Page 1

HM62G18512 Series

8M Synchronous Fast Static RAM

(512k-word × 18-bit)

ADE-203-1185 (Z)

Preliminary

Rev. 0.0

Jun. 12, 2000

Description

The HM62G18512 is a synchronous fast static RAM organized as 512-kword × 18-bit. It has realized high

speed access time by employing the most advanced CMOS process and high speed circuit designing

technology. It is most appropriate for the application which requires high speed, high density memory and

wide bit width configuration, such as cache and buffer memory in system. It is packaged in standard 119bump BGA.

Note: All power supply and ground pins must be connected for proper operation of the device.

Features

• Power supply: 3.3 V +10%, –5%

• Clock frequency: 200 MHz to 250 MHz

• Internal self-timed late write

• Byte write control (2 byte write selects, one for each 9-bit)

• Optional ×36 configuration

• HSTL compatible I/O

• Programmable impedance output drivers

• User selective input trip-point

• Differential, HSTL clock inputs

• Asynchronous G output control

• Asynchronous sleep mode

• Limited set of boundary scan JTAG IEEE 1149.1 compatible

• Protocol: Single clock register-register mode

Preliminary: The specifications of this device are subject to change without notice. Please contact your

nearest Hitachi’s Sales Dept. regarding specifications.

Page 2

HM62G18512 Series

Ordering Information

Type No. Access time Cycle time Package

HM62G18512BP-4

HM62G18512BP-5

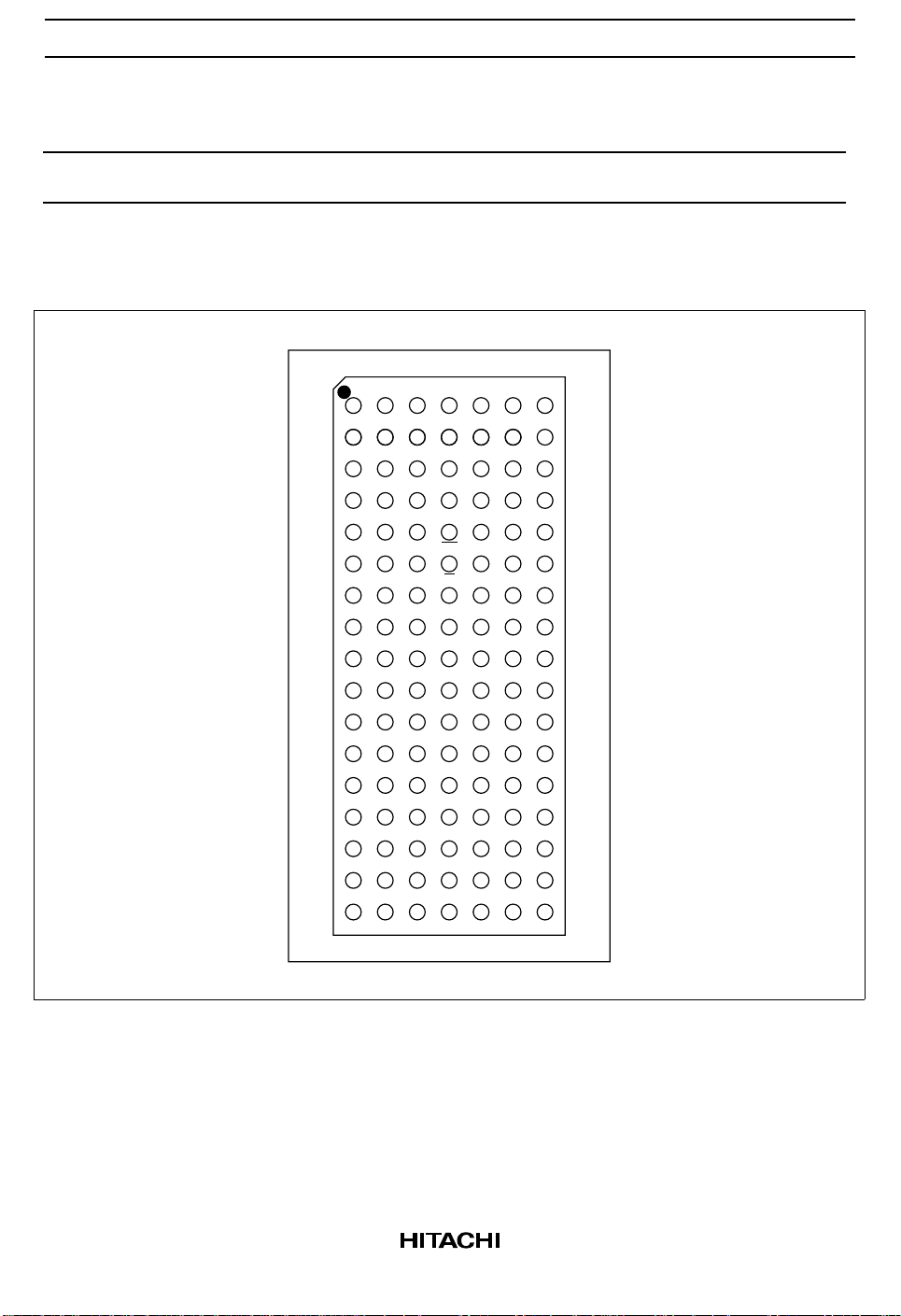

Pin Arrangement

2.1 ns

2.5 ns

4.0 ns

5.0 ns

119-bumps BGA

1234567

A

VDDQ SA0 SA6 NC SA4 SA2 VDDQ

B

NC NC SA7 NC SA8 SA18 NC

C

NC SA13 SA3 VDD SA5 SA1 NC

D

DQb0 NC VSS ZQ VSS DQa4 NC

E

NC DQb1 VSS SS VSS NC DQa5

F

VDDQ NC VSS G VSS DQa6 VDDQ

G

NC DQb2 SWEb NC NC DQa7

H

DQb3 NC VSS NC VSS DQa8 NC

J

VDDQ VDD VREF VDD VREF VDD VDDQ

K

NC DQb8 VSS K VSS NC DQa3

L

DQb7 NC K SWEa DQa2 NC

M

VDDQ DQb6 VSS SWE VSS NC VDDQ

N

DQb5 NC VSS SA16 VSS DQa1 NC

P

NC DQb4 VSS SA14 VSS NC DQa0

R

NC SA9 M1 VDD M2 SA10 NC

T

NC SA17 SA11 NC SA12 SA15 ZZ

U

VDDQ TMS TDI TCK TDO NC VDDQ

VSS

VSS

119-bump 1. 27 mm

14 mm × 22 mm BGA (BP-119A)

(Top view)

2

Page 3

HM62G18512 Series

Pin Description

Name I/O type Descriptions Notes

V

DD

V

SS

V

DDQ

V

REF

K Input Clock input. Active high.

K Input Clock input. Active low.

SS Input Synchronous chip select

SWE Input Synchronous write enable

SAn Input Synchronous address input n = 0, 1, 2...18

SWEx Input Synchronous byte write enables x = a, b

G Input Asynchronous output enable

ZZ Input Power down mode select

ZQ Input Output impedance control 1

DQxn I/O Synchronous data input/output x = a, b

M1, M2 Input Output protocol mode select

TMS Input Boundary scan test mode select

TCK Input Boundary scan test clock

TDI Input Boundary scan test data input

TDO Output Boundary scan test data output

NC — No connection

Supply Core power supply

Supply Ground

Supply Output power supply

Supply Input reference: provides input reference voltage

n = 0, 1, 2...8

M1 M2 Protocol Notes

V

SS

V

DD

Synchronous register to register operation 2

Notes: 1. ZQ is to be connected to VSS via a resistance RQ where 150 Ω ≤ RQ ≤ 300 Ω, if ZQ = V

open, output buffer impedance will be maximum. A case of minimum impedance, it needs to

connect over 120 Ω between ZQ and V

2. There is 1 protocol with mode pin. Mode control pins (M1, M2) are to be tied either V

.

SS

DD

respectively. The state of the Mode control inputs must be set before power-up and must not

change during device operation. Mode control inputs are not standard inputs and may not meet

V

or VIL specification. This SRAM is tested only in the synchronous register to register

IH

operation.

DDQ

or V

or

SS

3

Page 4

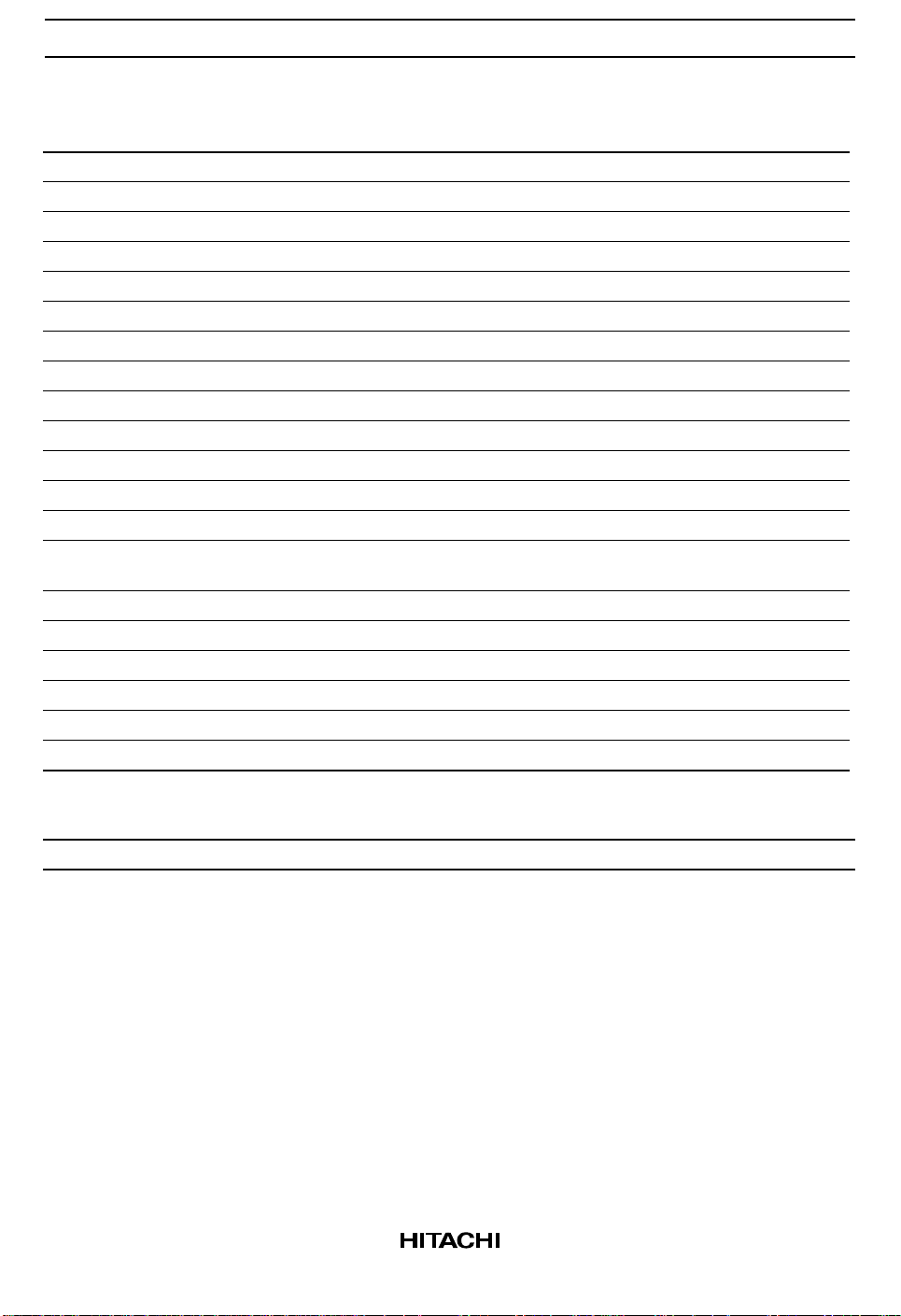

HM62G18512 Series

Block Diagram

A0 to A18

SS

SWE

SWEx

ZZ

V

REF

ZQ

19

JTAG

register

JTAG

register

JTAG

register

2

JTAG

register

G

K

K

JTAG

register

JTAG

register

JTAG

register

JTAG

register

JTAG

register

R-Add

register

SS

register

SWE

register

SWEx

register

CLK

control

19

W-Add

register

2

Impedance

contorol logic

19

MUX

1

WRC

Match

DOC

D-in

register

Memory

cell array

(512k × 18)

Row decoder

Column decoder

WA

Multiplex

D-out

register

OB

18

SA

DQa0-8

DQb0-8

TDI

TCK

TMS

JTAG tap

controller

TDO

4

Page 5

HM62G18512 Series

Operation Table

ZZ SS G SWE SWEa SWEb K K Operation DQ (n) DQ (n + 1)

H ЧЧЧЧЧЧЧsleep mode High-Z High-Z

LH××××L-H H-L Dead

(not selected)

L × H ЧЧЧЧЧDead

(Dummy read)

LLLH××L-H H-L Read × Dout

LL× L L L L-H H-L Write a, b byte High-Z Din (a,b)0-8

LL× L L H L-H H-L Write a byte High-Z Din (a)0-8

LL× L H L L-H H-L Write b byte High-Z Din (b)0-8

Notes: 1. × means don’t care for synchronous inputs, and H or L for asynchronous inputs.

2. SWE, SS, SWEa to SWEb , SA are sampled at the rising edge of K clock.

3. Although differential clock operation is implied, this SRAM will operate properly with one clock

phase (either K or K) tied to V

specified within this document will be met.

. Under such single-ended clock operation, all parameters

REF

× High-Z

High-Z High-Z

(a,b)0-8

5

Page 6

HM62G18512 Series

Absolute Maximum Ratings

Parameter Symbol Value Unit Notes

Input voltage on any pin V

Core supply voltage V

Output supply voltage V

Operating temperature T

Storage temperature T

IN

DD

DDQ

OPR

STG

–0.5 to V

–0.5 to 3.9 V 1

–0.5 to 2.2 V 1, 4

0 to 70 °C

–55 to 125 °C

Junction temperature Tj 110 °C

Output short–circuit current I

Latch up current I

OUT

LI

25 mA

200 mA

Package junction to case thermal resistance θJC 2 °C/W 5, 7

Package junction to ball thermal resistance θJB 5 °C/W 6, 7

Notes: 1. All voltage is referred to VSS.

2. Permanent device damage may occur if Absolute Maximum Ratings are exceeded. Functional

operation should be restricted the Operation Conditions. Exposure to higher than recommended

voltages for extended periods of time could affect device reliability.

3. These CMOS memory circuits have been designed to meet the DC and AC specifications shown

in the tables after thermal equilibrium has been established.

4. The supply voltage application sequence need to be powered up in the following manner: V

V

, V

, V

DD

DDQ

then VIN. Remember, according to the Absolute Maximum Ratings table, V

REF

not to exceed 3.9 V, whatever the instantaneous value of V

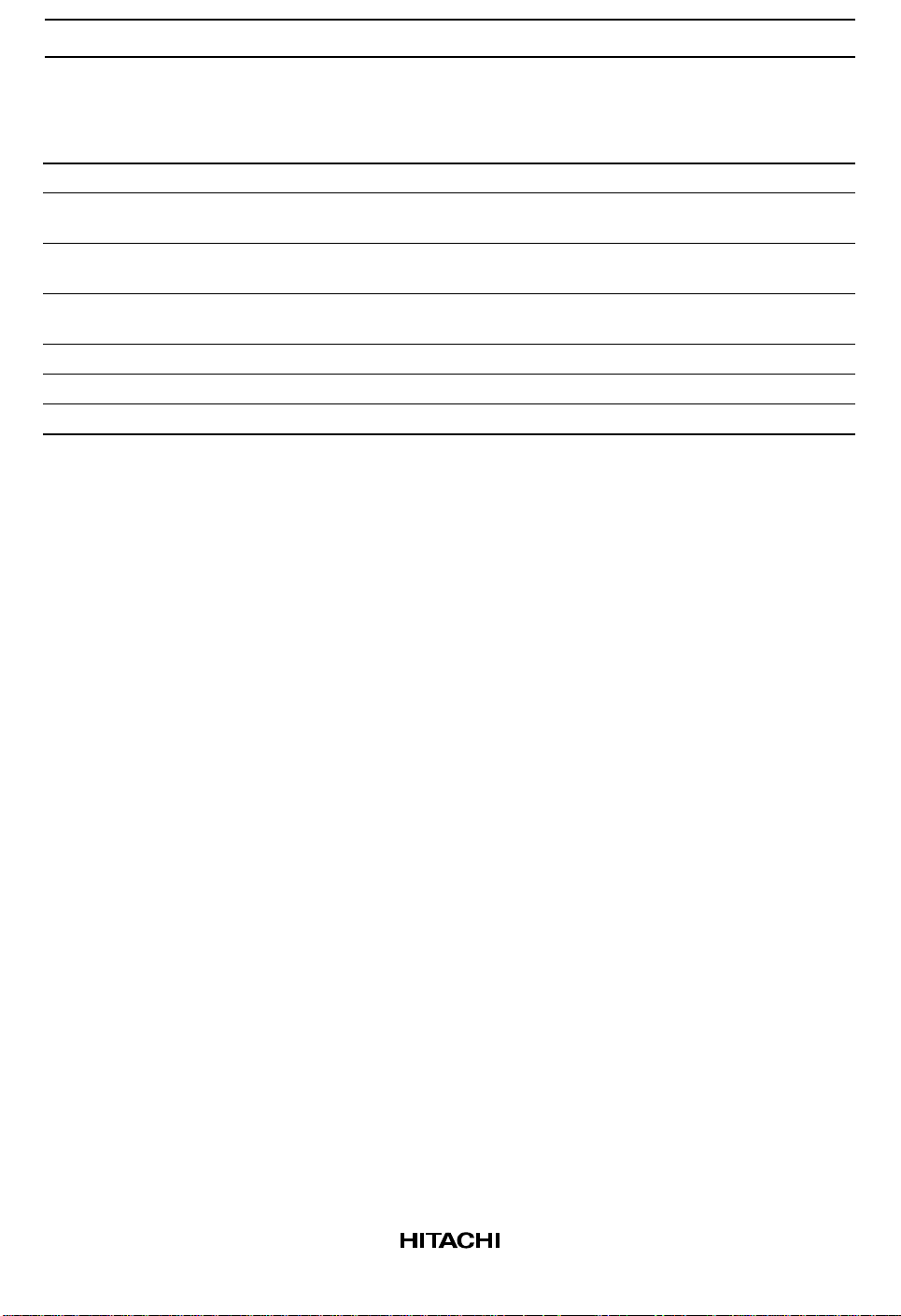

5. θJC is measured at the center of mold surface in fluorocarbon (See Figure “Definition of

Measurement”).

6. θJB is measured on the center ball pad after removing the ball in fluorocarbon (See Figure

“Definition of Measurement”).

7. These thermal resistance values have error of ± 5°C/W.

+ 0.5 V 1, 4

DDQ

.

DDQ

DDQ

,

SS

is

θJC

θJB

T.C.

Fluorocarbon

T.C.

Fluorocarbon

Definition of Measurement

6

Page 7

HM62G18512 Series

Note: The following the DC and AC specifications shown in the Tables, this device is tested under the

minimum transverse air flow exceeding 500 linear feet per minute.

DC Operating Conditions (Ta = 0 to 70°C [Tj max = 110°C])

Parameter Symbol Min Typ Max Unit Notes

Supply voltage (Core) V

Supply voltage (I/O) V

Supply voltage V

Input reference voltage (I/O) V

Input high voltage V

Input low voltage V

Clock differential voltage V

Clock common mode voltage V

DD

DDQ

SS

REF

IH

IL

DIF

CM

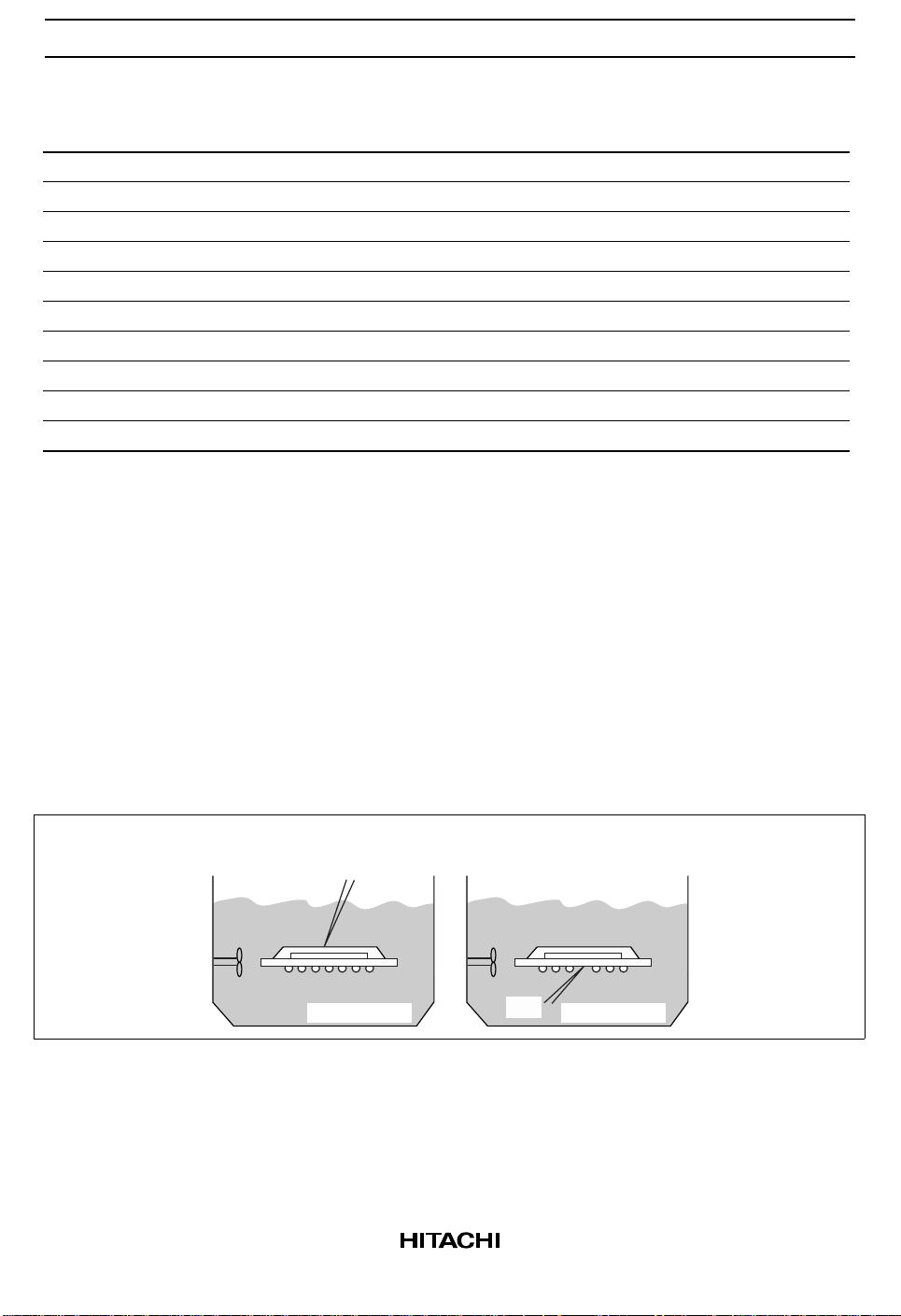

Notes: 1. Peak to peak AC component superimposed on V

2. Minimum differential input voltage required for differential input clock operation.

3. See following figure.

4. V

= 0.75 V (typ).

REF

3.135 3.30 3.63 V

1.4 1.5 1.6 V

000 V

0.65 0.75 0.90 V 1

V

+ 0.1 — V

REF

–0.5 — V

0.1 — V

+ 0.3 V 4

DDQ

– 0.1 V 4

REF

+ 0.3 V 2, 3

DDQ

0.55 — 0.90 V 3

may not exceed 5% of V

REF

REF

.

V

DDQ

V

SS

V

DIF

V

CM

Differential Voltage/Common Mode Voltage

7

Page 8

HM62G18512 Series

DC Characteristics (Ta = 0 to 70°C, [Tj max = 110°C], VDD = 3.3 V +10%, –5%)

Parameter Symbol Min Typ Max Unit Notes

Input leakage current I

Output leakage current I

Standby current I

VDD operating current,

excluding output drivers

4 ns cycle

VDD operating current,

excluding output drivers

5 ns cycle

Quiescent active power

supply current

Output low voltage V

Output high voltage V

ZQ pin connect

resistance

Output low current I

Output high current I

Notes: 1. 0 ≤ Vin ≤ V

2. 0 ≤ Vout ≤ V

DDQ

DDQ

3. All inputs (except clock) are held at either V

guaranteed at 75°C junction temperature.

4. Iout = 0 mA, read 50%/write 50%, V

5

. Iout = 0 mA, read 50%/write 50%, V

6. Minimum impedance push pull output buffer mode, I

7. Measured at V

8. Measured at V

9. Output buffer impedance can be programmed by terminating the ZQ pin to V

precision resister (RQ). The value of RQ is five times the output impedance desired. The

allowable range of RQ to guarantee impedance matching with a tolerance of 15% is between

150 Ω and 300 Ω. If the status of ZQ pin is open, output impedance is maximum. Maximum

impedance occurs with ZQ connected to V

occurs when the SRAM is in High-Z. Write and Deselect operations will synchronously switch

the SRAM into and out of High-Z, therefore triggering an update. The user may choose to

invoke asynchronous G updates by providing a G setup and hold about the K clock to guarantee

the proper update. At power-up, the output impedance defaults to minimum impedance. It will

take 2048 cycles for the impedance to be completely updated if the programmed impedance is

much higher than minimum impedance.

LI

LO

SBZZ

I

DD4

I

DD5

I

DD2

OL

OH

RQ 150 250 300 Ω

OL

OH

for all input pins (except V

, DQ in High-Z.

OL

OH

——2 µA1

——5 µA2

— — 100 mA 3

— — 700 mA 4

— — 600 mA 4

— — 200 mA 5

= 1/2 V

= 1/2 V

V

SS

V

– 0.4 — V

DDQ

(V

/2)/[(RQ/5)–15%] — (V

DDQ

(V

/2)/[(RQ/5–4)+15%] — (V

DDQ

REF

= VDD max, VIN = VIH or VIL, Frequency = minimum cycle.

DD

= VDD max, VIN = VIH or VIL, Frequency = 3 MHz.

DD

.

DDQ

.

DDQ

—VSS + 0.4 V 6

DDQ

/2)/[(RQ/5)+15%] mA 7, 9

DDQ

/2)/[(RQ/5–4)–15%] mA 8, 9

DDQ

, ZQ, M1, M2 pin).

or VIL, ZZ is held at VIH, Iout = 0 mA, Spec is

IH

= –6 mA, IOL = 6 mA.

OH

SS

. The impedance update of the output driver

DDQ

V6

through a

8

Page 9

HM62G18512 Series

Capacitance (Ta = 25°C, f = 1 MHz)

Parameter Symbol Min Max Unit Note

Input capacitance (SAn, SS, SWE, SWEx)C

Input capacitance (K, K, G)C

Input/Output capacitance (DQxn) C

Note: 1. This parameter is sampled and not 100% tested.

IN

CLK

IO

AC Characteristics (Ta = 0 to 70°C, [Tj max = 110°C], VDD = 3.3 V +10%, –5%)

Test Conditions

— 4 pF 1

— 7 pF 1

— 5 pF 1

• Input pulse levels (K, K): V

= 0.75 V, VCM = 0.75 V

DIF

• Input timing reference level (K, K): Differential cross point

• Input pulse levels (except K, K): VIL = 0.25 V, VIH = 1.25 V

• Input and output timing reference levels (except K, K): V

= 0.75 V

REF

• Input rise and fall time: 0.5 ns (10% to 90%)

• Measurement condition: the minimum impedance push pull output buffer mode, IOH = –6 mA, IOL = 6

mA

• Output driver supply voltage: V

DDQ

= 1.5 V

• Output load: See figure

50 Ω

0.75 V

50 Ω

0.75 V

DQ

16.7 Ω

16.7 Ω

16.7 Ω 50 Ω

50 Ω

5 pF

5 pF

0.75 V

9

Page 10

HM62G18512 Series

Single Differential Clock Register-Register Mode (M1 = VSS, M2 = VDD)

HM62G18512

-4 -5

Parameter Symbol Min Max Min Max Unit Notes

CK clock cycle time t

CK clock high width t

CK clock low width t

Address setup time t

Data setup time t

Address hold time t

Data hold time t

Clock high to output valid t

Clock high to output hold t

Clock high to output valid

(SS control)

Clock high to output High-Z t

Output enable low to output Low-Z t

Output enable low to output valid t

Output enable low to output High-Z t

Sleep mode recovery time t

Sleep mode enable time t

Notes: 1. Guaranteed by design.

2. Refer to the Test Conditions.

3. Transitions are measured at start point of output high impedance from output low impedance.

4. Output driver impedance updates during High-Z.

5. Transitions are measured ±50 mV from steady state voltage.

6. When ZZ is switching, clock input K must be at same logic levels for reliable operation.

KHKH

KHKL

KLKH

AVKH

DVKH

KHAX

KHDX

KHQV

KHQX

t

KHQX2

KHQZ

GLQX

GLQV

GHQZ

ZZR

ZZE

4.0 — 5.0 — ns

1.5 — 1.5 — ns

1.5 — 1.5 — ns

0.5 — 0.5 — ns

0.5 — 0.5 — ns

0.75 — 1.0 — ns 1

0.75 — 1.0 — ns 1

— 2.1 — 2.5 ns 2

0.5 — 0.5 — ns 2

— 2.1 — 2.5 ns 2, 5

— 2.5 — 3.0 ns 2, 3

0.5 — 0.5 — ns 2, 5

— 2.5 — 2.5 ns 2, 3

— 2.5 — 2.5 ns 2, 3

10.0 — 10.0 — ns 6

— 10.0 — 10.0 ns 2, 3, 6

10

Page 11

Timing Waveforms

Read Cycle-1

HM62G18512 Series

K

K

SA

A1 A2 A3 A4

SS

SWE

SWEx

DQ

Note: G, ZZ = V

t

KHKH

t

AVKH

t

AVKH

t

AVKH

t

KHKLtKLKH

t

KHAX

t

KHAX

t

KHAX

t

KHQX

Do 1Do 0 Do 2

t

KHQV

IL

11

Page 12

HM62G18512 Series

Read Cycle-2 (SS Controlled)

K

K

SA

A1 A3 A4

SS

SWE

SWEx

DQ

Note: G, ZZ = V

t

AVKH

t

KHAX

t

AVKH

t

KLKH

t

KHQZ

t

KHAX

t

KHAX

t

KHKH

t

AVKH

t

KHKL

Do 0 Do 1 Do 3

t

KHQX2

IL

12

Page 13

Read Cycle-3 (G Controlled)

HM62G18512 Series

t

KHKH

t

KHKL

t

KLKH

K

K

SA

t

AVKH

A1 A2 A3 A4

t

AVKH

t

KHAX

t

KHAX

SS

t

AVKH

t

KHAX

SWE

SWEx

G

t

GHQZ t

GLQV

DQ Do 1Do 0 Do 3

t

Note: ZZ = V

IL

GLQX

13

Page 14

HM62G18512 Series

Write Cycle

K

K

SA

SS

SWE

SWEx

G

DQ

Note: ZZ = V

t

KHAX

t

KLKH

t

KHKH

t

AVKH

t

KHKL

A1 A2 A3 A4

t

AVKH

t

AVKH

t

AVKH

t

DVKH

t

KHAX

t

KHAX

t

KHAX

t

KHDX

Di 0 Di 1 Di 2 Di 3

IL

14

Page 15

Read-Write Cycle

HM62G18512 Series

SA

SS

SWE

SWEx

G

DQ

Note: ZZ = V

ZZ Control

READ WRITEREAD

(G control)

t

KHKH

t

KHKL

t

KLKH

READ DEAD

(SS control)

WRITE

K

K

t

AVKH

t

KHAX

A7A6A4A3A1

t

AVKH

t

KHAX

t

AVKH

t

AVKH

t

GHQZ

t

KHAX

t

KHAX

t

DVKHtKHDX

t

GLQV

Do 0 Do 1 Do 4Di 3 Di 6

t

KHQX

t

KHQV

t

GLQX

t

KHQZ

IL

K

K

SA

SS

SWE

SWEx

ZZ

Sleep active

DQ

Note: G = V

t

KHKH

t

AVKH

t

AVKH

IL

t

ZZR

A1

t

KHKL

t

KHAX

t

KHAX

t

KLKH

Sleep off

Do 1

Sleep active

t

ZZE

15

Page 16

HM62G18512 Series

Boundary Scan Test Access Port Operations

In order to perform the interconnect testing of the modules that include this SRAM, the serial boundary

scan test access port (TAP) is designed to operate in a manner consistent with IEEE Standard 1149.1 -

1990. But does not implement all of the functions required for 1149.1 compliance The HM62Gxx series

contains a TAP controller. Instruction register, Boundary scans register, Bypass register and ID register.

Test Access Port Pins

Symbol I/O Name

TCK Test clock

TMS Test mode select

TDI Test data in

TDO Test data out

Note: This Device does not have a TRST (TAP Reset) pin. TRST is optional in IEEE 1149.1.

To disable the TAP, TCK must be connected to V

To test Boundary scan, ZZ pin need to be kept below V

TAP DC Operating Conditions (Ta = 0 to 70°C, [Tj max = 110°C])

. TDO should be left unconnected.

SS

– 0.4 V.

REF

Parameter Symbol Min Max Unit Notes

Boundary scan input high voltage V

Boundary scan input low voltage V

Boundary scan input leakage current I

Boundary scan output low voltage V

Boundary scan output high voltage V

IH

IL

LI

OL

OH

2.0 VDD + 0.3 V

–0.5 0.8 V

–2 2 µA1

— 0.4 V 2

2.4 — V 3

Notes: 1. 0 ≤ Vin ≤ VDD for all logic input pin.

2. I

= 8 mA.

OL

3. I

= –8 mA.

OH

16

Page 17

HM62G18512 Series

TAP AC Characteristics (Ta = 0 to 70°C, [Tj max = 110°C])

Parameter Symbol Min Max Unit Note

Test clock cycle time t

Test clock high pulse width t

Test clock low pulse width t

Test mode select setup t

Test mode select hold t

Capture setup t

Capture hold t

TDI valid to TCK high t

TCK high to TDI don’t care t

TCK low to TDO unknown t

TCK low to TDO valid t

THTH

THTL

TLTH

MVTH

THMX

CS

CH

DVTH

THDX

TLQX

TLQV

Note: 1. tCS + tCH defines the minimum pause in RAM I/O pad transitions to assure pad data capture.

TAP Test Conditions

67 — ns

30 — ns

30 — ns

10 — ns

10 — ns

10 — ns 1

10 — ns 1

10 — ns

10 — ns

0—ns

—20ns

• Input pulse levels: 0 to 3.0 V

• Input and output timing reference levels: 1.5 V

• Input rise and fall time: 2 ns (10% to 90%) (typ)

• Output Load: See figure

DUT

Z

0

TDO

VT = 1.5 V

50 Ω

= 50 Ω

17

Page 18

HM62G18512 Series

TAP Controller Timing Diagram

t

THTHtTHTLtTLTH

TCK

t

MVTH

t

THMX

TMS

t

DVTH

t

THDX

TDI

t

TLQV

t

TLQX

TDO

RAM

t

CS

t

CH

Address

Test Access Port Registers

Register name Length Symbol Note

Instruction register 3 bits IR [0;2]

Bypass register 1 bit BP

ID register 32 bits ID [0;31]

Boundary scan register 51 bits BS [1;51]

18

Page 19

HM62G18512 Series

TAP Controller Instruction Set

IR2 IR1 IR0 Instruction Operation

0 0 0 SAMPLE-Z Tristate all data drivers and capture the pad value

0 0 1 IDCODE

0 1 0 SAMPLE-Z Tristate all data drivers and capture the pad value

0 1 1 BYPASS

1 0 0 SAMPLE

1 0 1 BYPASS

1 1 0 BYPASS

1 1 1 BYPASS

Note: This Device does not perform EXTEST, INTEST or the preload portion of the PRELOAD command

in IEEE 1149.1.

19

Page 20

HM62G18512 Series

Boundary Scan Order

Bit No. Bump ID Signal name Bit No. Bump ID Signal name

15RM2272BNC

2 6T SA15 28 3A SA6

3 4P SA14 29 3C SA3

4 6R SA10 30 2C SA13

5 5T SA12 31 2A SA0

6 7T ZZ 32 1D DQb0

7 7P DQa0 33 2E DQb1

8 6N DQa1 34 2G DQb2

9 6L DQa2 35 1H DQb3

10 7K DQa3 36 3G SWEb

11 5L SWEa 37 4D ZQ

12 4L K 38 4E SS

13 4K K 39 4G NC

14 4F G 40 4H NC

15 6H DQa8 41 4M SWE

16 7G DQa7 42 2K DQb8

17 6F DQa6 43 1L DQb7

18 7E DQa5 44 2M DQb6

19 6D DQa4 45 1N DQb5

20 6A SA2 46 2P DQb4

21 6C SA1 47 3T SA11

22 5C SA5 48 2R SA9

23 5A SA4 49 4N SA16

24 6B SA18 50 2T SA17

25 5B SA8 51 3R M1

26 3B SA7

Notes: 1. Bit number1 is the first scan bit to exit the chip.

2. The NC pads listed in this table are indeed no connects, but are represented in the boundary

scan register by a “Place Holder”. Placeholder registers are internally connected to V

3. In Boundary scan mode, differential input K and K are referred to each other and must be at

opposite logic levels for reliable operation.

4. ZZ must remain at V

5. In boundary scan mode, ZQ must be driven to V

6. M1 and M2 must be driven to V

during boundary scan.

IL

or VSS supply rail to ensure consistent results.

DD

or VSS supply rail to ensure consistent results.

DDQ

.

SS

20

Page 21

ID register

Bit No.

31×30×29×28×2702602512412312202102001911811701601501401301201101009080706050403121110

Value

HM62G18512 Series

1

Vendor

Revision No.

Depth Width Use in the future Vendor ID No. Fix

TAP Controller State Diagram

1

0

Test-Logic-

Reset

0

Run-Test/

Idle

Select-

DR-Scan

Capture-DR

Shift-DR

Exit1-DR

Pause-DR

Exit2-DR

11

0

0

0

1

1

00

00

1

1

IR-Scan

11

Capture-IR

Shift-IR

Exit1-IR

Pause-IR

00

Exit2-IR

Select-

1

0

0

0

1

1

1

1

Update-DR

1

Note: The value adjacent to each state transition in this figure represents the signal present

at TMS at the time of a rising edge at TCK.

No matter what the original state of the controller, it will enter Test-Logic-Reset when

TMS is held high for at least five rising edges of TCK.

00

Update-IR

1

21

Page 22

HM62G18512 Series

Package Dimensions

HM62G18512BP Series (BP-119A)

Unit: mm

0.204 ×

4 × C1.2

Pin 1 Index

22.00

B

0.60 ± 0.10

φ

119 × 0.75 ± 0.15

φ

0.30

φ

0.15 C

M

CAB

M

14.00

13.0 ± 0.10

A

2.10 ± 0.25

C

0.35 C

0.15 C

21.0 ± 0.10

1.27

1.27

Y

1234567

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

22

Details of the part Y

Hitachi Code

JEDEC

EIAJ

(reference value)

Mass

BP-119A

Conforms

—

1.2 g

Page 23

HM62G18512 Series

Cautions

1. Hitachi neither warrants nor grants licenses of any rights of Hitachi’s or any third party’s patent,

copyright, trademark, or other intellectual property rights for information contained in this document.

Hitachi bears no responsibility for problems that may arise with third party’s rights, including

intellectual property rights, in connection with use of the information contained in this document.

2. Products and product specifications may be subject to change without notice. Confirm that you have

received the latest product standards or specifications before final design, purchase or use.

3. Hitachi makes every attempt to ensure that its products are of high quality and reliability. However,

contact Hitachi’s sales office before using the product in an application that demands especially high

quality and reliability or where its failure or malfunction may directly threaten human life or cause risk

of bodily injury, such as aerospace, aeronautics, nuclear power, combustion control, transportation,

traffic, safety equipment or medical equipment for life support.

4. Design your application so that the product is used within the ranges guaranteed by Hitachi particularly

for maximum rating, operating supply voltage range, heat radiation characteristics, installation

conditions and other characteristics. Hitachi bears no responsibility for failure or damage when used

beyond the guaranteed ranges. Even within the guaranteed ranges, consider normally foreseeable

failure rates or failure modes in semiconductor devices and employ systemic measures such as failsafes, so that the equipment incorporating Hitachi product does not cause bodily injury, fire or other

consequential damage due to operation of the Hitachi product.

5. This product is not designed to be radiation resistant.

6. No one is permitted to reproduce or duplicate, in any form, the whole or part of this document without

written approval from Hitachi.

7. Contact Hitachi’s sales office for any questions regarding this document or Hitachi semiconductor

products.

Hitachi, Ltd.

Semiconductor & Integrated Circuits.

Nippon Bldg., 2-6-2, Ohte-machi, Chiyoda-ku, Tokyo 100-0004, Japan

Tel: Tokyo (03) 3270-2111 Fax: (03) 3270-5109

URL NorthAmerica : http://semiconductor.hitachi.com/

Europe : http://www.hitachi-eu.com/hel/ecg

Asia : http://www.hitachi.com.sg/grp3/sicd

Japan : http://www.hitachi.co.jp/Sicd/indx.htm

For further information write to:

Hitachi Semiconductor

(America) Inc.

179 East Tasman Drive,

San Jose,CA 95134

Tel: <1> (408) 433-1990

Fax: <1>(408) 433-0223

Hitachi Europe GmbH

Electronic Components Group

Dornacher Straße 3

D-85622 Feldkirchen, Munich

Germany

Tel: <49> (89) 9 9180-0

Fax: <49> (89) 9 29 30 00

Hitachi Europe Ltd.

Electronic Components Group.

Whitebrook Park

Lower Cookham Road

Maidenhead

Berkshire SL6 8YA, United Kingdom

Tel: <44> (1628) 585000

Fax: <44> (1628) 585160

Hitachi Asia Ltd.

16 Collyer Quay #20-00

Hitachi Tower

Singapore 049318

Tel: 535-2100

Fax: 535-1533

Hitachi Asia Ltd.

Taipei Branch Office

3rd Flr, Hung Kuo Building, No.167,

Tun Hwa North Road, Taipei (105)

Taiwan

Tel: <886> (2) 2718-3666

Fax: <886> (2) 2718-8180

Telex: 23222 HAS-TP

Copyright © Hitachi, Ltd., 2000. All rights reserved. Printed in Japan.

Hitachi Asia (Hong Kong) Ltd.

Group III (Electronic Components)

7th Flr, North Tower, World Finance Centre,

Harbour City, Canton Road, Tsim Sha Tsui,

Kowloon, Hong Kong

Tel: <852> (2) 735 9218

Fax: <852> (2) 730 0281

Telex: 40815 HITEC HX

Colophon 1.0

23

Loading...

Loading...