Page 1

HIP9022

PRELIMINARY

Data Sheet October 1998 File Number 4509.1

Dual High Speed Laser Driver

The HIP9022 Dual High Speed Laser Driver is designed to

operate with a constant current drain from the power supply.

This current defines the laser operating power . The current is

accurately controlled in the range of 0.5A to 2A to deliver

constant optical power from the laser when used with an

external Pow erFETandPower Sense resistor. The operating

circuit allows flexibility in choosing driver current le vels.

Eight S/H circuits are multiplex bus controlled to provide

analog data for the dual laser drivers. The bus is updated

during the blanking period of the laser printer scan with a

data rate up to 2.5MHz. A “thermo-electric-cooler” control

circuit provides temperature control of the laser. Two on-chip

ESD diodes protect each laser.

A principle advantageof the Dual High Speed Laser Driver is

accomplished by managing the high currents externally with

discrete PowerFETs and thereby not forcing large switching

currents to exist on the same IC substrate with the precision

control circuitry.

Ordering Information

TEMP.

PART NUMBER

HIP9022AM

RANGE (oC) PACKAGE PKG. NO.

0 to 100

68 Ld PLCC N68.95

Features

• Dual High Speed Laser Driver with Data Rates up to

2.5MHz

• 0.5A to 2A Range of Constant Current Source Controlled

to 0.1% Full Scale

• Low Signal Transients with Controlled Constant Current

Switching

• Laser Optical Power Controlled to Better than 0.5%

• Thermoelectric Cooler (TEC) Circuit to Control

Temperature to within 0.25

o

C

• Multiplexed Sample/Hold (S/H) Bus Interface

• Serial Diagnostic Bus with Multiplexed Output

• High Current ESD Diodes for Laser Diode Protection

Applications

• Dual Laser Printer Driver

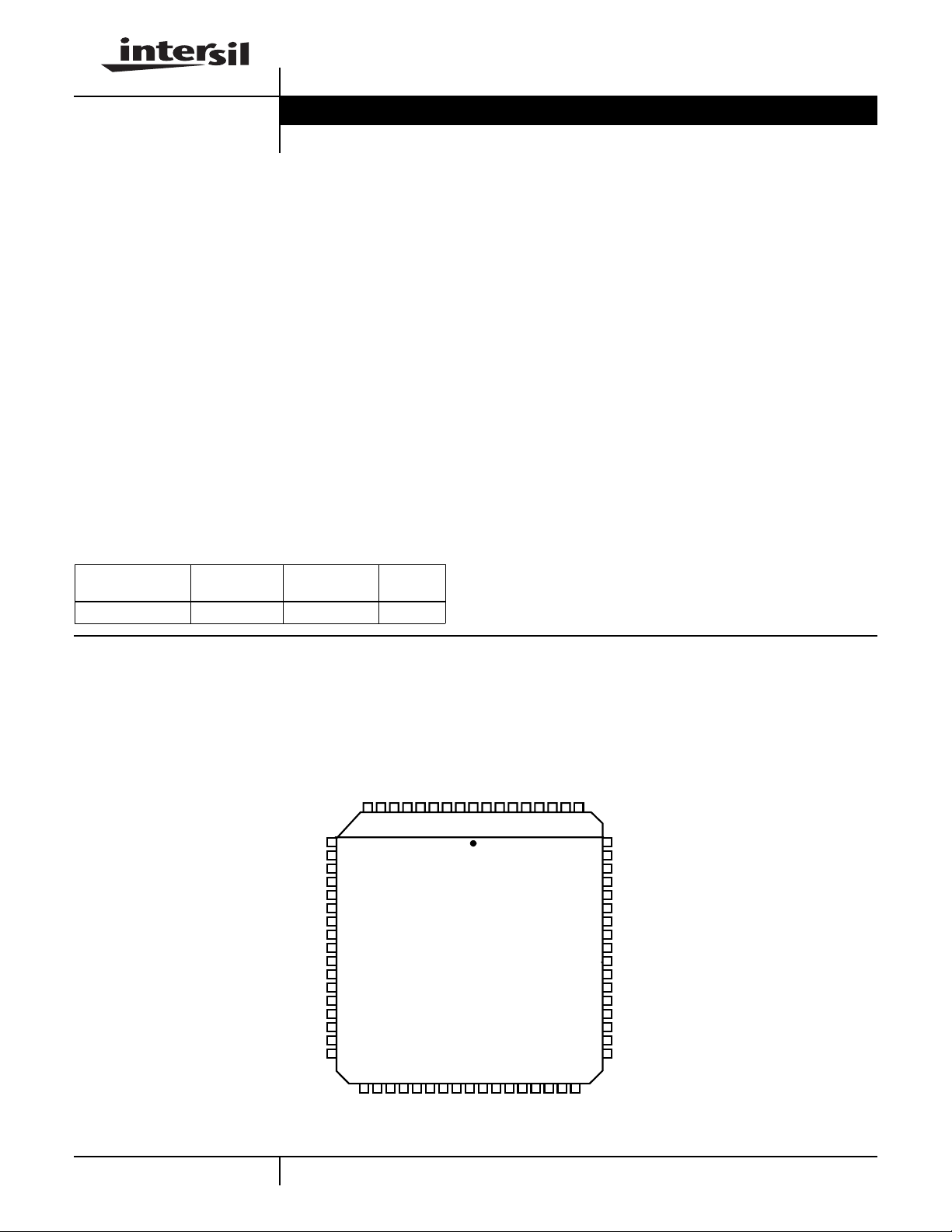

Pinout

VUP1

SG_1

VLOW1

V

GNDA1

GNDD1

CC1

XTEN1+

XTEN1CTC1-10K

CTC1-27K

LASERON1B

OC1

TECFB1

TECREF1

TECGDR1

TRES1

HIP9022 (PLCC)

TOP VIEW

ESD LASER GND

ESD LASER GND

ESD SHUNT DRAIN-1

ESD SHUNT DRAIN-1

ESD SHUNT DRAIN-1

ESD LASER PS-1

ESD LASER PS-1

VDDNC

10

11

12

13

EE

14

15

16

17

18

19

20

21

22

23

24

25

26

27 28 29 30 31 32 33

NC

OT1

INVERT

RESETB

DIAGINB

NULLB

ESD SHUNT DRAIN-2

123456789

68 67 66 65 64 63 62 61

34

IN

A3

CC

NC

V

V

SB_H

ESD SHUNT DRAIN-2

ESD SHUNT DRAIN-2

ESD LASER PS-2

ESD LASER PS-2

RLY_IN

RLY_OUT

V9P

434241403938373635

A0

A1

A2

DIAG

NC

TECREFR

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

VUP2

SG_2

VLOW2

GNDA2

GNDD2

CC2

XTEN2+

XTEN2CTC2-10K

CTC2-27K

LASERON2B

OC2

TECFB2

TECREF2

TECGDR2

TRES2

OT2

4-1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

Page 2

X

HIP9022

+12V

1µF

NC

VUP1

SG_1

VLOW1

-5V

1µF

V

EE

GNDA1

GNDD1

CC1

XTEN1+

XTEN1-

CTC2-10K

CTC1-27K

LASER_ON1B

OC1

TECFB1

TECREF1

TECGDR1

TRES1

OT1

NC

INVERT

ESD

LASERPS-1

7

8

V

V

DD

DD

9

10

11

12

13

14

15

16

17

18

19

20

21

PU

22

23

24

25

26

27

28

29 30 31 32 33

RESETB

DIAGINB

SHUNT

DRAIN-1

56

9V REG.

V/I REF.

LASER DRIVER-1

PUPU PUPDPD

NULLB

ESD

4

V9P

SB_H

3

LD1

34

NC

ESD

LASER

GNDGND

12

SAMPLE/HOLD

SYSTEM

35 37 38 39 40

V

IN

ESD

SHUNT

DRAIN-2

68

LD2

36

V

A3 A2 A1 A0

CC

+5V

LASERPS-2

6667

ESDD2ESDD1

LASER

GATE

DRIVE

A5

12kΩ

30kΩ

PU PU PU PU

ESD

65

64

A4

+

-

OTA GATE

DRIVE AMP.

+

-

A2

CURRENT

MONITOR

1kΩ

AMP.

A1

ON/OFF

O. C.

COMP.

TEC DRIVER

(THERMO

ELECTRIC

COOLER

CIRCUIT)

AND

OVER/UNDER

TEMPERATURE

COMPARATOR

LASER DRIVER-2

V

TEST

OUT

DIAG

A3

+

-

11kΩ

11kΩ

V

CC

+

-

X10

THERM.

COMP

+

-

+

-

41 42

A6

PU

1.9V

NC

63

RLY_IN

PD

62

RLY_OUT

V9P

61

60

VUP2

59

SG_2

58

VLOW2

57

GNDA2

56

GNDD2

55

CC2

54

XTEN2+

53

XTEN2-

52

CTC2-10K

51

CTC2-27K

50

LASER_ON2B

49

OC2

48

TECFB2

47

TECREF2

46

TECGDR2

45

TRES2

44

OT2

NOTE:

PU = 60kΩ PULLUP RESISTOR

PD = 60kΩ PULLDOWN RESISTOR

= SCHMITT TRIGGER HYSTERESIS

43

TECREFR

(TEMP. REF.

RESISTOR)

5 - 10kΩ

V

CC

+9V

1µF

1µF

1µF

0.1µF

0.1µF

(THERMO-RESISTOR

SENSES LASER TEMP.,

NEG. TEMP. COEF.,

TEC COOLS LASER.)

TO V

CC

TO GND

LASER P.S.

3 TO 5V

Q3

RF3V49092

Q2

0.02µF

RFD3055

OR

EQUIV.

RELAY1

LASER

I

DL

R

S

0.25Ω

TEC P.S.

3V

Q1

TEC

X

THERMAL RELATED COMPONENTS

FIGURE 1. HIGH SPEED LASER DRIVER FUNCTIONAL BLOCK DIAGRAM SHOWN IN QUIESCENT P.S. CURRENT TEST MODE

4-2

Page 3

HIP9022

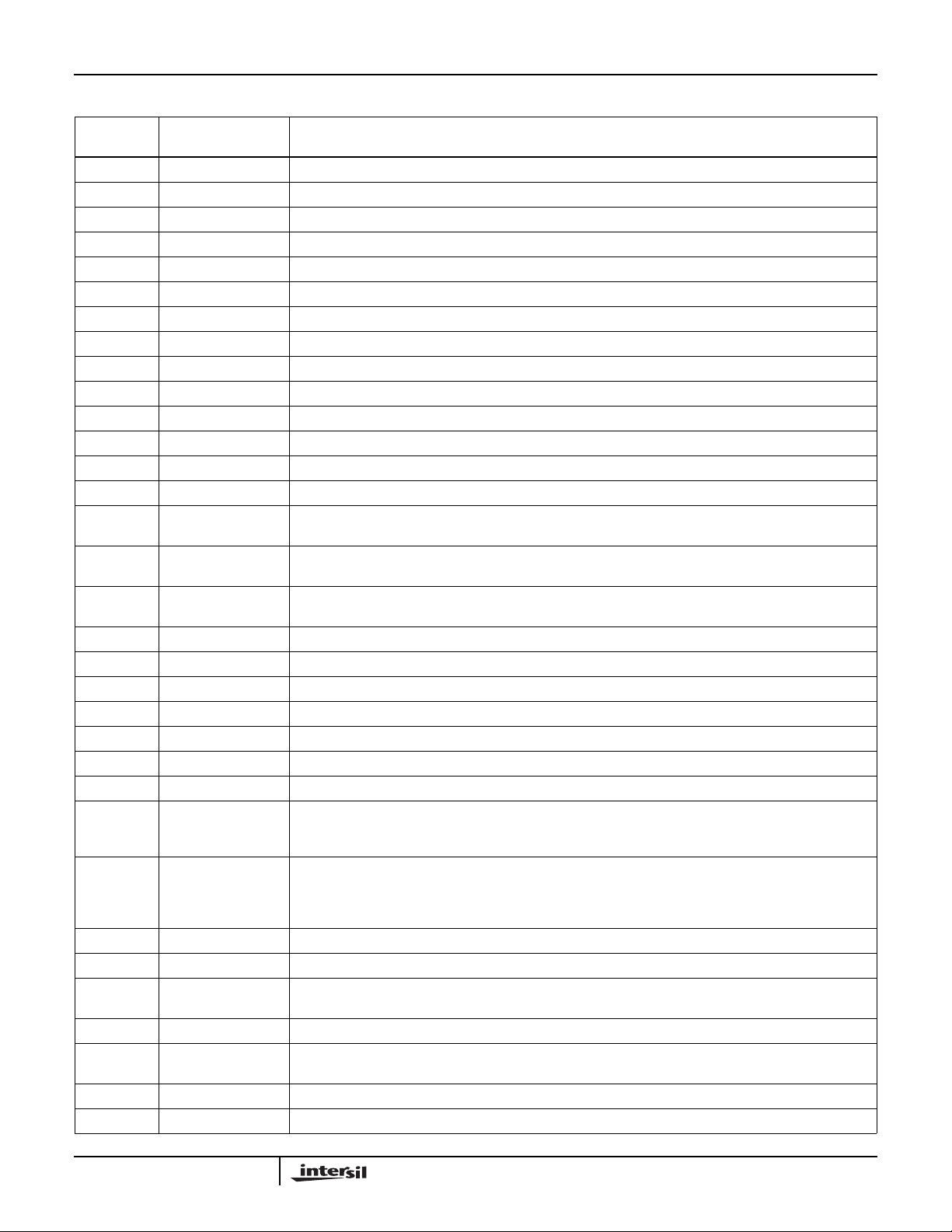

Pin Descriptions

PIN

NUMBER SYMBOL DESCRIPTION

1, 2 ESD LASER GND Laser supply and system ground.

3, 4, 5 ESD SHUNT DRAIN-1 Laser diode ESD protection.

6, 7 SD LASER PS-1 Laser power supply ESD protection.

8VDDInput for 12V power supply.

9 NC No connection.

10 VUP1 Filter capacitor for internally generated shunt gate upper voltage level (1µF).

11 SG_1 Drive output to shunt Power FET gate.

12 VLOW1 Filter capacitor for internally generated shunt Power FET gate lower drive voltage level (1µF).

13 V

14 GNDA1 Analog Ground.

15 GNDD1 Digital Ground.

16 CC1 Gate drive to the current source Power FET.

17 XTEN1+ Times 10 constant current monitor amplifier input from the high side of the sense resistor.

18 XTEN1- Times 10 constant current monitor amplifier input from the low side of the sense resistor.

19 CTC1-10K Thermal compensation short time constant where TTC= External C x 10kΩ. (External C typically equal

20 CTC1-27K Thermal compensation long time constant where TTC= External C x 27kΩ. (External C typically equal

21 LASERON1B Input control turns shunt Power FET gate drive ON/OFF with 5V CMOS logic. Low turns the shunt Power

22 OC1 Laser over-current indicator flag.

23 TECFB1 Feedback to stabilize the TEC loop.

24 TECREF1 Feedback to stabilize the TEC loop.

25 TECGDR1 Thermo-Electric Cooler Power FET gate drive.

26 TRES1 Thermo-Resistor output to ground connection for TEC control.

27 OT1 Laser out of temperature range indication.

28 NC No connection.

29 INVERT High input converts to operation with Pmos Current source and NDmos shunt Power FET external

30 RESETB WhenRESETB is held low,three reset actions occur. The LASERONB input is defeated to a Laser Off con-

31 DIAGINB Low level activates the diagnostic mode. This pin has an internal pull-up.

32 NULLB Auto-zeros the S/H amplifier selected by address when held low. This pin has an internal pull-up.

33 SB_H Samplesthe selected address when held low.The setup time for address is <25ns. This pin has an internal

34 NC No connection.

35 V

36 V

37 A3 Refer to the Table 1 Address Map. The A3 - A0 pins have an internal pull-up.

EE

IN

CC

Input for -5V power supply.

0.02µF).

0.1µF).

FET OFF and the Laser ON. These pins have an internal pull-up.

transistors. Low input converts to operation with NDmos Current source and Pmos high side shunt Power

FET external transistors. This pin has an internal pull-down.

dition. The SG_1, 2 outputs are switched to VLOW when in the INVERT low mode and to VUP when in the

INVERT high mode. The TEC amplifier is turned off to switch the TECGDR1, 2 outputs to Ground. This pin

has an internal pull-down.

pull-up.

Analog voltage sampled by selected S/H. The input voltage range is 0 to 5V. There is an internal voltage

clamp for voltage outside of this range. There is an internal 2 - 3µs filter for noise rejection.

Input for 5V power supply.

4-3

Page 4

HIP9022

Pin Descriptions

PIN

NUMBER SYMBOL DESCRIPTION

38 A2 Refer to the Table 1 Address Map. The A3 - A0 pins have an internal pull-up.

39 A1 Refer to the Table 1 Address Map. The A3 - A0 pins have an internal pull-up.

40 A0 Refer to the Table 1 Address Map. The A3 - A0 pins have an internal pull-up.

41 DIAG Diagnostic output, A 0V - 5V analog signal output limits internally to a range of -0.3V to 5.3V. The output is

42 NC No connection.

43 TECREFER External resistor to ground with a resistor value equal to the valueof the thermo-resistor at the desired laser

44 OT2 Laser out of temperature range indication.

45 TRES2 Thermo-Resistor output to ground connection for TEC control.

46 TECGDR2 Thermo-Electric Cooler Power FET gate drive.

47 TECREF2 Feedback to stabilize the TEC loop.

48 TECFB2 Feedback to stabilize the TEC loop.

49 OC2 Laser over-current indicator flag.

50 LASERON2B Input control turns shunt Power FET gate drive ON/OFF with 5V CMOS logic. Low turns the shunt Power

51 CTC2-27K Thermal compensation long time constant where TTC= External C x 27kΩ. (External C typically equal

52 CTC2-10K Thermal compensation short time constant where TTC= External C x 10kΩ. (External C typically equal

53 XTEN2- Times 10 constant current monitor amplifier input from the low side of the sense resistor.

54 XTEN2+ Times 10 constant current monitor amplifier input from the high side of the sense resistor.

55 CC2 Gate drive to the current source Power FET.

56 GNDD2 Digital Ground.

57 GNDA2 Analog Ground.

58 VLOW2 Filter capacitor for internally generated shunt Power FET gate lower drive voltage level (1µF).

59 SG_2 Drive output to shunt Power FET gate.

60 VUP2 Filter capacitor for internally generated shunt gate upper voltage level (1µF).

61 V9P Filter capacitor bypass for internally generated 9V power source (1µF).

62 RLY_OUT Relay output drive from an N-channel FET controls an external relay to switch the Laser power supply or

63 RLY_IN Relay input control with 5V CMOS logic. A high switches on the relay. This pin has an internal pulldown.

64, 65 ESD LASER PS-2 Laser power supply ESD protection.

66, 67, 68 ESD SHUNT DRAIN-2 Laser diode ESD protection.

(Continued)

the channel addressed by A0 - A3.

temperature. (Typically in the 5kΩ to 10kΩ range)

FET OFF and the Laser ON. These pins have an internal pull-up.

0.1µF).

0.02µF).

power supply interlock ON/OFF for both Laser Drivers.

4-4

Page 5

HIP9022

Absolute Maximum Ratings Thermal Information

Maximum Analog Supply Voltage, VDD . . . . . . . . . . . -0.3V to 14V

Logic Supply Voltage, VCC. . . . . . . . . . . . . . . . . . . . . . -0.3V to 6V

Analog Negative Supply Voltage, VEE . . . . . . . . . . . . . 0.3V to -5.5

Maximum Laser Protection Diode Current . . . . . . . . . . 10A, 200ns

Operating Conditions

VDD Supply Voltage Range, VDD . . . . . . . . . . . . . . 11.4V to 12.6V

VCC Supply Voltage Range, VCC . . . . . . . . . . . . . . . . 4.5V to 5.5V

VEE Supply Voltage Range, VEE. . . . . . . . . . . . . . . . -4.5V to -5.5V

Laser Power Supply Range, V

TEC Power Supply Range, V

Laser Operating Current Range, IDL. . . . . . . . . . . . . . . . . 0A to 2A

TEC Operating Current Range, I

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

. . . . . . . . . . . . . . . . . . 3V to 5V

LAS

. . . . . . . . . . . . . . . . . . . 3V to 5V

TEC

. . . . . . . . . . . . . . . . . 0A to 2A

TEC

Thermal Resistance (Typical, Note 1) θJC(oC/W)

PLCC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Maximum Operating Junction Temperature, TJ. . . . . . . . . . . 100oC

Maximum Storage Temperature Range, T

. . . . -55oC to 150oC

STG

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300oC

Die Characteristics

Back Side Potential . . . . . . . . . . . . . . . . . . . . . . . . . -VEE, Substrate

Electrical Specifications T

= 100οC, VDD = 12V, VCC = 5V, VEE = -5V, INVERT Low (Figure 1 Configuration)

J

Unless Otherwise Specified

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

POWER SUPPLIES

V9P Voltage, No External Load V9P 1µF Tantalum

-9-V

Capacitor to V9P

V9P Thermal Shutdown 150 - V9P Thermal Shutdown Recovery - - 125

o

o

V9P Current Limiting 65 - - mA

Power Supply Current I

V

DD

V

Power Supply Current I

CC

Power Supply Current I

V

EE

DD

CC

EE

-2575mA

- 1.5 25 mA

-75 -23 - mA

LOGIC/DIGITAL INPUTS (A0-A3,NULLB and SB_H, LASERON1B, LASERON2B with 60kΩ Pullup Resistors; INVERT,RESETB,RLY_IN 60kΩ

with Pulldown Resistors)

Low Level Input Voltage V

High Level Input Voltage V

Minimum Hysteresis V

Low Level Input Current (Inputs with Pullups) I

High Level Input Current (Inputs with Pulldowns) I

IL

IH

HYS

IL

IH

0 - 1.5 V

3.5 - VCC+ 0.3 V

0.3 - - V

-140 - - µA

- - 140 µA

CONSTANT CURRENT CONTROLLER

OTA Gate Drive Amp. (A2) Voltage Output Range V

Current Monitor Amp. (A1) Gain A

Current Monitor Amp. Differential Sense Input Range V

Current Monitor Amp. Input Offset V

Current Monitor Amp. Common Mode Input Range V

SHUNT CURRENT SWITCH CONTROLLER (Note 2) V

UPPER

G

VS

IN

IO

IC

= 2V, V

= -1V, Gate Load = 5000pF, VUP1, 2; 1µF Filter Capacitor to

LOWER

-4 - V

CC

9.8 10 10.2 0 - 500 mV

-5 - 5 mV

0-5V

GND, VLOW1, 2; 1µF Filter Capacitor to GND, Unless Otherwise Specified

Shunt Gate Output Rise/Fall time t

R/tF

10% -90% Rise,

- - 20 ns

90% -10% Fall

Propagation Delay, LASERONB1, 2 to SG_1, 2 t

Drive Output Voltage V

UPPER

V

LOWER

TJ = 100oC - 80 110 ns

D

= -25oC - 60 95 ns

T

J

0-VCCV

-4 - V

CC

C

C

V

V

4-5

Page 6

HIP9022

Electrical Specifications T

= 100οC, VDD = 12V, VCC = 5V, VEE = -5V, INVERT Low (Figure 1 Configuration)

J

Unless Otherwise Specified (Continued)

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Driver Maximum Output Current I

Shunt Controller Switching Frequency f

DRSW

SC

-1 - 1 A

0 - 2.5 MHz

ANALOG SAMPLE/HOLD AMPLIFIERS

Low Level Input Voltage V

Low Level Input Current I

High Level Input Voltage V

Minimum Hysteresis V

Analog Input Voltage Range V

IL

IL

IH

HYS

IN

0 - 1.5 V

-140 - - µA

3.5 - VCC+ 0.3 V

0.3 - - V

0-V

- 0.2 V

CC

Minimum Sample/Hold Pulse Width - 10 - µs

Droop Rate, Constant Current Addresses #’s 1, 2 - - 0.006 V/s

Droop Rate, Other Addresses #’s 3 - 8 - - 0.06 V/s

Maximum Analog Multiplexing Frequency - - 30 kHz

DIAGNOSTIC OUTPUT (DIAG Output)

Voltage Follower Voltage Range V

Voltage Follower Maximum Clamp Voltage V

CL

O

0-V

--V

- 0.2 V

CC

+ 0.3 V

CC

O. C. (OVER CURRENT) COMPARATOR (OC1, 2 Outputs)

Threshold (%) O.C. Detection Programmed Current

- 140 - %

as Ref.

Output Voltage, Low Level V

Output Current, Low Level I

Output Voltage, High Level V

Output Current, High Level I

OL

OL

OH

OH

0 - 1.5 V

-12-mA

3.5 - VCC- 0.5 V

-4-mA

TEC REF. RESISTOR AND DRIVE OUTPUT

TECREFR Output Voltage to Reference Resistor V

TECGDR1, 2 Drive Output Voltage V

REFR

TECG

1.71 1.9 2.09 V

0-9V

OVER/UNDER TEMPERATURE COMPARATOR (To OT Output)

Under Temp. Limit T

Over Temp. Limit T

Output Voltage, Low Level V

Output Current, Low Level I

Output Voltage, High Level V

Output Current, High Level I

LOW

HIGH

OL

OL

OH

OH

2.07 2.1 2.13 V

1.67 1.7 1.73 V

0 - 1.5 V

-12-mA

3.5 - VCC- 0.5 V

-4-mA

RELAY DRIVER

Driver Output Current I

Drain to Source Resistance r

RLY

DS(ON)

- - 30 mA

-20-Ω

LASER PROTECTION DIODES See Figure 1

Maximum Diode Forward Voltage Drop V

Maximum Reverse Diode Current I

V

ESDX

LDX

10A Peak Current - - 2 V

LDX,

--1µA

NOTE:

2. The drive control sets the high and low voltages to the gate of the Power FET driver (shunt switch). Both the upper and lower levels are set by

values held in two of the sample/hold amplifiers. External capacitors at VUP1, 2 and VLOW1, 2 are required for stabilization.

4-6

Page 7

Address, Timing and Waveforms

DIGITAL

CONTROL

HIP9022

S/H

INT. TEST

TEST NULL OR S/H

ADDRESS NUMBERS

SAMPLE

(SH_B INPUT)

NULLB

INPUT

V

INPUT

DIAGNOSTIC

(DIAGINB INPUT)

IN

#11 to 14 #15#1 to 8 #1 to 8#1 to 8 #1 to 8

#9 or 10

(NULL OR S/H) (RESET)

FIGURE 2. ADDRESS WITH SAMPLE, NULL, VIN AND DIAGONAL WAVEFORMS

TABLE 1. HIP9022 ADDRESS MAP

ADDRESS

A3 A2 A1 A0

NO.

0000 1 ANALOG V

0001 2 ANALOG V

0010 3 ANALOG V

0011 4 ANALOG V

0100 5 ANALOG V

0101 6 ANALOG V

0110 7 ANALOG V

0111 8 ANALOG V

FUNCTION

TYPE FUNCTION NAME

Voltage for Constant Current Level, Laser Driver #1

IN(DL)

Voltage for Constant Current Level, Laser Driver #2

IN(DL)

Level, Laser Driver #1

LOWER

Level, Laser Driver #2

LOWER

Level, Laser Driver #1

UPPER

Level, Laser Driver #2

UPPER

Thermal Compensation Level, Laser Driver #1

IN(DL)

Thermal Compensation Level, Laser Driver #2

IN(DL)

1000 9 DIGITAL Test Mode: S/H Amp, Auto Zero Null Voltage (Note 4)

1001 10 DIGITAL Test Mode: S/H Amp Output Voltage (Note 4)

1010 11 DIGITAL Test Mode: Set VUP and V

Amps to Three-State (Note 4)

LOW

1011 12 DIGITAL VLOW#1 Set to Positive Output (Default is Negative)

1100 13 DIGITAL VLOW#2 Set to Positive Output (Default is Negative)

1101 14 DIGITAL Thermal Compensation Activated (Default is Deactivated)

1110 15 DIGITAL Reset Digital Address (9-14) to Default State

1111 16 DIGITAL Idle Condition (S/H Pin Defeated) (Note 3)

NOTES:

3. The Idle address is protective in that SB_H input noise cannot disturb the chip if the Idle address is selected; also, the Address inputs are High

(selecting Idle state) if the pins are open.

4. Address Numbers 9 - 11 are shaded to indicate test mode conditions and are shown for information only. These addresses are used in original

production testing and not required for user applications. However, note that Address No. 15 will force a reset for Address Numbers 9 - 14.

5. DigitalProgramming: To set the digital addresses, only the proper digital address and a negative pulse >100ns on SB_H is needed. To reset the

digital addresses to the default states, Address 15 and a SB_H pulse >100ns is needed. Normally the digital addresses will be set first, and the

analog addresses programmed next. The test modes, Address Numbers 9 - 11, will normally only be used during factory testing. An address

15 Reset should normally precede most programming in order to assure that the digital address states begin in their default state. Otherwise,

the digital address states will be undefined because there is no power-up-reset.

6. Analog Programming: To program the eight S/H circuits, addresses of 0-5V analog signal on VINand negative pulses on NullB (10µs) and SB_H

(20µs) pins are needed. The NullB pulse is valid only during the SB_H pulse and should occur during the first half of the SB_H pulse. The S/H

amplifier is auto-zeroed for zero offset when both NullB and SB_H are low.The input VINis captured on the S/H storage capacitor during SB_Hlow.

7. The Diagnostic mode reads map addresses 1 - 8 via the DIAG output when DIAGINB is low.

4-7

Page 8

HIP9022

Circuit Block Descriptions

Laser Drive Circuitry

In Figure 3, the gate of the external current source Power

FET, Q2 is driven via the Operational Transconductance

Amplifier (OTA), A2 on the IC. The voltage on the current

sense resistor, RS in the source of the Power FET is

monitored by a X10 gain of the feedback amplifier, A1. The

stability of the current loop is established with an external

0.1µF capacitor to ground at the gate of the PowerFET. The

sampled voltage range is 0 to 0.5V when the proper value of

sense resistor, RS is chosen (typically 0.25Ω for 2A). The

OTA, A2 compares the X10 gain signal toa0to5Vreference

signal from an on-chip Sample and Hold (First S/H) circuit.

The Q2 drain current (Laser Drive current), IDL is:

V

I

DL

where V

voltage reference signal.

The S/H reference for the Laser Drive Current current is

updated with other multiplexed S/H circuits from a serial bus

and an off-chip D/A converter. Laser constant current is fully

controllable by the multiple x analog S/H b us, allo wing accur ate

calibration of the laser output and corrections as the laser ages.

In Figure 1, the laser drive current from Q2 is digitally switched

to either flow through or is shunted around the laser diode by

switchingthe external Shunt Pow erFET, Q3 on or off. The gate

of the Shunt FET is switched between two voltages (Upper and

Lower) which are provide by 2nd and 3rd S/H circuits. These

Shunt FET gate drive levels are fully progr ammab le via the

multiplexed analog S/H b us . By adjusting these le vels to

account for the laser power supply, the Shunt FET threshold

and channel resistance; minimum Shunt FET gate drive power

levels can be established. The Upper and Lo w er gate v oltage

driver circuits are two high current OTA amplifiers with two filter

capacitors. The upper voltage is programmab le in the 0V to

V

programmablein the range of -4V to VCC. The -4V extension is

accomplished by an optional on-chip voltage inv erter circuit.

The input to amplifier A3 is either direct from the S/H input or

inverted by amplifier A5.

The maximum laser on-off switching speeds are dependent

on the selection of Shunt FETs. A Harris dual

complementary MOSFET, RF3V49092 or RF3S49092 has

been designed specifically for this application. With the

constant current set at 0.8A, a typical laser switching speed

of 20ns has been measured.

Thermal Compensation

A 4th S/H circuit is used to set the amplitude of an optional

thermal compensation signal which can be used to

modulate the constant laser current source as a two pole

filtered effect of the laser on-off data. This feature may be

disabled when it is not required. This circuit is designed to

compensate for the temperature variations in the laser as

the laser is tur ned on and off. The bypass capacitors at the

Thermal Comparator(CTCx-10K, CTCx-27K) represent the

respective poles for the filter.

IN DL()

-------------------------=

RS10×()

is the programmed VIN for the First S/H

IN(DL)

range at the input of amplifier A4. The lower voltage is

CC

(EQ. 1)

A laser cools after it has been off for a period of time and is

more efficient when it is turned-on. Compensation for the

increased efficiency is made by slightly reducing the

current level of the constant current source FET. The level

will be reduced by a programmable amount of 0 to 5% of

full scale. The programmable amount is fixed by the level of

compensation to S/H addresses 7 and 8 (see Table 1). The

percent of modulation (change) in drive current is

calculated as follows:

Modulation °°⁄

IN TC()

---------------------

V

IN DL()

5°°⁄×=

(EQ. 2)

V

For example, if we control the Laser Drive current with 2V

programmed with address 1 and 2 for the First S/H’s, given

that V

= V

I

DL

= 2V and RS = 0.25Ω. Then, from EQ. 1,

IN(DL)

/(RS x 10) = 2/(0.25 x 10) = 0.8A.

IN(DL)

If 2V is programmed to addresses 7 and 8 as Thermal

Compensation, V

for the 4th S/H’s, then,

IN(TC)

Mod.% = (2/2) x 5% = 5%.

In Figure 3, the correction is applied from the output of the

Thermal Compensation circuit (where the current is

2V/20kΩ = 0.1mA) to the input of amplifier A2. The 0.1mA is

forced into the 1kΩ resistor (and the low Z output of A1) to

increase the voltage at the inverting input of A2 by 0.1V or 5%

of the +V

by the 0 to V

input (2V) to A2. The modulation input is limited

IN(DL)

input range of S/H maximum VIN.

CC

Input Data

Q2

A2

+

-

A1

1kΩ

12kΩ

30kΩ

X10

+

-

VOLT. TO

CURRENT

27kΩ

+

-

O. C.

COMP.

-

THERMAL

COMP.

VOLT. TO

CURRENT

20kΩ

S/H SYS

FIGURE 3. LASER CONSTANT CURRENT SOURCE DRIVER

WITH OVER CURRENT DETECTION AND

THERMAL COMPENSATION

+

10kΩ

55

CC2

54

XTEN2+

53

XTEN2OC2

49

CTC2-27K

51

CTC2-10K

52

0.1µF

0.02µF

0.1µF

0.25Ω

R

S

4-8

Page 9

HIP9022

Both analog and digital data is input to control the action of

the dual laser driver. Address codes and input data are

described in the Table 1 Address Map. Digital data is

normally entered first, followed by the analog data via the

multiplexed analog bus which updates the S/H stored

voltage levels. Four bit digital addresses to pins A3, A2, A1

and A0 are decoded to define the programming functions

for data input. It is important to note that Address 15 is a

reset for Addresses 9 - 14 and should be performed as the

first step in programming because there is no power-onreset on-chip.

Diagnostic Output Data

For the purpose of monitoring on-chip signals, the

multiplexed bus can be used to output signals (at the DIAG

pin) via an analog diagnostic amplifier. This mode has the

capability to monitor the multiplexed output of four (0-5V)

analog signals for each laser channel. Note that the

diagnostic information at the VLOW (Amplifier A3) output is

2:1 resistor divided to +5V (V

) to return this signal to a 0

CC

to 5V range. To minimize noise problems the monitoring

function is normally performed during the laser scan for only

one signal per scan. In addition, there are 3 test modes

which allows the bus to present analog signals for testing the

performance of the eight S/H circuits.

Thermo-Electric-Cooler (TEC) Circuitry

Figure 4 shows the Thermal Electric Cooler (TEC) drive

circuit with an external reference resistance, a thermoresistor to sense temperature plus feedback components for

stable drive. There is a thermo-resistor reference input on

the chip for monitoring the laser's temperature via a 5-10kΩ

thermo-resistor which must be mounted near the laser. A

reference voltage on the external reference resistor is

established by a current from a stable bias source. This

current is mirrored to the thermo-resistor (one for each laser

driver system). A comparator senses the voltage across the

reference resistor versus the voltage across the thermo-

resistor and drives the gate of the TEC FET driver. As such,

the TEC circuit senses the thermo-resistor input as a

measure of the laser temperature and the TEC drive is

adjusted to maintain a stable Laser temperature slightly

below the ambient temperature. An external Power FET is

needed to provide the high TEC driver currents. An out of

range temperature output for each laser is also provided.

Laser Protection Diodes

Another feature included on the chip is two high current ESD

diodes which, in the printer system, are used to protect the

Laser Diodes from ESD damage. Another component of Laser

protection in printer systems are relays to disconnect the

Lasers when in a non-operating mode. For this purpose, a

single relay driver is included.

Over Current Flag Output (OC1, OC2)

Over-current detection is also included on-chip. The circuit of

Figure 3 shows the over current detection circuit. F or each

laser source current driver,the overcurrent monitor compares

the S/H input of amplifier A2 to the output of amplifier A1. If

the output voltage of A1 exceeds the input of A2 by 40%, then

an over current state exists and the OC output will go high.

Invert Option

An INVERT input reconfigures the device such that the

constant current source can be high side instead of the

normal low side. This provides functionality for driving laser

diodes in a common cathode configuration as opposed to

the normal common anode configuration. The INVERT must

be low (or open with the internal pull down) for the Figure 1

circuit.

Reset Action

The RESETB (active low) controls three things:

(1) The TEC driver is turned off.

(2) The Shunt driver is turned on to turn off the laser.

(3) The Constant current driver is turned off.

+

CURRENT

MIRROR

12

1.9V

+

-

O.T.

U.T.

FIGURE 4. TEC (THERMAL ELECTRIC COOLER) CIRCUIT WITH REFERENCE RESISTOR AND THERMAL RESISTOR SENSOR OF

LASER TEMPERATURE

+

-

TEMP.

COMP.

-

+

48

47

46

45

44

43

TECFB2

TECREF2

TECGDR2

TRES2

OT2

TECREFR

Q2

TEC

REFERENCE

RESISTOR

+

LASER2

THERMORESISTOR

(TEMPERATURE SENSOR)

THERMALLY

COUPLED

COMPONENTS

4-9

Page 10

HIP9022

Plastic Leaded Chip Carrier Packages (PLCC)

0.042 (1.07)

0.048 (1.22)

PIN (1) IDENTIFIER

0.020 (0.51) MAX

3 PLCS

C

L

D1

D

0.026 (0.66)

0.032 (0.81)

0.045 (1.14)

MIN

0.042 (1.07)

0.056 (1.42)

0.050 (1.27) TP

VIEW “A” TYP.

C

L

EE1

0.013 (0.33)

0.021 (0.53)

0.025 (0.64)

MIN

0.004 (0.10) C

0.025 (0.64)

0.045 (1.14)

D2/E2

D2/E2

A1

A

-C-

VIEW “A”

0.020 (0.51)

MIN

SEATING

PLANE

N68.95 (JEDEC MS-018AE ISSUE A)

68 LEAD PLASTIC LEADED CHIP CARRIER PACKAGE

R

SYMBOL

A 0.165 0.180 4.20 4.57 -

A1 0.090 0.120 2.29 3.04 -

D 0.985 0.995 25.02 25.27 D1 0.950 0.958 24.13 24.33 3

D2 0.441 0.469 11.21 11.91 4, 5

E 0.985 0.995 25.02 25.27 E1 0.950 0.958 24.13 24.33 3

E2 0.441 0.469 11.21 11.91 4, 5

N68 686

INCHES MILLIMETERS

NOTESMIN MAX MIN MAX

Rev. 2 11/97

NOTES:

1. Controllingdimension: INCH. Converted millimeterdimensionsare

not necessarily exact.

2. Dimensions and tolerancing per ANSI Y14.5M-1982.

3. DimensionsD1 and E1 do not include mold protrusions. Allowable

mold protrusion is 0.010 inch (0.25mm) per side. Dimensions D1

and E1 include mold mismatch and are measured at the extreme

material condition at the body parting line.

4. To be measured at seating plane contact point.

-C-

5. Centerline to be determined where center leads exit plastic body.

6. “N” is the number of terminal positions.

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However,no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

4-10

Loading...

Loading...