Page 1

HIP1011D

Data Sheet November 1999

Dual PCI Hot Plug Controller

The HIP1011D is the first IC available for independent

control of two PCI Hot Plug slots. The HIP1011D has all the

features and functionality of two single PCI Hot Plug slot

controllers such as the HIP1011A but in the same foot print

area.

The HIP1011D is designed to be physically placed in close

proximity to two adjacent PCI slots servicing each

independently but reducing layoutcomplexityandplacement

costs in assembly. It creates two independent power control

solutions with discrete power MOSFETs and a few passive

components. The four supplies +5V, +3.3V, +12V, and -12V

for each slot are independently controlled. There are four

integrated current sensing switches for the +12V and -12V

and for the +5V and +3.3V supplies overcurrent protection is

provided by sensing the voltage across external currentsense resistors. In addition, on-chip references are used to

monitor the +5V, +3.3V and +12V outputs for undervoltage

conditions. The two PWRON inputs control the state of the

switches, one each for slot A and slot B outputs. During an

overcurrent condition on any output, or an undervoltage

condition on the +5V, +3.3V or +12V outputs, a LOW (0V) is

asserted on the associated FLTN output and all associated

switches are latched-off. The outputs servicing the adjacent

slot are unaffected.

File Number 4725.1

Features

• Independent Power Control of 2 PCI Slots

• Turn-Off Delay Time Adjustability

• Internal MOSFET Switches for +12V and -12V Outputs

• µP Interface for On/Off Control and Fault Reporting

• Adjustable Overcurrent Protection for All Eight Supplies

• Provides Fault Isolation

• Adjustable Turn-On Slew Rate

• Minimum Parts Count Solution

• No Charge Pump

• 100ns Response Time to Over Current

Applications

• PCI Hot-Plug

Ordering Information

TEMP.RANGE

PART NUMBER

HIP1011DCA 0 to 70 28 Ld SSOP M28.15

HIP1011DCA-T 0 to 70 Tape and Reel

(oC) PACKAGE

PKG.

NO.

The time to FLTN signal going LOW and MOSFET latch off

is user determined by a single capacitor from each FLTN pin

to ground. This added feature enables the HIP1011D to

ignore system noise transients. The FLTN latch is cleared

when the PWRON input is toggled low again. During initial

power-up of the main VCC supply (+12V), the PWRON input

is inhibited from turning on the switches,andthelatchisheld

in the Reset state until the VCC input is greater than 10V.

User programmability of the overcurrent threshold and turnon slew rate is provided. A resistor connected to the OCSET

pin programs the overcurrent threshold for both slots.

Capacitors connected to the gate pins set the turn-on rate.

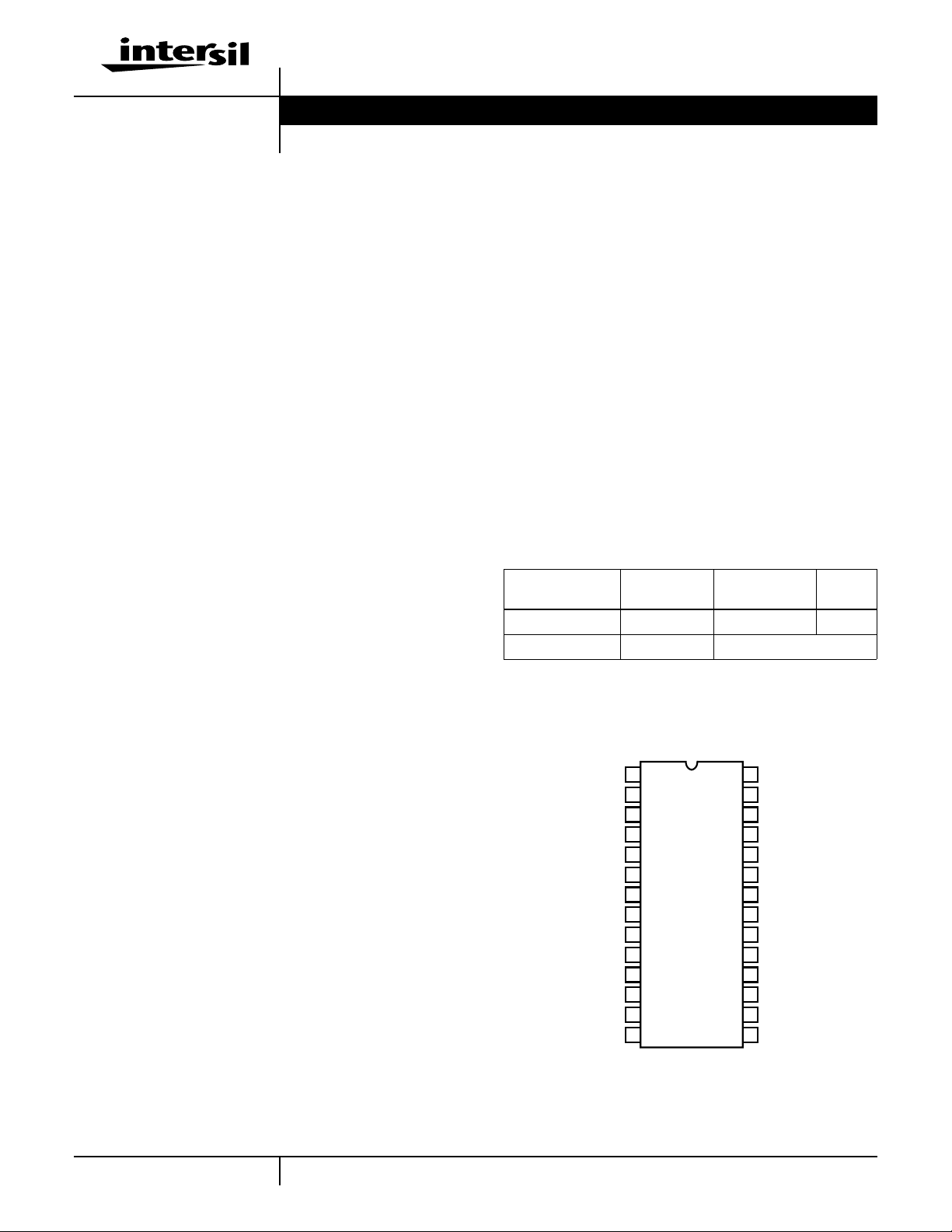

Pinout

M12VO_2

M12VG_2

PWRON_2

VSS

12VG_2

12VO_2

12VO_1

12VG_1

OCSET

FLTN_1

PWRON_1

M12VG_1

M12VO_1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

HIP1011D

(SSOP)

TOP VIEW

28

27

26

25

24

23

22

21

20

19

18

17

16

15

M12VIN_2

3VISEN_2

3VS_2

5VISEN_2FLTN_2

5VS_2

3V5VG_2

12VIN_2

12VIN_1

3V5VG_1

5VS_1

5VISEN_1

3VS_1

3VISEN_1

M12VIN_1

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Copyright © Intersil Corporation 1999

Page 2

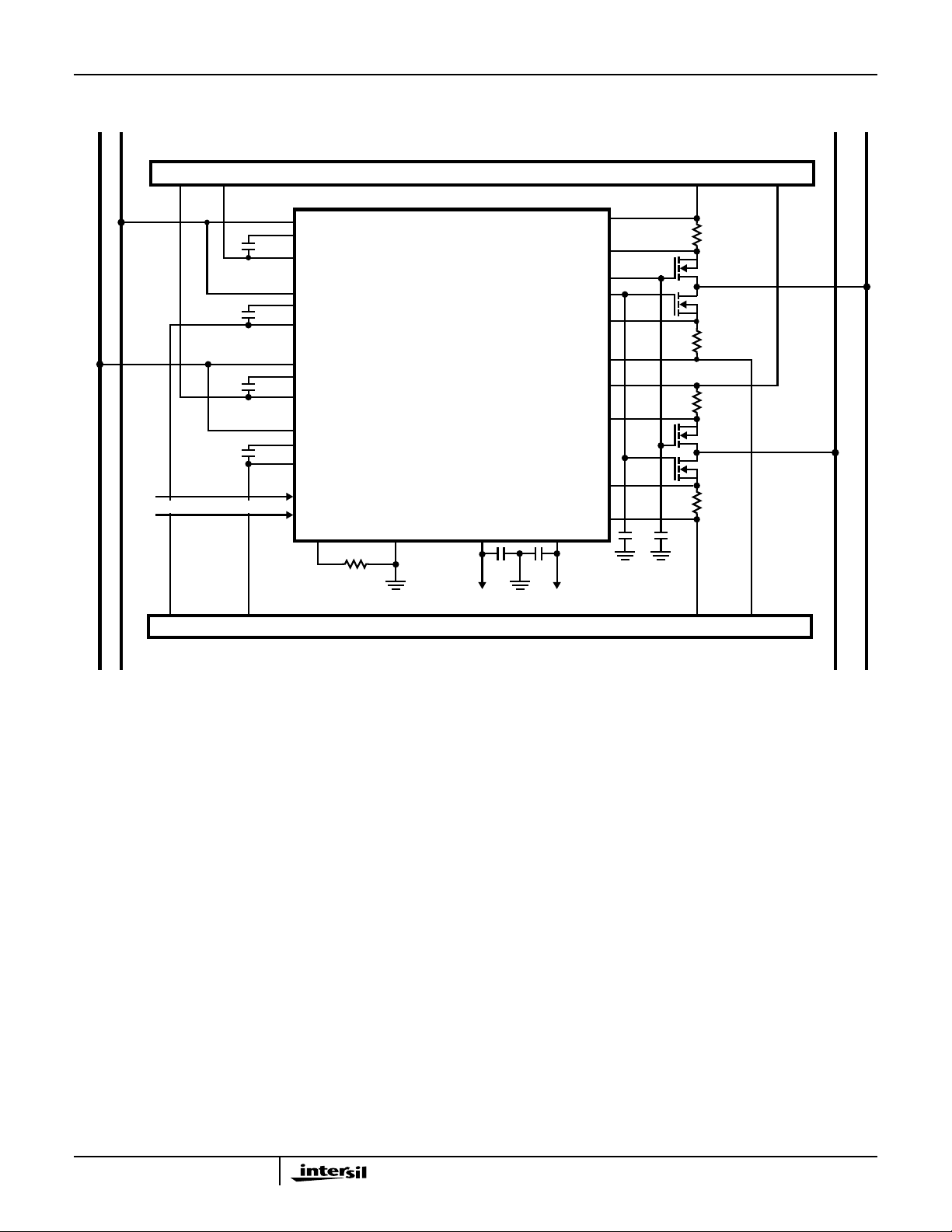

Typical Application

HIP1011D

-12V BUS

+12V BUS

SYSTEM CONTROLLER

-12V12V 3.3V5V

M12VIN_1

M12G_1

C1

M12VO_1

M12VIN_2

M12G_2

C2

M12VO_2

12VIN_1

12VG_1

C3

12VO_1

12VIN_2

12VG_2

C4

12VO_2

FROM

PWRON_1

PWRON_2

OCSET

R5

SLOT 1

HIP1011D

FLTN_1VSS

OPT. OPT.

TO SYSTEM CONTROLLER

SLOT 2

5VISEN_1

3V5VG_1

3V5VG_2

5VISEN_2

3VISEN_1

3VISEN_2

FLTN_2

5VS_1

5VS_2

3VS_1

3VS_2

C5 C6

Q1

Q2

Q3

Q4

R1

R2

R3

R4

5V BUS

3.3V BUS

5V3.3V12V-12V

FIGURE 1.

2

Page 3

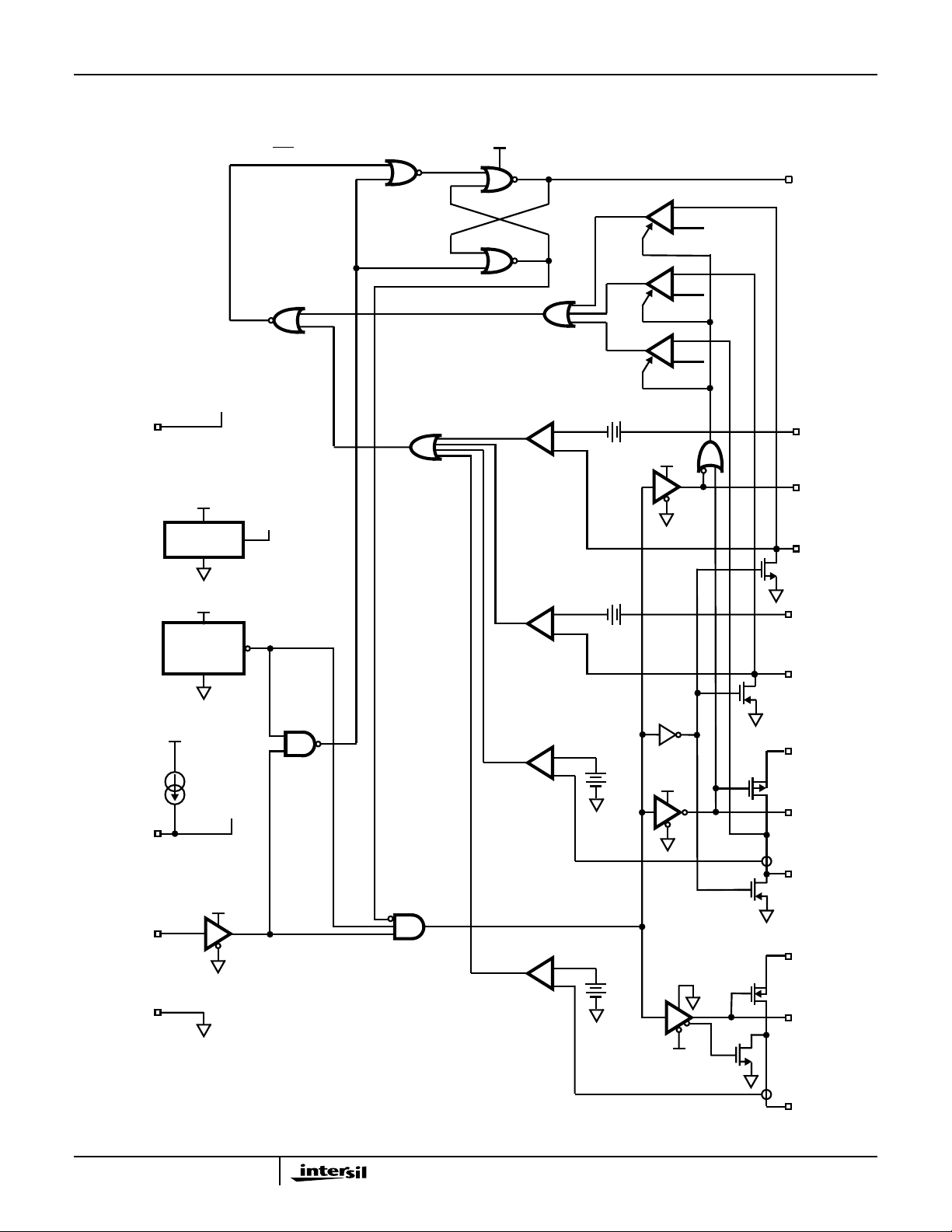

Simplified Schematic (1/2 HIP1011D)

SET (LOW = FAULT)

12VIN

12VIN

HIP1011D

RESET

5VREF

COMP

FAULT LATCH

+

-

LOW = FAULT

COMP

COMP

COMP

-

+

+

INHIBIT

-

+

INHIBIT

-

+

INHIBIT

12VIN

FLTN

4.6V

2.9V

10.6V

5VS

100µA

OCSET

PWRON

GND

12VIN

5V ZENER

REFERENCE

12VIN

12VIN

POWER-ON

RESET

12VIN

V

OCSET

12VIN

5VREF

LOW WHEN

12VIN < 10V

HIGH = FAULT

COMP

+

-

COMP

-

+

HIGH = SWITCHES ON

COMP

-

+

3V5VG

5VISEN

-

+

+

-

+

-

12VIN

0.3Ω

0.7Ω

3VS

3VISEN

12VIN

12VG

12VO

M12VIN

M12VG

M12VIN

FIGURE 2.

M12VO

3

Page 4

HIP1011D

Pin Descriptions

PIN NO. DESIGNATOR FUNCTION DESCRIPTION

15, 28 M12VIN -12V Input -12V Supply Input. Also provides power to the -12V overcurrent circuitry.

4, 11 FLTN Fault Output 5V CMOS Fault Output; LOW=FAULT. An optional capacitor may be place from this pin to

ground to provide additional immunity from power supply glitches.

20, 23 3V5VG 3.3V/5V Gate Output Drive the gates of the 3.3V and 5V MOSFETs. Connect a capacitor to ground to set the

start-up ramp. During turn on, this capacitor is charged with a 25µA current source.

UV comparator disabled when this pin below 9.6V nominal.

21, 22 12VIN 12V Input 12V supply input for IC and 12VO. Both 12VIns to be connected to a single +12V supply.

16, 27 3VISEN 3.3V Current Sense Connect to the load side of the currentsenseresistorinserieswithsourceofexternal 3.3V

MOSFET.

17, 26 3VS 3.3V Source Connect to source of 3.3V MOSFET. This connection along with (3VISEN) senses the

voltage drop across the sense resistor.

19, 24 5VS 5V Source Connect to source of 5V MOSFET switch. This connection along with (5VISEN) senses the

voltage drop across the sense resistor.

18, 25 5VISEN 5V Current Sense Connect to the load side of the current sense resistor in series with source of external 5V

MOSFET.

3, 12 PWRON Power On Control Controls all four switches. High to turn switches ON, Low to turn them OFF.

6, 9 12VG Gate of Internal PMOS Connect a capacitor between 12VG and 12VO to set the start-up ramp for the +12V supply.

This capacitor is charged with a 25µA current source during start-up.

UV comparator disabled when this pin >1.4Vnominal.

7, 8 12VO Switched 12V Output Switched 12V output. Rated for 0.5A.

2, 13 M12VG Gate of Internal NMOS Connect a capacitor between M12VG and M12VO to set the start-up ramp for the M12V

supply. This capacitor is charged with 25µA during start-up.

1, 14 M12VO Switched -12V

Output

10 OCSET Overcurrent Set Connect a resistor from this pin to ground to set the overcurrent trip point of all eight

5 VSS Ground Connect to common of power supplies.

Switched 12V Output. Rated for 100mA.

switches. All eight over current trips can be programmed by changing the value of this

resistor. The default (6.04kΩ, 1%) is compatible with the maximum allowable currents as

outlined in the PCI specification.

4

Page 5

HIP1011D

Absolute Maximum Ratings Thermal Information

12VIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +14.0V

12VO, 12VG, 3V5VG . . . . . . . . . . . . . . . . . . . .-0.5V to 12VIN +0.5V

M12VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -14.0V to +0.5V

M12VO, M12VG. . . . . . . . . . . . . . . . . . . . . . V

M12VIN

-0.5V to +0.5V

3VISEN, 5VISEN . . . . . . . . . .-0.5V to the Lesser of 12VIN or +7.0V

Voltage, Any Other Pin. . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +7.0V

12VO Output Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3A

M12VO Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8A

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2KeV (HBM)

Operating Conditions

12VIN Supply Voltage Range . . . . . . . . . . . . . . . .+10.8V to +13.2V

5V and 3.3V Input Supply Tolerances. . . . . . . . . . . . . . . . . . . . . . ±10%

12VO Output Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 to +0.5A

M12VO Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . 0 to +0.1A

Temperature Range (TA) . . . . . . . . . . . . . . . . . . . . . . . .0oC to 70oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

2. All voltages are relative to GND, unless otherwise specified.

Thermal Resistance (Typical, Note 1) θJA (oC/W)

SSOP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . .150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300oC

(SSOP - Lead Tips Only)

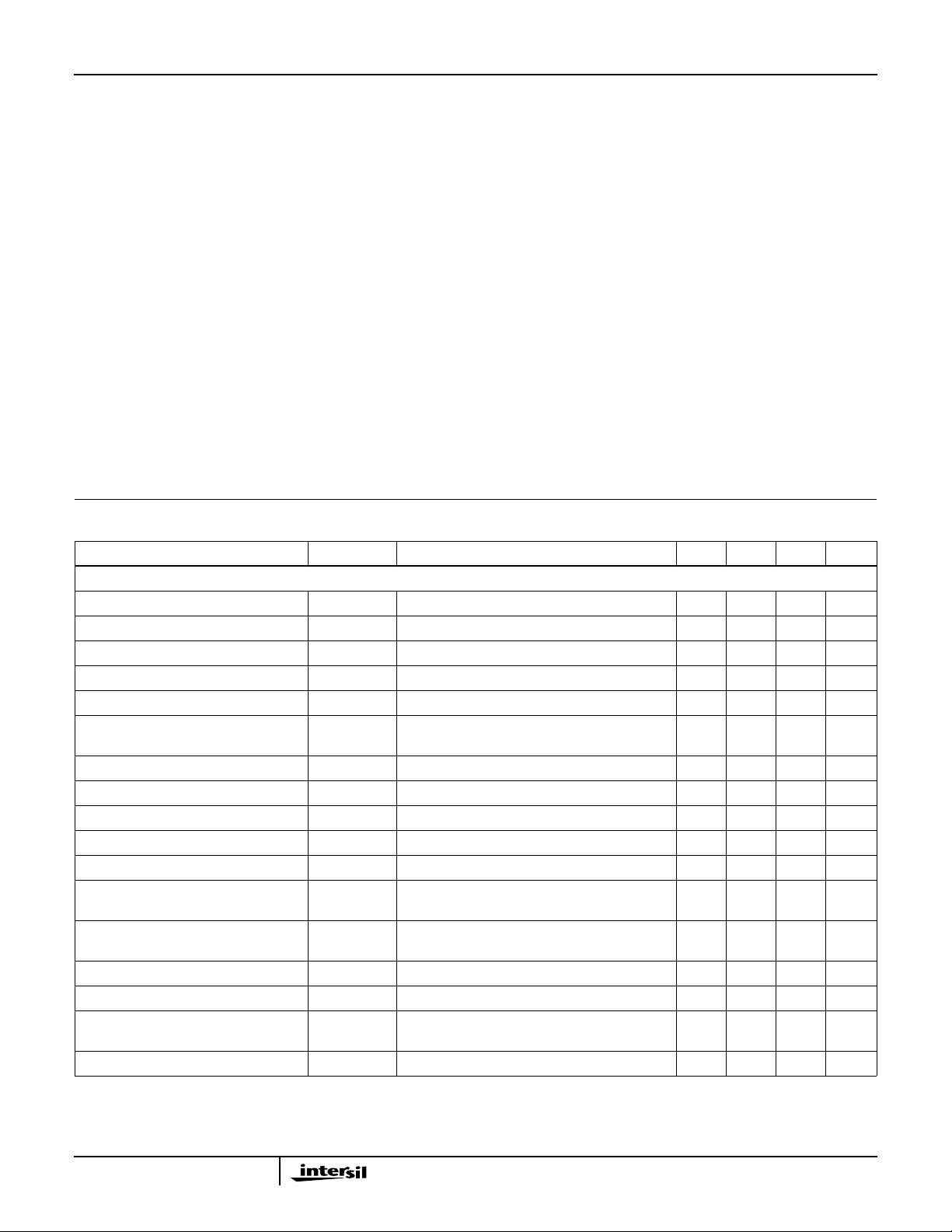

Electrical Specifications Nominal 5.0V and 3.3V Input Supply Voltages,

12VIN = 12V, M12VIN = -12V, TA = TJ= 0 to 70oC, Unless Otherwise Specified

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

5V/3.3V SUPPLY CONTROL

5V Overcurrent Threshold I

5V Overcurrent Threshold Voltage V

5V Overcurrent Threshold Voltage V

5V Undervoltage Trip Threshold V

5V Undervoltage Fault Response Time t

5V Turn-On Time

OC5V

OC5V_1

OC5V_2VOCSET

5VUV

5VUV

t

ON5V

(PWRON High to 5VOUT = 4.75V)

3V Overcurrent Threshold I

3V Overcurrent Threshold Voltage V

3V Overcurrent Threshold Voltage V

3V Undervoltage Trip Threshold V

3V Undervoltage Fault Response Time t

3V5VG Undervoltage Enable Threshold

OC3V

OC3V_1

OC3V_2

3VUV

3VUV

V

3V5VGenVth

Voltage

3V Turn-On Time

t

ON3V

(PWRON High to 3VOUT = 3.00V)

3V5VG Vout High Vout_hi_35VG PWRON = High, FLTN = High 11.5 11.8 - V

Gate Output Charge Current IC

Gate Turn-On Time

3V5VG

t

ON3V5V

(PWRON High to 3V5VG = 11V)

Gate Turn-Off Time t

OFF3V5VC3V5VG

See Figure 24, Typical Application - 8 - A

V

= 0.6V 33 42 50 mV

OCSET

= 1.2V 70 80 90 mV

4.42 4.65 4.7 V

- 110 160 ns

C

3V5VG

= 0.022µF, C

= 2000µF, RL = 1Ω - 6.5 - ms

5VOUT

See Figure 24, Typical Application - 10 - A

V

V

= 0.6V 41 52 62 mV

OCSET

= 1.2V 89 98 108 mV

OCSET

2.74 2.86 2.9 V

- 110 160 ns

- 9.6 - V

C

3V5VG

= 0.022µF, C

3VOUT

= 2000µF,

- 6.5 - ms

RL = 0.43Ω

PWRON = High, V

C

= 0.033µF, 3V5VG Rising 10% to 90% - 280 - µs

3V5VG

= 4V 19 25.0 29 µA

3V+5VG

= 0.033µF, 3V5VG Falling 90% to 10% - 2 - µs

5

Page 6

HIP1011D

Electrical Specifications Nominal 5.0V and 3.3V Input Supply Voltages,

12VIN = 12V, M12VIN = -12V, TA = TJ= 0 to 70oC, Unless Otherwise Specified (Continued)

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

+12V SUPPLY CONTROL

On Resistance of Internal PMOS r

Overcurrent Threshold I

Overcurrent Threshold I

DS(ON)12

OC12V_1

OC12V_2

12V Undervoltage Trip Threshold V

Undervoltage Fault Response Time t

Gate Charge Current IC

Turn-On Time

t

(PWRON High to 12VG = 1V)

Turn-Off Time t

OFF12V

-12V SUPPLY CONTROL

On Resistance of Internal NMOS r

Overcurrent Threshold I

Overcurrent Threshold I

DS(ON)M12

OC12V_1

OC12V_2

Gate Output Charge Current IC

Turn-On Time

t

ONM12V

(PWRON High to M12VO = -10.8V)

Turn-Off Time t

OFFM12VCM12VG

M12VIN Input Bias Current IB

CONTROL I/O PINS

Supply Current I

OCSET Current I

Overcurrent Fault Response Time t

PWRON Threshold Voltage V

THPWRON

FLTN Output Low Voltage V

FLTN Output High Voltage V

FLTN,OHIFLTN

FLTN Output Latch Threshold V

12V Power On Enable Threshold V

12V Power On Reset Threshold V

POR,THriseVCC

POR,THfallVCC

12VUV

12VUV

12VG

ON12V

M12VG

M12VIN

VCC

OCSET

OC

FLTN,OLIFLTN

FLTN,TH

PWRON = High, ID = 0.5A, TA = TJ = 25oC - 0.3 0.35 Ω

V

V

PWRON = High, V

C

C

= 0.6V 0.6 0.75 0.9 A

OCSET

= 1.2V 1.25 1.50 1.8 A

OCSET

12VG

= 0.033µF, 12VG Falling 90% - 10% - 16 - ms

12VG

= 0.022µF, 12VG Rising 10% - 90% - 3 - µs

12VG

PWRON = High, ID = 0.1A, TA = TJ = 25oC - 0.7 1 Ω

V

V

PWRON = High, V

C

= 0.6V 0.13 0.18 0.25 A

OCSET

= 1.2V 0.23 0.38 0.52 A

OCSET

3VG

= 0.033µF, C

M12VG

= 0.033µF, M12VG Falling 90% to 10% - 3 - µs

PWRON = High - 2.5 5 mA

= 2mA - 0.5 0.7 V

= 0 to -4mA 4.0 4.3 V

FLTN High to Low transition 1.8 2.3 3 V

Voltage Rising 9.4 10 10.2 V

Voltage Falling 8.9 9.1 9.3 V

TA = TJ = 70oC - 0.35 0.50 Ω

10.25 10.6 10.8 V

- 110 - ns

= 10V 19 25.0 29 µA

TA = TJ = 70oC - 1.0 1.3 Ω

= -10V 19 25 29 µA

=50µF, RL= 120Ω -16-ms

M12VO

5.3 8 mA

93 100 107 µA

- 500 960 ns

1.0 1.6 2.1 V

6

Page 7

HIP1011D

Introduction

The HIP1011D is the first device designed to provide control

and protection of the four PCI power supplies independently

to two PCI slots. Like the widely used HIP1011 this device

complies with the PCI Hot Plug specification facilitating the

service, upgrading or expansion of PCI based servers

without the need to power down the server. The HIP1011D

protects against over current (OC) for the -12V, +12V,+3.3V,

+5V and under voltage (UV) conditions for the +12V, +3.3V,

+5V supplies.

Figure 1 illustrates the typical implementation of the

HIP1011D. Additional components for optimizing

performance for particular applications, or desired features

may be necessary.

Key Feature Description and Operation

The HIP1011D, four power MOSFETs and a few passive

components as configured in Figure 1, create a small yet

complete power control solution for two PCI slots. It provides

an OC trip level greater than the maximum PCI specified

current for each supply to each slot. Over current monitoring

and protection for the 3.3V and 5V supplies is provided by

sensing the voltage across external current-sense resistors.

For the +12V and -12V inputs, over current protection is

provided internally. On-chip references are used to monitor

the +5V, +3.3V and +12V outputs for under voltage

conditions. During an over current condition on any output,

or an under voltage condition on the +5V, +3.3V or +12V

outputs, all slot specific MOSFETs are immediately latchedoff and a LOW (0V) is presented to the appropriate FLTN

output. During initial power-up of the main V

(+12V), the

PWRON inputs are inhibited from turning on the

switches,and the latch is held in the reset state until the V

CC

supply

CC

input is greater than 10V.After a fault has been asserted and

FLTN is latched low cycling PWRON low then high will clear

the FLTN latch. User programing of the OC thresholds for

both controlled slots is provided by a single resistor

connected to the OCSET pin along with Rsense. In addition

delaytime to latch off after a fault condition can be increased

by increasing the FLTN to ground capacitance and the turnon ramp rate can be increased by increasing the gate pin

capacitance.

Customizing Circuit Performance

Over Current (OC) Set Functionality and Resistor

Choice

The HIP1011D allows easy custom programming of the over

current (OC) levels of all 4 supplies simultaneously for both

PCI slots by simply changing the resistor value between

OCSET, (pin 10), and ground. The R

OCSET 100

µA current source sets a voltage that is used in

each of eight comparators, (one for each supply for both

slots). The voltages developed across the 3.3V and 5V

sense resistors are applied to the inputs of their respective

OCSET

value and the

comparators. The +12V and -12V currents are sensed

internally with pilot devices. Once any comparator trips, that

output is fed through logic circuits resulting in the

appropriate FLTN, (pin 4 or pin 11), going low, indicating a

fault condition on that particular slot. Because of the internal

current monitoring of the +12V and -12V switches, their

programming flexibility is limited to R

OCSET

changes. The

3.3V and 5V over current trip points depend on both

R

and the value chosen for each sense resistor.

OCSET

Overcurrent design guidelines and recommendations are as

follows:

1. For PCI applications, set R

OCSET

to 6.04kΩ, and use

5mΩ 1% sense resistors (see Figure 24).

2. For non PCI specified applications, the following

precautions and limitations apply:

A. Do not exceed the maximum power of the integrated

NMOS and PMOS. High power dissipation must be

coupled with effective thermal management. The

integrated PMOS has an r

DS(ON)

of 0.3Ω. Thus, with 1A

of steady load current on each of the PMOS devices the

powerdissipation is 0.6W.The thermal impedance of the

package is 95 degrees Celsius per watt, limiting the

average DC current on the 12V supply to about 1A on

each slot and imposing an upper limit on the R

resistor. Do not use an R

resistor greater than

OCSET

OCSET

15kΩ.

The average current on the -12V supply should not

exceed 0.7A. Since the thermal restrictions on the +12V

supply are more severe,the +12V supply restricts the use

of the HIP1011 to applications where the ±12V supplies

drawrelatively little current. Since both supplies only have

one degree of freedom, the value of R

OCSET

, the flexibility

of programming is quite limited. For applications where

more power is required on the +12V supply, contact your

local Intersil sales representative for information on other

Hot Plug solutions.

B. Do not try to sense voltages across the external sense

resistors that are less than 33mV. Spurious faults due to

noise and comparator input sensitivity may result. The

minimum recommended R

value is 6kΩ. This will

OCSET

set the nominal OC voltage thresholds at 52mV and

42mV for the 3.3V and 5V comparators respectively. This

isthe voltage levelatwhich the OC fault (I

OUTxRSENSE

will occur.

C. Minimize V

RSENSE

so as to not significantly reduce the

voltage delivered to the adapter card. Remember PCB

traceand connector distribution voltage losses also need

to be considered. Make sure that the R

SENSE

resistor

can adequately handle the dissipated power. For best

resultsuse a 1%precision resistor with a lowtemperature

coefficient.

D. Minimize external FET r

DS(ON)

.Lowr

DS(ON)

or multiple

MOSFETs in parallel are recommended. See Intersil for

a complete selection of MOSFET offerings.

)

7

Page 8

HIP1011D

TABLE 1.

SUPPLY

+3.3V I

+5.0V I

+12V I

-12V I

OC

OC

OC

OC

HOW TO DETERMINE NOMINAL (±10%) I

FOR EACH SUPPLY

((100µA x R

((100µA x R

(100µA x R

(100µA x R

OCSET

OCSET

OCSET

OCSET

)/11.5)/R

)/14.5)/R

)/0.8

)/3.3

RSENSE

RSENSE

OC

Time Delay to Latch-Off

Time delay to latch-off allows for a predetermined delay from

an OC or UV event to the simultaneous latch-off of all four

supply switches of the affected slot by the HIP1011D. This

delay period is set by the capacitance value to ground from

the FLTN pins for each slot. This capacitance value tailors

the FLTN signal going low ramp rate. This provides a delay

to the fault signal latch-off threshold voltage, FLTN, Vth. By

increasing this time, the HIP1011D delays immediate latchoff of the bus supply switches, thus ignoring transient OC

and UV conditions. See additional information in the “Using

the HIP1011DEVAL1 Platform” section of this data sheet.

Caution: The primary purpose of a protection device such

as the HIP1011D is to quickly isolate a faulted card from the

voltage bus. Delaying the time to latch-off works against this

primary concern so care must be taken when using this

feature. Ensure adequate sizing of external FETs to carry

additional current during time out period. Understand that

voltage bus disruptions must be minimized for the time delay

period in the event of a crow bar failure.

Devices using an unadjustable preset delay to latch-off time

present the user with the inability to eliminate these

concerns increasing cost and the chance of additional ripple

through failures.

HIP1011D Soft Start and Turn-Off Considerations

The HIP1011D does allow the user to select the rate of ramp

up on the voltage supplies. This start-up ramp minimizes inrush current at start-up while the on card bulk capacitors

charge. The ramp is created by placing capacitors on

M12VG to M12VO, 12VG to 12VO and 3V5VG to ground.

These capacitors are each charged up by a nominal 25µA

current during turn on. The same value for all gate timing

capacitors is recommended. A recommended minimum

value of 0.033µF as a smaller value may cause overcurrent

faultsat power up.This recommendation results in a nominal

gate voltage ramp rate of 0.76V/ms. The gate capacitors

must be discharged when a fault is detected to turn off the

powerFETs. Thus, larger caps slow the response time. If the

gate capacitors are too large the HIP1011D may not be able

to adequately protect the bus or the power FETs. The

HIP1011D has internal discharge FETs to discharge the

load when disabled. Upon turn-off these internal switches on

each output discharge the load capacitance pulling the

output to gnd. These switches are also on when PWRON is

low thus an open slot is held at the gnd level.

Decoupling Precautions and Recommendations

For the HIP1011D proper decoupling is a particular concern

during the normal switching operation and especially during

a card crowbar failure. If a card experiences a crow bar short

to ground, the supply to the other card will experience

transients until the faulted card is isolated from the bus. In

addition the common IC nodes between the two sides can

fluctuate unpredictably resulting in a false latch-off of the

second slot. Additionally to the mother board bulk

capacitance, it is recommended that 10µF capacitors be

placed on both the +12V and -12V lines of the HIP1011D as

close to the chip as possible.

Recommended PCB Layout Design Best Practices

To ensure accurate current sensing, PCB traces that

connect each of the current sense resistors to the HIP1011D

must not carry any load current. This can be accomplished

by two dedicated PCB kelvin traces directly from the sense

resistors to the HIP1011D, see examples of correct and

incorrect layouts below in Figure 3. To reduce parasitic

inductance and resistance effects, maximize the width of the

high-current PCB traces.

CORRECT

TO HIP1011D

VS AND VISEN

SENSE RESISTOR

FIGURE 3. SENSE RESISTOR PCB LAYOUT

INCORRECT

TO HIP1011D

VS AND VISEN

CURRENT

8

Page 9

Typical Performance Curves

HIP1011D

340

320

+12 (mΩ)

300

ON

PMOS r

280

260

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

NMOS -12 r

ON

PMOS +12 r

TEMPERATURE (oC)

ON

FIGURE 4. rON vs TEMPERATURE FIGURE 5. UV TRIP vs TEMPERATURE

10.59

10.57

1000

900

800

700

600

-12 (mΩ)

ON

NMOS r

4.632

4.631

4.630

4.629

5V UVTRIP (V)

4.628

4.627

4.626

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE (oC)

100

3V OCVth, VOCSET = 1.2V

85

70

5 UV

3.3 UV

5V OCVth, VOCSET = 1.2V

2.862

2.861

2.860

3.3V UVTRIP (V)

2.859

2.858

12 UV TRIP (V)

10.55

10.53

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE (oC)

OC Vth (mV)

3V OCVth, VOCSET = 0.6V

55

40

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE (oC)

FIGURE 6. 12 UV TRIP vs TEMPERATURE FIGURE 7. OC Vth vs TEMPERATURE

6

+12V BIAS

5

4

-12V BIAS

3

ABS +/-12V BIAS (MA)

2

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE (oC)

10.0

9.75

9.5

9.25

+12V THRESHOLDS (V)

+12V POWER ON RESET

9.0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE (oC)

5V OCVth, VOCSET = 0.6V

+12V POWER ON ENABLE

FIGURE 8. BIAS CURRENT vs TEMPERATURE FIGURE 9. 12V ENABLE AND RESET THRESHOLD

VOLTAGES vs TEMPERATURE

9

Page 10

Typical Performance Curves (Continued)

HIP1011D

1.5

1.25

1.0

0.75

+12V OVER CURRENT (A)

0.5

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

VOCSET = 1.2V

VOCSET = 0.6V

TEMPERATURE (

o

C)

0.4

VOCSET = 1.2V

0.3

0.2

VOCSET = 0.6V

0.1

-12V OVER CURRENT (A)

0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE (

o

C)

FIGURE 10. +12V OVER CURRENT LEVEL vs TEMPERATURE FIGURE 11. -12V OVER CURRENT vs TEMPERATURE

102

101

100

2.4

2.35

2.3

IOC SET (µA)

99

98

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE (oC)

2.25

FLTN LATCH OFF THRESHOLD (V)

2.2

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE (

o

C)

FIGURE 12. OCSET CURRENT vs TEMPERATURE FIGURE 13. FLTNLATCH-OFF THRESHOLD VOLTAGE vs

TEMPERATURE

100

90

80

70

OV / UV TO FAULT RESPONSE TIME (ns)

60

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE (

o

C)

FIGURE 14. OVER CURRENT AND UNDERVOLTAGE TO FLTN RESPONSE TIME vs TEMPERATURE

10

Page 11

HIP1011D

Using the HIP1011DEVAL1 Platform

General and Biasing Information

The HIP1011DEVAL1platform (Figure 24) comes as a three

part set consisting of 1 mother board emulator and 2 load

cards. This evaluationplatform allows a designer to evaluate

and modify the performance and functionality of the

HIP1011D in a simple environment.

Test point numbers (TP#) correspond to the HIP1011D

device (U5) pin numbers thus TP3 and TP12 are PWRON_2

and PWRON_1 respectively.These 2 pins are the HIP1011D

control inputs for each of the 2 integrated but independent

PCI power controllers in the HIP1011D.

On the HIP1011DEVAL1 platform are 4 HUF76132SK8,

(11.5mΩ, 30V, 11.5A) N-Channel power MOSFETs, (Q1-

Q4) these are used as the external switches for the +5V and

+3.3V supplies to the load card connectors, P1 and P2.

Current sensing is facilitated by the four 5mΩ 1W metal strip

resistors (R1-R4), the voltages developed across the sense

resistors are compared to references on board the

HIP1011D.

The HIP1011DEVAL1 platform is powered through the J1 to

J5 connector jacks near the top of the board, see Table 2 for

bias voltage assignments.

TABLE 2. HIP1011DEVAL1 BIAS ASSIGNMENTS

J1 J2 J3 J4 J5

GND +5V -12V +12V +3.3V

Evaluating Time Delay to Latch-Off

Provided for delay to latch-off evaluation are 2 locations for

1206 SMD capacitors, C7 and C8. Filling these locations

places a capacitor to ground from each of the HIP1011D

FLTN pins thus tailoring the FLTN signal going low ramp

rate. This provides a delay to the fault signal latch-off

threshold voltage, FLTN Vth. By increasing this time the

HIP1011D delays immediate latch-off of the bus supply

switches,thus ignoring transient OC and UV conditions. See

Table 3 illustrating the time it takes for switch gate turn-off

from the FLTN start of response to an OC or UV condition.

The FLTN response to an OC or UV condition is 110ns. See

Figures 20 through 23 for waveforms.

The intent of any protection device is to isolate the supply

quickly so a faulty card does not drag down a supply. A

longer latch-off delay results in less isolation from a faulty

card to supply.

TABLE 3.

C7 AND C8 VALUE OPEN 0.001µF 0.01µF 0.1µF

FLTN to Gate Response 0.1µs 0.44µs 2.9µs28µs

FLTN

3V5VG

FLTN, Vth

After properly biasing the HIP1011D and ensuring there is

an adequate ground return from the HIP1011DEVAL1

platform to the power supplies, (otherwise anomalous and

unpredictable results will occur) signal the PWRON inputs

low then insert the load cards as shown in Figure 15.

Signaling either or both PWRON pins high (>2.4V) will turn

on the appropriate FET switches and apply voltage to the

load cards.

LOAD CARDS

HIP1011D

FIGURE 16. TIMING DIAGRAM

10ms

1ms

100µs

10µs

1µs

100ns

10ns

1ns

0.001µF 0.1µF1µF10µFOPEN 0.01µF

FIGURE 17. TYPICAL OC/UV TO VG RESPONSE vs FLTN CAP

FIGURE 15. cORRECT INSTALLATION OF LOAD CARDS

11

Page 12

Typical Performance Curves (Continued)

HIP1011D

SUPPLY CURRENT

SUPPLY CURRENT

CH2

CH1

CH1 AND CH2 VOLTAGE (5V/DIV) TIME (100ms/DIV)

CH3 CURRENT (2A/DIV)

ENABLE 2

ENABLE 1

FIGURE 18. HIP1011DEVAL13.3V SUPPLYCURRENT AS

EACH SLOT CONTROLLER TURNS ON INTO

LOAD CARD

VG

CH3

CH2

CH1

ENABLE 1

CH1 AND CH2 VOLTAGE (5V / DIV) TIME (100ms/DIV)

CH3 CURRENT (2A/DIV)

ENABLE 2

FIGURE 19. HIP1011DEVAL13.3V SUPPLYCURRENT AS

CONTROLLER 1 TURNS ON INTO SHORTED

LOAD CARD

VG

FLTN

FLTN

VOLTAGE (2V/DIV)

TIME (1µs /DIV)

FLTN = OPEN

FIGURE 20. FLTN TO 35VG DELAY FIGURE 21. FLTN TO 35VG DELAY

VG

FLTN

VOLTAGE (2V/DIV) TIME (2µs/DIV)

FLTN = 0.01µF

FIGURE 22. FLTN TO 35VG DELAY FIGURE 23. FLTN TO 35VG DELAY

VOLTAGE (2V/DIV) TIME (1µs /DIV)

FLTN = 0.001µF

VG

FLTN

VOLTAGE (2V/DIV) TIME (10µs/DIV)

FLTN = 0.1µF

12

Page 13

HIP1011D

J3

-12V BUS

J1

J4

+12V BUS

12V -12V 5V

M12VIN_1

M12G_1

C1

M12VO_1

M12VIN_2

M12G_2

C2

M12VO_2

TP3

TP12

C3

C4

12VIN_1

12VG_1

12VO_1

12VIN_2

12VG_2

12VO_2

PWRON_1

PWRON_2

OCSET

R5

HIP1011D

U1

P1

5VISEN_1

5VS_1

3V5VG_1

3V5VG_2

5VS_2

5VISEN_2

3VISEN_1

3VS_1

3VS_2

FLTN_1VSS

R6

3VISEN_2

FLTN_2

R7

C7

No Pop

Q1

Q2

Q3

Q4

R1

R2

R3

R4

5V BUS

3.3V BUS

C8

No Pop

3.3V

TP11

TP4

C5

J2

C6

J5

P2

FIGURE 24.

D1

D2

5v3.3v-12v 12v

13

Page 14

HIP1011D

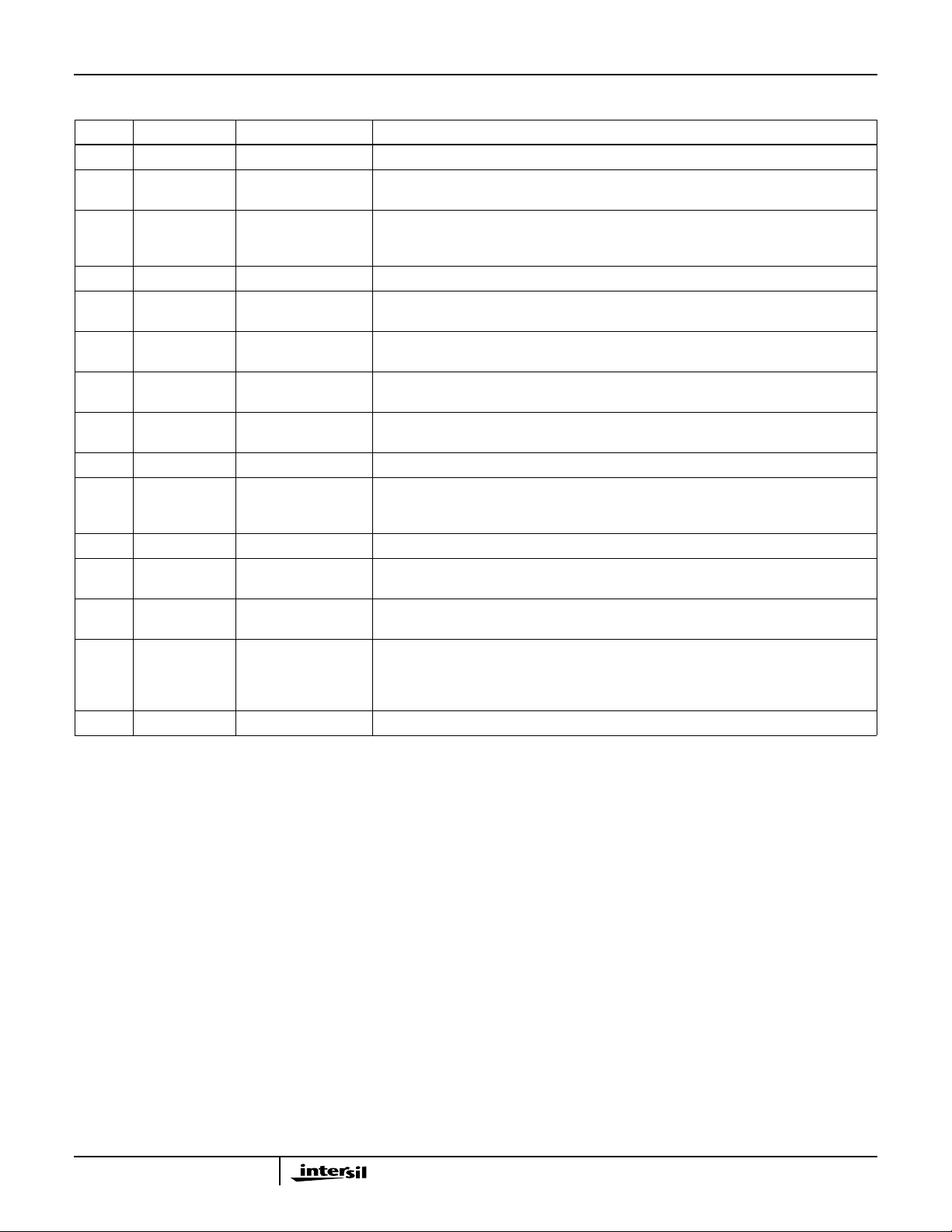

TABLE 4. HIP1011DEVAL1 BOARD COMPONENT LISTING

COMPONENT

DESIGNATOR COMPONENT NAME COMPONENT DESCRIPTION

U1 HIP1011DCB PCI HotPlug Controller Intersil, HIP1011DCB Dual PCI HotPlug Controller

Q1, Q2, Q3, Q4 HUF76132SK8 Intersil, HUF76132SK8, 11.5mΩ, 30V, 11.5A Logic Level N-Channel

MOSFET

R1 - R4 Sense Resistor for 3.3V and 5V Supplies Dale, WSL-2512 5mΩ Metal Strip Resistor

C1 - C6 Gate Timing Capacitors 0.033µF 805 Chip Capacitor

R5 Over Current Set Resistor 6kΩ 805 Chip Resistor

C7, C8 (Not Provided) Latch-Off Delay Capacitors Place provided for 805 Chip Cap

R6, R7 LED Series Resistors 470Ω 805 Chip Resistors

D1, D2 Fault Indicating LED Green SMD LED

TP1 - TP28 Test Point for Corresponding Device Pin Number

P1, P2 Connectors for Load Cards Sullins EZM06DRXH

RL1 3.3V Load Board Resistor 1.1Ω, 10W

RL2 5.0V Load Board Resistor 2.5Ω, 10W

RL3 +12V Load Board Resistor 47Ω, 5W

RL4 -12V Load Board Resistor 240Ω, 2W

CL1, CL2 +3.3V and +5.0V Load Board Capacitors 2200µF

CL3, CL4 +12V and -12V Load Board Capacitors 100µF

3.3V

5.0V

+12V

-12V

RL1

CL1

RL2

CL2

RL3

CL3

RL4

CL4

FIGURE 25. LOAD BOARD (2x)

14

Page 15

HIP1011D

Shrink Small Outline Plastic Packages (SSOP)

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

GAUGE

PLANE

0.25

0.010

h x 45

L

o

α

e

B

0.17(0.007) C AM BS

M

A1

0.10(0.004)

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2

of Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs. Mold flash, protrusion and gate burrs shall not exceed

0.15mm (0.006 inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010 inch)

per side.

5. The chamfer on the body is optional. If it is not present, a visual index feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “B” does not include dambar protrusion. Allowable dambar protrusion shall be 0.10mm (0.004 inch) total in excess of “B”

dimension at maximum material condition.

10. Controllingdimension: INCHES. Converted millimeter dimensions

are not necessarily exact.

A2

C

M28.15

28 LEAD SHRINK NARROW BODY SMALL OUTLINE

PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.053 0.069 1.35 1.75 A1 0.004 0.010 0.10 0.25 A2 - 0.061 - 1.54 -

B 0.008 0.012 0.20 0.30 9

C 0.007 0.010 0.18 0.25 -

D 0.386 0.394 9.81 10.00 3

E 0.150 0.157 3.81 3.98 4

e 0.025 BSC 0.635 BSC -

H 0.228 0.244 5.80 6.19 -

h 0.0099 0.0196 0.26 0.49 5

L 0.016 0.050 0.41 1.27 6

N28 287

o

α

0

o

8

o

0

o

8

NOTESMIN MAX MIN MAX

-

Rev. 0 2/95

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (321) 724-7000

FAX: (321) 724-7240

15

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...