Page 1

INT100

N/C

PI-1067-101493

V

DDH

HS RTN

HS RTN

HS OUT

N/C

N/C

V

DD

HS IN

LS IN

COM

LS RTN

LS OUT

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

HS RTN

COM

N/C

Half-Bridge Driver IC

Low-Side and High-side Drive

with Simultaneous Conduction Lockout

Product Highlights

5 V CMOS Compatible Control Inputs

• Combines logic inputs for low and high-side drives

• Schmidt-triggered inputs for noise immunity

HV

®

Built-in High-voltage Level Shifters

• Can withstand up to 800 V for direct interface to the HVreferenced high-side switch

• Pulsed internal high-voltage level shifters reduce power

consumption

Gate Drive Outputs for External MOSFETs

• Provides 300 mA sink/150 mA source current

• Can drive MOSFET gates at up to 15 V

• External MOSFET allows flexibility in design for various

motor sizes

Built-in Protection Features

• Simultaneous conduction lockout protection

• Undervoltage lockout

Description

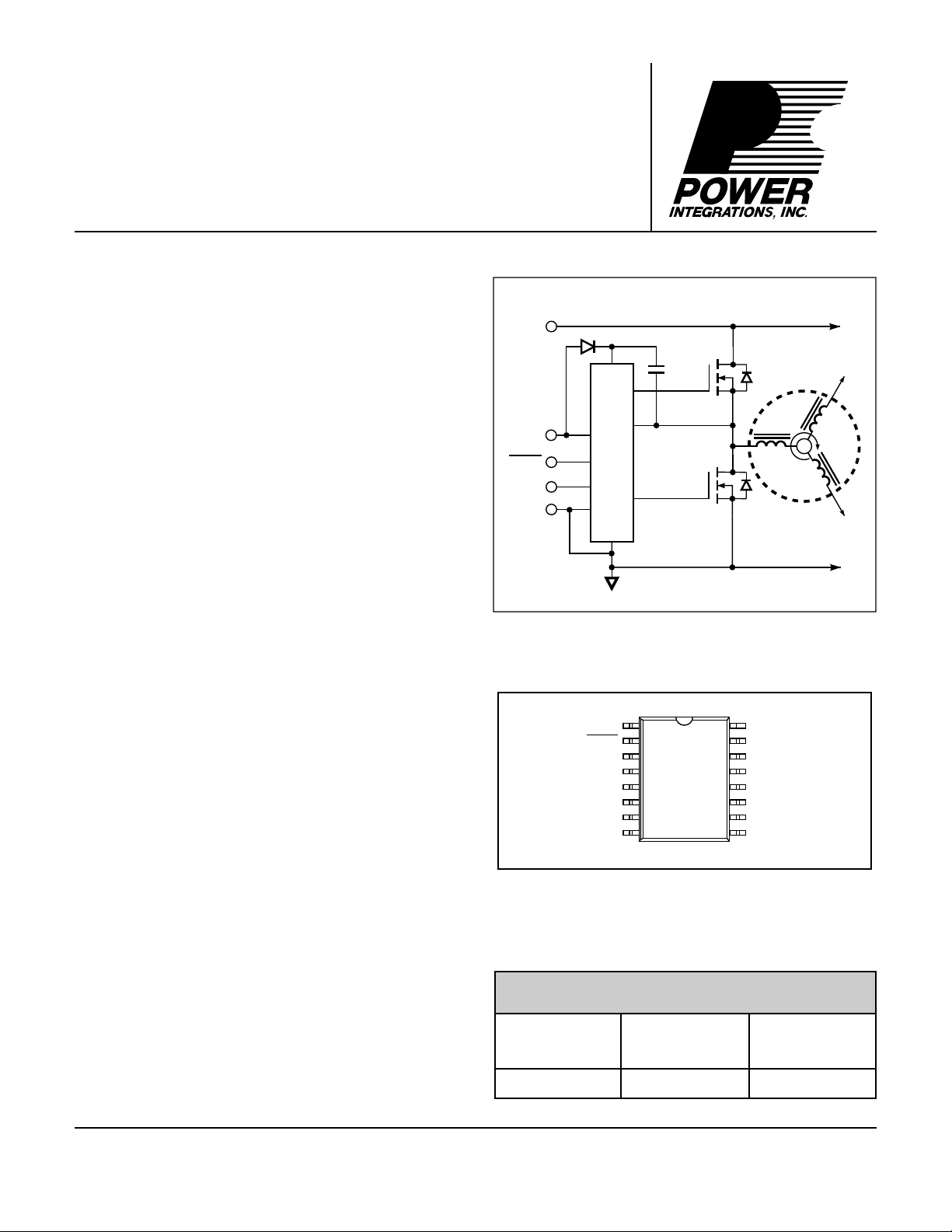

The INT100 half-bridge driver IC provides gate drive for

external low-side and high-side MOSFET switches. The INT100

provides a simple, cost-effective interface between low-voltage

control logic and high-voltage loads. The INT100 is designed

to be used with rectified 110 V or 220 V supplies. Both highside and low-side switches can be controlled independently

from ground-referenced 5 V logic inputs.

V

DDH

HS OUT

V

DD

HS IN

LS IN

COM

Figure 1. Typical Application

HS RTN

LS OUT

LS

RTN

INT100

PI-1807-031296

Built-in protection logic prevents both switches from turning

on at the same time and shorting the high voltage supply. Pulsed

internal level shifting saves power and provides enhanced noise

immunity. The circuit is powered from a nominal 15 V supply

to provide adequate gate drive for external N-channel MOSFETs.

A floating high-side supply is derived from the low-voltage rail

by using a simple bootstrap technique.

Applications for the INT100 include motor drives, electronic

ballasts, and uninterruptible power supplies. Multiple devices

can also be used to implement full-bridge and multi-phase

configurations.

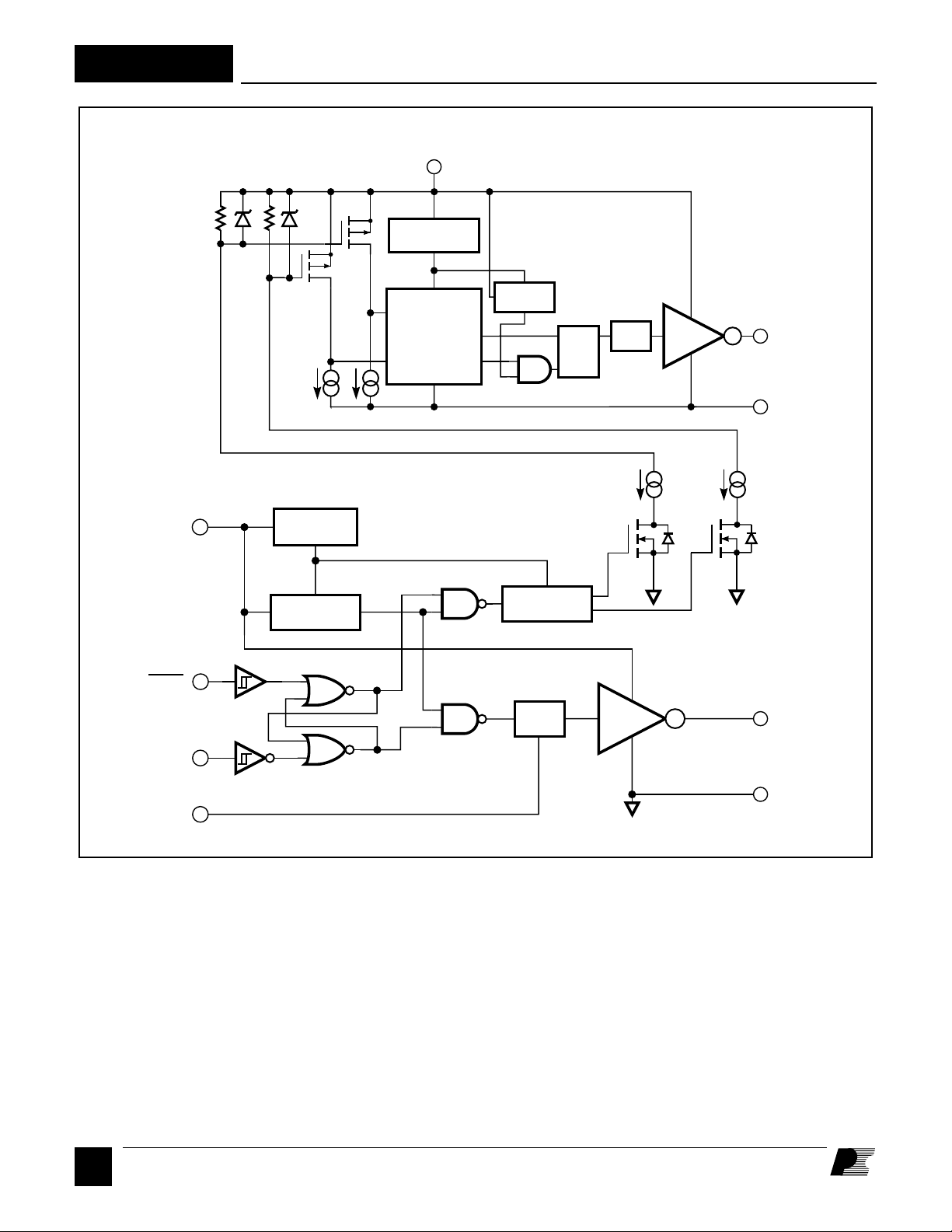

The INT100 is available in a 16-pin plastic SOIC package.

Figure 2. Pin Configuration.

ORDERING INFORMATION

PART

NUMBER

INT100S

PACKAGE

OUTLINE

ISOLATION

VOLTAGE

800 VS16A

June 1996

Page 2

INT100

V

DDH

LINEAR

REGULATOR

UV

LOCKOUT

V

DD

HS IN

LS IN

LINEAR

REGULATOR

UV

LOCKOUT

DISCRIMINATOR

PULSE

CIRCUIT

DELAY

DELAY

QS

R

HS OUT

HS RTN

LS OUT

COM

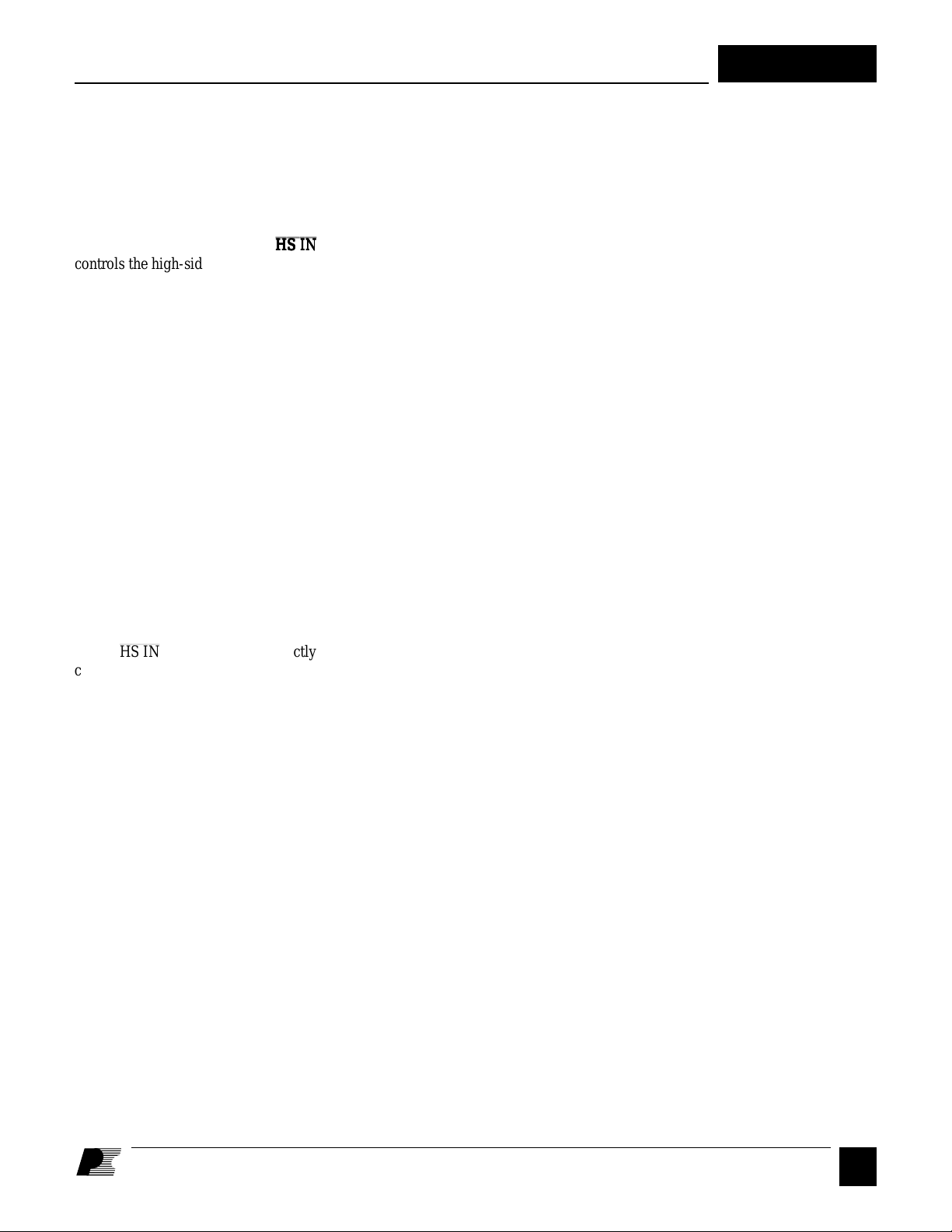

Figure 3. Functional Block Diagram of the INT100

C

2

6/96

LS RTN

PI-1083A-013194

Page 3

Pin Functional Description

INT100

Pin 1:

V

supplies power to the logic, high-

DD

side interface, and low-side driver.

Pin 7:

LS RTN is the power reference point for

the low-side circuitry, and should be

connected to the source of the low-side

Pin 2:

Active-low logic level input

HSINHSIN

HSIN

HSINHSIN

controls the high-side driver output.

MOSFET and to the COM pin.

Pin 8:

LS OUT is the driver output which

Pin 3:

controls the low-side MOSFET.

Active-high logic level input LS IN

controls the low-side driver output.

Pin 11:

HS OUT is the driver output which

Pin 4, 5:

controls the high-side MOSFET.

COM connection is used as the analog

reference point for the circuit.

INT100 Functional Description

5 V Regulators

Both low-side and high-side driver

circuits incorporate a 5 V linear regulator

circuit. The low-side regulator provides

the supply voltage for the control logic

and high-voltage level shift circuit. This

allows

HSIN

and LS IN to be directly

compatible with 5 V CMOS logic

without the need of an external 5 V

supply. The high-side regulator provides

the supply voltage for the noise rejection

circuitry and high-side control logic.

Undervoltage Lockout

The undervoltage lockout circuit for the

low-side driver disables both the LS

OUT and HS OUT pins whenever the

VDD power supply falls below typically

9.0 V, and maintains this condition until

the VDD power supply rises above

typically 9.35 V. This guarantees that

both MOSFETs will remain off during

power-up or fault conditions.

The undervoltage lockout circuit for the

high-side driver disables the HS OUT

pin whenever the V

power supply

DDH

falls below typically 9.0 V, and maintains

this condition until the V

DDH

power

supply rises above typically 9.35 V.

This guarantees that the high-side

MOSFET will be off during power-up

or fault conditions.

Level Shift

The level shift control circuitry of the

low-side driver is connected to integrated

high-voltage N-channel MOSFET

transistors which perform the levelshifting function for communication to

the high-side driver. Controlled current

capability allows the drain voltage to

float with the high-side driver. Two

individual channels produce a true

differential communication channel for

accurately controlling the high-side

driver in the presence of fast moving

high-voltage waveforms. The high

voltage level shift transistors employed

exhibit very low output capacitance,

minimizing the displacement currents

between the low-side and high-side

drivers during fast moving voltage

transients created during switching of

the external MOSFETs. As a result,

power dissipation is minimized and noise

immunity optimized.

The pulse circuit provides the two highvoltage level shifters with precise timing

Pin 12,13,14:

HS RTN is the power reference point

for the high-side circuitry, and should be

connected to the source of the high-side

MOSFET.

Pin 15:

V

supplies power to the high-side

DDH

control logic and output driver. This is

normally connected to a high-side

referenced bootstrap circuit or can be

supplied from a separate floating power

supply.

signals. These signals are used by the

discriminator to reject spurious noise.

The combination of differential

communication with the precise timing

provides maximum immunity to noise.

Simultaneous Conduction Lockout

A latch prevents the low-side driver and

high-side driver from being on at the

same time, regardless of the input signals.

Delay Circuit

The delay circuit matches the low-side

propagation delay with the combination

of the pulse circuit, high voltage level

shift, and high-side driver propagation

delays. This ensures that the low-side

driver and high-side driver will never be

on at the same time during switching

transitions in either direction.

Driver

The CMOS drive circuitry on both lowside and high-side driver ICs provide

drive power to the gates of the external

MOSFETs. The drivers consist of a

CMOS buffer capable of driving external

transistor gates at up to 15 V.

6/96

C

3

Page 4

INT100

100

0

0 100 200

Gate Charge (nC)

Switching Frequncy (kHz)

200

300

400

PI-1663-112095

VIN = 200 V

VIN = 300 V

VIN = 400 V

HV+

D1

V

DD

HS IN

LS IN

C1

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

INT100

HV-

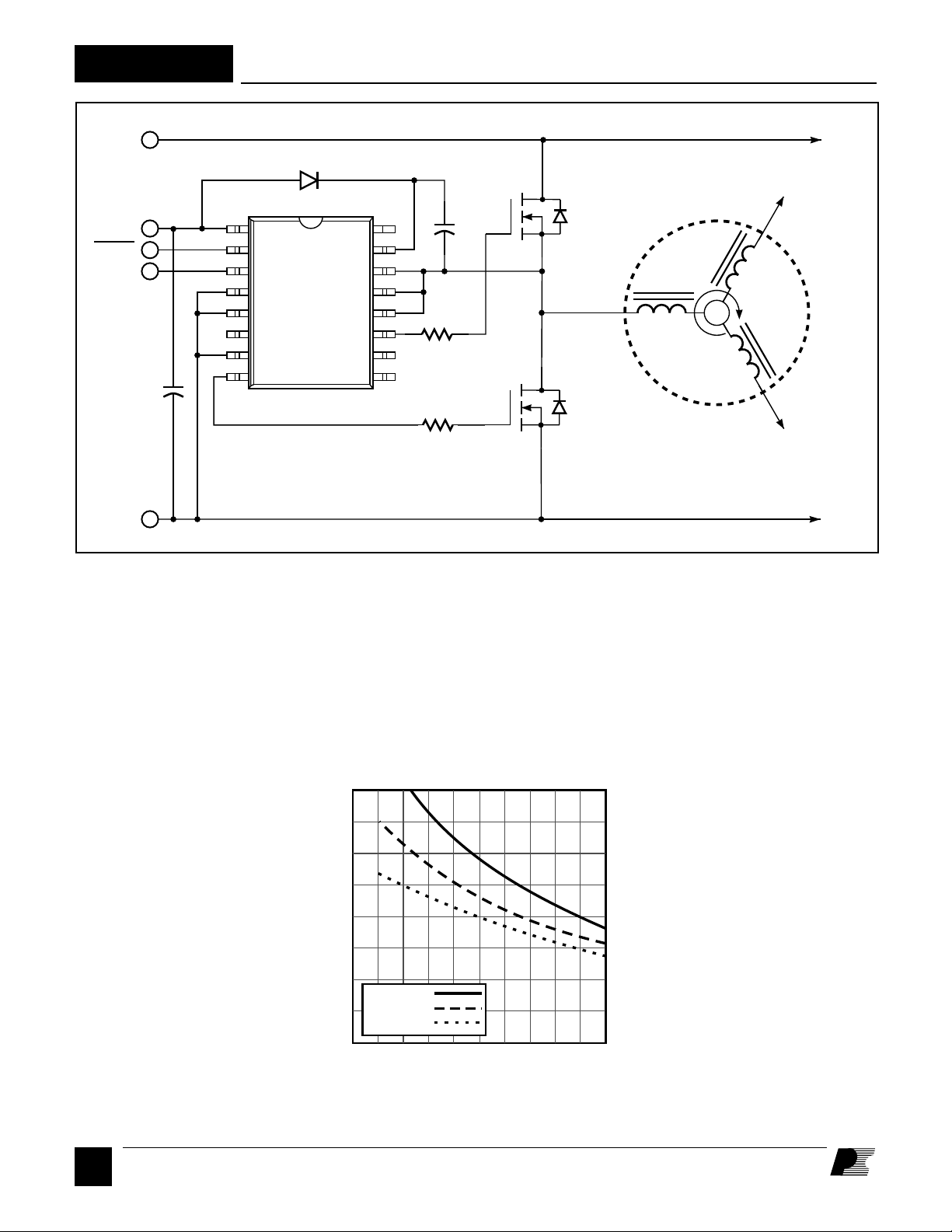

Figure 4. Using the INT100 in a 3-phase Configuration.

C2

Q2

PHASE 2

PHASE 1

R2

R1

Q1

PHASE 3

PI-1458-042695

C

4

6/96

Figure 5. Gate Charge versus Switching Frequency.

Page 5

General Circuit Operation

INT100

One phase of a three-phase motor drive

circuit is shown in Figure 4 to illustrate

an application of the INT100. The LS

IN signal directly controls MOSFET

Q1. The

HS IN

signal controls MOSFET

Q2 via the high voltage level shift

transistors communicating with the highside driver. The INT100 will ignore

input signals that would command both

Q1 and Q2 to conduct simultaneously,

protecting against shorting the HV+ bus

to HV-.

Local bypassing for the low-side driver

is provided by C1. Bootstrap bias for the

high-side driver is provided by D1 and

C2. Slew rate and effects of parasitic

oscillations in the load waveforms are

controlled by resistors R1 and R2.

The inputs are designed to be compatible

with 5 V CMOS logic levels and should

not be connected to VDD. Normal CMOS

power supply sequencing should be

observed. The order of signal application

should be VDD, logic signals, and then

HV+. VDD should be supplied from a

low impedance voltage source.

The output returns (HS RTN and LS

RTN) are isolated from one another by

the internal high-voltage MOSFET level

shifters. The level shift circuitry is

designed to operate properly even when

the HS RTN swings as much as 5 V

below the LS RTN pin with V

DDH

biased

at 15 V. The INT100 will also safely

tolerate more negative voltages (as low

as -V

below LS RTN).

DDH

Maximum frequency of operation is

limited by power dissipation due to highvoltage switching, gate charge, and bias

power. Figure 5 indicates the maximum

switching frequency as a function of

input voltage and gate charge. For higher

ambient temperatures, the switching

frequency should be derated linearly.

The bootstrap capacitor must be large

enough to provide bias current over the

entire on-time of the high-side driver

without significant voltage sag or decay.

The high-side MOSFET gate charge

must also be supplied at the desired

switching frequency. Figure 6 shows

the maximum high-side on-time versus

gate charge of the external MOSFET.

Applications with extremely long highside on times require special techniques

discussed in AN-10.

The high-side driver is latched on and

off by the edges of the appropriate lowside logic signal. The high-side driver

will latch off and stay off if the bootstrap

capacitor discharges below the

undervoltage lockout threshold.

Undervoltage lockout-induced turn off

can occur during conditions such as

power ramp up, motor start, or low speed

operation.

C

BOOTSTRAP

1000

100

10

1

0.1

QG = 100 nC

QG = 20 nC

vs. ON TIME

Bootstrap Capacitance (µF)

0.01

0.01 0.1 1 10 100

High Side On Time (ms)

Figure 6. High-side On Time versus Bootstrap Capacitor.

PI-566B-030692

6/96

C

5

Page 6

INT100

ABSOLUTE MAXIMUM RATINGS

VDD Voltage ................................................................16.5 V

V

Voltage ........................................... HS RTN + 16.5 V

DDH

HS RTN............................................. 800 V - V

DDH

to -V

DDH

HS RTN Slew Rate ...................................................10V/ns

Logic Input Voltage ...................................... -0.3V to 5.5 V

LS OUT Voltage ................ LS RTN - 0.3 V to VDD + 0.3 V

HS OUT Voltage..............HS RTN - 0.3 V to V

DDH

+ 0.3 V

Storage Temperature ....................................... –65 to 125°C

Conditions

(Unless Otherwise Specified)

Parameter Symbol V

= VDD = 15 V Min Typ Max Units

DDH

HS RTN = LS RTN = COM = 0 V

TA = -40 to 85°C

LOGIC

Input Current,

High or Low

Input Voltage

High

I

IH, IIL

V

IH

VIH = 4.0 V

VIL = 1.0 V

1

Ambient Temperature........................................ -40 to 85°C

Junction Temperature ................................................. 150°C

Lead Temperature

(2)

. ................................................... 260°C

Power Dissipation (TA = 25°C).................................. 2.3 W

(TA = 70°C).................................. 1.5 W

Thermal Impedance (θJA)......................................... 55°C/W

1. Unless noted, all voltages referenced to COM, TA = 25°C

2. 1/16" from case for 5 seconds.

0 10 150

-20 0 20

4.0

µA

V

Input Voltage

Low

Input Voltage

Hysteresis

LS OUT/HS OUT

Output

Voltage High

Output

Voltage Low

Output Short

Circuit Current

Turn-on Delay

Time

Rise

Time

Turn-off Delay

Time

V

V

V

OH

V

OL

I

OS

t

d(on)LS

t

d(on)HS

t

t

d(off)LS

t

d(off)HS

HY

r

IL

1.0

0.3 0.7

LS OUT

VDD-1.0 VDD-0.5

Io= -20 mA

HS OUT

Io= 40 mA

Vo= 0 V

V

DDH

-150

-1.0 V

-0.5

DDH

0.3 1.0

See Note 1

Vo= 15 V

LS OUT

300

0.6 1.0

See Figure 7

HS OUT

See Figure 7

LS OUT

1.0 1.5

80 120

500 1000

See Figure 7

HS OUT

420 600

V

V

V

V

mA

µs

ns

ns

Fall

Time

6

C

6/96

t

f

See Figure 7

50 100

ns

Page 7

Parameter Symbol V

LEVEL SHIFT

Breakdown

Voltage

BV

DSS

Conditions

(Unless Otherwise Specified)

= VDD = 15 V Min Typ Max Units

DDH

HS RTN = LS RTN = COM = 0 V

TA = -40 to 85°C

V

= HS OUT = HS RTN

DDH

I

= 100 µA

HS RTN

800

INT100

V

Leakage

Current

I

HS RTN)

Interface

Capacitance

SYSTEM RESPONSE

Deadtime (Low

Off to High On)

Deadtime (High

Off to Low On)

Dt

Dt

P+

P-

UNDERVOLTAGE LOCKOUT

V

Input UV

Trip-off Voltage

DD(UV)

V

DDH(UV)

Input UV

Hysteresis

SUPPLY

Supply

Current

IDD, I

DDH

V

= HS OUT = HS RTN = 500 V

DDH

V

= HS OUT = HS RTN = 500 V

DDH

See Figure 7

See Figure 7

See Note 2

0.2 30

20

0 450

0 300

8.5 9.0 10

175 350

1.5 3.0

µA

pF

ns

ns

V

mV

mA

Supply

Voltage

NOTES:

1. Applying a short circuit to the LS OUT or HS OUT pin for more than 500 µs will exceed the thermal rating of the

package, resulting in destruction of the part.

2. VDD, V

supply must have less than 30Ω output impedance.

DDH

VDD, V

DDH

10 16

6/96

V

C

7

Page 8

INT100

INPUT

CL

1000 pF

5 V

0 V

15 V

0 V

15 V

0 V

t

d(off)LS

Dt

50%

t

f

90%

50%

10% 10%

p+

50%

INPUT

15 V

1

2

3

4

5

6

7

8

16

15

14

13

12

INT100

11

10

9

100 nF

CL

1000 pF

LS OUT

1 µF

HS OUT

50% 50%

t

d(on)LS

t

r

90%

50%

Dt

p-

t

d(off)HS

t

f

90%

50%

10% 10%

t

d(on)HS

t

r

90%

PI-1459-042695

Figure 7. Switching Time/Deadtime Test Circuit.

BREAKDOWN vs. TEMPERATURE

1.1

1.0

PI-176B-051391

PACKAGE POWER DERATING

2.5

2.0

1.5

1

PI-1808-032096

(Normalized to 25°C)

Breakdown Voltage (V)

0.9

-50 -25 0 25 50 75 100 125 150

Junction Temperature (°C)

C

8

6/96

0.5

Power Dissipation (W)

0

0 25 50 75 100 125

Junction Temperature (°C)

150

Page 9

INT100

S16A Plastic SO-16 (W)

DIM inches mm

A .398-.413 10.10-10.50

B .050 BSC 1.27 BSC

C .014-.018 0.36-0.46

E .093-.104 2.35-2.65

F .004-.012 0.10-0.30

J .394-.418 10.01-10.62

L .009-.012 0.23-0.32

M .020-.040 0.51-1.02

N .291-.299 7.40-7.60

Notes:

1. Package dimensions conform to JEDEC

specification MS-013-AA for standard small outline

(SO) package, 16 leads, 7.50 mm (.300 inch) body

width (issue A, June 1985).

2. Controlling dimensions are in mm.

3. Dimensions are for the molded body and do not

include mold flash or protrusions. Mold flash or

protrusions shall not exceed .15 mm (.006 inch) on

any side.

4. Pin 1 side identified by chamfer on top edge of

the package body or indent on Pin 1 end.

16

1

(3)

A

9

(3)

N

8

J

L

E

C

B

F

0-8˚ TYP.

M

PI-1846-050196

6/96

C

9

Page 10

INT100

Notes

10

C

6/96

Page 11

Notes

INT100

6/96

C

11

Page 12

INT100

Power Integrations reserves the right to make changes to its products at any time to improve reliability or manufacturability.

Power Integrations does not assume any liability arising from the use of any device or circuit described herein, nor does it

convey any license under its patent rights or the rights of others.

PI Logo and

TOPSwitch

are registered trademarks of Power Integrations, Inc.

©Copyright 1994, Power Integrations, Inc. 477 N. Mathilda Avenue, Sunnyvale, CA 94086

WORLD HEADQUARTERS

Power Integrations, Inc.

477 N. Mathilda Avenue

Sunnyvale, CA 94086

USA

Main: 408•523•9200

Customer Service:

Phone: 408•523•9265

Fax: 408•523•9365

JAPAN

Power Integrations, K.K.

Keihin-Tatemono 1st Bldg.

12-20 Shin-Yokohoma 2-Chome, Kohoku-ku

Yokohama-shi, Kanagawa 222 Japan

Phone: 81•(0)•45•471•1021

Fax: 81•(0)•45•471•3717

AMERICAS

For Your Nearest Sales/Rep Office

Please Contact Customer Service

Phone: 408•523•9265

Fax: 408•523•9365

ASIA & OCEANIA

For Your Nearest Sales/Rep Office

Please Contact Customer Service

Phone: 408•523•9265

Fax: 408•523•9365

EUROPE & AFRICA

Power Integrations (Europe) Ltd.

Mountbatten House

Fairacres

Windsor SL4 4LE

United Kingdom

Phone: 44•(0)•1753•622•208

Fax: 44•(0)•1753•622•209

APPLICATIONS HOTLINE

World Wide 408•523•9260

APPLICATIONS FAX

Americas 408•523•9361

Europe/Africa

44•(0)•1753•622•209

Japan 81•(0)•45•471•3717

Asia/Oceania 408•523•9364

12

C

6/96

Loading...

Loading...