Page 1

IS456

IS456

High Speed Response Type

OPIC Light Detector

■ Features

1. High speed response (t

2. Uses a pattern to allow for possible

positional deviation of the semiconductor

laser spot.

3. Compact, mini-flat package

: TYP.230ns

PHL

■ Applications

1. Laser beam printers

■ Absolute Maximum Ratings

*1

Parameter

Supply voltage

High level output voltage

Low level output current

Operating temperature

Storage temperature

*2

Soldering temperature

Power dissipation

RO terminal power dissipation

*3

Incident light intensity

*3

Radiant intensity

*1 For 1 minute

*2 For 3 seconds at the position shown in the follow-

ing drawing.

*3 Maximum allowable incident light intensity and

radiant intensity of laser beam (λ = 780nm) to

the device.

Soldering area Soldering area

Symbol

V

CC

V

OH

I

OL

T

opr

T

stg

T

sol

P 150 mW

P

RO

P

I

E

e

■ Electro-optical Characteristics

Parameter Symbol Conditions MIN. TYP. MAX. Unit

High level output voltage V

Low level output voltage V

High level supply current I

Low level supply current I

*4

“High→Low ” threshold illuminance 1

*4

“High→Low ” threshold illuminance 2

“ High→Low ” threshold incident light intensity

“ High→Low”

propagation delay time

“ Low→High”

propagation delay time

2 represent illuminance by CIE standard light source A (tungsten lamp) when output goes from high to low.

VHL

*4 E

Response

time

1, E

VHL

)

(

Ta=25˚C

Rating Unit

-0.5 to + 7

7V

20 mA

-25 to+ 80

-40 to+ 85

260 ˚C

24

5

60

OH

OL

CCH

CCL

E

VHL1

E

VHL2

P

IHL

t

PHL

t

PLH

r

f

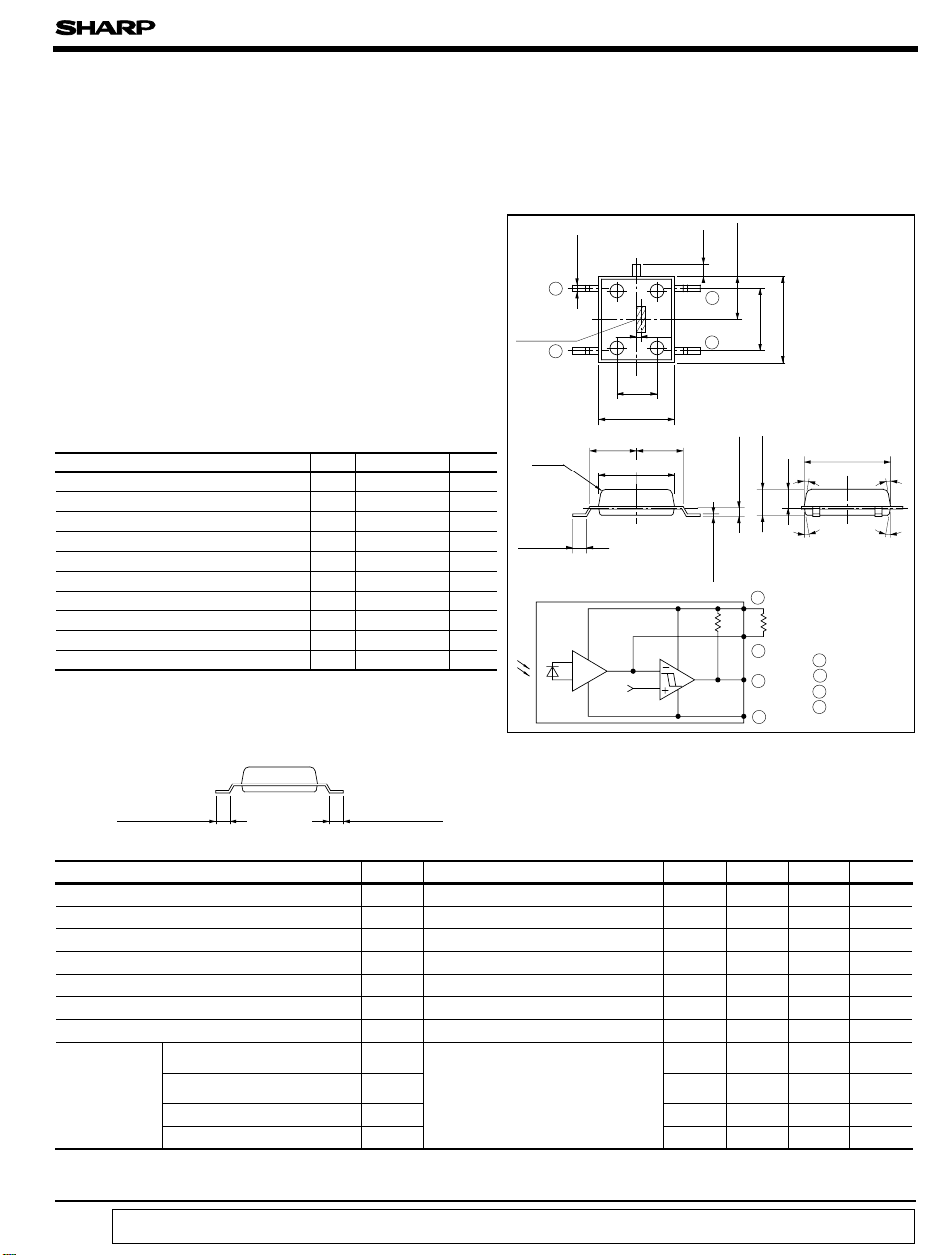

■ Outline Dimensions

0.3-0.1

+

0.4

1

Detector

center

2

V

˚C

˚C

mW

mW

WB

)

(

0.8

2.7

)

R0.2

+

0.2

-

0.4

Internal connection

diagram

V

2.75

4.4± 0.1

+

0.5

-

0

4.4

REF

±

2.7

± 0.1

0.2

0.25

+

-

(

Unit :mm

0.2

±

0.7

2.5

4

0.3

0.1

±

±

5.0

3.81

3

0.5

0

+

0.3-0

0.15

0.3-0.2

+

0.5

0.1

±

4

1

2

3

1.07

1.5

Gain resistor(Ro

(

Outer mounting

±

5.0

10˚

10˚ 10˚

1 R

O

2 V

O

3 GND

4 V

CC

)

0.1

10˚

)

)

*“OPIC” (Optical IC) is a trademark of the SHARP Corporation.

An OPIC consists of a light-detecting element and signal processing circuit integrated onto a single chip.

)

R

=51kΩ , E

O

IOL=10mA, E

=0

V

=1 000lx

V

(

= 5V, Ta= 25˚C

V

CC

4.9 - - V

- 0.4 0.6 V

RO=51kΩ , EV=0 - 2.6 4.5 mA

RO=51kΩ , E

RO=51kΩ 330 470 600

RO=5.1kΩ --

=1 000lx

V

- 3.8 6.6 mA

lx

5 800

lx

RO=5.1kΩ , l =780nm - 100 - µW

=15pF, Duty=1: 1

C

L

PI=0.2mW, λ =780nm

RO=5.1kΩ , RL=510Ω

- 230 400 ns

- 230 400 ns

- 60 200 ns Rise time t

- 20 100 ns Fall time t

“ In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that occur in equipment using any of SHARP's devices, shown in catalogs,

data books, etc. Contact SHARP in order to obtain the latest version of the device specification sheets before using any SHARP's device.”

Page 2

■ Recommended Operating Conditions

Parameter Symbol MIN. MAX. Unit

Operating supply voltage V

Operating temperature T

Incident light intentity (λ = 780nm

In order to stabilize power supply line, connect a by-pass capacitor of 0.1µF

between Vcc and GND near the device.

)

P

4.5 5.5 V

cc

opr

I

060˚C

- 2.5 mW

IS456

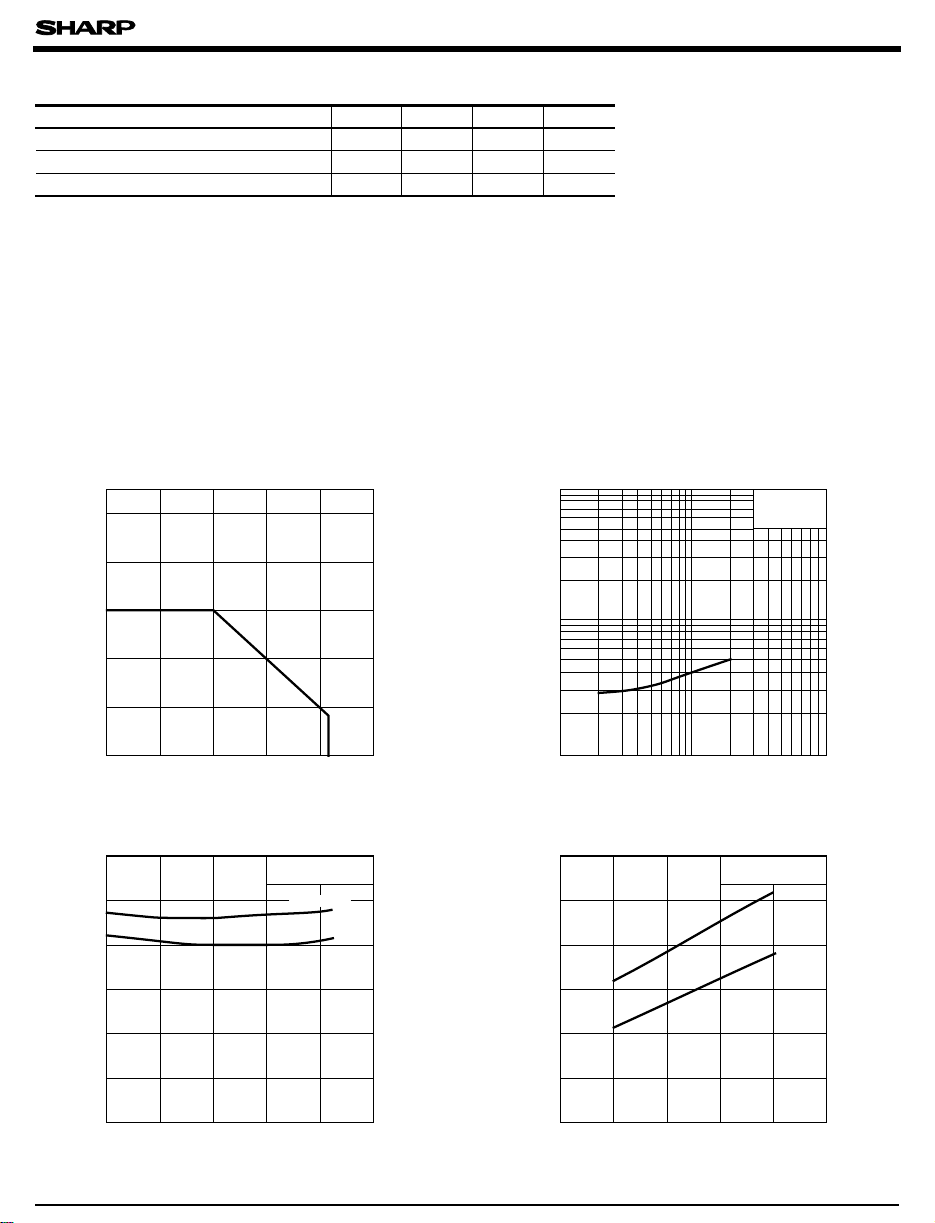

Fig. 1 Total Power Dissipation vs.

Ambient Temperature

250

)

200

mW

(

150

100

Total power dissipation P

0

Ambient temperature Ta (˚C

)

Fig. 3 Low Level Output Voltage vs.

Ambient Temperature

0.6

0.5

)

mA

(

0.4

OL

0.3

0.2

0.1

Low level output voltage V

0

025

Ambient temperature T

VCC=5V

I

= 20mA

OL

10mA

50

75 100-25 3

)

(˚C

a

Fig. 2 Low Level Output Voltage vs.

Low Level Output Current

10

5

)

V

(

OL

2

1

0.5

0.2

Low level output voltage V

1

100755025-25500

11052

Low level output Current IOL (mA

VCC=5V

T

= 25˚C

a

)

1005020

Fig. 4 Supply Current vs. Supply Voltage

6

5

)

mA

4

(

CC

3

2

Supply current I

1

0

Supply voltage VCC (V

Ta= 25˚C

I

CCL

I

CCH

)

87654

Page 3

IS456

Fig. 5 Supply Current vs.

Ambient Temperature

6

VCC= 5.0V

)

4

mA

(

CC

2

I

CCL

I

CCH

Supply current I

0

0-25

25 50 75 100 01234567

Ambient temperature Ta (˚C

)

Fig. 7 “High→Low” Threshold Incident Light

Intensity vs. Ambient Temperature

a

(˚C

VCC= 5.0V

= 5.1kΩ

R

O

)

80

140

)

120

µ W

(

IHL

100

light intensity P

“High→Low” threshold incident

80

0

-25 25 50 75

0

Ambient temperature T

Fig. 9 Propagation Delay Time vs.

Incident Light Intensity

250

)

200

ns

(

PHL

, t

150

PLH

100

50

Propagation delay time t

0

0.5

0.2

Incident light intensity P

R

O

t

PLH

(mW

I

VCC= 5.0V

R

= 510Ω

L

T

= 25˚C

a

RO: Dotted line

t

PHL

)

2.52.01.51.00

Fig. 6 “High→Low” Threshold Incident Light

Intensity vs. Gain Resistanse

2000

1000

)

500

µ W

(

200

IHL

V

T

=5V

CC

= 25˚C

a

100

50

20

“High→Low” threshold

incident light intensity P

10

Gain resistance RO (k Ω

)

Fig. 8 “High→Low” Threshold Incident Light

Intensity vs. Supply Voltage

200

Ta= 25˚C

= 5.1kΩ

R

O

150

)

µ W

(

100

IHL

50

“High→Low” threshold incident

light intensity P

0

3

4

5678

Supply voltage VCC (V

)

Fig.10 Propagation Delay Time vs.

Gain Resistance

500

)

ns

400

(

PHL

, t

300

PLH

200

100

Propagation delay time t

0

0

Gain resistance R

VCC= 5V, PI= 0.6mW

R

= 510kΩ , Ta= 25˚C

L

t

PLH

t

PHL

)

(kΩ

O

654321

Page 4

IS456

Fig.11 Propagation Delay Time vs.

Ambient Temperature

400

VCC= 5V, RO=5.1KΩ

R

= 510Ω

L

)

ns

(

300

PHL

, t

PLH

200

t

PHL

t

PLH

t

PLH

t

PHL

100

Propagation delay time t

0

Ambient temperature Ta (˚C

)

Fig.13 Rise Time, Fall Time vs.

Ambient Temperature

100

VCC= 5V, RO= 5.1KΩ

= 510Ω

R

L

80

)

ns

(

f

, t

60

r

40

20

Rise time, fall time t

t

r

t

f

Fig.12 Rise Time, Fall Time vs.

Load Resistance

300

Ta= 25˚C

=5V

V

CC

250

)

ns

(

200

f

, t

r

t

r

150

100

Rise time, fall time t

50

t

100755025-25 0

0

0123456

Load resistance RL (K Ω

f

)

Fig.14 Spectral Sensitivity

100

80

)

%

(

60

40

Relative sensitivity

20

T

a

= 25˚C

0

Ambient temperature T

a

(˚C

0

100755025-25 0

)

300 400 500 600 700 800 900

Wavelength λ (nm

1000 1100

)

Page 5

Test Circuit for Response Time

IS456

Constant

current

Laser

diode

V

Incident

light

intensity

t

PHL

Output

t

f

● Please refer to the chapter “Precautions for Use.”

VCC= 5V

5.1

510Ω

kΩ

0.1µ F

ref

C

L

Output

0.2mW

0.1mW

t

PLH

0mW

90%

1.5V

10%

t

r

Loading...

Loading...