Page 1

HSP50110

Data Sheet January 1999 File Number

Digital Quadrature Tuner

The Digital Quadrature Tuner (DQT) provides many of the

functions required for digital demodulation. These functions

include carrier LO generation and mixing, baseband

sampling, programmable bandwidth filtering, baseband AGC,

and IF AGCerror detection. Serial control inputs are provided

which can be used to interface with external symbol and

carrier tracking loops. These elements make the DQT ideal

for demodulator applications with multiple operational modes

or data rates. The DQT may be used with HSP50210 Digital

Costas Loop to function as a demodulator for BPSK, QPSK,

8-PSK OQPSK, FSK, FM, and AM signals.

The DQT processes a real or complex input digitized at rates

up to 52 MSPS. The channel of interest is shifted to DC by a

complex multiplication with the internal LO. The quadrature

LO is generated by a numerically controlled oscillator (NCO)

with a tuning resolution of 0.012Hz at a 52MHz sample rate.

The output of the complex multiplier is gain corrected and fed

into identical low pass FIR filters. Each filter is comprised of a

decimating low pass filter followed by an optional

compensation filter. The decimating low pass filter is a 3

stage Cascaded-Integrator-Comb (CIC) filter. The CIC filter

can be configured as an integrate and dump filter or a third

order CIC filter with a (sin(X)/X)

filters are provided to flatten the (sin(X)/X)

CIC. If none of the filtering options are desired, they may be

bypassed. The filter bandwidth is set by the decimation rate of

the CIC filter. The decimation rate may be fixed or adjusted

dynamically by a symbol tracking loop to synchronize the

output samples to symbol boundaries. The decimation rate

may range from 1-4096. An internal AGC loop is provided to

maintain the output magnitude at a desired level. Also, an

input level detector can be used to supply error signal for an

external IF AGC loop closed around the A/D.

The DQT output is provided in either serial or parallel formats

to support interfacing with a variety DSP processors or digital

filter components. This device is configurable o ver a general

purpose 8-bit parallel bidirectional microprocessor control bus.

3

response. Compensation

N

response of the

3651.4

Features

• Input Sample Rates to 52 MSPS

• Internal AGC Loop for Output Level Stability

• Parallel or Serial Output Data Formats

• 10-Bit Real or Complex Inputs

• Bidirectional 8-Bit Microprocessor Interface

• Frequency Selectivity <0.013Hz

• Low Pass Filter Configurable as Three Stage CascadedIntegrator-Comb (CIC), Integrate and Dump, or Bypass

• Fixed Decimation from 1-4096, or Adjusted by NCO

Synchronization with Baseband Waveforms

• Input Level Detection for External IF AGC Loop

• Designed to Operate with HSP50210 Digital Costas Loop

• 84 Lead PLCC

Applications

• Satellite Receivers and Modems

• Complex Upconversion/Modulation

• Tuner for Digital Demodulators

• Digital PLL’s

• Related Products: HSP50210 Digital Costas Loop;

A/D Products HI5703, HI5746, HI5766

• HSP50110/210EVAL Digital Demod Evaluation Board

Ordering Information

TEMP.

PART NUMBER

HSP50110JC-52 0 to 70 84 Ld PLCC N84.1.15

HSP50110JI-52 -40 to 85 84 Ld PLCC N84.1.15

RANGE (oC) PACKAGE PKG. NO.

Block Diagram

10

REAL OR COMPLEX

INPUT DATA

10

IF AGC

CONTROL

CONTROL/STATUS

BUS

LEVEL

DETECT

3-229

COMPLEX

MULTIPLIER

8

LOOP

LOW PASS FIR

FILTER

o

o

NCO

LOW PASS FIR

FILTER

FILTER

RE-SAMPLING

http://www.intersil.com or 407-727-9207

GCA

90

0

GCA

PROGRAMMABLE

CONTROL

INTERFACE

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

NCO

LEVEL

DETECT

DUMP

10

I DATA

CARRIER

TRACKING CONTROL

10

Q DATA

SAMPLE STROBE

SAMPLE RATE

CONTROL

| Copyright © Intersil Corporation 1999

Page 2

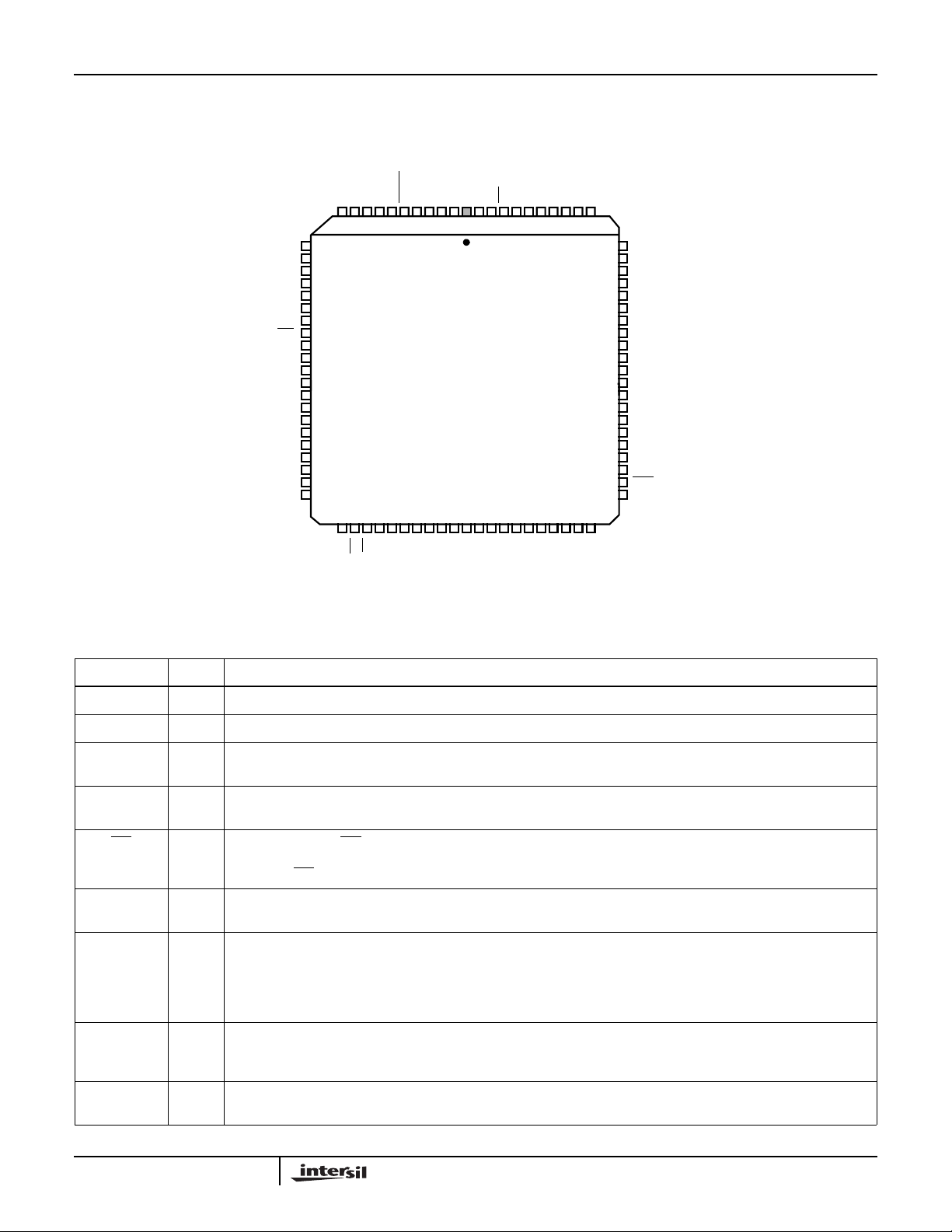

Pinout

IIN5

IIN4

IIN3

IIN2

GND

IIN1

IIN0

ENI

QIN9

QIN8

QIN7

QIN6

QIN5

QIN4

V

QIN3

QIN2

QIN1

QIN0

PH1

PH0

HSP50110

HSP50110 (PLCC)

TOP VIEW

IOUT4

IOUT5

IOUT6

GND

IOUT7

IOUT8

IOUT9

OEI

LOTP

SPH0

SPH1

SPH2

SPH3

VCCSPH4

SSTRB

HI/LO

IIN9

IIN8

IIN7

IIN6

111098765432184838281807978777675

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

CC

27

28

29

30

31

32

33 343536 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

IOUT3

IOUT2

IOUT1

IOUT0

DATARDY

V

CC

CLK

GND

QOUT9

QOUT8

QOUT7

QOUT6

QOUT5

GND

QOUT4

QOUT3

QOUT2

QOUT1

QOUT0

OEQ

V

CC

CFLD

WR

GND

V

COF

COFSYNC

SOF

SOFSYNC

GND

CC

C0

C1

C2

C3

C4

C5

C6

C7

A0

A1

A2

RD

Pin Description

NAME TYPE DESCRIPTION

V

CC

GND - Ground.

IIN9-0 I In-Phase Input. Data input for in-phase (real) samples. Format may be either two’s complement or offset binary format

QIN9-0 I Quadrature Input. Data input for quadrature (imaginary) samples. Format may be either two’s complement or offset bi-

ENI I Input Enable. When ENI is active ‘low’, data on IIN9-0 and QIN9-0 is clocked into the processing pipeline by the rising

PH1-0 I Carrier Phase Offset. The phase of the internally generated carrier frequency may be shifted by 0, 90, 180, or 270 de-

CFLD I Carrier Frequency Load. This input loads the Carrier Frequency Register in the Synthesizer NCO (see

- +5V Power Supply.

(see I/O Formatting/Control Register in Table 10). IIN9 is the MSB.

nary format (see I/O Formatting/Control Register in Table 10). QIN9 is the MSB.

edge of CLK. This input also controls the internal data processing as described in the Input Controller Section of the

data sheet. ENI is active ‘low’.

grees bycontrolling these pins (see Synthesizer/Mixer Section). The phase mapping for these inputs is givenin Table 1.

Synthesizer/Mixer Section). When this input is sampled ‘high’ by clock, the contents of the Microprocessor Interface

Holding Registers are transferred to the carrier frequency register in the Synthesizer NCO (see Microprocessor Interface Section).

NOTE: This pin must be ‘low’ when loading other configuration data via the Microprocessor In-

terface. Active high Input.

COF I Carrier Offset Frequency Input. This serial input is used to load the Carrier Offset Frequency into the Synthesizer NCO

(see Serial Interface Section). The new offset frequency is shifted in MSB first by CLK starting with the clock cycle after

the assertion of COFSYNC.

COFSYNC I Carrier Offset FrequencySync.This signal is asserted one CLK cycle before the MSB of the offset frequency data word

(see Serial Interface Section).

3-230

Page 3

HSP50110

Pin Description

NAME TYPE DESCRIPTION

SOF I Sampler Offset Frequency. This serial input is used to load the Sampler Offset Frequency into the Re-Sampler NCO

SOFSYNC I Sampler Offset Frequency Sync. This signal is asserted one CLK cycle before the MSB of Sampler Offset Frequency

A2-0 I Address Bus. These inputs specify a target register within the Microprocessor Interface (see Table 5). A2 is the MSB.

C7-0 I/0 Control Bus. This is the bidirectional data bus for reads and writes to the Microprocessor Interface (see Microprocessor

WR I Write. This is the write strobe for the Microprocessor Interface (see Microprocessor Interface Section).

RD I Read. This is the read enable for the Microprocessor Interface (see Microprocessor Interface Section).

IOUT9-0 O In-Phase Output. The data on these pins is output synchronous to CLK. New data on IOUT9-0 is indicated by the as-

QOUT9-0 O Quadrature Output. The data on these pins is output synchronous to CLK. New data on the QOUT(9-0) pins is indicated

DATARDY O Data Ready. This output is asserted on the first clock cycle that new data is available on the IOUT and QOUT data

(Continued)

(see Serial Interface Section). The new offset frequency is shifted in MSB first by CLK starting with the clock cycle after

assertion of SOFSYNC.

data word (see Serial Interface Section).

This input is setup and held to the rising edge of WR.

Interface Section). C7 is the MSB.

sertion of the DATARDYpin. Data may be output parallel or serial mode (see Output Formatter Section). In the parallel

mode, IOUT9 is the MSB. When the serial mode is used, IOUT0 is data, and IOUT9 is the serial clock. Other pins not

used in serial mode may be set high or low via the control interface.

by the DATARDY pin. Data may be output parallel or serial mode. In the parallel mode, IOUT9 is the MSB. When the

serial mode is used, QOUT0 is data.

busses (see Output Formatter Section). This pin may be active ‘high’ or ‘low’ depending on the configuration of the I/O

Formatting/Control Register (see Table10). In serial mode, DATARDYis asserted one IQ clock before for first bit of serial data.

OEI I In-Phase Output Enable. This pin is the three-state control for IOUT9-0. When OEI is ‘high’, the IOUT bus is held in the

high impedance state.

OEQ I Quadrature Output Enable. This pin is the three-state control for QOUT9-0. When OEQ is ‘high’, the QOUT bus is held

in the high impedance state.

LOTP 0 LocalOscillator Test Point. This output is the MSB of the Synthesizer NCO phase accumulator (see Synthesizer/Mixer

Section). This is provided as a test point for monitoring the frequency of the Synthesizer NCO.

SSTRB 0 Sample Strobe. This is the bit rate strobe for the bit rate NCO. SSTRB has two modes of operation: continuous update

and sampled. In continuous update mode, this is the carry output of the Re-Sampler NCO. In sampled mode, SSTRB

is active synchronous to the DATARDY signal for parallel output mode. The sampled mode is provided to signal the

nearest output sample aligned with or following the symbol boundary.This signal can be used with SPH(4-0) below to

control a resampling filter to time shift its impulse response to align with the symbol boundaries.

SPH4-0 0 Sample Phase. These are five of the most significant 8 bits of the Re-Sampler NCO phase accumulator. Which five bits

of the eight is selected via the Chip Configuration Register (see Table 12). These pins update continuously when the

SSTRB output is in the continuous update mode. When the SSTRB pin is in the sampled mode, SPH4-0 update only

when the SSTRB pin is asserted. In the sampled mode, these pins indicate how far the bit phase has advanced past

the symbol boundary when the output sample updates. SPH4 is the MSB.

HI/LO 0 HI/LO. The output of the Input Level Detector is provided on this pin (see Input Level Detector Section). The sense of

the HI/LO pin is set via the Chip Configuration Register (see Table 12). This signal can be externally averagedandused

to control the gain of an amplifier to close an AGC loop around the A/D converter. This type of AGC sets the level based

on the median value on the input.

CLK I Clock. All I/O’s with the exception of the output enables and the microprocessor interface are synchronous to clock.

3-231

Page 4

HSP50110

HI/LO

IIN0-9

CLK

QIN0-9

ENI

INPUT MODE†

INPUT FORMAT†

COFSYNC

WORD WIDTH†

SOFSYNC

LEVEL

DETECT

10

10

PH0-1

CFLD

COF

COF EN†

SOF

A0-2

WR

RD

C0-7

HI/LO OUTPUT SENSE†

THRESHOLD FOR

EXTERNAL AGC†

SYNTHESIZER/MIXER

INPUT

CONTROLLER

SHIFT REG

MULTIPLIER

COS SIN

SYNTHESIZER

MICROPROCESSOR INTERFACE

COMPLEX

10

NCO

UPPER LIMIT†

LOWER LIMIT†

LOOP

AGC

12

12

10

32

CENTER

FREQUENCY†

8

PHASE

OFFSET†

LOTP

FILTER

LOW PASS FILTERING

DECIMATING COMPENSATION

FILTER FILTER

CLK

†

Indicates data downloaded via microprocessor interface

LOOP GAIN †

11

11

DIVIDER

RE-SAMPLER

NCO

SHIFT REG

RE-SAMPLER

AGC THRESHOLD†

10

10

5

32

SAMPLER CENTER

FREQUENCY†

SOF EN†

WORD WIDTH†

LEVEL

DETECT

F

O

R

M

A

T

OEI

IOUT0-9

DATARDY

QOUT0-9

OEQ

SSTRB

SPH0-4

FIGURE 1. FUNCTIONAL BLOCK DIAGRAM OF HSP50110

Functional Description

The Digital Quadrature Tuner (DQT) provides many of the

functions needed for digital demodulation including: carrier

LO generation, mixing, low-pass filtering, baseband

sampling, baseband AGC, and IF AGC error detection. A

block diagram of the DQT is provided in Figure 1. The DQT

processes a real or complex input at rates up to 52 MSPS.

The digitized IF is input to the Synthesizer/Mixer where it is

multiplied by a quadrature LO of user programmable

frequency. This operation tunes the channel of interest to DC

where it is extracted by the Low Pass FIR Filtering section.

The filter bandwidth is set through a user programmable

decimation factor. The decimation factor is set by the ReSampler which controls the baseband sampling rate. The

baseband sample rate can be adjusted by an external

symbol tracking loop via a serial interface. Similarly, a serial

interface is provided which allows the frequency of the

Synthesizer/Mixer’s NCO to be controlled by an external

carrier tracking loop. The serial interfaces were designed to

mate with the output of loop filters on the HSP50210 Digital

Costas Loop.

The DQT provides an input level detector and an internal

AGC to help maintain the input and output signal

magnitudes at user specified levels. The input level detector

compares the input signal magnitude to a programmable

level and generates an error signal. The error signal can be

externally averaged to set the gain of an amplifier in front of

the A/D which closes the AGC loop. The output signal level

is maintained by an internal AGC loop closed around the

Low Pass Filtering. The AGC loop gain and gain limits are

programmable.

Input Controller

The input controller sets the input sample rate of the

processing elements. The controller has two operational

modes which include a Gated Input Mode for processing

sample rates slower than CLK, and an Interpolated Input

Mode for increasing the effective time resolution of the

samples. The mode is selected by setting bit 1 of the I/O

Formatting Control Register in Table 10.

In Gated Input Mode, the Input Enable (

data flow into the input pipeline and the processing of the

internal elements. When this input is sampled “low” by CLK,

the data on IIN0-9 and QIN0-9 is clocked into the processing

pipeline; when

ENI is sampled “high”, the data inputs are

disabled. The Input Enable is pipelined to the internal

ENI) controls the

3-232

Page 5

HSP50110

processing elements so that they are enabled once for each

time

ENI is sampled low. This mode minimizes the

processing pipeline latency, and the latency of the part’s

serial interfaces while conserving power.

Note: the

effective input sample rate to the internal processing

elements is equal to the frequency with which

ENI is

asserted “low”.

In Interpolated Input Mode, the ENI input is used to insert

zeroes between the input data samples. This process

increases the input sample rate to the processing elements

which improves the time resolution of the processing chain.

When

ENI is sampled “high” by CLK, a zero is input into the

processing pipeline. When

data is fed into the pipeline.

ENI is sampled “low” the input

Note: Due to the nature of the

rate change operation, consideration must be given to

the scaling and interpolation filtering required for a

particular rate change factor.

In either the Gated or Interpolated Input Mode, the

Synthesizer NCO is gated by the

ENI input. This only allows

clocking of the NCO when external samples are input to the

processing pipeline. As a result, the NCO frequency must be

set relative to the input sample rate, not the CLK rate (see

Synthesizer/Mixer Section).

NOTE: Only fixed

interpolation rates should be used when operating the

part in Interpolated Mode at the Input Controller.

Input Level Detector

The Input Level Detector generates a one-bit error signal for

an external IF AGC filter and amp. The error signal is

generated by comparing the magnitude of the input samples

to a user programmable threshold. The HI/LO pin is then

driven “high” or “low” depending the relationship of its

magnitude to the threshold. The sense of the HI/LO pin is

programmable so that a magnitude exceeding the threshold

can either be represented as a “high” or “low” logic state.

The threshold and the sense of the HI/LO pin are configured

by loading the appropriate control registers via the

Microprocessor Interface (see Tables 8 and 12).

The high/low outputs can be integrated by an external loop

filter to close an AGC loop. Using this method the gain of the

loop forces the median magnitude of the input samples to

the threshold. When the magnitude of half the samples are

above the threshold and half are below, the error signal is

integrated to zero by the loop filter.

6.5%. For real inputs, the magnitude detector reduces to a

an absolute value detector with negligible error.

Note: an external AGC loop using the Input Level

Detector may go unstable for a real sine wave input

whose frequency is exactly one quarter of the sample

rate (F

/4). The Level Detector responds to such an

S

input by producing a square wave output with a 50%

duty cycle for a wide range of thresholds. This square

wave integrates to zero, indicating no error for a range

of input signal amplitudes.

Synthesizer/Mixer

The Synthesizer/Mixer spectrally shifts the input signal of

interest to DC for subsequent baseband filtering. This

function is performed by using a complex multiplier to

multiply the input with the output of a quadrature numerically

controlled oscillator (NCO). The multiplier operation is:

I

= IIN x cos (ωc) - QIN x sin (ωc) (EQ. 3)

OUT

= IIN x sin (ωc) + QIN x cos (ωc) (EQ. 4)

Q

OUT

The complex multiplier output is rounded to 12 bits. For real

inputs this operation is similar to that performed by a

quadrature downconverter. For complex inputs, the

Synthesizer/Mixer functions as a single-sideband or image

reject mixer which shifts the frequency of the complex

samples without generating images.

TO COMPLEX MULTIPLIER

SINCOS

10 10

0

REG

REG

SIN/COS

ROM

11

32

CF

+

REG

+

REG

R

PHASE OFFSET †

8

E

G

0

MUX

PHASE

ACCUMULATOR

LOAD†

Controlled via

†

microprocessor interface.

PH0-1

LOTP

COF

ENABLE †

R

E

G

REG

COF

2

MUX

32

REG

The algorithm for determining the magnitude of the complex

input is given by:

Mag(I,Q) = |I| + .375 x |Q| if |I| > |Q| (EQ. 1)

or:

Mag(I,Q) = |Q| + .375 x |I| if |Q| > |I|, (EQ. 2)

Using this algorithm, the magnitude of complex inputs can

be estimated with an error of <0.55dB or approximately

3-233

COFSYNC

COF

CFLD

SYNC

SHIFT REG

R

E

G

FIGURE 2. SYNTHESIZER NCO

CARRIER

FREQUENCY†

SYNC

LOAD CARRIER

FREQUENCY

†

Page 6

HSP50110

The quadrature outputs of the NCO are generated by driving

a sine/cosine lookup table with the output of a phase

accumulator as shown in Figure 2. Each time the phase

accumulator is clocked, its sum is incremented by the sum of

the contents of the Carrier Frequency (CF) Register and the

Carrier Offset Frequency (COF) Register. As the

accumulator sum transitions from 0 to 2

32

, the SIN/COS

ROM produces quadrature outputs whose phase advances

o

from 0

to 360o. The sum of the CF and COF Registers

represent a phase increment which determines the

frequency of the quadrature outputs. Large phase

increments take fewer clocks to transition through the sine

wave cycle which results in a higher frequency NCO output.

The NCO frequency is set by loading the CF and COF

Registers. The contents of these registers set the NCO

frequency as given by the following,

F

= FS x (CF + COF)/232, (EQ. 5)

C

where f

is the sample rate set by the Input Controller, CF is

S

the 32-bit two’s complement value loaded into the Carrier

Frequency Register, and COF is the 32-bit two’s

complement value loaded into the Carrier Offset Frequency

Register. This can be rewritten to have the programmed CF

and COF value on the left:

(CF + COF) = INT FC/F

()2

[]

32

S

HEX

(EQ. 5A)

As an example, if the CF Register is loaded with a value of

3000 0000 (Hex), the COF Register is loaded with a value of

1000 0000 (Hex), and the input sample rate is 40 MSPS, an

the NCO would produce quadrature terms with a frequency

of 10MHz. When the sum of CF and COF is a negative

value, the cos/sin vector generated by the NCO rotates

clockwise which downconverts the upper sideband; when

the sum is positive, the cos/sin vector rotates

counterclockwise which upconverts the lower sideband.

Note: the input sample rate FSis determined by the rate

at which

Section). If

ENI is asserted low (see Input Controller

ENI is tied low, the input sample rate is equal

to the CLK rate.

The Carrier Frequency Register is loaded via the

Microprocessor Interface and the Carrier Offset Frequency is

loaded serially using the COF and COFSYNC inputs. The

procedure for loading these registers is discussed in the

Microprocessor Interface Section and the Serial Input

Section.

The phase of the NCO’s quadrature outputs can be adjusted

by adding an offset value to the output of the phase

accumulator as shown in Figure 2. The offset value can be

loaded into the Phase Offset (PO) Register or input via the

PH0-1 inputs. If the PO Register is used, the phase can be

adjusted from -π to π with a resolution of ~1.4

o

. The phase

offset is given by the following equation,

φ = π x (PO/128), (EQ. 6)

where PO is the 8-bit two’s complement value loaded into the

Phase Offset Register (see Phase Offset Register in Table 6).

As an example, a value of 32, (20

), loaded into the

HEX

Phase Offset Register would produce a phase offset of 45

An alternative method for controlling the NCO Phase uses

the PH0-1 inputs to shift the phase of NCO’s output by 0

o

90

, 180o, or 270o. The PH0-1 inputs are mapped to phase

o

,

shifts as shown in Table 1. The phase may be updated every

clock supporting the π/2 phase shifts required for modulation

or despreading of CDMA signals.

The output of the complex multiplier is scaled by 2

-36

. See

“Setting DQT Gains” below.

TABLE 1. PH0-1 INPUT PHASE MAPPING

PH1-0 PHASE SHIFT

00 0

01 90

10 270

11 180

o

o

o

o

AGC

The level of the Mixer output is gain adjusted by an AGC

closed around the Low Pass Filtering. The AGC provides the

coarse gain correction necessary to help maintain the output

of the HSP50110 at a signal level which maintains an

acceptable dynamic range. The AGC consists of a Level

Detector which generates an error signal, a Loop Gain

multiplier which amplifies the error, and a Loop Filter which

integrates the error to produce gain correction (see

Figure 4).

The Level Detector generates an error signal by comparing the

magnitude of the DQT output against a user programmable

threshold (see AGC Control Register in Table 9). In the normal

mode of operation, the Level Detector outputs a -1 for

magnitudes above the threshold and +1 for those belo w the

threshold. The ±1 outputs are then multiplied by a

programmableloop gain to generate the error signal integrated

by the Loop Filter. The Level Detector uses the magnitude

estimation algorithm described in the Input Level Detector

Section. The sense of the Level Detector Output ma y be

changed via the Chip Configuration Register, bit 0 (see Table

12).

The Loop Filter consists of a multiplier, an accumulator and a

programmablelimiter.Themultiplier computes the product of

the output of the Level Detector and the Programmable Loop

Gain. The accumulator integrates this product to produce the

AGC gain, and the limiter keeps the gain between preset

limits (see AGC Control Register, Table 9). The output of the

AGC Loop Filter Accumulator can be read via the

Microprocessor Interface to estimate signal strength (see

Microprocessor Interface Section).

o

.

3-234

Page 7

HSP50110

The Loop Filter Accumulator uses a pseudo floating point

format to provide up to ~48dB of gain correction. The format

of the accumulator output is shown in Figure 3. The AGC

gain is given by:

Gain

LOOP FILTER ACCUMULATOR PARAMETER

This Value Can Be Read By The Microprocessor.

See The Microprocessor Interface Section.

= (1.0 + M) x 2

AGC

MAPS TO AGC

UPPER AND LOWER LIMITS

L

LLLLLLL

22120

2

EM

EXPONENT

FIGURE 3. BINARY FORMATFOR LOOP FILTER

.

EE MMMXGGGGGGGG

0 TO 7

MAPS TO µP AGC

ACCUMULATOR

E

2-12-22-32-42-52-62-72-82-92

MANTISSA

0.0 to 0.9375

PROGRAMMABLE

LOOP GAIN

(EQ. 7)

-102-112-122-13

where M is the 4-bit mantissa value ranging from 0.0 to

0.9375, and E is the three bit exponent ranging from 0 to 7.

The result is a piece wise linear transfer function whose

overall response is logarithmic, as shown in Figure 5. The

exponent bits provide a coarse gain setting of 2

corresponds to a gain range from 0dB to 42dB (2

(EEE)

. This

0

to 27) with

the MSB representing a 24dB gain, the next bit a 12dB gain,

and the final bit a 6dB gain. The fourmantissa bits map to an

additional gain of 1.0 to 1.9375 (0 to ~6dB). Together, the

exponent and the mantissa portion of the limit set a gain

range from 0 to ~48dB.

DISABLE

LEVEL

DETECTOR

I DATA

AGC

Q DATA

AGC GAIN

REG LIMIT

UPPER

GAIN

LIMIT †

AGC L.D. SENSE†

AGC THRESHOLD †

AGC LOOP FILTER

+

LOWER

GAIN

LIMIT †

REG

PROGRAMMABLE

LOOP GAIN

†

† Indicates data downloaded via microprocessor interface.

FIGURE 4. AGC BLOCK DIAGRAM

The limiter restricts the AGC gain range by keeping the

accumulator output between the programmed limits. If the

accumulator exceeds the upper or lower limit, then the

accumulator is held to that limit. The limits are programmed

via eight bit words which expressthe valuesof the upper and

lower limits as eight bit pseudo floating point numbers as

shown in Figure 3 (see AGC Control Register, Table 9). The

format for the limits is the same as the format of the eight

most significant bits of the Loop Filter Accumulator.

Examples of how to set the limits for a specific output signal

levelare provided in the “Setting DQT Gains” Section below.

NOTE: A fixed AGC gain may be set by programming

the upper and lower limits to the same value.

256

240

224

208

192

176

160

144

128

112

96

GAIN (LINEAR)

80

64

48

32

16

0

(8 MSBs OF LOOP FILTER ACCUMULATOR)

FIGURE 5. GAIN CONTROL TRANSFER FUNCTION

GAIN CONTROL WORD

dB

LINEAR

48

42

36

30

24

GAIN (dB)

18

12

6

0

2402242081921761601441281129680644832160

The response time of the AGC is determined by the

Programmable Loop Gain. The Loop Gain is an unsigned

8-bit value whose significance relative to the AGC gain is

shown in Figure 3. The loop gain is added or subtracted from

the accumulator depending on the output of the Level

Detector. The accumulator is updated at the output sample

rate. If the accumulator exceeds the upper or lower limit, the

accumulator is loaded with that limit. The slew rate of the

AGC ranges between ~0.001dB and 0.266dB per output

sample for Loop Gains between 01(HEX) and FF (HEX)

respectively.

†

The user should exercise care when using maximum loop

gain when the (x/sin(x)) or the (x/sin(x))

3

compensation filter is

enabled. At high decimation rates, the delay through the

compensation filter may be large enough to induce

oscillations in the AGC loop. The Basic Architectur al

Configurations Section contains the necessary detailed block

diagrams to determine the loop delay for diff erent matched

filter configurations.

Low Pass Filtering

The gain corrected signal feedsa Low Pass Filtering Section

comprised of a Cascaded Integrator Comb (CIC) and

compensation filter. The filtering section extracts the channel

of interest while providing decimation to match the output

sample rate to the channel bandwidth. A variety of filtering

configurations are possible which include integrate and

dump, integrate and dump with x/sin(x) compensation, third

order CIC, and third order CIC with ((x)/sin(x))3

compensation. If none of these filtering options are desired,

the entire filtering section may be bypassed.

3-235

Page 8

HSP50110

The Integrate and Dump filter exhibits a frequency response

given by

I

--- -

Hf()

πfR()/sin(πf)sin=

R

(EQ. 8)

where f is normalized frequency relative to the input sample

rate, F

, and R is the decimation rate [1]. The decimation

S

rate is equivalent to the number of samples in the integration

period. As an example, the frequency response for an

integrate and dump filter with decimation of 64 is shown in

Figure 6. The decimation rate is controlled by the

Re-Sampler and may range in value from 2 to 4096 (see

Re-Sampler Section).

10

0

-10

CIC

FILTER

-20

-30

MAGNITUDE (dB)

-40

-50

-60

NOTE: Example plotted is for R = 64 with 64 samples/symbol.

FIGURE 6. INTEGRATE AND DUMP FILTER (FIRST ORDER

COMPOSITE FILTER

f

f

3f

2f

S

2R

S

R

SAMPLE TIMES

2R

S

S

R

CIC) FREQUENCY RESPONSE

COMPENSATION

FILTER

5f

3f

S

2R

R

7f

2R

4f

S

S

For applications requiring better out of band attenuation, the

Third Order CIC filter may be selected. This filter has a

frequency response given by

3

H(f) = [sin(πfR)/sin(πf)]

[1/R]

3

(EQ. 9)

where f is normalized frequency relative to the input sample

rate, and R is the decimation rate [1]. As with the integrate

and dump filter, the decimation rate is controlled by the ReSampler. The decimation rate may range in value from

2-4096 when using CLK, or 3-4096 when using the ReSampler NCO as a CLK source to the filter. The frequency

response for the third order CIC with a decimation rate of 64

is shown in Figure 7.

Compensation filters may be activated to flatten the frequency

responses of the integrate and dump and third order CIC

filters. The compensation filters operate at the decimated data

rate, and flatten the roll off the decimating filters from DC to

approximately one half of the output sample rate. Together,

the Integrate and Dump filter and x/sin(x) compensation filter

typically yield a lowpass frequency response that is flat to

0.45F

with 0.03dB of ripple, and the third order CIC with

S

((x)/sin(x))

0.45F

3

compensation typically yields a flat passband to

with 0.08dB of ripple. The overall passband ripple

S

degrades slightly for decimation rates of less than 10. Some

examples of compensation filter performance for the Integrate

and dump and third order CIC filter are shown overlaid on the

frequency responses of the uncompensated filters in Figure 6

and Figure 7. The coefficients for the compensation filters are

given in Table 2.

10

0

-10

-20

CIC

FILTER

-30

MAGNITUDE (dB)

-40

-50

-60

COMPOSITE FILTER

f

f

S

S

2R

R

3f

2f

S

2R

S

R

SAMPLE TIMES

COMPENSATION

FILTER

5f

3f

S

2R

S

R

7f

2R

4f

S

S

R

NOTE: Example plotted is for R = 64 with 64 samples/symbol.

FIGURE 7. THIRD ORDER CIC FREQUENCY RESPONSE

TABLE 2. COMPENSATION FILTER COEFFICIENTS

S

R

COEFFICIENT INDEX x/sin(x) [2] [x/sin(x)]

0-1-1

3

124

2 -4 -16

31032

4 -34 -64

5 384 136

6 -34 -352

7 10 1312

8 -4 -352

9 2 136

10 -1 -64

11 32

12 -16

13 4

14 -1

The out of band channels and noise attenuated by the

decimating filters are aliased into the output spectrum as a

result of the decimating process. A summation of the alias

terms at each frequency of the output spectrum produce

alias profiles which can be used to determine the usable

output bandwidth. A set of profiles representative of what

would be observed for decimation factors of ~10 or more are

shown in Figures 8 through 11. The Integrate and Dump

filter is typically used as a matched filter for square pulses

3-236

Page 9

HSP50110

and less as a high order decimating filter. This is evident by

the narrow alias free part of the output bandwidth as shown

in Figures 8 and 9. The more rapid roll off of the third order

CIC produces an output spectrum containing a much higher

usable bandwidth versus output sample rate as shown in

Figures 10 and 11. For example, the aliasing noise at F

/4

S

for the uncompensated third order CIC filter is approximately

~29dB below the full scale input.

Understanding the Alias Profile

For digital filters that utilize decimation techniques to reduce

the rate of the digital processing, care must be taken to

understand the ramifications, in the frequency domain, of

decimation (rate reduction). Of primary concern is the “noise”

level increase due to signals that may be aliased inside the

band of interest. The potential magnitude of these signals

may render significant portions of the previously thought

usable bandwidth, unusable for applications that require

significant (>60dB) attenuation of undesired signals.

10

0

-10

-20

-30

MAGNITUDE (dB)

-40

ALIAS PROFILE

FILTER RESPONSE

Consider a digital filter with sampling frequency fs, whose

frequency response shown in Figure 12A, the top spectrum.

At first glance the usable bandwidth would appear to be the

3dB bandwidth of the main lobe. This filter is to be

decimated to a rate of 1/8 f

those elements less than f

. We concern ourselves with

S

/2, as shown in Figure 12B. The

S

decimation process will fold the various lobes of the

frequency response around the new sampling folding

frequency of f

/2R. The first lobe is folded overthe dotted line

S

and a significant portion of the first lobe appears in the

passband of the filter. Any unwanted signals in this part of the

spectrum will appear in the band of interest with the greatest

amplitude. The second lobe is translated down to be centered

on the dashed line. The third lobe is spectrally inverted and

translated to be centered on the dotted line. The fourth lobe is

simply translated to be centered on the dotted line. If there

were more lobes to the filter, the process would contin ue to

spectrally invert the odd numbered lobes prior to translation to

f

/2R. This process is shown in the “C” portion of Figure 12.

S

10

0

-10

-20

-30

MAGNITUDE (dB)

-40

FILTER RESPONSE

ALIAS PROFILE

-50

-60

0

f

16R

f

S

S

8R

(EXAMPLE PLOTTED IS FOR R = 64

WITH 64 SAMPLES/SYMBOL)

3f

f

5f

S

16R

S

4R

SAMPLE TIMES

16R

3f

S

S

8R

7f

16R

S

FIGURE 8. ALIAS PROFILE: INTEGRATE/DUMP FILTER,NO

COMPENSATION

10

0

-10

-20

-30

MAGNITUDE (dB)

-40

-50

-60

0

f

16R

S

FILTER RESPONSE

(EXAMPLE PLOTTED IS FOR R = 64

WITH 64 SAMPLES/SYMBOL)

f

3f

S

8R

S

16R

SAMPLE TIMES

f

4R

ALIAS PROFILE

5f

3f

S

S

16R

8R

7f

S

S

16R

2R

2R

-50

-60

f

S

0

f

f

S

16R

S

8R

(EXAMPLE PLOTTED IS FOR R = 64

WITH 64 SAMPLES/SYMBOL)

3f

f

5f

S

16R

S

4R

SAMPLE TIMES

16R

3f

S

S

8R

7f

16R

f

S

S

2R

FIGURE 9. ALIAS PROFILE: INTEGRATE/DUMPFILTER

WITH COMPENSATION

10

0

-10

-20

-30

MAGNITUDE (dB)

-40

-50

-60

f

S

0

FILTER RESPONSE

f

f

S

16R

S

8R

ALIAS PROFILE

(EXAMPLE PLOTTED IS FOR R = 64

WITH 64 SAMPLES/SYMBOL)

3f

f

5f

S

16R

S

4R

SAMPLE TIMES

16R

3f

S

S

8R

7f

16R

f

S

S

2R

FIGURE 10. ALIAS PROFILE: 3RD ORDER CIC,

NO COMPENSATION

3-237

FIGURE 11. ALIAS PROFILE: 3RD ORDER CIC WITH

COMPENSATION

Page 10

HSP50110

A

B

C

D

f

f

2R

S

S

2

FIGURE 12.

To create the alias profile, a composite response, the

components of which are shown in the”D” portion of

Figure 12, is made from the sum of all the alias elements.

The primary use of an alias profile is used to determine what

bandwidth yields the desired suppression of unwanted

signals for a particular application.

Reviewing Figures 9 through 11, note the following

observations:

1. The uncompensated I&D (1st order CIC) filter yields

about 12dB of alias suppression at f

/16R. This usable

S

bandwidth is considerably narrower than the 3dB filter

bandwidth. The I&D filter is the matched filter for square

wave data that has not been bandlimited.

2. The compensated I&D filter offers a flatter, wider bandwidth than just the I&D alone. This filter compensates for

the frequency roll off due to the A/D converter.

3. Theuncompensated 3rd orderCIC filter yieldsover60dB

of alias suppression at f

/16R. Typical application is

S

found in tuners, where the DQT is followed by a very narrow band filter.

4. The 3rd order CIC with compensation yields alias suppression comparable to the 3rd order CIC, but with the

flatter, wider passband. This filter is selected for most

SATCOM applications.

Which filter is selected, is dependent on the application. It is

important to utilize these alias responses in calculating the

filter to be used, so that the signal suppression prediction will

accurately reflect the digital filter performance.

Noise Equivalent Bandwidth

The noise equivalent bandwidth (BN) performance of the

channel filter is dependent on the combination of Decimation

Filter and Compensation Filter chosen. For configurations

using the Integrate and Dump filter, B

regardless of decimation rate. However, for configurations

which use the third order CIC filter, B

is constant

N

converges to a

N

constant for decimation factors of over ~50. A summary of

equivalent IF BN’s for different filter configurations and

decimation rates is given in Table 3. These noise bandwidths

are provided so that output SNR can be calculated from input

SNR. In detection applications this bandwidth indicates the

detection bandwidth.

TABLE 3. DOUBLE SIDED NOISE EQUIVALENTBANDWIDTH

FOR DIFFERENT FILTER CONFIGURATIONS AND

OUTPUT SAMPLE RATES

3RD

INTEGRATE/

INTEGRATE/

DEC

2 1.0000 1.3775 0.6250 1.3937

10 1.0000 1.3775 0.5525 1.0785

f

S

18 1.0000 1.3775 0.5508 1.0714

26 1.0000 1.3775 0.5504 1.0698

34 1.0000 1.3775 0.5502 1.0691

42 1.0000 1.3775 0.5501 1.0688

50 1.0000 1.3775 0.5501 1.0687

58 1.0000 1.3775 0.5501 1.0686

66 1.0000 1.3775 0.5501 1.0685

74 1.0000 1.3775 0.5500 1.0684

82 1.0000 1.3775 0.5500 1.0684

90 1.0000 1.3775 0.5500 1.0684

98 1.0000 1.3775 0.5500 1.0684

106 1.0000 1.3775 0.5500 1.0684

114 1.0000 1.3775 0.5500 1.0683

122-

4096

DUMP

1.0000 1.3775 0.5500 1.0683

DUMP W/

x/sin(x)

3RD

ORDER

CIC

ORDER

CIC W/

[x/sin(x)]

3

Re-Sampler

The Re-Sampler sets the output sample rate by controlling

the sample rate of the decimation filters (see Low Pass Filter

Section). The output sample rate may be fixed or adjusted

dynamically to synchronize with baseband waveforms. The

reduction in sample rate between the Low Pass Filter input

and output represents the decimation factor.

The Decimating filter output is sampled by the programmable

divider shown in Figure 13. The divider is a counter which is

decremented each time it is clocked. When the divider reaches

its terminal count, the output of the decimating filter is sampled.

The divider may be programmed with a divisor of from 1 to

4096 (see Table 11 Decimating Filter Configuration Register).

One of two internal clock sources are chosen for the divider

based on whether a fixed or adjustable sample rate is

desired. For fixed output sample rates, a clock equal to the

input sample rate is selected (see Decimating Filter

Configuration Table 11). For adjustable output sample rates,

a clock generated by the carry out from the Re-Sampler

NCO is chosen.

3-238

Page 11

HSP50110

TO DECIMATING FILTERS

PROGRAMMABLE

SAMPLE PHASE

OUT CONTROL

DATARDY

RE-SAMPLER

SOF ENABLE †

SOFSYNC

SOF

†

SYNC

CLK

32-BIT ADDER

CARRY OUTPUT

NCO

MUX

32

SOF

REG

SYNC

SHIFT REG

DIVIDER

MUX

SHIFTER

32

32

0

SCF

SAMPLER

CENTER

FREQUENCY†

MODE †

REG

5

8

REG MUX

+

REG

REG

SYNC

SSTRB

SPH0-4

0

LOAD

RESAMPLER

NCO †

LOAD

ON CF

WRITE

† Controlled via microprocessor interface.

FIGURE 13. RE-SAMPLER

The calculation of the decimation factor depends on whether

the output sample rate is fixed or adjusted dynamically. For a

fixed sample rate, the decimation f actor is equal to the divisor

loaded into the programmable divider. For example, if the

divider is configured with a divisor of 8, the decimation factor

is 8 (i.e., the output data rate is F

is adjusted dynamically, it is a function of both the

programmable divisor and the frequency of carry outs from

the Re-Sampler NCO (F

CO

Decimation Factor =

(Programmable Divisor) x F

For example, if the programmable divisor is 8 and F

40, the decimation factor would be 320.

NOTE: The CIC filter architecture only supports

decimation factors up to 4096.

The phase accumulator in the Re-Sampler NCO generates

the carry outs used to clock the programmable divider . The

frequency at which carry outs are generated (F

determined by the values loaded into the Sampler Center

Frequency (SCF) and Sampler Offset Frequency (SOF)

Registers. The relationship between the values loaded into

these registers and the frequency of the carry outs is given by:

F

= Fs x (SCF + SOF)/2

CO

where F

is the input sample rate of the Low Pass Filter

s

Section, SCF is the 32-bit value loaded into the Sampler

/8). If the decimation factor

s

) as given by:

s/FCO

32

CO

(EQ. 10)

s/FCO

) is

(EQ. 11)

=

Center Frequency Register, and SOF is the 32-bit value

loaded into the Sample Offset Frequency Register. The SCF

Register is loaded through the Microprocessor Interface (see

Microprocessor Interface Section), and the SOF Register is

loaded serially via the SOF and SOFSYNC inputs (see Serial

Input Section). The sample rate F

Controller Mode. If the Controller is in Gated Input Mode, F

the frequency with which

Mode, F

is the CLK frequency (see Input Controller Section).

s

ENI is asserted. In Interpolated Input

is a function of the Input

s

s

The carry out and 5 of the most significant 8 bits of the

NCO’sphase accumulator are output to control a resampling

filter such as the HSP43168. The resampling filter can be

used to provide finer time (symbol phase) resolution than

can be achieved by the sampling clock alone. This may be

needed to improve transmit/receive timing or better, align a

matched filter’s impulse response with the symbol

boundaries of a baseband waveform at high symbol rates.

The carry out of the NCO’s phase accumulator is output on

SSTRB, and a window of 5 of the 8 most significant 8 bits of

the Phase Accumulator are output on SPH0-4.

Output Formatter

The Output Formatter supports either Word Parallel or Bit

Serial output modes. The output can be chosen to have a

two’s complement or offset binary format. The configuration

is selected by loading the I/O Formatting/Control Register

(see Table 10).

In parallel output mode, the in-phase and quadrature

samples are output simultaneously at rates up to the

maximum CLK. The DATARDY output is asserted on the first

CLK cycle that new data is available on IOUT0-9 and

QOUT0-9 as shown in Figure 14. Output enables (

OEQ) are provided to individually three-state IOUT0-9 and

QOUT0-9 for output multiplexing.

CLK

DATARDY

IOUT9-0/

QOUT9-0

NOTE: DATARDY may be programmed active high or low.

FIGURE 14. PARALLEL OUTPUT TIMING

When bit serial output is chosen, two serial output modes are

provided, Simultaneous I/Q Mode and I Follow ed by Q Mode.

In Simultaneous I/Q Mode, the 10-bit I and Q samples are

output simultaneously on IOUT0 and QOUT0 as shown in

Figure 15. In I Followed b y Q Mode , both samples are output

on IOUT0 with I samples followed by Q samples as shown in

Figure 16. In this mode, the I and Q samples are packed into

separate 16-bit serial words (10 data bits + 6 zero bits). The

10 data bits are the 10 MSBs of the serial word, and the I

sample is differentiated from the Q sample by a 1 in the LSB

position of the 16-bit data word. A continuous serial output

clock is provided on IOUT9 which is derived by dividing the

OEI,

is

3-239

Page 12

HSP50110

CLK by a programmable factor of 2, 4, or 8. When the

programmable clock factor is 1, IOUT9 is pulled high, and the

CLK signal should be used as the clock. The beginning of a

serial data word is signaled by the assertion of DATARD Yone

serial clock before the first bit of the output word. In I followed

by Q Mode, DATARDY is asserted prior to each 16-bit data

word. For added flexibility,the Formatter may be configured to

output the data words in either MSB or LSB first format

IOUT9

DATARDY

IOUT0/

QOUT0

NOTE: Assumes data is being output LSB first.

FIGURE 15. SERIAL TIMING (SIMULTANEOUS I/Q MODE)

IOUT9

DATARDY

IOUT0

DATARDY

LEADS 1st BIT

NOTE: Assumes data is being output MSB first.

DATARDY may be programmed active high or low.

FIGURE 16. SERIAL TIMING (I FOLLOWED BY Q MODE)

LSB

DATARDY LEADS 1st BIT

I DATA WORD

MSB LSB

LSBMSB 0

I OUTPUT IDENTIFIED

BY 1 IN LSB OF DATA WORD

.

1

MSB

Q DATA

WORD

Gain Distribution

The gain distribution in the DQT is shown in Figure 17. These

gains consist of a combination of fixed, programmable, and

adaptive gains. The fixed gains are introduced by processing

elements like the Synthesizer/Mixer and CIC Filter. The

programmable and adaptive gains are set to compensate for

the fixed gains as well as variations in input signal strength.

The bit range of the data path between processing elements

is shown in Figure 17. The quadrature inputs to the data path

are 10-bit fractional two’s complement n umbers . They are

multiplied by a 10-bit quadrature sinusoid and rounded to

12-bits in the Synthesizer/Mixer. The I and Q legs are then

scaled by a fixed gain of 2

case gain of the CIC filter. Next, a gain block with an adaptive

and programmable component is used to set the output signal

levelwithin the desired range of the 10-bit output (see Setting

DQT Gains Section). The adaptive component is produced by

the AGC and has a gain range from 1.0 to 1.9375*2

programmable component sets the gain range of the CIC

shifter which may range from 2

when setting the AGC gain limits and the CIC Shifter gain

since the sum of these gains could shift the CIC Scaler output

beyond the bit range (-2

CIC Filter introduces a gain factor given by R

decimation rate of the filter and N is the CIC order. The CIC

order is either 1 (integrate and dump filter) or 3. Depending on

configuration, the CIC Filter introduces a gain factor from 2

36

2

. The output of the CIC Filter is then rounded and limited to

an 11-bit window between bit positions 2

outside this range saturate to these 11 bits. The

Compensation Filter introduces a final gain factor of 1.0, 0.65,

-36

to compensate for the worst

0

to 263. Care must be taken

8

-46

to 2

) of the CIC Filter input. The

N

1

to 2-9. Values

7

. The

where R is the

0

to

INPUT

(0.0625 STEPS)

SYNTHESIZER/

G = 0.9990

= 0dB GdB = -216.74dB GdB = G

G

dB

0

-2

-1

2

-9

2

G = -6.02dB

-2

2

2

-10

2

RND

CIC

SCALERMIXER

G = 2

1

0

-1

FIGURE 17. GAIN DISTRIBUTION AND INTERMEDIATE BIT WEIGHTINGS

3-240

AGC GAIN

MANTISSA

1.0 - 1.9375

-36

BINARY POINT

-35

-2

-46

2

EXPONENT

0-27

2

G = 1.0 - 1.9375*2

AGC

G

SHIFTER

CIC BARREL

SHIFTER

0-263

2

70

+

BIT RANGE OF DATA PATH

GdB = 20log[fS/fD]

8

-2

N = 1, 3

0

2

-1

2

-46

2

RND

FILTER

G = 2

= 20log[R]

CIC

0

N

- 2

(RN)

36

N

COMPENSATION

FILTER

GAIN

G = 1.0, 0.65, 0.77

(BYPASS, x/sin(x), (x/sin(x))

LIMIT LIMIT

-2

2

2

2

RND

= 0dB GdB = 0dB

G

dB

8

0

-1

-9

GdB =

0dB BYP ASS

-3.74dB

1

-2

-2.27dB

0

2

-1

2

-9

2

-2

2

2

RND

3

3

0

2

-1

-9

0

-2

-1

2

-9

2

OUTPUT

Page 13

HSP50110

or 0.77 depending on whether the bypass, x/sin(x) or

(x/sin(x))

3

configuration is chosen. The Compensation Filter

output is then rounded and limited to a 10-bit output range

corresponding to bit positions 2

0

to 2-9.

Setting DQT Gains

The AGC and CIC Shifter gains are programmed to maintain

the output signal at a desired level. The gain range required

depends on the signal levels expected at the input and the A/D

backoff required to prevent signal + noise from saturating the

A/D. The signal level at the input is based on the input SNR

which itself is derived from the either output SNR or output

E

. Below are two examples which describe setting the

S/N0

gains using either an output SNR or E

In applications based on the transmission of digital data, it is

useful to specify the DQT’s output in terms of E

following e xample uses this parameter and the others giv en in

Table 4 to show how the DQT’s gain settings can be derived.

TABLE 4. EXAMPLE SYSTEM PARAMETERS

PARAMETER

Input Sample Rate (2) 40 MSPS

OutputSampleRate(F

Input Filter Noise Bandwidth (NBW) (10) 10MHz

Minimum Output ES/N

Signal + Noise Backoff at A/D Input (18), (19) 12dB

Output Signal Magnitude (0 to 1) (21) 0.5

Number of CIC stages (11) 3

Compensation Filter (11) (x/sin(x))

Noise Eq. Bandwidth of Comp. Filter

(BN*F

Input Type (Real/Complex) (4) Real

NOTES:

1. Two samples per symbol assumed.

2. Decimation = 40 MSPS/32 KSPS = 1250.

SOUT

)

)(Notes1,2) (8), (9) 32 KSPS

SOUT

0

specification.

S/N0

S/N0

MAIN MENU

ITEM SETTING

(15) -3dB

N/A 34.18kHz

. The

NOTE: 10log10(x) is used because these items are power

related.

Thus, the minimum input signal will then be -42.96dB below

full scale (-30.96dB -12dB for A/D backoff). Note: in this

example the symbol rate is assumed to be one half of the

output sample rate (i.e., there are 2 samples per symbol).

The output signal is related to the input signal by:

S

= SIN x G

OUT

G

SHIFTER

x G

CIC

Using this equation, limits for G

MIXER

x G

x G

COMP

SCALER

AGC

x G

and G

x (EQ.13)

AGC

SHIFTER

(EQ. 14)

can be

determined from the minimum and maximum input signal

conditions as given below (all gains specified in dB):

Min Input Level (Maximum Gain Required):

-6.02dB ≥ -42.96 - 6.02 - 216.74 + G

6

20 x log((40 x 10

/32 x 103)3) - 2.27 (EQ. 15)

AGC

+ G

SHIFTER

+

Max Input Level (MinimumInput Gain Required)

-6.02dB ≤ -12 - 6.02 - 216.74 + G

6

20 x log((40 x 10

/32 x 103)3) - 2.27 (EQ. 16)

AGC

+ G

SHIFTER

+

NOTE: 20log10(x) is used because these items are

amplitude related.

Solving the above inequalities for G

AGC

and G

SHIFTER

, the

gain range can be expressed as,

45.20dB < (G

AGC

+ G

SHIFTER

) < 76.16dB. (EQ. 17)

The shifter gain provides a programmable gain which is a

factor of 2. Since G

AGC

≥ 1.0, G

SHIFTER

is set as close to

the minimum gain requirement as possible:

G

3

SHIFTER

= 2N, (EQ. 18)

where

(G

N = floor(log

= floor(log

(10

2

(10

2

/20)

MIN

(45.20/20)

))

)) = 7

The limits on the AGC gain can then be determined by

substituting the shifter gain into Equation 18 above. The

resulting limits are given by:

First, the maximum and minimum input signal levels m ust be

determined. The maximum input signal level is achiev ed in a

noise free environment where the input signal is attenuated by

12dB as a result of the A/D backoff. The minim um input signal

is determined by converting the minimum output E

S/N0

specification into an Input SNR. Using the example parameters

in Table 4 the minimum input SNR is given by:

SNR

= 10log10(ES/N0) + 10log10(Symbol Rate)

IN

-10log

= -3dB + 10log

(NBW)

10

(0.5x32 x 103) - 10log10(10 x 106)

10

= -30.96dB (EQ. 12)

3-241

3.05dB < G

<34.02dB. (EQ. 19)

AGC

In some applications it is more desirable to specify the DQT

output in terms of SNR. This example, covers derivation of

the gain settings based on an output SNR of 15dB. The

other system parameters are given in Table 4.

As in the previous examples the minimum and maximum

input signal levels must be determined. The minimum input

signal strength is determined by from the minimum output

SNR as given by:

SNR

= SNR

IN

= 15 - 10log(10 x 10

- 10log(NBW) + 10log(BN x F

OUT

6

) + 10log(34.18 x 103)

SOUT

)

= -9.66dB (EQ. 20)

Page 14

HSP50110

Thus, the minimum input signal will be -21.66dB below full

scale (-9.66 -12 for A/D Backoff). As before the maximum

input signal in the absence of noise is -12dB down due to

A/D backoff.

From Equation 14, the gain relationships for maximum and

minimum input can be written as follows:

Min Input Level

-6.02dB ≥ -21.66 -6.02 - 216.74 + G

20*log((40 x 10

6

/32 x 103)3)-2.27 (EQ. 21)

AGC

+ G

SHIFTER

+

Max Input Level

-6.02dB ≤ -12 - 6.02 - 216.74 + G

20 x log((40 x 10

6

/32 x 103)3) -2.27 (EQ. 22)

AGC

+ G

SHIFTER

+

Using the upper and lower limits foundabove,the gain range

can be expressed as,

45.20dB < G

Using Equation 2 in the previous example, the shifter gain is

determined to be 2

< G

<12.72dB. (EQ. 24)

AGC

+ G

AGC

SHIFTER

7

, resulting in an AGC gain range of 3.05dB

< 54.86dB. (EQ. 23)

Basic Architectural Configurations

Detailed architectural diagrams are presented in Figures 18

through 20 for the basic configurations,Integrate/Dump filtering

with optional compensation, 3rd Order CIC filtering with

optional compensation, and Decimating Filter bypass.Only one

of the data paths is shown since the processing on either the

inphase or quadrature legs is identical. These diagrams are

useful for determining the throughput pipeline delay or the loop

delay of the AGC as all the internal registers are shown.

All registers with the exception of those denoted by daggers (

are enabled ev ery CLK rate to minimize pipeline latency. The

registers marked by daggers are enabled at the output sample

rate as required by the filtering operation performed. The Loop

Filter accumulator in the AGC is enabled once per output

sample, and represents a delay of one output sample. The

accumulators in the CIC filter each represent a delay of one

CLK, but they are enabled f or processing once per input

sample. In Interpolated Input Mode the accumulators are

enabled ev ery CLK since the sample rate is determined by the

CLK rate (see Input Controller Section). In Gated Input Mode,

the processing delay of the accumulators is one CLK but the y

are only enabled once for each sample gated into the

processing pipeline. As a result, the latency through the

accumulators is 3 CLKs rather than 3 input sample periods

when configured as a 3rd order CIC filter.

†)

3-242

Page 15

3-243

G

HI/LO

IIN0-9/

QIN0-9

R

R

E

E

G

G

LEVEL

DETECT

R

E

G

SIN/COS

VECTOR FROM

CARRIER NCO

R

E

X

G

COMPLEX

MULTIPLIER

R

R

E

E

G

G

CIC SCALER

-36

2

R

E

G

MANTISSA (1.0 - 1.9375)

-63

FROM

DIVIDER

0

- 27)

R

EXPONENT (2

CIC SHIFTER

+

20-2

A

C

31

C

PROGRAMMABLE

W/ PROGRAMMABLE

1ST ORDER CIC (I & D FILTER)

†

ACCUMULATOR

LIMITS

-1

†

R

+

E

G

R

E

G

LOOP

GAIN

COMPENSATION

1

LEVEL

DETECT

FILTER

†

L

M

T

11 TAP

FIR FILTER

FIGURE 18. DATA FLOW FOR INTEGRATE/DUMP CONFIGURATION

LEGEND:

ACC = ACCUMULATOR

LMT = LIMIT

R = DOWN SAMPLER

MUX = MULTIPLEXER

REG

REG

M

U

X

L

M

T

REG = REGISTER

† INDICATES ELEMENTS RUNNING

AT THE OUTPUT SAMPLE RATE

SERIALIZE

M

R

R

R

R

U

X

R

E

E

E

E

E

G

G

G

G

G

IOUT0-9/

QOUT0-9

HI/LO

IIN0-9/

QIN0-9

HI/LO

IIN0-9/

QIN0-9

R

R

E

E

G

G

LEVEL

DETECT

R

E

G

R

R

E

E

G

G

LEVEL

DETECT

R

E

G

SIN/COS

VECTOR FROM

CARRIER NCO

R

E

X

G

COMPLEX

MULTIPLIER

SIN/COS

VECTOR FROM

CARRIER NCO

R

E

X

G

COMPLEX

MULTIPLIER

R

R

E

E

G

G

R

E

G

CIC SCALER

-36

2

R

E

G

CIC SCALER

-36

2

R

R

E

E

G

G

MANTISSA (1.0 - 1.9375)

EXPONENT (2

CIC SHIFTER

-63

20-2

+

(TOP BITS ALIGNED)

A

A

C

55

C

A

C

C

C

C

0

- 27)

R

FROM

BIT RATE

NCO

ACCUMULATOR

W/ PROGRAMMABLE

LIMITS

3RD ORDER CIC FILTER COMPENSATION

-1 3

†

R

E

G

†

R

+

E

G

FIGURE 19. DATA FLOW FOR 3RD ORDER CIC CONFIGURATION

MANTISSA (1.0 - 1.9375)

0

EXPONENT (2

CIC SHIFTER

+

0-2-63

2

- 27)

21

ACCUMULATOR

W/ PROGRAMMABLE

LIMITS

COMPENSATION

FILTER

L

M

T

FIGURE 20. DATA FLOW WITH CIC STAGE BYPASSED

+

R

E

G

LOOP

GAIN

-3

†

R

E

G

R

E

G

11-15 TAP

FIR FILTER

†

+

LOOP

GAIN

LEVEL

DETECT

1

L

M

T

LEVEL

DETECT

FILTER

†

15 TAP

FIR FILTER

REG

REG

M

U

X

L

M

T

REG

REG

M

U

X

SERIALIZE

M

U

X

LEGEND:

ACC = ACCUMULATOR

LMT = LIMIT

R = DOWN SAMPLER

MUX = MULTIPLEXER

REG = REGISTER

† INDICATES ELEMENTS RUNNIN

AT THE OUTPUT SAMPLE RATE

SERIALIZE

L

M

T

M

R

R

R

U

X

LEGEND:

ACC = ACCUMULATOR

LMT = LIMIT

R = DOWN SAMPLER

MUX = MULTIPLEXER

REG = REGISTER

R

R

R

E

E

E

G

G

G

R

E

E

E

E

G

G

G

G

R

R

IOUT0-9/

E

E

QOUT0-9

G

G

R

E

G

HSP50110

IOUT0-9/

QOUT0-9

Page 16

HSP50110

Serial Input Interfaces

Frequency control data for the NCOs contained in the

Synthesizer/Mixerand the Re-Sampler are loaded through two

separate serial interfaces. The Carrier Offset Frequency

Register controlling the Synthesizer NCO is loaded via the COF

and COFSYNC pins. The Sample Offset Frequency Register

controlling the Re-Sampler NCO is loaded via the SOF and

SOFSYNC pins.

CLK

COFSYNC/

SOFSYNC

COF/

SOF

NOTE: Data must be loaded MSB first.

FIGURE 21. SERIAL INPUT TIMING FOR COF AND SOF INPUTS

32†

30

28

26

†

24

22

20

18

16

†

14

12

10

8†

SHIFT COUNTER VALUE

6

4

2

0

†Serial word width can be: 8, 16, 24, 32 bits wide.

†† TDis determined by the COFSYNC, COFSYNC rate. Note that

TD can be 0, and the fastest rate is with 8-bit word width.

FIGURE 22. SERIAL DATALOAD TO HOLDING REGISTERS

SEQUENCE

The procedure for loading data through these two pin

interfaces is identical. Each serial word has a programmable

word width of either 8, 16, 24, or 32 bits (see Chip

Configuration Register in Table 12). On the rising edge CLK,

data on COF or SOF is clocked into an Input Shift Register.

The beginning of a serial word is designated by asserting

either COFSYNC or SOFSYNC “high” one CLK prior to the

first data bit as shown in Figure 21. The assertion of the

SOFSYNC starts a count down from the programmed word

width. On following CLKs, data is shifted into the register until

the specified number of bits have been input. At this point data

shifting is disabled and the contents of the register are

transferred from the Shift Register to the respective 32-bit

Holding Register. The Shift Register is enabled to accept new

data on the following CLK. If the serial input word is defined to

be less than 32 bits, it will be transferred to the MSBs of the

MSB

ASSERTION OF

COFSYNC, SOFSYNC

DATA TRANSFERED

TO HOLDING REGISTER

(8)

CLK TIMES

(24)

(16)

(32)

LSB

MSB

54504642383430262218141062

T

††

D

T

††

D

T

††

D

T

††

D

32-bit holding register and the LSBs of the holding register will

be zeroed. See Figure 22 for details.

Note: serial data must

be loaded MSB first, and COFSYNC or SOFSYNC should

not be asserted for more than one CLK cycle.

Test Mode

The Test Mode is used to program each of the output pins to

“high” or “low” state via the Microprocessor Interface. If this

mode is enabled, the output pins are individually set or

cleared through the control bits of the TestRegister in Table 6.

When serial output mode is selected, the Test Register may

be used to set the state of the unused output bits.

Microprocessor Interface

The Microprocessor Interface is used for writing data to the

DQT’s Control Registers and reading the contents of the

AGC Loop accumulator (see AGC Section). The

Microprocessor Interface consists of a set of four 8-bit

holding registers and one 8-bit Address Register. These

registers are accessed via a 3-bit address bus (A0-2) and an

8-bit data bus (C0-7). The address map for these registers is

given in Table 5. The registers are loaded by setting up the

address (A0-2) and data (C0-7) to the rising edge of

TABLE 5. ADDRESS MAP FOR MICROPROCESSOR

INTERFACE

A2-0 REGISTER DESCRIPTION

0 Holding Register 0. Transfers to bits 7-0 of the 32-bit Desti-

nation Register. Bit 0 is the LSB of the 32-bit register.

1 Holding Register 1. Transfers to bits 15-8 of a 32-bit Destina-

tion Register.

2 Holding Register 2. Transfers to bits 23-16 of a 32-bit Desti-

nation Register.

3 Holding Register 3. Transfers to bits 31-24 of a 32-bit

Destination Register. Bit 31 is the MSB of the 32-bit register.

4 This is the Destination Address Register. On the fourth CLK

following a write to this register, the contents of the Holding

Registers are transferred to the Destination Register. The

lower 4 bits written to this register are decoded into the Destination Register address. The destination address map is

given in Tables 6-15.

The HSP50110 is configured by loading a series of nine

32-bit Control Registers via the Microprocessor Interface. A

Control Register is loaded by first writing the four 8-bit

Holding Registers and then writing the destination address

to the Address Register as shown in Figure 23. The Control

Register Address Map and bit definitions are given in Tables

6-15. Data is transferred from the Holding Registers to a

Control Register on the fourth clock following a write to the

Address Register. As a result, the Holding Registers should

not be updated any sooner than 4 CLK’s after an Address

Register write (see Figure 23).

NOTE: the unused bits in a

Control Register need not be loaded into the Holding

Register.

WR.

3-244

Page 17

HSP50110

For added flexibility, the CFLD input provides an alternative

mechanism for transferring data from the Microprocessor

Interfaces’s Holding Registers to the Center Frequency

Register. When CFLD is sampled “high” by the rising edge

of clock, the contents of the Holding Registers are

transferred to the Center Frequency Register as shown in

Figure 23. Using this loading mechanism, an update of the

Center Frequency Register can be synchronized with an

external event. Caution should be taken when using the

CFLD since the Holding Register contents will be

transferred to the Center Frequency Register whenever

CFLD is asserted.

NOTE: CFLD should not be asserted

any sooner than 2 CLK’s following the last Holding

Register load.

As Shown in Figure 24, the next

Configuration Register can be loaded one CLK after CFLD

has been loaded on the rising edge of CLK.

WR

RD

A0-2

SIGNALS

PROCESSOR

C0-7

The Microprocessor Interface can be used to read the upper

8 bits of the AGC Loop Filter Accumulator. The procedure for

reading the Loop Accumulator consists of first sampling the

loop accumulator by writing 9 to the Destination Address

Register and then reading the loop accumulator value on

C0-7 by asserting RD. The sampled value is enabled for

output on C0-7 by forcing RD “low” no sooner than 6 CLK’s

after the writing the Destination Register as shown in

Figure 25. The 8-bit output corresponds to the 3 exponent

bits and 5 fractional bits to the right of the binary point (see

Figure 3). The 3 exponent bits map to C7-5 with C7 being

the most significant. The fractional bits map to C4-0 in

decreasing significance from C4 to C0.

DON’T CARE

43210 01

CLK

LOAD

CONFIGURATION

DAT A

LOAD ADDRESS OF

TARGET CONTROL

REGISTER AND

WAIT 4 CLKs

1234

EARLIEST TIME

ANOTHER LOAD

CAN BEGIN

LOAD NEXT

CONFIGURATION

REGISTER

NOTE: These processor signals are representative. The actual shape of the waveforms will be set by the microprocessor used. Verify that the microprocessor waveforms meet the parameters in the Waveforms Section of this data sheet to ensure proper operation. While the microprocessor

waveforms are not required to be synchronous to CLK, they are shown as synchronous waveforms for clarity in the illustration.

FIGURE 23. CONTROL REGISTER LOADING SEQUENCE

1

2

CLK

WR

CFLD

1

A0-2

0123

C0-7

CONFIGURATION

LOAD

DAT A

NEXT CLK

FOLLOWING

CFLD

0

LOAD NEXT

CONFIGURATION

REGISTER

2

3

NOTE: These processor signals are meant to be representative.

The actual shape of the waveforms will be set by the microprocessor

used. Verify that the processor waveforms meet the parameters in

theWaveforms Section of this data sheetto ensure proper operation.

The Processor waveforms are not required to be synchronous to

CLK. They are shown that way to clarify the illustration.

FIGURE 24. CENTER FREQUENCY CONTROL REGISTER

1

23

CLK

WR

RD

A0-2

C0-7

4

9

LOAD ADDRESS

OF TARGET

CONTROL REGISTER

AND WAIT 6 CLK’S

NOTE: These processor signals are meant to be representative.

The actual shape of the waveforms will be set by the microprocessor

used. Verify that the processor waveforms meet the parameters in

theWaveforms Section of this data sheetto ensure proper operation.

The Processor waveforms are not required to be synchronous to

CLK. They are shown that way to clarify the illustration.

FIGURE 25. AGC READ SEQUENCE

4 56

DON’T CARE

THREE-STATE

INPUT BUS

ASSERT

TO ENABLE DATA

OUTPUT ON C0-7

RD

LOADING SEQUENCE USING CF LOAD

3-245

Page 18

HSP50110

l

TABLE 6. CENTER FREQUENCY REGISTER

DESTINATION ADDRESS = 0

BIT

POSITIONS FUNCTION DESCRIPTION

31-0 Center Frequency This register controls the center frequency of the Synthesizer/Mixer NCO. This 32-bit two’s complement

value sets the center frequency as described in the Synthesizer/Mixer Section. Center

Center Frequency CF

C

-------

H

2

F

S

˙

COF

–==

H

H

F

32

Format: [XXXXXXXX]H Range: (0000000 - FFFFFFF)H.

TABLE 7. SAMPLER CENTER FREQUENCY REGISTER

DESTINATION ADDRESS = 1