Page 1

HSP9501

Data Sheet January 1999 File Number

Programmable Data Buffer

The HSP9501 is a 10-Bit wide programmable data buffer

designed for use in high speed digital systems.Two different

modes of operation can be selected through the use of the

MODSEL input. In the delay mode, a programmable data

pipeline is created which can provide 2 to 1281 clock cycles

of delay between the input and output data. In the data

recirculate mode, the output data path is internally routed

back to the input to provide a programmable circular buffer.

The length of the buffer or amount of delay is programmed

through the use of the 11-bit LengthControl Input Port (LC0-

10) and the Length Control Enable (

is applied to the LC0-10 inputs,

next selected clock edge loads the new count value into the

Length Control Register. The delay path of the HSP9501

consists of two registers with a programmable delay RAM

between them, therefore, the value programmed into the

Length Control Register is the desired length - 2. The range

of values which can be programmed into the Length Control

Register are from 0 to 1279, which in turn results in an

overall range of programmable delays from 2 to 1281.

Clock select logicisprovided to allow theuseofapositive or

negative edge system clock as the CLK input to the

HSP9501. The active edge of the CLK input is controlled

through the use of the CLKSEL input. All synchronous timing

(i.e., data setup, hold, and output delays) are relative to the

clock edge selected by CLKSEL. An additional clock enable

input (

CLKEN) provides a means of disabling the internal

clock and holding the existing contents temporarily. All

outputs of the HSP9501 are three-state outputs to allow

direct interfacing to system or multi-use busses.

The HSP9501 is recommended for digital video processing

or any applications which require a programmable delay or

circular data buffer.

LCEN). An 11-bit value

LCEN is asserted, and the

2786.4

Features

• DC to 32MHz Operating Frequency

• Programmable Buffer Length from 2 to 1281 Words

• Supports Data Words to 10-Bits

• Clock Select Logic for Positive or Negative Edge

System Clocks

• Data Recirculate or Delay Modes of Operation

• Expandable Data Word Width or Buffer Length

• Three-State Outputs

• TTL Compatible Inputs/Outputs

• Low Power CMOS

Applications

• Sample Rate Conversion

• Data Time Compression/Expansion

• Software Controlled Data Alignment

• Programmable Serial Data Shifting

• Audio/Speech Data Processing Video/Image Processing

Video/Image Processing

• 1-H Delay Line of 910 NTSC, 1135 PAL or 1280 Samples:

- High Resolution Monitor Delay Line

- Comb Filter Designs

- Progressive Scanning Display

- TV Standards Conversion

- Image Processing

Ordering Information

TEMP.

PART NUMBER

HSP9501JC-25 0 to 70 44 Ld PLCC N44.65

HSP9501JC-32 0 to 70 44 Ld PLCC N44.65

HSP9501JC-2596 0 to 70 44 Ld PLCC

RANGE (oC) PACKAGE

Tape and Reel

PKG.

NO.

N44.65

191

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207 | Copyright © Intersil Corporation 1999

Page 2

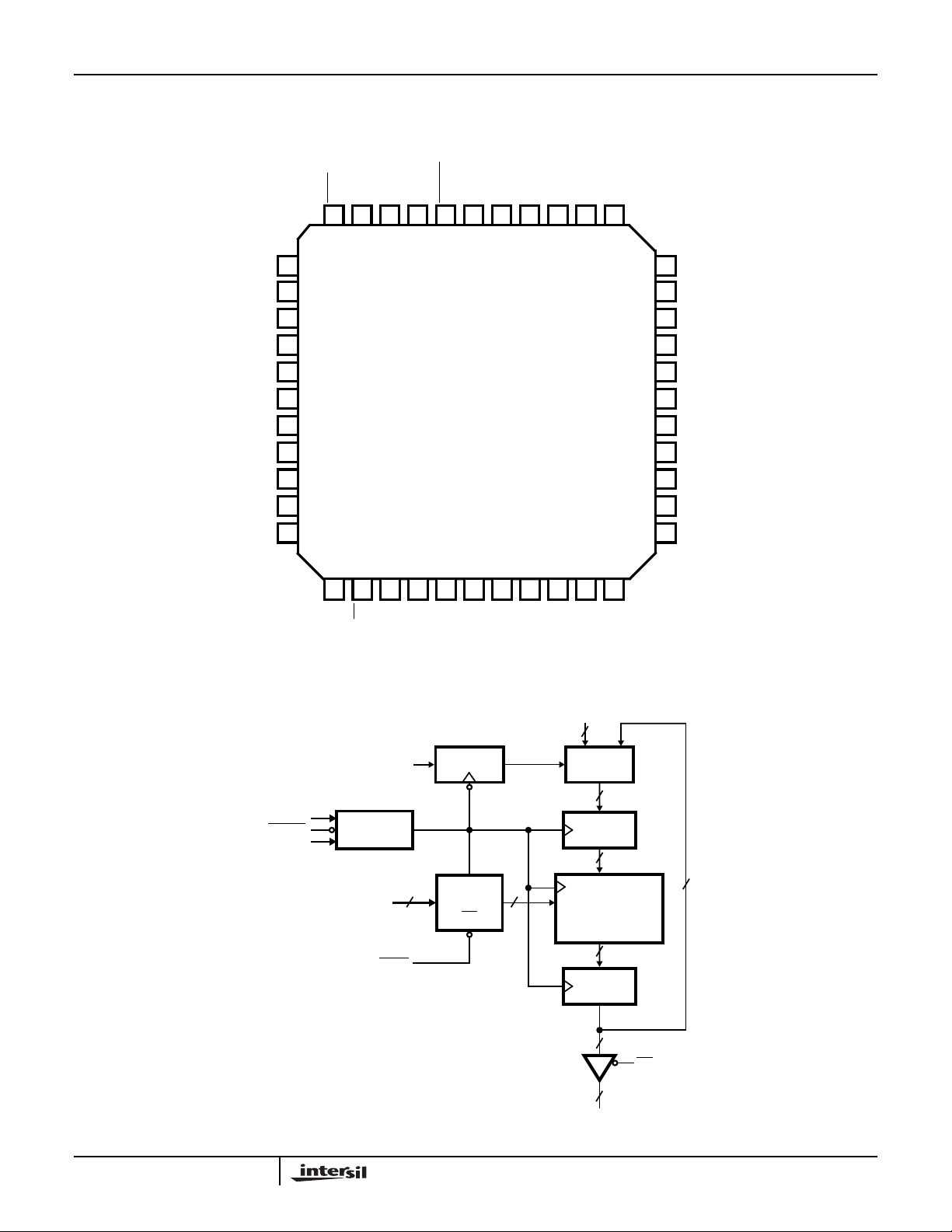

Pinout

HSP9501

44 LEAD PLCC

TOP VIEW

DO0

DO1

DO2

DO3

DO4

V

CC

GND

DO5

DO6

DO7

DO8

CLKSEL

LCEN

7

8

9

10

11

12

13

14

15

16

17

18 19 20 21 22 23 24 25 26 27 28

OE

DO9

NC

LC0

NC

LC1

CLK EN

LC10

CLK

LC9

LC2

LC8

LC3

LC7

LC4

LC6

LC5

DI9

MODSEL

4065 321444342414

NC

39

DI0

38

DI1

37

DI2

36

DI3

35

DI4

34

V

CC

33

GND

32

DI5

31

DI6

30

DI7

29

DI8

Block Diagram

CLKSEL

CLKEN

CLK

MODSEL

CLOCK

GENERATOR

LC0 -10

LCEN

11

REGISTER

REGISTER

EN

DI 0 -9

10

MUX

10

REGISTER

10

11

PROGRAMMABLE

DELAY RAM

0-1279 DELAYS

10

REGISTER

10

10

DO0-9

10

OE

192

Page 3

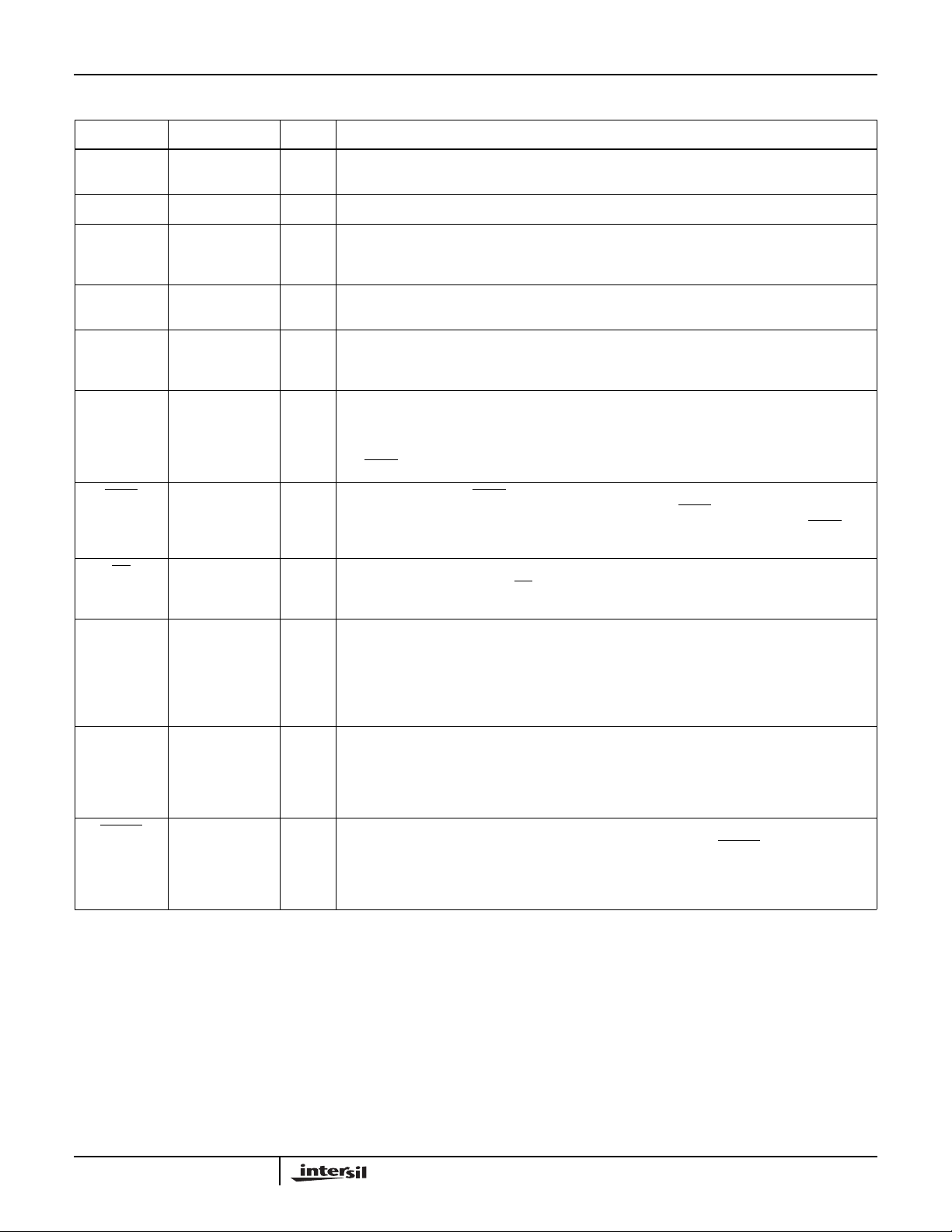

HSP9501

Pin Descriptions

NAME PIN NUMBER TYPE DESCRIPTION

V

CC

GND 13, 33 The device ground.

CLK 1 I Input Clock. This clock signal is used to control the datamovementthroughtheprogrammablebuff-

DIO-9 27, 29-32, 35-39 I Data Inputs. This 10-bit input port is used to provide the input data. When MODSEL is low, data

DO0-9 7-11, 14-18 O Data Outputs. This 10-bit port provides the output data from the Internal Delay Registers. Data

LC0-10 20-26, 41-44 I Length Control Inputs. These inputs are used to specify the number of clock cycles of delay be-

LCEN 6 I Length Control Enable. LCEN is used in conjunction with LC0-10 and CLK to load a new length

OE 19 I Output Enable. This input controls the state of the DO0-9 output port. A low on this control line en-

12, 34 The +5V power supply pin. A 0.1µF capacitor between the VCC and GND pin is

recommended.

er. It is also the signal which latches the input data, length control word and mode select. Input

setup and hold times with respect to the clock must be met for proper operation.

on the DI0-9 inputs is latched on the clock edge selected by CLKSEL.

latched into the DI0-9 inputs will appear at the DO0 9 outputs on the Nth clock cycle, where N is

the total delay programmed.

tween the DI0-9 inputs and the DO0-9 outputs. An integer value between 0 and 1279 is placed on

the LC0-10 inputs, and the total delay length (N) programmed is the LC0-10 value plus 2. In order

to properly load an active length control word, the value must be presented to the LC0-10 inputs

and LCEN must be asserted during an active clock edge selected by CLKSEL.

control word. An 11-bit value is loaded on the LC0-10 inputs, LCEN is asserted, and the next selected clock edge will load the new count value. Since this operation is synchronous, LCEN must

meet the specified setup/hold times with respect to CLK for proper operation.

ables the port for output. When OE is high, the output drivers are in the high impedance state. Internal latching or transfer of data is not affected by this input.

MODSEL 40 I Mode Select. This input is used to control the mode of operation of the HSP9501. A low on MOD-

SEL causes the device to latch new data at the DI0-9 inputs on every clock cycle, and operate as

a programmablepipeline register.When MODSEL is high, the HSP9501 is in the recirculate mode,

and will operate as a programmablelength circular buffer.This control signal may be used in a synchronous fashion during device operation, however,care must be taken to ensure the required setup/hold times with respect to CLK are met.

CLKSEL 5 I Clock Select Control. This input is used to determine which edge of the CLK signal is used for con-

trolling all internal events. A low on CLKSEL selects the negative going edge, therefore, all setup,

hold, and output delay times are with respect to the negative edge of CLK. When CLKSEL is high,

the positive going edge is selected and all synchronous timing is with respect to the positive edge

of the CLK signal.

CLKEN 2 I Clock Enable. This control signal can be used to enable or disable the CLK input. When low, the

CLK input is enabled and will operate in a normal fashion. A high on CLKEN will disable the CLK

input and will “hold'' all internal operations and data. This control signal may also be used in a synchronousfashion,however,setup and holdrequirements with respect to CLK must be met for proper device operation. This signal takes effect on the clock following the one that latches it in.

193

Page 4

HSP9501

Functional Description

The HSP9501 is a 10-bit wide programmable length data

buffer. The length of delay is programmable from 2 to 1281

delays in single delay increments.

Data into the delay line may be selected from the data input

bus (DI0-9) or as recirculated output, depending on the state

of the mode select (MODSEL) control input.

Mode Select

The MODSEL control pin selects the source of the data

moving into the delay line. When MODSEL is low, the data

input bus (DI0-9) is the source of the data. When MODSEL

is high, the output of the HSP9501 is routed back to the input

to form a circular buffer.

The MODSEL control line is latched at the input by the CLK

signal. The edge which latches this control signal is determined by the CLKSEL control line. In either case, the

MODSEL line is latched on one edge of the CLK signal with

the following edge moving data into and through the

HSP9501. Refer to the functional timing waveforms for

specific timing references.

Clock Select Logic

The clock select logic is provided to allow the use of positive

or negative edge system clocks. The active edge of the CLK

input to the HSP9501 is controlled through the use of the

CLKSEL input.

When CLKSEL is low, the negative going edge of CLK is

used to control all internal operations. A high on CLKSEL

selects the positive going edge of CLK.

All synchronous timing (i.e., setup, hold and output

propagation delay times are relative to the CLK edge

selected by CLKSEL. Functional timing waveforms for each

state of CLKSEL are provided (refer to Timing Waveforms for

details).

Delay Path Control

The HSP9501 buffer length is programmable from 2to 1281

data words in one word increments. The minimum number of

delays which can be programmed is two, consisting of the

input and Output Buffer Registers only.

The length control inputs (LC0-10) are used to set the length

of the programmable delay ram which can vary in length

from 0 to 1279. The total length of the HSP9501 data buffer

will then be equal to the programmed value on LC0-10 plus

2. The programmed delay is established by the 11-bit integer

value of the LC0-10 inputs with LC-10 as the MSB and LC0

as the LSB.

For example,

LC10 9 8 7 6 5 4 3 2 1 LC0

0 000100000 1

programs a length value of 2

the delay will be 65 + 2 or 67 delays.

Table 1 indicates several programming values. The decimal

value placed on LC0-10 must not exceed 1279. Controlled

operation with larger values is not guaranteed.

Values on LC0-10 are latched on the CLK edge selected by

the CLKSEL control line, when

LCEN must meet the specified setup and hold times relative

to the selected CLK edge for proper device operation.

6

+ 20 = 65. The total length of

LCEN is active. LC0-10 and

TABLE 1. LENGTH CONTROL PROGRAMMING EXAMPLES

TOTAL

LC9

10

LC10 2

0 0000000000 0 2

0 0 0 0 1 1 1 0 1 1 0 118 120

0 1 1 0 0 1 0 1 0 0 0 808 810

1 0 0 0 0 0 1 1 0 0 1 1049 1051

1 0 0 1 1 1 1 1 1 1 1 1279 1281

LS8

9

2

LC7

8

2

LC6

7

2

LC5

6

2

LC4

5

2

LC3

4

2

LC2

3

2

LC1

2

2

LC0

1

2

0

2

PROGRAMMED

LENGTH

LENGTH

194

N

Page 5

HSP9501

Absolute Maximum Ratings Thermal Information

Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +8.0V

Input, Output or Voltage Applied . . . . . . . .GND -0.5V to VCC +0.5V

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . .0oC to 70oC

Voltage Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . +4.75V to 5.25V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

Thermal Resistance (Typical, Note 1) θJA (oC/W)

PLCC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.2

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . .150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300oC

(PLCC - Lead Tips Only)

DC Electrical Specifications V

= 5.0V +5%, TA = 0oC to 70oC, Commercial

CC

PARAMETER SYMBOL TEST CONDITIONS MIN MAX UNITS

Logical One Input Voltage V

Logical Zero Input Voltage V

Output HIGH Voltage V

Output LOW Voltage V

Input Leakage Current I

Output Leakage Current I

Standby Current I

Operating Power Supply Current I

Input Capacitance C

Output Capacitance C

AC Electrical Specifications V

= 5.0V ±5%, TA = 0oC to +70oC, Commercial, (Note 5)

CC

PARAMETER SYMBOL

Clock Period t

Clock Pulse Width High t

Clock Pulse Width Low t

Data Input Setup Time t

Data Input Hold Time t

Output Enable Time t

Output Disable Time t

CLKEN to Clock Setup t

CLKEN to Clock Hold t

LC0-10 Setup Time t

LC0-10 Hold Time t

LCEN to Clock Setup t

LCEN to Clock Hold t

IH

IL

OH

OL

I

O

CCSB

CCOP

IN

O

CP

PWH

PWL

DS

DH

ENA

DIS

ES

EH

LS

LH

LES

LEH

VCC = 5.25V 2.0 - V

VCC = 4.75V - 0.8 V

IOH = -4mA VCC = 4.75V 2.4 - V

IOL = +4.0mA VCC = 4.75V - 0.4 V

VIN = GND or VCC VCC = 5.25V -10 10 µA

V

= GND or VCC = 5.25V -10 10 µA

OUT

VIN = VCC or GND, VCC = 5.25V, Note 3 - 500 µA

f = 25MHz, VIN = VCC or GND

- 125 mA

VCC = 5.25V, Notes 2, 3

FREQ = 1MHz, VCC = Open, All

-10 pF

measurements are referenced to device

GND

-10 pF

-32 -25

UNITS NOTESMIN MAX MIN MAX

31 - 40 - ns 12 - 15 - ns 12 - - 15 ns 10 - 12 - ns -

2-2-ns-

- 20 - 25 ns -

- 24 - 25 ns Note 4

10 - 12 - ns -

2-2-ns-

10 - 13 - ns -

2-2-ns-

10 - 13 - ns -

2-2-ns-

195

Page 6

HSP9501

AC Electrical Specifications V

= 5.0V ±5%, TA = 0oC to +70oC, Commercial, (Note 5) (Continued)

CC

-32 -25

PARAMETER SYMBOL

MODSEL Setup Time t

MODSEL Hold Time t

Clock to Data Out T

Output Hold from Clock T

Rise, Fall Time T

MS

MH

OUT

OH

RF

10 - 13 - ns -

2-2-ns-

- 16 - 22 ns -

4-4-ns-

-6-6nsNote 4

UNITS NOTESMIN MAX MIN MAX

NOTES:

2. Power supply current is proportional to operating frequency. Typical rating for I

CCOP

is 5mA/MHz.

3. Output load per test load circuit with switch open and CL = 40pF.

4. Controlled by design or process parameters and not directly tested. Characterized upon initial design and after major process and/or design

changes.

5. AC Testing is performed as follows: Input levels: 0V and 3.0V, timing reference levels = 1.5V, input rise and fall times driven at 1ns/V, output

load CL = 40pF.

Test Load Circuit

SWITCH S1 OPEN FOR I

NOTE: Includes stray and jig capacitance.

DUT

CCSB

C

L

AND I

S

1

(NOTE)

CCOP

±

I

OH

EQUIVALENT CIRCUIT

1.5V I

OL

196

Page 7

Timing Waveforms

CLK

MODSEL

HSP9501

t

CP

t

t

MS

PWH

t

PWL

t

MH

DI 0 -9

OE

DO 0 -9

CLKEN

INTERNAL

CLOCK

CLK

t

OUT

t

DH

t

DIS

t

DS

t

OH

FIGURE 1. FUNCTIONAL TIMING (CLKSEL = LOW)

t

ES

T

EH

t

ES

FIGURE 2. CLEN TIMING (CLKSEL = LOW)

1.3

1.7

t

ENA

CLK

t

2.0V

0.8V

t

RF

2.0V

0.8V

LCEN

t

RF

LC0 -10

LES

t

LS

t

LEH

t

LH

FIGURE 3. OUTPUT RISE AND FALL TIMES FIGURE 4. LENGTH CONTROL TIMING (CLKSEL = LOW)

197

Page 8

HSP9501

Timing Waveforms

CLK

MODSEL

DI 0 -9

OE

DO 0 -9

CLK

CLKEN

(Continued)

t

MS

t

CP

t

PWL

t

DS

t

OH

t

OUT

t

PWH

t

DH

t

DIS

FIGURE 5. FUNCTIONAL TIMING (CLKSEL = HIGH)

t

ES

t

EH

t

ES

1.7

1.3

t

ENA

t

MH

INTERNAL

CLOCK

FIGURE 6. CLKEN TIMING (CLKSEL = HIGH)

CLK

LCEN

LC 0 -10

t

LES

t

LS

t

LEH

t

LH

FIGURE 7. LENGTH CONTROL TIMING (CLKSEL = HIGH)

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However ,no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

198

Loading...

Loading...