Page 1

©

1999 IMP, Inc. 408-432-9100/www.impweb.com 1

Key Features

Applications

◆ Embedded control systems

◆ Battery–operated systems

◆ Intelligent instruments

◆ Wireless communication systems

◆ PDAs and handheld equipment

◆ µP/µC power supply monitoring

◆

Design improvement over Maxim

MAX690A/692A/802L/802M/805L

— 70% lower current than Maxim:

100µA maximum

— RESET Operation to 1.1V

◆

Two precision supply-voltage monitor options

— 4.65V (IMP690A/802L/805L)

— 4.40V (IMP692A/802M)

◆

Battery-backup power switch on-chip

◆

Watchdog timer: 1.6 second timeout

◆

Power failure/low battery detection

◆

Short-circuit protection and thermal limiting

◆

Small 8-pin SO package

◆

No external components

◆

Specified over full temperature range

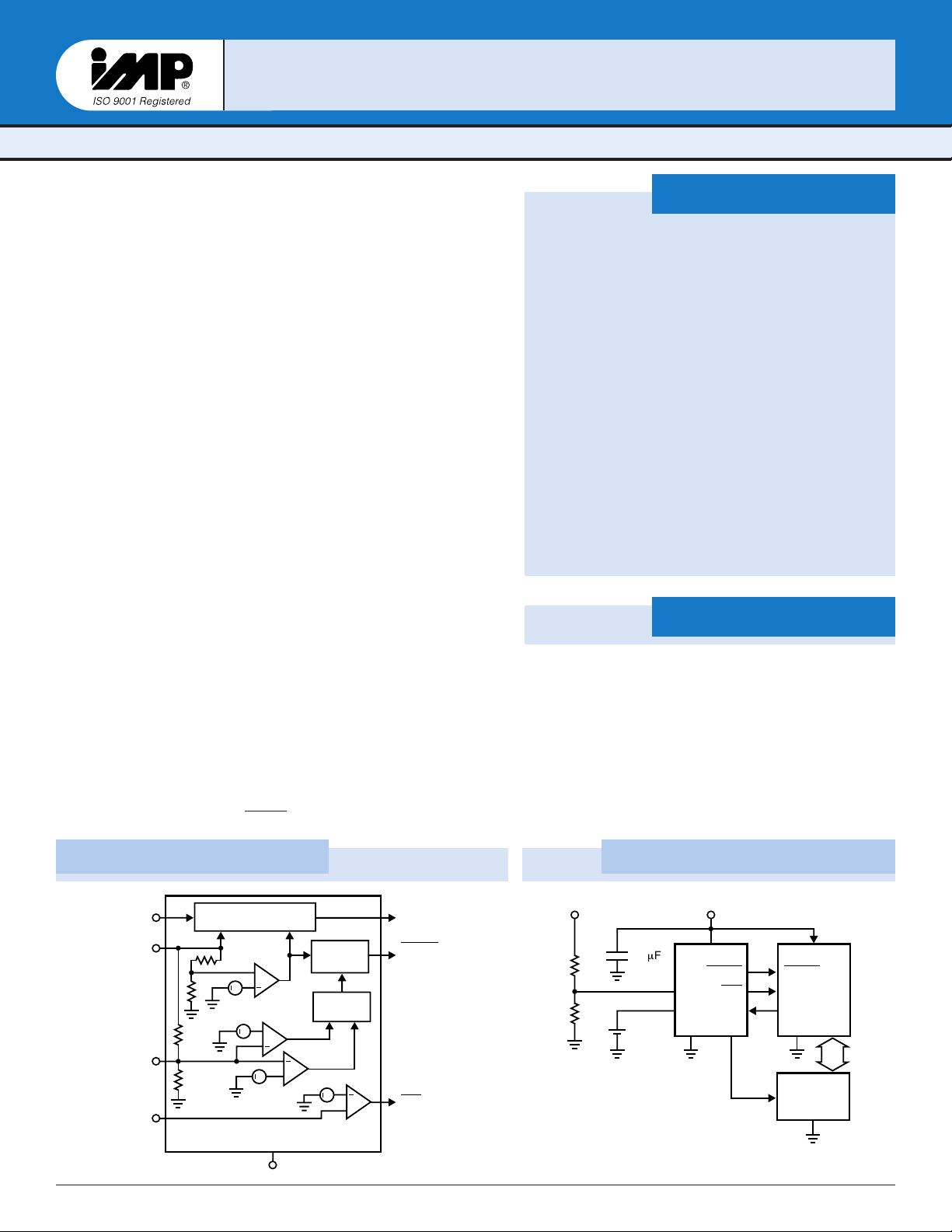

Block Diagrams

IMP690A

IMP690A

, 692A

, 692A

, 802L/M, 805L

, 802L/M, 805L

POWER MANAGEMENT

µµP Super

P Super

visor wit

visor wit

h Batt

h Battereryy

Bac

Bac

kup Switc

kup Switchh

The IMP690A/IMP692A/IMP802L/IMP802M/IMP805L simplify power

supply monitoring and control in microprocessor systems. Each circuit

implements four functions: Reset control, watchdog monitoring, batterybackup switching and power-failure monitoring. In addition to

microprocessor reset under powerup and power-down conditions, these

devices provide battery-backup switching to maintain control in powerloss and brown-out situations. Additional monitoring capabilities

can provide an early warning of unregulated power-supply loss before

the voltage regulator drops out. The important features of these four

functions are:

a) 1.6 second watchdog timer to keep microprocessor responsive

b) 4.40V or 4.65V V

CC

threshold for microprocessor reset at power-up

and power-down

c) SPDT (single-pole, double-throw) PMOS switch connects backup

power to RAM if V

CC

fails

d) 1.25V threshold detector for power loss or general purpose voltage

monitoring

While these features are pin–compatible with the industry standard

power–supply supervisors offered by Maxim, the IMP devices are superior replacements and can reduce power requirements by 70 percent

when compared to Maxim MAX690/MAX692A/MAX802L/MAX802M/

MAX805L devices. Short-circuit and thermal protection have also

been added.

The IMP690A/IMP802L/IMP805L generate a reset pulse when the

supply voltage drops below 4.65V, and the IMP692A/IMP802M

generate a reset below 4.40V. The IMP802L/IMP802M have power–fail

accuracy to ±2%. The IMP805L is the same as the IMP690A except that

RESET is provided instead of RESET.

+

+

+

+

+

+

+

+

V

CC

V

OUT

1

7

5

3

PFI

WDI

GND

V

BATT

8

2

6

4

PFO

IMP690A, IMP692A, IMP802L, IMP802M,

IMP805L

RESET

(RESET)

( ) IMP805L

Battery-Switchover

Circuit

Reset

Generator

Watchdog

Timer

3.5V

1.25V

1.25V

0.8V

690A_03.eps

Typical Application

Unregulated DC Regulated +5V

R

R

0.1mF

1

2

3.6V

+

Lithium

–

Battery

V

CC

RESET

PFO

PFI

V

WDI

BATT

V

OUT

GND

IMP690A

V

RESET

NMI

I/O LINE

GND

CMOS

RAM

V

CC

GND

CC

BUS

690A_01.eps

Page 2

2

408-432-9100/www.impweb.com

©

1999 IMP, Inc.

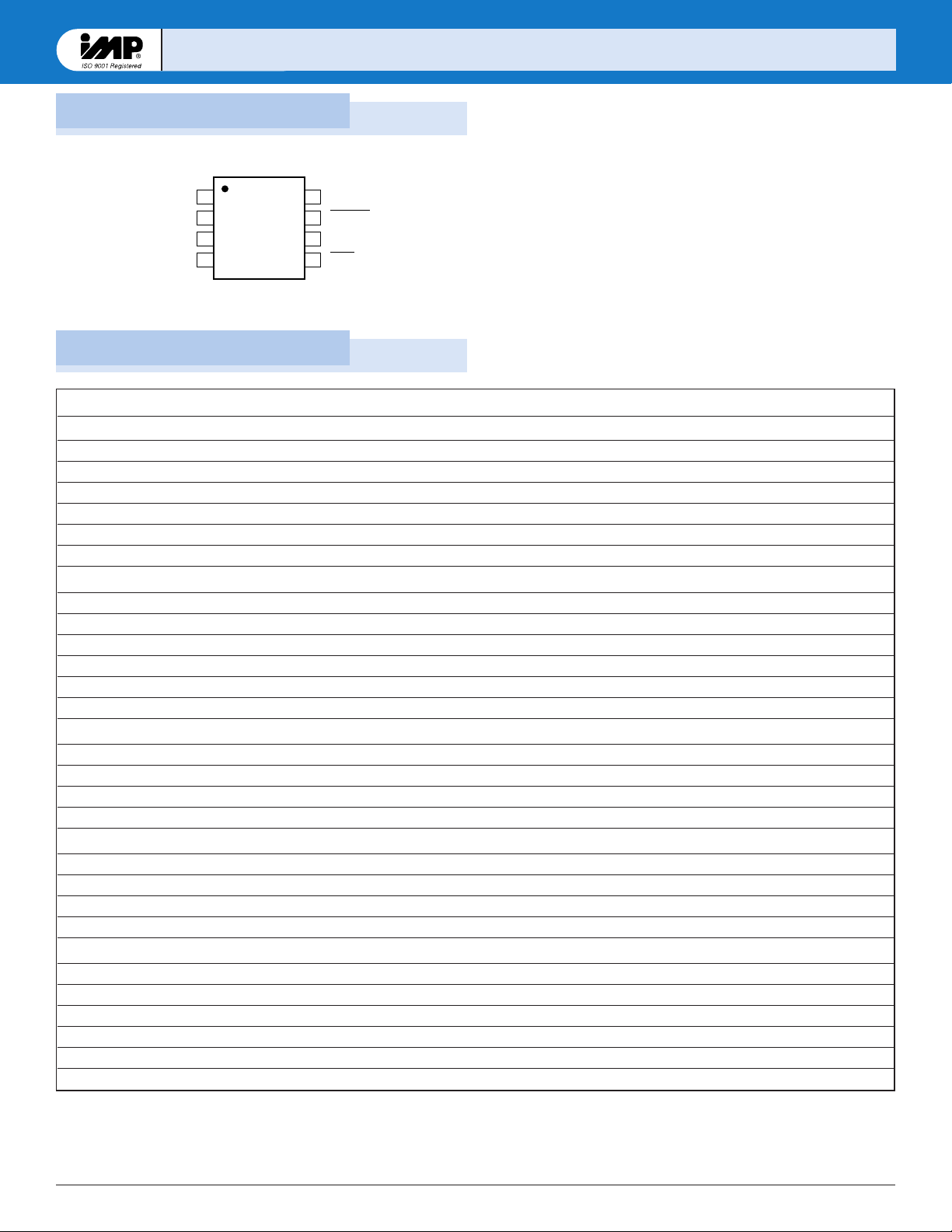

Ordering Information

Pin Configuration

IMP690A

IMP690A

, 692A

, 692A

, 802L, 802M, 805L

, 802L, 802M, 805L

4PFI

3GND

2V

CC

1V

OUT

5 PFO

6 WDI

7 RESET (RESET)

8V

BATT

690A_02.eps

IMP690A

IMP692A

IMP802L

IMP802M

IMP805L

( ) IMP805L

Plastic/CerDip/SO

Part Number Reset Threshold (V) Temperature Range Pins-Package

IMP690A

IMP690ACPA 4.5 to 4.75 0°C to +70°C 8-Plastic DIP

IMP690ACSA 4.5 to 4.75 0°C to +70°C 8-SO

IMP690AC/D 4.5 to 4.75 25°C DICE

IMP690AEPA 4.5 to 4.75 –40°C to +85°C 8-Plastic DIP

IMP690AESA 4.5 to 4.75 –40°C to +85°C 8-SO

IMP690AMJA 4.5 to 4.75 Contact Factory 8-CerDIP

IMP692A

IMP692ACPA 4.25 to 4.50 0°C to +70°C 8-Plastic DIP

IMP692ACSA 4.25 to 4.50 0°C to +70°C 8-SO

IMP692AC/D 4.25 to 4.50 25°C DICE

IMP692AEPA 4.25 to 4.50 – 40°C to +85°C 8-Plastic DIP

IMP692AESA 4.25 to 4.50 – 40°C to +85°C 8-SO

IMP692AMJA 4.25 to 4.50 Contact Factory 8-CerDIP

IMP802L

IMP802LCPA 4.5 to 4.75 0°C to +70°C 8-Plastic DIP

IMP802LCSA 4.5 to 4.75 0°C to +70°C 8-SO

IMP802LEPA 4.5 to 4.75 –40°C to +85°C 8-Plastic DIP

IMP802LESA 4.5 to 4.75 –40°C to +85°C 8-SO

IMP802M

IMP802MCPA 4.25 to 4.50 0°C to +70°C 8-Plastic DIP

IMP802MCSA 4.25 to 4.50 0°C to +70°C 8-SO

IMP802MEPA 4.25 to 4.50 –40°C to +85°C 8-Plastic DIP

IMP802MESA 4.25 to 4.50 –40°C to +85°C 8-SO

IMP805L

IMP805LCPA 4.5 to 4.75 0°C to +70°C 8-Plastic DIP

IMP805LCSA 4.5 to 4.75 0°C to +70°C 8-SO

IMP805LC/D 4.5 to 4.75 25°C DICE

IMP805LEPA 4.5 to 4.75 –40°C to +85°C 8-Plastic DIP

IMP805LESA 4.5 to 4.75 –40°C to +85°C 8-SO

IMP805LMJA 4.5 to 4.75 Contact Factory 8-CerDIP

Page 3

©

1999 IMP, Inc. 408-432-9100/www.impweb.com 3

Pin Number

IMP690A/IMP692A

IMP802L/IMP802M IMP805L Name Function

11V

OUT

Voltage supply for RAM. When VCCis above the reset threshold, V

OUT

connects to VCCthrough a P-channel MOS device. If VCCfalls below the

reset threshold, this output will be connected to the backup supply at

V

BATT

(or VCC, whichever is higher) through the MOS switch to provide

continuous power to the CMOS RAM.

22V

CC

+5V power supply input

3 3 GND Ground

4 4 PFI Power failure monitor input. PFI is connected to the internal power fail

comparator which is referenced to 1.25V. The power fail output (PFO)

is active LOW but remains HIGH if PFI is above 1.25V. If this feature is

unused, the PFI pin should be connected to GND or V

OUT

.

5 5 PFO Power-fail output. PFO is active LOW whenever the PFI pin is less than

1.25V.

6 6 WDI Watchdog input. The WDI input monitors microprocessor activity. An

internal timer is reset with each transition of the WDI input. If WDI is held

HIGH or LOW for longer than the watchdog timeout period, typically 1.6

seconds, RESET (or RESET) is asserted for the reset pulse width time,

tRS, of 140ms, minimum.

7 –––– RESET Active-LOW reset output. When triggered by VCCfalling below the reset

threshold or by watchdog timer timeout, RESET (or RESET) pulses low

for the reset pulse width, tRS, typically 200ms. It will remain low if VCCis

below the reset threshold (4.65V in the IMP690A/IMP802L and 4.4V in

the IMP692A/IMP802L) and remains low for 200ms after VCCrise above

the reset threshold.

–––– 7 RESET Active-HIGH reset output. The inverse of RESET.

88V

BATT

Auxiliary power or backup-battery input. V

BATT

should be connected to

GND if the function is not used. This input has about 40mV of hysteresis

to prevent rapid toggling between VCCand V

BATT

.

IMP690A

IMP690A

, 692A

, 692A

, 802L, 802M, 805L

, 802L, 802M, 805L

Absolute Maximum Ratings

Pin Description

Pin Terminal Voltage with Respect to Ground

V

CC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 6.0V

V

BATT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 6.0V

All Other Inputs* . . . . . . . . . . . . . . . . . . . – 0.3V to (V

CC

+ 0.3V)

Input Current at V

CC

. . . . . . . . . . . . . . . . . . 200mA

Input Current at V

BATT

. . . . . . . . . . . . . . . . . 50mA

Input Current at GND . . . . . . . . . . . . . . . . . 20mA

Output Current:

V

OUT

. . . . . . . . . . . . . . . Short circuit protected

All Other Inputs . . . . . . . . . . . . . . . . . . . 20mA

Rate of Rise: V

BATT

and VCC . . . . . . . . . . 100V/µs

Continuous Power Dissipation

Plastic DIP (derate 9mW/°C above 70°C) . . . 800mW

SO (derate 5.9mW/°C above 70°C) . . . . . . . . 500mW

CerDIP (derate 8mW/°C above 70°C) . . . . . . 650mW

Operating Temperature Range (C Devices) . . . . 0°C to 70°C

Operating Temperature Range (E Devices) . . . . – 40°C to 85°C

Storage Temperature Range . . . . . . . . . . . . . . . . . – 65°C to 160°C

Lead Temperature Soldering, (10 sec) . . . . . . . . 300°C

* The input voltage limits on PFI and WDI may be exceeded if the

current is limited to less than 10mA

These are stress ratings only and functional operation is not implied.

Exposure to absolute maximum ratings for prolonged time periods may

affect device reliability.

Page 4

4

408-432-9100/www.impweb.com

©

1999 IMP, Inc.

IMP690A

IMP690A

, 692A

, 692A

, 802L, 802M, 805L

, 802L, 802M, 805L

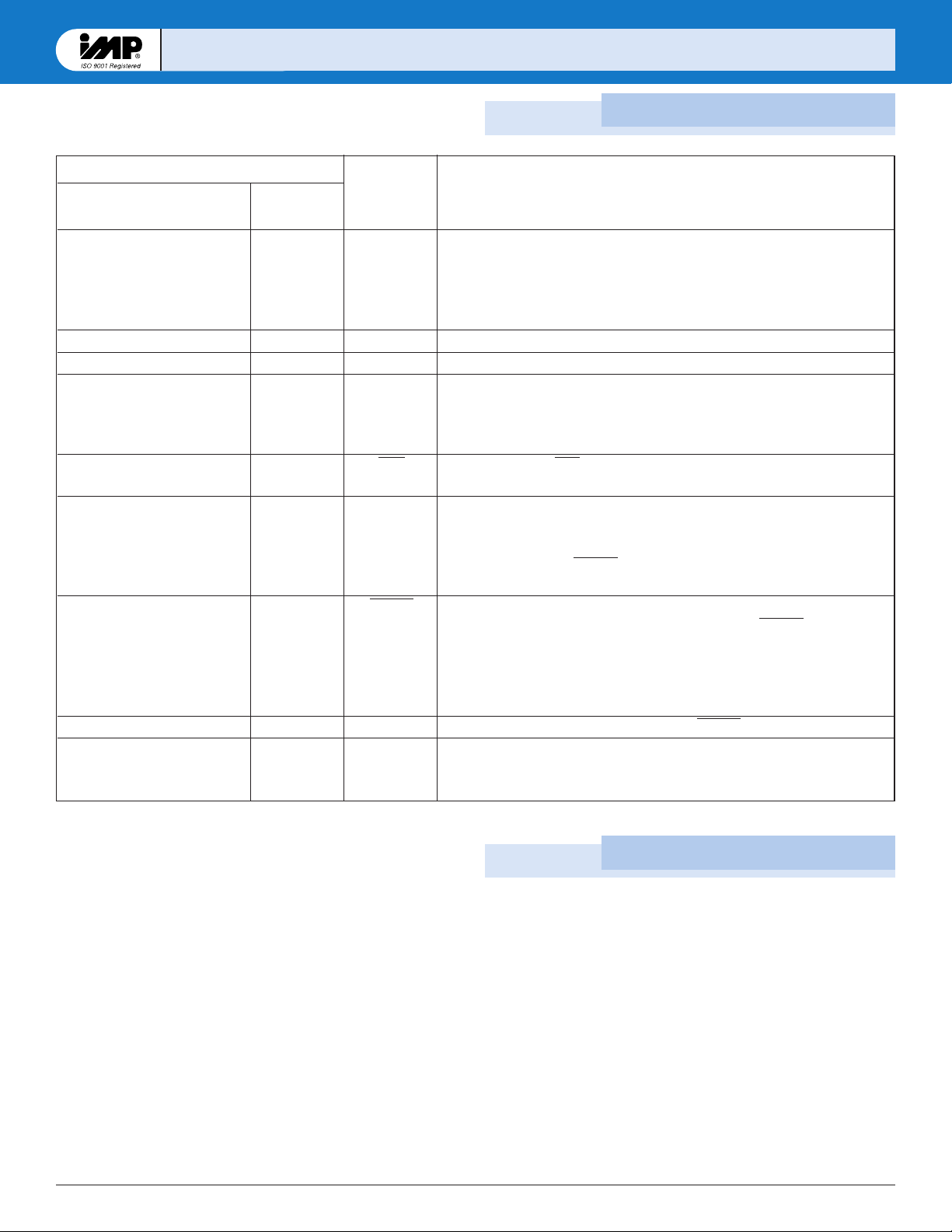

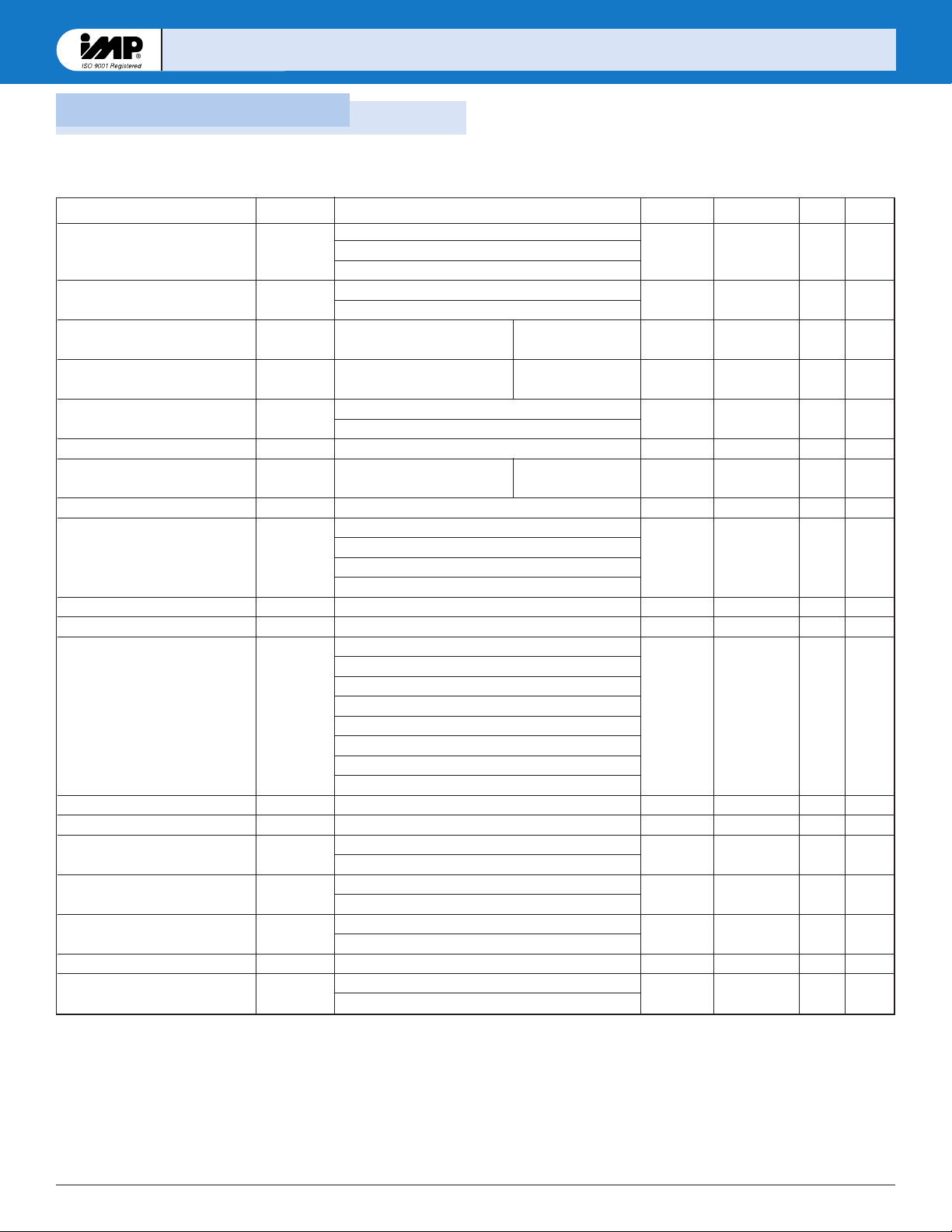

Electrical Characteristics

Parameter Symbol Conditions Min Typ Max Units

VCC, V

BATT

Voltage Range IMP69_AC, IMP802_C 1.1 5.5 V

(Note 1) IMP805LC 1.1 5.5

IMP69_AE, IMP80_ _E 1.1 5.5

Supply Current Excluding I

OUT

I

S

IMP69_AC, IMP802_C 35 100 µA

IMP69_AE, IMP802_E, IMP805LE 35 100

I

SUPPLY

in Battery-Backup Mode V

CC

= 0V, V

BATT

= 2.8V TA= 25°C 1.0 µA

(Excluding I

OUT

)T

A

= T

MIN

to T

MAX

5.0

V

BATT

Standby Current 5.5V > VCC> V

BATT

– 0.2V TA= 25°C –0.1 0.02 µA

(Note 2) TA= T

MIN

to T

MAX

–1.0 0.02

V

OUT

Output I

OUT

= 5mA VCC– 0.025 VCC– 0.010 V

I

OUT

= 50mA VCC– 0.25 VCC– 0.10

V

OUT

in Battery-Backup Mode I

OUT

= 250µA, VCC< V

BATT

– 0.2V V

BATT

– 0.1 V

BATT

– 0.001 V

Battery Switch Threshold, V

CC

< V

RT

Power-up 20 mV

VCCto V

BATT

Power-down –20

Battery Switchover Hysteresis 40 mV

Reset Threshold V

RT

IMP690A/802L/805L 4.50 4.65 4.75 V

IMP692A, IMP802M 4.25 4.40 4.50

IMP802L, TA= 25°C, VCCfalling 4.55 4.70

IMP802M, TA= 25°C, VCCfalling 4.30 4.45

Reset Threshold Hysteresis 40 mV

Reset Pulse Width t

RS

140 200 280 ms

Reset Output Voltage I

SOURCE

= 800µA V

CC

– 1.5 V

I

SINK

= 3.2mA 0.4

IMP69_AC, IMP802_C, VCC= 1.0V, I

SINK

= 50µA 0.3

IMP69_AE, IMP802_E, VCC= 1.2V, I

SINK

= 100µA 0.3

IMP805LC, I

SOURCE

= 4µA, V

CC

= 1.1V 0.8

IMP805LE, I

SOURCE

= 4µA, V

CC

= 1.2V 0.9

IMP805L, I

SOURCE

= 800µAV

CC

– 1.5

IMP805L, I

SINK

= 3.2mA 0.4

Watchdog Timeout t

WD

1.00 1.60 2.25 sec

WDI Pulse Width t

WP

VIL= 0.4V, V

IH

= 0.8V

CC

50 ns

WDI Input Current WDI = V

CC

50 150 µA

WDI = 0V –150 –50

WDI Input Threshold VCC= 5V, Logic LOW 0.8 V

(Note 3) VCC= 5V, Logic HIGH 3.5

PFI Input Threshold IMP69_A, IMP805L, VCC= 5V 1.20 1.25 1.30 V

IMP802_C/E, VCC= 5V 1.225 1.250 1.275

PFI Input Current –25 0.01 25 nA

PFO Output Voltage I

SOURCE

= 800µA VCC– 1.5 V

I

SINK

= 3.2mA 0.4

Unless otherwise noted VCC= 4.75V to 5.5V for the IMP690A/IMP802L/IMP805L and VCC= 4.5V to 5.5V for the IMP692A/IMP802M;

V

BATT

= 2.8V; and TA= T

MIN

to T

MAX

.

Notes: 1. If VCCor V

BATT

is 0V, the other must be greater than 2.0V.

2. Battery charging-current is “–”. Battery discharge-current is “+”.

3. WDI is guaranteed to be in an intermediate level state if WDI is floating and V

CC

is within the operating voltage range. WDI input

impedance is 50kΩ. WDI is biased to 0.3V

CC

.

Page 5

©

1999 IMP, Inc. 408-432-9100/www.impweb.com 5

IMP690A

IMP690A

, 692A

, 692A

, 802L, 802M, 805L

, 802L, 802M, 805L

Application Information

Reset Output

It is important to initialize a microprocessor to a known state in

response to specific events that could create code execution errors

and “lock-up”. The reset output of these supervisory circuits send

a reset pulse to the microprocessor in response to power-up,

power-down/power-loss or a watchdog time-out. The reset pulse

width, t

RS

, is typically around 200ms and is LOW for the

IMP690A, IMP692A, IMP802 and HIGH for the IMP805L.

Power-up reset occurs when a rising V

CC

reaches the reset thresh-

old, V

RT

, forcing a reset condition in which the reset output is

asserted in the appropriate logic state for the duration of t

RS

.

Figure 2 shows the reset pin timing.

Power-loss or “brown-out” reset occurs when V

CC

dips below the

reset threshold resulting in a reset assertion for the duration of t

RS

.

The reset signal remains asserted as long as VCCis between V

RT

and 1.1V, the lowest VCCfor which these devices can provide a

guaranteed logic-low output. To ensure logic inputs connected to

the IMP690A/692A/802 RESET pin are in a known state when

V

CC

is under 1.1V, a 100kΩ pull-down resistor at RESET is needed:

the logic-high IMP805L will need a pull-up resistor to V

CC

.

A Watchdog time-out reset occurs when a logic “1” or logic “0” is

continuously applied to the WDI pin for more than 1.6 seconds.

After the duration of the reset interval, the watchdog timer starts

a new 1.6 second timing interval; the microprocessor must service

the watchdog input by changing states or by floating the WDI pin

before this interval is finished. If the WDI pin is held either HIGH

or LOW, a reset pulse will be triggered every 1.8 seconds (the 1.6

second timing interval plus the reset pulse width t

RS

).

+

+

+

+

+

+

+

+

V

CC

V

OUT

1

7

5

3

PFI

WDI

GND

V

BATT

8

2

6

4

PFO

IMP690A, IMP692A, IMP802L, IMP802M,

IMP805L

RESET

(RESET)

( ) IMP805L

Battery-Switchover

Circuit

Reset

Generator

Watchdog

Timer

3.5V

1.25V

1.25V

0.8V

690A_03.eps

Figure 1. Block Diagram

V

CC

V

OUT

V

BATT

= PFI = 3.0V

I

OUT

= 0mA

PFO

+5V

+5V

+0V

+0V

3.0V

+5V

+0V

+5V

+0V

+5V

+0V

( ) IMP805L

3.0V

RESET

(RESET)

690A_04.eps

t

RS

Figure 2. Timing Diagram

Page 6

6

408-432-9100/www.impweb.com

©

1999 IMP, Inc.

IMP690A

IMP690A

, 692A

, 692A

, 802L, 802M, 805L

, 802L, 802M, 805L

Application Information

Microprocessor Interface.

The IMP690 has logic-LOW RESET output while the IMP805 has

an inverted logic-HIGH RESET output. Microprocessors with bidirectional reset pins (69HC11 for example) can pose a problem

when the supervisory circuit and the microprocessor output pins

attempt to go to opposite logic states. The problem can be

resolved by placing a 4.7kΩ resistor between the RESET output

and the microprocessor reset pin. This is shown in Figure 3. Since

the series resistor limits drive capabilities, the reset signal to other

devices should be buffered.

Figure 3. Interfacing with bi-directional microprocessor

reset inputs

Watchdog Input

As discussed in the Reset section, the Watchdog Input is used to

monitor microprocessor activity. It can be used to insure that the

microprocessor is in a continually responsive state by requiring

that the WDI pin be toggled every second. If the WDI pin is not

toggled within the 1.6 second window (minimum t

WD

+ tRS),

a reset pulse will be asserted to return the microprocessor to the

initial start-up state. Pulses as short as 50ns can be applied to the

WDI pin. If this feature is not used, the WDI pin should be opencircuited or the logic placed into a high-impedance state to allow

the pin to float.

690A_05.eps

GND GND

RESETRESET

V

CC

IMP690A

V

CC

4.7k

Buffered RESET to Other System Components

Backup-Battery Switchover

A power loss can be made less severe if the system RAM contents

are preserved. This is achieved in the IMP690/692/802/805 by

switching from the failed V

CC

to an alternate power source con-

nected at V

BATT

when VCCis less than the reset threshold voltage

(V

CC

< VRT), and VCCis less than V

BATT

. The V

OUT

pin is normally

connected to V

CC

through a 2Ω PMOS switch but a brown-out or

loss of V

CC

will cause a switchover to V

BATT

by means of a 20Ω

PMOS switch. Although both conditions (V

CC

< VRTand VCC<

V

BATT

) must occur for the switchover to V

BATT

to occur, V

OUT

will

be switched back to V

CC

when VCCexceeds VRTirrespective of the

voltage at V

BATT

. It should be noted that an internal device diode

(D1 in Figure 4) will be forward biased if V

BATT

exceeds VCCby

more than a diode drop when V

CC

is switched to V

OUT

. Because of

this it is recommended that V

BATT

be no greater than V

RT

+0.6V.

Figure 4. Internal device configuration of battery

switch-over function

V

CC

> Reset Threshold

V

CC

< Reset Threshold and

V

CC

> V

BATT

V

CC

< Reset Threshold and

V

CC

< V

BATT

IMP690A/IMP802L / IMP805L Reset Threshold = 4.65V

IMP692A/IMP802M Reset Threshold = 4.4V

Closed

Open

Open

Closed

Closed Open

CONDITION SW1/SW2 SW3/SW4

690A_06.eps

SW4SW3D2D1

D3

IMP690A

IMP692A

IMP802L

IMP802M

IMP805L

SW1 SW2

V

CC

V

OUT

V

BATT

Page 7

©

1999 IMP, Inc. 408-432-9100/www.impweb.com 7

IMP690A

IMP690A

, 692A

, 692A

, 802L, 802M, 805L

, 802L, 802M, 805L

Application Information

Table 1. Pin Connections in Battery Backup Mode

During the backup power mode, the internal circuitry of the

supervisory circuit draws power from the battery supply. While

V

CC

is still alive, the comparator circuits remain alive and the cur-

rent drawn by the device is typically 35µA. When V

CC

drops more

than 1.1V below V

BATT

, the internal switchover comparator, the

PFI comparator and WDI comparator will shut off, reducing the

quiescent current drawn by the IC to less than 1µA.

Backup Power Sources - Batteries

Battery voltage selection is important to insure that the battery

does not discharge through the parasitic device diode D1 (see

Figure 4) when V

CC

is less than V

BATT

and VCC> VRT.

Table 2. Maximum Battery Voltages

Although most batteries that meet the requirements of Table 2 are

acceptable, lithium batteries are very effective backup source due

to their high-energy density and very low self-discharge rates.

Battery Replacement while Powered

Batteries can be replaced even when the device is in a powered

state as long as V

CC

remains above the reset threshold voltage VRT.

In the IMP devices, a floating V

BATT

pin will not cause a powersupply switchover as can occur in some other supervisory

circuits. If V

BATT

is not used, the pin should be grounded.

Part No. MAXIMUM Battery Voltage

IMP690A 4.80

IMP802L 4.80

IMP805L 4.80

IMP692A 4.55

IMP802M 4.55

Pin Connection

V

OUT

Connected to V

BATT

through internal PMOS switch

V

BATT

Connected to V

OUT

PFI Disabled

PFO Logic-LOW

RESET Logic LOW (except on IMP805 where it is HIGH)

WDI Watchdog timer disabled

Backup Power Sources - SuperCap

TM

Capacitor storage, with very high values of capacitance, can be

used as a back-up power source instead of batteries. SuperCap

TM

are capacitors with capacities in the fractional farad range. A 0.1

farad SuperCap

TM

would provide a useful backup power source.

Like the battery supply, it is important that the capacitor voltage

remain below the maximum voltages shown in Table 2. Although

the circuit of Figure 5 shows the most simple way to connect the

SuperCap

TM

, this circuit cannot insure that an overvoltage condition will not occur since the capacitor will ultimately charge up to

V

CC

. To insure that an overvoltage condition does not occur,

the circuit of Figure 6 is preferred. In this circuit configuration, the

diode-resistor pair clamps the capacitor voltage at one diodedrop below V

CC

. VCCitself should be regulated within ±5% of

5V for the IMP692A/802M or within ±10% of 5V for the

IMP690A/802L/805L to insure that the storage capacitor does not

achieve an overvoltage state.

Note: SuperCap

TM

is a trademark of Baknor Industries

Figure 5. Capacitor as a backup power source

Figure 6. Capacitor as back-up Power Source - Voltage

clamped to 0.5V below V

CC

690A_08.eps

+5V

GND

IMP692A

IMP802M

( ) IMP805L

100k

+

0.1F

V

BATT

V

CC

To mP

To Static RAM

RESET

V

OUT

+

690A_07.eps

+5V

GND

( ) IMP805L

0.1F

V

BATT

V

CC

To mP

To Static RAM

RESET

(RESET)

V

OUT

Page 8

8

408-432-9100/www.impweb.com

©

1999 IMP, Inc.

IMP690A

IMP690A

, 692A

, 692A

, 802L, 802M, 805L

, 802L, 802M, 805L

Application Information

Operation Without a Backup Power Source

When operating without a back-up power source, the V

BATT

pin

should be connected to GND and V

OUT

should be connected to

V

CC

, since power source switchover will not occur. Connecting

V

OUT

to VCCeliminates the voltage drop due to the ON-resistance

of the PMOS switch.

Power-Fail Comparator

The Power Fail feature is an independent voltage monitoring

function that can be used for any number of monitoring activities.

The PFI function can provide an early sensing of power supply

failure by sensing the voltage of the unregulated DC ahead of

the regulated supply sensing seen by the backup-battery

switchover circuitry.

The PFI pin is compared to a 1.25V internal reference. If the voltage at the PFI pin is less than this reference voltage, the PFO pin

goes low. By sensing the voltage of the raw DC power supply, the

microprocessor system can prepare for imminent power-loss,

especially if the battery backup supply is not enabled. The input

voltage at the PFI pin results from a simple resistor voltage

divider as shown in Figure 7.

Figure 7. Simple Voltage divider sets PFI trip point

690A_09.eps

+5V

GND

0V

PFO

+5V

A

AB

B

IMP690A

IMP692A

IMP802L

IMP802M

IMP805L

R

2

PFI

V

CC

PFO

R

1

Power Fail Hysteresis

A noise margin can be added to the simple monitoring circuit of

Figure 7 by adding positive feedback from the PFO pin. The circuit

of Figure 8 adds this positive “latching” effect by means of an

additional resistor R3 connected between PFO and PFI which

helps in pulling PFI in the direction of PFO and eliminating an

indecision at the trip point. Resistor R3 is normally about 10 times

higher in resistance than R2 to keep the hysteresis band reasonable and should be larger than 10kΩ to avoid excessive loading on

the PFO pin. The calculations for the correct values of resistors to

set the hysteresis thresholds are given in Figure 8. A capacitor can

be added to offer additional noise rejection by low-pass filtering.

Figure 8. Hysteresis added to PFI pin

690A_10.eps

V

TRIP

V

L

V

H

V

IN

0V

PFO

+5V

0V

V

IN

GND

IMP690A

IMP692A

IMP802L

IMP802M

IMP805L

R

2

PFI

V

CC

R

1

PFO

+5V

R

3

To mP

*Optional

C1*

5

125

2

12

R

RR

V

+

< .

5

125

2

12

R

RR

V

+

> .

V

R

RR

V

RR

RRR

V

RRR

TRIP

IH

L

=

+

=

+

−

+

−

=

125

125

125 5 125 125

2

22

23

123

132

.

.

...

Page 9

©

1999 IMP, Inc. 408-432-9100/www.impweb.com 9

IMP690A

IMP690A

, 692A

, 692A

, 802L, 802M, 805L

, 802L, 802M, 805L

Application Information

Monitoring Capabilities of the Power-Fail Input

Although designed for power supply failure monitoring, the PFI

pin can be used for monitoring any voltage condition that can be

scaled by means of a resistive divider. An example is the negative

power supply monitor configured in Figure 9. In this case a good

negative supply will hold the PFI pin below 1.25V and the PFO

pin will be at a logic “0”. As the negative voltage declines,

the voltage at the PFI pin will rise until it exceeds 1.25V and

the PFO pin will go to a logic “1”.

Figure 9. Using PFI to monitor negative supply voltage

5 1 25 1 25

12

−

=

−..RV

R

TRIP

690A_11.eps

+5V

GND

V

TRIP

0V

PFO

+5V

0V

V–

IMP690A

IMP692A

IMP802L

IMP802M

IMP805L

R

2

V–

PFI

V– = V

TRIP

V

CC

PFO

R

1

Page 10

10

408-432-9100/www.impweb.com

©

1999 IMP, Inc.

IMP690A

IMP690A

, 692A

, 692A

, 802L, 802M, 805L

, 802L, 802M, 805L

IMP690A

IMP690A

, 692A

, 692A

, 802L, 802M, 805L

, 802L, 802M, 805L

Package Dimensions

Plastic DIP (8-Pin)

L

0°– 8°

C

H

E

e

D

B

A1

A

SO (8-Pin).eps

Inches Millimeters

Min Max Min Max

Plastic DIP (8-Pin)*

A ––––– 0.210 –––– 5.33

A1 0.015 ––––– 0.38 –––––

A2 0.115 0.195 2.92 4.95

b 0.014 0.022 0.36 0.56

b2 0.045 0.070 1.14 1.78

b3 0.030 0.045 0.80 1.14

D 0.355 0.400 9.02 10.16

D1 0.005 ––––– 0.13 –––––

E 0.300 0.325 7.62 8.26

E1 0.240 0.280 6.10 7.11

e 0.100 ––––– 2.54

eA 0.300 ––––– 7.62

eB ––––– 0.430 ––––– 10.92

eC ––––– 0.060

L 0.115 0.150 2.92 3.81

CerDIP (8-Pin)

A ––––– 0.200 –––– 5.08

A1 0.015 0.070 0.38 1.78

b 0.014 0.023 0.36 0.58

b2 0.038 0.065 0.97 1.65

C 0.008 0.015 0.20 0.38

D ––––– 0.405 ––––– 10.29

D1 0.005 ––––– 0.13 –––––

E 0.290 0.320 7.37 8.13

E1 0.220 0.310 5.59 7.87

e 0.100 2.54

L 0.125 0.200 3.18 5.08

SO (8-Pin)**

A 0.053 0.069 1.35 1.75

A1 0.004 0.010 0.10 0.25

B 0.013 0.020 0.33 0.51

C 0.007 0.010 0.19 0.25

e 0.050 1.27

E 0.150 0.157 3.80 4.00

H 0.228 0.244 5.80 6.20

L 0.016 0.050 0.40 1.27

D 0.189 0.197 4.80 5.00

SO (8-Pin)

* JEDEC Drawing MS-001BA

** JEDEC Drawing MS-012AA

CerDIP (8-Pin)

D1

D

A2

A

L

A1

e

b2

b

E

E1

0°–15°

C

eA

eB

Plastic DIP (8-Pin)a.eps

D1

D

A

L

A1

e

b2

b

E

E1

0°–15°

C

Ceramic DIP (8-Pin)a.eps

Page 11

IMP690A

IMP690A

, 692A

, 692A

, 802L, 802M, 805L

, 802L, 802M, 805L

IMP, Inc.

Corporate Headquarters

2830 N. First Street

San Jose, CA 95134-2071

Tel: 408-432-9100

Tel: 800-438-3722

Fax: 408-434-0335

e-mail: info@impinc.com

http://www.impweb.com

The IMP logo is a registered trademark of IMP, Inc.

All other company and product names are trademarks of their respective owners.

© 1999 IMP, Inc.

Printed in USA

Publication #: 1016

Revision: A

Issue Date: 08/17/99

Type: Preliminary

Loading...

Loading...