Page 1

IS24C16

IS24C16

ISSI

ISSI

®

®

16,384-BIT SERIAL ELECTRICALLY

ERASABLE PROM

FEATURES

• Low power CMOS

– Active current less than 3.0 mA

– Standby current less than 35 µA

• Hardware write protection

– Write control pin

• Internally organized as eight banks

– 256 pages x 8 bytes

• Two-wire serial interface

— Bidirectional data transfer protocol

• Flexible byte write and 16-byte page-write

modes

• High-reliability

– Endurance: 100,000 cycles per byte

– Data retention: 100 years

• Automatic word address incrementing

— Sequential register read

• Filtered inputs for noise suppression

OVERVIEW

The IS24C16 is a low cost, low power, low voltage

serial EEPROM and organized as 2,048 x 8 bits. The

memory is configured as 128 pages of 16 bytes each. It is

fabricated using ISSI’s advanced CMOS EEPROM technology and operates from a single supply.

The IS24C16 is internally organized as a 256 x 8 memory

bank. The IS24C16 features a serial interface and software protocol allowing operation on a simple 2-wire bus.

Included is a bidirectional serial data bus synchronized by

a clock offering flexible byte write and a faster 16-byte

page write. A write protect pin can protect data in the upper

quadrant of memory.

ADVANCE INFORMATION

OCTOBER 1997

• 8-pin PDIP or SOIC packages

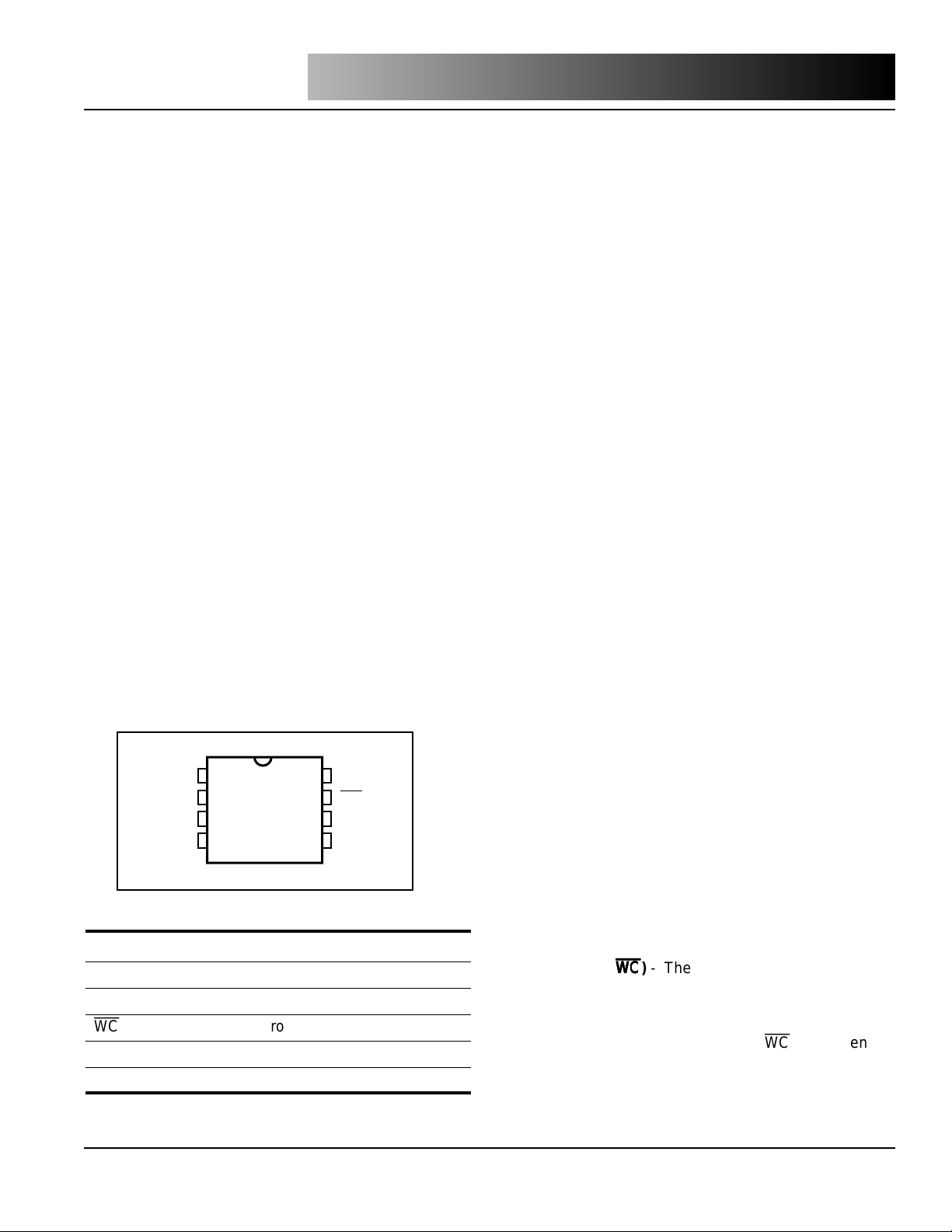

PIN CONFIGURATION

8-Pin DIP and SOIC

8

A0

A1

A2

GND

1

2

3

4

VCC

7

WC

6

SCL

5

SDA

PIN DESCRIPTIONS

A0-A2 Address Inputs (No connection)

SDA Serial Data I/O

SCL Serial Clock Input

WC

Vcc Power

GND Ground

Write Control Input

PIN DESCRIPTIONS

Serial Clock (SCL) - The SCL input is used to clock all data

into and out of the device. In the WRITE mode, data must

remain stable when SCL is HIGH. In the READ mode, data

is clocked out on the falling edge of SCL.

Serial Data (SDA) - The SDA pin is a bidirectional pin used

to transfer data into and out of the device. Data may

change only when SCL is LOW. It is an open-drain output,

and may be wire-ORed with any number of open-drain or

open-collector outputs.

A0, A1, and A2: These pins are not connected.

Write Control (

disable any attempt to write to the memory. When HIGH,

the upper half of array is protected against write operations; when LOW, the write function is normal. The part can

be read independent of the state of WC pin. When not

connected this pin will be pulled LOW.

WCWC

WC

) - The Write Control input is used to

WCWC

This document contains ADVANCE INFORMATION data. ISSI reserves the right to make changes to its products at any time without notice in order to improve design and supply the best possible

product. We assume no responsibility for any errors which may appear in this publication. © Copyright 1997, Integrated Silicon Solution, Inc.

Integrated Silicon Solution, Inc.

ADVANCE INFORMATION EE001-0C

10/03/97

1

Page 2

IS24C16

ISSI

®

GENERAL DESCRIPTION

The IS24C16 features a SERIAL communication, and

supports bidirectional data transmission protocol allowing

one IS24C16 operation on a simple two-wire bus. The twowire bus is defined as a serial data line (SDA), and a serial

clock line (SCL). (Refer to Figure 1. Typical System Bus

Configuration.)

The protocol defines any device that sends data onto the

SDA bus as a transmitter, and the receiving device as a

receiver. The device controlling the data transmission is

named MASTER device, and the controlled device is

named SLAVE device.

The IS24C16 does not use any device address bits but

instead the three bits are used for memory page addressing. These page addressing bits should be considered the

most significant bits of the data word address which

follows. The A0, A1, and A2 pins are no connect.

The eighth bit of the device address is the read/write

operation select bit. A read operation is initiated if this bit

is HIGH and a write operation is initiated if this bit is LOW.

The ACKnowledge is used to indicate successful data

transfers. The transmitting device will release the data bus

(SDA goes HIGH) after transmitting eight bits (one data bit

is transfered at the falling edge of each clock cycle). During

the ninth clock cycle, the receiver will pull the SDA line

LOW to ACKnowledge the transmitter that it received the

eight bits of data. (Refer to Figure 2. ACKnowledge Response from Receiver Diagram.)

DEVICE OPERATION

START and STOP Conditions

Both SDA and SCL lines remain HIGH when the SDA bus

is not busy. A HIGH-to-LOW transition of SDA line, while

SCL is HIGH, is defined as the START condition. A LOWto-High transition of SDA line, while SCL is HIGH, is

defined as the STOP condition. (Refer to Figure 3. Start

and Stop Conditions.)

Data Validity Protocol

One data bit is transferred during each clock cycle. The

data on the SDA line must remain stable during the HIGH

period of the clock cycle, because changes on SDA line

during the SCL HIGH period will be interpreted as START

or STOP control signals. (Refer to Figure 4. Data Validity

Protocol.)

Device Addressing Byte Definitions

The most significant four bits of Device Addressing Byte

(Bit 7 to Bit 4) are defined as the device type identifier. For

IS24C16, this is fixed as 1010. The next three significant

address bits (Bit 3 to Bit 1) are address memory bits. One

IS24C16 device can be connected on the bus. The last bit

Bit 0 defines the write or read operation to be performed.

When set to “1”, a READ operation is selected; when set

to “0” a WRITE operation is selected. (Refer to Figure 5.

Device Addressing Byte Definitions.)

WRITE OPERATION

Byte Write

For a WRITE operation, the IS24C16 requires another

8-bit data word address following the Device Addressing

Byte and ACKnowledgement. This data word address

provides access to any one of the 256 data words of

device's memory array.

Upon receipt of the data word address, the IS24C16

responds with an ACKnowledge on SDA, and waits for the

next 8-bit data word, then again responding with an

ACKnowledge. The master device terminates the Byte

Write Operation by generating a STOP condition, afterward the IS24C16 begins the internal WRITE cycle to the

nonvolatile memory array. Refer to Write Cycle Timing. All

inputs are disabled during this write cycle and the device

will not response to any requests from the master. (Refer

to Figure 6. Write Operation for the Address, ACKnowledge,

and Data Transfer Sequence.)

Page Write

The IS24C16 is capable of 8-byte page- WRITE operation.

A page-WRITE is initiated in the same manner as a byte

write, but instead of terminating the internal write cycle

after the first data word is transfered, the master device

can transmit up to 15 more words. After the receipt of each

data word, the IS24C16 responds immediately with an

ACKnowledge on SDA line, and the four lower order data

word address bits are internally incremented by one while

the four higher order bits of the data word address remain

constant. If the master device should transmit more than

8 words, prior to issuing the STOP condition, the address

counter will “roll over,” and the previously written data will

be overwritten. All inputs are disabled until completion of

the internal WRITE cycle. (Refer to Figure 7. Write Operation for the Address, ACKnowledge, and Data Transfer

Sequence.)

2

Integrated Silicon Solution, Inc.

ADVANCE INFORMATION EE001-0C

10/03/97

Page 3

IS24C16

ISSI

®

Acknowledge Polling

Once the internal write cycle has started and the

IS24C16 inputs are disabled, acknowledge polling can be

initiated. This involves sending a start condition followed

by the Device Addressing Byte. The read/write bit is

representive of the operation desired. Only if the internal

write cycle has been completed will the IS24C16 respond

with an acknowledge on the SDA bus allowing the read or

write sequence to continue.

READ OPERATION

READ operations are initiated in the same manner as

WRITE operations, except that the read/write bit of the

device addressing byte is set to “1”. There are three READ

operation options: current address read, random address

read and sequential read.

Current Address Read

The IS24C16 contains an internal address counter which

maintains the address of the last data word accessed,

incremented by one. For example, if the previous operation either a read or write operation addressed to the

address location n, the internal address counter would

increment to address location n+1. When the IS24C16

receives the Device Addressing Byte with a READ operation (read/write bit set to “1”), it will respond an ACKnowledge

and transmit the 8-bit data word stored at address location

n+1. If the Current Address READ operation only accesses a single byte of data, the master device terminates

the Current Address READ operation by pulling

ACKnowledge HIGH (lack of ACKnowledge) indicating the

last data word to be read, followed by a STOP condition.

(Refer to Figure 8. Current Address Read Diagram.)

Random Access Read

Random Address READ operation allows the master

device to access any memory location in a random fashion. This operation involves a two-step process. First, the

master device generates a START condition and initiates

Device Addressing Byte with a WRITE operation (read/

write bit sets to “0”), followed by the address of the data

word the master device is to READ. This procedure stores

the desired address of data word to the internal address

counter of the IS24C16.

After the data word address ACKnowledge is received by

the master device, the master device now initiates a

CURRENT ADDRESS READ

dressing Byte with a READ operation (read/write bit sets to

“1”). The IS24C16 responds with an ACKnowledge and

transmits the eight data bits stored at the address location

where the master device is to READ. At this point, the

master device terminates the operation by pulling

ACKnowledge HIGH (lack of ACKnowledge) indicating the

last data word to be read, followed by a STOP condition.

(Refer to Figure 9. Random Address Read Diagram.)

Sequential Read

Sequential Reads can be initiated as either a Current

Address Read or Random Address Read. The first data

word is transmitted as with the other byte read modes, the

master device now responds with an ACKnowledge indicating that it requires additional data from the IS24C16.

The IS24C16 continues to output data for each

ACKnowledge received. the master device terminates the

sequential READ operation by pulling ACKnowledge HIGH

(lack of ACKnowledge) indicating the last data word to be

read, followed by a STOP condition.

The data output is sequential, with the data from

address n followed by the date from address n+1, ... etc.

The address counter increments by one automatically,

allowing the entire memory contents to be serially read

during sequential read operation. When the memory address boundry (address 255) is reached, the address

counter “rolls over” to address 0, and the IS24C16 continues to output data for each ACKnowledge received. (Refer

to Figure 910. Sequential Read Operation Starting with a

Random Address READ Diagram.)

by sending Device Ad-

Integrated Silicon Solution, Inc.

ADVANCE INFORMATION EE001-0C

10/03/97

3

Page 4

IS24C16

SCL

SDA

Vcc

ISSI

®

Master

Transmitter/

Receiver

SCL

Data In

Data Out

START

Slave

Receiver

Slave

Transmitter/

Receiver

Master

Transmitter

Figure 1. Typical System Bus Configuration

189

Master

Transmitter/

Receiver

ACKNOWLEDGE

SCL

SDA

START

Condition

Figure 2. Output Acknowledge

Condition

STOP

Figure 3. START and STOP Conditions

4

Integrated Silicon Solution, Inc.

ADVANCE INFORMATION EE001-0C

10/03/97

Page 5

IS24C16

SCL

SDA

Data Change

Data Stable Data Stable

Figure 4. Data Validity Protocol

BIT 7 BIT 4 BIT 3 BIT 1 BIT 0

0101

MSB

R

A0A1A2

W

LSB

ISSI

®

SDA

Bus

Activity

S

T

A

R

T

M

S

B

SDA

Bus

Activity

Device

Address

S

T

A

Device

R

Address

T

M

S

B

W

R

I

T

Word Address (n)

E

A

R

C

***

W

K

L

S

B

Figure 5. Device Addressing

W

R

I

T

E

R

W

L

S

B

First

Word Address

A

C

***

K

M

S

B

Second

Word Address

A

C

K

A

C

K

L

S

B

Figure 6. Byte Write

First

Second

Word Address (n)

A

C

K

A

C

K

Data

S

T

O

P

A

C

K

S

T

Data (n+x)Data (n)

A

C

K

O

P

A

C

K

Integrated Silicon Solution, Inc.

ADVANCE INFORMATION EE001-0C

10/03/97

Figure 7. Page Write

5

Page 6

IS24C16

SDA

Bus

Activity

S

T

A

R

T

Device

Address

M

S

B

R

E

A

D

A

R

C

W

K

L

S

B

Data

N

O

A

C

K

Figure 8. Current Access Read

®

ISSI

S

T

O

P

SDA

Bus

Activity

SDA

Bus

Activity

Device

Address

S

T

A

Device

R

Address

T

M

S

B

W

R

I

T

E

A

C

R

***

K

W

L

S

B

DUMMY WRITE

1st, 2nd

Word

Address n

S

T

A

Device

R

Address

T

A

C

K

R

E

A

D

Data n

A

C

K

R

E

A

D

N

O

A

C

K

Figure 9. Random Access Read

R

E

A

D

R/W

Data Byte n+3Data Byte n+2Data Byte n+1Data Byte

A

C

K

A

C

K

A

C

K

A

C

K

S

T

O

P

N

O

A

C

K

Figure 10. Sequential Read

6

Integrated Silicon Solution, Inc.

ADVANCE INFORMATION EE001-0C

10/03/97

Page 7

IS24C16

ISSI

®

ABSOLUTE MAXIMUM RATINGS

(1)

Symbol Parameter Value Unit

VS Supply Voltage 2.7 to +5.5 V

VP Voltage on Any Pin –0.5 to Vcc + 0.5 V

TBIAS Temperature Under Bias –40 to +85 °C

TSTG Storage Temperature –65 to +150 °C

IOUT Output Current 5 mA

Notes:

1. Stress greater than those listed under ABSOLUTE MAXIMUM RATINGS may cause

permanent damage to the device. This is a stress rating only and functional operation of the

device at these or any other conditions above those indicated in the operational sections of

this specification is not implied. Exposure to absolute maximum rating conditions for extended

periods may affect reliability.

OPERATING RANGE

Range Ambient Temperature VCC

Commercial 0°C to +70°C 5V ± 10%

Industrial –40°C to +85°C 5V ± 10%

CAPACITANCE

(1,2)

Symbol Parameter Conditions Max. Unit

CIN Input Capacitance VIN = 0V 5 pF

COUT Output Capacitance VOUT = 0V 8 pF

Notes:

1. Tested initially and after any design or process changes that may affect these parameters.

2. Test conditions: T

A = 25°C, f = 1 MHz, Vcc = 5.0V.

Integrated Silicon Solution, Inc.

ADVANCE INFORMATION EE001-0C

10/03/97

7

Page 8

IS24C16

ISSI

DC ELECTRICAL CHARACTERISTICS

TA = 0°C to +70°C for IS24C16 and –40°C to +85°C for IS24C16-I, Vcc = 4.5V to 5.5V.

Symbol Parameter Test Conditions Min. Max. Unit

VOL1 Output LOW Voltage VCC = 2.7V., IOL = 0.15 mA — 0.25 V

VOL2 Output LOW Voltage VCC = 3.0V., IOL = 2.1 mA — 0.4 V

VIH Input HIGH Voltage — VCC + 0.5 V

VIL Input LOW Voltage –1.0 — V

ILI Input Leakage Current VIN = VCC max. — 3 µA

ILO Output Leakage Current — 3 µA

POWER SUPPLY CHARACTERISTICS

TA = 0°C to +70°C for IS24C16 and –40°C to +85°C for IS24C16-I, Vcc = 4.5V to 5.5V.

Symbol Parameter Test Conditions Min. Max. Unit

ICC1 Vcc Operating Current READ at 100 KHz — 0.9 mA

ICC2 Vcc Operating Current WRITE at 100 KHz — 3.0 mA

®

ISB1 Standby Current Vcc = 4.5V — 20 µA

ISB2 Standby Current Vcc = 5.5V — 35 µA

8

Integrated Silicon Solution, Inc.

ADVANCE INFORMATION EE001-0C

10/03/97

Page 9

IS24C16

ISSI

AC ELECTRICAL CHARACTERISTICS

TA = 0°C to +70°C for IS24C16 and –40°C to +85°C for IS24C16-I, Vcc = 4.5V to 5.5V

5.5V

Symbol Parameter Test Conditions Min. Max. Unit

fSCL SCL Clock Frequency 0 400 KHz

(1)

(1)

(1)

(1)

—50 ns

1.2 — µs

— 300 ns

— 300 ns

tI Noise Suppression Time

tLOW Clock LOW Period 1.2 — µs

tHIGH Clock HIGH Period 0.6 — µs

tBUF Bus Free Time Before New Transmission

tSU:STA Start Condition Setup Time 0.6 — µs

tSU:STO Stop Condition Setup Time 0.6 — µs

tHD:STA Start Condition Hold Time 0.6 — µs

tHD:STO Stop Condition Hold Time 0.6 — µs

tSU:DAT Data In Setup Time 100 — ns

tHD:DAT Data In Hold Time 0 — µs

tDH Data Out Hold Time SCL LOW to SDA Data Out Change 50 — ns

tAA Clock to Output SCL LOW to SDA Data Out Valid 0.1 0.9 µs

tR SCL and SDA Rise Time

tF SCL and SDA Fall Time

tWR Write Cycle Time — 10 ms

Note:

1. This parameter is characterized but not 100% tested.

®

AC WAVEFORMS

BUS TIMING

SCL

IN

SDA

SDAOUT

tSU:STA

tLOW

tF tHIGH tLOW

tHD:DAT

tHD:STA

tDHtAA

tSU:DAT

tR

tSU:STO

tBUF

Integrated Silicon Solution, Inc.

ADVANCE INFORMATION EE001-0C

10/03/97

9

Page 10

IS24C16

WRITE CYCLE

SCL

ISSI

®

SDA

WORD n

8th BIT

8th BIT

ACK

STOP

Condition

ORDERING INFORMATION

Commercial Range: 0°C to +70°C

Frequency Order Part Number Package

100 KHz IS24C16-P 300-mil Plastic DIP

100 KHz IS24C16-G Small Outline (JEDEC STD)

ORDERING INFORMATION

t

WR

START

Condition

10

Industrial Range: –40°C to +85°C

Frequency Order Part Number Package

100 KHz IS24C16-PI 300-mil Plastic DIP

100 KHz IS24C16-GI Small Outline (JEDEC STD)

Integrated Silicon Solution, Inc.

Toll Free: 1-800-379-4774

e-mail: sales@issiusa.com

Integrated Silicon Solution, Inc.

ADVANCE INFORMATION EE001-0C

®

ISSI

2231 Lawson Lane

Santa Clara, CA 95054

Fax: (408) 588-0806

http://www.issiusa.com

10/03/97

Loading...

Loading...