Page 1

HSP45116-DB

USER’S MANUAL May 1999

HSP45116 Daughter Board

The HSP45116-DB is a daughter board designed to mate

with the HSP-EVAL for rapid evaluation and prototyping of

the HSP45116 Numerically Controlled Oscillator Modulator.

Together, the board set provides a mechanism to evaluate

HSP45116 operation using IBM PC

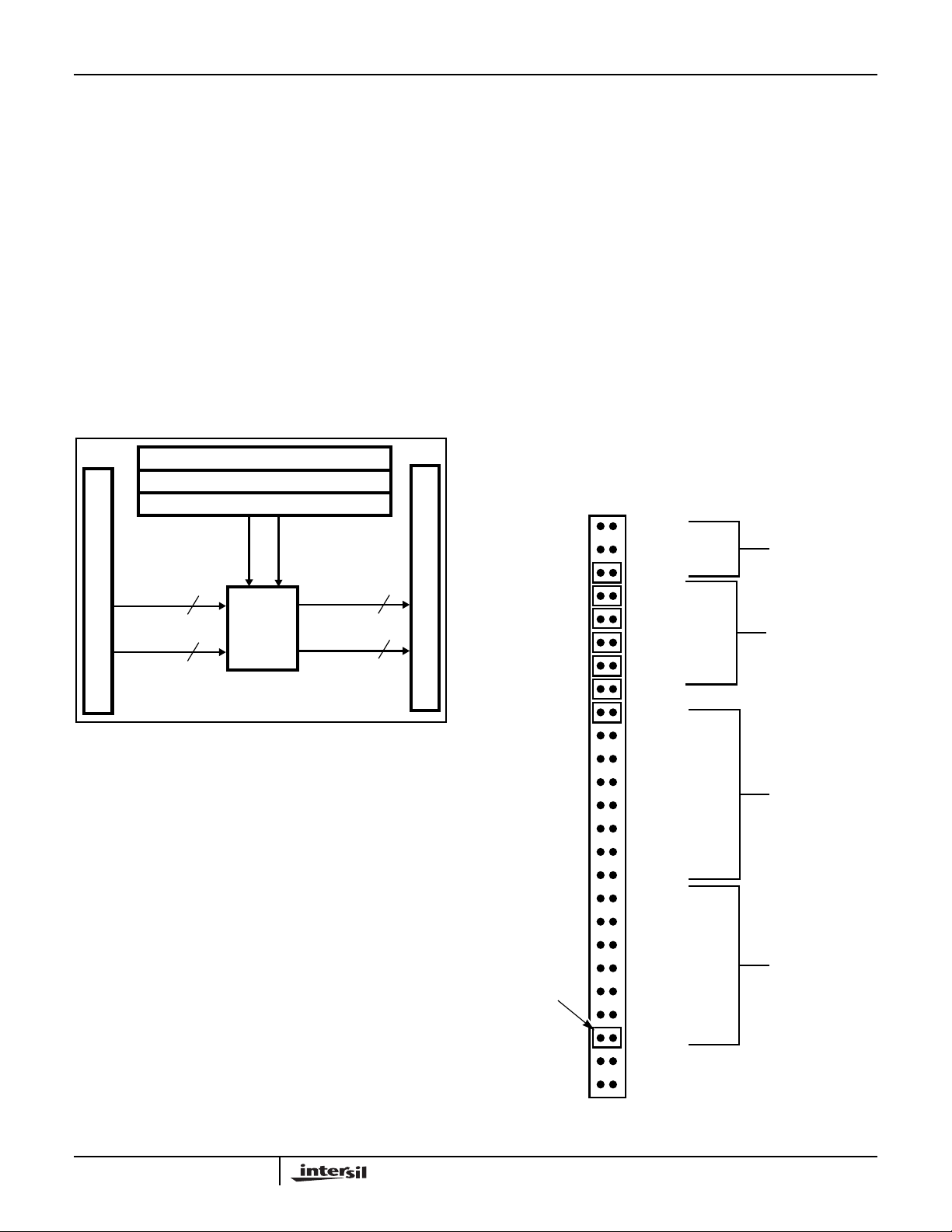

As shown in Figure 1, the HSP45116-DB maps the input,

output, and control signals of the HSP45116 to three 50 pin

headers. These headers mate with connectors on board the

HSP-EVAL to interface the HSP45116’s various I/O and

control signals with the HSP-EVAL’s data busses. This

interface establishes a path for PC

of the HSP45116-DB via the HSP-EVAL.

An IBM PC

controls operation to the HSP45116-DB/HSP-EVAL board

set. The software package provides the user with a DOS

command line interface and graphical user interface for

daughter board I/O and control. Since the software supports

data acquisition from the HSP45116, software based signal

analysis may be used to quantify part performance.

TM

based software package is supplied which

TM

based I/O and control.

TM

based I/O and control

File Number

exert real time control. If a software controlled clock is

provided, the HSP45116-DB can be driven with a user

defined data set, while storing results back to the PC forlater

analysis.

The HSP45116-DB is a 6 layer printed circuit board which

comes populated with one HSP45116GC-25. The PC based

software required to control the daughter board via the

HSP-EVAL is also provided.

3367.3

Features

• Designed for Use with HSP-EVAL

• Access to HSP45116s Input, Output, and Control Signals

Through Three 50 Pin Headers

• HSP45116 Control Signal States May be Set Through

Hardware Configuration or Software

• Two Separate Software Packagesfor Daughter Board I/O

and Control

• High Speed I/O Supported

The degree of control exerted by the software varies

depending upon the clock supplied to the HSP45116-DB. If

a high speed clock is supplied via the HSP-EVAL'son board

oscillator or external clock pin, the software can be used to

HSP45116 Daughter Board

Applications

• PC Based Performance Analysis of HSP45116 When

Used with HSP-EVAL

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

IBM PC™ is trademark of IBM Corporation.

Page 2

HSP45116-DB

Getting Started

This section describes the initial evaluation system setup for

the HSP45116-DB and HSP-EV AL board set. The system

setup consists of mother/daughter board assembly, software

installation, and system test to verify proper operation of the

board set.

Assembly

The evaluation board set is assembled by mating the

HSP45116-DB daughter board with the HSP-EV AL

motherboard. This is accomplished by inserting the header

pins sticking through the bottom (solder side) of the daughter

board into the three 2 x 25 pin connectors on the

motherboard. Proper alignment requires that the J1, J2, and

J3 headers on the HSP45116-DB mate with the J1, J2, and

J3 connectors on the HSP-EVAL. A moderate amount of force

is required to seat the header pins in the motherboard

connectors.

CONFIGURATION JUMPER FIELD A

50 PIN CONTROL HEADER (J2)

CONFIGURATION JUMPER FIELD B

CONTROL

RIN0-15

IMIN0-15

50 PIN INPUT HEADER (J1)

FIGURE 1. HSP45116-DB BLOCK DIAGRAM

16

16

HSP45116

HSP45116-DB

As part of the initial assembly , the HSP-EVAL and HSP45116DB must be provided with the default jumper configuration to

ensure proper operation with the system test software. Each

board leaving the factory is supplied with the default

configuration, but the respective configurations are e xamined

hereforcompleteness. The motherboard'sdefaultconfiguration

is realized by inserting jumpers into the HSP EVAL'sJ4 jumper

field as shown in Figure 2 (see the HSP-EV AL User’s Manual

for more detailed information). The default configuration for the

HSP45116-DB requires jumper placement across the

Configuration Jumper Fields A and B and the J3 Control

Header as shown in Table 1.

Before using the board set with the supplied software, pow er

must be supplied to the boards, and the HSP-EVAL must be

connected to the parallel port of the target PC. Pow er is

provided totheboardsbyconnectingtheV

the J6 header on the HSP-EV AL to a standard 5V±5% supply.

As an alternative, power may be supplied through the HSPEV AL’s 96-Pin DIN connectors. The HSP-EVAL is connected to

the target PC by connecting the HSP-EVAL’s 26-PIN shrouded

header to the PC’s parallel port using the supplied ribbon cable.

CLK

RO0-15

IO0-15

and GND pins of

CC

16

16

50 PIN OUTPUT HEADER (J3)

System Requirements for the Evaluation Board Software

The PC system targeted to run the HSP45116-DB software

(NCOM-SOFT) and interface with the ev aluation board set

must meet the following requirements:

- IBM PC/XT/A T, PS/2, or 100% compatible with a minimum

of 640K of random access memory (RAM) (NCOM-SOFT

does not require extended memory)

- At least 200kB of free disk space on your hard disk

- DOS Version 3.0 or higher

- One parallel port with 27 Pin D-Sub connector

Software Installation

The distribution diskette contains a program called

INSTALL.EXE which installs the NCOM-SOFT software onto

the target hard disk.

you are installing NCOM-SOFT from a diskette in drive A:

onto a hard drive C:. If a different configuration is used,

substitute the letter of the drive where the diskette is

located for drive A;. Substitute the letter for the hard drive

for drive C:

DEFAULT JUMPER

PLACEMENT INDICATOR

FIGURE 2. CONFIGURATION JUMPER FIELD J4

Note: The steps in this section assume

EXT_CLK

OSC_CL

CTL0

OE_BUS1

OE_BUS2

OE_BUS3

OECTLLO

OECTLHI

ADDR0

ADDR1

ADDR2

ADDR3

ADDR4

ADDR5

ADDR6

ADDR7

STAT0

STAT1

STAT2

STAT3

PCRD0

PCRD1

SR_RD

N.C.

N.C.

CLOCK SELECT

JUMPERS

OUTPUT ENABLE

JUMPERS

BOARD ADDRESS

JUMPERS

OUTPUT SELECT

JUMPERS

2

Page 3

HSP45116-DB

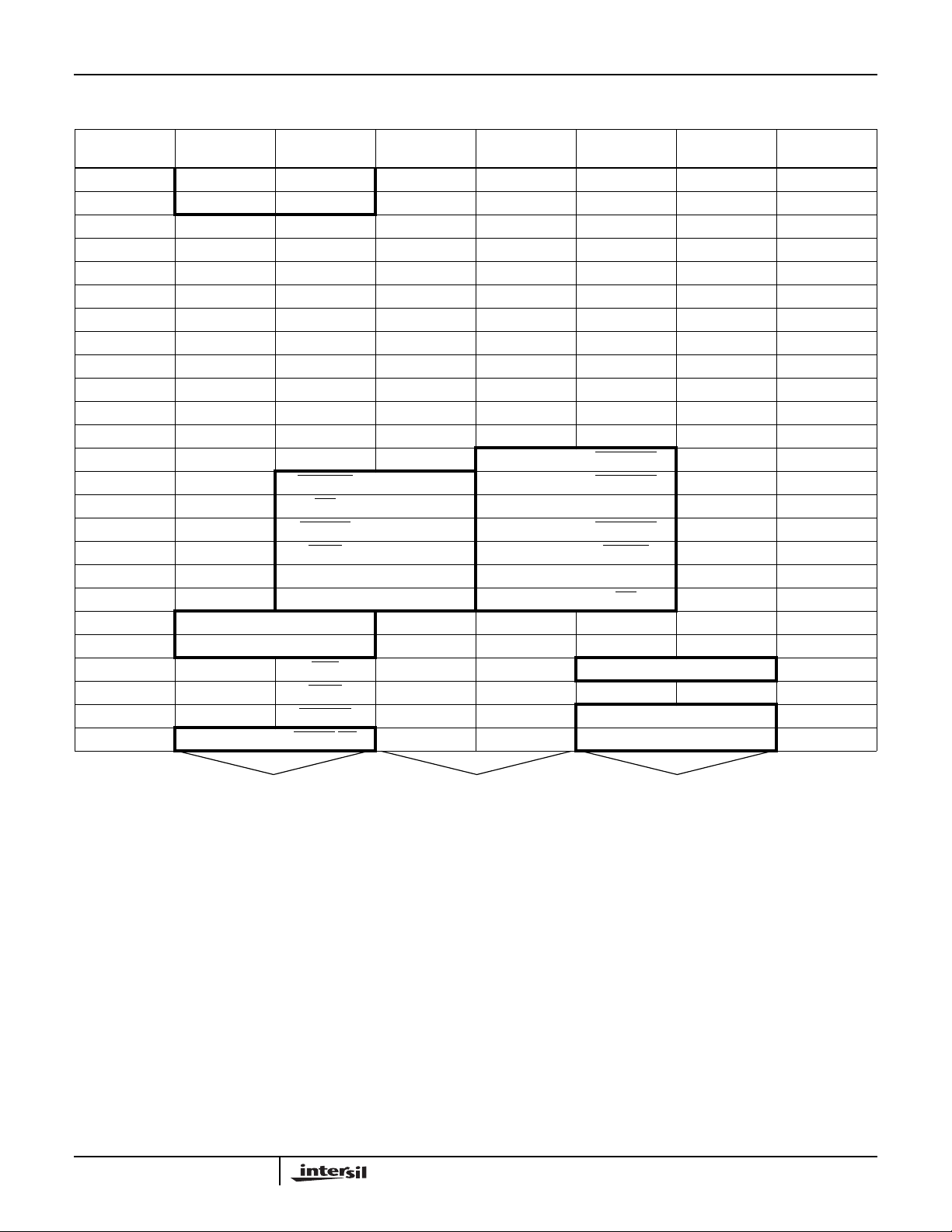

TABLE 1. OVERLAY OF DEFAULT JUMPER CONFIGURATION ONTO THE SIGNAL MAPPING FOR THE J3 CONTROL HEARDER AND

THE CONFIGURATION JUMPER FIELDS A AND B

PIN

NUMBER

1 CLKOUT BUF_IN N.C. GND N.C. GND 1

2 BUF_OUT CLK_IN C0 C1 N.C. GND 2

3 GND PULL UP C2 C3 N.C. GND 3

4 GND PULL UP C4 C5 N.C. GND 4

5 GND N.C. C6 C7 N.C. GND 5

6 GND N.C. GND C8 N.C. GND 6

7 GND N.C. C9 C10 N.C. GND 7

8 GND N.C. C11 C12 N.C. GND 8

9 GND N.C. C13 C14 N.C. GND 9

10 GND N.C. C15 GND N.C. GND 10

11 GND N.C. N.C. N.C. N.C. GND 11

12 GND N.C. CTL1 CT2 N.C. GND 12

13 GND PULL UP CTL3 CTL4 ENPHREG GND 13

14 GND ENTIREG CTL5 CTL6 ENOFREG GND 14

15 GND ENI CTL7 GND N.C. GND 15

16 GND CLROFR CTL8 CTL9 ENCFREG GND 16

17 GND LOAD CTL10 CTL11 BINFMT GND 17

18 GND PMSEL CTL12 CTL13 AD0 GND 18

19 GND AD1 CTL14 CTL15 WR GND 19

20 GND MUX0 GND N.C. N.C. GND 20

21 GND MUX1 GND N.C. N.C. GND 21

22 GND PACI GND N.C. ACC GND 22

23 GND PEAK GND N.C. N.C. GND 23

24 GND RBYTILD GND N.C. MOD0 GND 24

25 GND MODPI/2PI GND N.C. MOD1 GND 25

JA SIGNAL

MNEMONIC

SA SIGNAL

MNEMONIC

J3A SIGNAL

MNEMONIC

J3B SIGNAL

MNEMONIC

SB SIGNAL

MNEMONIC

JB SIGNAL

MNEMONIC

PIN

NUMBER

FIELD A

J3 CONTROL HEADERJUMPER CONFIGURATION

To start the installation program:

Make sure computer is on and the DOS prompt is displayed.

Type: C:<Enter>

Create a subdirectory to contain the NCOM-SOFT Programs

by typing:

MD \NCOMSOFT <Enter>

Change current directory to the NCOMSOFT directory:

CD \NCOMSOFT <Enter>

Start the installation process by typing:

A:INSTALL <Enter>

3

JUMPER CONFIGURATION

FIELD B

The INSTALL program downloads the NCOM-SOFT

programs, NCOMCTRL and NCOM_CMD, to the

NCOMSOFT subdirectory on the target hard drive. In

addition, a subdirectory called NCOM_CHK is created into

which files used to perform functional verification are

downloaded.

Modifications to AUTOEXEC.BAT

To run the NCOM-SOFT programs, DOS must be able to

find the executablefiles.To ensure that DOS can always find

the NCOM-SOFT executables, modify the search path to

include the location of the NCOM-SOFT directory. For

example,iftheNCOM-SOFTprogramsareinstalledondrive

C: in a subdirectory called \NCOMSOFT, add the following

Page 4

HSP45116-DB

line to the end of the existing Path command in the

AUTOEXEC.BAT file:

;C:\NCOMSOFT

If your AUTOEXEC.BAT file does not contain a PATH

command, add the following command to the file:

PATH=C:\NCOMSOFT

Reboot the PC so that the search path changes will take

effect.

System Test

Test software is provided to verify operation of the HSPEVAL and HSP45116-DB board set. Prior to performing the

system test, it is assumed that the evaluation board set has

been assembled and configured as described above; power

has been applied to the board set, and the 26-Pin shrouded

header on board the HSP-EVAL has been connected to the

parallel port of the target PC via the supplied cable. The

system test is initiated by the following:

Change the current directory to that which contains the

software required for the system test by typing

CD C:\NCOMSOFT\NCOM_CHK <Enter>

Run the system test software by typing:

NCOM_CHK <Enter>

The NCOM_CHK.BAT batch file makesuseoftheCommand

Line Interface (see Command Line Interface Section) to

initialize the evaluation board set; clock a data vector

through the HSP45116-DB, and store the output to a file.

The output file is then compared, using the DOS command

COMP, to a file containing a set of vectors generated by a

properly functioning board set. If the files match, the

assembled board set passes operational verification.

the user should answer NO to the COMP command

prompt to compare additional files.

NOTE:

HSP45116-DB Control Panel Software

The HSP45116-DB Control Panel is a graphical user

interface for controlling the operation of the HSPEVAL/HSP45116-DB Board Set via an IBM PC or

compatible. The control panel, as shown in Figure 3,

supports loading the HSP45116's frequency, phase, and

timer accumulator configuration registers, as well as setting

the state of various control inputs. In addition, the control

panel is used to specify files which serve as a data source

fortheHSP45116'sRIN0-15andIMIN0-15inputsanda data

sink for the RO0-15 and IO0-15 outputs. Operation of the

control panel software is dependent on the clock source

provided to the HSP45116-DB as specified in the clock

select portion of the control panel. The HSP45116-DB

Control Panel is invoked by typing:

NCOMCTRL <Enter>

Port Configuration

Communication between the Control Panel software and the

evaluation board set requires that the software kno ws which

of the PC'sparallelports isbeingusedf orcommunication with

the HSP-EV AL and which board address the HSP-EVAL has

been configured for . The default configuration assumes that

LPT1 is being used and the HSP-EV AL has been configured

for a board address of 0. The P ort Configuration can be

inspected by opening up the port configuration window using

the F9 function key. As shown in Figure 4, the window

displays the av ailable parallel ports and their addresses. Also

displayed are the current port and HSP-EVAL Board address

being used by the Control Panel software.

The NCOM_CHK system test assumes that the LPT1 printer

port is being used for communication with the HSP-EVAL. If

another printer port is used, the Command Line Interface,

NCOM_CMD, must be used to configure the software for

using the other port (see NCOM_CMD’s PC and P#

command).

4

Page 5

HSP45116-DB

HSP45116-DB CONTROL PANEL

CLOCK SELECT FILE I/O SELECT

MANUAL CLK

√

PORT CLK

OSC. CLK

EXTERNAL CLKA

CONTROL SIGNALS

0 ENPHREG

0 CLROFR

1

LOAD

1 BINFMT

1 PMSEL

CENTER FREQUENCY REGISTER 40000000

OFFSET FREQUENCY REGISTER 00000000

F1 - HELP F2 - START CLOCK F0 - PORT CONFIG F10 - QUIT

FIGURE 3. CONTROL PANEL SCREEN AS DISPLAYED ON PC

INPUT FILE: INPUT.DAT

√

OUTPUT FILE: OUTPUT.DAT

√

(RINO-15) 7FFF

(IMINO-15) 0000

HSP45116-DB CONTROL PANEL

HSP45116

NCOM

CLOCK NUMBER 0

PHASE OFFSET REGISTER 0000

TIME ACCUMULATOR REGISTER 00000000

0000 (RO0-15)

0000 (IO0-15)

CLOCK SELECT FILE I/O SELECT

MANUAL CLK

PORT CLK

√

OSC. CLK

EXTERNAL CLKA

CONTROL SIGNALS

0 ENPHREG#

0 CLROFR#

1 LOAD #

1 BINFMT#

1 PMSEL

CENTER FR

OFFSET FREQ

F1 - HELP ESC - RETURN F10 - QUIT

AVAILABLE PRINTER PORTS

CURRENT PORT SELECTION : LPT1

CURRENT HSP-EVAL ADDRESS : 0

FIGURE 4. PORT CONFIGURATION WINDOW AS DISPLAYED ON PC

INPUT FILE: 1MHZCMP

OUTPUT FILE: UPCNVRTI

LPT1

LPT2

LPT3

PORT CONFIGURATION

ADDRESS (HEX)

0x3BC

0x378

0x3BC

0-15)

0-15)

000

00000000

5

Page 6

HSP45116-DB

The current port and HSP-EVAL address are changed by

opening up the PortConfigurationWindow, using the up/down

arrow keys to select the desired parameter, and toggling the

space bar to change the selection. Proper operation of the

control panel software requires that the HSP-EVAL Board

address specified in the port configuration window matches

the address jumpered in the Address Selection Section of the

HSP-EV AL’s J4 jumper field (see HSP-EVAL User’s Manual).

Clock Select

The Clock Select portion of the control panel is used to tell

the Control Panel software which of four different clock

sources is being supplied to the HSP45116-DB. The choices

include one of two different software generated clocks

(Manual CLK or Port CLK), an oscillator clock provided by

the HSP-EVAL (OSC. CLK), or an externally supplied clock

(External CLK). The clock mode selected must be consistent

with the Clock Select jumper position in the HSP-EVAL’s J4

jumper field. If either Manual CLK or Port CLK are specified

in the Control Panel, the clock select jumper must be

inserted in the CTL0 position. If either OSC. CLK or External

CLK is specified, the jumper must be inserted at the

OSC_CLK or EXT_CLK position respectively.

In Manual CLK mode, single clock pulses are sent to the

HSP45116 by depressing the F2 function key. The clock

pulse is softwaregeneratedbysettingandclearingtheCTL0

bit of the CTL Control Register on the HSP-EVAL.Aftereach

clock, the HSP45116-DB's RO0-15 and IO0-15 outputs are

serialized and read into the PC for display in the Control

Panel. In this mode, file input and output is supported (see

File I/O Select Section).

In Port CLK mode, a free running clock is sent to the

HSP45116 by depressing the F2 function key. The clock

pulses are software generated by continually setting and

clearing the CTL0 bit of the CTL0-15 Register on the HSPEVAL. After each clock the HSP45116-DB's RO0-15 and

IO0-15 outputs are serialized and read into the PC for

display in the Control Panel. In this mode, file input and

output is supported (See File I/O Select Section).

In OSC. CLK mode, the HSP45116 is supplied with a clock

by the oscillator on-board the HSP-EVAL. In this mode, the

Control Panel can be used for modifying the various control

signal states, the configuration registers, and the complex

inputs to the NCOM. However, the software is unable to

provide file based I/O to the evaluation board set since the

data rate required by the oscillator clock is orders of

magnitude greater than that possible through the parallel

port of the PC. As a result, the Control Panel disables file

based I/O and the display of NCOM output in this mode.

In External CLK mode, the HSP45116 is supplied with a

clock through the 96-Pin DIN connector P1 on the HSPEVAL. In this mode, the Control Panel can be used for

modifying control signal states, the various configuration

registers, and the complex inputs to the NCOM. However,

the softwaredoesnotsupport file based I/O to the evaluation

board set since the data rate required may be much greater

than that capable through the parallel port of the PC. In this

mode, the Control Panel disables file based I/O and the

display of NCOM output.

The clocking mode used by the control panel is indicated by

the position of the “check mark” symbol within the Clock

Select portion of the Control Panel. A different clocking

mode may be selected by positioning the “check mark”

symbol in front of the desired clocking mode. The position of

the “check mark” is changed by using the cursor keys to

move the active window to the desired position and then

toggling the space bar to move the “check mark”.

File I/O Select

The File I/O Select portion of the Control Panel allows the

user to specify files which can be used as an input data

source or an output data sink for the HSP45116-DB. If file

based input is selected, Control Panel software down loads

data from the specified file to registers on the HSP-EVAL

and clocks the data into the RIN0-15 and IMIN0-15 inputs of

the HSP45116. If file based output is specified, the software

reads the data on the RO0-15 and IO0-15 outputs of the

HSP45116 via the HSP-EVAL’s output shift register and

stores the data in the specified file. The input data is loaded

on to the input busses prior to the software generated clock

and the output data is read from the output busses following

the software generated clock.

File based I/O is activated by using the space bar to toggle

the “check mark” symbol in the window proceeding the Input

and Output File identifier in the Control Panel's File I/O

Section. If either file input or output is activated, the

respective file name must be entered in the window to the

right of the I/O file identifier. File input or output may be

disabled at any time by toggling the respective “checkmark”.

Note: file I/O is only valid when either the ‘Manual CLK’

or ‘Port CLK’ clocking modes are selected and it is

disabled if other clocking modes are specified.

The input and output data files are ASCII based and have a

format as described in Appendix A. There is no limitation to

the input and output file size, and care must be taken if file

output is specified since data is collected in the file until file

output is deactivated or the NCOMCTRL Program is exited.

HSP45116 Complex Data Inputs

The data windows to the left of the HSP45116 icon are used

to specify hexadecimalvalues which drivethepart's complex

inputs, RIN0-15 and IMIN0-15. Data entered into these

windows is down loaded to registers on the HSP-EVAL

which drive the HSP45116-DB's complex input busses.

Note: Jumpers must be inserted into the OE_BUS1 and

OE_BUS2 positions of the HSP-EVAL's J4 jumper field

to enable the register outputs containing the complex

data.

6

Page 7

HSP45116-DB

The complex inputs may be changed by entering

hexadecimalvaluesintothedatawindows. The contents of a

particular data window may be edited by depressing the

<Enter> key and using the arrow keys to position the cursor

on the hexadecimal character to be modified.

If file input is selected, the complex inputs are driven with

data from the specified file. On each clock the data windows

are updated with the complex sample down loaded from the

file. In this mode the complex input data windows maynotbe

manually updated.

Control Signals

The Control Signal portion of the control panel is used to

define the state of various control signal inputs to the

HSP45116. The logical state of a control signal is set by

using the space bar to toggle the signal state in the window

preceding the specified control signal. For the control signal

states displayed in the Control Panel to be active at the

HSP45116, the respective control signals must be jumpered

to the HSPEVAL’s CTL0-15 Bus via the HSP45116-DB's J3

jumper field as shown in the default jumper configuration

displayed in Table 1 (see Jumper Configuration Section).

The Control Signal descriptions are contained in the

HSP45116 Data Sheet.

Configuration Registers

The bottom of the control panel displays four data windows

which contain the hexadecimal values loaded into the

HSP45116's Center Frequency, Offset Frequency, Phase

Offset, and Time Accumulator Registers. The contents of a

particular configuration register may be updated by entering

a new hexadecimal value into the data window. The current

value in a window may also be edited by depressing the

<Enter> key and using the arrow keys to position the cursor

on the hexadecimal character to be modified.

terminating an edit by the <Enter> key. If the data window is

associated with the Phase Offset Register, the 16-Bit

hexadecimal value is down loaded into the HSP45116's

Phase Input Register. If the data window is one of the three

32-bit windows associated with the Center Frequency, Offset

Frequency, of TimerAccumulatorRegisters ,the 32-bit value is

loaded into the HSP45116's MS and LS Input Registers and

either

ENCFREG, ENOFREG, or ENTIREG is asserted

respectively. Then, the enable signal is de-asserted and

registered on chip by another software generated clock. In

either Manual or Port Clock modes, a PC generated cloc k is

issued to ensure that the corresponding enable signal is

registered on chip (see HSP45116 Data Sheet). In either of

the other two clock modes, it is assumed that the clock rate is

high enough to register the enable signal before another

Configuration Register is updated. For proper operation, the

register enables,

WR, and A0-1 inputs must be jumpered to

the HSP-EV AL's control bus and inputs via the J3 Control

Header as shown in the Default Jumper Configuration

(Table 1).

Help

Help windows are provided as a source of information for

control panel usage. The help window is activated by the F1

function key, and contains information based on the current

active data window.

Command Line Interface

As an alternative to the control panel, a command line

interface is provided which allows the user to control the

HSP45116-DB by issuing commands from the DOS prompt.

The commands perform basic I/O and configuration

functions by up or down loading data to the HSP45116

through the HSP-EVAL. The Command Line program has

the following usage:

The value entered into the data window is down loaded to the

HSP45116 after leaving the window via the arrow keys or

TABLE 2. COMMAND LIST FOR COMMAND LINE INTERFACE SOFTWARE

COMMAND

CF 32-BIT

HEXADECIMAL VALUE

OF 32-BIT

HEXADECIMAL VALUE

TI 32-BIT

HEXADECIMAL VALUE

PO 16-BIT

HEXADECIMAL VALUE

CL 16-BIT

HEXADECIMAL VALUE

RI 16-BIT

HEXADECIMAL VALUE

II 16-BIT

HEXADECIMAL VALUE

ARGUMENT

#1

ARGUMENT

#2 COMMAND DESCRIPTION

Loads HSP45116’sCenter Frequency Registerwithhexadecimal value specified in

Argument #1. See Notes 1 and 2.

Loads HSP45116’s Offset Frequency Register with hexadecimal valuespecified in

Argument #1. See Notes 1 and 2.

Loads HSP45116’s TimeAccumulatorRegister with hexadecimalvalue specified in

Argument #1. See Notes 1 and 2.

Loads HSP45116’sPhase Input Register withhexadecimal value specified inArgument #1. See Note 2.

Loads the HSP-EVAL’s CTL Control Register with the 16-bit value specified in Argument #1.

Loads thespecifiedHex value intotheHSP-EVALRegister(InputRegister #2) driving the Real Input bus (RIN0-15) Of The HSP45116-DB. See Note 3.

Loads The Specified Hex Value Into The HSP-EVAL Register (Input Register #1)

driving the imaginary Input Bus (IMIN0-15) Of The HSP45116-DB. See Note 3.

7

NCOM_CMD [Command] [ARG 1] [ARG 2]

Page 8

HSP45116-DB

TABLE 2. COMMAND LIST FOR COMMAND LINE INTERFACE SOFTWARE (Continued)

ARGUMENT

COMMAND

PF INPUT FILE OUTPUT

CK Issues softwaregeneratedclock pulse to HSP45116-DBby toggling theCTL0bit in

RD Reads data on the HSP45116-DB’s RO0-15 and IO0-15 outputs and prints data to

SM Displays signal mapping between the CTL Control Register and the HSP45116

CR Displays current state of CTL Control Register.

PC Displays the printer port and HSP-EVAL board address that the NCOM_CMD pro-

P# PORT NUMBER

? List available commands together with a brief description.

NOTES:

1. The CF, OF, TI commands load the specified 32-bit valueintotheHSP45116’sMSandLSinputregisters. After the configuration data has been

loaded into the MSandLSRegisters,the corresponding enable, ENCFREG, ENOFREG, or ENTIREG isasserted.Theenable signal is then registered on chip by a single software generated clock provided a jumper is inserted at the CTL0 position of the J4 jumper field on the HSP-EVAL.

Otherwise, it isassumedthat the selected clock source isfastenough to register the enable signalpriorto a subsequent load of oneofanother 32bit configuration register.Theregister enables, ENCFREG, ENOFREG, andENTIREG must be jumpered to the CTLControlBus as in the default

configuration shown in Table 1.

2. When commands are issued to load registers internal to the HSP45116, it is assumed that the microprocessor interface signals, WR and A0-1

are jumpered to the CTL0-15 bus as in the default configuration shown in Table 1.

3. If the complexinputbusesof the HSP45116-DB are to be driven by the HSP-EVAL’sInputRegisters1 and 2, their outputs must be enabled by

placing jumpers in the OE_BUS1 and OE_BUS2 positions of the J4 jumper field on the HSP-EVAL.

4. Thiscommandis onlyvalidif asoftware generated clocksource has beenselected by insertinga jumper inthe CTL0 positionof theHSP-EVAL’s

J4 jumper field.

5. Commands requiredtoreaddata on the HSP45116-DB’s complex outputs only functionproperlyifthe output of the shift register isselectedfor

reading by inserting a jumper in the SR_RD position of the HSP-EVAL’s J4 jumper field.

#1

(1-3)

ARGUMENT

#2 COMMAND DESCRIPTION

FILE

BOARD

ADDRESS

(0-7)

Down loads complex samples stored in the file specified by Argument #1 into the

HSP-EVAL Registers driving the Real and Imaginary Input Buses of the

HSP45116-DB, clocks the data into the part, and stores the complex output to the

file specified by Argument#2.Theinputandoutputfile formats are specified in Appendix A. See Notes 3, 4 and 5.

the HSP-EVAL’s CTL0-15 Register. See Note 4.

screen. See Note 4 and 5.

control inputs (assumes default jumper configuration shown in Table 1).

gram is using for communication between the PC and the HSP-EVAL. The HSPEVALboard address is set by inserting a jumper in the ADDR0-7 positions of it’s J4

Jumper Field.

Change The Printer Port And HSP-EVAL Board Address that the NCOM_CMD Programisusing forcommunication betweenthePC andtheHSP-EVALto those specified

in Arguments 1 and 2. The HSP-EVAL Board Address is set by inserting a Jumper in

the ADDR0-7 positions of it’s J4 Jumper Field.

The Command specifies 1 of 14 actions to be taken, and the

Arguments (ARG1, ARG2) represent additional data

required by the command. For example, the HSP45116's

Center Frequency Register would be loaded with a value of

40000000(HEX) by typing:

NCOM_CMD CF 40000000 <Enter>

A summary of the command set is contained in Table 2.

Proper operation of the Command Line software is ensured

if the default jumper configurations for the HSP45116-DB

and the HSP-EVAL shown in Table 1 and Figure 2 are used.

However,modifications to this configuration may be required

depending on the clock source and the mode of operation.

The Command Line Interface gives the user the ability to

control the evaluation board set via DOS batch files or

system calls from a programming language. The

NCOM_CHK.BAT file discussed in the System Test Section

8

is an example of how the Command Line program might be

used in a DOS batch file.

Signal Headers

The HSP45116-DB maps the NCOM's inputs and outputs to

three 50-pin signal headers, J1-J3. The signal headers are

used to connect the NCOM’s I/O and control pins to the

HSP-EVAL’s I/O and control busses through three 50

position connectors. The Control Panel and Command Line

interfacesoftwarecontrolthe operation of the HSP45116-DB

by up or down loading data to registers on-board the HSPEVAL which drive or monitor the I/O and control busses.

The J1 Input Header maps two 16-bit busses to the real and

imaginary inputs of the HSP45116, RIN0-15 and IMIN0-15.

In addition, a bidirectional clock line is routed to this header

as shown by the signal map in Table3.Whenmated with the

J1 connector on the HSP-EVAL, the HSP45116's real and

imaginary inputs map to the HSP-EVAL's Input Bus 2 and 1,

IN2_0-15 and IN1_0-15, respectively.

Page 9

HSP45116-DB

TABLE 3. SIGNALASSIGNMENTSFOR 50 POSITION INPUT

CONNECTOR J1

PIN

NUMBER

1 N.C. GND

2 RIN0 RIN1

3 RIN2 RIN3

4 RIN4 RIN5

5 RIN6 RIN7

6 GND RIN8

7 RIN9 RIN10

8 RIN11 RIN12

9 RIN134 RIN14

10 RIN15 GND

11 N.C. IMIN0

12 IMIN1 IMIN2

13 IMIN3 IMIN4

14 IMIN5 IMIN6

15 IMIN7 GND

16 IMIN8 IMIN9

17 IMIN10 IMIN11

18 IMIN12 IMIN13

19 IMIN14 IMIN15

20 GND CLKIN

21 GND N.C.

22 GND V

23 GND V

24 GND V

25 GND V

J1A SIGNAL

MNEMONIC

J1B SIGNAL

MNEMONIC

CC

CC

CC

CC

TABLE 4. SIGNAL ASSIGNMENTS FOR 50 POSITION OUT-

PUT CONNECTOR J2

PIN

NUMBER

1 OER GND

2 RO0 RO1

3 RO2 RO3

4 RO4 RO5

5 RO6 RO7

6 GND RO8

7 RO9 RO10

8 RO11 RO12

9 RO13 RO14

10 RO15 GND

11 OEI IO0

12 IO1 IO2

13 IO3 IO4

14 IO5 IO6

15 IO7 GND

16 IO8 IO9

17 IO10 IO11

18 IO12 IO13

19 IO14 IO15

20 GND CLKOUT

21 GND TICO

22 GND PACO

23 GND N.C.

24 GND N.C.

25 GND N.C.

J2A SIGNAL

MNEMONIC

J2B SIGNAL

MNEMONIC

The J2 Output Header maps two 16-bit busses to the real

and imaginary outputs of the HSP45116, RO0-15 and IO0-

15. In addition, two HSP45116 status outputs,

PACO and

TICO, two HSP45116 output enables, OER and OE, and a

bidirectional clock line are routed to this header as shown by

the signal map in Table 4. When mated with the J2

connector on the HSP-EVAL, the HSP45116's real and

imaginary outputs map to the HSP-EVAL'sOutputBus2and

1, OUT2_0-15 and OUT1_0-15, respectively.

The J3 Control Header maps one 16-bit bus to the

HSP45116's control input, C0-15, and provides jumper

positions for the Configuration Jumper Fields that flank the

header. When mated with the HSP-EVAL's J3 Control

Connector the HSP45116's Control Inputs, C0-15, are

mapped to the HSP-EVAL's Input Bus 3, IN3_0-15, and the

jumper positions are mapped the HSP-EVAL's Control Bus,

CTL0-15. The signal map fortheJ3ControlHeaderisshown

in Table 1.

9

Configuration Jumper Field

The Configuration Jumper Fields A and B flank either side of

the Control Header J3 as shown in Table 1. Positions within

the Jumper Field's SA and SB signal rows map to various

HSP45116 control inputs. The control inputs may be

jumpered to ground or the HSP-EVAL'sCTL4-15 bus via the

J3 Control Header. If a control signal mapped to SA and SB

is not jumpered to GND or CTL4-15, the signal is pulled

high.

The Configuration Jumper Field A is also used to select

whether the HSP45116's clock source is provided through

the J1 Input Header or the J2 Output Header. If jumpers are

inserted as shown in Figure 5, a clock signal supplied

through the CLK_IN pin of the J1 Input Header drives a

buffer whose output clocks the HSP45116. The jumper

inserted between JA1 and JA2 feeds the buffered clock

signal to the CLK_OUT pin of the J2 Output Header. If

jumpers are inserted as shown in Figure 6, the CLK_OUT

pin of the J2 Output Connector drives the clock buffer which

Page 10

HSP45116-DB

in turn drives the clock input of the HSP45116. The jumper

inserted between JA2 and SA2 allows the Input Header’s

CLK_IN pin to be driven by the buffer output.

NOTE: The

jumper placement shown in Figure 5 is the standard

configuration.

FIGURE 5. JUMPER CONFIGURATION IF CLOCK IS SUP-

FIGURE 6. JUMPER CONFIGURATION IF CLOCK IS SUP-

.

JASAJ3A

1

PLIED THROUGH J1 INPUT HEADER

JASAJ3A

1

PLIED THROUGH J2 OUTPUT HEADER

The HSP45116-DB is shipped from the factory with the

default jumper configuration shown by the overlay of heavy

lines onto the signal map in Table 1. For the Control Panel

and Command Line Interface software to properly control

operation of the HSP45116, it is assumed that the

HSP45116 control inputs are jumpered as specified in the

default configuration. Also, the system test software,

NCOM_CHK, must be run using the default configuration.

Appendix A

Data File Structures

The Input/Output data files used by the HSP45116-DB

Control PanelandCommand Line Interfacesoftwarecontain

complex data samples. The data files consist of a seven line

header followed by the data itself. The header section must

follow this format:

Line 1: Comment #1

Line 2: Comment #2

Line 3: Comment #3

Line 4: Comment #4

Line 5: Comment #6

Line 7: c 1 n

(Real Component) (Imaginary Component)

•

•

•

The ‘n’ on the 7th line of the header should be replaced by

the number of complex samples in the file. Following the

header,the complex samples are listed one per row with the

real part listed first followed by the complex part. The real

and imaginary components of the complex data sample are

represented as 16-bit two’s complement values. As a result,

the real and imaginary parts of the data sample are integer

values bounded by 32767 and -32768. The CMPRFILE

installed in the NCOM_CHK subdirectory is an example of

the input data file structure.

10

Page 11

HSP45116-DB

VCC

C5

0.01µF

C1

0.01µF

C2

0.01µF

C3

0.01µF

OER

OEI

12345678910111213141516171819202122232425

J2B

RO1

RO3

RO5

RO7

RO8

RO10

RO12

RO0

RO2

RO4

RO6

RO9

RO11

123456789

J2A

C4

0.01µF

IO4

IO3

IO6

IO5

IO7

IO9

IO8

IO11

IO10

IO13

IO12

IO15

IO14

RO14

IO0

IO2

RO13

RO15

IO1

101112131415161718192021222324

CKOUT

25

RIN[0..15]

IMIN[0..15]

ENCFREG

ENOFREG

VCC

GND

VCC

C[0..15]

NCOMCK

123456789

SB

12345678910111213141516171819202122232425

JB

12345678910111213141516171819202122232425

J3B

C10

C1C3C5C7C8

C0C2C4

123456789

J3A

C12

C6

C9

C11

ENPHREG

101112131415161718192021222324

CTL0

CTL2

CTL4

CTL6

CTL9

C14

C13

C15

CTL5

CTL7

CTL8

CTL3

CTL1

101112131415161718192021222324

AD0

BINFMT

CTL11

CTL13

CTL10

CTL12

WR

CTL15

CTL14

ACC

MOD0

MOD1

Z9

7 2 3 4 5 6 8 9 0

1

25

25

VCC

U1D

1

11

74AC86

12345678910111213141516171819202122232425

J1B

VCC

RIN1

RIN3

RIN5

RIN0

RIN2

RIN4

123456789

J1A

TICO

PACO

RIN7

RIN6

RIN8

RIN10

RIN12

RIN14

IMIN0

RIN9

RIN11

RIN13

RIN15

101112131415161718192021222324

IMIN4

IMIN2

IMIN1

IMIN3

IMIN6

IMIN5

IMIN7

IMIN9

IMIN11

IMIN10

IMIN8

IMIN13

IMIN12

CKIN

IMIN15

IMIN14

12345678910111213141516171819202122232425

JA

CKOUT

12345678910111213141516171819202122232425

SA

CKIN

3

6

74AC86

U1A

25

IO[0..15]

RO[0..15]

U1B

1

2

4

5

74AC86

9

U1C

8

10

74AC86

ENTIREG

ENI

CLROFR

LOAD

AD1

MUX0

PMSEL

PACI

MUX1

PEAK

RBYTILD

MODPI/2PI

13

12

VCC

1

Z8

2

3 4 5 6 7 8 9 0

1

2 3 4 5 6 7 8 9 0

1

Z7

1

VCC

11

Page 12

RO[0..15]

HSP45116-DB

PACO

IO[0..15]

TICO

VCC

GND

RO0

RO1

RO2

RO3

RO4

RO5

RO6

RO7

RO8

RO9

RO10

RO11

RO12

RO13

RO14

RO15

K13

L15

J13

H14

G15

F15

G14

F14

F13

E15

E14

RO0 M15

RO1

RO2 K14

RO3

RO4 J14

RO5

RO6 K15

RO7

RO8 H13

RO9 G13

RO10

RO11

RO12

RO13

RO14

RO15

RIN0

RIN1

RIN2

RIN3

RIN4

RIN5

RIN6

RIN7

RIN8

RIN9

RIN10

RIN11

RIN12

RIN13

RIN14

RIN15

RIN16

K2J2K1J1J3H3H2F1G3G2E1F2F3D1E2C1E3D2C2D3B2C3C4A2B3C5B4A3A4B5A5C6B6B7A6A7C7

RIN0

RIN1

RIN2

RIN3

RIN4

RIN5

RIN6

RIN7

RIN8

RIN9

RIN10

RIN11

RIN12

RIN13

RIN14

RIN15

RO16

D15

C15

RO17

RO18

RIN17

RIN18

D14

RO19

U2

IMIN0

IMIN0

IO0

IO1

IO2

IO3

IO0 E13

IO1 C14

IO2 B15

IO3 D13

HSP45116

IMIN1

IMIN2

IMIN3

IMIN4

IMIN1

IMIN2

IMIN3

IMIN4

IO4

IO5

B14

IO4 C13

IO5

IMIN5

IMIN6

IMIN5

IMIN6

IO6

IO7

B13

IO6 C12

IO7

IMIN7

IMIN8

IMIN7

IMIN8

IO8

IO9

C11

IO8 B12

IO9

IMIN9

IMIN10

IMIN9

IMIN10

IO10

IO11

A13

B11

IO10

IO11

IMIN11

IMIN12

IMIN11

IMIN12

IO12

IO13

A12

C10

IO12

IO13

IMIN13

IMIN14

IMIN14

IMIN13

IO14

IO15

B10

A11

IO14

IO15

IMIN15

IMIN16

IMIN15

IMIN17

A10

B8

IO16B9IO17C9IO18

IO19

PACO L13

TICO P1

IMIN18

C0Q14

C1

C3P12

C4Q13

C8

P13C2N11

C0C1C2C3C4C5C6C7C8C9C10

C5Q12

DET0 N15

C6P11

L14

DET1

C7Q11

C8N10

C9P10

N14

M

1

M13

P14

M

2

N

2

L

2

K

3

L

1

P

2

L

3

P

3

N

4

P

4

N

6

Q

4

P

5

Q

3

N

5

1

MN

1

P

6

GND

4

VCC

OEIEX

T

OEI

OEREX

T

OER

PEA

K

BINFM

T

ACC

SH1

SH0

PAC

I

RBYTILD

PMSEL

LOA

D

CLROF

MODPI/2PI

C10P9

C11Q10

C12Q9

C13N9

C14N8

C15P8

ADR0N7ADR1P7CLKQ5WR

C11

C12

C13

C14

C15

ENI

ENTIREG

ENPHA

ENCFREG

ENOFREG

ENPHREG

C

OUTMUX0

MOD0N3MOD1

N13

Q6

M3

R

C

S

OUTMUX1

N12

Z2

2 1

3

4

5

6

7

8

9

10

RIN8

RIN9

RIN10

RIN11

RIN12

RIN13

RIN14

RIN15

Z1

2 1

3

4

5

6

7

8

9

10

RIN0

RIN1

RIN2

RIN3

RIN4

RIN5

RIN6

RIN7

Z4

2 1 3

IMIN8

IMIN9

Z3

2 1 3

IMIN0

IMIN1

RIN[0..15]

4

5

IMIN10

IMIN11

4

5

IMIN2

IMIN3

6

7

IMIN12

IMIN13

6

7

IMIN4

IMIN5

8

9

10

IMIN14

IMIN15

8

9

10

IMIN6

IMIN7

Z6

2 1

3

CIN8

CIN9

Z5

2 1

3

CIN0

CIN1

IMIN[0..15]

4

5

CIN10

CIN11

4

5

CIN2

CIN3

6

7

CIN12

CIN13

6

7

CIN4

CIN5

8

9

CIN14

CIN15

8

9

CIN6

CIN7

10

10

AD0

C[0..15]

AD1

NCOMCK

WR

MOD0

MOD1

MUX1

MUX0

ENCFREG

ENPHREG

ENOFREG

ENI

ENTIREG

MODPI/2PI

CLROFR

LOAD

PMSEL

RBYTILD

PEAK

BINFMT

OER

OEI

ACC

PACI

12

Page 13

HSP45116-DB

HSP-EVAL Limited Warranty

Intersil warrants the HSP-EVAL to be free of defects in

material and workmanship under normal use for a period of

ninety (90) days. Intersil also warrants that the HSP-EVAL

User's Manual is substantially complete and contains all the

information which Intersil considers necessary to use the

HSP-EVAL, and that the HSP-EVAL functions substantially

as described in the HSP-EVAL User's Manual. Intersil will

replace the HSP-EVAL as Intersil's sole duty under this

warranty only if you ship it, postage prepaid, to Intersil within

ninety (90) days of such acquisition and provide proof of

date of acquisition.

This limited warranty does not extend to any products which

have been damaged as a result of accident, misuse, abuse,

or as a result of service or modification by anyone other than

Intersil or Intersil's authorized representatives.

Intersil makes no other express or implied warranty with

respect to the HSP-EVAL other than the limited warranty set

forth above. Intersil disclaims all implied warranties of

merchantability and/or fitness foraparticularpurpose.Inany

event,allimpliedwarranties shall be limited tothedurationof

this warranty. The liability of Intersil, if any, shall under

any tort, contract or other legal theory be limited to the

actual price paid for such product and shall in no event

include incidental, consequential, special or indirect

damages of any kind, even if Intersil is aware of the

possibility of such damages.

HSP45116-DB Software License

Agreement

In return for the purchase price of the HSP45116-DB

product, the Purchaser receives from Intersil Corporation

(“Intersil”) a non-exclusive nontransferable (except as set for

below) license under Intersil copyrights to use the software

subject to the following terms and conditions:

[1] The Software is protected by both United States

Copyright Law and International Treaty provisions.

Therefore, you must treat the Software like any other

copyrighted material (e.g. a book) and may not copy,

distribute or make derivatives of any part thereof except

that you may either a) make one copy of the Software

solely for archival purposes, or b) transfer the Software

to a single hard disk provided you keep the original

solely for backup or archival purposes.

[2] The Software may be transferred to a third party on a

permanent basis provided you retain no copies and the

recipient agrees,inwriting to Intersil, to the terms of this

Agreement.

[3] If the software package contains both 3.5" and 5.25"

disks, then you may use only the disks appropriate for

your single-user computer. You may not use the other

disks on another computer or loan, rent, lease, or

transfer them to another user except as part of the

permanent transfer (as provided above) of all Software.

Intersil reserves the right to revise and make changes to this

manual and the HSP-EVAL from time to time without

obligation to notify any person of, or to provide any person

with, such revisions or changes.

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold bydescriptiononly. Intersil Corporation reserves the right to make changes incircuitdesign and/or specifications at any time without notice. Accordingly , the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

13

Loading...

Loading...