Page 1

HIP1011B

Data Sheet March 2000

PCI Hot Plug Controller

The HIP1011B, the third product in the HIP1011 family, is an

electronic circuit breaker that monitors, reports and protects

circuits from excessive load currents. As a pin-for-pindrop-in

alternative offering similar functionality to the widely used

HIP1011, the HIP1011B is compatible with CompactPCI

peripheral boards and PCI Hot Plug systems where voltage

“health” monitoring and reporting are centralized by the

system controller IC. The HIP1011B does not monitor nor

respond to under voltage conditions thus making control of a

wide range of voltages possible.

The HIP1011B creates a small and simple yet complete

power control solution to control the four independent

supplies (+5V, +3.3V, +12V, and -12V) found in PCI and

CompactPCI systems. For the +12V and -12V supplies,

overcurrent protection is provided internally with integrated

current sensing FET switches. For the +5V and +3.3V

supplies, overcurrent protection is provided by sensing the

voltage across the external current-sense resistors. The

PWRON input controls the state of both internal and external

switches. During an overcurrent condition on any output, all

MOSFETs are latched-off and a LOW (0V) is asserted on

the FLTN output. The FLTN latch is cleared when the

PWRONinput is toggled low again. During initial power-up of

the main V

from turning on the switches, and the latch is held in the

Reset state until the V

User programmability of the overcurrent threshold, response

time and turn-on slew rate is provided. A resistor connected

to the OCSET pin programs the overcurrent thresholds. A

capacitor may be added to the FLTN pin to adjust the fault

reporting and power-supply latch-off response times after an

over-current event. Capacitors connected to the gate pins

determine the turn-on rate.

supply (+12V), the PWRON input is inhibited

CC

input is greater than 10V.

CC

File Number 4640.3

Features

• Allows for System Centralized Voltage Monitoring

• Adjustable Delay to Fault Notification and Latch-Off

• Controls Four Supplies: +5V, +3.3V, +12V, and -12V

• Internal MOSFET Switches for +12V and -12V Outputs

• µP Interface for On/Off Control and Fault Reporting

• Adjustable Overcurrent Protection for All Supplies

• Provides Overcurrent Fault Isolation

• Adjustable Turn-On Slew Rate

• Minimum Parts Count Solution

• No Charge Pump

Applications

• PCI Hot Plug

CompactPCI

•

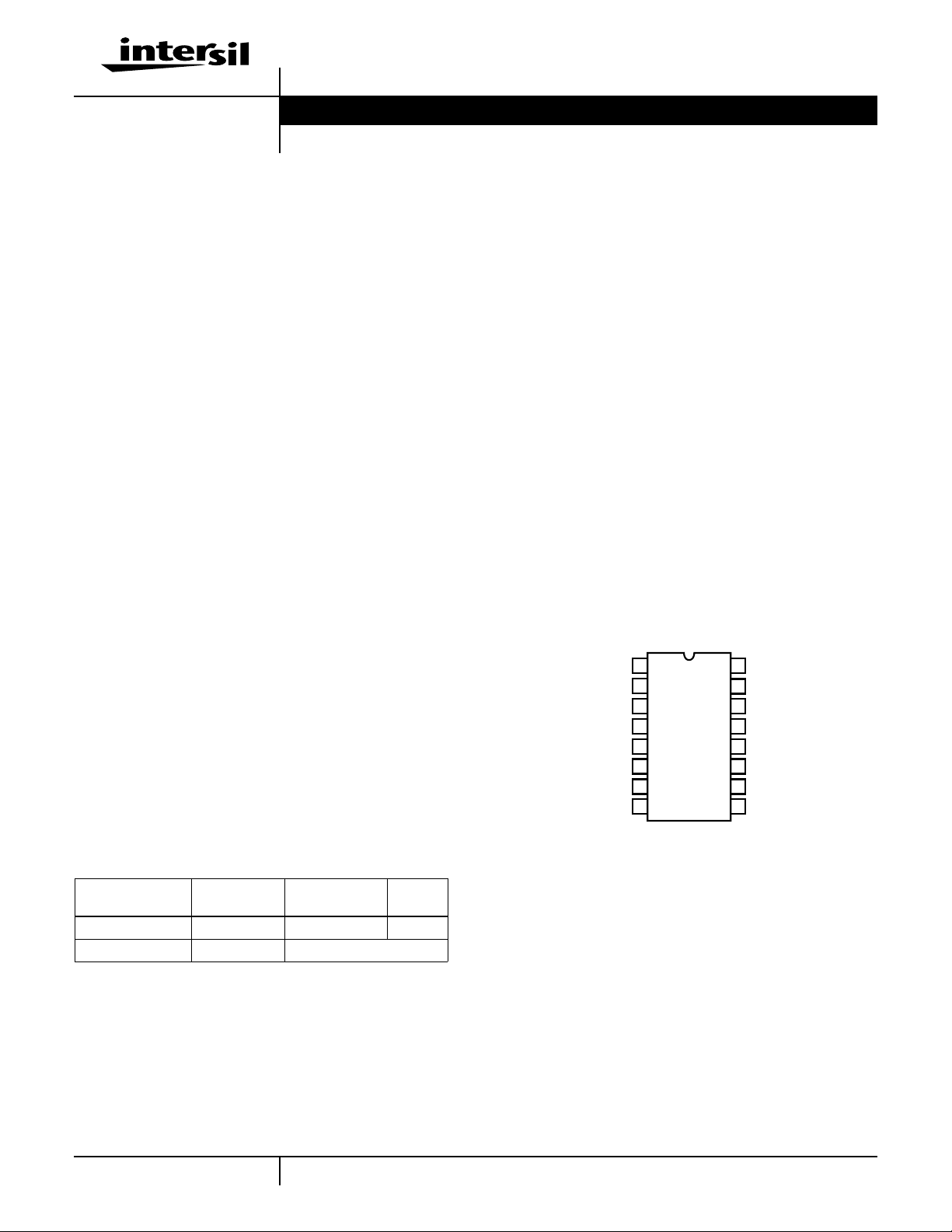

Pinout

HIP1011B

(SOIC)

TOP VIEW

M12VIN

FLTN

3V5VG

V

CC

12VIN

3VISEN

3VS

OCSET

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

M12VO

M12VG

12VG

GND

12VO

5VISEN

5VS

PWRON

Ordering Information

TEMP.RANGE

PART NUMBER

HIP1011BCB 0 to 70 16 Ld SOIC M16.15

HIP1011BCB-T 0 to 70 Tape and Reel

(oC) PACKAGE

1

PKG.

NO.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Copyright © Intersil Corporation 2000

Page 2

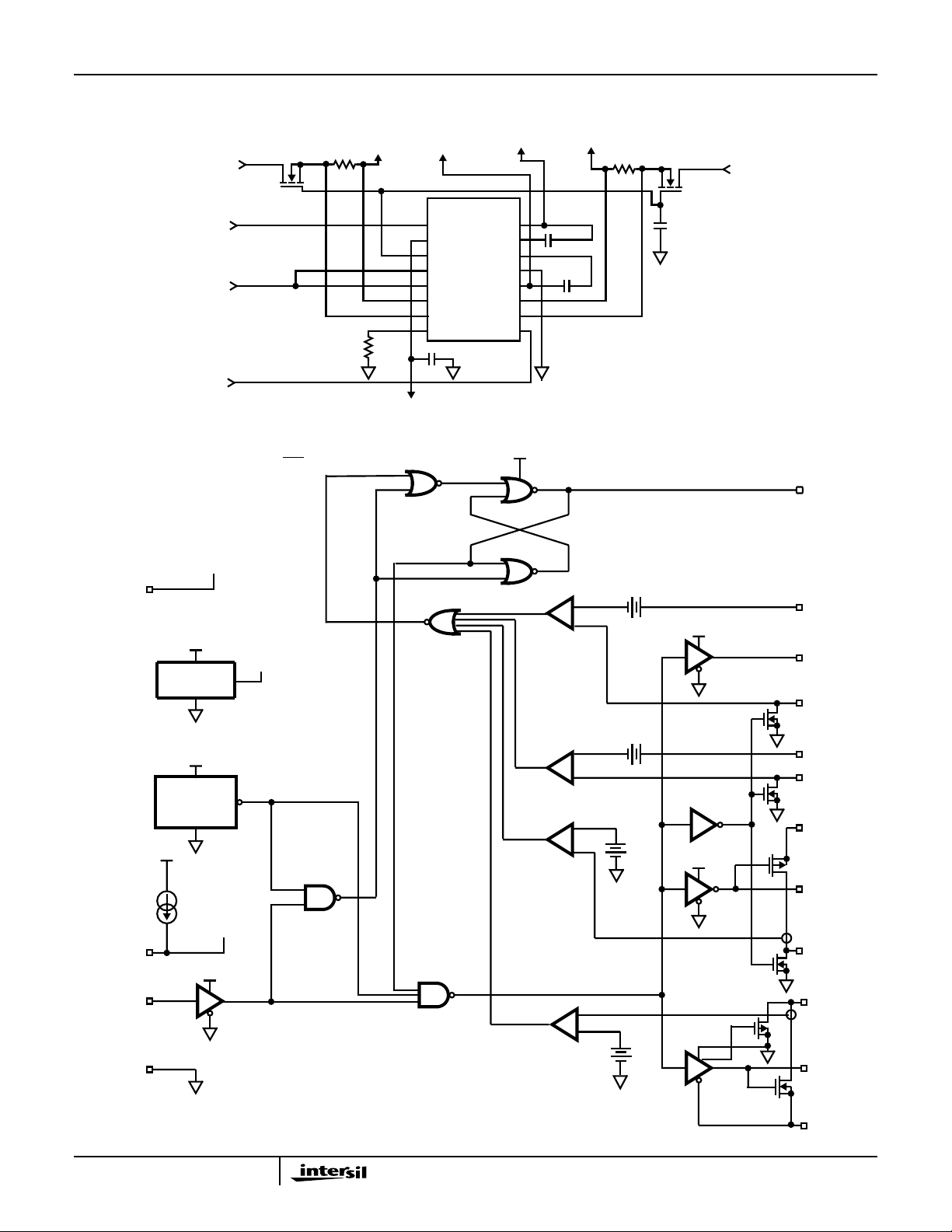

Typical Application

3.3V INPUT

-12V INPUT

12V INPUT

POWER CONTROL INPUT

FAULT OUTPUT (ACTIVE LOW)

Simplified Schematic

3.3V,

7.6A OUT

5mΩ, 1%

6.04kΩ

1%

SET (LOW = FAULT)

HIP1011B

12V,

0.5A OUT 0.1A OUT 5A OUT

HIP1011B

M12VIN

FLTN

3V5VG

V

12V

3VISEN

3VS

OCSET

M12VO

M12VG

CC

IN

5VISEN

PWRON

(OPTIONAL)

12VG

GND

12VO

5VS

V

CC

FAULT LATCH

5V,-12V,

0.033µF

0.033µF

NOTE:

ALL CAPACITORS ARE ±10%.

5mΩ, 1%

5V INPUT

HUF761315K8

0.033µF

LOW = FAULT

FLTN

V

CC

100µA

OCSET

PWRON

GND

V

V

CC

5V ZENER

REFERENCE

V

CC

12VIN

POWER-ON

RESET

V

CC

V

V

CC

5V

REF

LOW WHEN VCC < 10V

OCSET

CC

HIGH =

FAULT

RESET

COMP

COMP

COMP

HIGH = SWITCHES ON

COMP

V

OCSET

V

+

-

V

OCSET

+

-

V

OCSET

-

+

+

-

/3.3

OCSET

-

-

+

-

+

-

/13.3

/0.8

/17

+

V

CC

+

V

CC

0.3Ω

5VS

3V5VG

5VISEN

3VS

3VISEN

12VIN

12VG

12VO

M12VO

M12VG

0.7Ω

M12VIN

2

Page 3

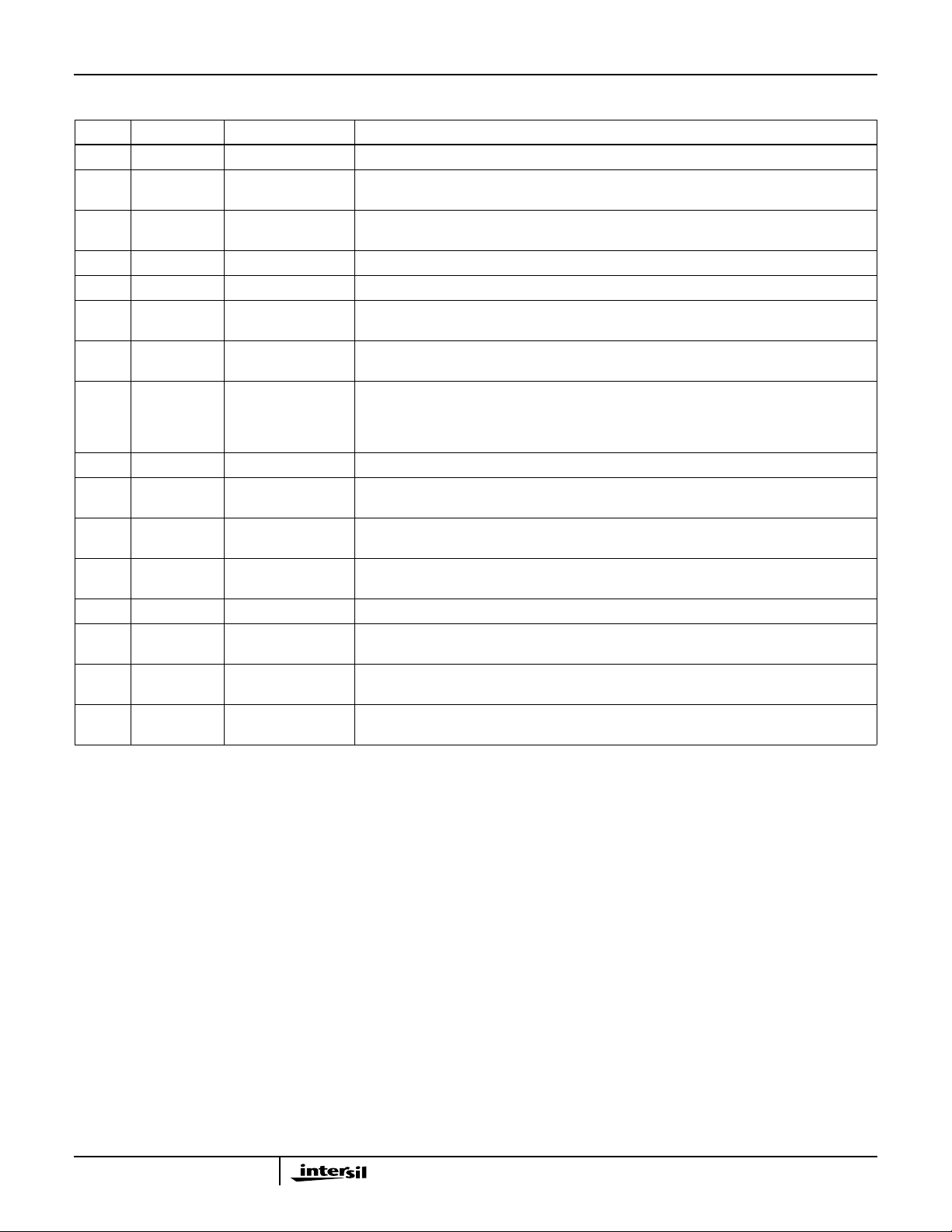

HIP1011B

Pin Descriptions

PIN DESIGNATOR FUNCTION DESCRIPTION

1 M12VIN -12V Input -12V Supply Input. Also provides power to the -12V overcurrent circuitry.

2 FLTN Fault Output 5V CMOS Fault Output; LOW = FAULT. A capacitor may be placed from this pin to ground to

provide delay time to fault notification and power supply latch-off.

3 3V5VG 3.3V/5V Gate

Output

4VCC12V VCC Input Connect to unswitched 12V supply.

5 12V

6 3VISEN 3.3V Current Sense Connect to the load side of the current sense resistor in series with source of external 3.3V

7 3VS 3.3V Source Connect to Source of 3.3V MOSFET. This connection along with pin 6 (3VISEN) senses the

8 OCSET Overcurrent Set Connect a resistor from this pin to ground to set the overcurrent trip point of all four switches. All

9 PWRON Power On Control Controls all Four Switches. High to Turn Switches ON, Low to turn them OFF.

10 5VS 5V Source Connectto Source of 5V MOSFET Switch. This connection along with pin 11 (5VISEN) senses

11 5VISEN 5V Current Sense Connectto the load side ofthe current sense resistor in serieswith source of external 5V MOSFET.

12 12VO Switched 12V

13 GND Ground Connect to common of power supplies.

14 12VG Gate of Internal

15 M12VG Gate of Internal

16 M12VO Switched -12V

IN

12V Input Switched 12V supply input.

Output

PMOS

NMOS

Output

Drive the Gates of the 3.3V and 5V MOSFETs. Connect a capacitor to ground to set the startup ramp. During turn on, this capacitor is charged with a 25µA current source.

MOSFET. This pin tied to GND when FET switch outputs disabled.

voltage drop across the sense resistor.

four over current trips can be programmed by changing the value of this resistor. The default

(6.04kΩ, 1%) is compatible with the maximum allowable currents as outlined in the PCI

specification.

the voltage drop across the sense resistor.

This pin tied to GND when FET switch outputs disabled.

Switched 12V output. This pin tied to GND when FET switch outputs disabled.

Connect a capacitor between 12VG and 12VO to set the start up ramp for the +12V supply.

This capacitor is charged with a 25µA current source during start-up.

Connect a capacitor between M12VG and M12VO to set the start-up ramp for the M12V

supply. This capacitor is charged with 25µA during start-up.

Switched 12V Output. This pin tied to GND when FET switch outputs disabled.

3

Page 4

HIP1011B

Absolute Maximum Ratings Thermal Information

VCC, 12VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +14.0V

12VO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to V12VIN+ 0.5V

12VO, 12VG, 3V5VG . . . . . . . . . . . . . . . . . . . . -0.5V to VCC+ 0.5V

M12VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -15.0V to + 0.5V

M12VO, M12VG. . . . . . . . . . . . . . . . . . . . . V

M12VIN

-0.5V to + 0.5V

3VISEN, 5VISEN . . . . . . . . . . . -0.5V to the lesser of VCC or + 7.0V

Voltage, Any Other Pin. . . . . . . . . . . . . . . . . . . . . . . -0.5V to + 7.0V

12VO Output Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A

M12VO Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8A

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4KeV (HBM)

Operating Conditions

VCC Supply Voltage Range. . . . . . . . . . . . . . . . . +10.8V to +13.2V

12VO Output Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 to +0.5A

M12VO Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . 0 to +0.1A

Temperature Range (TA) . . . . . . . . . . . . . . . . . . . . . . . 0oC to 70oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. θJA is measured with the component mounted on a low effective thermal conductivity test board in free air. See Tech Brief 379 for details.

2. All voltages are relative to GND, unless otherwise specified.

Thermal Resistance (Typical, Note 1) θJA (oC/W)

SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . 125oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300oC

(SOIC - Lead Tips Only)

Die Characteristics

Number of Transistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Electrical Specifications Nominal 5V and 3.3V Input Supply Voltages,

VCC = 12VIN = 12V, M12VIN = -12V, TA = TJ= 0 to 70oC, Unless Otherwise Specified

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

5V/3.3V SUPPLY CONTROL

5V Overcurrent Threshold I

5V Overcurrent Threshold Voltage V

5V Overcurrent Threshold Voltage V

5V Turn-On Time

OC5V_1

OC5V_2

t

(PWRON High to 5VOUT = 4.75V)

5VS Input Bias Current IB

5VISEN Input Bias Current IB

3V Overcurrent Threshold I

3V Overcurrent Threshold Voltage V

3V Overcurrent Threshold Voltage V

3V Turn-On Time

OC3V_1

OC3V_2

t

(PWRON High to 3VOUT = 3.00V)

3VS Input Bias Current IB

3VISEN Input Bias Current IB

3V5VG V

High V

OUT

OUT_HI_35VG

Gate Output Charge Current IC

Gate Turn-On Time

t

ON3V5V

(PWRON High to 3V5VG = 11V)

OC5V

ON5V

5VS

5VISEN

OC3V

ON3V

3VS

3VISEN

3V5VG

See Figure 1, Typical Application - 8 - A

V

= 0.6V 30 36 42 mV

OCSET

V

= 1.2V 66 72 79 mV

OCSET

C

= 0.022µF, C

3V5VG

5VOUT

RL = 1Ω

PWRON = High -40 -26 -20 µA

PWRON = High -160 -140 -110 µA

See Figure 1, Typical Application 10 A

V

= 0.6V 42 49 56 mV

OCSET

V

= 1.2V 88 95 102 mV

OCSET

C

= 0.022µF, C

3V5VG

3VOUT

RL = 0.43Ω

PWRON = High -40 -26 -20 µA

PWRON = High -160 -140 -110 µA

3V5VG IOUT = 5µΑ 11 11.7 - V

PWRON = High, V

C

= 0.1µF - 280 500 µs

3V5VG

3V5VG

= 2000µF,

= 2000µF,

- 6.5 - ms

- 6.5 - ms

= 2V 22.5 25.0 27.5 µA

Gate Turn-Off Time t

OFF3V5V

Gate Turn-Off Time C

4

C

= 0.1µF, 3V5VG from 9.5V to 1V - 13 17 µs

3V5VG

= 0.022µF, 3V5VG Falling 90% to 10% - 2 - µs

3V5VG

Page 5

HIP1011B

Electrical Specifications Nominal 5V and 3.3V Input Supply Voltages,

VCC = 12VIN = 12V, M12VIN = -12V, TA = TJ= 0 to 70oC, Unless Otherwise Specified (Continued)

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

+12V SUPPLY CONTROL

On Resistance of Internal PMOS r

Overcurrent Threshold I

Overcurrent Threshold I

Gate Charge Current IC

Turn-On Time (PWRON High to

DS(ON)12

OC12V_1

OC12V_2

12VG

t

ON12V

12VG = 1V)

Turn-Off Time t

OFF12V

Turn-Off Time C

-12V SUPPLY CONTROL

On Resistance of Internal NMOS r

Overcurrent Threshold I

Overcurrent Threshold I

Gate Output Charge Current IC

Turn-On Time (PWRON High to

DS(ON)M12

OC12V_1

OC12V_2

M12VG

t

ONM12V

M12VG = -1V)

Turn-On Time (PWRON High to

t

ONM12V

M12VO = -10.8V)

Turn-Off Time t

OFFM12V

Turn-Off Time C

M12VIN Input Bias Current IB

M12VIN

CONTROL I/O PINS

PWRON = High, ID = 0.5A, TA = TJ = 25oC 0.18 0.3 0.35 Ω

V

= 0.6V 0.6 0.75 0.9 A

OCSET

V

= 1.2V 1.25 1.50 1.8 A

OCSET

PWRON = High, V

C

= 0.022µF - 16 20 ms

12VG

C

= 0.1µF, 12VG - 9 12 µs

12VG

= 0.022µF, 12VG Rising 10% - 90% - 3 - µs

12VG

= 3V 22.5 25 28.5 µA

12VG

PWRON = High, ID = 0.1A, TA = TJ = 25oC 0.5 0.7 0.9 Ω

V

= 0.6V 0.15 0.18 0.25 A

OCSET

V

= 1.2V 0.30 0.37 0.50 A

OCSET

PWRON = High, V

C

= 0.022µF - 160 300 µs

M12VG

C

= 0.022µF, C

M12VG

C

= 0.1µF, M12VG - 18 23 µs

M12VG

= 0.022µF, M12VG Falling 90% to 10% - 3 - µs

M12VG

= -4V 22.5 25 28.5 µA

3VG

= 50µF, RL = 120Ω -16-ms

M12VO

PWRON = High - 2 2.6 mA

Supply Current I

OCSET Current I

Overcurrent Fault Response Time t

PWRON Threshold Voltage V

THPWRON

FLTN Output Low Voltage V

FLTN Output High Voltage V

FLTN Output Latch Threshold V

FLTN,OHIFLTN

FLTN,TH

12V Power On Reset Threshold V

5

VCC

OCSET

OC

FLTN,OLIFLTN

POR,TH

VCC Voltage Falling 8.7 9.4 9.9 V

4 5 5.8 mA

95 100 105 µA

- 500 960 ns

0.8 1.6 2.1 V

= 2mA - 0.6 0.9 V

= 0 to -4mA 3.9 4.3 4.9 V

1.45 1.8 2.25 V

Page 6

Typical Performance Curves

HIP1011B

340

320

+ 12 (mΩ)

300

ON

PMOS r

280

260

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

NMOS -12 r

TEMPERATURE (oC)

ON

PMOS +12 r

ON

FIGURE 1. rON vs TEMPERATURE FIGURE 2. OC VTH vs TEMPERATURE (VR

102

101

100

I OCSET (µA)

99

1000

900

800

700

600

-12 (mΩ)

ON

NMOS r

105

95

85

OC VTH (mV)

75

65

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

9.5

9.4

9.3

VTH (V)

POR

V

9.2

3V OCVTH

5V OCVTH

TEMPERATURE (oC)

OCSET

= 1.21V)

98

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE (oC)

9.1

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE (oC)

FIGURE 3. OCSET CURRENT vs TEMPERATURE FIGURE 4. VCC POWER ON RESET VTH vs TEMPERATURE

Adjusting the Fault Reporting and Power

Supply Latch-Off Delay Times

Figure 5 illustrates the relationship between the FLTN signal

and the gate drive outputs. Duration

between FLTN starting to transition from High to Low,

(indicating a fault has occurred) and the start of the gate

drive outputs latching off. The latch-off is initiated by the

falling FLTN signal reaching the output latch threshold

voltage, VFLTN, TH. For additional details and wave forms

see HIP1011A Data Sheet FN4631. Table 1 illustrates the

effect of the FLTN capacitor on the response times.

TABLE 1. RESPONSE TIME TABLE

3V5VG Response a 0.85µs37µs 3.8ms

a, indicates the time

0.001µF 0.1µF10µF

a

T1 T2

FIGURE 5. TIMING DIAGRAM

V

FLTN,TH

FLTN

3V5VG

6

Page 7

HIP1011B

Applications

Implementing the HIP1011B in the CompactPCI

Hot Swap Application

This application offers to the CompactPCI peripheral board

designer programmable Over Current (OC) protection,

programmabledelays to latch off, and soft start ramp turn on

for all four supplies with simultaneous latch off upon OC fault

detection.

Figure 6 illustrates the HIP1011EVAL2 evaluation board for

CompactPCI Hot Swap implementation. The shaded

components are the external components necessary to

accomplish both controlled power up and turn-on. For

minimum PCB area single gate logic can be used.

Insertion Sequence

Because of the staggered pin lengths in the CompactPCI

connector, as the board is inserted into the slot, the ground

bus plane is connected first via the longest pins referencing

the HIP1011B by way of the PWRON, OCSET and GND

pins through R4 and R3. Additionally the three-state driver,

U1 address line is referenced through R6.

Subsequently the medium length pins engage to connect the

+3.3V, +5V, +12V , -12V lines to the inputs , activ ating the

HIP1011B, and the 2 logic devices, U1 and U2. At this time the

HIP1011B is in control holding off all the MOSFET switches, as

PWRON is being held low. With the logic devices powered the

inverter U2 input is pulled high putting a low on the three-state

driver U1 input which is passed through to the PWRON pin.

Upon complete insertion the shortest length pin, “board

present” which is tied to ground on the backplane finally

contacts the inverter input. The inverter output pulls high

turning on the HIP1011B through U1 thus, the board is fully

powered on only upon complete insertion.

Fault Reset

If an overcurrent condition is detected on the board by the

HIP1011B the FLTN signal transitions low, once the

V

FLTN,TH

switched off protecting the system, the board and its

components. The system controller is notified of the fault

occurrence by the FLTN signal.

Reset of the faulted card is accomplished by a positive pulse

on the three-state

high Z state allowing R4 to pull the HIP1011B PWRON pin

low, resetting the HIP1011B. The HIP1011B switches turn

back on when U1

PWRON going high. The reset pulse can be generated by

either the system restart/reset to the master board or from

the master system board to any of the peripheral boards in

the system.

is reached all the switches are simultaneously

oe input. The pulse puts U1 output into a

oe input returns to a low state resulting in

5VOUT-12V

3.3VOUT

3.3V INPUT

Q1, Q2

-12V INPUT

12V INPUT

NOTES:

3. Each test point (TP) on HIP1011EVAL2 refers to device pin number.

4. SIGNAL_GND, SHIELD_GND and SHORTPIN_GND can be jumpered together for ease of evaluation.

5. HIP1011B devices can be placed into HIP1011EVAL2 board for evaluation or contact INTERSIL for a HIP1011B equipped evaluation board.

R2

HIP1011

M12VIN

FLTN

3V5VG

V

CC

12VIN

3VISEN

R3

FIGURE 6. HIP1011B CompactPCI APPLICATION CIRCUIT

3VS

OCSET

FLTN

M12VO

M12VG

12VG

GND

12VO

5VISEN

5VS

PWRON

C4

OUT

R1

C1

C2

R5

U1 U2

R6

R4

oe

PULSE HIGH TO RESET FAULT

5V INPUT

Q3, Q4

C3

+12VOUT

BOARD PRESENT

PIN ON

BACKPLANE

7

Page 8

HIP1011B

HIP1011 Split Load Application

All of the members of the HIP1011 family, including the

HIP1011B, can be used in an application where two

electrically isolated loads are to be powered from a common

bus. This may occur in a system that has a power

management feature controlled by a system controller IC

invokinga sleep or standby state. Thus one load can be shut

down while maintaining power to a second isolated circuit.

The circuit shown in Figure 7 shows the external FETs, and

sense resistor configuration for the 3.3V and/or 5V load that

has such a requirement. The HIP1011 is represented by pin

names in rectangles. Q1 and Q2 are the N-Channel FETs for

each load on this rail, these are sized appropriately for each

load. R1 and R2 are needed to pull down the supply slot pins

or load when slot power is disabled as the load discharge

FETs (Q3) on the VISEN pins are no longer attached to the

load. When power is turned off to the load these (~100Ω)

FETs turn on, thus some low current, (10mA) continues to

be drawn from the supply in addition to the sleep load

current resulting in a 4

VS

VISEN

3V5VG

PWRON

SYSTEM POWER MGT CONTROLLER

o

C die temperature rise.

V

SUPPLY

R

SENSE

Q3

Q1

Q2

TO FULL LOAD

R1

TO SLEEP LOAD

R2

HIP1011 High Power Circuit

Instances occur when a noncompliant card is designed for

use in a PCI environment. Although the HIP1011 family has

proven to be very design flexible, controlling high power

+12V supplies requires special attention. This is due to

thermal considerations that limit the integrated power

device on the +12V supply to about 1.5A. To address this

an external add on circuit as shown in Figure 8 enables the

designer to add the OC monitoring and control of a high

power +12V supply in addition to the 3 other power

supplies. The HIP1011 is represented by pin names in

rectangles.

This circuit primarily requires that an external P-Channel

MOSFET be connected in parallel to the internal HIP1011

PMOS device and that the discrete device have a much

lowerr

DS(ON)

to carry the majority of the current load. By monitoring the

voltage across the sense resistor carrying the combined

load current of both the internal and external FETs and by

using a comparator with a common mode input voltage

range to the positive rail and a low input voltage threshold

offset to reduce distribution losses, a high precision OC

detector can be designed to control a much higher current

load than can be tolerated by the HIP1011.

An alternative circuit for moderate current levels where both

accuracy and cost are lowered can be accomplished by a

single external P-Channel MOSFET in parallel with the

internal P-Channel MOSFET. For example, if 2X the OC

level is desired a 0.3Ω r

used thus approximately doubling the +12 IOUT before

latch-off. IOC

FET/r

DS(ON)

valuethan the internal PMOS device in order

P-Channel MOSFET can be

DS(ON)

TOTAL

= IOC

INTERNAL

(1 + r

DS(ON)

of internal

of external FET).

12VIN

FIGURE 7. SPLIT LOAD CIRCUIT

8

12VG

12VO

R2

Q1

R1

R

SENSE

TO +12V LOAD

FIGURE 8. HIGH POWER +12V CIRCUIT

12VIN

+

-

R3

FLTN

Q2

Page 9

Small Outline Plastic Packages (SOIC)

HIP1011B

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45

o

α

e

B

0.25(0.010) C AM BS

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension“E”doesnot includeinterleadflash orprotrusions.Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch)

10. Controllingdimension: MILLIMETER.Converted inch dimensions

are not necessarily exact.

A1

C

0.10(0.004)

M20.3 (JEDEC MS-013-AC ISSUE C)

20 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0926 0.1043 2.35 2.65 -

A1 0.0040 0.0118 0.10 0.30 -

B 0.013 0.0200 0.33 0.51 9

C 0.0091 0.0125 0.23 0.32 D 0.4961 0.5118 12.60 13.00 3

E 0.2914 0.2992 7.40 7.60 4

e 0.050 BSC 1.27 BSC H 0.394 0.419 10.00 10.65 h 0.010 0.029 0.25 0.75 5

L 0.016 0.050 0.40 1.27 6

N20 207

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However ,no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (321) 724-7000

FAX: (321) 724-7240

9

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...