Page 1

HSP48901

Data Sheet May 1999

3 x 3 Image Filter

The Intersil HSP48901 is a high speed 9-Tap FIR Filter

which utilizes 8-bit wide data and coefficients. It can be

configured as a one dimensional (1-D) 9-Tap filter for a

variety of signal processing applications, or as a two

dimensional (2-D) filter for image processing. In the 2-D

configuration, the device is ideally suited for implementing 3

x 3 kernel convolution. The 30MHz clock rate allows a large

number of image sizes to be processed within the required

frame time for real-time video.

Data is provided to the HSP48901 through the use of

programmable data buffers such as the HSP9500 or any

other Programmable Shift Register. Coefficient and pixel

input data are 8-bit signed or unsigned integers, and the

20-bit extended output guarantees no overflow will occur

during the filtering operation.

There are two internal register banks for storing independent

3 x 3 filter kernels, thus, facilitating the implementation of

adaptive filters and multiple filter operations on the same

data.

The configuration of the HSP48901 Image Filter is controlled

through a standard microprocessor interface and all inputs

and outputs are TTL compatible.

File Number

2459.5

Features

• DC to 30MHz Clock Rate

• Configurable for 1-D and 2-D Correlation/Convolution

• Dual Coefficient Mask Registers, Switchable in a Single

Clock Cycle

• Two’s Complement or Unsigned 8-Bit Input Data and

Coefficients

• 20-Bit Extended Precision Output

• Standard µP Interface

Applications

• Image Filtering

• Edge Detection/Enhancement

• Pattern Matching

• Real Time Video Filters

Ordering Information

TEMP.

PART NUMBER

RANGE (oC) PACKAGE

HSP48901JC-20 0 to 70 68 Ld PLCC N68.95

HSP48901JC-30 0 to 70 68 Ld PLCC N68.95

HSP48901GC-20 0 to 70 68 Ld PGA G68.A

HSP48901GC-30 0 to 70 68 Ld PGA G68.A

PKG.

NO.

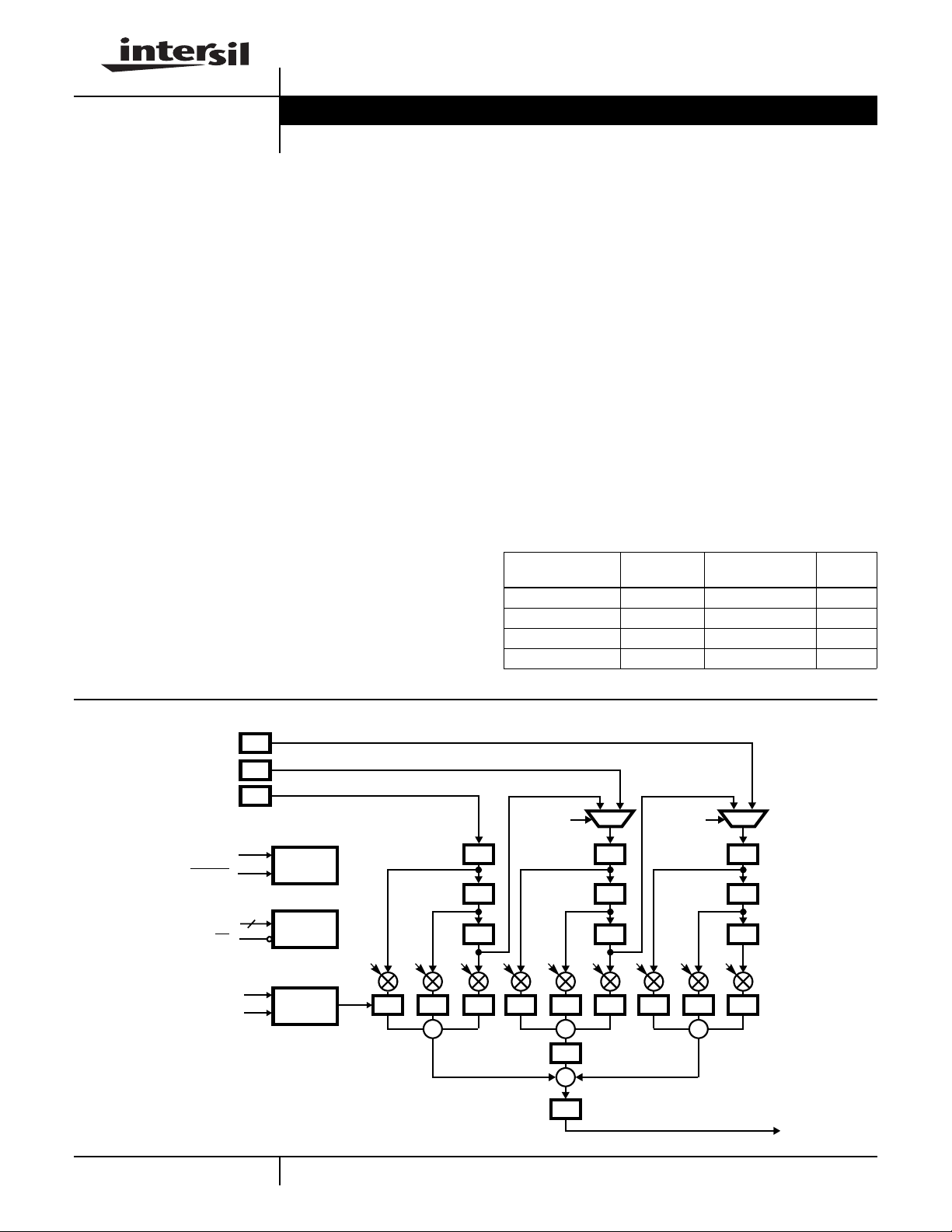

Block Diagram

DIN3 (0-7)

DIN2 (0-7)

DIN1 (0-7)

FRAME

CIN0-7

A0-2

LD

CLK

HOLD

-1

Z

-1

Z

-1

Z

3

CONTROL

LOGIC

ADDRESS

DECODER

INTERNAL

CLOCK

CLOCK

GEN

MODE MODE

-1

Z

-1

Z

-1

Z

-1

-1

-1

Z

Z

Z

+ + +

-1

Z

2:1

-1

Z

-1

Z

-1

Z

-1

-1

-1

Z

-1

Z

+

-1

Z

Z

Z

2:1

-1

Z

-1

Z

-1

Z

ABCDEFGHI

-1

-1

Z

Z

DOUT 0-19

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207 | Copyright © Intersil Corporation 1999

Page 2

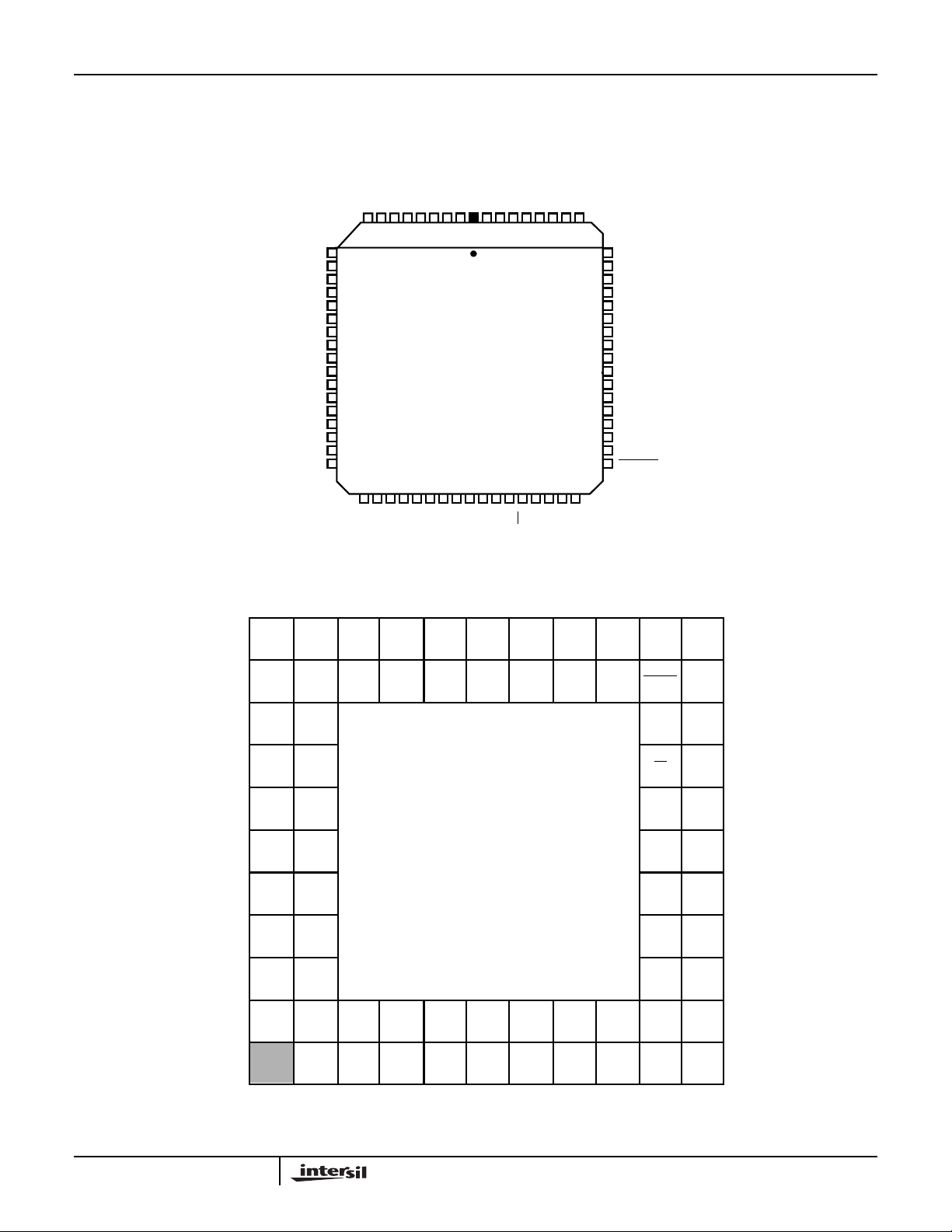

Pinouts

HSP48901

68 LEAD PLCC

TOP VIEW

DOUT3

A2A1A0

HOLD

DOUT4

DOUT5

4327 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

CC

V

DOUT6

60

DOUT7

59

DOUT8

58

DOUT9

57

GND

56

DOUT10

55

DOUT11

54

DOUT12

53

DOUT13

52

DOUT14

51

DOUT15

50

DOUT16

49

DOUT17

48

DOUT18

47

DOUT19

46

V

45

CC

FRAMES

44

DIN2 (7)

DIN2 (6)

DIN2 (5)

DIN2 (4)

DIN2 (3)

DIN2 (2)

DIN2 (1)

DIN2 (0)

GND

DIN3 (7)

DIN3 (6)

DIN3 (5)

DIN3 (4)

DIN3 (3)

DIN3 2)

DIN3 (1)

DIN3 (0)

VCCDIN1 (0)

DIN1 (1)

DIN1 (2)

DIN1 (3)

DIN1 (4)

DIN1 (5)

DIN1 (6)

DIN1 (7)

GND

DOUT0

DOUT1

DOUT2

9 8 7 6 5 4 3 2 1 6867666564636261

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

CC

V

CLK

GND

CIN7

CIN6

CIN5

CIN4

CIN3

CIN2

CIN1

CIN0

GND

LD

68 PIN GRID ARRAY (PGA)

TOP VIEW

11

DOUT6

DOUT7

DOUT9

DOUT10

DOUT12

DOUT14

DOUT16

DOUT18

V

CC

10

DOUT5

9

DOUT3

8

DOUT1

7

GND

DIN1 (6)

6

5

DIN1 (4)

4

DIN1 (2)

3

DIN1 (0)

2

V

CC

1

V

CC

DOUT4

DOUT2

DOUT0

DIN1 (7)

DIN1 (5)

DIN1 (3)

DIN1 (1)

DIN2 (7)

DIN2 (6)

BCDEFGHJKLA

DOUT6

DIN2 (5)

DIN2 (4)

GND

DIN2 (3)

DIN2 (2)

DOUT11

DIN2 (1)

DIN2 (0)

DOUT13

GND

DIN2 (7)

DOUT15

DIN3 (6)

DIN3 (5)

DOUT17

DIN3 (4)

DIN3 (3)

DOUT19

DIN3 (2)

DIN3 (1)

FRAME

A2

LD

CIN0

CIN2

CIN4

CIN6

GND

V

CC

DIN3 (0)

A0

A1

HOLD

GND

CIN1

CIN3

CIN5

CIN7

CLK

2

Page 3

HSP48901

Pin Descriptions

NAME PLCC PIN TYPE DESCRIPTION

V

CC

GND 18, 29, 38, 56 The device ground.

CLK 28 I Input and System clock. Operations are synchronous with therising edgeof this clock signal.

DIN1(7-0) 1-8 I Pixel Data Input Bus #1. These inputs are used to provide 8-bit pixel data to the HSP48901.

DIN2(7-0) 10-17 I Pixel Data Input Bus #2. Same as above. These inputs should be grounded when operating

DIN3(7-0) 19-26 I Pixel Data Input Bus #3. Same as above. These inputs should be grounded when operating

CIN7-0 30-37 I Coefficient Data Input Bus. This input bus is used to load the Coefficient Mask Register(s)

DOUT19-0 46-55, 57-60,

FRAME 44 I FRAME is an asynchronous new frame or vertical sync input. A low on this input resets all

HOLD 40 I The Hold Input is used to gate the clock from all of the internal circuitry of the HSP48901.

A2-0 41-43 I Control RegisterAddress. These linesare decodedto determine whichregister in thecontrol

LD 39 I Load Strobe. LD is usedfor loading the Internal Registers of theHSP48901. The rising edge

9, 27, 45, 61 The +5V power supply pins. 0.1µF capacitors between the VCC and GND pins are

recommended.

The data must be provided in a synchronous fashion, andis latched on the rising edge of the

CLK signal. The DIN1(0-7) inputs are also used to input data when operating in the 9-Tap

FIR mode.

in the 1D mode.

in the 1D mode.

and the Initialization Register. The register to be loaded is defined by the register address

bits A0-2. The CIN0-7 data is loaded to the addressed register through the use of the LD

input.

O Output Data Bus. This 20-Bit output port is used to provide the convolution result. The result

62-67

is the sum of products of the input data samples and their corresponding coefficients.

internalcircuitry except for the Coefficientand INT Registers. Thus, aftera FRAME resethas

occurred, a new frame of pixels may be convolved without reloading these registers.

This signal is synchronous, is sampled on the rising edge of CLK and takes effect on the

following cycle. While this signal is active (high), the clock will have no effect on the

HSP48901 and internal data will remain undisturbed.

logic is the destination for the data on the CIN0-7 inputs. Register loading is controlled by

the A0-2 and LD inputs.

of LD will latch the CIN0-7 data into the register specified by A0-2. The Address on A0-2

must be setup with respect to the falling edge of LD and must be held with respect to the

rising edge of LD.

3

Page 4

HSP48901

Functional Description

The HSP48901 can perform convolution of a 3 x 3 filter kernel

with 8-bit image data. It accepts the image data in a raster

scan, non-interlaced format, convolves it with the filter k ernel

and outputs the filtered image. The input and filter kernel data

are both 8-bits, while the output data is 20 bits to prevent

overflowduring the convolution operation. Image data is input

via the DIN1, DIN2, and DIN3 busses. This data would

normally be provided by programmable data buffer such as

the HSP9501 as illustrated in the Operations Section of this

specification. The data is then convolved with the 3 x 3 arr ay

of filter coefficients. The resultant output data is then stored in

the Output Register. The HSP48901 ma y also be used in a

one-dimensional mode. In this configuration, it functions as a

1-D 9-tap FIR filter. Data would be input via the DIN1(0-7) bus

for operation in this mode.

Initialization of the convolveris done using the CIN0-7 bus to

load configuration data and the filter kernel(s). The address

lines A0-2 are used to address the Internal Registers for

initialization. The configuration data is loaded using the

A0-2, CIN0-7 and

enable, respectively. This interface is compatible with

standard microprocessors without the use of any additional

glue logic.

Filtered image data is output from the convolver over the

DOUT0-19 bus. This output bus is 20 bits wide to provide

room for growth during the convolution operation.

LD controls as address, data and write

8-Bit Multiplier Array

The multiplier array consists of nine 8 x 8 multipliers. Each

multiplier forms the product of a filter coefficient with a

corresponding pixel in the input image. Input and coefficient

data may be in either two's complement or unsigned integer

format. The nine coefficients form a 3 x 3 filter kernel which

is multiplied by the input pixel data and summed to form a

sum of products for implementation of the convolution

operation as shown below:

FILTER KERNEL INPUT DATA

A B C P1P2P3

D E F P4P5P6

G H I P7P8P9

OUTPUT = (A x P1) + (B x P2) + (C x P3)

+ (D x P4) + (E x P5) + (F x P6)

+ (G x P7) + (H x P8) + (I x P9)

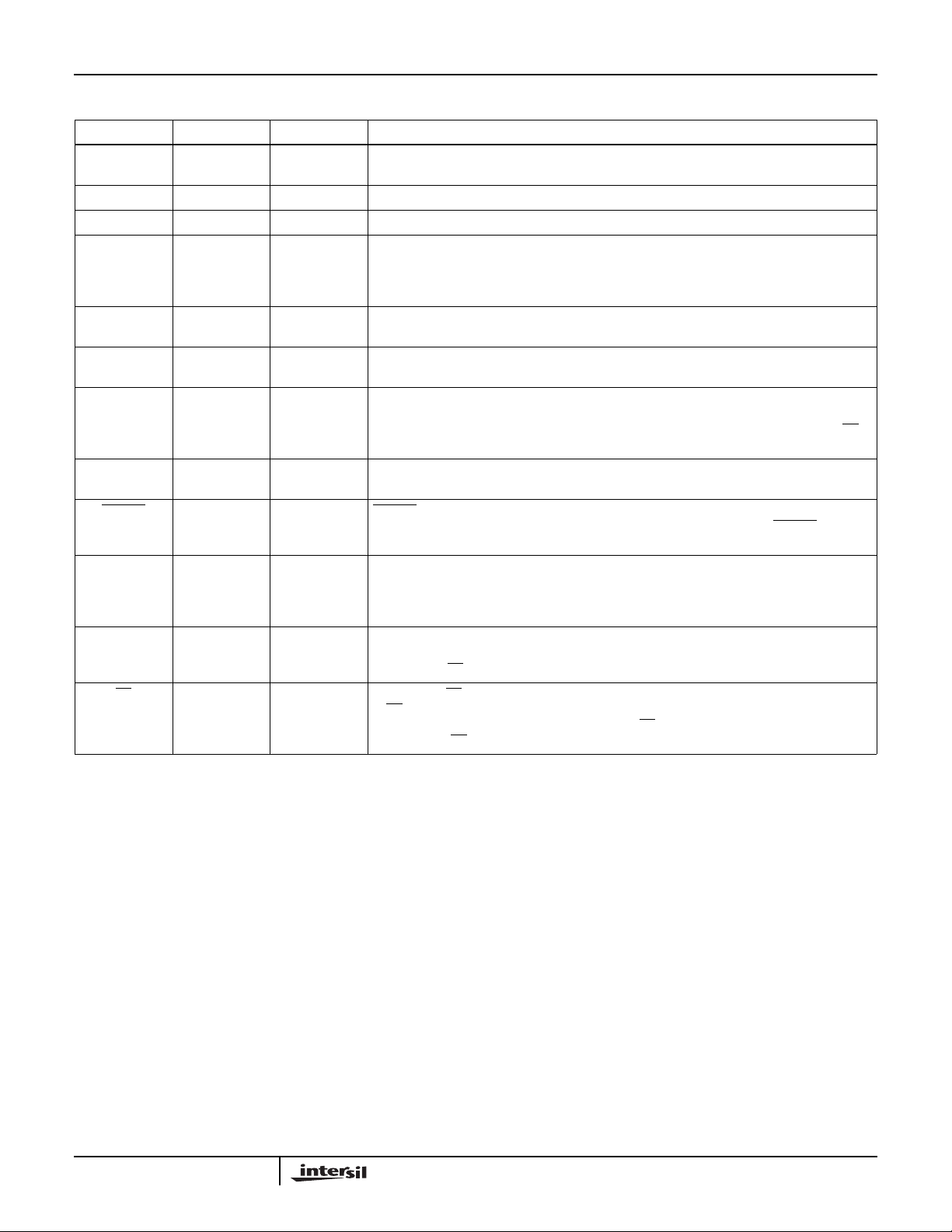

Control Logic

The control logic (Figure 1) contains the Initialization

Register and the Coefficient Registers. The control logic is

updated by placing data on the CIN0-7 bus and using the

A0-2 and

(see Address Decoder). All of the Control Logic Registers

are unaffected by

LD control lines to write to the addressed register

FRAME.

A0 - 2

LD

CIN0 - 7

CR1

ENCR1

ENCR0

3

SQ

C Q

ENCRO

ADDRESS

CODE

INITIALIZATION REGISTER

CAS

(INT)

I0

E H0 E G0 EF0EE0E

IHGFEDCBA

I1 E H1 E G1 EF1EE1E

FIGURE 1. CONTROL LOGIC BLOCK DIAGRAM

ENCR1

CAS

CR1

CRO

INITIALIZATION

DAT A

COEFFICIENT

REGISTER 0

COEFFICIENT

REGISTER 1

D1

D0

C0

E

E

EB0E A0 ECR0

C1

EB1E A1 E

4

Page 5

HSP48901

Initialization Register

The Initialization Register is used to appropriately configure

the convolverfor a particularapplication. It is loaded through

the use of the CIN0-7 bus along with the

defines the input data and coefficients format (unsigned or

two's complement); Bit-1 defines the mode of operation (1-D

or 2-D); and Bit-2 and Bit-3 determine the type of rounding to

occur on the DOUT0-19 bus; The complete definition of the

Initialization Register bits is given in Table 1.

TABLE 1. INITIALIZATION REGISTER

INITIALIZATION REGISTER

FUNCTION = INPUT AND COEFFICIENT

BIT 0

0 Unsigned Integer Format

1 Two’s Complement Format

BIT 1 FUNCTION = OPERATING MODE

0 1-D 9-Tap Filter

1 2-D 3 x 3 Filter

3 BIT 2 FUNCTION = OUTPUT ROUNDING

0 0 No Rounding

0 1 Round to 16 Bits (i.e., DOUT19-4)

1 0 Round to 8 Bits (i.e., DOUT19-12)

1 1 Not Valid

DATA FORMAT

Coefficient Registers (CREG0, CREG1)

The control logic contains two coefficient register banks,

CREG0 and CREG1. Each of these register banks is

capable of storing nine 8-bit filter coefficient values (3 x 3

Kernel). The output of the registers are connected to the

coefficient input of the corresponding multiplier in the 3 x 3

multiplier array (designated A through I). The register bank

to be used for the convolution is selectable by writing to the

appropriate address (see address decoder). All registers in a

given bank are enabled simultaneously, and one of the

banks is always active.

For most applications, only one of the register banks is

necessary.The user can simply load CREG0 after power up,

and use it forthe entire convolution operation. (CREG0 is the

Default Register). The alternate register bank allows the

user to maintain two sets of filter coefficients and switch

between them in real time. The coefficient masks are loaded

via the CIN0-7 bus by using A0-2 and

the particular register bank to be used in processing is also

done by writing to the appropriate address (See address

decoder). For example, if CREG0 is being used to provide

coefficients to the multipliers, CREG1 can be updated at a

low rate by an external processor; then, at the proper time,

CREG1 can be selected, so that the new coefficient mask is

used to process the data. Thus, no clock cycles have been

lost when changing between alternate 3 x 3 filter kernels.

LD input. Bit-0

LD. The selection of

The nine coefficients must be loaded sequentially over the

CIN0-7 bus from A to I. The address of CREG0 or CREG1 is

placed on A0-2, and then the coefficients are written to the

corresponding Coefficient Register one at a time by using

the

LD input.

Address Decoder

The address decoder (see Figure 1) is used for writing to the

control logic of the HSP48901. Loading an Internal Register

is done by selecting the Destination Register with the A0-2

address lines, placing the data on CIN0-7, and asserting

control line. When

LD goes high, the data on ClN0-7 is

latched into the addressed register. The address map for the

A0-2 bus is shown in Table 2.

While loading of the control logic registers is asynchronous

to CLK, the target register in the control logic is being read

synchronous to the internal clock. Therefore, care must be

taken when modifying the convolver setup parameters

during processing to avoid changing the contents of the

registers near a rising edge of CLK. The required setup time

relative to CLK is given by the specification TLCS. For

example, in order to change the active coefficient register

from CREG0 to CREG1 during an active convolution

operation, a write will be performed to the address for

selecting CREG1 for internal processing (A0-2 = 110). In

order to provide proper uninterrupted operation,

LD should

be deasserted at least TLCS prior to the next rising edge of

CLK. Failure to meet this setup time may result in

unpredictable results on the output of the convolver. Keep in

mind that this requirement applies only to the case where

changes are being made in the control logic duringan active

convolution operation. In a typical convolver configuration

routine, where the configuration data is loaded prior to the

actual convolution operation, this specification would not

apply.

TABLE 2. ADDRESS MAPS

CONTROL LOGIC ADDRESS MAP

A2-0 FUNCTION

0 0 0 Reserved for Future Use.

0 0 1 Reserved for Future Use.

0 1 0 Load Coefficient Register 0 (CREG0).

0 1 1 Load Coefficient Register 1 (CREG1).

1 0 0 Load Initialization Register (INT).

1 0 1 Select CREG0 for Internal Processing.

1 1 0 Select CREG1 for Internal Processing.

1 1 1 No Operation.

LD

5

Page 6

HSP48901

Control Signals

HOLD

The HOLD control input provides the ability to disable

internal clock and stop all operations temporarily. HOLD is

sampled on the rising edge of CLK and takes effect during

the following clock cycle (refer to Figure 2). This signal can

be used to momentarily ignore data at the input of the

convolver while maintaining its current output data and

operational state.

CLK

HOLD

INTERNAL

CLOCK

FIGURE 2. HOLD OPERATION

FRAME

The FRAME input initializes all internal flip flops and

registers except for the coefficient and Initialization

Registers. It is used as a reset between video frames and

eliminates the need to reinitialize the entire HSP48901 or

reload the coefficients. The registers and flip flops will

remain in a reset state as long as

is an asynchronous input and may occur at any time.

However, it must be deasserted at least t

rising clock edge that is to begin operation for the next frame

in order to ensure the new pixel data is properly loaded.

Operation

A single HSP48901 can be used to perform 3 x 3 convolution

on 8-bit image data. A Block Diagram of this configuration is

shown in Figure 3. The inputs of an external data buffer (such

as the HSP9501) are connected to the input data in parallel

with the DlN1(0-7) lines; the outputs of the data buffer are

connected tothe DIN2(0-7) bus. Asecond external data buffer

is connected between the outputs of the first buffer and the

DIN3(0-7) inputs. To perform the convolution operation, a

group of nine image pixels is multiplied by the 3 x 3 arr ay of

filter coefficients and their products are summed and sent to

the output. For the example in Figure 3, the pixel value in the

output image at location m, n is given by:

DOUT(m,n) = A x Pm-1, n-1 + B x Pm-1,n +C x Pm-1, n+1

+ D x Pm, n-1 + E x Pm, n + F x Pm, n+1

+ G x Pm+1,n-1 + H x Pm+1,n +I xPm+1, n+1

This process is continually repeated until the last pixel of the

last row of the image has been input. It can then start again

with the first row of the next frame. The

clear the Internal Multiplier Registers and DOUT0-19

Registers between frames. The row length of the image to be

convolved is limited only by the maximum length of the

external data buffers.

The setup is straightforward. The user must first setup the

HSP48901 by loading a new value into the Initialization

FRAME is active. FRAME

ns prior to the

FS

FRAME pin is used to

Register. The coefficients can now be loaded one at a time

from A to I via the CIN0-7 coefficient bus, and the A0-2 and

LD control lines.

DAT A

BUFFER

DAT A

BUFFER

A

B

D

E

F

H

8

DAT A

C

F

I

DIN 1 (0 -7)

DOUT 0 -19

DIN 2 (0 -7)

HSP48901

DIN 3 (0 -7)

P

M -1, N -1PM -1, NPM -1, N +1

P

M, N -1

P

M+1, N -1PM+1, NPM+1, N +1

P

20

M, N

FILTERED

IMAGE

DAT A

P

M, N +1

IMAGE

DAT A

INITIALIZATION

FILTER KERNEL IMAGE DATA

FIGURE 3. 3 x 3 KERNEL ON AN 8-BIT IMAGE

Multiple filter kernels can also be used on the same image

data using the dual Coefficient Registers CREG0 and

CREG1. This type of filtering is used when the characteristics

of the input pixel data change over the image in such a w ay

that no one filter produces satisfactory results for the entire

image. In order to filter such an image, the characteristics of

the filter itself must change while the image is being

processed. The HSP48901 can perform this function with the

use of an external processor. The processor is used to

calculate the required new filter coefficients, loads them into

the Coefficient Register not in use, and selects the newly

loaded Coefficient Register at the proper time. The first

Coefficient Register can then be loaded with new coefficients

in preparation for the next change . This can be carried out

with no interruption in processing, provided that the new

register is selected synchronous to the convolver CLK signal.

The HSP48901 can also operate as a one dimensional 9-tap

FIR filter by programming the Initialization Register to 1-D

mode (i.e., INT bit-1 = 0). This configuration will provide for

nine sequential input values to be multiplied by the coefficient

values in the selected Coefficient Register and provide the

proper filtered output. The input bus to be used when

operating in this mode is the DIN1(0-7) inputs.

The equation for the output in the 1-D 9-tap FIR case

becomes:

D0UTn = A x Dn-8 + B x Dn-7 + C x Dn-6 + D x Dn-5

+ E x Dn-4 + F x Dn-3 + G x Dn-2 + H x Dn-1

+ l x Dn

Frame Rate

The total time to process an image is given by the formula:

T = R x C/F, where:

T = Time to process a frame

R = Number of rows in the image

C = Number of pixels in a row

F = Clock rate of the HSP48901

6

Page 7

HSP48901

Absolute Maximum Ratings Thermal Information

Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +8.0V

Input, Output or I/O Voltage Applied . . . . .GND -0.5V to VCC +0.5V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Class 1

Operating Conditions

Voltage Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.75V to 5.25V

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . .0oC to 70oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

Thermal Resistance (Typical, Note 1) θJA (oC/W) θJC (oC/W)

PLCC Package. . . . . . . . . . . . . . . . . . . 43 N/A

PGA Package. . . . . . . . . . . . . . . . . . . . 38 8

Maximum Junction Temperature

PLCC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150oC

PGA Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300oC

(PLCC - Lead Tips Only)

Die Characteristics

Number of Transistors or Gates. . . . . . . . . . . . . . . . . . 13,594 Gates

DC Electrical Specifications V

= 5.0V ±5%, TA = 0oC to 70oC

CC

PARAMETER SYMBOL TEST CONDITIONS MIN MAX UNITS

Logical One Input Voltage V

Logical Zero Input Voltage V

High Level Clock Input V

Low Level Clock Input V

Output HIGH Voltage V

Output LOW Voltage V

Input Leakage Current I

Standby Power Supply Current I

CCSB

IHC

VCC = 5.25V 2.0 - V

IH

VCC = 4.75V - 0.8 V

IL

VCC = 5.25V 3.0 - V

VCC = 4.75V - 0.8 V

ILC

IOH = 400µA, VCC = 4.75V 2.6 - V

OH

IOL = +2.0mA, VCC = 4.75V - 0.4 V

OL

VIN = VCC or GND, VCC = 5.25V -10 10 µA

I

VIN = VCC or GND, VCC = 5.25V,

Outputs Open

Operating Power Supply Current I

CCOP

f = 20MHz, VIN=VCCor GND, VCC= 5.25V

(Note 2)

Input Capacitance C

f = 1MHz, VCC = Open, All Measurements

IN

are referenced to device GND (Note 3).

Output Capacitance C

O

NOTES:

2. Power supply current is proportional to operating frequency. Typical rating for I

CCOP

3. Not tested, but characterized at initial design and at major process/design changes.

- 500 µA

- 120 mA

-10pF

-15pF

is 6mA/MHz.

AC Electrical Specifications V

PARAMETER SYMBOL NOTES

Clock Period t

Clock Pulse Width High t

Clock Pulse Width Low t

Data Input Setup Time t

Data Input Hold Time t

Clock to Data Out t

Address Setup Time t

CYCLE

PWH

PWL

DS

DH

OUT

7

= 5.0V ±5%, TA = 0oC to 70oC

CC

CONDITIONS

AS

TEST

-30 -40

UNITSMIN MAX MIN MAX

33-50-ns

13-20-ns

13-20-ns

14-16-ns

0-0-ns

- 21 - 30 ns

5-5-ns

Page 8

HSP48901

AC Electrical Specifications V

PARAMETER SYMBOL NOTES

Address Hold Time t

Configuration Data Setup Time t

Configuration Data Hold Time t

LD Pulse Width t

LD Setup Time t

HOLD Setup Time t

HOLD Hold Time t

FRAME Pulse Width t

FRAME Setup Time t

Output Rise t

Output Fall Time t

= 5.0V ±5%, TA = 0oC to 70oC

CC

AH

CS

CH

LPH

LCS

HS

HH

FPW

FS

R

F

Note 4 31 t

Note 5 28 - 40 - ns

From 0.8V to 2.0V - 8 - 8 ns

From 2.0V to 0.8V - 8 - 8 ns

TEST

CONDITIONS

-30 -40

UNITSMIN MAX MIN MAX

2-2-ns

10-12-ns

0-0-ns

13-20-ns

+2 40 t

CYCLE

CYCLE

+2 ns

10-12-ns

0-0-ns

t

CYCLE

-t

CYCLE

-ns

NOTES:

4. This specification applies only to the case where a change in the active Coefficient Register is being selected duringa convolutionoperation. It must

be met in order to achieve predictable results at the next rising clock edge. In most applications, this selection will be made asynchronously, and the

t

Specification may be disregarded.

LCS

5. While FRAME isasynchronous with respect to CLK, it must be deasserteda minimum of tFSns prior to the rising clock edge which isto begin loading

new pixel data for the next frame.

6. AC Testingis performed as follows: Input levels(CLK Input) = 4.0V and 0V; input levels (all other inputs) = 0V to 3.0V; input timing reference levels:

(CLK) = 2.0V, (others) = 1.5V; other timing references: VOH≥ 1.5V, VOL≤ 1.5V; output load test load circuit with CL = 40pF.

Test Load Circuit

(NOTE 7) C

NOTES:

7. Includes stray and jig capacitance.

8. Switch S1 Open for I

CCSB

and I

DUT

CCOP

L

Tests.

S

1

I

OH

EQUIVALENT CIRCUIT

1.5V I

±

OL

8

Page 9

Timing Waveforms

t

CLK

DIN 0-7

PWL

HSP48901

t

CYCLE

t

PWH

t

DS

t

DH

LD

A0-2

t

AS

t

LPW

t

AH

t

OUT

DOUT 0-19

CIN0-7

FIGURE 4. FUNCTIONAL TIMING FIGURE 5. CONFIGURATION TIMING

CLK

t

CLK

LD

t

LCS

HOLD

INTERNAL

CLOCK

HS

FIGURE 6. SYNCHRONOUS LOAD TIMING FIGURE 7. HOLD TIMING

t

FRAME

FPW

t

CS

t

HH

t

HS

t

CH

t

FS

CLK

FIGURE 8. FRAME TIMING

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only.Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly ,the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

9

Loading...

Loading...