q

2

IRF7832

REFIN2: STATIC 0V TO 2.5V

REFIN2 TIED TO 3.3V = 1.05V

REFIN2 TIED TO VCC = 3.3V

VCC

OUT2-GFX

TRACK REFIN2/10A

C

C

2

2 x 330µF

4mΩ

6.3V

VCC

R

4

200kΩ 200kΩ

R

6

POK1

VCC

TON

POK2

PAD

FREQUENCY-DEPENDENT COMPONENTS

t

1.25V/1.05V SMPS

SWITCHING

FREQUENCY

L

1

L

2

C

2

C

11

3.3µH

2.7µH

2 x 330µF

330µF

=VCC

ON

200kHz/300kHz

FIGURE 62. ISL6237 TYPICAL GFX APPLICATION CIRCUIT

21

FN6418.4

March 18, 2008

C

C

11

330µF

9mΩ

6.3V

VIN: 5.5V TO 25V

C

10

10µF

OUT1

1.5V/5A

L1: 3.3µH

FB1 TIED TO GND= 5V

FB1 TIED TO VCC = 1.5V

SI4816BDY

Q3a

Q3b

VCC

3.3V

VCC

0.1µF

ON

C

VCC

C

1µF

9

R

3

200kΩ

OFFONOFFOFF

ISL6237

5V

8

PVCC

VIN

BOOT1

UGATE1

PHASE1

LGATE1

OUT1

EN1

BYP

FB1

AGND

ILIM1

SKIP

EN_LDO

TON

C

1µF

VCC

ISL6237

PAD

5

LDO

LDOREFIN

BOOT2

UGATE2

PHASE2

LGATE2

PGND

OUT2

EN2

REFIN2

ILIM2

REF

POK1

POK2

VCC

Q1a

C

4

0.22µF

Q1b

VCC

REFIN2: STATIC 0V TO 2.5V

REFIN2 TIED TO 3.3V = 1.05V

R

REFIN2 TIED TO VCC = 3.3V

5

200kΩ

C7

0.1µF

LDOREFIN TIED TO GND = 5V

LDOREFIN TIED TO VCC = 3.3V

C

C

1

10

10µF

L2: 2.2µF

SI4816BDY

VCC

R

200kΩ

LDO

4

C

6

4.7µF

OUT2

1.05V/5A

C

C

330µF

4mΩ

6.3V

VCC

F

2

R

6

200kΩ

FREQUENCY-DEPENDENT COMPONENTS

1.5V/1.05V SMPS

SWITCHING

FREQUENCY

L

1

L

2

C

2

C

11

I

FIGURE 63. ISL6237 TYPICAL SYSTEM REGULATOR APPLICATION CIRCUIT

22

t

=VCC

ON

200kHz/300kHz

3.3µH

2.7µH

330µF

330µF

FN6418.4

March 18, 2008

VIN: 5.5V TO 25V

ISL6237

C5

1µF

C11

330µF

9mΩ

6.3V

OUT1

5V/7A

C10

10µF

IRF7807V

L1: 4.7µH

IRF7811AV

Q3

C9

C9

0.1µF

Q4

FB1 TIED TO GND = 5V

FB1 TIED TO VCC = 1.5V

ON

GND

VCC

200kΩ

OFFONOFFOFF

R3

PVCC

VIN

BOOT1

UGATE1

PHASE1

LGATE1

OUT1

EN1

BYP

FB1

AGND

ILIM1

SKIP

EN LDO

TON

VCC

ISL6237

PAD

LDO

LDOREFIN

BOOT2

UGATE2

PHASE2

LGATE2

PGND

OUT2

EN2

REFIN2

ILIM2

REF

POK1

POK2

R5

150kΩ

C1

C1

10µF

10

Q1

C4

0.1µF

VCC

VCC

0.1µF

C7

IRF7821

L2: 4.7µH

Q2

IRF7832

REFIN2: STATIC 0 TO 2.5V

REFIN2 TIED TO VREF3 = 1.05V

REFIN2 TIED TO VCC = 3.3V

VCC

LDO

R4

200kΩ

C6

4.7µF

OUT2

3.3V/11A

C2

C2

330µF

VCC

R6

200kΩ

9mΩ

4V

FIGURE 64. ISL6237 TYPICAL 3.3V/5V SYSTEM REGULATOR APPLICATION CIRCUIT

23

FN6418.4

March 18, 2008

ISL6237

BOOT1

UGATE1

PHASE1

LGATE1

GND

ILIM1

FB1

OUT1

BYP

PVCC

SMPS1

SYNCHRONOUS

PWM BUCK

CONTROLLER

OUT1

SW THRESHOLD

-

-+-

+

+

EN1

POK1

TON

SKIP

SMPS2

SYNCHRONOUS

PWM BUCK

CONTROLLER

EN2

POK2

OUT2

BOOT2

UGATE2

PHASE2

PVCC

LGATE2

PGND

ILIM2

REFIN2

OUT2

POK2

POK1

LDO

LDOREFIN

VIN

EN_LDO

EN1

EN2

LDO

POWER-ON

SEQUENCE

CLEAR FAULT

LATCH

THERMAL

THERMAL

SHUTDOWN

SHUTDOWN

FIGURE 65. DETAILED FUNCTIONAL DIAGRAM ISL6237

INTERNAL

LOGIC

REF

VCC

Ω

10

PVCC

REF

24

FN6418.4

March 18, 2008

ISL6237

VIN

ILIM_

PHASE_

OUT_

FB_

VCC

TON

5µA

DECODER

OUT_

REFIN2 (SMPS2)

VREF

+

+

SLOPE COMP

FB

MIN. t

OFF

TRIG

Q

ONE SHOT

+

++

+

+

+

+

+

COMP

+

+

S

+

+

+

++

SKIP

+

++

+

++

OV_LATCH_

UV_LATCH_

+

+

+

PGOOD_

20ms

BLANKING

0.9V

1.1V

0.7V

REF

REF

REF

BOOT

DETECT

Q

Q

Q

S

S

S

R

R

R

Q

Q

Q

R

R

R

S

S

S

UV

FAULT

FAULT

LATCH

LATCH

LOGIC

TO UGATE_DRIVER

Q

Q

Q

Q

BOOT_

TO LGATE_ DRIVER

FIGURE 66. PWM CONTROLLER (ONE SIDE ONLY)

25

FN6418.4

March 18, 2008

ISL6237

Automatic Pulse-Skipping Switchover

(Idle Mode)

In Idle Mode (SKIP = GND), an inherent automatic

switchover to PFM takes place at light loads. This switchover

is affected by a comparator that truncates the low-side

switch on-time at the inductor current's zero crossing. This

mechanism causes the threshold between pulse-skipping

PFM and non skipping PWM operation to coincide with the

boundary between continuous and discontinuous

inductor-current operation (also known as the critical

conduction point):

KV

⋅

VINV

OUT

I

LOAD SKIP()

------------------------

=

2L⋅

where K is the on-time scale factor (see “On- Time One-Shot

(t

” on page 19). The load-current level at which

ON)

PFM/PWM crossover occurs, I

the peak-to-peak ripple current, which is a function of the

inductor value (Figure 67). For example, in the ISL6237

typical application circuit with V

L = 7.6µH, and K = 5µs, switchover to pulse-skipping

operation occurs at I

LOAD

The crossover point occurs at an even lower value if a

swinging (soft-saturation) inductor is used.

I

D

VIN-V

VIN-V

VIN-V

V-V

=

=

=

=

t

t

t

t

L

L

L

OUT

–

OUT

------------------------------- -

V

IN

LOAD(SKIP)

OUT1

, is equal to half

=5V, VIN=12V,

= 0.96A or about on-fifth full load.

I

PEAK

I

= I

LOAD

(EQ. 3)

PEAK/2

The switching waveforms may appear noisy and

asynchronous when light loading causes pulse-skipping

operation, but this is a normal operating condition that

results in high light-load efficiency. Trade-offs in PFM noise

vs light-load efficiency are made by varying the inductor

value. Generally, low inductor values produce a broader

efficiency vs load curve, while higher values result in higher

full-load efficiency (assuming that the coil resistance remains

fixed) and less output voltage ripple. Penalties for using

higher inductor values include larger physical size and

degraded load-transient response (especially at low

input-voltage levels).

DC output accuracy specifications refer to the trip level of the

error comparator. When the inductor is in continuous

conduction, the output voltage has a DC regulation higher

than the trip level by 50% of the ripple. In discontinuous

conduction (SKIP

= GND, light load), the output voltage has

a DC regulation higher than the trip level by approximately

1.0% due to slope compensation.

Forced-PWM Mode

The low-noise, forced-PWM (SKIP = VCC) mode disables

the zero-crossing comparator, which controls the low-side

switch on-time. Disabling the zero-crossing detector causes

the low-side, gate-drive waveform to become the

complement of the high-side, gate-drive waveform. The

inductor current reverses at light loads as the PWM loop

strives to maintain a duty ratio of V

OUT/VIN

forced-PWM mode is to keep the switching frequency fairly

constant, but it comes at a cost: the no-load battery current

can be 10mA to 50mA, depending on switching frequency

and the external MOSFETs.

. The benefit of

INDUCTOR CURRENT

ON-TIME TIME

0

FIGURE 67. ULTRASONIC CURRENT WAVEFORMS

40µs (MAX)

INDUCTOR

Zero-Crossing

ZERO-CROSSING

DETECTION

0A

FB < REG .POINT

ON-TIME (t

ON-TIME (tON)

FIGURE 68. ULTRASONIC CURRENT WAVEFORMS

CURRENT

Forced-PWM mode is most useful for reducing

audio-frequency noise, improving load-transient response,

providing sink-current capability for dynamic output voltage

adjustment, and improving the cross-regulation of

multiple-output applications that use a flyback transformer or

coupled inductor.

Enhanced Ultrasonic Mode

(25kHz (min) Pulse Skipping)

Leaving SKIP unconnected or connecting SKIP to REF

activates a unique pulse-skipping mode with a minimum

switching frequency of 25kHz. This ult rasonic pulse- skipping

mode eliminates audio-frequency modulation that would

otherwise be present when a lightly loaded controller

automatically skips pulses. In ultrasonic mode, the controller

automatically transitions to fixed-frequency PWM operation

when the load reaches the same critical conduction point

(ILOAD(SKIP)).

An ultrasonic pulse occurs when the controller detects that

no switching has occurred within the last 20µs. Once

triggered, the ultrasonic controller pulls LGATE high, turning

on the low-side MOSFET to induce a negative inductor

26

FN6418.4

March 18, 2008

ISL6237

current. After FB drops below th e re gu l a ti on po i nt , the

controller turns off the low-side MOSFET (LGA TE pulled low)

and triggers a constant on-time (UGATE driven high). When

the on-time has expired, the controller re-enables the

low-side MOSFET until the controller detects that the

inductor current dropped below the zero-crossing threshold.

Starting with a LGATE pulse greatly reduces the peak output

voltage when compared to starting with a UGATE pulse, as

long as VFB < VREF, LGATE is off and UGA TE is on, similar

to pure SKIP mode.

Reference and Linear Regulator (REF and

LDO)

The 2V reference (REF) is accurate to ±1% over

temperature, making REF useful as a precision system

reference. Bypass REF to GND with a 0.1µF (min) capacitor.

REF can supply up to 50µA for external loads.

An internal regulator produces a fixed 5V

(LDOREFIN < 0.2V) or 3.3V (LDOREFIN > VCC - 1V). In an

adjustable mode, the LDO output can be set from 0.7V to

4.5V. The LDO output voltage is equal to two times the

LDOREFIN voltage. The LDO regulator can supply up to

100mA for external loads. Bypass LDO with a minimum

4.7µF ceramic capacitor. When the LDOREFIN < 0.2V and

BYP voltage is 5V, the LDO bootstrap-switchover to an

internal 0.7Ω P-channel MOSFET switch connects BYP to

LDO pin while simultaneously shutting down the internal

linear regulator. These actions bootstrap the device,

powering the loads from the BYP input voltages, rather than

through internal linear regulators from the battery. Similarly,

when the BYP = 3.3V and LD OREFIN = VCC, th e LDO

bootstrap-switchover to an internal 1.5Ω P-Channel

MOSFET switch connects BYP to LDO pin while

simultaneously shutting down the internal linear regulator.

No switchover action in adjustable mode.

Current-Limit Circuit (ILIM_) with r

DS(ON)

Temperature Compensation

The current-limit circuit employs a "valley" current-sensing

algorithm. The ISL6237 uses the on-resistance of the

synchronous rectifier as a current-sensing element. If the

magnitude of the current-sense signal at PHASE_ is above

the current-limit threshold, the PWM is not allowed to initiate a

new cycle. The actual peak current is greater than the currentlimit threshold by an amount equal to the inductor ripple

current. Therefore, the exact current-limit characteristic and

maximum load capability are a function of the current-limit

threshold, inductor value and input and output voltage.

temperature rise. The ISL6237 controller has a built-in 5µA

current source as shown in Figure 70. Place the hottest

power MOSFETs as close to the IC as possible for best

thermal coupling. The current limit varies with the onresistance of the synchronous rectifier. When combined with

the undervoltage-protection circuit, this current-limit method

is effective in almost every circumstance.

A negative current limit prevents excessive reverse inductor

currents when VOUT sinks current. The negative

current-limit threshold is set to approximately 120% of the

positive current limit and therefore tracks the positive current

limit when ILIM_ is adjusted. The current-limit threshold is

adjusted with an external resistor for ISL6237 at ILIM_. The

current-limit threshold adjustment range is from 20mV to

200mV. In the adjustable mode, the current-limit threshold

voltage is 1/10th the voltage at ILIM_. The voltage at ILIM

pin is the product of 5µA*R

. The threshold defaults to

ILIM

100mV when ILIM_ is connected to VCC. The logic

threshold for switch-over to the 100mV default value is

approximately VCC - 1V.

The PC board layout guidelines should be carefully

observed to ensure that noise and DC errors do not corrupt

the current-sense signals at PHASE_.

I

PEAK

I

INDUCTOR CURRENT

LOAD

I

LIMIT

I

I

I

I

LOAD(MAX)

I

I

=

=

=

I

)(

)(

)(

)(

VALLIM

LOAD

TIME

Δ

−

−

−=

−

2

Δ

I

FIGURE 69. “VALLEY” CURRENT LIMIT THRESHOLD POINT

R

ILIM

V

V

++

++

ILIM

ILIM_

5µA

VCC

+

+

+

+

TO CURRENT

9R

9R

LIMIT LOGIC

For lower power dissipation, the ISL6237 uses the

on-resistance of the synchronous rectifier as the

current-sense element. Use the worst-case maximum value

for r

for the rise in r

from the MOSFET data sheet. Add some margin

DS(ON)

with temperature. A good general rule

DS(ON)

is to allow 0.5% additional resistance for each °C of

27

R

R

FIGURE 70. CURRENT LIMIT BLOCK DIAGRAM

March 18, 2008

FN6418.4

ISL6237

MOSFET Gate Drivers (UGATE_, LGATE_)

The UGATE_ and LGATE_ gate drivers sink 2.0A and 3.3A

respectively of gate drive, ensuring robust gate drive for

high-current applications. The UGATE_ floating high-side

MOSFET drivers are powered by diode-capacitor charge

pumps at BOOT_. The LGATE_ synchronous-rectifier

drivers are powered by PVCC.

The internal pull-down transistors that drive LGATE_ low

have a 0.6Ω typical on-resistance. These low on-resistance

pull-down transistors prevent LGATE_ from being pulled up

during the fast rise time of the inductor nodes due to

capacitive coupling from the drain to the gate of the low-side

synchronous-rectifier MOSFETs. However, for high-current

applications, some combinations of high- and low-side

MOSFETs may cause excessive gate-drain coupling, which

leads to poor efficiency and EMI-producing shoot-through

currents. Adding a 1Ω resistor in series with BOOT_

increases the turn-on time of the high-side MOSFETs at the

expense of efficiency, without degrading the turn-off time

(Figure 71).

Adaptive dead-time circuits monitor the LGATE_ and

UGATE_ drivers and prevent either FET from turning on until

the other is fully off. This algorithm allows operation without

shoot-through with a wide range of MOSFETs, minimizing

delays and maintaining efficiency. There must be low

resistance, low-inductance paths from the gate drivers to the

MOSFET gates for the adaptive dead-time circuit to work

properly. Otherwise, the sense circuitry interprets the

MOSFET gate as "off" when there is actually charge left on

the gate. Use very short, wide traces measuring 10 to 20

squares (50 mils to 100 mils wide if the MOSFET is 1” from

the device).

maximum operating duty cycle (this occurs at minimum input

voltage). The minimum gate to source voltage (V

GS(MIN)

) is

determined by:

V

GS MIN()

PVCC

BOOT

---------------------------------------

⋅=

C

+

BOOTCGS

(EQ. 4)

C

where:

• PVCC is 5V

•C

is the gate capacitance of the high-side MOSFET

GS

Boost-Supply Refresh Monitor

In pure skip mode, the converter frequency can be very low

with little to no output loading. This produces very long off

times, where leakage can bleed down the BOOT capacitor

voltage. If the voltage falls too low, the converter may not be

able to turn on UGATE when the output voltage falls to the

reference. To prevent this, the ISL6237 monitors the BOOT

capacitor voltage, and if it falls below 3V, it initiates an

LGATE pulse, which will refresh the BOOT voltage.

POR, UVLO, and Internal Digital Soft-Start

Power-on reset (POR) occurs when VIN rises above

approximately 3V, resetting the undervoltage, overvoltage,

and thermal-shutdown fault latches. PVCC

undervoltage-lockout (UVLO) circuitry inhibits switching

when PVCC is below 4V. LGATE_ is low during UVLO. The

output voltages begin to ramp up once PVCC exceeds its 4V

UVLO and REF is in regulation. The internal digital soft-start

timer begins to ramp up the maximum-allowed current limit

during start-up. The 1.7ms ramp occurs in five steps. The

step size are 20%, 40%, 60%, 80% and 100% of the positive

current limit value.

5V5V

5V

BOOT_

BOOT_

BOOT_

BOOT_

BOOT_

UGATE_

UGATE_

UGATE_

UGATE_

ISL6237

ISL6237

ISL88734

FIGURE 71. REDUCING THE SWITCHING-NODE RISE TIME

C

BOOT

10

10

10

10

10

Ω

PHASE_

VIN

Q1

OUT_

OUT_

OUT_

OUT_

Boost-Supply Capacitor Selection (Buck)

The boost capacitor should be 0.1µF to 4.7µF, depending on

the input and output voltages, external components, and PC

board layout. The boost capacitance should be as large as

possible to prevent it from charging to excessive voltage, but

small enough to adequately charge during the minimum

low-side MOSFET conduction time, which happens at

28

Power-Good Output (POK_)

The POK_ comparator continuously monitors both output

voltages for undervoltage conditions. POK_ is actively held

low in shutdown, standby , and soft-st art. POK1 releases and

digital soft-start terminates when VOUT1 outputs reach the

error-comparator threshold. POK1 goes low if VOUT1 output

turns off or is 10% below its nominal regulation point. POK1

is a true open-drain output. Likewise, POK2 is used to

monitor VOUT2.

Fault Protection

The ISL6237 provides overvoltage/undervoltage fault

protection in the buck controllers. Once activated, the

controller continuously monitors the output for undervoltage

and overvoltage fault conditions.

OVERVOLTAGE PROTECTION

When the output voltage of VOUT1 is 11% (16% for VOUT2)

above the set voltage, the overvoltage fault protection

activates. This latches on the synchronous rectifier MOSFET

with 100% duty cycle, rapidly discharging the output

capacitor until the negative current limit is achieved. Once

FN6418.4

March 18, 2008

ISL6237

negative current limit is met, UGATE is turned on for a

minimum on-time, followed by another LGATE pulse until

negative current limit. This effectively regulates the

discharge current at the negative current limit in an effort to

prevent excessively large negative currents that cause

potentially damaging negative voltages on the load. Once an

overvoltage fault condition is set, it can only be reset by

toggling SHDN

, EN_, or cycling VIN (POR).

UNDERVOLTAGE PROTECTION

When the output voltage drops below 70% of its regulation

voltage for at least 100µs, the controller sets the fault latch

and begins the discharge mode (see the following Shutdown

and Output Discharge sections). UVP is ignored for at least

20ms (typical), after start-up or after a rising edge on EN_.

Toggle EN_ or cycle VIN (POR) to clear the undervoltage

fault latch and restart the controller. UVP only applies to the

buck outputs.

THERMAL PROTECTION

The ISL6237 has thermal shutdown to protect the devices

from overheating. Thermal shutdown occurs when the die

temperature exceeds +150°C. All internal circuitry shuts

down during thermal shutdown. The ISL6237 may trigger

thermal shutdown if LDO_ is not bootstrapped from OUT_

while applying a high input voltage on VIN and drawing the

maximum current (including short circuit) from LDO_. Even if

LDO_ is bootstrapped from OUT_, overloading the LDO_

causes large power dissipation on the bootstrap switches,

which may result in thermal shutdown. Cycling EN_,

EN_LDO, or VIN (POR) ends the thermal-shutdown state.

Discharge Mode (Soft-Stop)

When a transition to standby or shutdown mode occurs, or

the output undervoltage fault latch is set, the outputs

discharge to GND through an internal 25Ω switch. The