Page 1

HSP45240

September 1997

Features

• Block Oriented 24-Bit Sequencer

• Configurable as Two Independent 12-Bit Sequencers

• 24 x 24 Crosspoint Switch

• Programmable Delay on 12 Outputs

• Multi-Chip Synchronization Signals

• Standard µP Interface

• 100pF Drive on Outputs

• DC to 50MHz Clock Rate

Applications

• 1-D, 2-D Filtering

• Pan/Zoom Addressing

• FFT Processing

• Matrix Math Operations

Ordering Information

TEMP.

PART NUMBER

HSP45240JC-33 0 to 70 68 Ld PLCC N68.95

HSP45240JC-40 0 to 70 68 Ld PLCC N68.95

HSP45240JC-50 0 to 70 68 Ld PLCC N68.95

HSP45240GC-33 0 to 70 68 Ld PGA G68.A

HSP45240GC-40 0 to 70 68 Ld PGA G68.A

HSP45240GC-50 0 to 70 68 Ld PGA G68.A

RANGE (oC) PACKAGE

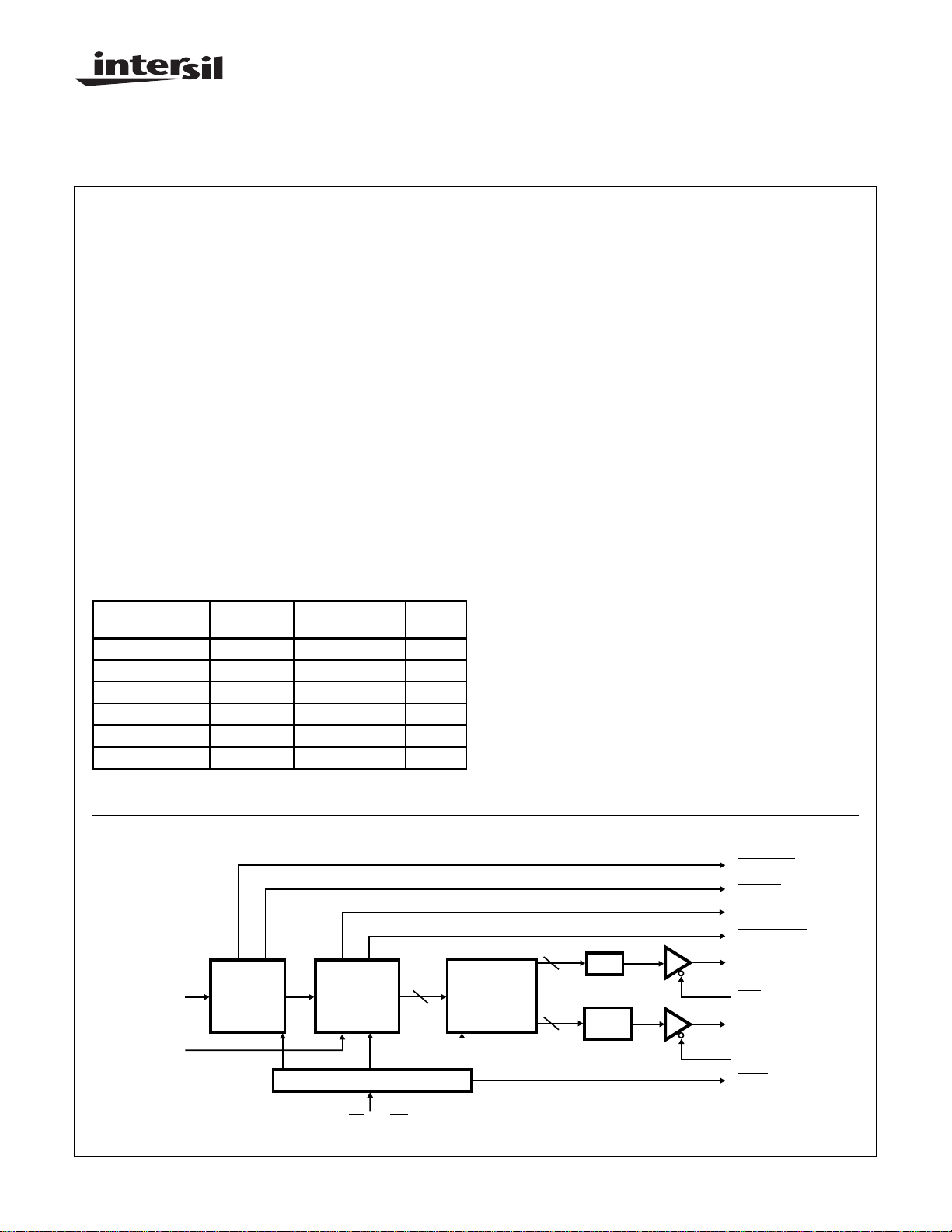

Address Sequencer

Description

The Intersil HSP45240 is a high speed Address Sequencer

which provides specialized addressing for functions like

FFTs, 1-D and 2-D filtering, matrix operations, and image

manipulation. The sequencer supports block oriented

addressing of large data sets up to 24-bits at clock speeds

up to 50MHz.

Specialized addressing requirements are met by using the

onboard 24 x 24 crosspoint switch. This feature allows the mapping of the 24 address bits at the output of the address generator to the 24 address outputs of the chip. As a result, bit rev erse

addressing, such as that used in FFTs, is made possible.

A single chip solution to read/write addressing is also made

possible by configuring the HSP45240 as two 12-bit

sequencers. To compensate for system pipeline delay, a programmable delay is provided on 12 of the address outputs.

The HSP45240 is manufactured using an advanced CMOS

process, and is a low power fully static design. The configuration of the device is controlled through a standard microprocessor interface and all inputs/outputs, with the e xception

of clock, are TTL compatible.9-

PKG.

NO.

Block Diagram

12

STARTIN

DLYBLK

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

START

CIRCUITRY

SEQUENCE

GENERATOR

PROCESSOR INTERFACE

CS, A0, WR

D0-6,

| Copyright © Intersil Corporation 1999

24

CROSSPOINT

SWITCH

9-1

12

REG

DELAY

1-8

STARTOUT

ADDVAL

DONE

BLOCKDONE

OUT12-23

OEH

OUT0-11

OEL

BUSY

File Number 2489.3

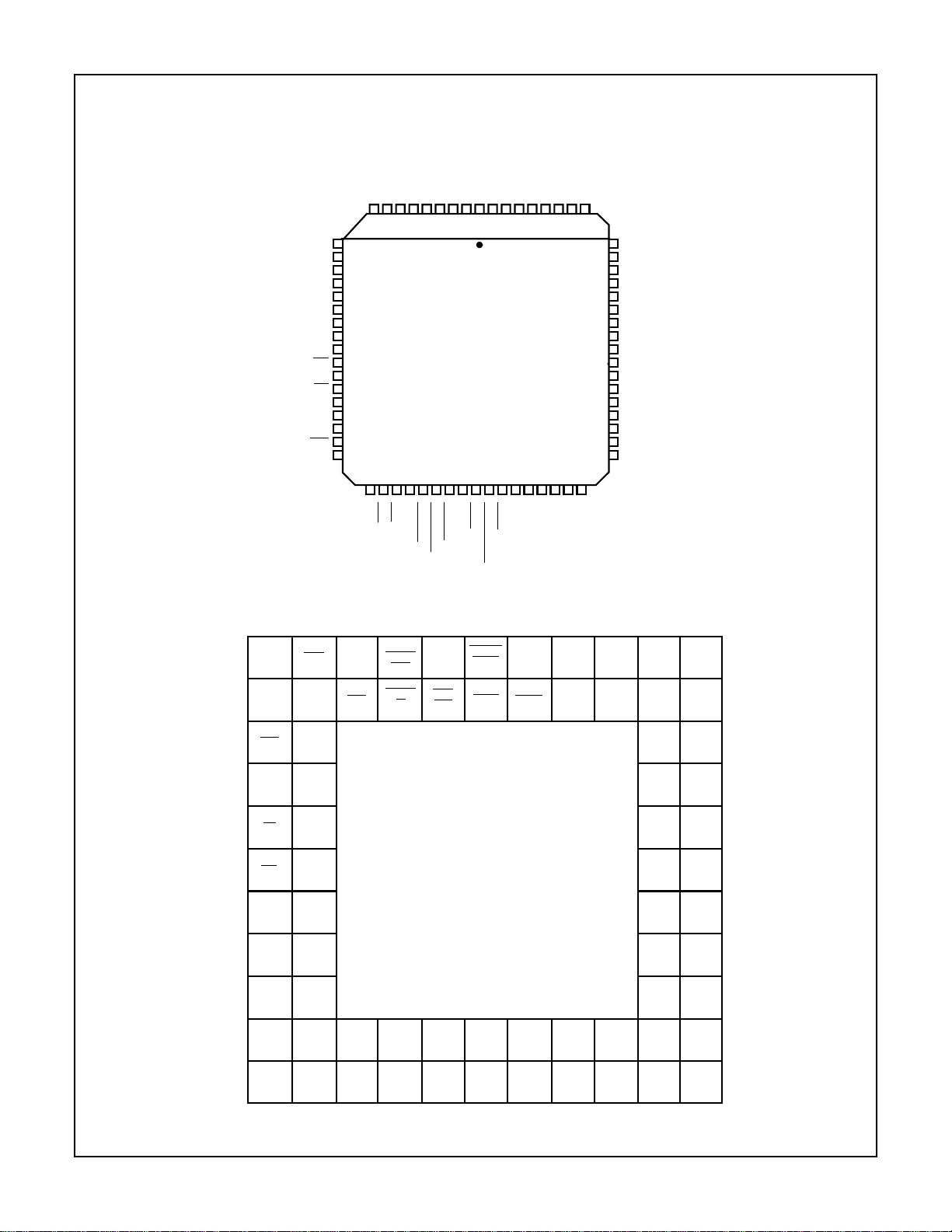

Page 2

Pinouts

HSP45240

ADDRESS SEQUENCER HSP45240

68 PIN PLASTIC LEADED CHIP CARRIER (PLCC)

GND

OUT23

OUT22

VCCOUT21

OUT20

GND

OUT19

OUT18

VCCOUT17

OUT16

GND

OUT15

9876543216867666564636261

NC

10

D0

11

D1

12

D2

13

D3

14

15

D4

16

D5

17

D6

18

GND

19

WR

20

A0

21

CS

22

GND

23

CLK

24

V

CC

25

RST

26

NC

OUT14

OUT13

4327 2829 30 31 32 33 34 35 36 37 38 39 40 41 42

NC

NC

60

OUT12

59

GND

58

OUT11

57

OUT10

56

V

55

CC

OUT9

54

OUT8

53

GND

52

OUT7

51

OUT6

50

V

49

CC

OUT5

48

OUT4

47

GND

46

OUT3

45

NC

44

NC

OEH

OEL

DLYBLK

STARTIN

STARTOUT

ADDVAL

CC

V

BUSY

GND

OUT0

DONE

BLOCKDONE

OUT1

CC

NC

V

OUT2

68 PIN GRID ARRAY (PGA)

BOTTOM VIEW

V

CC

ADD

VAL

BLOCK

DONE

BUSY

GND

DONE

OUT1

OUTO

OUT2

V

CC

NC

NC

GND

OUT5

OUT6

GND

OUT9

OUT10

OUT3

OUT4

V

CC

OUT7

OUT8

V

CC

OUT11

OEL

START

OUT

START

IN

L

K

J

H

G

F

E

D

NC

RST

CLK

CS

WR

D6

D4

OEH

NC

V

CC

GND

A0

GND

D5

D3

DLYBLK

OUT12

D2

C

B

A

D1

D0

NC

GND

2345678910111

OUT22

OUT23

OUT21

GND

OUT18

OUT17

OUT20

V

CC

OUT19

GND

OUT14

V

OUT16

CC

OUT15

GND

NC

OUT13

NC

9-2

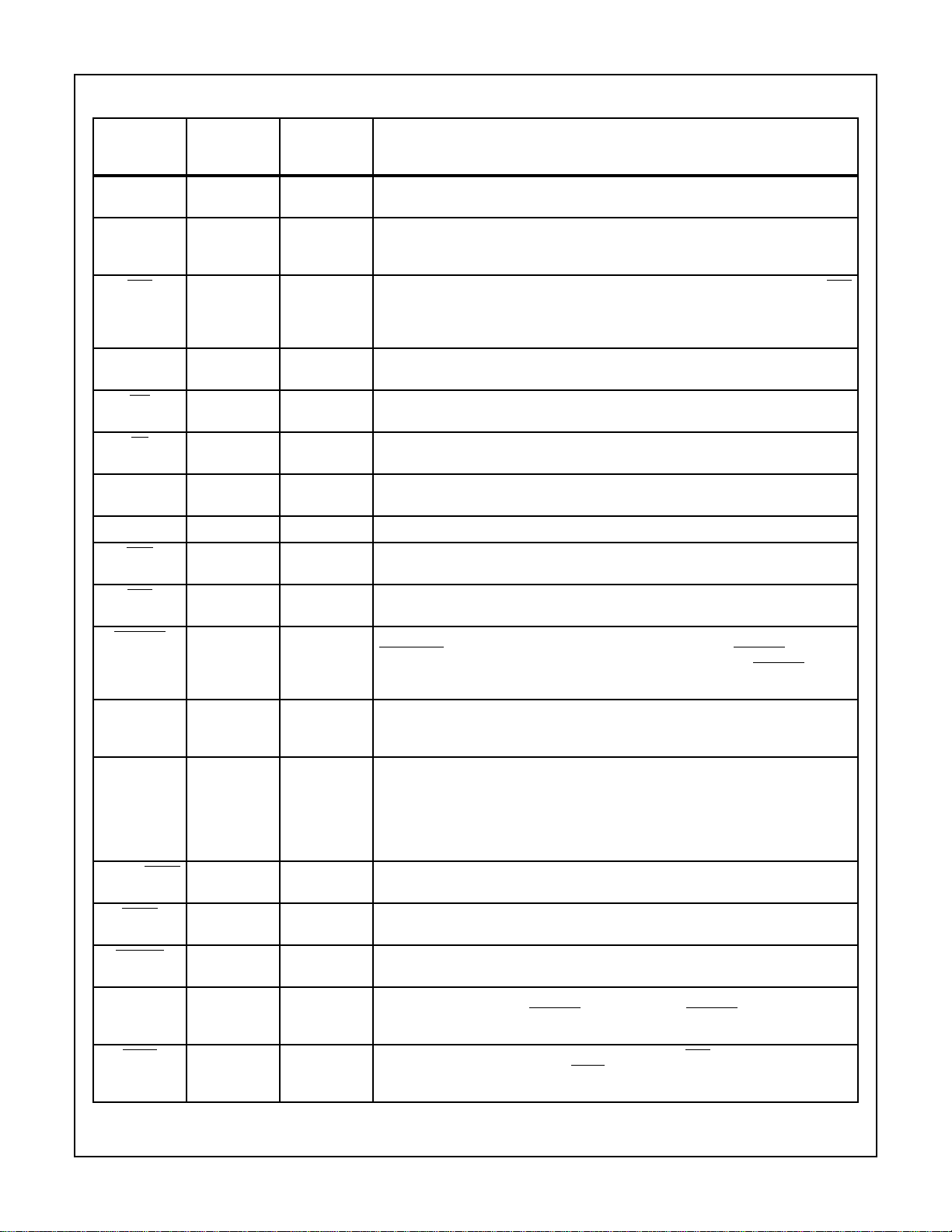

Page 3

Pin Descriptions

NAME TYPE

HSP45240

PLCC

PIN

NUMBER DESCRIPTION

V

CC

GND I 3, 9, 18, 22,

RST I 25 RESET: This active low input causes a chip reset which lasts for 26 clocks after RST

CLK I 23 CLOCK: The “CLK” signal is a CMOS input which provides the basic timing for address

WR I 19 WRITE: The rising edge of this input latches the data/address on D0-6 to be latched

CS I 21 CHIP SELECT: This active “low” input enables the configuration data/address on

A0 I 20 ADDRESS 0: This input defines D0-6 as a configuration register address if “high”, and

D0-6 I 11-17 DATA BUS: Data bus for Processor Interface.

OEH I 28 OUTPUT ENABLE HIGH: This asynchronous input is used to enable the output buffers

OEL I 29 OUTPUT ENABLE LOW: This asynchronous input is used to enable the output buffers

STARTIN I 31 START-IN: This active low input initiates an addressing sequence. May be tied to

DLYBLK I 30 DELA Y BLOCK: This activ e “high” input ma y be used to halt address gener ation on ad-

OUT0-23 O 39, 40, 42, 45,

BLOCK DONE O 36 BLOCK DONE: This active low output signals when the last address in an address block

DONE O 37 DONE: This active low output signals when the last address of an address sequence is

ADDVAL O 33 ADDRESS VALID: This active low output signals when the first address of an address

START-OUT O 32 ST ART-OUT: This active lo w output is generated when an address sequence is initiated

BUSY O 35 BUSY: This active low output is asserted one CLK after RST is deasserted and will re-

NOTE: #Denotes active low.

I 6, 24, 34, 41

49, 55, 68

38, 46, 52,

58, 65

47, 48, 50, 51,

53, 54, 56, 57,

59, 62-64, 66,

67, 1, 2, 4, 5,

7, 8

+5V power supply pin.

GROUND.

has been deasserted. The reset initializes the Crosspoint Switch and some of the configuration registers as described in the Processor Interface Section. The chip must be

clocked for reset to complete.

generation.

into the Processor Interface.

D0-6 to be latched into the Processor Interface.

configuration data if “low”, (see Processor Interface text).

for OUT 12-23.

for OUT0-11.

STARTOUT of another H5P45240 for multichip synchronization. STARTIN should only

be asserted for one CLK because address sequencing begins after STARTIN is deasserted.

dress block boundaries (see Sequence Generator text). The required timing relationship of this signal to the end of an address block is shown in Application Note 9205.

OUTPUT BUS: TTL compatible 24-bit Address Sequencer output.

is on OUT0-23.

on OUT0-23.

sequence is on 0UT0-23.

by a mechanism other thanSTARTIN. Ma y be tied to theSTAR TIN of other H5P45240’ s

for multichip synchronization.

main asserted for 25 CLK’s. While BUSY is asserted, all writes to the Processor Interface are disabled.

9-3

Page 4

Functional Description

HSP45240

The Address Sequencer is a 24-bit programmable address

generator. As shown in the Block Diagram, the sequencer

consists of 4 functional blocks: the start circuitry, the

sequence generator, the crosspoint switch, and the processor interface. The addresses produced by the sequence

generator are input into the crosspoint switch. The crosspoint switch maps 24 bits of address input to a 24-bit output.

This allows for addressing schemes like “bit-reverse”

addressing for FFT’s. A programmable delay block is provided to allow the MSW of the output to be skewed from the

LSW . This feature may be used to compensate for processor

pipeline delay when the sequence generator is configured as

two independent 12-bit sequencers. Address Sequencer

operation is controlled by values loaded into configuration

registers associated with the sequence generator, crosspoint switch, and start circuitry. The configuration registers

are loaded through the processor interface.

Start Circuitry

The Start Circuitry generates the internal START signal

which causes the Sequence Generator to initiate an

addressing sequence. The START signal is produced by

writing the Processor Interface’s “Sequencer Start” address

(see Processor Interface text), by asserting the

input, or by the terminal address of a sequence generated

under “One-Shot Mode with Restart” (see Sequence Generator Section). Care should be taken to assert

only one clock cycle to ensure proper operation. A programmable delay from 1 to 31 clocks is provided to delay the initiation of an addressing sequence by delaying the internal

START signal (see Processor Interface text).

The Start Circuitry generates the output signal

which is asserted when the first valid output address is at the

pads. In addition, the Start Circuitry generates the

“

STARTOUT” signal for multichip synchronization. Note:

STARTOUT is only generated when an addressing

sequence is started by writing the “Sequencer Start”

address of the Processor Interface, or an internal START is

generated by reaching the end of an addressing sequence

produced by “One-Shot Mode with Restart”.

STARTlN

STARTlN for

ADDVAL

Sequence Generator

The Sequence Generator is a block oriented address generator. This means that the desired address sequence is subdivided into one or more address blocks, each containing a

user defined number of addresses. User supplied configuration data determines the number of address blocks and the

characteristics of the address sequence to be generated.

An address sequence is started when the control section of

the Sequence Generator receives the internal START signal

from the Start Circuitry. When the START signal is received,

the control section multiplexes the contents of the Start

Address Register and a “0” to the adder. The result of this

summation is the first address in the first block of the

address sequence. This value is stored in the Block Start

Address register by an enable generated from the control

section, and the multiplexers are switched to feed the output

of the Holding and Address Increment registers to the adder.

Address generation will continue with the Address Increment

added to the contents of the Holding Register until the first

address block has been completed.

An address block is completed when the number of

addresses generated since the beginning of the address

block equals the value stored in the Block Size register.

When the last address of the block is generated,

DONE is asserted to signal the end of the address block

(see Application Note 9205). On the following CLK, the multiplexers are configured to pass the contents of the Block

Start Address and Block Increment registers to the adder

which generates the first address of the next address block.

An enable from the control section allows this value to

update the Block Start Address register, and the multiplexers

are switched to feed the Holding and Address Increment registers to the adder for generation of the remaining addresses

in the block.

The address sequence is completed when the number of

address blocks generated equals the value loaded into the

Number of Blocks register. When the final address in the last

address block has been generated,

DONE are asserted to signal the completion of the address

sequence.

The parameters governing address generation are loaded

into five 24-bit configuration registers via the Processor

Interface. These parameters include the Start Address, the

beginning address of the sequence; the Block Size, the number of addresses in the address block; the Address Increment, the increment between addresses in a block; the

Number of Blocks, the number of address blocks in a

sequence (minimum 1); the Block Increment, the increment

between starting addresses of each block. The loading and

structure of these registers is detailed in the Processor Interface text.

DONE and BLOCK-

BLOCK-

As shown in Figure 1, the Sequence Generator is subdivided

into the address generation and control sections. The

address generation section performs an accumulation based

on the output of MUX1 and MUX2. The control section governs the operation of the multiplexers, enables loading of the

Block Start Address register, and signals completion of an

address sequence.

9-4

Page 5

CURRENT

BLOCK

START

ADDRESS

STEP SIZE

START

ADDRESS

BLOCK

STEP SIZE

HSP45240

R

E

G

R

E

G

R

E

G

R

E

G

“0”

“0”

M

U

X

1

M

U

X

2

A

D

D

E

R

12 MSB

12 LSB

12

M

U

X

HOLDING

REGISTER

12

R

E

G

24

TO

CROSSPOINT

SWITCH

ADDRESS

GENERATION

BLOCK

SIZE

NUMBER

OF

BLOCKS

MODE

R

E

G

R

E

G

R

E

G

TEST MODE

DAT A

FIGURE 1. SEQUENCE GENERATOR BLOCK

Three modes of operation may be selected by loading the 6-bit

Mode Control register (see Processor Interface). The three

modes of operation are:

1. One-Shot Mode without Restart Address generation halts

after completion of the user specified address sequence.

Address generation will not resume until the internal

ST AR T signal is generated by the Start Circuitry . When the

final address in the final block of the address sequence is

generated, both

DONE and BLOCKDONE are asserted

and the last address is held on OUT0-23 (See Application

Note 9205).

2. One-Shot Mode with Restart: This mode is identical to

One-Shot Mode without Restart with the exception that the

Start Circuitry automatically generates an inter nal START

at the end of the user specified sequence to restart address generation. The end of the address sequence is signaled by the assertion of

DONE, BLOCKDONE, and

STARTOUT as shown in Application Note 9205. In this

mode, the first address of the next sequence immediately

follows the last address of the current sequence if start delay is disabled.

3. Continuous Mode: Address generation never terminates.

Address generation proceeds based on the Start Address,

Address Increment, Block Size, and Block Increment Parameters. The Number of Blocks parameter is ignored, and

the

DONE signal is never asserted.

The Mode Control register is also used to configure the

Sequence Generator for operation as two independent 12-bit

address sequencers. In dual sequencer mode, the adder in

the sequence generator suppresses the carry from the 12

LSBs to the 12 MSBs. With the carry suppressed, two independent sequences may be produced. These 12-bit address

MUX CONTROLS/

REGISTER ENABLES

SEQUENCE

GENERATOR

CONTROL

“START”

CONTROL

DONE

BLOCKDONE

DLYBLK

sequences may be delay ed relativ e to each other b y prog ramming the Mode Control register for a delay up to 7 cloc ks . This

feature is useful to compensate for pipeline delay when using

dual sequencer mode to generate read/write addressing.

The DLYBLK input can be used to halt address generation at

the end of any address block within a sequence. In addition,

DLYBLK can be used to delay an address sequence from

restarting if asserted at the end of the final address bloc k generated under “One-Shot Mode with Restart”. See Application

Note 9205 for the timing relationship of DLYBLK to the end of

the address block required to halt address sequencing.

Crosspoint Switch

The crosspoint switch is responsible for reordering the

address bits output by the sequence generator. The switch

allows any of its 24 inputs to be independently connected to

any of its 24 outputs. The crosspoint switch outputs can be

driven by only one input, however, one input can drive any

number of switch outputs. If none of the inputs are mapped to

a particular output bit, that output will be “low”.

The input to output map is configured through the processor

interface. The I/O map is stored in a bank of 24 configuration

registers. Each register corresponds to one output bit. The

output bit is mapped to the input via a value, 0 to 23, stored in

the register. After power-up, the user has the option of configuring the switch in 1:1 mode by using the reset input, “

In 1:1 mode the crosspoint switch outputs are in the same

order as the input. More details on configuring the switch registers are contained in the Processor Interface text.

RST”.

9-5

Page 6

Processor Interface

HSP45240

The Processor Interface consists of a 10 pin microprocessor

interface and a register bank which holds configuration data.

The data is loaded into the register bank by first writing the

register address to the processor Interface and then writing

the data. An auto address increment mode is provided so that

a base address may be written followed by a number of data

writes.

The microprocessor interface consists of a 7 bit data bus (D0-

6), a one bit address select (A0) to specify D0-6 as either

address or data, a write input (

cessor Interface, and a chip select input (

WR) to latch data into the Pro-

CS) to enable writing

to the interface. The Processor Interface input is decoded as

either data or address as shown by the bit map in Table 1.

TABLE 1.

A0 D6 D5 D4 D3 D2 D1 D0

REGISTER ADDRESSES

Switch Output Registers. 1 x 0nnnnn

Sequencer Starting

Address.

Sequencer Block Size. 1 x 1001nn

Sequencer Number of

Blocks.

Sequencer Block. 1 x 1011nn

Address Increment.

Sequencer Address. 1 x 1100nn

Increment.

Mode Control. 1 x 110100

Test Control. 1 x 110101

Start Delay Control. 1 x 110110

Address Sequencer

“START”.

DATA WORDS

Current Address Data. 0 0nnnnnn

(No Address Increment).

Current Address Data

(Address Increment).

NOTES:

1. Table 1 “x” means “don’t care”, and “n” denotes bits which are decoded as an address in address registers and data in data registers.

2. When WR transitions “high” to write the Sequencer “Start” address

(1x111111), it must remain high until after a rising edge of clock. Otherwise, the sequencer “start” signal will not be generated.

1x1000nn

1x1010nn

1x111111

01nnnnnn

The register bank consists of a series of 6-bit registers which

may be addressed individually as shown in Table 1. The data in

these registers is down loaded into configuration registers in the

Start Circuitry, Sequence Generator, and Crosspoint Switch

when an address sequence is initiated by the internal START

signal (see Start Circuitry). This double buffered architecture

allows new configuration data to be down loaded to the Processor Interface while an address sequence is being completed

using previous configuration data.

The register bank has five sets of four registers which contain address generation parameters. These parameters

include: Address Start, Block Size, Number of Blocks, Block

Increment, and Address Increment. Each register set maps

to one of five 24-bit configuration registers in the Sequence

Generator block (see Sequence Generator). The mapping of

the 6-bit registers in the register bank to the 24-bit configuration registers is determined by the 2 LSBs of the register

address. The higher the value of the 2 LSBs the higher the

relative mapping of the 6-bit register to the 24-bit register.

For example , if the 2 LSBs of the register address are both 0,

the register contents will map to the 6 LSBs of the configuration register.

The register bank has 24 registers which contain the data for

Cross point Switch I/O mapping. These registers are

accessed via the 5 LSBs of the address for the Crosspoint

Mapping registers in Table 1. A value from 0 to 23 accesses

the mapping registers for OUTO-23 respectively. A value

greater than 23 is ignored. The output bit represented by a

particular register is mapped to the input by the 6-bit value

loaded into the register. If the value loaded into the register

exceeds 23, the corresponding output bit will be “0”. For

example, if the 5 LSBs of the Crosspoint Mapping address

are equal to 3, and the valued loaded into the register

accessed by this address is equal to 23, OUT3 would be

mapped to the MSB of the sequence generator output.

After a reset, the Mode Control, Test Control, and Start

Delay registers are reset as described in the section describing each register’s bit map; the Crosspoint Mapping registers

are reset to a 1:1 crosspoint switch mapping; the registers

which hold the five address generation parameters are not

affected.

To save the user the expense of alternating between

address and data writes, an auto address increment mode is

provided. The address increment mode is invoked by performing data writes with a “1” in the D6 location of the data

word as shown in Table 1. For example, the crosspoint

switch could be configured by 25 writes to the Processor

Interface (one write for the starting address of the crosspoint

mapping registers followed by 24 data writes to those registers).

Mode Control Register

The Mode Control Register is used to control the operation

of the sequence generator. In addition, it also controls the

output delay between the MSW and the LSW of OUTO-23.

The following tables illustrate the structure of the mode control register.

TABLE 2. MODE CONTROL REGISTER FORMAT

ADDRESS LOCATION: 1x11O1OO

D5 D4 D3 D2 D1 D0

OD2 OD1 OD0 DS M1 M0

9-6

Page 7

HSP45240

ODx - Output Delay: Delays OUTO-1 1 from OUT12-23 by

the following number of clocks.

OD2 OD1 OD0

0 0 0 Output Delay of 0.

0 0 1 Output Delay of 1.

0 1 0 Output Delay of 2.

0 1 1 Output Delay of 3.

1 0 0 Output Delay of 4.

1 0 1 Output Delay of 5.

1 1 0 Output Delay of 6.

1 1 1 Output Delay of 7.

DS - Dual Sequencer Enable: Allows two independent 12- bit

sequences to be generated.

0 A 24-bit sequence is generated.

1 Two 12-bit sequences are generated.

Mx - Mode: Sequencer Mode.

M1 M0

0 0 One-Shot Mode without Restart.

0 1 One-Shot Mode with Restart.

1 x Continuous Mode (x = don’t care).

During reset, this register will be reset to all zeroes. This will

configure the chip as a 24-bit sequencer with zero delays on

the outputs. The chip will also be in one-shot mode without

restart.

Start Delay Control Register

The Start Delay Control Register is used to configure the

start circuitry for delayed starts from 1 to 31 clock cycles.

Internal “START”, external “START”, and restarts will be

delay by the programmed amount. The structure of the Start

Delay Control Register is shown in Table 3.

TABLE 3. START DELAY CONTROL REGISTER FORMAT

ADDRESS LOCATION: 1x110110

D5 D4 D3 D2 D1 D0

SDE SD4 SD3 SD2 SD1 SD0

SDE - Start Delay Enable: Enables “START” to be delayed

by the programmed amount. When Start Delay is enabled, a

minimum of “1” is required for the programmed delay.

0 Start Delay is Disabled.

1 Start Delay is Enabled.

SDx - Start Delay: Delays the “START” by the decoded number of clocks.

SD4 SD3 SD2 SD1 SD0

00001Start Delay of 1.

00010Start Delay of 2.

00011Start Delay of 3.

11111Start Delay of 31.

During reset, this register will be reset to all zeros. This will

bring the chip up in a mode with Start Delay disabled.

Test Control Register

A Test Control Register is provided to configure the

sequence generator to produce test sequences. In this

mode, the sequence generator can be configured to multiplex out the contents of the down counters in the sequence

generator control circuitry, Figure 2. These counters are

used to determine when a block or sequence is complete. As

shown in Figures 1 and 2, the MSW or LSW in the down

counters is multiplexed to the MSW of the address gener ator

output. In addition, a test mode is provided in which the

sequence generator performs a shifting operation on the

contents of the start address register. The structure of the

Test Control Register is shown in Table 4.

TO ADDRESS

GENERATION SECTION

12

MUX

24

24

24

24

MUX CONTROLS/

REGISTER ENABLES

CONTROL

“START”

DONE

BLOCKDONE

DLYBLK

REGISTERED

BLOCK SIZE

REGISTERED

NUMBER OF

BLOCKS

REGISTERED

MODE

D

C

O

O

W

U

N

N

T

E

R

#

1

D

C

O

O

W

U

N

N

T

E

R

#

2

FIGURE 2. SEQUENCE GENERATOR CONTROL

TABLE 4. TEST CONTROL REGISTER FORMAT

ADDRESS LOCATION: 1x110101

D5 D4 D3 D2 D1 D0

xx xx SE COE CS1 CS0

Bits “D5” and “D6” are currently not used.

SE - Shifter Enable: Input to crosspoint switch is generated

by shifting Start Address Register one bit per clock.

9-7

Page 8

HSP45240

0 Sequence Generator Functions Normally.

1 Sequence Generator Functions as Shift Register.

CCE - Counter Output Enable: Enable contents of down

counters in the sequence generator control circuitry to be

muxed to the 12 MSBs of the address generator output.

0 Disable Muxing of down counters.

1 Enable Muxing of down counters.

CS - Counter Select: Selects which 12-bit word of the down

counters is muxed to the MSW of the address generator output.

CSl CS0

0 0 Select Counter 1, bits 0-11.

0 1 Select Counter #1, bits 12-23.

1 0 Select Counter #2, bits 0-11.

1 1 Select Counter #2, bits 12-23.

During reset, this register will be reset to all zeroes. This will

bring the chip up in the mode with all of the test features disabled.

Applications

Image Processing

The application shown in Figure 3 uses the HSP45240

Address Sequencer to satisfy the addressing requirements

for a simple image processing system. In this example the

controller configures the sequencers to generate specialized

addressing sequences for reading and writing the frame

buffers. A typical mode of operation for this system might be

to perform edge detection on a subsection of an image

stored in the frame buffer. In this application, data is fed to

the 2-D Convolver by the address sequence driving the input

frame buffer.

A graphical interpretation of sub-image addressing is shown

in Figure 4. Each dot in the figure corresponds to an image

pixel stored in memory. It is assumed that the pixel values

are stored by row. For example, the first 16 memory locations would contain the first row of pixel values. The 17th

memory location would contain the first pixel of the second

row.

SYNC

HSP48808

2D

CONVOLVER

CONTROLLER

FRAME

BUFFER

HSP45420

SEQUENCER

FRAME

BUFFER

I/O

ADDRESSING

HSP45420

SEQUENCER

FIGURE 3. IMAGE PROCESSING SYSTEM

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0

0

16

32

48

64

80

96

112

128

144

160

178

192

208

224

240

FIGURE 4. SEQUENCER SUB IMAGE ADDRESSING

OUTPUTINPUT

I/O

ADDRESSING

The sub-image address sequence shown in Figure 3 is generated by configuring the sequence generator with the following:

1. Start Address = 35 4. Step Size = 1

2. Block Size = 8 5. Block Step Size = 16

3. Number of Blocks = 8

In this example the start address corresponds to the address

of the first pixel of the first row. The row length corresponds

to the Block Size which is programmed to 8. Within the bloc k,

consecutive addresses are generated by programming the

Step Size to 1. At the completion of first block of addresses,

the Block Step Size of 16 is added to the Start Address to

generate the address of the first pixel of the second row.

Finally, 8 rows of addressing are generated by setting the

Number of Blocks to 8.

In this application, the sub-image is processed one time and

then a new sub-image area is chosen. As a result, the Mode

Control Register would be configured for One-Shot mode

without Restart. Also, the Start Delay Control register of the

Sequencer driving the output frame buffer would be configured with a start delay to compensate for the pipeline delay

introduced by the 2-D Convolver. Finally, the crosspoint

9-8

Page 9

HSP45240

switch would be configured in 1:1 mode so that the

sequence generator output has a 1 to 1 mapping to the chip

output.

For applications requiring decimation of the original image,

the Step Size could be increased to provide addressing

which skips over pixels along a row. Similarly, the Block Step

Size could be increased such that pixel rows are skipped.

FFT Processing

The application shown in Figure 5 depicts the architecture of

a simplified radix 2 FFT processor. In this application the

Address Sequencer drives a memory bank which feeds the

arithmetic processor with data. In a radix 2 implementation,

the arithmetic processor takes two complex data inputs and

produces two results. These results are then stored in the

registers from which the data came. This type of implementation is referred to as an “in place” FFT algorithm.

The arithmetic processing unit performs an operation know as

the radix 2 butterfly which is shown graphically in Figure 6. In

this diagram the node in the center of the butterfly represents

summing point while the arrow represents a multiplication

point. The flow of an FFT computation is described by diagrams comprised of many butterflies as shown in Figure 7.

The FFT processing shown in Figure 7 consists of three

stages of radix 2 butterfly computation. The read/write

addressing, expressed in binary, for each stage is shown in

Table 5. The specialized addressing required here is produced by using the crosspoint switch to map the address bits

from the sequence generator to the chip output.

The mapping for the sequencer’s crosspoint switch is determined, by inspecting the addressing for each stage. For

example, the first stage of addressing is generated by configuring the crosspoint switch so that bit 0 of the switch input

is mapped to bit 2 of the switch output, bit 1 of the switch

input is mapped to bit 0 of the output, and bit 2 of the switch

input is mapped to bit 1 of the switch output. The remainder

of the switch I/O map is configured 1:1, i.e., bit-3 of the

switch input is mapped to bit 3 of the switch output. Under

this configuration, a sequence generator output of

0,1,2,3,4,5,6,7 will produce a crosspoint switch output of

0,4,1,5,2,6,3,7. The switch maps for the other stages, as w ell

as a map for the bit-reverse addressing of the FFT result is

given in Table 5.

tion. Thus, while one address sequence is being completed,

the crosspoint switch is being configured for the next stage

of FFT addressing. When one stage of addressing is complete, the new switch configuration is loaded into the current

state registers by an internal or externally generated start or

restart.

The crosspoint switch is configured for the first stage of

addressing by writing a 0 to switch output register 2, a 2 to

switch output register 1, and a 0 to switch output register 2.

These values are loaded by first writing the address of

switch output register 0 and then loading data using autoaddress increment mode (see Table 1). The remaining registers are assumed to be configured in 1:1 mode as a result of

a prior “RESET”. The second and third stages of addressing

are generated by reconfiguring the above three registers.

The Address Sequencer can be configured in dual

sequencer mode to provide both read and write addressing

for each butterfly. Since 2 independent 12-bit sequences can

be generated by the Address Sequencer, it can be used to

provide read/write addressing for FFT’s up to 4096 points.

The programmable delay between the MSW and LSW of the

Sequencer output is used to compensate for the pipeline

delay associated with the arithmetic processor.

TABLE 5. FFT ADDRESSING BY COMPUTATIONAL STAGE

STAGE 1

R/WADDR.

000 000 000 000

100 010 001 100

001 001 010 010

101 011 011 110

010 100 100 001

110 110 101 101

011 101 110 011

111 111 111 111

SWITCH MAPPING

021 201 210 012

STAGE 2

R/W/ADDR.

STAGE 3

R/W/ADDR.

OUTPUT

ADDRESSING

The serial count required as input for the crosspoint switch is

generated by configuring the sequence generator with the

following:

1. Start Address = 0 4. Step Size = 1

2. Block Size = 8 5. Block Step Size = 0

3. Number of Blocks = 1

Under this configuration the sequence generator will pro-

duce a count from 0 to 7 in increments of 1. The FFT length

corresponds to the Block Size, in this case 8.

The serial count from the sequence generator is converted

into the desired addressing sequence by applying the appropriate map to the crosspoint switch. In this application, the

switch mapping changes for each stage of the FFT computa-

9-9

Page 10

HSP45240

HSP45240

SEQUENCER

CONTROLLER

MEMORY

ARITHMETIC

PROCESSOR

FIGURE 5. FFT PROCESSOR

A

B

X = A + B

k

W

N

Y = (A • B) W

k

N

N = FFT LENGTH

k

W

= e - j

N

FIGURE 6. BUTTERFLY FOR DECIMATION-IN-FREQUENCY

X(0)

0

W

X(1)

0

X(2)

X(3)

X(4)

X(5)

X(6)

X(7)

0

W

1

W

2

W

3

W

W

2

W

W

0

W

0

W

0

W

2

0

W

2 π K

N

X(0)

X(4)

X(2)

X(6)

X(1)

X(5)

X(3)

X(7)

FIGURE 7. COMPLETE EIGHT-POINT-IN-PLACE DECIMATION-IN-FREQUENCY FFT

9-10

Page 11

HSP45240

Absolute Maximum Ratings T

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+8.0V

Input, Output or I/O Voltage Applied. . . . . GND -0.5V to VCC +0.5V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 1

=25oC Thermal Information

A

Thermal Resistance (Typical, Note 3) θJA (oC/W) θJC (oC/W)

PLCC Package . . . . . . . . . . . . . . . . . . 43.1 15.1

PGA Package . . . . . . . . . . . . . . . . . . . 37.1 10.1

Maximum Package Power Dissipation at 70oC

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+5.0V ±5%

Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0oC to 70oC

PLCC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.86W

PGA Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.84W

Maximum Junction Temperature

PLCC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150oC

PGA Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175oC

Maximum Storage Temperature Range . . . . . . . . . .-65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300oC

Die Characteristics

Number of Transistors or Gates . . . . . . . . . . . . . . . . . . .8388 Gates

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

3. θJA is measured with the component mounted on an evaluation PC board in free air.

DC Electrical Specifications V

PARAMETER SYMBOL TEST CONDITIONS MIN MAX UNITS

Logical One Input Voltage V

Logical Zero Input Voltage V

High Level Clock Input V

Low Level Clock Input V

Output HIGH Voltage V

Output LOW Voltage V

Input Leakage Current I

I/O Leakage Current I

Standby Power Supply Current I

= 5.0V + 5%, TA = 0oC to 70oC

CC

VCC = 5.25V 2.0 - V

IH

VCC = 4.75V - 0.8 V

IL

IHC

CCSB

VCC = 5.25V 3.0 - V

VCC = 4.75V - 0.8 V

ILC

IOH = 400µA, VCC = 4.75V 2.6 - V

OH

IOL = +2.0mA, VCC = 4.75V - 0.4 V

OL

VIN = VCC or GND, VCC = 5.25V -10 10 µA

I

V

O

= VCC or GND, VCC = 5.25V -10 10 µA

OUT

VIN = VCC or GND, VCC = 5.25V,

Outputs Open

- 500 µA

Operating Power Supply Current I

CCOP

f = 33MHz, VIN = VCC or GND, VCC =

5.25V, Outputs Open, (Note 4)

Input Capacitance C

f = 1MHz, VCC = Open, All Measurements

IN

are referenced to device GND. (Note 5).

Output Capacitance C

O

NOTES:

4. Power supply current is proportional to operating frequency. Typical rating for I

CCOP

5. Not tested, but characterized at initial design and at major process/design changes.

9-11

-99mA

-10pF

-10pF

is 3mA/MHz.

Page 12

HSP45240

AC Electrical Specifications V

= 5.0V +5%, TA = 0oC to 70oC, (Note 7)

CC

-33 (33MHz) -40 (40MHz) -50 (50MHz)

PARAMETER SYMBOL NOTES

Clock Period t

Clock Pulse Width High t

Clock Pulse Width Low t

Setup Time D0-6 to WR High t

Hold Time D0-6 from WR High t

Setup Time A0, CS, to WR Low t

Hold Time A0, CS, from WR High t

Pulse Width for WR Low t

Pulse Width for WR High t

WR Cycle Time t

Setup Time STARTIN, DLYBLK to Clock High t

Hold Time STARTIN, DLYBLK to Clock High t

Clock to Output Prop., Delay on OUT0-23 t

Clock to Output Prop. Delay on STARTOUT,

CP

CH

CL

DS

DH

AS

AH

WRL

WRH

WP

IS

IH

PDO

t

PDS

30 - 25 - 20 - ns

12 - 10 - 9 - ns

12 - 10 - 9 - ns

14 - 13 - 12 - ns

0-0-0-ns

5-5-5-ns

0-0-0-ns

13 - 12 - 10 - ns

13 - 12 - 10 - ns

30 - 25 - 20 - ns

12 - 10 - 8 - ns

0-0-0-ns

-15-13-12ns

-15-13-12ns

UNITSMIN MIN MIN MAX MIN MAX

BLKDONE, DONE, ADDVAL andBUSY

Output Enable Time t

Output Disable Time t

Output Rise/Fall Time t

RST Low Time t

EN

OD

ORF

RST

Note 6 - 20 - 15 - 13 ns

Note 6 - 5 - 3 - 3 ns

-20-15-13ns

2 Clock Cycles ns

NOTES:

6. Controlled by design or process parameters and not directly tested. Characterized upon initial design and after major process and/or design changes.

7. AC Testing is performed as follows: Input levels (CLK input) = 4.0V and 0V; input levels (all other inputs) = 0V and 3.0V; input timing

reference levels: (CLK) = 2.0, Others) = 1.5V; Output timing references: VOH≥ 1.5V, VOL≤ 1.5V.

AC Test Load Circuit

S

1

DUT

L

I

(NOTE 8) C

NOTES:

8. Includes stray and jig capacitance.

9. Switch S1 Open for I

CCSB

OH

EQUIVALENT CIRCUIT

and I

CCOP

±

Tests.

1.5V I

OL

OUTPUT PIN C

BLOCKDONE

DONE

ADDVAL

STARTOUT

BUSY

OUTTO-23 100pF

9-12

L

40pF

Page 13

Timing Diagrams

HSP45240

WR

D0-6

t

DS

t

DH

CLK

t

CP

t

CH

t

CL

FIGURE 8. CLOCK AC PARAMETERS FIGURE 9. DATA SETUP AND HOLD

WR

A0,

CS

t

AS

t

AH

WR

t

WRH

t

WP

t

WRL

FIGURE 10. ADDRESS/CHIP SELECT SETUP AND HOLD FIGURE 11. WR AC PARAMETERS

CLK

t

CLK

STARTIN

DLYBLK

OUTO - 23

t

IS

t

IH

STARTOUT

BLOCKDONE

DONE

ADDVAL

BUSY

t

PDO

PDS

FIGURE 12. INPUT SET AND HOLD FIGURE 13. OUTPUT PROPAGATION DELAY

OEL,

OEH

2.0VV

0.8V

t

ORF

OUT0 - 23

IH

t

EN

1.7V

1.3V

t

OD

V

IL

t

ORF

FIGURE 14. OUTPUT ENABLE, DISABLE TIMING FIGURE 15. OUTPUT RISE AND FALL TIMING

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries f or its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

9-13

Loading...

Loading...