Page 1

SEMICONDUCTOR

4-252

August 1996

82C59A

CMOS Priority Interrupt Controller

Features

• 12.5MHz, 8MHz and 5MHz Versions Available

- 12.5MHz Operation. . . . . . . . . . . . . . . . . . .82C59A-12

- 8MHz Operation . . . . . . . . . . . . . . . . . . . . . . . 82C59A

- 5MHz Operation . . . . . . . . . . . . . . . . . . . . . .82C59A-5

• High Speed, “No Wait-State” Operation with 12.5MHz

80C286 and 8MHz 80C86/88

• Pin Compatible with NMOS 8259A

• 80C86/88/286 and 8080/85/86/88/286 Compatible

• Eight-Level Priority Controller, Expandable to

64 Levels

• Programmable Interrupt Modes

• Individual Request Mask Capability

• Fully Static Design

• Fully TTL Compatible

• Low Power Operation

- ICCSB . . . . . . . . . . . . . . . . . . . . . . . . . 10µA Maximum

- ICCOP . . . . . . . . . . . . . . . . . . . . . 1mA/MHz Maximum

• Single 5V Power Supply

• Operating Temperature Ranges

- C82C59A . . . . . . . . . . . . . . . . . . . . . . . . .0

o

C to +70oC

- I82C59A. . . . . . . . . . . . . . . . . . . . . . . . -40

o

C to +85oC

- M82C59A. . . . . . . . . . . . . . . . . . . . . . -55

o

C to +125oC

Description

The Harris 82C59A is a high performance CMOS Priority

Interrupt Controller manufactured using an advanced 2µm

CMOS process. The 82C59A is designed to relieve the system CPU from the task of polling in a multilevel

priority system. The high speed and industry standard

configuration of the 82C59A make it compatible with microprocessors such as 80C286, 80286, 80C86/88, 8086/88,

8080/85 and NSC800.

The 82C59A can handle up to eight vectored priority interrupting sources and is cascadable to 64 without additional

circuitry. Individual interrupting sources can be masked or

prioritized to allow custom system configuration. Two modes

of operation make the 82C59A compatible with both 8080/85

and 80C86/88/286 formats.

Static CMOS circuit design ensures low operating power.

The Harris advanced CMOS process results in performance

equal to or greater than existing equivalent products at a

fraction of the power.

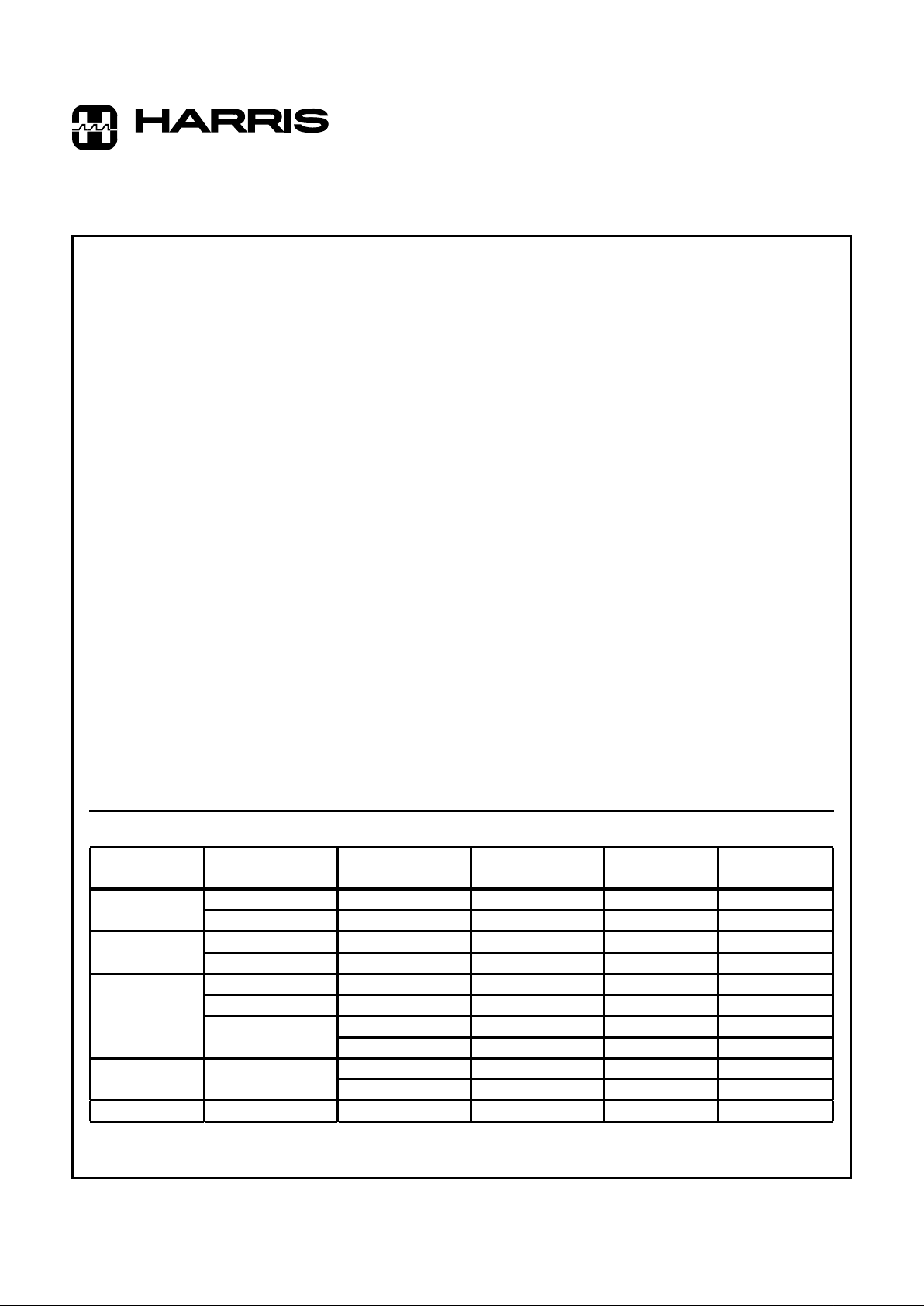

Ordering Information

PACKAGE

TEMPERATURE

RANGE 5MHz 8MHz 12.5MHz PKG. NO.

Plastic DIP 0oC to +70oC CP82C59A-5 CP82C59A CP82C59A-12 E28.6

-40oC to +85oC IP82C59A-5 IP82C59A IP82C59A-12 E28.6

PLCC 0oC to +70oC CS82C59A-5 CS82C59A CS82C59A-12 N28.45

-40oC to +85oC IS82C59A-5 IS82C59A IS82C59A-12 N28.45

CERDIP 0oC to +70oC CD82C59A-5 CD82C59A CD82C59A-12 F28.6

-40oC to +85oC ID82C59A-5 ID82C59A ID82C59A-12 F28.6

-55oC to +125oC MD82C59A-5/B MD82C59A/B MD82C59A-12/B F28.6

SMD# 5962-8501601YA 5962-8501602YA - F28.6

LCC -55oC to +125oC MR82C59A-5/B MR82C59A/B MR82C59A-12/B J28.A

SMD# 5962-85016013A 5962-85016023A - J28.A

SOIC 0oC to +70oC CM82C59A-5 CM82C59A CM82C59A-12 M28.3

CAUTION: These devices are sensitive to electrostatic discharge. Users should follow proper IC Handling Procedures.

Copyright

© Harris Corporation 1996

File Number 2784.2

Page 2

4-253

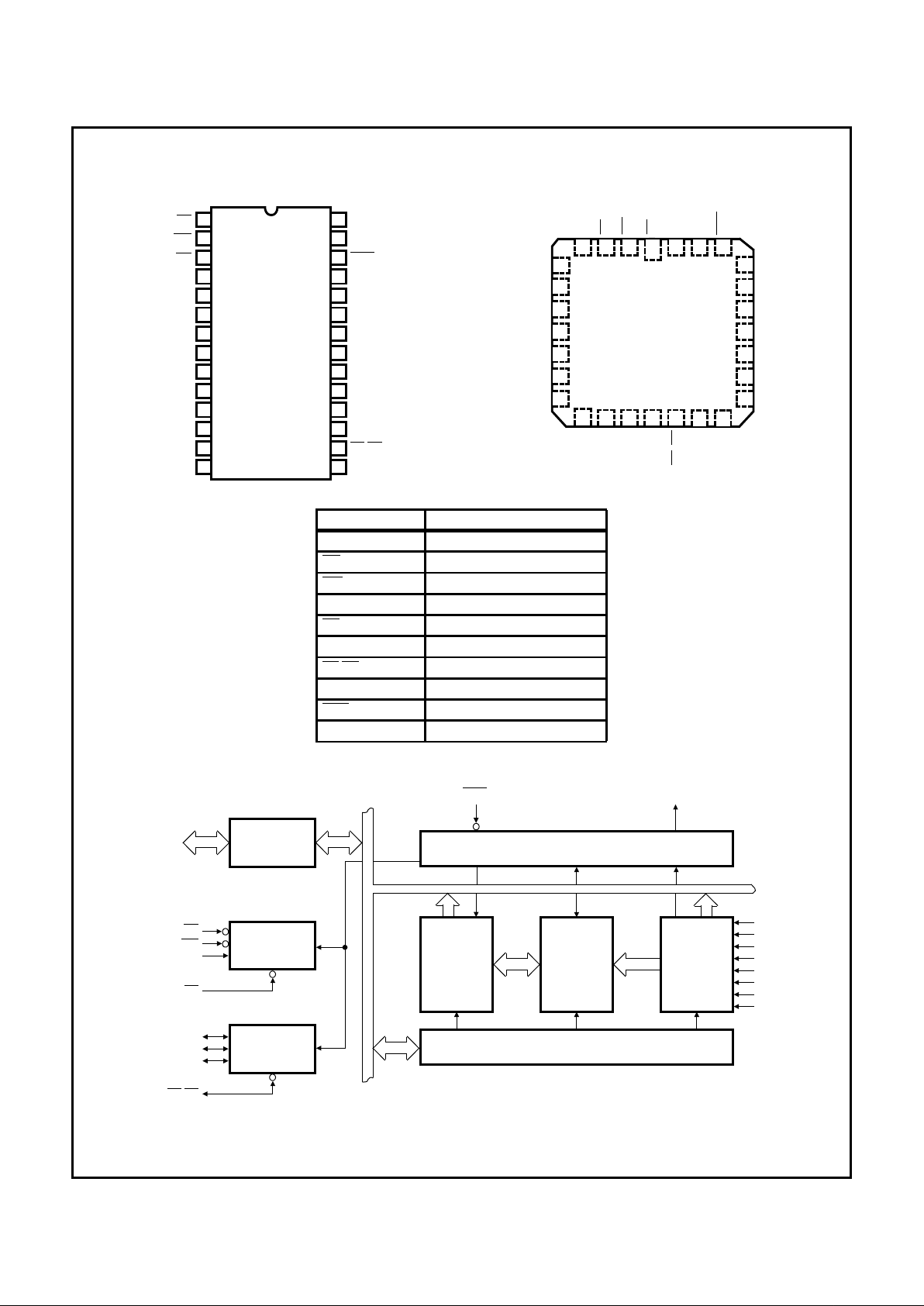

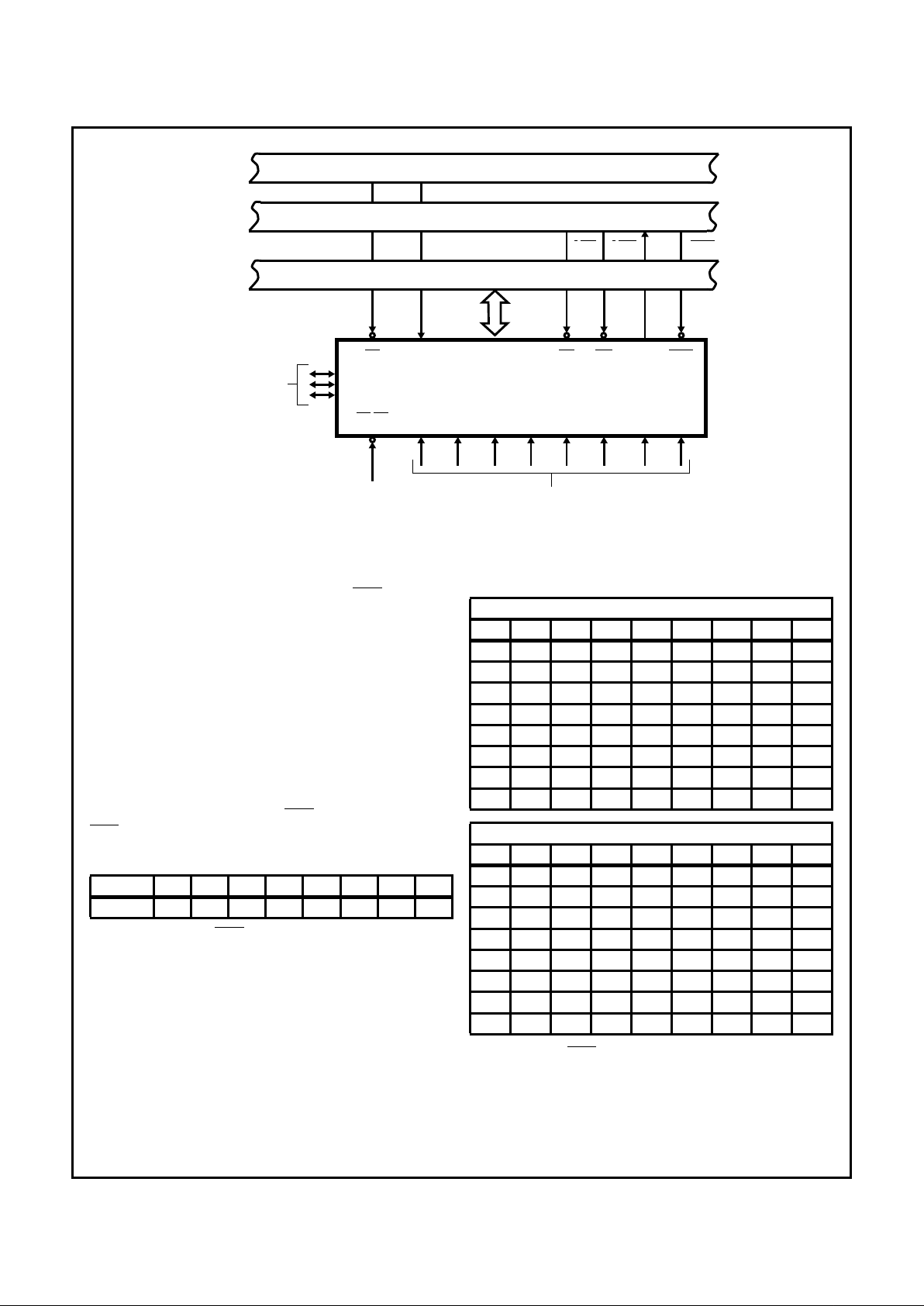

Functional Diagram

Pinouts

28 LEAD DIP

TOP VIEW

28 LEAD LCC

TOP VIEW

PIN DESCRIPTION

D7 - D0 Data Bus (Bidirectional)

RD Read Input

WR Write Input

A0 Command Select Address

CS Chip Select

CAS 2 - CAS 0 Cascade Lines

SP/EN Slave Program Input Enable

INT Interrupt Output

INTA Interrupt Acknowledge Input

IR0 - IR7 Interrupt Request Inputs

CS

WR

RD

D7

D6

D5

D4

D3

D2

D1

D0

CAS 0

CAS 1

GND

V

CC

INTA

IR7

IR6

IR5

IR3

IR1

IR0

INT

SP/EN

CAS 2

A0

IR4

IR2

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

23

24

25

22

21

20

19

11

3 2

1

4

14 15 16 17 18

12

13

28 27 26

10

5

6

7

8

9

D7

V

CC

A0

RD

WR

CS

INTA

D6

D5

D4

D3

D2

D1

D0

IR7

IR6

IR5

IR4

IR3

IR2

IR1

CAS 0

IR0

CAS 1

GND

CAS 2

SP/ EN

INT

PRIORITY

RESOLVER

IR0

IR1

IR2

IR3

IR4

IR5

IR6

IR7

INTERRUPT

REQUEST

REG

(IRR)

INTERRUPT MASK REG

(IMR)

CONTROL LOGIC

INTERNAL BUS

INT

DATA

BUS

BUFFER

CASCADE

BUFFER

COMPARATOR

CAS 0

CAS 1

CAS 2

READ/

WRITE

LOGIC

SP/EN

WR

RD

INTA

IN -

SERVICE

REG

(ISR)

CS

D

7-D0

A

0

FIGURE 1.

82C59A

Page 3

4-254

Functional Description

Interrupts in Microcomputer Systems

Microcomputer system design requires that I/O devices such

as keyboards, displays, sensors and other components

receive servicing in an efficient manner so that large

amounts of the total system tasks can be assumed by the

microcomputer with little or no effect on throughput.

The most common method of servicing such devices is the

Polled approach. This is where the processor must test each

device in sequence and in effect “ask” each one if it needs

servicing. It is easy to see that a large portion of the main

program is looping through this continuous polling cycle and

that such a method would have a serious, detrimental effect

on system throughput, thus, limiting the tasks that could be

assumed by the microcomputer and reducing the cost effectiveness of using such devices.

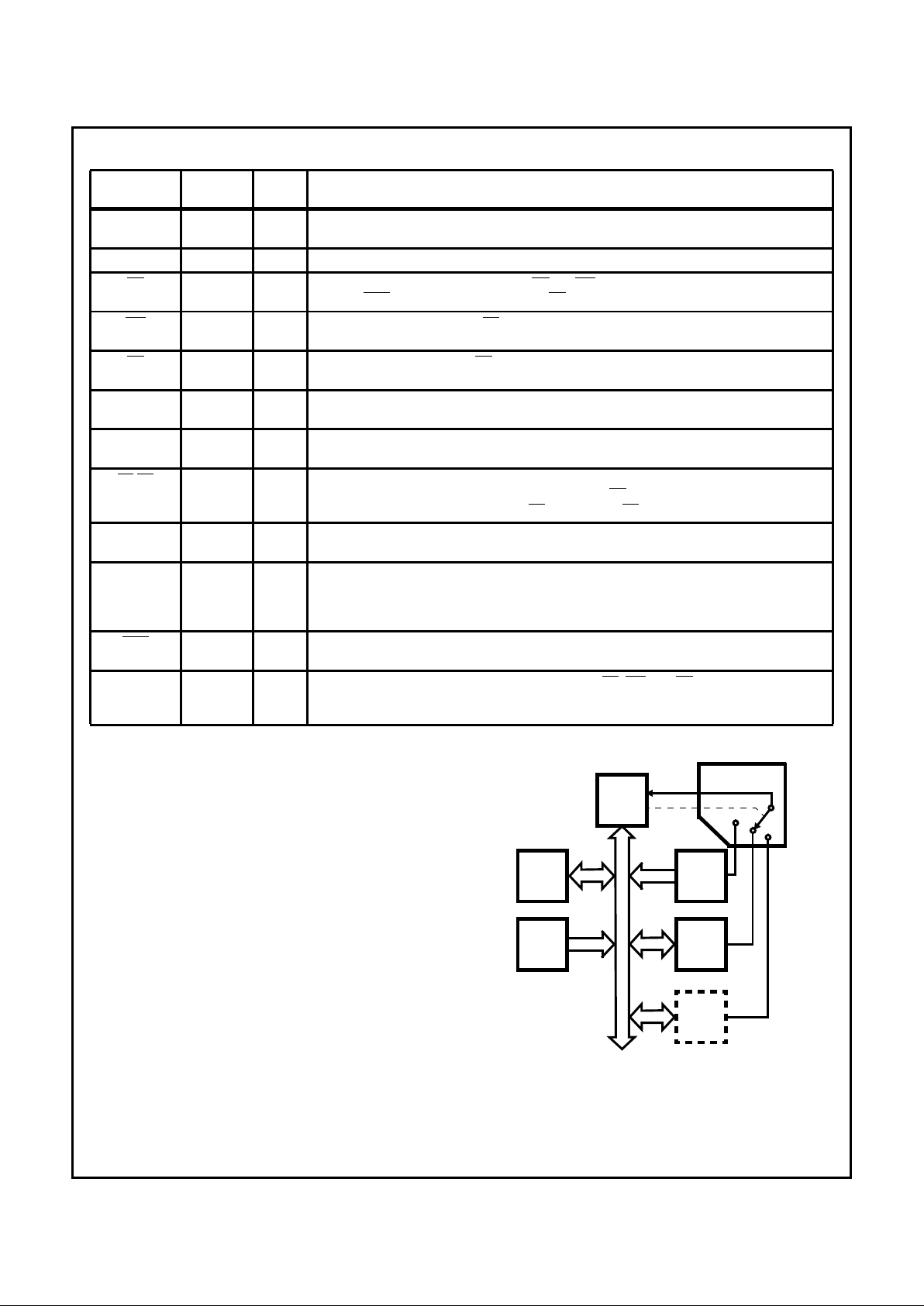

Pin Description

SYMBOL

PIN

NUMBER TYPE DESCRIPTION

V

CC

28 I VCC: The +5V power supply pin. A 0.1µF capacitor between pins 28 and 14 is recommended for

decoupling.

GND 14 I GROUND

CS 1 I CHIP SELECT: A low on this pin enablesRD and WR communications between the CPU and the

82C59A. INT A functions are independent ofCS.

WR 2 I WRITE: A low on this pin when CS is low enables the 82C59A to accept command words from

the CPU.

RD 3 I READ: A low on this pin when CS is low enables the 82C59A to release status onto the data bus

for the CPU.

D7 - D0 4 - 11 I/O BIDIRECTIONAL DATA BUS: Control, status, and interrupt-vector information is transferred via

this bus.

CAS0 - CAS2 12, 13, 15 I/O CASCADE LINES: The CAS lines form a private 82C59A bus to control a multiple 82C59A struc-

ture. These pins are outputs for a master 82C59A and inputs for a slave 82C59A.

SP/EN 16 I/O SLAVE PROGRAM/ENABLE BUFFER: This is a dual function pin. When in the Buffered Mode it

can be used as an output to control buffer transceivers (EN). When not in the Buffered Mode it is

used as an input to designate a master (SP = 1) or slave (SP = 0).

INT 17 O INTERRUPT: This pin goes high whenever a valid interrupt request is asserted. It is used to inter-

rupt the CPU, thus, it is connected to the CPU's interrupt pin.

IR0 - IR7 18 - 25 I INTERRUPT REQUESTS: Asynchronous inputs. An interrupt request is executed by raising an

IR input (low to high), and holding it high until it is acknowledged (Edge Triggered Mode), or just

by a high level on an IR input (Level Triggered Mode). Internal pull-up resistors are implemented

on IR0 - 7.

INTA 26 I INTERRUPT ACKNOWLEDGE: This pin is used to enable 82C59A interrupt-vector data onto the

data bus by a sequence of interrupt acknowledge pulses issued by the CPU.

A0 27 I ADDRESS LINE: This pin acts in conjunction with the CS, WR, and RD pins. It is used by the

82C59A to decipher various Command Words the CPU writes and status the CPU wishes to read.

It is typically connected to the CPU A0 address line (A1 for 80C86/88/286).

ROM

I/O (N)

I/O (2)

I/O (1)RAM

CPU

CPU - DRIVEN

MULTIPLEXER

FIGURE 2. POLLED METHOD

82C59A

Page 4

4-255

A more desirable method would be one that would allow the

microprocessor to be executing its main program and only

stop to service peripheral devices when it is told to do so by

the device itself. In effect, the method would provide an

external asynchronous input that would inform the processor

that it should complete whatever instruction that is currently

being executed and fetch a new routine that will service the

requesting device. Once this servicing is complete, however,

the processor would resume exactly where it left off.

This is the Interrupt-driven method. It is easy to see that system throughput would drastically increase, and thus, more

tasks could be assumed by the microcomputer to further

enhance its cost effectiveness.

The Programmable Interrupt Controller (PlC) functions as an

overall manager in an Interrupt-Driven system. It accepts

requests from the peripheral equipment, determines which

of the incoming requests is of the highest importance (priority), ascertains whether the incoming request has a higher

priority value than the level currently being serviced, and

issues an interrupt to the CPU based on this determination.

Each peripheral device or structure usually has a special

program or “routine” that is associated with its specific functional or operational requirements; this is referred to as a

“service routine”. The PlC, after issuing an interrupt to the

CPU, must somehow input information into the CPU that can

“point” the Program Counter to the service routine associated with the requesting device. This “pointer” is an address

in a vectoring table and will often be referred to, in this document, as vectoring data.

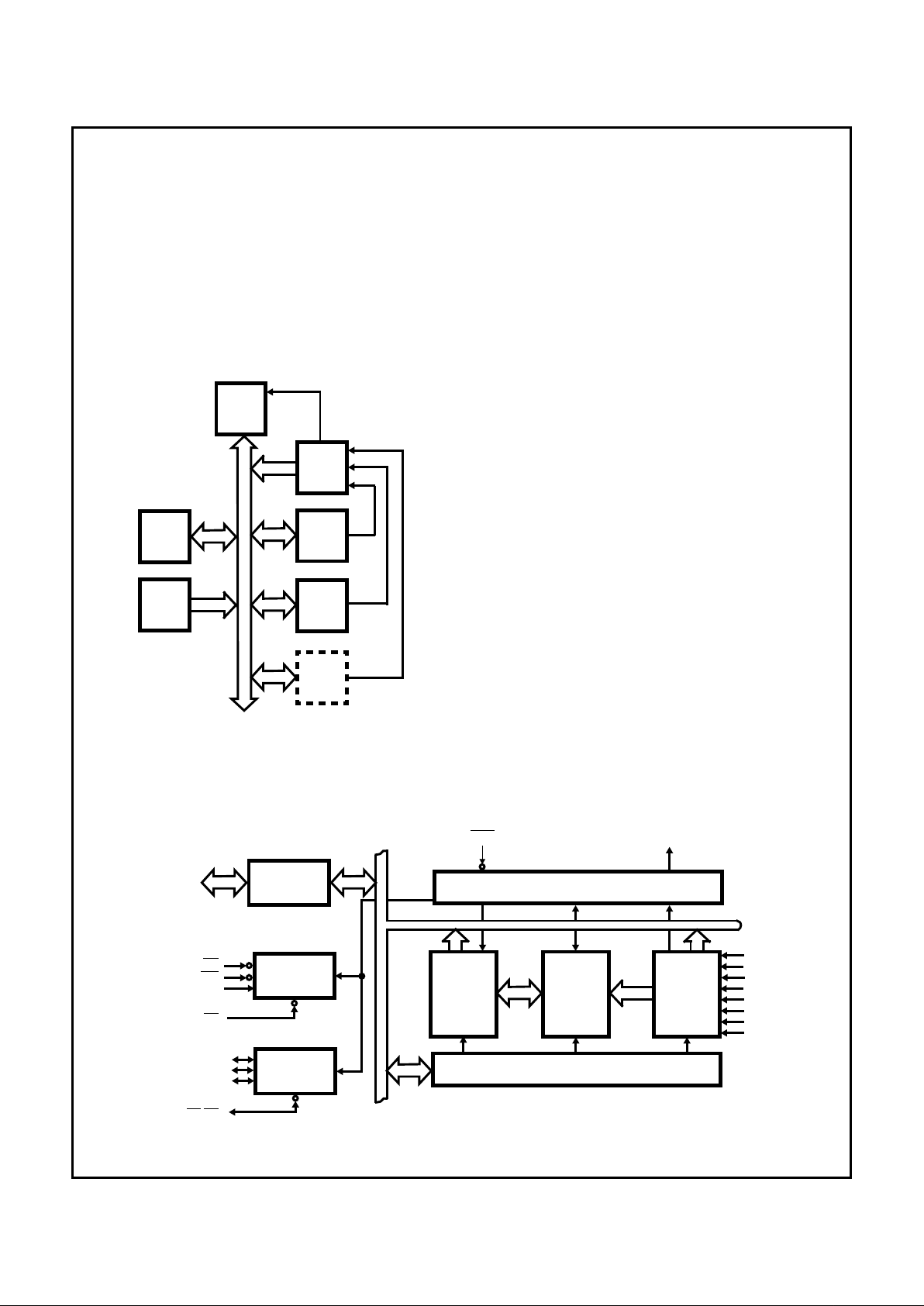

82C59A Functional Description

The 82C59A is a device specifically designed for use in real

time, interrupt driven microcomputer systems. It manages

eight levels of requests and has built-in features for expandability to other 82C59As (up to 64 levels). It is programmed

by system software as an I/O peripheral. A selection of priority modes is available to the programmer so that the manner

in which the requests are processed by the 82C59A can be

configured to match system requirements. The priority

modes can be changed or reconfigured dynamically at any

time during main program operation. This means that the

complete interrupt structure can be defined as required,

based on the total system environment.

Interrupt Request Register (IRR) and In-Service Register

(ISR)

The interrupts at the IR input lines are handled by two registers

in cascade, the Interrupt Request Register (lRR) and the InService Register (lSR). The IRR is used to indicate all the interrupt levels which are requesting service, and the ISR is used to

store all the interrupt levels which are currently being serviced.

ROM

I/O (2)

RAM

CPU

INT

I/O (1)

I/O (N)

PIC

FIGURE 3. INTERRUPT METHOD

IR0

IR1

IR2

CASCADE

BUFFER

COMPARATOR

READ/

WRITE

LOGIC

DAT A

BUS

BUFFER

IN

SERVICE

REG

(ISR)

PRIORITY

RESOLVER

INTERRUPT MASK REG

(IMR)

INTERRUPT

REQUEST

REG

(IRR)

CONTROL LOGIC

INT

INTA

IR3

IR4

IR5

IR6

IR7

CAS 0

CAS 1

CAS 2

RD

WR

A

0

SP/EN

CS

D

7

- D

0

INTERNAL BUS

FIGURE 4. 82C59A FUNCTIONAL DIAGRAM

82C59A

Page 5

4-256

Priority Resolver

This logic block determines the priorities of the bits set in the

lRR. The highest priority is selected and strobed into the corresponding bit of the lSR during the INTA sequence.

Interrupt Mask Register (IMR)

The lMR stores the bits which disable the interrupt lines to

be masked. The IMR operates on the output of the IRR.

Masking of a higher priority input will not affect the interrupt

request lines of lower priority.

Interrupt (INT)

This output goes directly to the CPU interrupt input. The

VOH level on this line is designed to be fully compatible with

the 8080, 8085, 8086/88, 80C86/88, 80286, and 80C286

input levels.

Interrupt Acknowledge (

INTA)

INTA pulses will cause the 82C59A to release vectoring

information onto the data bus. The format of this data

depends on the system mode (µPM) of the 82C59A.

Data Bus Buffer

This 3-state, bidirectional 8-bit buffer is used to interface the

82C59A to the System Data Bus. Control words and status

information are transferred through the Data Bus Buffer.

Read/Write Control Logic

The function of this block is to accept output commands from

the CPU. It contains the Initialization Command Word (lCW)

registers and Operation Command Word (OCW) registers

which store the various control formats for device operation.

This function block also allows the status of the 82C59A to

be transferred onto the Data Bus.

Chip Select (

CS)

A LOW on this input enables the 82C59A. No reading or

writing of the device will occur unless the device is selected.

Write (

WR)

A LOW on this input enables the CPU to write control words

(lCWs and OCWs) to the 82C59A.

Read (

RD)

A LOW on this input enables the 82C59A to send the status

of the Interrupt Request Register (lRR), In-Service Register

(lSR), the Interrupt Mask Register (lMR), or the interrupt

level (in the poll mode) onto the Data Bus.

A0

This input signal is used in conjunction with

WR and RD signals to write commands into the various command registers,

as well as to read the various status registers of the chip.

This line can be tied directly to one of the system address

lines.

The Cascade Buffer/Comparator

This function block stores and compares the IDs of all

82C59As used in the system. The associated three I/O pins

(CAS0 - 2) are outputs when the 82C59A is used as a master and are inputs when the 82C59A is used as a slave. As a

master, the 82C59A sends the ID of the interrupting slave

device onto the CAS0 - 2 lines. The slave, thus selected will

send its preprogrammed subroutine address onto the Data

Bus during the next one or two consecutive

INTA pulses.

(See section “Cascading the 82C59A”.)

Interrupt Sequence

The powerful features of the 82C59A in a microcomputer

system are its programmability and the interrupt routine

addressing capability. The latter allows direct or indirect

jumping to the specified interrupt routine requested without

any polling of the interrupting devices. The normal sequence

of events during an interrupt depends on the type of CPU

being used.

These events occur in an 8080/8085 system:

1. One or more of the INTERRUPT REQUEST lines

(IR0 - IR7) are raised high, setting the corresponding IRR

bit(s).

2. The 82C59A evaluates those requests in the priority

resolver and sends an interrupt (INT) to the CPU, if

appropriate.

3. The CPU acknowledges the lNT and responds with an

INTA pulse.

4. Upon receiving an

lNTA from the CPU group, the highest

priority lSR bit is set, and the corresponding lRR bit is

reset. The 82C59A will also release a CALL instruction

code (11001101) onto the 8-bit data bus through D0 - D7.

5. This CALL instruction will initiate two additional

INTA

pulses to be sent to 82C59A from the CPU group.

6. These two

INTA pulses allow the 82C59A to release its

preprogrammed subroutine address onto the data bus.

The lower 8-bit address is released at the first

INTA pulse

and the higher 8-bit address is released at the second

INTA pulse.

7. This completes the 3-byte CALL instruction released by

the 82C59A. In the AEOI mode, the lSR bit is reset at the

end of the third

INTA pulse. Otherwise, the lSR bit

remains set until an appropriate EOI command is issued

at the end of the interrupt sequence.

The events occurring in an 80C86/88/286 system are the

same until step 4.

4. The 82C59A does not drive the data bus during the first

INTA pulse.

5. The 80C86/88/286 CPU will initiate a second

INTA pulse.

During this

INTA pulse, the appropriate ISR bit is set and

the corresponding bit in the IRR is reset. The 82C59A

outputs the 8-bit pointer onto the data bus to be read by

the CPU.

82C59A

Page 6

4-257

6. This completes the interrupt cycle. In the AEOI mode, the

ISR bit is reset at the end of the second

INTA pulse. Otherwise, the ISR bit remains set until an appropriate EOI

command is issued at the end of the interrupt subroutine.

If no interrupt request is present at step 4 of either sequence

(i.e., the request was too short in duration), the 82C59A will

issue an interrupt level 7. If a slave is programmed on IR bit

7, the CAS lines remain inactive and vector addresses are

output from the master 82CS9A.

Interrupt Sequence Outputs

8080, 8085 Interrupt Response Mode

This sequence is timed by three

INTA pulses. During the first

lNTA pulse, the CALL opcode is enabled onto the data bus.

First Interrupt Vector Byte Data: Hex CD

During the second

INTA pulse, the lower address of the

appropriate service routine is enabled onto the data bus.

When interval = 4 bits, A5 - A7 are programmed, while

A0 - A4 are automatically inserted by the 82C59A. When

interval = 8, only A6 and A7 are programmed, while A0 - A5

are automatically inserted.

During the third

INTA pulse, the higher address of the appropriate service routine, which was programmed as byte 2 of the

initialization sequence (A8 - A15), is enabled onto the bus.

D7 D6 D5 D4 D3 D2 D1 D0

Call Code 11001101

ADDRESS BUS (16)

CONTROL BUS

DATA BUS (8)

I/OR I/OW INT INTA

CASCADE

LINES

CAS 0

CAS 1

CAS 2

SP/EN

CS RD WR INTAINTD7 - D

0

A

0

SLAVE PROGRAM/

ENABLE BUFFER

INTERRUPT

REQUESTS

82C59A

IRQ IRQ IRQ IRQ IRQ IRQ IRQ IRQ

7

6

5

4

3

2

1

0

FIGURE 5. 82C59A STANDARD SYSTEM BUS INTERFACE

CONTENT OF SECOND INTERRUPT VECTOR BYTE

IR Interval = 4

D7 D6 D5 D4 D3 D2 D1 D0

7A7A6A511100

6A7A6A511000

5A7A6A510100

4A7A6A510000

3A7A6A501100

2A7A6A501000

1A7A6A500100

0A7A6A500000

IR Interval = 8

D7 D6 DS D4 D3 D2 Dl DO

7A7A6111000

6A7A6110000

5A7A6101000

4A7A6100000

3A7A6011000

2A7A6010000

1A7A6001000

0A7A6000000

82C59A

Page 7

4-258

80C86, 8OC88, 80C286 Interrupt Response Mode

80C86/88/286 mode is similar to 8080/85 mode except that

only two Interrupt Acknowledge cycles are issued by the processor and no CALL opcode is sent to the processor. The

first interrupt acknowledge cycle is similar to that of 8080/85

systems in that the 82C59A uses it to internally freeze the

state of the interrupts for priority resolution and, as a master,

it issues the interrupt code on the cascade lines. On this first

cycle, it does not issue any data to the processor and leaves

its data bus buffers disabled. On the second interrupt

acknowledge cycle in the 86/88/286 mode, the master (or

slave if so programmed) will send a byte of data to the processor with the acknowledged interrupt code composed as

follows (note the state of the ADI mode control is ignored

and A5 - A11 are unused in the 86/88/286 mode).

Programming the 82C59A

The 82C59A accepts two types of command words generated by the CPU:

1. Initialization Command Words (ICWs): Before normal

operation can begin, each 82C59A in the system must be

brought to a starting point - by a sequence of 2 to 4 bytes

timed by

WR pulses.

2. Operation Command Words (OCWs): These are the

command words which command the 82C59A to operate

in various interrupt modes. Among these modes are:

a. Fully nested mode.

b. Rotating priority mode.

c. Special mask mode.

d. Polled mode.

The OCWs can be written into the 82C59A anytime after initialization.

Initialization Command Words (lCWs)

General

Whenever a command is issued with A0 = 0 and D4 = 1, this

is interpreted as Initialization Command Word 1 (lCW1).

lCW1 starts the initialization sequence during which the following automatically occur:

a. The edge sense circuit is reset, which means that follow-

ing initialization, an interrupt request (IR) input must make

a low-to-high transition to generate an interrupt.

b. The Interrupt Mask Register is cleared.

c. lR7 input is assigned priority 7.

d. Special Mask Mode is cleared and Status Read is set to

lRR.

e. If lC4 = 0, then all functions selected in lCW4 are set to

zero. (Non-Buffered mode (see note), no Auto-EOI,

8080/85 system).

NOTE: Master/Slave in ICW4 is only used in the buffered mode.

Initialization Command Words 1 and 2 (ICW1, lCW2)

A5 - A15: Page starting address of service routines. In an

8080/85 system the 8 request levels will generate CALLS to

8 locations equally spaced in memory. These can be programmed to be spaced at intervals of 4 or 8 memory locations, thus, the 8 routines will occupy a page of 32 or 64

bytes, respectively.

CONTENT OF THIRD INTERRUPT VECTOR BYTE

D7 D6 D5 D4 D3 D2 D1 D0

A15 A14 A13 A12 A11 A10 A9 A8

CONTENT OF INTERRUPT VECTOR BYTE FOR

80C86/88/286 SYSTEM MODE

D7 D6 D5 D4 D3 D2 D1 D0

lR7 T7 T6 T5 T4 T3 1 1 1

lR6 T7 T6 T5 T4 T3 1 1 0

IR5 T7 T6 T5 T4 T3 1 0 1

IR4 T7 T6 T5 T4 T3 1 0 0

IR3 T7 T6 T5 T4 T3 0 1 1

IR2 T7 T6 T5 T4 T3 0 1 0

IR1 T7 T6 T5 T4 T3 0 0 1

IR0 T7 T6 T5 T4 T3 0 0 0

ICW1

ICW2

IN

CASCADE

MODE

ICW3

IS ICW4

NEEDED

ICW4

READY TO ACCEPT

INTERRUPT REQUESTS

NO (SNGL = 1)

YES (SNGL = 0))

YES (IC4 = 1)

NO (IC4 = 0)

FIGURE 6. 82C59A INITIALIZATION SEQUENCE

82C59A

Page 8

4-259

D

7

A

O

D

6

D

5

D

4

D

3

D

2

D

1

D

0

0

A

7

A

6

A

5

LTIM1 ADI SNGL IC4

ICW1

1 = ICWR needed

0 = No ICW4 needed

1 = Single

0 = Cascade Mode

CALL address interval

1 = Interval of 4

0 = Interval of 8

1 = Level triggered mode

0 = Edge triggered mode

A

7

- A5 of Interrupt vector address

(MCS-80/85 mode only)

D

7

A

O

D

6

D

5

D

4

D

3

D

2

D

1

D

0

1

A

15

A

14

A

13

A

11

A

10

A

9

A

8

A

12

T

7

T

6

T

5

T

4

T

3

ICW2

A15 - A8 of interrupt vector address

(MCS80/85 mode)

T

7

- T3 of interrupt vector address

(8086/8088 mode)

D

7

A

O

D

6

D

5

D

4

D

3

D

2

D

1

D

0

1S

7

S

6

S

5

S

3

S

2

S

1

S

0

S

4

ICW3 (MASTER DEVICE)

1 = IR input has a slave

0 = IR input does not have a slave

D

7

A

O

D

6

D

5

D

4

D

3

D

2

D

1

D

0

1000 0ID

2ID1

ID

0

0

ICW3 (SLAVE DEVICE)

SLAVE ID (NOTE 1)

01 5234 67

01 1010 01

00 0110 11

00 1001 11

D

7

A

0

D6D

5

D4D

3

D2D1D

0

1 0 0 0 BUF M/S AEOI µPMSFNM

ICW4

1 = 8086/8088 mode

0 = MCS-80/85 mode

1 = Auto EOI

0 = Normal EOI

0

1

11

0

X- Non buffered mode

- Buffered mode slave

- Buffered mode master

1 = Special fully nested moded

0 = Not special fully nested mode

FIGURE 7. 82C59A INITIALIZATION COMMAND WORD FORMAT

NOTE: Slave ID is equal to the corresponding master IR input.

82C59A

Page 9

4-260

The address format is 2 bytes long (A0 - A15). When the

routine interval is 4, A0 - A4 are automatically inserted by

the 82C59A, while A5 - A15 are programmed externally.

When the routine interval is 8, A0 - A5 are automatically

inserted by the 82C59A while A6 - A15 are programmed

externally.

The 8-byte interval will maintain compatibility with current

software, while the 4-byte interval is best for a compact jump

table.

In an 80C86/88/286 system, A15 - A11 are inserted in the

five most significant bits of the vectoring byte and the

82C59A sets the three least significant bits according to the

interrupt level. A10 - A5 are ignored and ADI (Address interval) has no effect.

LTlM: If LTlM = 1, then the 82C59A will operate in the level

interrupt mode. Edge detect logic on the interrupt

inputs will be disabled.

ADI: ALL address interval. ADI = 1 then interval = 4; ADI

= 0 then interval = 8.

SNGL: Single. Means that this is the only 82C59A in the

system. If SNGL = 1, no ICW3 will be issued.

IC4: If this bit is set - lCW4 has to be issued. If lCW4 is

not needed, set lC4 = 0.

Initialization Command Word 3 (ICW3)

This word is read only when there is more than one 82C59A

in the system and cascading is used, in which case

SNGL = 0. It will load the 8-bit slave register. The functions of

this register are:

a. In the master mode (either when

SP = 1, or in buffered

mode when M/S = 1 in lCW4) a “1” is set for each slav e in

the bit corresponding to the appropriate IR line for the

slave. The master then will release byte 1 of the call

sequence (for 8080/85 system) and will enable the corresponding slave to release bytes 2 and 3 (for 80C86/88/

286, only byte 2) through the cascade lines.

b. In the slave mode (either when SP = 0, or if BUF = 1 and

M/S = 0 in lCW4), bits 2 - 0 identify the slave. The slave

compares its cascade input with these bits and if they are

equal, bytes 2 and 3 of the call sequence (or just byte 2 for

80C86/88/286) are released by it on the Data Bus.

NOTE: (The slave address must correspond to the IR line it is connected to in the master ID).

Initialization Command Word 4 (ICW4)

SFNM: If SFNM = 1, the special fully nested mode is pro-

grammed.

BUF: If BUF = 1, the buffered mode is programmed. In

buffered mode,

SP/EN becomes an enable output

and the master/slave determination is by M/S.

M/S: If buffered mode is selected: M/S = 1 means the

82C59A is programmed to be a master, M/S = 0

means the 82C59A is programmed to be a slave. If

BUF = 0, M/S has no function.

AEOI: If AEOI = 1, the automatic end of interrupt mode is

programmed.

µPM: Microprocessor mode: µPM = 0 sets the 82C59A for

8080/85 system operation, µPM = 1 sets the

82C59A for 80C86/88/286 system operation.

Operation Command Words (OCWs)

After the Initialization Command Words (lCWs) are programmed into the 82C59A, the device is ready to accept

interrupt requests at its input lines. However, during the

82C59A operation, a selection of algorithms can command

the 82C59A to operate in various modes through the Operation Command Words (OCWs).

Operation Control Word 1 (OCW1)

OCW1 sets and clears the mask bits in the Interrupt Mask

Register (lMR) M7 - M0 represent the eight mask bits. M = 1

indicates the channel is masked (inhibited), M = 0 indicates

the channel is enabled.

Operation Control Word 2 (OCW2)

R, SL, EOI - These three bits control the Rotate and End of

Interrupt modes and combinations of the two. A chart of

these combinations can be found on the Operation Command Word Format.

L2, L1, L0 - These bits determine the interrupt level acted

upon when the SL bit is active.

Operation Control Word 3 (OCW3)

ESMM - Enable Special Mask Mode. When this bit is set to 1

it enables the SMM bit to set or reset the Special Mask

Mode. When ESMN = 0, the SMM bit becomes a “don’t

care”.

SMM - Special Mask Mode. If ESMM = 1 and SMM = 1, the

82C59A will enter Special Mask Mode. If ESMM = 1 and

SMM = 0, the 82C59A will revert to normal mask mode.

When ESMM = 0, SMM has no effect.

Fully Nested Mode

This mode is entered after initialization unless another mode

is programmed. The interrupt requests are ordered in priority

from 0 through 7 (0 highest). When an interrupt is acknowledged the highest priority request is determined and its vector placed on the bus. Additionally, a bit of the Interrupt

Service register (ISO - 7) is set. This bit remains set until the

microprocessor issues an End of Interrupt (EOI) command

OPERATION CONTROL WORDS (OCWs)

AD D7 D6 D5 D4 D3 D2 D1 D0

OCW1

1 M7M6M5M4M3M2M1M0

OCW2

0 R SL EOI 0 0 L2 L1 L0

OCW3

0 0 ESSM SMM 0 1 P RR RIS

82C59A

Page 10

4-261

immediately before returning from the service routine, or if

the AEOI (Automatic End of Interrupt) bit is set, until the trailing edge of the last

INTA. While the IS bit is set, all further

interrupts of the same or lower priority are inhibited, while

higher levels will generate an interrupt (which will be

acknowledged only if the microprocessor internal interrupt

enable flip-flop has been re-enabled through software).

After the initialization sequence, IRO has the highest priority

and IR7 the lowest. Priorities can be changed, as will be

explained in the rotating priority mode or via the set priority

command.

D

7

A

O

D

6

D

5

D

4

D

3

D

2

D

1

D

0

1M

7

M

6

M

5

M

3

M

2

M

1

M

0

M

4

OCW1

Interrupt Mask

1 = Mask set

0 = Mask reset

D

7

A

O

D

6

D

5

D

4

D

3

D

2

D

1

D

0

1 R SL EOI 0 L

2

L

1

L

0

0

OCW2

IR LEVEL TO BE

01 5234 67

01 1010 01

00 0110 11

00 1001 11

001

011

101

100

0

1

1

0

0

1

1

10

0

1

0

Non specific EOI command

Specific EOI command

Rotate on non specific EOI command

Rotate in automatic EOI mode (set)

Rotate in automatic EOI mode (clear)

Rotate on specific EOI command

Set priority command

No operation

†

†

†

ACTED UPON

End of interrupt

Automatic rotation

Specific rotation

† L

0

- L2 are used

D

7

A

O

D

6

D

5

D

4

D

3

D

2

D

1

D

0

0 0 ESMM SMM 1 P RR R1S0

OCW3

0011

1100

No Action

Read IR reg on

next RD pulse

Read IS reg on

next

RD pulse

1 = Poll command

0 = No poll command

0011

1100

No Action

Reset special

mask

Set special

mask

READ REGISTER COMMAND

FIGURE 8. 82C59A OPERATION COMMAND WORD FORMAT

SPECIAL MASK MODE

82C59A

Page 11

4-262

End of Interrupt (EOI)

The In-Service (IS) bit can be reset either automatically following the trailing edge of the last in sequence

INTA pulse

(when AEOI bit in lCW1 is set) or by a command word that

must be issued to the 82C59A before returning from a service routine (EOI Command). An EOI command must be

issued twice if servicing a slave in the Cascade mode, once

for the master and once for the corresponding slave.

There are two forms of EOl command: Specific and NonSpecific. When the 82C59A is operated in modes which preserve the fully nested structure, it can determine which IS bit

to reset on EOI. When a Non-Specific command is issued

the 82C59A will automatically reset the highest IS bit of

those that are set, since in the fully nested mode the highest

IS level was necessarily the last level acknowledged and

serviced. A nonspecific EOI can be issued with OCW2

(EOl = 1, SL = 0, R = 0).

When a mode is used which may disturb the fully nested

structure, the 82C59A may no longer be able to determine

the last level acknowledged. In this case a Specific End of

Interrupt must be issued which includes as part of the command the IS level to be reset. A specific EOl can be issued

with OCW2 (EOI = 1, SL = 1, R = 0, and LO - L2 is the binary

level of the IS bit to be reset).

An lRR bit that is masked by an lMR bit will not be cleared by

a nonspecific EOI if the 82C59A is in the Special Mask

Mode.

Automatic End of Interrupt (AEOI) Mode

If AEOI = 1 in lCW4, then the 82C59A will operate in AEOl

mode continuously until reprogrammed by lCW4. In this

mode the 82C59A will automatically perform a nonspecific

EOI operation at the trailing edge of the last interrupt

acknowledge pulse (third pulse in 8080/85, second in

80C86/88/286). Note that from a system standpoint, this

mode should be used only when a nested multilevel interrupt

structure is not required within a single 82C59A.

Automatic Rotation (Equal Priority Devices)

In some applications there are a number of interrupting

devices of equal priority. In this mode a device, after being

serviced, receives the lowest priority, so a device requesting

an interrupt will have to wait, in the worst case until each of 7

other devices are serviced at most once. For example, if the

priority and “in service” status is:

Before Rotate (lR4 the highest priority requiring service)

After Rotate (lR4 was serviced, all other priorities rotated

correspondingly)

There are two ways to accomplish Automatic Rotation using

OCW2, the Rotation on Non-Specific EOI Command (R = 1,

SL = 0, EOI = 1) and the Rotate in Automatic EOI Mode

which is set by (R = 1, SL = 0, EOI = 0) and cleared by

(R = 0, SL = 0, EOl = 0).

Specific Rotation (Specific Priority)

The programmer can change priorities by programming the

lowest priority and thus, fixing all other priorities; i.e., if IR5 is

programmed as the lowest priority device, then IR6 will have

the highest one.

The Set Priority command is issued in OCW2 where: R = 1,

SL = 1, L0 - L2 is the binary priority level code of the lowest

priority device.

Observe that in this mode internal status is updated by software control during OCW2. Howev er, it is independent of the

End of Interrupt (EOI) command (also executed by OCW2).

Priority changes can be executed during an EOI command

by using the Rotate on Specific EOl command in OCW2

(R = 1, SL = 1, EOI = 1, and LO - L2 = IR level to receive lo west priority).

Interrupt Masks

Each Interrupt Request input can be masked individually by

the Interrupt Mask Register (IMR) programmed through

OCW1. Each bit in the lMR masks one interrupt channel if it

is set (1). Bit 0 masks IRO, Bit 1 masks IR1 and so forth.

Masking an IR channel does not affect the operation of other

channels.

Special Mask Mode

Some applications may require an interrupt service routine

to dynamically alter the system priority structure during its

execution under software control. For example, the routine

may wish to inhibit lower priority requests for a portion of its

execution but enable some of them for another portion.

The difficulty here is that if an Interrupt Request is acknowledged and an End of Interrupt command did not reset its IS

bit (i.e., while executing a service routine), the 82C59A

would have inhibited all lower priority requests with no easy

way for the routine to enable them.

That is where the Special Mask Mode comes in. In the Special Mask Mode, when a mask bit is set in OCW1, it inhibits

further interrupts at that level and enables interrupts from all

other levels (lower as well as higher) that are not masked.

Thus, any interrupts may be selectively enabled by loaning

the mask register.

IS7 1S6 IS5 IS4 1S3 IS2 IS1 IS0

“IS” Status 0 1010000

Priority

Status

76543210

lowest highest

IS7 IS6 IS5 IS4 IS3 IS2 IS1 IS0

“IS” Status 01000000

Priority

Status

21076543

highest lowest

82C59A

Page 12

4-263

The special Mask Mode is set by OCW3 where: ESSM = 1,

SMM = 1, and cleared where ESSM = 1, SMM = 0.

Poll Command

In this mode, the INT output is not used or the microprocessor internal Interrupt Enable flip flop is reset, disabling its

interrupt input. Service to devices is achieved by software

using a Poll command.

The Poll command is issued by setting P = 1 in OCW3. The

82C59A treats the next

RD pulse to the 82C59A (i.e., RD =

0,

CS = 0) as an interrupt acknowledge, sets the appropriate

IS bit if there is a request, and reads the priority level. Interrupt is frozen from

WR to RD.

The word enabled onto the data bus during

RD is:

W0 - W2: Binary code of the highest priority level request-

ing service.

I: Equal to a “1” if there is an interrupt.

This mode is useful if there is a routine command common to

several levels so that the

INTA sequence is not needed (saves

ROM space). Another application is to use the poll mode to

expand the number of priority levels to more than 64.

Reading the 82C59A Status

The input status of several internal registers can be read to

update the user information on the system. The following

registers can be read via OCW3 (lRR and ISR) or OCW1

(lMR).

Interrupt Request Register (IRR): 8-bit register which contains the levels requesting an interrupt to be acknowledged.

The highest request level is reset from the lRR when an

interrupt is acknowledged. lRR is not affected by lMR.

In-Service Register (ISR): 8-bit register which contains the

priority levels that are being serviced. The ISR is updated

when an End of Interrupt Command is issued.

Interrupt Mask Register: 8-bit register which contains the

interrupt request lines which are masked.

The lRR can be read when, prior to the

RD pulse, a Read

Register Command is issued with OCW3 (RR = 1, RIS = 0).

The ISR can be read when, prior to the

RD pulse, a Read

Register Command is issued with OCW3 (RR = 1, RIS = 1).

There is no need to write an OCW3 before every status read

operation, as long as the status read corresponds with the

previous one: i.e., the 82C59A “remembers” whether the lRR

or ISR has been previously selected by the OCW3. This is

not true when poll is used. In the poll mode, the 82C59A

D7 D6 D5 D4 D3 D2 D1 D0

1----W2W1W0

EDGE

SENSE

LATCH

LTIM BIT

0 = EDGE

1 = LEVEL

V

CC

IR

8080/85

MODE

80C86/

88/286

MODE

INTA

FREEZE

INTA

FREEZE

FREEZE READ

IRR

WRITE

MASK

READ IMR

READ ISR

MASTER CLEAR

MASK LATCH

REQUEST

LATCH

IN - SERVICE

LATCH

NONMASKED

REQ

CLR

Q

SET

TO OTHER PRIORITY CELLS

PRIORITY

RESOLVER

CONTROL

LOGIC

SET ISR

CLR ISR

ISR BIT

QD

C

CLR

QD

CQ

CLR

SET

Q

NOTES:

1. Master clear active only during ICW1.

2. Freeze is active during INTA and poll sequence only.

3. Truth Table for D-latch.

C D Q Operation

1 D1 D1 Follow

0 X Qn-1 Hold

FIGURE 9. PRIORITY CELL - SIMPLIFIED LOGIC DIAGRAM

82C59A

Page 13

4-264

treats the

RD following a “poll write” operation as an INTA.

After initialization, the 82C59A is set to lRR.

For reading the lMR, no OCW3 is needed. The output data bus

will contain the lMR whenever

RD is active and A0 = 1 (OCW1).

Polling ov errides status read when P = 1, RR = 1 in OCW3.

Edge and Level Triggered Modes

This mode is programmed using bit 3 in lCW1.

If LTlM = “0”, an interrupt request will be recognized by a low to

high transition on an IR input. The IR input can remain high

without generating another interrupt.

If LTIM = “1”, an interrupt request will be recognized by a “high”

level on an IR input, and there is no need f or an edge detection.

The interrupt request must be removed before the EOI command is issued or the CPU interrupt is enabled to prevent a

second interrupt from occurring.

The priority cell diagram shows a conceptual circuit of the level

sensitive and edge sensitive input circuitry of the 82C59A. Be

sure to note that the request latch is a transparent D type latch.

In both the edge and level triggered modes the IR inputs

must remain high until after the falling edge of the first

INTA.

If the IR input goes low before this time a DEFAULT lR7 will

occur when the CPU acknowledges the interrupt. This can

be a useful safeguard for detecting interrupts caused by spurious noise glitches on the IR inputs. To implement this feature the lR7 routine is used for “clean up” simply executing a

return instruction, thus, ignoring the interrupt. If lR7 is

needed for other purposes a default lR7 can still be detected

by reading the ISR. A normal lR7 interrupt will set the corresponding ISR bit, a default IR7 won’t. If a default IR7 routine

occurs during a normal lR7 routine, however, the ISR will

remain set. In this case it is necessary to keep track of

whether or not the IR7 routine was previously entered. If

another lR7 occurs it is a default.

In power sensitive applications, it is advisable to place the

82C59A in the edge-triggered mode with the IR lines normally high. This will minimize the current through the internal

pull-up resistors on the IR pins.

The Special Fully Nested Mode

This mode will be used in the case of a big system where

cascading is used, and the priority has to be conserved

within each slave. In this case the special fully nested mode

will be programmed to the master (using lCW4). This mode

is similar to the normal nested mode with the following

exceptions:

a. When an interrupt request from a cer tain slave is in ser-

vice, this slave is not locked out from the master’s priority

logic and further interrupt requests from higher priority

IRs within the slave will be recognized by the master and

will initiate interrupts to the processor. (In the normal

nested mode a slave is masked out when its request is in

service and no higher requests from the same slave can

be serviced.

b. When exiting the Interrupt Service routine the software

has to check whether the interrupt serviced was the only

one from that slave. This is done by sending a nonspecific

End of Interrupt (EOI) command to the slave and then

reading its In-Service register and checking for zero. If it

is empty, a non-specified EOI can be sent to the master,

too. If not, no EOI should be sent.

Buffered Mode

When the 82C59A is used in a large system where bus driving buffers are required on the data bus and the cascading

mode is used, there exists the problem of enabling buffers

The buffered mode will structure the 82C59A to send an

enable signal on

SP/EN to enable the buffers. In this mode,

whenever the 82C59A’s data bus outputs are enabled, the

SP/EN output becomes active.

LATCH

ARM

(NOTE 1)

EARLIEST IR

CAN BE

REMOVED

LATCH

ARM

(NOTE 1)

8080/85

LATCH

ARM

(NOTE 1)

80C86/88/286

80C86/88/286

8080/85

IR

INT

INTA

NOTE:

1. Edge triggered mode only.

FIGURE 10. IR TRIGGERING TIMING REQUIREMENTS

82C59A

Page 14

4-265

This modification forces the use of software programming to

determine whether the 82C59A is a master or a slave. Bit 3

in ICW4 programs the buffered mode, and bit 2 in lCW4

determines whether it is a master or a slave.

Cascade Mode

The 82C59A can be easily interconnected in a system of

one master with up to eight slaves to handle up to 64 priority

levels.

The master controls the slaves through the 3 line cascade

bus (CAS2 - 0). The cascade bus acts like chip selects to the

slaves during the

INTA sequence.

In a cascade configuration, the slave interrupt outputs (INT)

are connected to the master interrupt request inputs. When

a slave request line is activated and afterwards acknowledged, the master will enable the corresponding slave to

release the device routine address during bytes 2 and 3 of

INTA. (Byte 2 only for 80C86/88/286).

The cascade bus lines are normally low and will contain the

slave address code from the leading edge of the first INTA

pulse to the trailing edge of the last

INTA pulse. Each

82C59A in the system must follow a separate initialization

sequence and can be programmed to work in a different

mode. An EOI command must be issued twice: once for the

master and once for the corresponding slave. Chip select

decoding is required to activate each 82C59A.

NOTE: Auto EOI is supported in the slave mode for the 82C59A.

The cascade lines of the Master 82C59A are activated only

for slave inputs, non-slave inputs leave the cascade line

inactive (low). Therefore, it is necessary to use a slave

address of 0 (zero) only after all other addresses are used.

FIGURE 11. CASCADING THE 82C59A

CS

82C59A

SLAVE A

CAS 0

CAS 1

CAS 2

INTA0D7 - D0INTA

SP/EN 7 56 43210

GND

756 43210

CS

82C59A

SLAVE B

CAS 0

CAS 1

CAS 2

INTA0D7 - D0INTA

SP/EN 7 56 43210

GND

756 43210

CS

MASTER 82C59A

CAS 0

CAS 1

CAS 2

INTA0D7 - D0INTA

SP/EN 7 56 43210

V

CC

75421036

INT REQ

DATA BUS (8)

CONTROL BUS

ADDRESS BUS (16)

INTERRUPT REQUESTS

82C59A

Page 15

4-266

Absolute Maximum Ratings Thermal Information

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+8.0V

Input, Output or I/O Voltage . . . . . . . . . . . . GND-0.5V to VCC+0.5V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class I

Operating Conditions

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . +4.5V to +5.5V

Operating Temperature Range. . . . . . . . . . . . . . . .-55oC to +125oC

Input Low Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0V to +0.8V

Thermal Resistance (Typical) θJA (oC/W) θJC (oC/W)

CERDIP Package . . . . . . . . . . . . . . . . 47.0 10

Ceramic LCC Package . . . . . . . . . . . . 55.0 9.0

Plastic DIP Package . . . . . . . . . . . . . . 55 -

Plastic LCC Package. . . . . . . . . . . . . . 65 -

Plastic SOIC Package. . . . . . . . . . . . . 75 -

Storage Temperature Range. . . . . . . . . . . . . . . . . .-65oC to +150oC

Maximum Junction Temperature Ceramic Package . . . . . . .+175oC

Maximum Junction Temperature Plastic Package. . . . . . . . .+150oC

Maximum Lead Temperature Ceramic Package . . . . . . . . . .+300oC

(Soldering 10s)

Maximum Lead Temperature Plastic Package . . . . . . . . . . .+260oC

(Soldering 10s)

Die Characteristics

Gate Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1250 Gates

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

DC Electrical Specifications V

CC

= +5.0V ±10%, TA = 0oC to +70oC (C82C59A), TA = -40oC to +85oC (I82C59A), TA = -55oC to

+125oC (M82C59A)

SYMBOL PARAMETER MIN MAX UNITS TEST CONDITIONS

V

lH

Logical One Input Voltage 2.0

2.2

-V

V

C82C59A, I82C59A

M82C59A

V

IL

Logical Zero Input Voltage - 0.8 V

V

OH

Output HIGH Voltage 3.0

VCC -0.4

-V

V

I

OH

= -2.5mA

lOH = -100µA

V

OL

Output LOW Voltage - 0.4 V lOL = +2.5mA

II Input Leakage Current -1.0 +1.0 µAVIN = GND or VCC, Pins 1-3, 26-27

IO Output Leakage Current -10.0 +10.0 µAV

OUT

= GND or VCC, Pins 4-13, 15-16

ILIR IR Input Load Current -

-

-200

10

µAµAVIN = 0V

VIN = V

CC

lCCSB Standby Power Supply Current - 10 µAVCC = 5.5V, VIN = VCC or GND Outputs

Open, (Note 1)

ICCOP Operating Power Supply Current - 1 mA/MHz VCC = 5.0V, CLK FREQ = 5MHz, VIN = VCC or GND,

Outputs Open, TA = 25oC, (Note 2)

NOTES:

1. Except for IR0 - lR7 where VIN = VCCor open.

2. ICCOP = 1mA/MHz of peripheral read/write cycle time. (ex: 1.0µs I/O read/write cycle time = 1mA).

Capacitance T

A

= +25oC

SYMBOL PARAMETER TYP UNITS TEST CONDITIONS

CIN Input Capacitance 15 pF FREQ = 1MHz, all measurements reference to

device GND.

COUT Output Capacitance 15 pF

CI/O I/O Capacitance 15 pF

82C59A

Page 16

4-267

AC Electrical Specifications V

CC

= +5.0V ±10%, GND = 0V, TA = 0oC to +70oC (C82C59A), TA -40oC to +85oC (l82C59A),

TA = -55oC to +125oC (M82C59A)

SYMBOL PARAMETER

82C59A-5 82C59A 82C59A-12

UNITS

TEST

CONDITIONSMIN MAX MIN MAX MIN MAX

TIMING REQUIREMENTS

(1) THRL A0/

CS Setup to RD/INTA 10 - 10 - 5 - ns

(2) TRHAX A0/CS Hold after RD/INTA 5-5-0- ns

(3) TRLRH RD/lNTA Pulse Width 235 - 160 - 60 - ns

(4) TAHWL A0/CS Setup to WR 0-000- ns

(5) TWHAX A0/CS Hold after WR 5-5-0- ns

(6) TWLWH WR Pulse Width 165 - 95 - 60 - ns

(7) TDVWH Data Setup to WR 240 - 160 - 70 - ns

(8) TWHDX Data Hold after WR 5-5-0- ns

(9) TJLJH Interrupt Request Width Low 100 - 100 - 40 - ns

(10) TCVlAL Cascade Setup to Second or Third INTA

Slave Only

55 - 40 - 30 - ns

(11) TRHRL EndofRD to next RD, End ofINT A within an

INT A sequence only

160 - 160 - 90 - ns

(12) TWHWL End of WR to next WR 190 - 190 - 60 - ns

(13) TCHCL

(Note 1)

End of Command to next command not

same command type), End of INTA

sequence to next INTA sequence

500 - 400 - 90 - ns

TIMING RESPONSES

(14) TRLDV Data Valid from RD/INTA - 160 - 120 - 40 ns 1

(15) TRHDZ Data Float after RD/INTA 5 100 5 85 5 22 ns 2

(16) TJHlH Interrupt Output Delay - 350 - 300 - 90 ns 1

(17) TlALCV Cascade Valid from First INTA

(Master Only)

- 565 - 360 - 50 ns 1

(18) TRLEL Enable Active from RD or INTA - 125 - 100 - 40 ns 1

(19) TRHEH Enable Inactive from RD or INTA - 60 - 50 - 22 ns 1

(20) TAHDV Data Valid from Stable Address - 210 - 200 - 60 ns 1

(21) TCVDC Cascade Valid to Valid Data - 300 - 200 - 70 ns 1

NOTE:

1. Worst case timing for TCHCL in an actual microprocessor system is typically greater than the values specified for the 82C59A,

(i.e. 8085A = 1.6µs, 8085A -2 = 1µs, 80C86 = 1µs, 80C286 -10 = 131ns, 80C286 -12 = 98ns).

82C59A

Page 17

4-268

AC Test Circuit

AC Testing Input, Output Waveform

TEST CONDITION DEFINITION TABLE

TEST

CONDITION V

1

R

1

R

2

C

1

1 1.7V 523Ω Open 100pF

2VCC1.8kΩ 1.8kΩ 50pF

V

1

R

1

R

2

C

1

(NOTE)

OUTPUT FROM

DEVICE UNDER

TEST

TEST

POINT

NOTE: Includes stray and jig capacitance.

Timing Waveforms

FIGURE 12. WRITE

INPUT

V

IH

+0.4V

V

IL

- 0.4V

1.5V

V

OH

OUTPUT

V

OL

1.5V

NOTE: AC Testing: All input signals must switch between VIL - 0.4V and VIH + 0.4V. Input rise and fall times are driven at 1ns/V.

WR

CS

ADDRESS BUS

A

0

DATA BUS

(7)

TDVWH

(8)

TWHDX

(4)

TAHWL

(5)

TWHAX

(6)

TWLWH

82C59A

Page 18

4-269

FIGURE 13. READ/INTA

FIGURE 14. OTHER TIMING

NOTES:

1. Interrupt Request (IR) must remain HIGH until leading edge of first

INTA.

2. During first INTA the Data Bus is not active in 80C86/88/286 mode.

3. 80C86/88/286.

4. 8080/8085 mode.

FIGURE 15. INTA SEQUENCE

Timing Waveforms

(Continued)

RD/INTA

EN

CS

ADDRESS BUS

DATA BUS

(20)

TAHDV

(14)

TRLDV

(1)

TAHRL

(18)

TRLEL

(3)

TRLRH

(19)

TRHEH

(2)

TRHAX

(15)

TRHDZ

A

0

(11)

TRHRL

(12)

TWHWL

(13)

TCHCL

RD

INTA

WR

RD

INTA

WR

RD

INTA

WR

IR

(9)

TJLJH

INT

INTA

SEE NOTE 1

DB

CAS 0 - 2

TCVIAL

(10)

SEE

NOTE 2

(17)

TIALCV

(21)

TCVDV

(10)

TCVIAL

SEE NOTE 3 SEE NOTE 4

(16)

TJHIH

82C59A

Page 19

4-270

Burn-In Circuits

MD82C59A CERDIP

MR82C59A CERAMIC LCC

R1

R1

R1

R1

R1

R1

R1

R1

R1

R1

R1

R3

R3

V

CC

R1

R2

R2

R2

R2

R2

R2

R3

R3

R1

R2

R2

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

C1

INTA

IR7

IR6

IR5

IR3

IR1

IR0

A

SP/EN

CAS 2

A0

IR4

IR2

WR

RD

D7

D6

D4

D2

D1

D0

CAS 0

CAS 1

GND

D5

D3

GND

V

CC

A

R3

R3

23

24

25

22

21

20

19

11

3 2 14

14 15 16 17 1812 13

28 27 26

10

5

6

7

8

9

CAS0

CAS1

GND

CAS2

SP/EN

IR0

V

CC

/2

R2

R2

R2

R2

R2

R2

R2

IR6

IR5

IR4

IR1

IR7

IR3

IR2

R1

R1

R1

R1

R1

R1

R1

D5

D4

D3

D0

D6

D2

D1

R1 R1 R1 R1 R4 R2

R1 R1 R1R1 R1 R1

D7 RD WR GND A0 INTA

VCCC1

NOTES:

1. VCC = 5.5V ±0.5V.

2. VIH = 4.5V ±10%.

3. VIL = -0.2V to 0.4V.

4. GND = 0V.

5. R1 = 47kΩ±5%.

6. R2 = 510Ω±5%.

7. R3 = 10Ω±5%.

8. R4 = 1.2kΩ±5%.

9. C1 = 0.01µF min.

10. F0 = 100kHz ±10%.

11. F1 = F0/2, F2 = F1/2, ...F8 = F7/2.

82C59A

Page 20

4-271

All Harris Semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Harris Semiconductor products are sold by description only. Harris Semiconductor reserves the right to make changes in circuit design and/or specifications at

any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Harris is

believed to be accurate and reliable. However, no responsibility is assumed by Harris or its subsidiaries for its use; nor for any infringements of patents or other

rights of third parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Harris or its subsidiaries.

Sales Office Headquarters

For general information regarding Harris Semiconductor and its products, call 1-800-4-HARRIS

NORTH AMERICA

Harris Semiconductor

P. O. Box 883, Mail Stop 53-210

Melbourne, FL 32902

TEL: 1-800-442-7747

(407) 729-4984

FAX: (407) 729-5321

EUROPE

Harris Semiconductor

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Harris Semiconductor PTE Ltd.

No. 1 Tannery Road

Cencon 1, #09-01

Singapore 1334

TEL: (65) 748-4200

FAX: (65) 748-0400

SEMICONDUCTOR

Die Characteristics

DIE DIMENSIONS: 143 x 130 x 19 ±1mils

METALLIZATION:

Type: Si-Al-Cu

Thickness: Metal 1: 8k

Å ± 0.75kÅ

Metal 2: 12kÅ ± 1.0kÅ

GLASSIVATION:

Type: Nitrox

Thickness: 108k

Å ± 3.0kÅ

Metallization Mask Layout

82C59A

D7

RD

WR

CS

V

CC

INTA

CAS0

CAS1

GND

CAS2

SP/EN

INT

D0 D1 D2 D3

D4 D5

IR1 IR2 IR3 IR4 IR5 IR6

A0

D6

IR0

IR7

82C59A

Loading...

Loading...