Datasheet IS27LV020-15T, IS27LV020-15PLI, IS27LV020-12TI, IS27LV020-12T, IS27LV020-12PLI Datasheet (ISSI)

...Page 1

ISS I

®

IS27LV020

Integrated Silicon Solution, Inc.

1

EP019-0A

12/19/97

ISSI reserves the right to make changes to its products at any time without notice in order to improve design and supply the best possible product. We assume no responsibility for any errors which

may appear in this publication. © Copyright 1997, Integrated Silicon Solution, Inc.

FEATURES

• Single 2.7V to 3.6V power supply

• Fast access time: 90 ns

• JEDEC-approved pinout

• Low power consumption

— 20 µA (max) CMOS standby current

— 10 mA (max) active current at 5 MHz

• High-speed programming

— Typically less than 16 seconds

• Industrial and commercial temperature ranges

available

• Standard 32-pin DIP, PLCC and TSOP

packages

DESCRIPTION

The ISSI IS27LV020 is a low voltage, low power, high-speed

1 megabit (256K-word by 8-bit) CMOS Programmable ReadOnly Memory. It utilizes the standard JEDEC pinout making it

funtionally compatible with the IS27C020 EPROM. The

IS27LV020 operates from a 2.7V to 3.6V power supply.

The superior access time combined with low power consumption is the result of innovative design and process technology.

Maximum power consumption in standby mode is 72 µW. If the

device is constantly accessed at 5 MHz, then the maximum

power consumption is increased to 36 mW. These power

ratings are significantly lower than the standard IS27C020

EPROM.

The IS27LV020 uses ISSI's write programming algorithm

which allows the entire chip to be programmed in typically less

than 30 seconds.

This product is available in One-Time Programmble (OTP)

PDIP, PLCC, and TSOP packages over commercial and

industrial temperature ranges.

IS27LV020

262,144 x 8 LOW VOLTAGE CMOS EPROM

ISSI

®

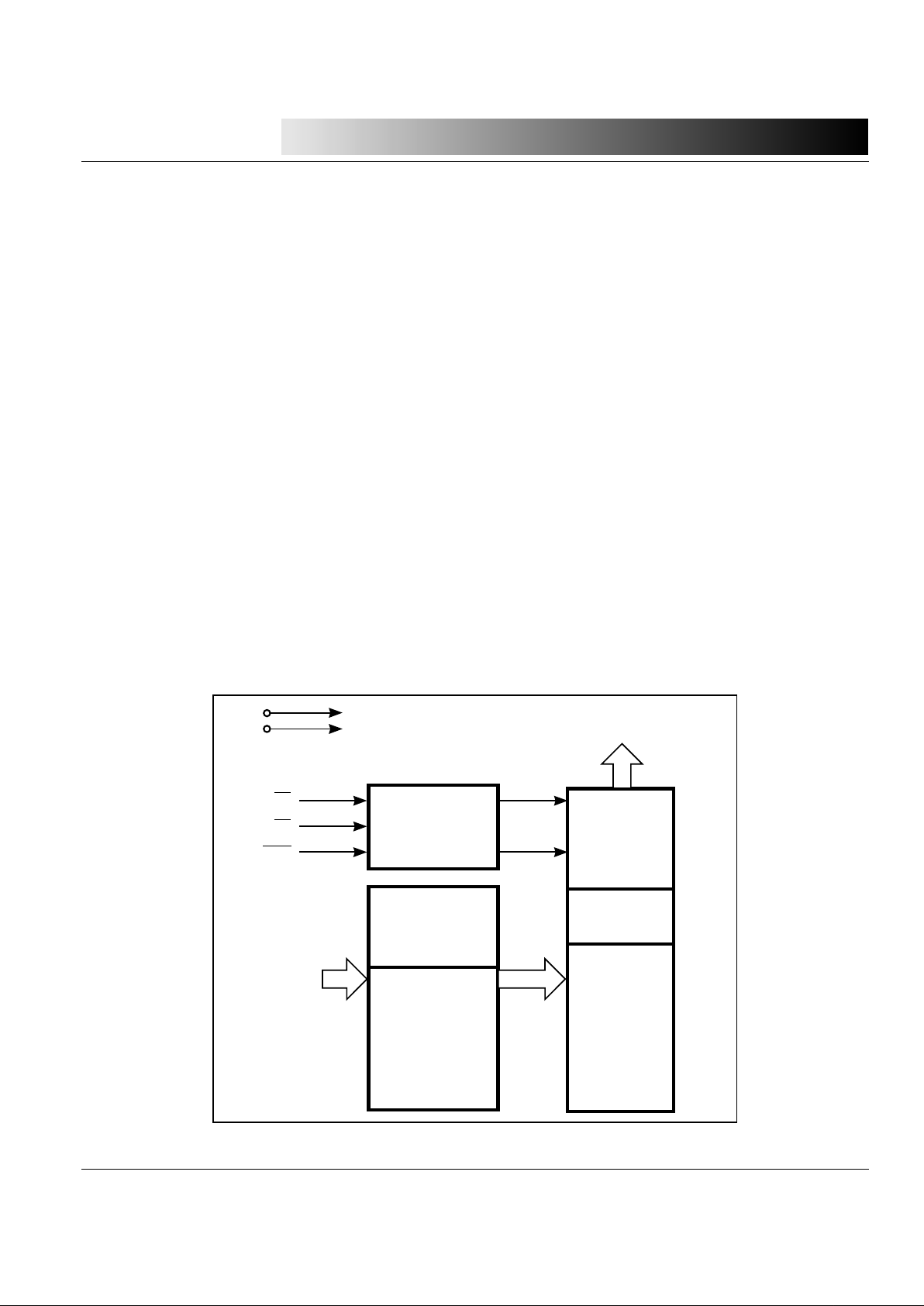

FUNCTIONAL BLOCK DIAGRAM

VCC

GND

OE

OUTPUT ENABLE

CHIP ENABLE

AND

PROG LOGIC

2,097,152-BIT

CELL MATRIX

CE

PGM

OUTPUT

BUFFERS

Y

GATING

X

DECODER

Y

DECODER

18

A0-A17

8

DQ0-DQ7

ADVANCE INFORMATION

DECEMBER 1997

Page 2

ISS I

®

IS27LV020

2

Integrated Silicon Solution, Inc.

EP019-0A

12/19/97

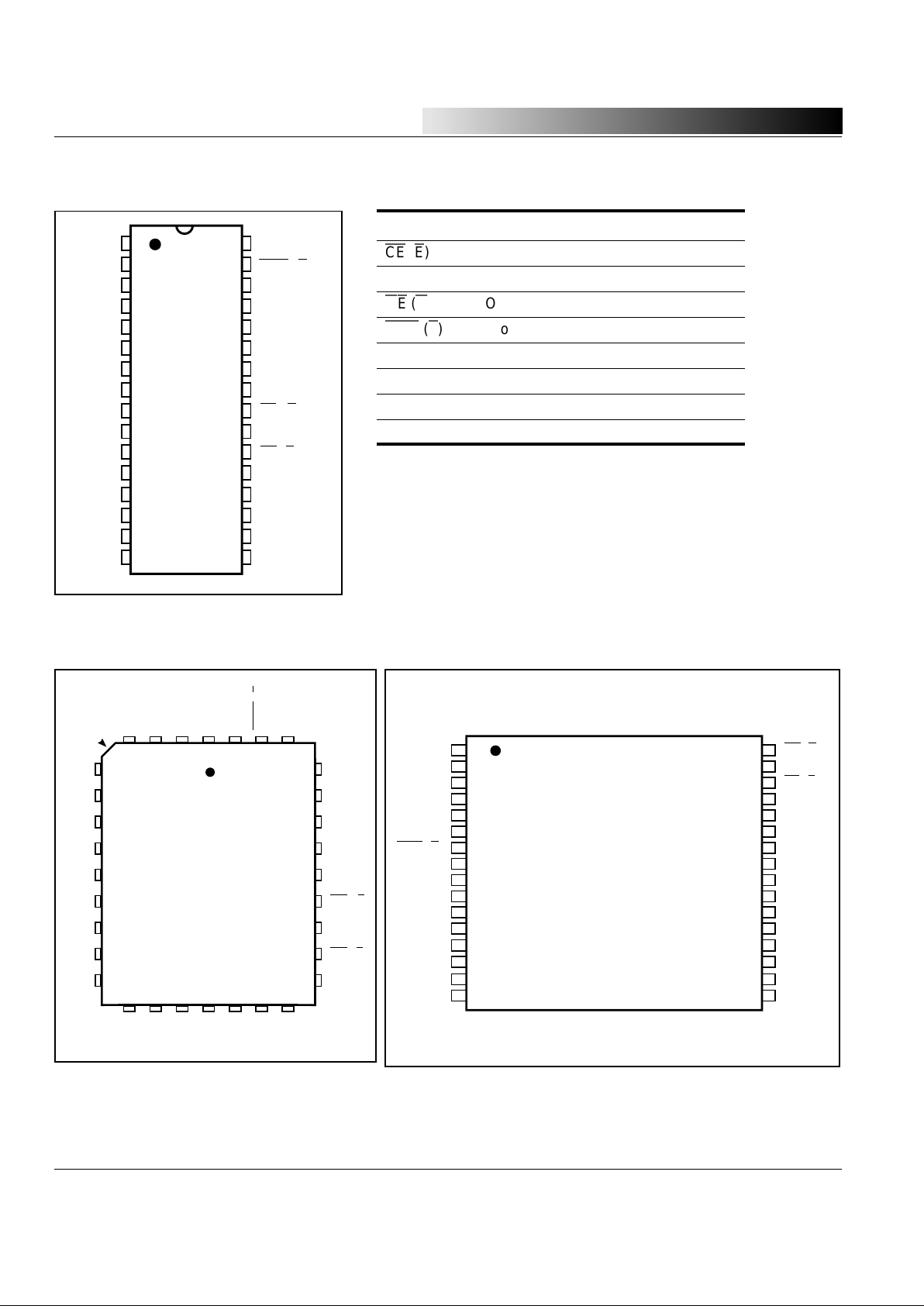

PIN CONFIGURATIONS

32-Pin DIP

PIN DESCRIPTIONS

A0-A17 Address Inputs

CE (E

) Chip Enable Input

DQ0-DQ7 Data Inputs/Outputs

OE (G

) Output Enable Input

PGM (P

) Program Enable Input

Vcc Power Supply Voltage

VPP Program Supply Voltage

GND Ground

NC No Internal Connection

32-Pin PLCC

32-Pin TSOP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

VPP

A16

A15

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

GND

VCC

PGM (P)

A17

A14

A13

A8

A9

A11

OE (G)

A10

CE (E)

DQ7

DQ6

DQ5

DQ4

DQ3

DQ1

DQ2

GND

DQ3

DQ4

DQ5

DQ6

A12

A15

A16

VPP

VCC

PGM (P)

A17

A14

A13

A8

A9

A11

OE (G)

A10

CE (E)

DQ7

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

5

6

7

8

9

10

11

12

13

29

28

27

26

25

24

23

22

21

INDEX

4 3 2 1 32 31 30

14 15 16 17 18 19 20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

A11

A9

A8

A13

A14

A17

PGM (P)

VCC

VPP

A16

A15

A12

A7

A6

A5

A4

OE (G)

A10

CE (E)

DQ7

DQ6

DQ5

DQ4

DQ3

GND

DQ2

DQ1

DQ0

A0

A1

A2

A3

Page 3

ISS I

®

IS27LV020

Integrated Silicon Solution, Inc.

3

EP019-0A

12/19/97

FUNCTIONAL DESCRIPTION

Programming the IS27LV020

Upon delivery, the IS27LV020 has 2,097,152 bits in the

"ONE", or HIGH state. "ZEROs" are loaded into the

IS27LV020 through the procedure of programming.

The programming mode is entered when 12.5V ± 0.25V is

applied to the VPP pin, VCC = 6V, CE and

PGM

is at VIL, and

OE

is at VIH. For programming, the data to be programmed

is applied eight bits in parallel to the data output pins.

The write programming algorithm reduces programming

time by using 100 µs programming pulses followed by a

byte verification to determine whether the byte has been

successfully programmed. If the data does not verify, an

additional pulse is applied for a maximum of 25 pulses.

This process is repeated while sequencing through each

address of the EPROM.

The write programming algorithm programs and verifies at

VCC = 6V and VPP = 12.5V. After the final address is

completed, all byte are compared to the original data with

VCC = 5.25V.

Program Inhibit

Programming of multiple IS27LV020s in parallel with different data is also easily accomplished. Except for CE, all

like inputs of the parallel IS27LV020 may be common. A

TTL low-level program pulse applied to an IS27LV020

CE

input with VPP = 12.5V ± 0.25V, PGM LOW and OE HIGH

will program that IS27LV020. A high-level CE input inhibits

the other IS27LV020 from being programmed.

Program Verify

A verify should be performed on the programmed bits to

determine that they were correctly programmed. The

verify should be performed with OE and CE at VIL,

PGM

at

VIH, and VPP between 12.25V and 12.75V.

Auto Select Mode

The auto select mode allows the reading out of a binary

code from an EPROM that will identify its manufacturer

and type. This mode is intended for use by programming

equipment for the purpose of automatically matching the

device to be programmed with its corresponding programming algorithm. This mode is functional in the 25°C ± 5°C

ambient temperature range that is required when programming the IS27LV020.

To activate this mode, the programming equipment must

force 12.0V ± 0.5V on address line A9 of the IS27LV020.

Two identifier bytes may then be sequenced from the

device outputs by toggling address line A0 from VIL to VIH.

All other address lines must be held at VIL during auto

select mode.

Byte 0 (A0 = VIL) represents the manufacturer code, and

byte 1 (A0 = VIH), the device identifier code. For the

IS27LV020, these two identifier bytes are given in the

Mode Select table. All identifiers manufacturer and device

codes will possess odd parity, with the MSB (DQ7) defined

as the parity bit.

Read Mode

The IS27LV020 has two control functions, both of which

must be logically satisfied in order to obtain data at the

outputs. Chip Enable (CE) is the power control and should

be used for device selection. Assuming that addresses are

stable, address access time (tACC) is equal to the delay

from CE to output (tCE). Output Enable (OE) is the output

control and should be used to get data to the output pins,

independent of device selection. Data is available at the

outputs tOE after the falling edge of OE assuming that

CE

has been LOW and addresses have been stable for at

least tACC – tOE.

Standby Mode

The IS27LV020 has a standby mode which reduces the

maximum VCC active current. It is placed in standby mode

when CE is at VCC ± 0.3V. The amount of current drawn in

standby mode depends on the frequency and the number

of address pins switching. The IS27LV020 is specified

with 50% of the address lines toggling at 5 MHz. A

reduction of the frequency or quantity of address lines

toggling will significantly reduce the actual standby current.

Page 4

ISS I

®

IS27LV020

4

Integrated Silicon Solution, Inc.

EP019-0A

12/19/97

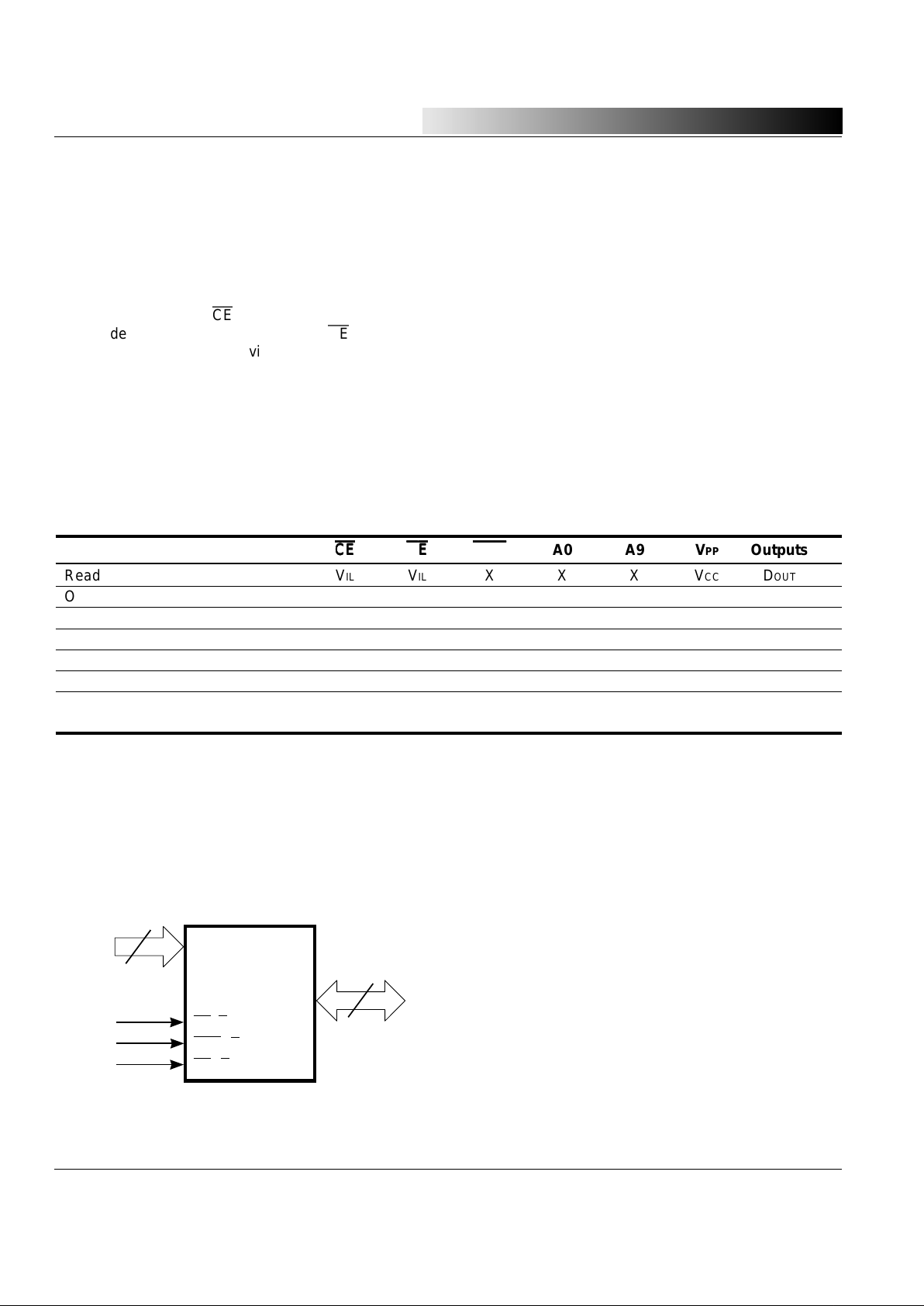

TRUTH TABLE

(1,2)

Mode

CECE

CECE

CE

OEOE

OEOE

OE

PGMPGM

PGMPGM

PGM

A0 A9 VPP Outputs

Read VIL VIL XXXVCC DOUT

Output Disable VIL VIH XXXVCC Hi-Z

Standby VIH XXXXVCC Hi-Z

Program VIL VIH VIL XXVPP DIN

Program Verify VIL VIL VIH XXVPP DOUT

Program Inhibit VIH XXXXVPP Hi-Z

Auto Select

(3,5)

Manufacturer Code VIL VIL XVIL VH VCC D5H

Device Code VIL VIL XVIH VH VCC 0EH

Notes:

1. VH = 12.0V ± 0.5V.

2. X = Either V

IH or VIL.

3. A1-A8 = A10-A17 = V

IL.

4. See DC Programming Characteristics for VPP voltage during programming.

5. The IS27LV020 can use the same write algorithm during program as other IS27C020 or IS27020 devices.

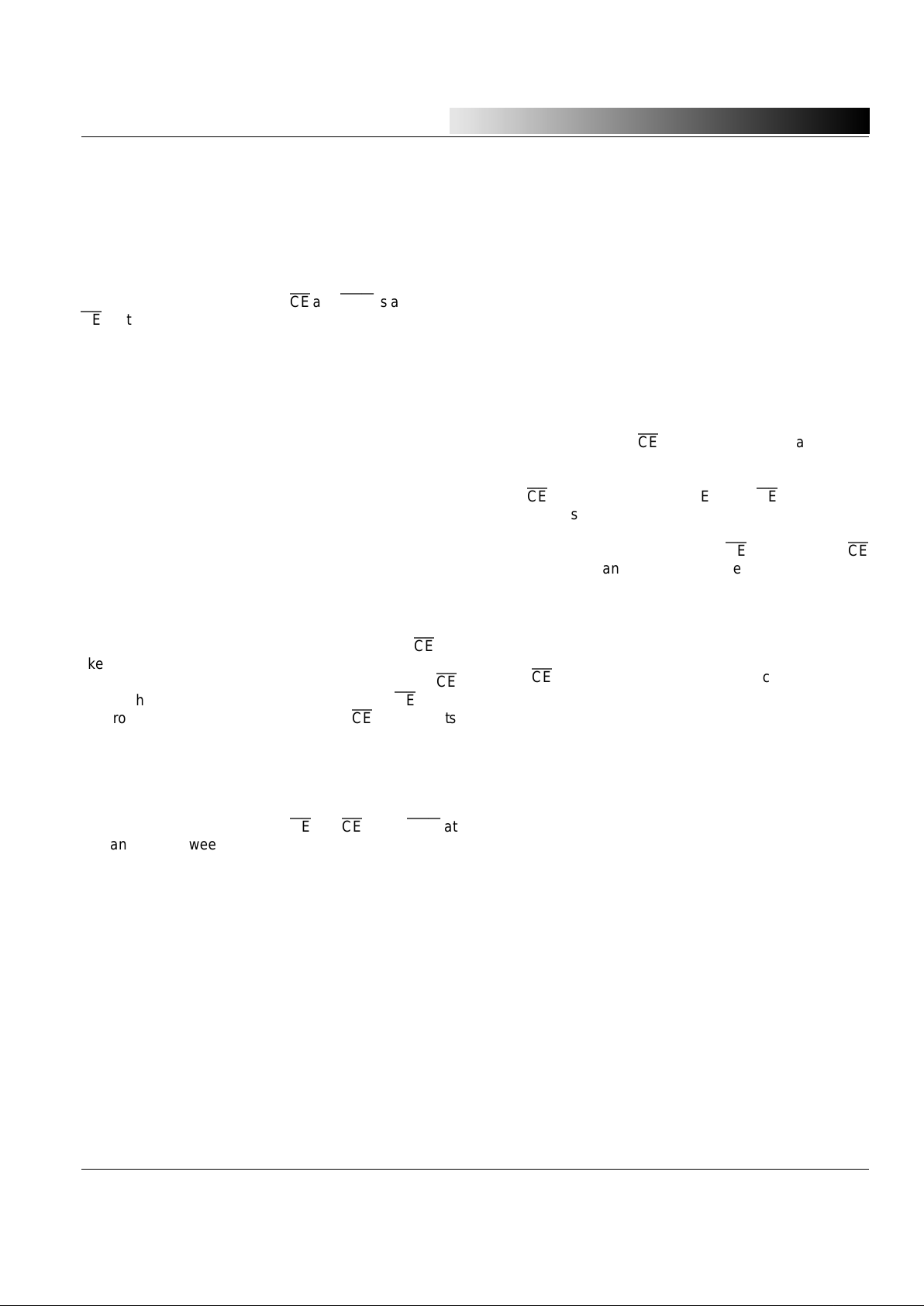

LOGIC SYMBOL

Output OR-Tieing

To accommodate multiple memory connections, a twoline control function is provided to allow for:

1. Low memory power dissipation, and

2. Assurance that output bus contention will not

occur.

It is recommended that CE be decoded and used as the

primary device-selecting function, while OE be made a

common connection to all devices in the array and connected to the READ line from the system control bus. This

assures that all deselected memory devices are in their

low-power standby mode and that the output pins are only

active when data is desired from a particular memory

device.

System Applications

During the switch between active and standby conditions,

transient current peaks are produced on the rising and

falling edges of Chip Enable. The magnitude of these

transient current peaks is dependent on the output capacitance loading of the device at a minimum, a 0.1 µF ceramic

capacitor (high-frequency, low inherent inductance) should

be used on each device between VCC and GND to minimize transient effects. In addition, to overcome the voltage

drop caused by the inductive effects of the printed circuit

board traces on EPROM arrays, a 4.7 µF bulk electrolytic

capacitor should be used between VCC and GND for each

eight devices. The location of the capacitor should be

close to where the power supply is connected to the array.

18

8

DQ0-DQ7

A0-A17

CE (E)

PGM (P)

OE (G)

Page 5

ISS I

®

IS27LV020

Integrated Silicon Solution, Inc.

5

EP019-0A

12/19/97

ABSOLUTE MAXIMUM RATINGS

(1)

Symbol Parameter Value Unit

VTERM Terminal Voltage with Respect to GND

All pins except A9 and VPP –0.6 to VCC + 0.5

(2)

V

VPP VCC – 0.3 to 13.5

(2,3)

V

A9 –0.6 to 13.5

(2,3)

V

VCC –0.6 to 7.0

(2)

V

TA Ambient Temperature with Power Applied –65 to +125 °C

TSTG Storage Temperature (OTP) –65 to +125 °C

TSTG Storage Temperature (All others) –65 to +150 °C

Notes:

1. Stress greater than those listed under ABSOLUTE MAXIMUM RATINGS may cause permanent damage to the

device. This is a stress rating only and functional operation of the device at these or any other conditions above

those indicated in the operational sections of this specification is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect reliability.

2. Minimum DC input voltage is –0.5V. During transitions, inputs may undershoot to –2.0V for periods less than 10

ns. Maximum DC voltage on output pins is Vcc + 0.5V which may overshoot to Vcc + 2.0V for periods less than

10 ns.

3. Maximum DC voltage on A9 or V

PP may overshoot to +13.5V for periods less than 10 ns.

OPERATING RANGE

Range Ambient Temperature VCC

Commercial 0°C to +70°C 2.7 – 3.6V

Industrial

(1)

–40°C to +85°C 2.7 – 3.6V

Note:

1. Operating ranges define those limits between which the

functionally of the device is guaranteed.

DC ELECTRICAL CHARACTERISTICS

(1,2,3)

(Over Operating Range)

Symbol Parameter Test Conditions Min. Max. Unit

VOH Output HIGH Voltage VCC = Min., IOH = –400 µA 2.4 — V

VOL Output LOW Voltage VCC = Min., IOL = 2.0 mA — 0.4 V

VIH Input HIGH Voltage

(4)

2.0 VCC + 0.5 V

VIL Input LOW Voltage

(4)

–0.3 0.8 V

ILI Input Load Current VIN = 0V to +VCC —5µA

ILO Output Leakage Current VOUT = 0V to +VCC —5µA

Notes:

1. VCC must be applied simultaneously or before VPP and removed simultaneously or after VPP. Never try to force VPP LOW to 1V

below V

CC. Manufacturer suggests to tie VPP and VCC together during the READ operation.

2. Caution: the IS27LV020 must not be removed from (or inserted into) a socket when V

CC or VPP is applied.

3. Minimum DC input voltage is –0.5V. During transitions, the inputs may undershoot to –2.0V for periods less than 10 ns.

Maximum DC voltage on output pins is V

CC + 0.5V which may overshoot to VCC + 2.0V for periods less than 10 ns.

4. Tested under static DC conditions.

Page 6

ISS I

®

IS27LV020

6

Integrated Silicon Solution, Inc.

EP019-0A

12/19/97

POWER SUPPLY CHARACTERISTICS

(1,2,5)

(Over Operating Range)

Symbol Parameter Test Conditions Min. Max. Unit

ICC1 Vcc Operating VCC = Max., CE = VIL —10mA

Supply Current

(3)

IOUT = 0 mA, f = 5 MHz

(Open outputs)

IPP1 VPP Current During VCC = Max., CE = OE = VIL —10µA

Read

(4)

VPP = VCC

ICCSB0 Vcc CMOS Standby

CE

= VCC + 0.3V (No toggling) — 20 µA

Current

ICCSB1 Vcc TTL Standby

CE

= VIH (No toggling) — 200 µA

Current

Notes:

1. V

CC must be applied simultaneously or before VPP and removed simultaneously or after VPP. Never try to force VPP LOW to 1V

below VCC. Manufacturer suggests to tie VPP and VCC together during the READ operation.

2. Caution: the IS27LV020 must not be removed from (or inserted into) a socket when V

CC or VPP is applied.

3. I

CC1 is tested with

OE

= VIH to simulate open outputs.

4. Maximum active power usage is the sum of ICC and IPP.

5. Minimum DC input voltage is –0.5V. During transitions, the inputs may undershoot to –2.0V for periods less than 10 ns.

Maximum DC voltage on output pins is V

CC + 0.5V which may overshoot to VCC + 2.0V for periods less than 10 ns.

CAPACITANCE

(1,2,3)

Symbol Parameter Conditions Typ. Max. Unit

CIN Input Capacitance VIN = 0V 8 10 pF

COUT Output Capacitance VOUT = 0V 8 12 pF

Notes:

1. Typical values are for nominal supply voltage.

2. This parameter is only sampled, but not 100% tested.

3. Test conditions: T

A = 25°C, f = 1 MHz.

SWITCHING TEST CIRCUIT

1.2KΩ

Device

Under

Test

3.3V

6.0KΩ

C

L

100 pF

SWITCHING TEST WAVEFORM

2.4V

0.4V

2.0V

0.8V

2.0V

0.8V

INPUT OUTPUT

Notes:

AC Testing:

1. Inputs are driven at 2.4V for a logic "1" and 0.4V for a logic "0".

2. Input pulse rise and fall times are ≤ 20 ns.

Page 7

ISS I

®

IS27LV020

Integrated Silicon Solution, Inc.

7

EP019-0A

12/19/97

SWITCHING CHARACTERISTICS

(1,3,4)

(Over Operating Range)

JEDEC Std. -90 -12 -15

Symbol Symbol Parameter Test Conditions Min. Max. Min. Max. Min. Max. Unit

tAVQA tACC Address to

CE

= OE = VIL — 90 — 120 — 150 ns

Output Delay

tELQV tCE Chip Enable to

OE

= VIL — 90 — 120 — 150 ns

Output Delay CL = CL1

tGLQV tOE Output Enable to

CE

= VIL —45—50—65ns

Output Delay

tEHOZ, tDF

(2)

Chip Enable HIGH or — 30 — 35 — 35 ns

tGHQZ Output Enable HIGH,

whichever comes first,

to Output Float

tAVOX tOH Output Hold from 0 — 0 — 0 — ns

Address, CE or

OE

whichever occured first

Notes:

1. V

CC must be applied simultaneously or before VPP and removed simultaneously or after VPP.

2. This parameter is only sampled, not 100% tested.

3. Caution: The IS27LV020 must not be removed from (or inserted into) a socket or board when V

PP or VCC applied.

4. Output Load: 1 TTL gate and C

L =100 pF.

Input Rise and Fall times: 20 ns.

Input Pulse Levels: 0.4V to 2.4V.

Timing Measurement Reference Level: 0.8V to 2V for inputs and outputs.

ADDRESS

CE

OE

OUTPUT

ADDRESS VALID

VALID OUTPUT

2.0V

0.8V

2.0V

0.8V

tDF

(2)

tOH

Hi-ZHi-Z

tOE

tACC

(1)

tCE

2.4V

0.4V

SWITCHING WAVEFORMS

Notes:

1.OE may be delayed up to tACC – tOE after the falling edge of CE without impact on tACC.

2. t

DF is specified from

OE

or CE, whichever occurs first.

Page 8

ISS I

®

IS27LV020

8

Integrated Silicon Solution, Inc.

EP019-0A

12/19/97

DC PROGRAMMING CHARACTERISTICS

(1,2,3,4)

(TA = +25°C ± 5°C)

Symbol Parameter Test Conditions Min. Max. Unit

VOH Output HIGH Voltage During Verify IOH = –400 µA 2.4 — V

VOL Output LOW Voltage During Verify IOL = 2.1 mA — 0.45 V

VIH Input HIGH Voltage 2.0 VCC + 0.5 V

VIL Input LOW Voltage (All Inputs) –0.3 0.8 V

VH A9 Auto Select Voltage 11.5 12.5 V

ILI Input Current (All Inputs) VIN = VIL or VIH — 10.0 µA

ICC Vcc Supply Current (Program & Verify) — 50 mA

IPP VPP Supply Current

CE

= VIL, OE = VIH —30mA

VCC Supply Voltage 5.75 6.25 V

VPP Programming Voltage 12.25 12.75 V

SWITCH PROGRAMMING CHARACTERISTICS

(1,2,3,4)

(TA = +25°C ± 5°C)

JEDEC Std.

Symbol Symbol Parameter Min. Max. Unit

tAVEL tAS Address Setup Time 2 — µs

tDZGL tOES

OE

Setup Time 2 — µs

tDVEL tDS Data Setup Time 2 — µs

tGHAX tAH Address Hold Time 0 — µs

tEHDX tDH Data Hold Time 2 — µs

tGHQZ tDFP

OE

HIGH to Output Float Delay 0 130 ns

tVPS tVPS VPP Setup Time 2 — µs

tELEH1 tPW

PGM

Program Pulse Width 95 105 µs

tVCS tVCS VCC Setup Time 2 — µs

tELPL tCES

CE

Setup Time 2 — µs

tGLQV tOE Data Valid from

OE

— 150 ns

Notes:

1. V

CC must be applied simultaneously or before VPP and removed simultaneously or after VPP.

2. V

PP must be ≥ VCC during the entire programming and verifying procedure.

3. When programming IS27LV020, a 0.1 µF capacitor is required across VPP and ground to suppress spurious voltage transients

which may damage the device.

4. Programming characteristics are sampled but not 100% tested at worst-case conditions.

Page 9

ISS I

®

IS27LV020

Integrated Silicon Solution, Inc.

9

EP019-0A

12/19/97

PROGRAMMING ALGORITHM WAVEFORM

(1,2)

PROGRAM

PROGRAM

VERIFY

t

AH

t

DFP

DATA

OUT

VALID

Hi-Z

DATAIN STABLE

t

AS

t

DS

t

VPS

t

VCS

t

CES

t

PW

t

DH

12.5V

5.75V-6.25V

≥Vcc–0.3V

5V±10%

t

OES

t

OE

Max

ADDRESS

DATA

V

PP

V

CC

CE

PGM

OE

Notes:

1. The timing reference level is 0.8V for V

IL and 2.0V for VIH.

2. tOE and tDFP are characteristics of the device but must be accommodated by the programmer.

Page 10

ISS I

®

IS27LV020

10

Integrated Silicon Solution, Inc.

EP019-0A

12/19/97

PROGRAMMING FLOW CHART

Start

Address = First Location

Vcc = 6V

V

PP

= 12.5V

X = 0

Program One 100 µs Pulse

Increment X

X = 25?

Yes

No

Last

Address?

Pass

Yes

No

Increment Address

Vcc = VPP = 5.25V

Fail

Device Failed

Device Passed

Pass

Verify

Byte

Interactive

programming

Section

Verify Section

Fail

Verify All

Bytes

Page 11

ISS I

®

IS27LV020

Integrated Silicon Solution, Inc.

11

EP019-0A

12/19/97

ORDERING INFORMATION

Commercial Rangle: 0°C to +70°C

Speed (ns) Order Part Number Package

90 IS27LV020-90W 600-mil Plastic DIP

IS27LV020-90PL PLCC – Plastic Leaded Chip Carrier

IS27LV020-90T TSOP

120 IS27LV020-12W 600-mil Plastic DIP

IS27LV020-12PL PLCC – Plastic Leaded Chip Carrier

IS27LV020-12T TSOP

150 IS27LV020-15W 600-mil Plastic DIP

IS27LV020-15PL PLCC – Plastic Leaded Chip Carrier

IS27LV020-15T TSOP

ORDERING INFORMATION

Industrial Rangle: –40°C to +85°C

Speed (ns) Order Part Number Package

90 IS27LV020-90PLI PLCC – Plastic Leaded Chip Carrier

IS27LV020-90TI TSOP

120 IS27LV020-12PLI PLCC – Plastic Leaded Chip Carrier

IS27LV020-12TI TSOP

150 IS27LV020-15PLI PLCC – Plastic Leaded Chip Carrier

IS27LV020-15TI TSOP

I SSI

®

Integrated Silicon Solution, Inc.

2231 Lawson Lane

Santa Clara, CA 95054

Fax: (408) 588-0806

Toll Free: 1-800-379-4774

http://www.issiusa.com

Loading...

Loading...