Page 1

HIP0045

Data Sheet April 1999

1A/50V Octal Low Side Power Driver With

Serial Bus Control and Fault Protection

The HIP0045 is a logic controlled, eight channel Octal Serial

Pow er Low Side Driv er. The serial peripheral interface (SPI)

utilized by the HIP0045 is a serial synchronous bus compatible

with Intersil CDP68HC05, or equivalent, microcomputers. As

shown in the Block Diagram f or the HIP0045, each of the open

drain MOS Output Drivers have individual protection f or o v ervoltage and over-current. Each output channel has separate

output latch control with fault unlatch and diagnostic or status

feedback.Undernormal ON conditions, each output driveris in

a low voltage, high current state of saturated turn-on.

Comparators in the diagnostic circuitry monitor the output

drivers to determine if an out of saturation condition exists. If a

fault is sensed, the respective output driver f or Channels 0 - 5

haveovercurrentlatch-off .Channels6 and 7 are configured for

lamp drivers and have current limiting with ov er-temper ature

latch-off. Channels 0 and 1 have direct par allel drive control for

PWM applications and are ORed with the SPI Bus control. All

channels are SPI Bus controlled and sense the output states

for diagnostic feedbac k.

The HIP0045 is fabricated in a Power BiMOS IC process,

and is intended for use in automotive and other applications

having a wide range of temperature and electrical stress

conditions. It is particularly suited for driving relays,

solenoids and lamps in applications where low standby

power, high operating voltage, and high output current in

high ambient temperature conditions is required.

The HIP0045 is in a 20 lead plastic Pow er SOP (PSOP)

Packagewithanintegralcopper‘slug’toconductheatdirectly

to a PCB interface or heat sink on the bottom of the package.

Ordering Information

PART NO. TEMP. RANGE (oC) PACKAGE PKG. NO.

HIP0045AB -40 to 125 20 Ld PSOP M20.433

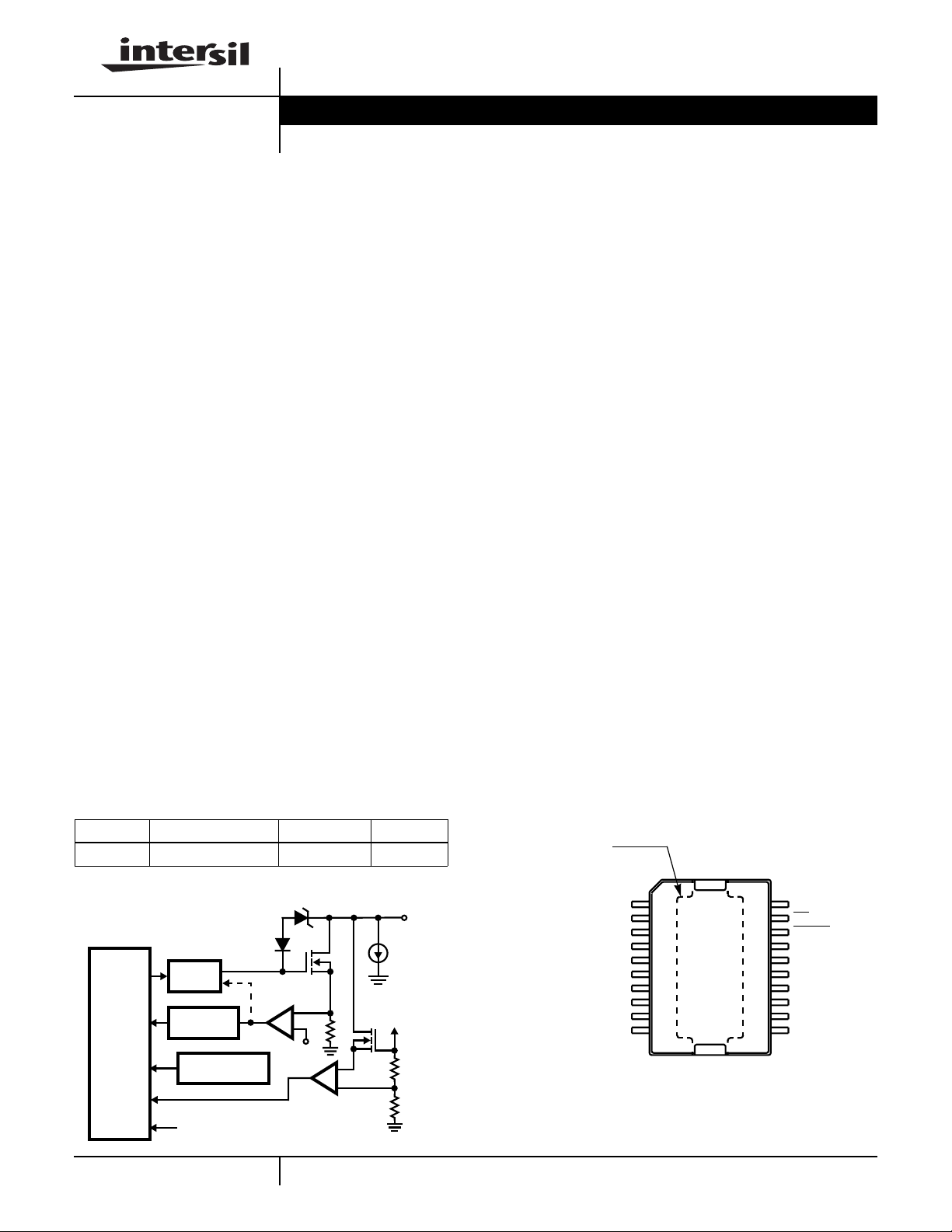

Driver Block Diagram

OUT

I

SK

V

CC

V

REF

SPI AND

DIRECT

INPUT

CONTROL

WITH

FAULT/

STATUS

OUTPUT

DRIVER

OC LATCH

(CH. 0-5)

OVER-TEMP.

DET. (CH. 6, 7)

RESET

OC LIMIT

(CH. 6, 7)

-

+

FAULT/STATUS

OC

REF

+

-

File Number

4047.2

Features

• Octal NDMOS Output Drivers in a High Voltage Power

BiMOS Process

• Over-Stress Protection - Each Output:

- Over-Current Protection . . . . . . . . . . . . . . . . . . . 1A Min

- Over-Voltage Clamp Protection . . . . . . . . . . . . 50V Typ

- Thermal Shutdown Protection (2 Channels)

• Open-Load Detection

• Power BiMOS Output Configuration

- Current Latch-Off Protection for 6 Channels; 2 with

External Drive Input and ORed with SPI Bus Control

- 2 Channels Configured for Lamp Drivers with Current

Limiting and Over-Temperature Latch-Off

• High Speed CMOS Logic Control

- SPI Bus Controlled Interface

- Individual Output Latch

- Individual Fault Unlatch and Feedback

- Common Reset Line

• Low Quiescent Current . . . . . . . . . . . . . . . . . . . 5mA Max

• Ambient Operating Temp. Range. . . . . . . -40

o

C to 125oC

Applications

• Automotive and Industrial Systems

• Solenoids, Relays and Lamp Drivers

• Logic and µP Controlled Drivers

• Robotic Controls

Pinout

HIP0045 (PSOP WITH HEAT SLUG)

TOP VIEW

INTEGRAL COPPER

HEAT SINK ‘SLUG’

FOR PCB CONTACT

OR EXT. HEAT SINK

GND

IN0

MISO

OUT0

OUT2

OUT4

OUT6

MOSI

SCK

GND

1

2

3

4

5

6

7

8

9

10

GND

20

CE

19

RESET

18

OUT7

17

OUT5

16

OUT3

15

OUT1

14

V

13

12

11

CC

IN1

GND

4-1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

Page 2

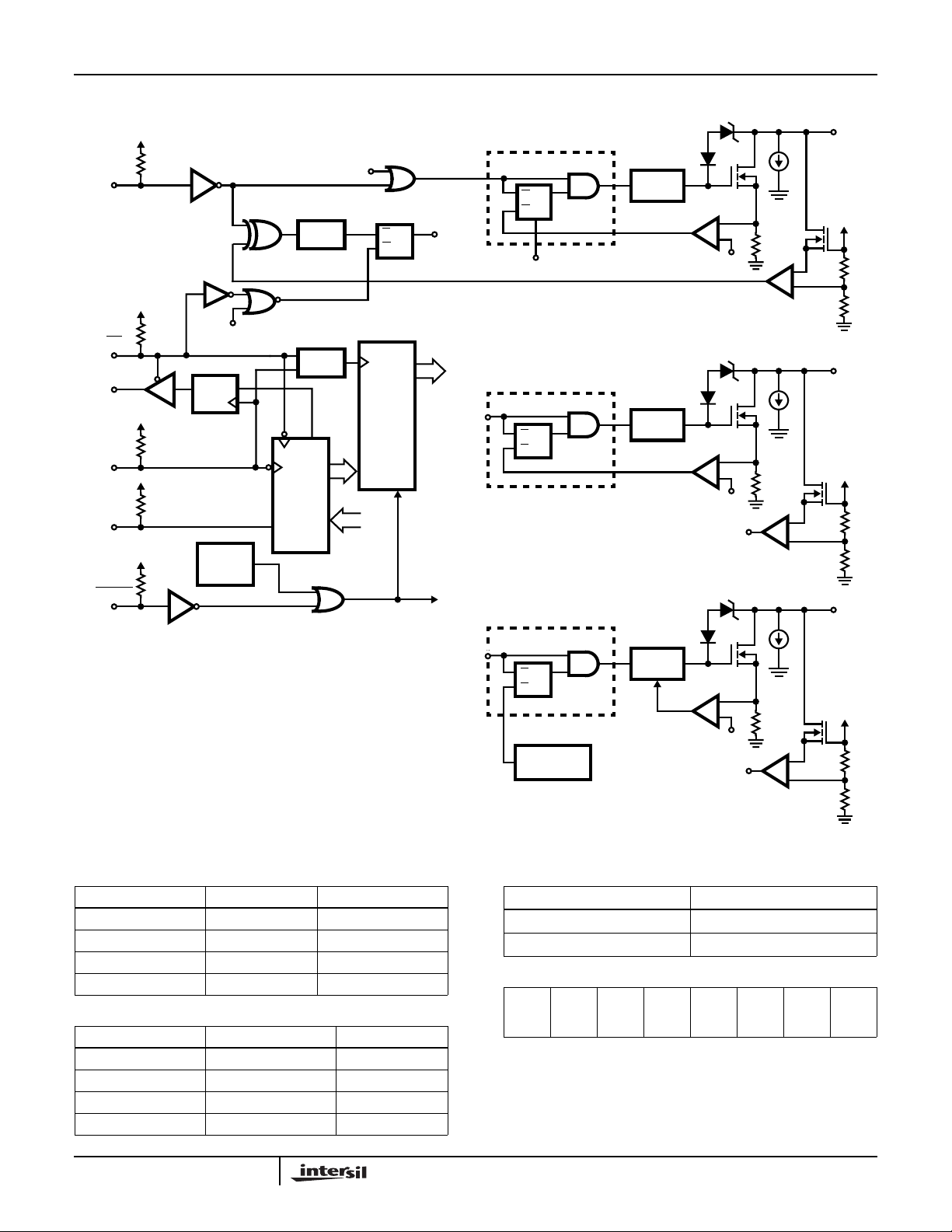

Detailed Block Diagram

HIP0045

SPI

REG

ON/OFF

FILTER

FILTER

OUT

Q0, 1

LATCH

FAULT LATCH

DIAG0-7

S

R

8-BIT

OUTPUT

LATCH

IN 0, 1

CE

MISO

SCK

MOSI

RESET

V

CC

V

CC

V

CC

V

CC

V

CC

RESET

Q

LOW

VOTAGE

RESET

D

SHIFT

IN

NOTES:

1. OC = Over-Current Voltage Ref. = 1.8V Typ.

2. ISK = Current Sink Pull-Down = 500µA Typ.

3. Diag0, 1 = Status bit when Q0, 1 controlling OUT0, 1.

4. Diag0, 1 = Fault bit when IN1, 0 controlling OUT0, 1.

5. Refer to text and Tables 6, 7 for diagnostic information.

Q

DIAG0, 1

STATUS/

FAULT

Q0-7

ON/OFF

LATCH

RESET

ON/OFF

LATCH

Q2 - 5

Q6, 7

OVERLOAD LATCH

QS

R

RESET

OVERLOAD LATCH

QS

R

OVERLOAD LATCH

QS

R

OVER-TEMP.

DET.

DRIVER

DRIVER

DRIVER

-

+

OC

REF

-

+

OC

REF

DIAG2-5

STATUS

-

+

OC

REF

DIAG6, 7

STATUS

I

OUT0, 1

SK

V

CC

V

+

REF

-

I

OUT2-5

SK

V

CC

+

V

REF

-

I

OUT6, 7

SK

V

CC

+

V

REF

-

Input to Output Control Tables

TABLE 1. OUTPUT 0

SPI BIT 0 IN0 OUT0

0 1 OFF

00ON

10ON

11ON

TABLE 2. OUTPUT 1

SPI BIT 1 IN1 OUT1

0 1 OFF

00ON

10ON

11ON

4-2

TABLE 3. OUTPUT 2 - 7

SPI BIT 2 - 7 OUT2 - 7

0 OFF

1ON

TABLE 4. OUTPUT CONTROL REGISTER, Q0 - 7

Q1 Q3 Q5 Q7 Q0 Q2 Q4 Q6

(D7I) (D6I) (D5I) (D4I) (D3I) (D2I) (D1I) (D0I)

MSB LSB

NOTE: The OutputControl Register bitsQ0 -7 have thesame order

asthe Diagnostic FailureRegister bits Diag0- 7as definedin Table 5.

Data bits D0I - D7I give the MOSI SPI serial data input flow

sequence.

Page 3

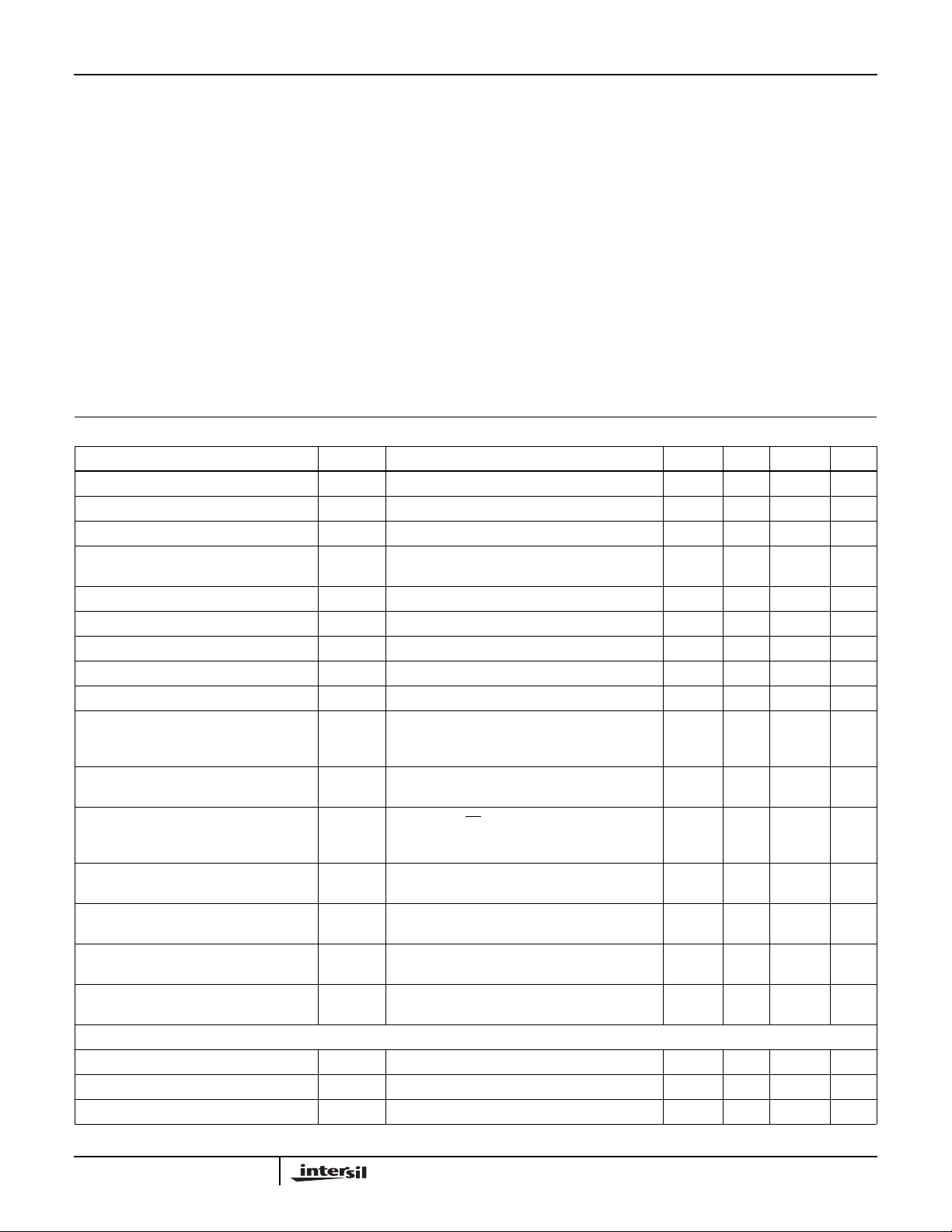

HIP0045

Absolute Maximum Ratings Thermal Information

Maximum Output Voltage, V

Peak Output Load Current, I

Continuous Output Load Current, I

Continuous Output Load Current, I

Total Average Current, I

OUT

Reverse Peak Current Drive, Any one Output, IRD; t ≤ 2ms . . . -3A

DC Logic Supply, VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3 to 7V

Input Voltage, All Inputs and Data Lines . . . . . . . -0.3 to VCC+0.3V

Operating Conditions

Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . -40oC to 125oC

Logic Supply Voltage, VCC . . . . . . . . . . . . . . . . . . . . . 4.5V to 5.5V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

6. θJA Rated with standard PC Board, θJC rated with infinite heat sink.

. . . . . . . . . . . . . . . . . . .-0.7 to V

OUT

. . . . . As Specified for ISC, I

LOAD

(All 8 Outputs ON) . . . . 0.5A

OUT

(Any one Output ON) . . 1A

OUT

OC

LIM

(All 8 Outputs) . . . . . . . . . . . . . . . 4.5A

Thermal Resistance (Typical, Note 6) θJA (oC/W) θJC (oC/W)

PSOP Package . . . . . . . . . . . . . . . . . . 40 2

Maximum Junction Temperature, TJ . . . . . . . . . . . . . . . . . . . .150oC

Maximum Storage Temperature Range, T

. . . . -55oC to 150oC

STG

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .265oC

Die Characteristics

Back Side Potential . . . . . . . . . . . . . . . . . . .V- (GND Pin, Heat Sink)

Electrical Specifications V

= 4.5V to 5.5V, TA = -40oC to 125oC, Unless Otherwise Specified

CC

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Standby Current, No Load I

Supply Current, Full Load I

Output Clamping Voltage (Note 7) V

Output Clamping Energy E

CCO

No Load - - 5 mA

All Outputs ON, 0.5A Load Per Output - - 5 mA

CC

OCILOAD

1ms Single Pulse Width, TA = 25oC,

OC

(Refer to Figure 4 for SOA)

Output Leakage Current 1 (Note 8) I

Output Leakage Current 2 (Note 8) I

Output Leakage Current 3 (Note 8) I

Drain-to-Source On Resistance, OUT0 - 7 r

Output Capacitance C

Turn-On Delay, OUT0, 1 t

Turn-On Delay, OUT2 - 7 t

Turn-Off Delay t

Turn-On Voltage Slew-Rate, OUT2 - 7 For V

Turn-On Voltage Slew-Rate, OUT0, 1 ForV

Turn-Off Voltage Slew-Rate, OUT0 - 7 For V

Turn-Off Voltage Slew-Rate, OUT0 - 7 For V

O LEAK1VOUT

O LEAK2VOUT

O LEAK3VOUT

DSONILOAD

OUTVOUT

d(ON)RL

d(ON)RL

d(OFF)RL

dV

-------------------

dV

-------------------

dV

----------------------

dV

----------------------

ON1

dt

ON2

dt

OFF1

dt

OFF2

dt

V

IN0,1

V

BATT

V

BATT

V

IN0,1

V

BATT

RL = 500Ω

RL = 500Ω

RL = 500Ω

V

BATT

FAULT PARAMETERS

Reverse Current Drive, OUT0 - 7 I

Reverse Voltage Drop, OUT0 - 7 V

∆ICC during Reverse Current Drive ∆I

RD

RDIOUT

CCIOUT

= 0.5A, Output Programmed OFF 45 - 62 V

20 45 - mJ

= 25V, Outputs OFF - - 100 µA

= 16V, Outputs OFF - - 100 µA

= 16V, Outputs OFF, VCC = 1V - - 10 µA

= 0.5A; TJ = 150oC - - 1.5 Ω

= 16V, f = 1MHz - - 20 pF

= 500Ω, VCE = 50% to V

= 50% to V

OUT

= 0.9 x V

OUT

= 0.9 x V

,

BATT

BATT

,

--5µs

= 16V

= 500Ω, VCE = 50% to V

OUT

= 0.9 x V

BATT

,

--10µs

= 16V

= 500Ω, VCE = 50% to V

= 50% to V

OUT

= 0.9 x V

OUT

= 0.1 x V

,

BATT

BATT

,

--10µs

= 16V

= 90%to 30% ofV

OUT

= 90% to30% of V

OUT

= 30% to90% of V

OUT

= 30% to 80% of V

OUT

BATT;VBATT

BATT;VBATT

BATT;VBATT

OC;

= 16V,

= 16V,

= 16V,

- 0.7 3.5 V/µs

- 2 10 V/µs

- 2 10 V/µs

- 2 15 V/µs

= 0.9 x VOC, RL = 500Ω

-500 - - mA

= -3A, t ≤2ms -1.5 - - V

= -3A, t ≤2ms - - 100 mA

4-3

Page 4

HIP0045

Electrical Specifications V

= 4.5V to 5.5V, TA = -40oC to 125oC, Unless Otherwise Specified (Continued)

CC

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Open Load Threshold Voltage V

Open Load Pull-Down Current I

Over-CurrentShutdown Threshold, OUT0 - 5 I

Short Circuit Current Limit, OUT6, 7 I

Short Circuit Shutdown Delay, OUT0 - 5 t

DisableFault DetectionTime,Channel IN0,

t

Open Load Fault Condition, Fault Detected If

REF

V

< V

OUT

REF

No Load, V

SK

VCC = 5V 1.05 1.4 2 A

SC

VCC = 5V 1.05 1.4 1.75 A

LIM

SC

DF

OUT

= V

= 16V 20 - 100 µA

BATT

0.32 x

V

CC

- 0.4x

0.2 - 12 µs

15 - 50 µs

IN1 After Input Switch Transition

Over-Temperature Detection Threshold T

OFF

155 165 175

LOGIC INPUTS (IN0, IN1, MOSI, SCK, RESET, CE)

Threshold Voltage at Falling Edge VT- 0.2xV

--V

CC

Threshold Voltage at Rising Edge VT+ - - 0.7xV

Hysteresis Voltage V

Input Current I

Input Pull-Up Resistance R

Input Capacitance C

Input Frequency, IN0, IN15 f

Active Supply Range for Reset State

V

HCC_RS

Change at RESET Pin

Low VCC Active Reset Threshold V

LCC_RST

VT+ - VT- 0.65 - - V

H

VIN = V

IN

IN

IN

IN

CC

RESET Pin Forced Reset. (Note: Normal V

Functional Operating Range is 4.0V to 5.5V)

T

Low VCC Forced Reset, (Low Voltage Reset

Active for 0 < VCC < V

LCC_RST

CC

)

- - +10 µA

50 80 200 kΩ

- - 10 pF

DC - 2 kHz

3.1 - 5.5 V

3.1 - 4 V

LOGIC OUTPUT (MISO)

Data Output LOW Voltage V

Data Output HIGH Voltage V

SOLISO

SOHISO

= -3.2mA - 0.2 0.4 V

= -4mA VCC-

--V

0.4V

Output Three-State Leakage Current I

Output Capacitance C

SOL

CE = High, 0V ≤ VSO≤ V

f

SO

= 3MHz - - 10 pF

OPER

CC

-10 - +10 µA

V

V

CC

o

C

V

CC

Serial Peripheral Interface Timing (MOSI, MISO Load Capacitor = 100pF, See Figure 1)

PARAMETER SYMBOL TEST CONDITION MIN TYP MAX UNITS

Clock Frequency, 50% Duty Cycle f

Enable Lead Time

(SCK Change Low to High after CE = Low)

Enable Lag Time

(Time for SCK Low before CE goes High)

Minimum Time SCK = High t

Minimum Time SCK = Low t

Data Setup Time (SCK Change from High to Low

after MOSI Data Valid)

Data Hold Time (MOSI Data Hold Time SCK

Change from High to Low)

Enable Time from CE = Low to Data at MISO t

Disable Time

(Time for CE Low to High to Output Data Float)

4-4

CLK

t

LEAD

t

LAG

WSCKH

WSCKL

t

SU

t

H

EN

t

DIS

3 - - MHz

100 - - ns

150 - - ns

160 - - ns

160 - - ns

20 - - ns

-20ns

- - 100 ns

- - 100 ns

Page 5

HIP0045

Serial Peripheral Interface Timing (MOSI, MISO Load Capacitor = 100pF, See Figure 1)

PARAMETER SYMBOL TEST CONDITION MIN TYP MAX UNITS

Data Valid Time, SCK to Data at MISO Valid t

Time forSCK Low beforeCE Low (SCKSetup Time

V

t

SCK_LEAD

before CE High to Low Change)

Time for SCK High after CE High t

SCK_LAG

CE Pulse Filter Time - Note 9 - ns

NOTES:

7. The MOSFET Output Drain is internally clamped with a Drain-to-Gate zener diode that turns-on the MOSFET; holdingthe Drain at the Output

Clamp Voltage, VOC.

8. The measurement ofOutput Leakage Current includesthe Output Pull-Down Current, ISK. EachOutput has a CurrentPull-Down which is used

to detect open load fault conditions.

9. The digital filter time for the output latch function determines if the output latch function will be enabled. The output latch function will only be

enabled if a positive CE slope occurs after 8 SCK clock cycles or a multiple of 8 SCK cycles since the last CE negative slope change.

VCC = 5V ±0.1V - - 100 ns

100 - - ns

150 - - ns

Timing Diagrams

CE

CE

(INPUT)

SCK

(INPUT)

MISO

(OUTPUT)

MOSI

(INPUT)

SCK

HIGH

Z

(CPOL = 0, CPHA = 1)

t

t

t

EN

WSCKH

LEAD

LAST BIT

TRANSMITTED

t

SU

MSB 6 5 4 3 2 1 LSB

INTERNAL STROBE FOR DATA CAPTURE

FIGURE 1A. DATA AND CLOCK TIMING DIAGRAM

t

LAG

t

WSCKL

D7O D6O D0O

t

V

D7I D6I D0I

t

H

t

DIS

FAULT-INDUCED

TURN-OFF

DRIVER

OUTPUT

OLD

4-5

FIGURE 1B. SPI TIMING DIAGRAM

t

DON

t

DOFF

NEW

t

DF

Page 6

HIP0045

Timing Diagrams

OUTPUTS

RESET

CE

SCK

MOSI

MISO

(Continued)

76543210

76543210

OLD NEW

FIGURE 2. BYTE TIMING DIAGRAM WITH ASYNCHRONOUS RESET

Signal Pin Descriptions

Power Output Drivers, OUT0 - OUT7 - The input and

output bits corresponding to Output 0 thru Output 7 are

transmitted and received most significant bit (MSB) first via

the SPI bus. Outputs OUT0 - 5 are provided with overcurrent shutdown. Current Limiting and Thermal Shutdown

are provided on OUT6, 7 for application use as Lamp

Drivers. After a fault shutdown, the control lines remain

active. The fault latches must be cleared by turning the

output off and on to reset the output to an ON state. OUT1, 2

latches may be cleared by the

RESET - Active low reset input. An internal pull-up is

provided on-chip. When this input line is low, all output

drivers are turned-off and the OUT1, 2 fault latches are

cleared. An internal low voltage reset is ORed with the

RESET input. When VCC is less than V

internal reset is active.

CE - Active low chip enable. The falling edge of CE loads the

shift register with the output status bits. Data is transferred

from the shift register to the outputs on the rising edge of CE.

The output driver for the MISO pin is enabled when CE goes

low .CE must be a logic low prior to the first serialclock(SCK)

and must remain low until after the last (eighth) serial clock

cycle. All eight MOSI bits of input data must be loaded in the

same sequence of SCK clock input. A digital filter is used in

the

CE line to insure that 8 (or a multiple of 8) clock cycles

occurs while

period, t

CE is active low. After SCK is low for a short

; CE maybe changed from low to high to latch the

LAG

input data. A lowlevel on CE alsoactivatesan internaldisable

circuit used for unlatching output states that are in a fault

mode as sensed by an out of saturation condition. A high on

CE forces MISO to a high impedance state. Also, when CE is

high, the octal driver ignores the SCK and MOSI signals.

IN0, 1 - IN0 and IN1 are Channels 0 and 1 direct parallel

input controls. Refer to ‘Special Input Conditions for Channel

0, 1‘ in the following te xt.

RESET pin.

LCC_RST

, the

RESET

FAULTS

SCK, MISO, MOSI - Refer to the ‘Serial Peripheral Interface’

(SPI) section in the following text.

Serial Peripheral Interface (SPI)

The Serial Peripheral Interface (SPI) is a serial synchronous

bus forcontrol and data transfers.The Clock (SCK), which is

generated by the microcomputer, is active only during data

transfers. In systems using CDP68HC05 family

microcomputers, the inactive clock polarity is determined by

the CPOL bit in the microcomputer’s control register. The

CPOL bit is used in conjunction with the clock phase bit,

CPHA to produce the desired clock data relationship

between the microcomputer and octal driver. The CPHA bit

in general selects the clock edge which captures data and

allows it to change states. For the HIP0045, the CPOL bit

must be set to a logic zero and the CPHA bit to a logic one.

Configured in this manner, MISO (output) data will appear

with every rising edge of the SCK clock pulse, and MOSI

(input) data will be latched into the shift register with every

falling edge of the SCK clock pulse. Also, the steady state

value of the inactive serial clock, SCK, will be at a low level.

Timing diagramsforthe serial peripheral interface are shown

in Figure 1.

SPI Signal Descriptions

MOSI (Master Out/Slave In) - Serial data input. Data bytes

are shifted in at this pin, most significant bit (MSB) first. The

data is passed directly to the shift register which in turn

controls the latches and output drivers.

MISO (Master In/Slave Out) -Serialdataoutput.Data bytes

are shifted out at this pin, most significant bit (MSB) first.

This pin is the serial output from the shift register and is

three stated when

information is given in Tables 6 and 7. Determination of the

fault condition may be done as a software sequence, based

on MOSI data latched into the shift register and subsequent

data clocked out of the MISO pin.

CE is high. Diagnostic Failure Register

4-6

Page 7

HIP0045

SCK - Serial clock input. The SCK signal clocks the shift

register and new MOSI (input) data will be latched into the

shift register on every falling edge of SCK. The SCK phase

bit, CPHA=1 and the polarity bit, CPOL=0, must be set in the

microcomputer’s control register.

Functional Descriptions

The HIP0045 is a low quiescent power, high voltage, high

current, octal, serial low side driver featuring eight channels

of open drain MOS output drivers. Referring to the Detailed

Block Diagram, the drivers have low r

saturation voltage with over-voltage drain-to-gate zener

clamp circuits. Each output is short circuit protected and

suited for driving resistive or inductive loads such as

solenoids, relays and lamps. Data is transmitted to the

device serially using the Serial Peripheral Interface (SPI)

protocol. Each channel is independently controlled by an

output latch and a common

RESET line that disables all

eight outputs. Byte timing with asynchronous reset is shown

in Figure 2.

CDP68HC05C4

MICROCOMPUTER

PORT

MOSI

MISO

SCK

RESET

FIGURE 3. TYPICAL MICROCOMPUTER INTERFACE WITH

THE HIP0045

The circuitreceives8-bit serial data bymeans of the serial input

(MOSI), andstoresthis data in an internal registertocontrol the

output drivers. The serial output (MISO) provides 8-bit

diagnostic data representing the voltage lev el at the driver

output. This allows the microcomputer to diagnose the

condition at the output drivers. The deviceisselectedwhenthe

chip enable (

CE) line is low . When (CE) is high, the de vice is

deselected and the serial output (MISO) is placed in a threestate high impedance mode. The device shifts serial data on

the rising edge of the serial clock (SCK), and latches data on

the falling edge. On the rising edge of chip enable (

input data from the shift register is latched to control the output

drivers. The falling edge of chip enable (

output drivers fault information back to the shift register. The

output drivers have low ON v oltage at r ated current, and are

monitored by a comparator for an out of saturation condition, in

which case the output driver with the fault becomes unlatched

and diagnostic data is sent to the microcomputer via the MISO

line. A typical microcomputer interface circuit is shown in

Figure 3.

and low

DSON

HIP0045

CE

MOSI

MISO

SCK

RESET

CE), new

CE) transfers the

SPI Shift Register

The SPI shift register has both serial and parallel inputs and

outputs. Serial output and input data are simultaneously

transferred to and from the SPI bus. The serial input data is

parallel latched into the 8-Bit Output Latch of the HIP0045 at

the end of a data transfer. Diagnostic data, Diag0-7 is

transferred to the shift register when

CE goes low at the

beginning of a data transfer cycle.

8-Bit Output Latch

The 8-Bit Output Latch is used to control the output drivers.

New serial data is transferred from the shift register to the

8-Bit Output Latch when CE goes high. The 8-Bit Output

Latch is cleared by an active low

RESET signal.

Output Drivers

The output drivers provide an active low output of 500mA

nominal with current limiting set to greater than 1.05A to

allow for high inrush currents. In addition, each output is

provided with a voltage drain-to-gate clamp circuit to limit

inductive transients. Each output driver is also monitored by

a comparator for an out of saturation condition. If the output

voltage of an ON output pin exceeds the saturation voltage

limit, a fault latch turns off the output. The threshold

comparators are used to detect shorts to the power supply,

shorts to ground and open loads. Each comparator provides

status data to the shift register for diagnostic feedback. An

internal pull-down current, I

at each output will provide an

SK

indicator for low output voltage if the output is programmed

OFF and the output line is open. Refer to Tables 6 and 7 for

Fault information versus output control and V

V

is the out-of-saturation threshold for an ON state.

REF

When the output is switched off and V

REF

. Note that

REF

is low, an open-

load or ground fault is indicated.

CE High to Low Transition

When CE is low the three-state MISO pin is enabled. On the

falling edge of

CE, diagnostic and status data from the

output voltage comparators will be latched into the shift

register.Duringthetime that

CE is low,databytescontrolling

the output drivers are shifted in at the MOSI pin most

significant bit (MSB) first. Tables 1, 2 and 3 define the logic

state for control of each output and Table 4 defines the

control bit structure.

CE Low to High Transition

When the last serial data bit has been shifted into the MOSI

pin,

CE pinispulled high to transferdatafrom the shift register

into the 8-bit parallel output latch to activate the outputs. The

serial clock input pin (SCK) should be low during

transitionstoavoid falseclockingof the shift register.The SCK

input isgatedby

CE sothattheSCK input is ignored when CE

is high.

CE

4-7

Page 8

HIP0045

Detecting Fault Conditions

Fault conditions ma y be checked as follo ws: SCK is alw ays

low when

output is taken out of the three-state mode and the Output

status information is latched into the shift register.While

low , data bits in the shift register are tr ansferred to the MISO

output on each positive SCK clock transition and data bits

present at theMOSIinputare transferred into the shiftregister

on each negative transition of SCK. To verify Status and

Diagnostic conditions, clock in a new control byte and wait

approximately 150µs to allow the outputs to settle. Clock in

the same control byte and compare this to the data output at

the MISO pin. If there is a disparity , use Tables 5, 6 and 7 to

determine the faultorstatuscondition. (Use Tables 1,2,3and

4 to establish the ON/OFF conditions for each output).

Based on the needs of the application, a software sequence

should be programmed into the microcontroller to set the

corrective action of each fault condition.

Diag1 Diag3 Diag5 Diag7 Diag0 Diag2 Diag4 Diag6

(D7O) (D6O) (D5O) (D4O) (D3O) (D2O) (D1O) (D0O)

MSB LSB

NOTE:

10. The Diagnostic Failure Register bitsDiag0 -7 have the same

OUTPUT

STATE

CE is changing. When CE goes low, the MISO

CE is

TABLE 5. DIAGNOSTIC FAILURE REGISTER STRUCTURE

order as the Control Register bits Q0 - 7 as defined in Table 4.

Data bits D0O - D7O give the MISO SPI serial output flow

sequence.

TABLE 6. DEFINITION OF Diag0, 1 FAULT BITS FOR OUT0,

1 IN PARALLEL-CONTROLLED MODE

STATUS

OFF >V

OFF <V

ON <V

ON >V

V

REF

REF

REF

REF

REF

FAULT

BIT

H No Fault

L Open Load or GND Short

H No Fault

L Short to V

FAULT

MODE

BATT

Special Conditions for Channel 0, 1

Referring to the Detailed Block Diagram, Channel’s 0, 1 are

configured to externally provide control of the ON/OFF state.

The inputs, IN0 and IN1, are ORed with the SPI ON/OFF

control bit. In this configuration with IN0 and IN1 high, SPI

control latches Diag0andDiag1 as status bits. When the IN0

and IN1 inputs are active, a fault condition is detected by a

comparison of IN0 and IN1 to OUT0 and OUT1 respectively

causing the Fault Detector to latch a fault bit. The resulting

Faultoutputis latched as diagnostic bit, Diag0 or Diag1. The

Diag0 and Diag1 outputs give the status or fault condition of

the output drivers as shown in Table 6. Fault detection is

disabled during switching/settling time.

The Diag0 and Diag1 bits from Channel 0 and 1 respectively

indicate a fault when the FAULT BIT is Low, given IN1 and

IN0 control. Otherwise Diag0 and Diag1 are status bits when

controlled by the SPI input. Note that the SPI Bit, given in

Tables 1 and 2 overrides the ON state control from IN0

and IN1.

1000

100

ENERGY (mJ)

SAFE OPERATING AREA

BELOW LINE

10

0.1 1 10 100

TIME (ms)

FIGURE 4. MAXIMUM SINGLEPULSE ENERGY SAFE

OPERATING AREA FOR EACH CLAMPED

OUTPUT DRIVER, TA = 25oC

T ABLE 7. DEFINITION OF Diag0-7 STATUS BITS FOR OUT0-7

OUTPUT

STATE

OFF >V

OFF <V

ON <V

ON >V

NOTES:

11. For Channel 0 (Diag0) and Channel 1 (Diag1):

Fault Bit High = No Fault; Fault Bit Low = Fault Occurred.

12. V

REF

Refer to the Electrical Specification for the V

V

REF

STATUS

is thethreshold referencelevel for detectingan OpenLoad.

REF

REF

REF

REF

STATUS

BIT

H No Fault

L Open Load or GND Short

L No Fault

H Short to V

or Over-Temperature Fault

(Chan. 6, 7)

FAULT

MODE

(Chan. 0-7);

BATT

voltage level.

REF

4-8

Page 9

HIP0045

Power Small Outline Plastic Package (PSOP)

SEATING

PLANE

E2

2 PLACES

(DATUM

S

A

S

CB

M

0.25

A3

D1

0.15

REF.

SLUG

N

D2

3.10 REF.

HEAT

PLANE A)

2 PLACES

-B-

DETAIL "A"

PIN 1

MARKER

E3

E1

E

A1

o

3

2

1.10 MAX. X 45

-A-

1

A2

SEE DETAIL "A"

B

L

1.60 REF.

D

-HA

C0.10

SEATING

PLANE

L1

B

-C-

e

GAUGE

PLANE

o

0-8

S

B

S

CA

M

0.25

b

M20.433

20 LEAD POWER SMALL OUTLINE PLASTIC

PACKAGE

INCHES MILLIMETERS

SYMBOL

0.122 0.142 3.10 3.60

A

A1 0.004 0.012 0.10 0.30 A2 0.118 0.130 3.00 3.30 A3 0.000 0.004 0.00 0.10 -

b 0.016 0.021 0.40 0.53 6, 7

b1 0.016 0.020 0.40 0.50 6, 7

c 0.009 0.013 0.23 0.32 7

c1 0.009 0.011 0.23 0.29 7

D 0.622 0.630 15.80 16.00 3

D1 0.496 0.512 12.60 13.00 D2 - 0.043 - 1.10 -

E 0.547 0.571 13.90 14.50 E1 0.429 0.437 10.90 11.10 4

E2 - 0.114 - 2.90 E3 0.228 0.244 5.80 6.20 -

e 0.050 BSC 1.27 BSC -

L 0.031 0.043 0.80 1.10 5

L1 0.014 BSC 0.35 BSC -

N20 20-

NOTES:

1. Dimensioning and tolerancing per ANSI Y14.5M-1982.

2. "C" isa reference datum.Seating plane is definedby

lead tips only.

3. DimensionD doesnotinclude moldflash, protrusions

or gate burrs. Mold flash, protrusions or gate burrs

shall not exceed 0.15 per side. D measured at -H-.

4. Dimension E1 does not include interlead flash or protrusion. Interlead flash or protrusion shall not exceed

0.15 per side. E1 measured at -H-.

5. Dimension "L" isthe length of terminalfor soldering to

a substrate.

6. The lead width dimension doesnot include dambar

protrusion. Allowable dambar protrusion shall be

0.08mm total in excess ofthe lead width dimension at

maximum material condition.

7. Section"B-B" tobedeter mined at0.10mm to0.25mm

from the lead tip.

8. Controlling dimension: MILLIMETER.

9. Dimensions conform withJEDEC OutlineMO-166AA

Issue B.

17.15

N

13.92

NOTESMIN MAX MIN MAX

-

Rev. 0 3/96

4.09

1.52

b1

c

SECTION "B-B"

4-9

4.22

7.26

c1

b

2.87

0.71

1

e

LAND PATTERN

4.09

2.21

Page 10

HIP0045

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only .Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. Howe ver, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

4-10

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...