August 1997

HI-574A, HI-674A,

HI-774

Complete, 12-Bit A/D Converters

with Microprocessor Interface

Features

• Complete 12-Bit A/D Converter with Reference and Clock

• Full 8-Bit, 12-Bit or 16-Bit Microprocessor Bus Interface

• Bus Access Time. . . . . . . . . . . . . . . . . . . . . . . . . .150ns

• No Missing Codes Over Temperature

• Minimal Setup Time for Control Signals

• Fast Conversion Times

- HI-574A (Max) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25µs

- HI-674A (Max) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15µs

- HI-774 (Max) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9µs

• Digital Error Correction (HI-774)

• Low Noise, via Current-Mode Signal

Transmission Between Chips

• Byte Enable/Short Cycle (A

Input)

O

- Guaranteed Break-Before-Make Action, Eliminating

Bus Contention During Read Operation. Latched by

Start Convert Input (T o Set the Conversion Length)

• Supply Voltage. . . . . . . . . . . . . . . . . . . . . ±12V to ±15V

Applications

• Military and Industrial Data Acquisition Systems

• Electronic Test and Scientific Instrumentation

• Process Control Systems

Description

The HI-X74(A) is a complete 12-bit, Analog-to-Digital

Converter, including a +10V reference clock, three-state outputs and a digital interface for microprocessor control. Successive approximation conversion is performed by two monolithic

dice housed in a 28 lead package. The bipolar analog die features the Intersil Dielectric Isolation process, which provides

enhanced AC performance and freedom from latch-up.

Custom design of each IC (bipolar analog and CMOS digital)

has yielded improved performance over existing versions of

this converter. The voltage comparator features high PSRR

plus a high speed current-mode latch, and provides precise

decisions down to 0.1 LSB of input overdrive. More than 2X

reduction in noise has been achieved by using current

instead of voltage for transmission of all signals between the

analog and digital ICs. Also, the clock oscillator is current

controlled for excellent stability over temperature.

The HI-X74(A) offers standard unipolar and bipolar input

ranges, laser trimmed for specified linearity, gain and offset

accuracy. The low noise buried zener reference circuit is

trimmed for minimum temperature coefficient.

Power requirements are +5V and ±12V to ±15V, with typical

dissipation of 385mW (HI-574A/674A) and 390mW (HI-774) at

12V. All models are available in sidebrazed DIP, PDIP, and

CLCC. For additional HI-Rel screening including 160 hour b urnin, specify “-8” suffix. For MIL-STD-883 compliant parts, request

HI-574A/883, HI-674A/883, and HI-774/883 data sheets.

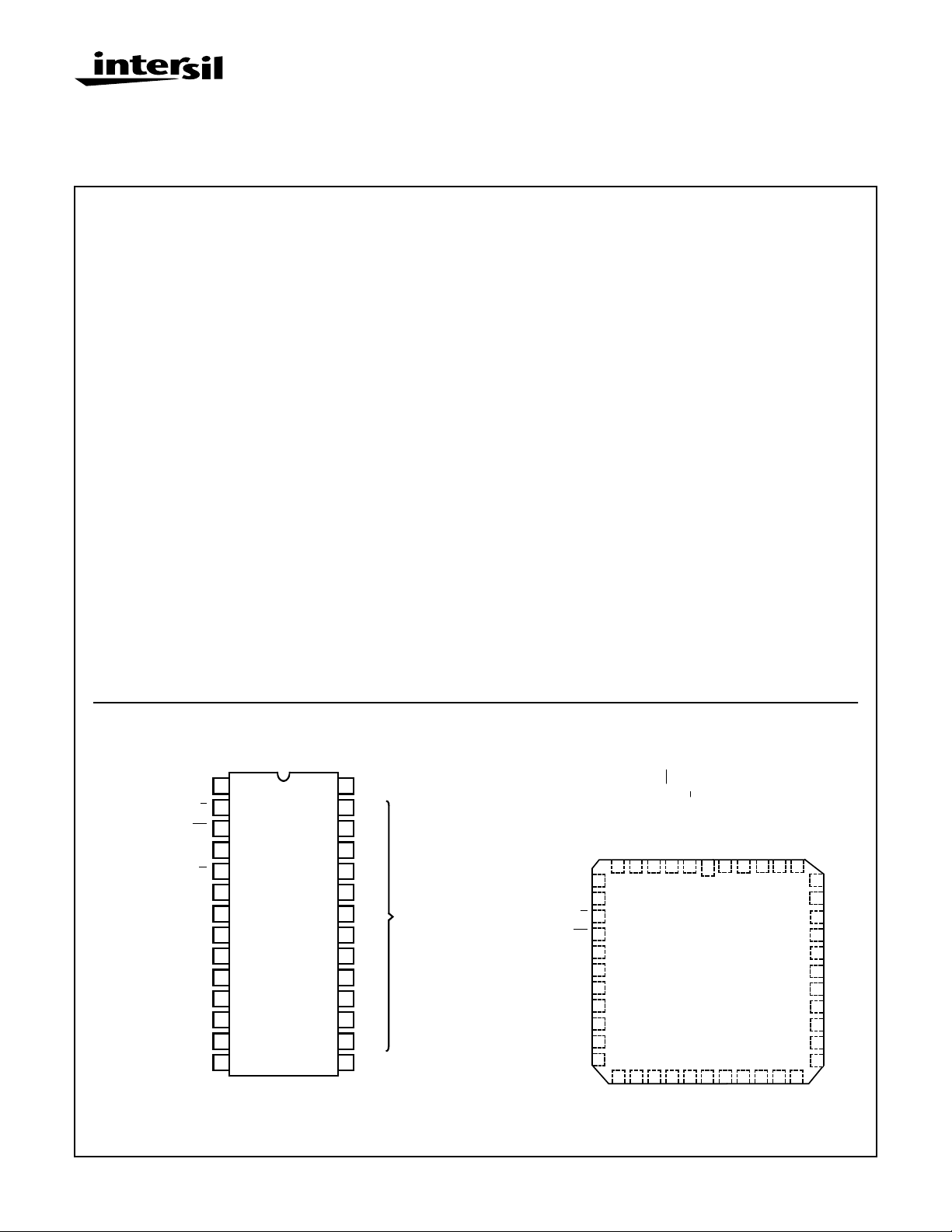

Pinouts

(PDIP, SBDIP)

TOP VIEW

+5V SUPPL Y, V

DATA MODE SEL, 12/

CHIP SEL, CS

BYTE ADDR/SHORT

CYCLE, A

READ/CONVERT , R/

CHIP ENABLE, CE

+12V/+15V SUPPL Y, V

+10V REF , REF OUT

ANALOG

COMMON, AC

REFERENCE INPUT

-12V/-15V SUPPLY , V

BIPOLAR OFFSET

BIP OFF

10V INPUT

20V INPUT

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143 | Copyright © Intersil Corporation 1999

LOGIC

CC

EE

1

2

8

3

4

O

5

C

6

7

8

9

10

11

12

13

14

28

STATUS, STS

27

DB11

26

DB10

25

DB9

24

DB8

23

DB7

22

DB6

21

DB5

20

DB4

19

DB3

18

DB2

17

DB1

16

DB0

DIG COMMON,

15

DC

MSB

DIGITAL

DATA

OUTPUTS

LSB

READ CONVERT, R/C

CHIP ENABLE, CE

+15V SUPPLY, V

+10V REFERENCE,

ANALOG COMMON, AC

REFERENCE INPUT,

REF OUT

-15V SUPPLY, V

BIPOLAR OFFSET,

6-952

REF IN

BIP OFF

NC

NC

CC

EE

NC

6 3

7

8

9

10

11

12

13

14

15

16

17

(CLCC)

TOP VIEW

BYTE ADDRESS/

NC

NC

4

NCNCNC

10V

20V

O

CS

SHORT CYCLE, A

CHIP SELECT,

SELECT, 12/8

DATA MODE

25

LOGIC

+5V SUPPLY, V

STATUS, STS

DB11, MSB

DB10

NC

NC

(LSB) DB0

NC

40414243

39

38

37

36

35

34

33

32

31

30

29

2827262524232221201918

DB1

1

NC

44

DC

DIG

COMMON,

NC

File Number 3096.4

NC

NC

DB9

DB8

DB7

DB6

DB5

DB4

DB3

NC

DB2

HI-574A, HI-674A, HI-774

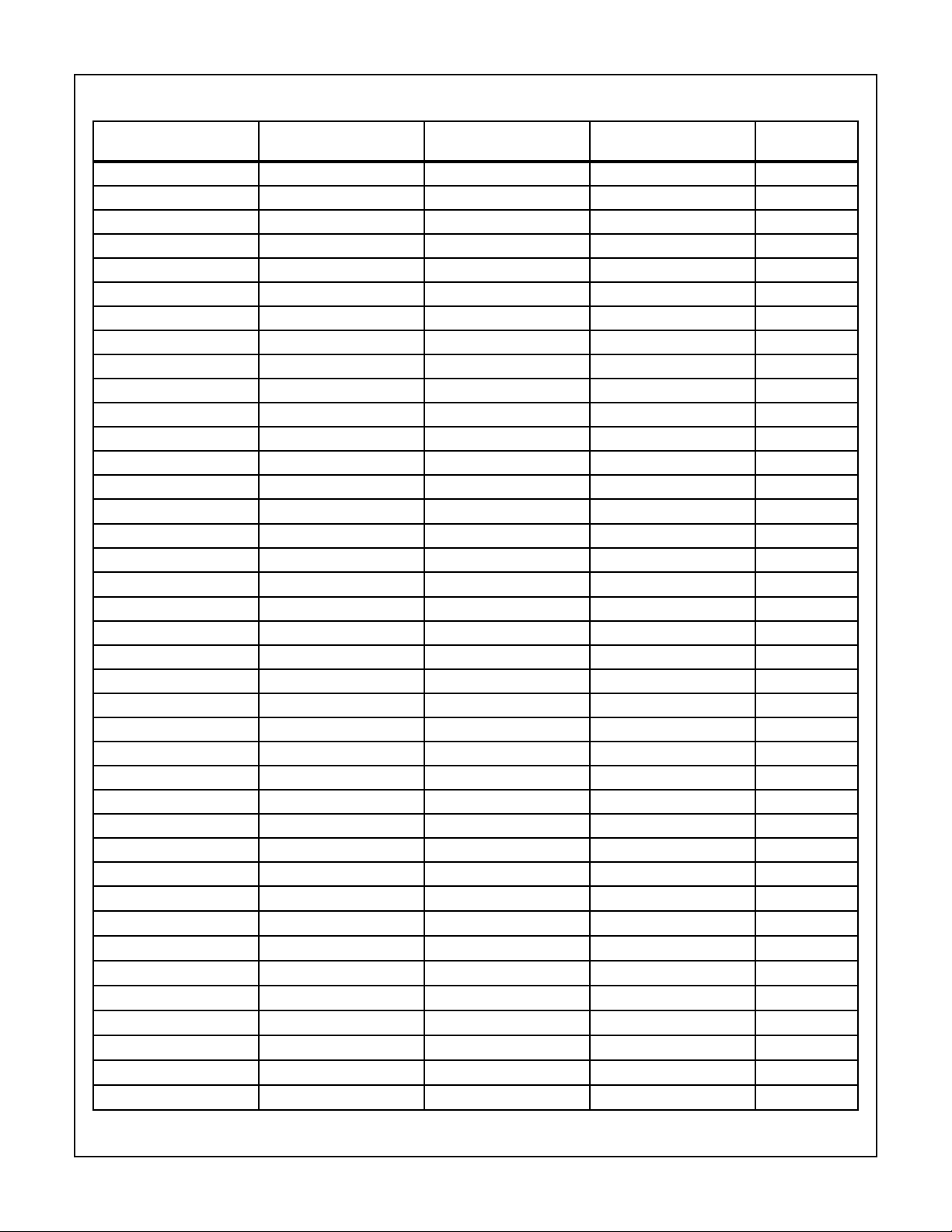

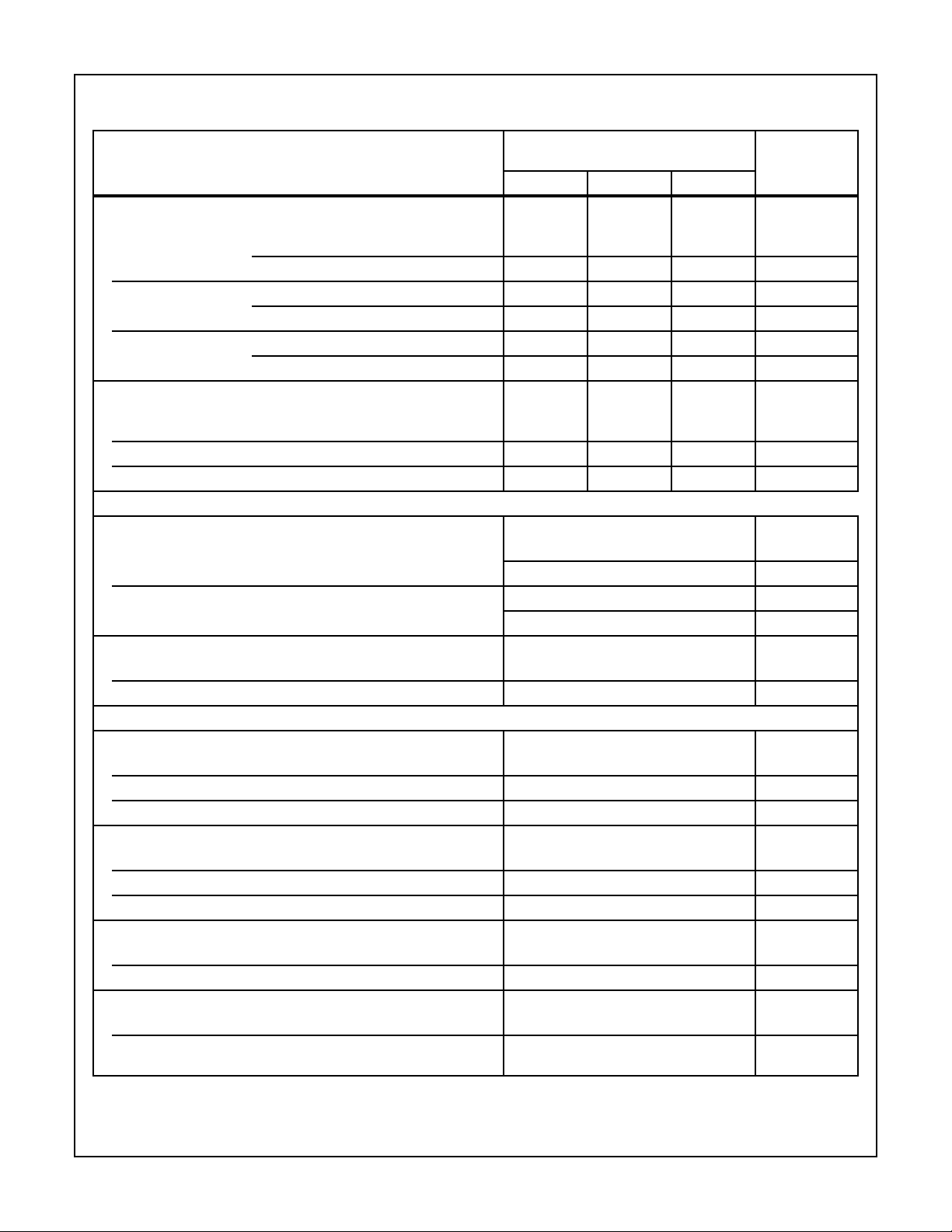

Ordering Information

TEMPERA TURE RANGE

PART NUMBER INL

HI3-574AJN-5 ±1.0 LSB 0 to 75 28 Ld PDIP E28.6

HI3-574AKN-5 ±0.5 LSB 0 to 75 28 Ld PDIP E28.6

HI3-574ALN-5 ±0.5 LSB 0 to 70 28 Ld PDIP E28.6

HI1-574AJD-5 ±1.0 LSB 0 to 75 28 Ld SBDIP D28.6

HI1-574AKD-5 ±0.5 LSB 0 to 75 28 Ld SBDIP D28.6

HI1-574ALD-5 ±0.5 LSB 0 to 75 28 Ld SBDIP D28.6

HI1-574ASD-2 ±1.0 LSB -55 to 125 28 Ld SBDIP D28.6

HI1-574ATD-2 ±0.5 LSB -55 to 125 28 Ld SBDIP D28.6

HI1-574AUD-2 ±0.5 LSB -55 to 125 28 Ld SBDIP D28.6

HI1-574ASD/883 ±1.0 LSB -55 to 125 28 Ld SBDIP D28.6

HI1-574ATD/883 ±0.5 LSB -55 to 125 28 Ld SBDIP D28.6

HI1-574AUD/883 ±0.5 LSB -55 to 125 28 Ld SBDIP D28.6

HI4-574ASE/883 ±1.0 LSB -55 to 125 44 Ld CLCC J44.A

HI4-574ATE/883 ±0.5 LSB -55 to 125 44 Ld CLCC J44.A

HI4-574AUE/883

HI3-674AJN-5 ±1.0 LSB 0 to 75 28 Ld PDIP E28.6

HI3-674AKN-5 ±0.5 LSB 0 to 75 28 Ld PDIP E28.6

HI3-674ALN-5

HI1-674AJD-5 ±1.0 LSB 0 to 75 28 Ld SBDIP D28.6

HI1-674AKD-5 ±0.5 LSB 0 to 75 28 Ld SBDIP D28.6

HI1-674ALD-5 ±0.5 LSB 0 to 75 28 Ld SBDIP D28.6

HI1-674ASD-2 ±1.0 LSB -55 to 125 28 Ld SBDIP D28.6

HI1-674ATD-2 ±0.5 LSB -55 to 125 28 Ld SBDIP D28.6

HI1-674AUD-2 ±0.5 LSB -55 to 125 28 Ld SBDIP D28.6

HI1-674ASD/883 ±1.0 LSB -55 to 125 28 Ld SBDIP D28.6

HI1-674ATD/883 ±0.5 LSB -55 to 125 28 Ld SBDIP D28.6

HI1-674AUD/883 ±0.5 LSB -55 to 125 28 Ld SBDIP D28.6

HI4-674ASE/883 ±1.0 LSB -55 to 125 44 Ld CLCC J44.A

HI4-674ATE/883 ±0.5 LSB -55 to 125 44 Ld CLCC J44.A

HI4-674AUE/883 ±0.5 LSB -55 to 125 44 Ld CLCC J44.A

HI3-774J-5

HI3-774K-5

HI1-774J-5

HI1-774K-5

HI1-774U-2

HI1-774T/883

HI4-774S/883

HI4-774T/883

HI4-774U/883

±0.5 LSB

±0.5 LSB

±1.0 LSB 0 to 75 28 Ld PDIP E28.6

±0.5 LSB 0 to 75 28 Ld PDIP E28.6

±1.0 LSB 0 to 75 28 LdSBDIP

±0.5 LSB 0 to 75 28 LdSBDIP

±0.5 LSB -55 to 125 28 Ld SBDIP

±0.5 LSB -55 to 125 28 Ld SBDIP

±1.0 LSB -55 to 125 44 Ld CLCC

±0.5 LSB -55 to 125 44 Ld CLCC

±0.5 LSB -55 to 125 44 Ld CLCC

(oC) PACKA GE PKG. NO.

-55 to 125 44 Ld CLCC J44.A

0 to 75 28 Ld PDIP E28.6

D28.6

D28.6

D28.6

D28.6

J44.A

J44.A

J44.A

6-953

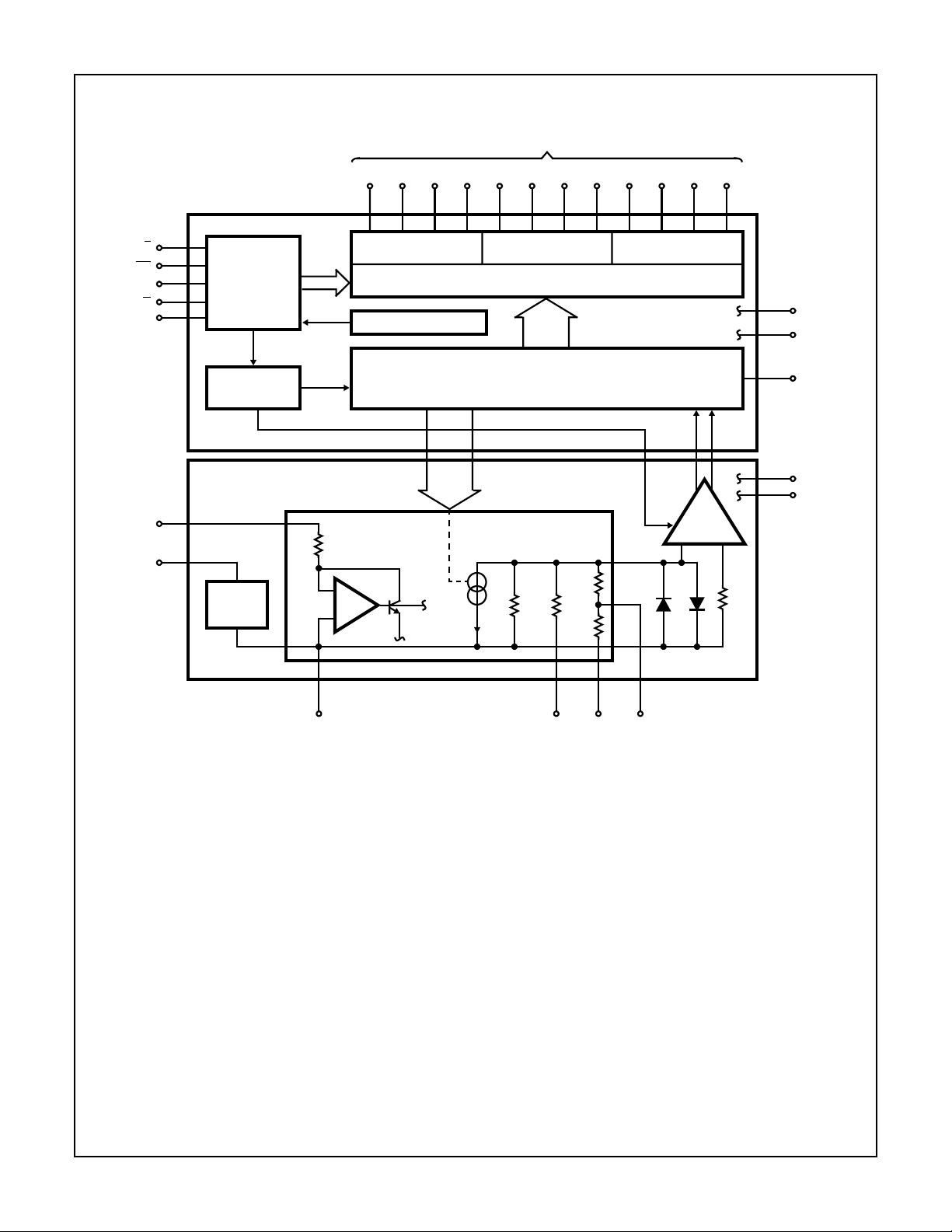

Functional Block Diagram

HI-574A, HI-674A, HI-774

BIT OUTPUTS

MSB LSB

12/8

CS

A

O

R/C

CE

IN

V

REF

V

OUT

REF

CONTROL

LOGIC

OSCILLATOR

DIGITAL CHIP

ANALOG CHIP

+10V

REF

THREE-STATE BUFFERS AND CONTROL

POWER-UP RESET

CLK

12 BITS

10K

+

-

5K

NIBBLE B (NOTE) NIBBLE C (NOTE)NIBBLE A (NOTE)

12 BITS

SAR

DAC

10K

STROBE

5K

5K

-

COMP

+

2.5K

V

LOGIC

DIGITAL

COMMON

STS

V

CC

V

EE

ANALOG

COMMON

NOTE: “Nibble” is a 4-bit digital word.

BIP

OFF

20V

INPUT

10V

INPUT

6-954

HI-574A, HI-674A, HI-774

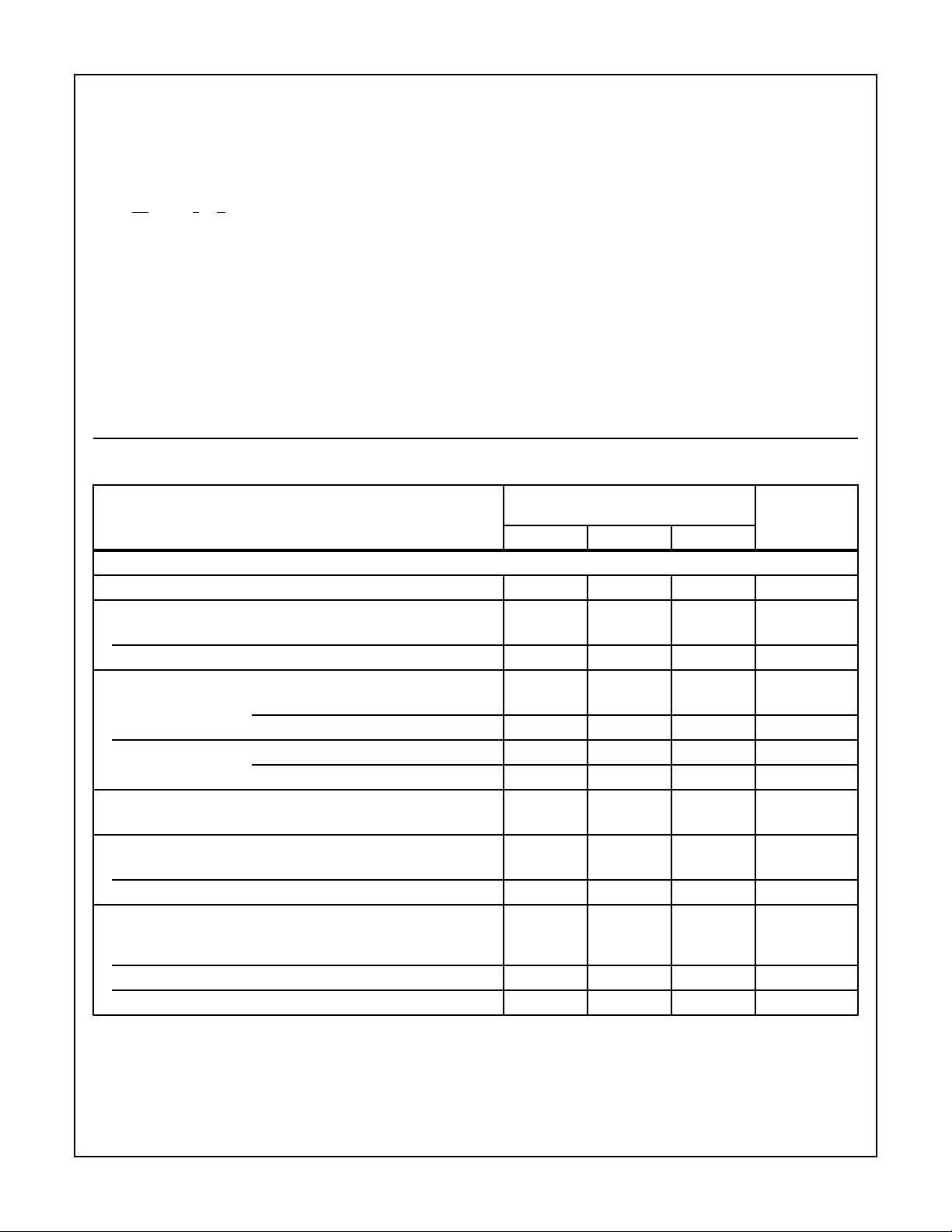

Absolute Maximum Ratings Thermal Information

Supply Voltage

VCC to Digital Common . . . . . . . . . . . . . . . . . . . . . . 0V to +16.5V

VEE to Digital Common. . . . . . . . . . . . . . . . . . . . . . . 0V to -16.5V

V

to Digital Common. . . . . . . . . . . . . . . . . . . . . . 0V to +7V

LOGIC

Analog Common to Digital Common±1V

Control Inputs

(CE, CS, AO, 12/8, R/C) to Digital Common . . -0.5V to V

Analog Inputs

(REFIN, BIPOFF, 10VIN) to Analog Common. . . . . . . . . . ±16.5V

20VIN to Analog Common . . . . . . . . . . . . . . . . . . . . . . . . . . ±24V

REFOUT . . . . Indefinite Short To Common, Momentary Short To V

LOGIC

+0.5V

Operating Conditions

Temperature Range

HI3-574AxN-5, HI1-574AxD-5 . . . . . . . . . . . . . . . . . .0oC to 75oC

HI3-674AxN-5, HI1-674AxD-5 . . . . . . . . . . . . . . . . . .0oC to 75oC

HI3-774xN-5, HI1-774xD-5. . . . . . . . . . . . . . . . . . . . .0oC to 75oC

HI1-574AxD-2, HI1-674AxD-2, HI1-774xD-2 . . . . -55oC to 125oC

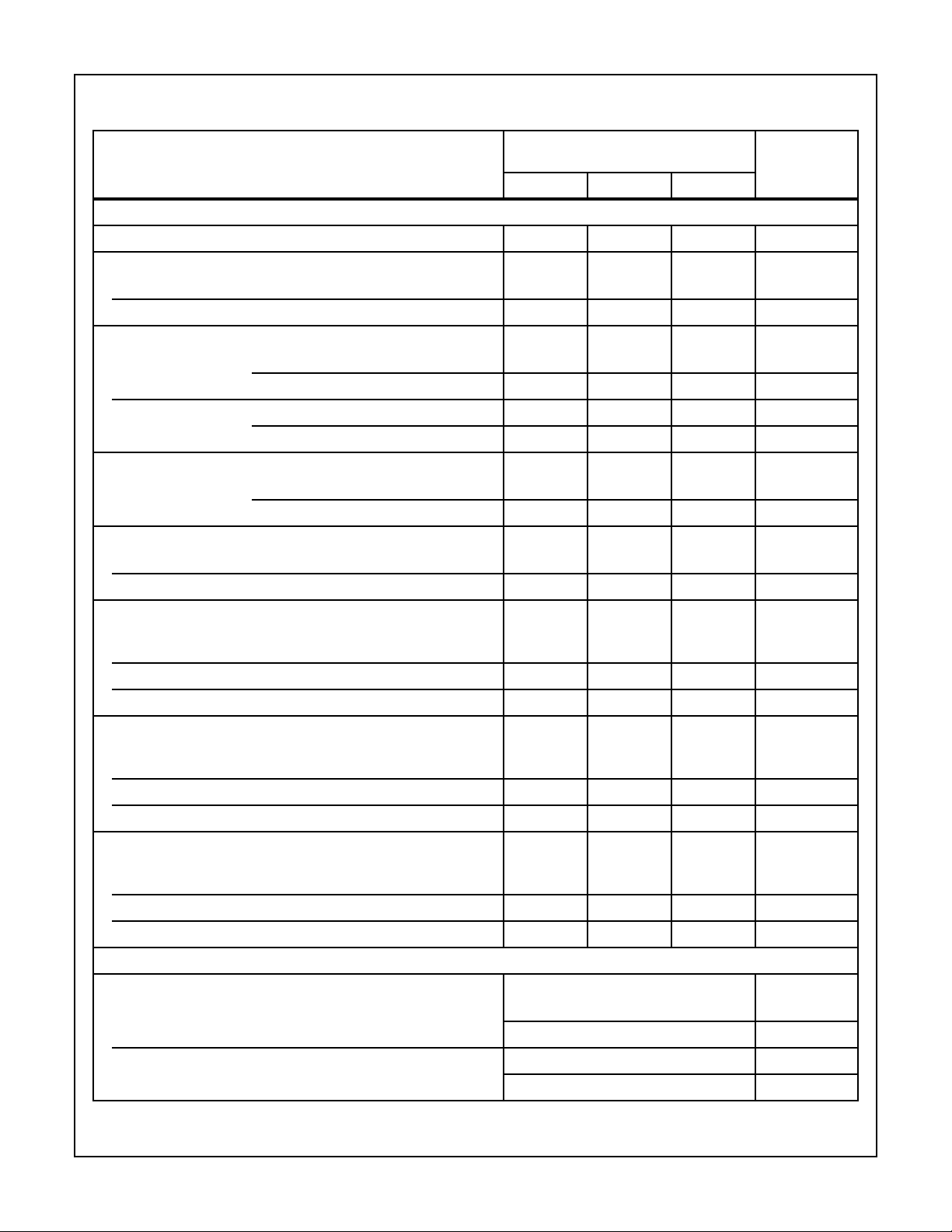

DC and Transfer Accuracy Specifications Typical at 25

Unless Otherwise Specified

PARAMETER

DYNAMIC CHARACTERISTICS

Resolution (Max) 12 12 12 Bits

Linearity Error

25oC (Max) ±1 ±1/

0oC to 75oC (Max) ±1 ±1/

Max Resolution For Which No Missing Codes Is Guaranteed

25oC HI-574A, HI-674A 12 12 12 Bits

HI-774 11 12 12 Bits

T

to T

MIN

MAX

Unipolar Offset (Max)

Adjustable to Zero ±2 ±1.5 ±1 LSB

Bipolar Offset (Max)

VIN = 0V (Adjustable to Zero) ±4 ±4 ±3 LSB

VIN = -10V ±0.15 ±0.1 ±0.1 % of FS

Full Scale Calibration Error

25oC (Max), With Fixed 50Ω Resistor From REF OUT To REF IN

(Adjustable to Zero)

T

T

MIN

MIN

to T

to T

(No Adjustment At 25oC) ±0.475 ±0.375 ±0.20 % of FS

MAX

(With Adjustment To Zero 25oC) ±0.22 ±0.12 ±0.05 % of FS

MAX

HI-574A, HI-674A 11 12 12 Bits

HI-774 11 12 12 Bits

Thermal Resistance (Typical, Note 1) θJA (oC/W) θJC (oC/W)

CLCC Package . . . . . . . . . . . . . . . . . . 65 14

SBDIP Package. . . . . . . . . . . . . . . . . . 60 18

HI3-574AxN-5, HI3-674AxN-5, HI3-774xN-5 65 N/A

Maximum Junction Temperature

HI3-574AxN-5, HI3-674AxN-5, HI3-774xN-5. . . . . . . . . . . . 150oC

HI1-574AxD-2, HI1-574AxD-5. . . . . . . . . . . . . . . . . . . . . . .175oC

HI1-674AxD-2, HI1-674AxD-5. . . . . . . . . . . . . . . . . . . . . . .175oC

HI1-774xD-2, HI1-774xD-5 . . . . . . . . . . . . . . . . . . . . . . . . .175oC

Maximum Storage Temperature Range

CC

HI3-574AxN-5, HI3-674AxN-5, HI3-774xN-5. . . . . .-40oC to 85oC

HI1-574AxD-2, HI1-574AxD-5. . . . . . . . . . . . . . . .-65oC to 150oC

HI1-674AxD-2, HI1-674AxD-5. . . . . . . . . . . . . . . .-65oC to 150oC

HI1-774xD-2, HI1-774xD-5 . . . . . . . . . . . . . . . . . .-65oC to 150oC

Maximum Lead Temperature (Soldering, 10s) . . . . . . . . . . . . 300oC

Die Characteristics

Transistor Count

HI-574A, HI-674A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1117

HI-774 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2117

o

C with VCC = +15V or +12V, V

TEMPERATURE RANGE

-5 (0oC to 75oC)

2

2

±0.25 ±0.25 ±0.15 % of FS

= +5V, VEE = -15V or -12V,

LOGIC

±1/

2

±1/

2

UNITSJ SUFFIX K SUFFIX L SUFFIX

LSB

LSB

6-955

HI-574A, HI-674A, HI-774

DC and Transfer Accuracy Specifications Typical at 25

o

C with VCC = +15V or +12V, V

= +5V, VEE = -15V or -12V,

LOGIC

Unless Otherwise Specified (Continued)

TEMPERATURE RANGE

-5 (0oC to 75oC)

PARAMETER

Temperature Coefficients

Guaranteed Max Change, T

MIN

to T

(Using Internal Reference)

MAX

Unipolar Offset HI-574A, HI-674A ±2 ±1 ±1 LSB

HI-774 ±2 ±1 ±1 LSB

Bipolar Offset HI-574A, HI-674A ±2 ±1 ±1 LSB

HI-774 ±2 ±2 ±1 LSB

Full Scale Calibration HI-574A, HI-674A ±9 ±2 ±2 LSB

HI-774 ±9 ±5 ±2 LSB

Power Supply Rejection

Max Change In Full Scale Calibration

+13.5V < VCC < +16.5V or +11.4V < VCC < +12.6V ±2 ±1 ±1 LSB

+4.5V < V

< +5.5V ±1/

LOGIC

2

±1/

2

±1/

2

-16.5V < VEE < -13.5V or -12.6V < VEE < -11.4V ±2 ±1 ±1 LSB

ANALOG INPUTS

Input Ranges

Bipolar -5 to +5 V

-10 to +10 V

Unipolar 0 to +10 V

0 to +20 V

Input Impedance

10V Span 5K, ±25% Ω

20V Span 10K, ±25% Ω

POWER SUPPLIES

Operating Voltage Range

V

LOGIC

V

CC

V

EE

+4.5 to +5.5 V

+11.4 to +16.5 V

-11.4 to -16.5 V

Operating Current

I

LOGIC

7 Typ, 15 Max mA

ICC +15V Supply 11 Typ, 15 Max mA

IEE -15V Supply 21 Typ, 28 Max mA

Power Dissipation

±15V, +15V 515 Typ, 720 Max mW

±12V, +5V 385 Typ mW

Internal Reference Voltage

T

to T

MIN

MAX

Output Current, Available For External Loads (External Load Should

+10.00 ±0.05 Max V

2.0 Max mA

Not Change During Conversion).

UNITSJ SUFFIX K SUFFIX L SUFFIX

LSB

6-956

HI-574A, HI-674A, HI-774

DC and Transfer Accuracy Specifications Typical at 25

o

C with VCC = +15V or +12V, V

= +5V, VEE = -15V or -12V,

LOGIC

Unless Otherwise Specified

TEMPERATURE RANGE

-2 (-55oC to 125oC)

PARAMETER

UNITSS SUFFIX T SUFFIX U SUFFIX

DYNAMIC CHARACTERISTICS

Resolution (Max) 12 12 12 Bits

Linearity Error

25oC ±1 ±1/

2

±1/

2

-55oC to 125oC (Max) ±1 ±1 ±1 LSB

Max Resolution For Which No Missing Codes Is Guaranteed

25oC HI-574A, HI-674A 12 12 12 Bits

HI-774 11 12 12 Bits

T

MIN

to T

MAX

HI-574A, HI-674A 11 12 12 Bits

HI-774 11 12 12 Bits

Unipolar Offset (Max)

Adjustable to Zero HI-574A, HI-674A ±2 ±1.5 ±1 LSB

HI-774 ±2 ±2 ±1 LSB

Bipolar Offset (Max)

VIN = 0V (Adjustable to Zero) ±4 ±4 ±3 LSB

VIN = -10V ±0.15 ±0.1 ±0.1 % of FS

Full Scale Calibration Error

25oC (Max), With Fixed 50Ω Resistor From REF OUT To REF IN

±0.25 ±0.25 ±0.15 % of FS

(Adjustable To Zero)

T

T

MIN

MIN

to T

to T

(No Adjustment At 25oC) ±0.75 ±0.50 ±0.275 % of FS

MAX

(With Adjustment To Zero At 25oC) ±0.50 ±0.25 ±0.125 % of FS

MAX

Temperature Coefficients

Guaranteed Max Change, T

MIN

to T

(Using Internal Reference)

MAX

Unipolar Offset ±2 ±1 ±1 LSB

Bipolar Offset ±2 ±2 ±1 LSB

Full Scale Calibration ±20 ±10 ±5 LSB

Power Supply Rejection

Max Change In Full Scale Calibration

+13.5V < VCC < +16.5V or +11.4V < VCC < +12.6V ±2 ±1 ±1 LSB

+4.5V < V

< +5.5V ±1/

LOGIC

2

±1/

2

±1/

2

-16.5V < VEE < -13.5V or -12.6V < VEE < -11.4V ±2 ±1 ±1 LSB

ANALOG INPUTS

Input Ranges

Bipolar -5 to +5 V

-10 to +10 V

Unipolar 0 to +10 V

0 to +20 V

LSB

LSB

6-957

HI-574A, HI-674A, HI-774

DC and Transfer Accuracy Specifications Typical at 25

Unless Otherwise Specified (Continued)

PARAMETER

Input Impedance

10V Span 5K, ±25% Ω

20V Span 10K, ±25% Ω

POWER SUPPLIES

Operating Voltage Range

V

LOGIC

V

CC

V

EE

Operating Current

I

LOGIC

ICC +15V Supply 11 Typ, 15 Max mA

IEE -15V Supply 21 Typ, 28 Max mA

Power Dissipation

±15V, +15V 515 Typ, 720 Max mW

±12V, +5V 385 Typ mW

Internal Reference Voltage

T

to T

MIN

MAX

Output current, available for external loads (External load should not

change during conversion).

o

C with VCC = +15V or +12V, V

TEMPERATURE RANGE

-2 (-55oC to 125oC)

+4.5 to +5.5 V

+11.4 to +16.5 V

-11.4 to -16.5 V

7 Typ, 15 Max mA

+10.00 ±0.05 Max V

2.0 Max mA

= +5V, VEE = -15V or -12V,

LOGIC

UNITSS SUFFIX T SUFFIX U SUFFIX

Digital Specifications All Models, Over Full Temperature Range

PARAMETER MIN TYP MAX

Logic Inputs (CE, CS, R/C, AO, 412/8)

Logic “1” +2.4V - +5.5V

Logic “0” -0.5V - +0.8V

Current - ±0.1µA ±5µA

Capacitance - 5pF -

Logic Outputs (DB11-DB0, STS)

Logic “0” (I

Logic “1” (I

Logic “1” (I

Leakage (High-Z State, DB11-DB0 Only) - ±0.1µA ±5µA

Capacitance - 5pF -

Timing Specifications (HI-574A) 25

SYMBOL PARAMETER MIN TYP MAX UNITS

CONVERT MODE

t

DSC

- 1.6mA) - - +0.4V

SINK

SOURCE

SOURCE

- 500µA) +2.4V - -

- 10µA) +4.5V - -

o

C, Note 2, Unless Otherwise Specified

STS Delay from CE - - 200 ns

6-958

HI-574A, HI-674A, HI-774

Timing Specifications (HI-574A) 25

o

C, Note 2, Unless Otherwise Specified (Continued)

SYMBOL PARAMETER MIN TYP MAX UNITS

t

HEC

t

SSC

t

HSC

t

SRC

t

HRC

t

SAC

t

HAC

t

C

CE Pulse Width 50 - - ns

CS to CE Setup 50 - - ns

CS Low During CE High 50 - - ns

R/C to CE Setup 50 - - ns

R/C Low During CE High 50 - - ns

AO to CE Setup 0 - - ns

AO Valid During CE High 50 - - ns

Conversion Time 12-Bit Cycle T

8-Bit Cycle T

MIN

MIN

to T

to T

MAX

MAX

15 20 25 µs

10 13 17 µs

READ MODE

t

t

t

t

SSR

t

SRR

t

SAR

t

HSR

t

HRR

t

HAR

t

DD

HD

HL

HS

Access Time from CE - 75 150 ns

Data Valid After CE Low 25 - - ns

Output Float Delay - 100 150 ns

CS to CE Setup 50 - - ns

R/C to CE Setup 0 - - ns

AO to CE Setup 50 - - ns

CS Valid After CE Low 0 - - ns

R/C High After CE Low 0 - - ns

AO Valid After CE Low 50 - - ns

STS Delay After Data Valid 300 - 1200 ns

Timing Specifications (HI-674A) 25

o

C, Note 2, Unless Otherwise Specified

SYMBOL PARAMETER MIN TYP MAX UNITS

CONVERT MODE

t

DSC

t

HEC

t

SSC

t

HSC

t

SRC

t

HRC

t

SAC

t

HAC

t

C

STS Delay from CE - - 200 ns

CE Pulse Width 50 - - ns

CS to CE Setup 50 - - ns

CS Low During CE High 50 - - ns

R/C to CE Setup 50 - - ns

R/C Low During CE High 50 - - ns

AO to CE Setup 0 - - ns

AO Valid During CE High 50 - - ns

Conversion Time 12-Bit Cycle T

8-Bit Cycle T

MIN

MIN

to T

to T

MAX

MAX

91215µs

6810µs

READ MODE

t

DD

t

HD

t

HL

Access Time from CE - 75 150 ns

Data Valid After CE Low 25 - - ns

Output Float Delay - 100 150 ns

6-959

HI-574A, HI-674A, HI-774

Timing Specifications (HI-674A) 25

o

C, Note 2, Unless Otherwise Specified (Continued)

SYMBOL PARAMETER MIN TYP MAX UNITS

t

SSR

t

SRR

t

SAR

t

HSR

t

HRR

t

HAR

t

HS

Timing Specifications (HI-774) 25

CS to CE Setup 50 - - ns

R/C to CE Setup 0 - - ns

AO to CE Setup 50 - - ns

CS Valid After CE Low 0 - - ns

R/C High After CE Low 0 - - ns

AO Valid After CE Low 50 - - ns

STS Delay After Data Valid 25 - 850 ns

o

C, Into a load with RL = 3kΩ and CL = 50pF, Note 2, Unless Otherwise Specified

SYMBOL PARAMETER MIN TYP MAX UNITS

CONVERT MODE

t

DSC

t

HEC

t

SSC

t

HSC

t

SRC

t

HRC

t

SAC

t

HAC

t

C

STS Delay from CE - 100 200 ns

CE Pulse Width 50 30 - ns

CS to CE Setup 50 20 - ns

CS Low During CE High 50 20 - ns

R/C to CE Setup 50 0 - ns

R/C Low During CE High 50 20 - ns

AO to CE Setup 0 0 - ns

AO Valid During CE High 50 30 - ns

Conversion Time 12-Bit Cycle T

8-Bit Cycle T

12-Bit Cycle T

8-Bit Cycle T

MIN

MIN

MIN

MIN

to T

to T

to T

to T

(-5) - 8.0 9 µs

MAX

(-5) - 6.4 6.8 µs

MAX

(-2) - 9 11 µs

MAX

(-2) - 6.8 8.3 µs

MAX

READ MODE

t

t

t

t

SSR

t

SRR

t

SAR

t

HSR

t

HRR

t

HAR

t

DD

HD

HL

HS

Access Time from CE - 75 150 ns

Data Valid After CE Low 25 35 - ns

Output Float Delay - 70 150 ns

CS to CE Setup 50 0 - ns

R/C to CE Setup 0 0 - ns

AO to CE Setup 50 25 - ns

CS Valid After CE Low 0 0 - ns

R/C High After CE Low 0 0 - ns

AO Valid After CE Low 50 25 - ns

STS Delay After Data Valid - 90 300 ns

NOTES:

1. Dissipation rating assumes device is mounted with all leads soldered to printed circuit board.

2. Time is measured from 50% level of digital transitions. Tested with a 50pF and 3kΩ load.

6-960

HI-574A, HI-674A, HI-774

Pin Descriptions

PIN SYMBOL DESCRIPTION

1V

2 12/8 Data Mode Select - Selects between

3 CS Chip Select - Chip Select high disables

4AOByte Address/Short Cycle - See Table

5R/C Read/Convert - See Table 1 for

6 CE Chip Enable - Chip Enable low disables

7VCCPositive Supply (+12V/+15V)

8 REF OUT +10V Reference

9 AC Analog Common

10 REF IN Reference Input

11 V

12 BIP OFF Bipolar Offset

13 10V Input 10V Input - Used for 0V to 10V and -5V

14 20V Input 20V Input - Used f or 0V to 20V and -10V

15 DC Digital Common

16 DB0 Data Bit 0 (LSB)

17 DB1 Data Bit 1

18 DB2 Data Bit 2

19 DB3 Data Bit 3

20 DB4 Data Bit 4

21 DB5 Data Bit 5

22 DB6 Data Bit 6

23 DB7 Data Bit 7

24 DB8 Data Bit 8

25 DB9 Data Bit 9

26 DB10 Data Bit 10

27 DB11 Data Bit 11 (MSB)

28 STS Status Bit - Status high implies a

LOGIC

EE

Logic supply pin (+5V)

12-bit and 8-bit output modes.

the device.

1 for operation.

operation.

the device.

Negative Supply (-12V/-15V).

to +5V input ranges.

to +10V input ranges.

conversion is in progress.

Definitions of Specifications

Linearity Error

Linearity error refers to the deviation of each individual code

from a line drawn from “zero” through “full scale”. The point

used as “zero” occurs

the first code transition (all zeros to only the LSB “on”). “Full

scale” is defined as a level 1

sition (to all ones). The deviation of a code from the true straight

line is measured from the middle of each particular code.

The HI-X74(A)K and L grades are guaranteed for maximum

nonlinearity of ±

analog value which falls exactly in the center of a given code

width will result in the correct digital output code. Values nearer

the upper or lower transition of the code width may produce the

next upper or lower digital output code. The HI-X74(A)J is

guaranteed to ±1 LSB max error. For this grade, an analog

value which falls within a given code width will result in either

the correct code for that region or either adjacent one.

Note that the linearity error is not user-adjustable.

Differential Linearity Error (No Missing Codes)

A specification which guarantees no missing codes requires

that every code combination appear in a monotonic increasing sequence as the analog input level is increased. Thus

every code must hav e a finite width. F or the HI-X74(A)K and L

grades, which guarantee no missing codes to 12-bit resolution, all 4096 codes must be present over the entire operating

temperature ranges. The HI-X74(A)J grade guarantees no

missing codes to 11-bit resolution over temperature; this

means that all code combinations of the upper 11 bits must be

present; in practice very few of the 12-bit codes are missing.

Unipolar Offset

The first transition should occur at a level

common. Unipolar offset is defined as the deviation of the

actual transition from that point. This offset can be adjusted as

discussed on the following pages. The unipolar offset temperature coefficient specifies the maximum change of the transition

point over temperature, with or without external adjustment.

Bipolar Offset

Similarly, in the bipolar mode, the major carry transition

(0111 1111 1111 to 1000 0000 0000) should occur for an

analog value

1

offset error and temperature coefficient specify the initial

deviation and maximum change in the error over temperature.

Full Scale Calibration Error

The last transition (from 1111 1111 1110 to 1111 1111

1111) should occur for an analog value 1

nominal full scale (9.9963V for 10.000V full scale). The full

scale calibration error is the deviation of the actual level at

the last transition from the ideal level. This error, which is

typically 0.05 to 0.1% of full scale, can be trimmed out as

shown in Figures 2 and 3. The full scale calibration error

over temperature is given with and without the initial error

trimmed out. The temperature coefficients for each grade

indicate the maximum change in the full scale gain from the

initial value using the internal 10V reference.

1

/2 LSB (1.22mV for 10V span) before

1

/2 LSB beyond the last code tran-

1

/2 LSB. For these grades, this means that an

1

/2 LSB above analog

/2 LSB below analog common. The bipolar

1

/2 LSB below the

6-961

HI-574A, HI-674A, HI-774

Temperature Coefficients

The temperature coefficients for full-scale calibration, unipolar offset, and bipolar offset specify the maximum change

from the initial (25oC) value to the value at T

MIN

or T

MAX

.

Power Supply Rejection

The standard specifications for the HI-X74A assume use of

+5.00V and ±15.00V or ±12.00V supplies. The only effect of

power supply error on the performance of the device will be

a small change in the full scale calibration. This will result in

a linear change in all lower order codes. The specifications

show the maximum change in calibration from the initial

value with the supplies at the various limits.

Code Width

A fundamental quantity for A/D converter specifications is

the code width. This is defined as the range of analog input

values for which a given digital output code will occur. The

nominal value of a code width is equivalent to 1 least significant bit (LSB) of the full scale range or 2.44mV out of 10V for

a 12-bit ADC.

Quantization Uncertainty

Analog-to-digital converters exhibit an inherent quantization

uncertainty of ±

1

/2 LSB. This uncertainty is a fundamental

characteristic of the quantization process and cannot be

reduced for a converter of given resolution.

Left-justified Data

Power Supplies

Supply voltages to the HI-X74(A) (+15V, -15V and +5V) must

be “quiet” and well regulated. Voltage spikes on these lines can

affect the converter’s accuracy, causing several LSBs to flicker

when a constant input is applied. Digital noise and spikes from

a switching power supply are especially troublesome. If switching supplies must be used, outputs should be carefully filtered

to assure “quiet” DC voltage at the converter terminals.

Further, a bypass capacitor pair on each supply voltage

terminal is necessary to counter the effect of variations in

supply current. Connect one pair from pin 1 to 15 (V

LOGIC

supply), one from pin 7 to 9 (VCC to Analog Common) and

one from pin 11 to 9 (V

to Analog Common). For each

EE

capacitor pair, a 10µF tantalum type in parallel with a 0.1µF

ceramic type is recommended.

Ground Connections

Pins 9 and 15 should be tied together at the package to

guarantee specified performance for the converter. In

addition, a wide PC trace should run directly from pin 9 to

(usually) +15V common, and from pin 15 to (usually) the +5V

Logic Common. If the converter is located some distance from

the system’s “single point” ground, make only these connections to pins 9 and 15: Tie them together at the package, and

back to the system ground with a single path. This path

should have low resistance. (Code dependent currents flow in

the V

, VEE and V

CC

terminals, but not through the

LOGIC

HI-X74(A)’s Analog Common or Digital Common).

The data format used in the HI-X74(A) is left-justified. This

means that the data represents the analog input as a fraction of full-scale, ranging from 0 to . This implies a

binary point to the left of the MSB.

4095

4096

Applying the HI-X74(A)

For each application of this converter, the ground

connections, power supply bypassing, analog signal source,

digital timing and signal routing on the circuit board must be

optimized to assure maximum performance. These areas

are reviewed in the following sections, along with basic operating modes and calibration requirements.

Physical Mounting and Layout Considerations

Layout

Unwanted, parasitic circuit components, (L, R, and C) can

make 12-bit accuracy impossible, even with a perfect A/D

converter. The best policy is to eliminate or minimize these

parasitics through proper circuit layout, rather than try to

quantify their effects.

The recommended construction is a double-sided printed

circuit board with a ground plane on the component side.

Other techniques, such as wire-wrapping or point-to-point

wiring on vector board, will have an unpredictable effect on

accuracy.

In general, sensitive analog signals should be routed between

ground traces and kept well away from digital lines. If analog

and digital lines must cross, they should do so at right angles.

Analog Signal Source

HI-574A and HI-674A

The device chosen to drive the HI-X74A analog input will see a

nominal load of 5kΩ (10V range) or 10kΩ (20V range).

However, the other end of these input resistors may change

±400mV with each bit decision, creating abrupt changes in current at the analog input. Thus, the signal source must maintain

its output voltage while furnishing these step changes in load

current, which occur at 1.6µs and 950ns intervals for the

HI-574A and HI-674A, respectively. This requires low output

impedance and fast settling by the signal source.

The output impedance of an op amp, for example, has an open

loop value which, in a closed loop, is divided by the loop gain

available at a frequency of interest. The amplifier should have

acceptable loop gain at 600KHz for use with the HI-X74A. To

check whether the output properties of a signal source are

suitable, monitor the HI-X74A’ s input (pin 13 or 14) with an oscilloscope while a conversion is in progress. Each of the twelve

disturbances should subside in 1µs or less for the HI-574A and

500ns or less for the HI-674A. (The comparator decision is

made about 1.5µs and 850ns after each code change from the

SAR for the HI-574A and HI-674A, respectiv ely.)

If the application calls for a Sample/Hold to precede the

converter, it should be noted that not all Sample/Holds are

compatible with the HI-574A in the manner described above.

These will require an additional wideband buffer amplifier to

lower their output impedance. A simpler solution is to use the

Intersil HA-5320 Sample/Hold, which was designed for use

with the HI-574A.

6-962

HI-574A, HI-674A, HI-774

HI-774

The device driving the HI-774 analog input will see a nominal

load of 5kΩ (10V range) or 10kΩ (20V range). However, the

other end of these input resistors may change as much as

±400mV with each bit decision. These input disturbances

are caused by the internal DAC changing codes which

causes a glitch on the summing junction. This creates abrupt

changes in current at the analog input causing a “kick back”

glitch from the input. Because the algorithm starts with the

MSB, the first glitches will be the largest and get smaller as

the conversion proceeds. These glitches can occur at 350ns

intervals so an op amp with a low output impedance and fast

settling is desirable. Ultimately the input must settle to within

the window of Figure 1 at the bit decision points in order to

achieve 12-bit accuracy.

The HI-774 differs from the most high-speed successive

approximation type ADC’s in that it does not require a high

performance buffer or sample and hold. With error correction

the input can settle while the conversion is underway, but

only during the first 4.8µs. The input must be within 10.76%

of the final value when the MSB decision is made. This

occurs approximately 650ns after the conversion has been

initiated. Digital error correction also loosens the bandwidth

requirements of the buffer or sample and hold. As long as

the input “kick back” disturbances settle within the window of

Figure 1 the device will remain accurate. The combined

effect of settling and the “kick back” disturbances must

remain in the Figure 1 window.

If the design is being optimized for speed, the input device

should have closed loop bandwidth to 3MHz, and a low output impedance (calculated by dividing the open loop output

resistance by the open loop gain). If the application requires

a high speed sample and hold the Intersil HA-5330 or

HA-5320 are recommended.

In any design the input (pin 13 or 14) should be checked

during a conversion to make sure that the input stays within

the correctable window of Figure 1.

Digital Error Correction

HI-774

The HI-774 features the smart successive approximation

register (SSAR) which includes digital error correction. This

has the advantage of allowing the initial input to vary within a

+31 to -32 LSB window about the final value. The input can

move during the first 4.8µs, after which it must remain stable

within ±

before the input has settled completely; however, it must be

within the window as described in Figure 1.

The conversion cycle starts by making the first 8-bit decisions

very quickly, allowing the inter nal DAC to settle only to 8-bit

accuracy. Then the converter goes through two error correction cycles. At this point the input must be stable within ±

LSB. These cycles correct the 8-bit word to 12-bit accuracy for

any errors made (up to +16 or -32 LSBs). This is up one count

or down two counts at 8-bit resolution. The converter then

continues to make the 4 LSB decisions, settling out to 12-bit

accuracy. The last four bits can adjust the code in the positive

1

/2 LSB. With this feature a conversion can start

1

direction by up to 15 LSBs. This results in a total correction

range of +31 to -32 LSBs. When an 8-bit conversion is performed, the input must settle to within ±

1

/2 LSB at 8-bit resolu-

tion (which equals ±8 LSBs at 12-bit resolution).

With the HI-774 a conversion can be initiated before the

input has completely settled, as long as it meets the constraints of the Figure 1 window. This allows the user to start

conversion up to 4.8µs earlier than with a typical analog to

digital converter. A typical successive approximation type

ADC must have a constant input during a conversion

because once a bit decision is made it is locked in and cannot change.

32

8-BIT CONVERSION

16

BIT DECISION POINTS

8

0

-8

-16

-31

OFFSET

100K

100K

100Ω

0V TO +10V

0V TO +20V

MSB BIT DECISION

~ 650ns

1234567 8

TIME (µs)

R1

+15V

GAIN

R2

100Ω

ALLOWABLE INPUT CHANGE

(LSBs AT 12-BIT RESOLUTION)

CONVERSION

INITIATED

FIGURE 1. HI-774 ERROR CORRECTION WINDOW vs TIME

-15V

ANALOG

INPUTS

/

2

~ 4.8µs

12-BIT CONVERSION

2 12/

8

CS

3

4A

O

5R/C

6CE

10 REF IN

8 REF OUT

12 BIP OFF

13 10V

IN

14 20V

9 ANA

COM

۠

IN

CONVERSION

1

/2 LSB

±

LAST BIT

DECISION

(12-BIT)

STS 28

HIGH BITS

24-27

MIDDLE BITS

20-23

LOW BITS

16-19

+5V 1

+15V 7

-15V 11

DIG COM 15

†When driving the 20V (pin 14) input, minimize capacitance on pin 13.

FIGURE 2. UNIPOLAR CONNECTIONS

END OF

(12 BIT)

6-963

ANALOG

INPUTS

±5V

±10V

R2

R1

GAIN

100Ω

100Ω

OFFSET

2 12/

8

CS

3

4A

O

5R/C

6CE

10 REF IN

8 REF OUT

12 BIP OFF

13 10V

IN

14 20V

†

IN

9 ANA

COM

HI-574A, HI-674A, HI-774

adjustment is complete. Therefore, calibration is performed

STS 28

HIGH BITS

24-27

MIDDLE BITS

20-23

LOW BITS

16-19

+5V 1

+15V 7

-15V 11

DIG COM 15

in terms of the observable code changes instead of the

midpoint between code changes.

For example, midpoint of the first LSB increment should be

positioned at the origin, with an output code of all 0’s. To do

this, apply an input of +

+2.44mV for the 20V range). Adjust the Offset potentiometer

R1 until the first code transition flickers between

0000 0000 0000 and 0000 0000 0001.

Next, perform a Gain Adjust at positive full scale. Again, the

ideal input corresponding to the last code change is applied.

This is 1

10V range; +19.9927V for 20V range). Adjust the Gain

potentiometer R2 for flicker between codes 1111 1111 1110

and 1111 1111 1111.

Bipolar Connections and Calibration

Refer to Figure 3. The gain and offset errors listed under

Specifications may be adjusted to zero using potentiometers R1 and R2 (see Note). If this isn’t required, either or

both pots may be replaced by a 50Ω, 1% metal film resistor.

1

/2 LSB (+1.22mV for the 10V range;

1

/2 LSBs below the nominal full scale (+9.9963V for

†When driving the 20V (pin 14) input, minimize capacitance on pin 13.

FIGURE 3. BIPOLAR CONNECTIONS

Range Connections and Calibration Procedures

The HI-X74(A) is a “complete” A/D converter, meaning it is

fully operational with addition of the power supply voltages, a

Start Convert signal, and a few external components as

shown in Figure 2 and Figure 3. Nothing more is required for

most applications.

Whether controlled by a processor or operating in the standalone mode, the HI-X74(A) offers f our standard input ranges:

0V to +10V, 0V to +20V,±5V and ±10V. The maximum errors

for gain and offset are listed under Specifications. If required,

however, these errors may be adjusted to zero as explained

below . Power supply and ground connections have been discussed in an earlier section.

Unipolar Connections and Calibration

Refer to Figure 2. The resistors shown (see Note) are for

calibration of offset and gain. If this is not required, replace

R2 with a 50Ω, 1% metal film resistor and remove the network on pin 12. Connect pin 12 to pin 9. Then, connect the

analog signal to pin 13 for the 0V to 10V range, or to pin 14

for the 0V to 20V range. Inputs to +20V (5V over the power

supply) are no problem - the converter operates normally.

Calibration consists of adjusting the converter’s most

negative output to its ideal value (offset adjustment), then,

adjusting the most positive output to its ideal value (gain

adjustment). To understand the procedure, note that in

principle, one is setting the output with respect to the midpoint of an increment of analog input, as denoted by two

adjacent code changes. Nominal value of an increment is

one LSB. However, this approach is impractical because

nothing “happens” at a midpoint to indicate that an

Connect the Analog signal to pin 13 for a ±5V range, or to

pin 14 for a ±10V range. Calibration of offset and gain is similar to that for the unipolar ranges as discussed above. First

apply a DC input voltage

1

/2 LSB above negative full scale

(i.e., -4.9988V for the ±5V range, or -9.9976V for the ±10V

range). Adjust the offset potentiometer R1 for flick er between

output codes 0000 0000 0000 and 0000 0000 0001. Next,

apply a DC input voltage 1

1

/2 LSBs below positive full scale

(+4.9963V for ±5V range; +9.9927V for ±10V range). Adjust

the Gain potentiometer R2 for flicker between codes 1111

1111 1110 and 1111 1111 1111.

NOTE: The 100Ω potentiometer R2 provides Gain Adjust f or the 10V

and 20V ranges. In some applications, a full scale of 10.24V (LSB

equals 2.5mV) or 20.48V (LSB equals 5.0mV) is more convenient.

For these, replace R2 by a 50Ω, 1% metal film resistor. Then, to provide Gain Adjust for the 10.24V range, add a 200Ω potentiometer in

series with pin 13. For the 20.48V range, add a 500Ω potentiometer

in series with pin 14.

Controlling the HI-X74(A)

The HI-X74(A) includes logic for direct interface to most

microprocessor systems. The processor may take full control of each conversion, or the converter may operate in the

“stand-alone” mode, controlled only by the R/

control consists of selecting an 8-bit or 12-bit conversion

cycle, initiating the conversion, and reading the output data

when ready-choosing either 12 bits at once or 8 followed b y

4, in a left-justified format. The five control inputs are all

TTL/CMOS-compatible: (12/

8, CS, AO, R/C and CE). Table

1 illustrates the use of these inputs in controlling the

converter’s operations. Also, a simplified schematic of the

internal control logic is shown in Figure 7.

C input. Full

6-964

HI-574A, HI-674A, HI-774

“Stand-Alone Operation”

The simplest control interface calls for a singe control line

connected to R/

A

are wired low, and the output data appears in words of

O

C. Also, CE and 12/8 are wired high,CS and

12 bits each.

The R/

C signal may have any duty cycle within (and

including) the extremes shown in Figures 8 and 9. In general, data may be read when R/

C is high unless STS is also

high, indicating a conversion is in progress. Timing parameters particular to this mode of operation are listed below

under “Stand-Alone Mode Timing”.

HI-574A STAND-ALONE MODE TIMING

SYMBOL PARAMETER MIN TYP MAX UNITS

t

t

t

t

Time is measured from 50% level of digital transitions. Tested with a

50pF and 3kΩ load.

Low R/C Pulse Width 50 - - ns

HRL

t

STS Delay from R/C - - 200 ns

DS

Data Valid after R/C L ow 25 - - ns

HDR

t

STS Delay after Data V alid 300 - 1200 ns

HS

High R/C Pulse Width 150 - - ns

HRH

Data Access Time - - 150 ns

DDR

HI-674A STAND-ALONE MODE TIMING

Conversion Length

A Convert Start transition (see Table 1) latches the state of

A

, which determines whether the conversion continues for

O

12 bits (A

low) or stops with 8 bits (AO high). If all 12 bits are

O

read following an 8-bit conversion, the last three LSBs will

read ZERO and DB3 will read ONE. A

is latched because it

O

is also involved in enabling the output buffers (see “Reading

the Output Data”). No other control inputs are latched.

TABLE 1. TRUTH TABLE FOR HI-X74(A) CONTROL INPUTS

CE CS R/C 12/8A

0XXXXNone

X 1 X X X None

↑ 0 0 X 0 Initiate 12-bit conversion

↑ 0 0 X 1 Initiate 8-bit conversion

1 ↓ 0 X 0 Initiate 12-bit conversion

1 ↓ 0 X 1 Initiate 8-bit conversion

10↓ X 0 Initiate 12-bit conversion

10↓ X 1 Initiate 8-bit conversion

1011XEnable 12-bit Output

10100Enable 8 MSBs Only

10101Enable 4 LSBs Plus 4 Trailing

O

Zeroes

OPERATION

SYMBOL PARAMETER MIN TYP MAX UNITS

t

t

t

t

Time is measured from 50% level of digital transitions. Tested with a

50pF and 3kΩ load.

SYMBOL PARAMETER MIN TYP MAX UNITS

t

t

t

t

Low R/C Pulse Width 50 - - ns

HRL

t

STS Delay from R/C - - 200 ns

DS

Data Valid after R/C L ow 25 - - ns

HDR

t

STS Delay after Data V alid 25 - 850 ns

HS

High R/C Pulse Width 150 - - ns

HRH

Data Access Time - - 150 ns

DDR

HI-774 STAND-ALONE MODE TIMING

Low R/C Pulse Width 50 - - ns

HRL

t

STS Delay from R/C - - 200 ns

DS

Data Valid after R/C L ow 20 - - ns

HDR

t

STS Delay after Data V alid - - 850 ns

HS

High R/C Pulse Width 150 - - ns

HRH

Data Access Time - - 150 ns

DDR

Conversion Start

A conversion may be initiated as shown in Table 1 by a logic

transition on any of three inputs: CE,

CS or R/C. The last of

the three to reach the correct state starts the conversion, so

one, two or all three may be dynamically controlled. The

nominal delay from each is the same, and if necessary, all

three may change state simultaneously. However, to ensure

that a particular input controls the start of conversion, the

other two should be set up at least 50ns earlier. See the

HI-774 Timing Specifications, Convert Mode.

This variety of HI-X74(A) control modes allows a simple

interface in most system applications. The Convert Start

timing relationships are illustrated in Figure 4.

The output signal STS indicates status of the converter by

going high only while a conversion is in progress. While STS

is high, the output buffers remain in a high impedance state

and data cannot be read. Also, an additional Start Convert

will not reset the converter or reinitiate a conversion while

STS is high.

Reading the Output Data

The output data buffers remain in a high impedance state

until four conditions are met: R/

C high, STS low , CE high and

CS low. At that time, data lines become active according to

the state of inputs 12/

8 and AO. Timing constraints are

illustrated in Figure 5.

6-965

HI-574A, HI-674A, HI-774

The 12/

though it is fully TTL/CMOS-compatible. With 12/

8 input will be tied high or low in most applications,

8 high, all

12 output lines become active simultaneously, for interface to

a 12-bit or 16-bit data bus. The A

With 12/

8 low, the output is organized in two 8-bit bytes,

selected one at a time by A

to be connected as shown in Figure 6. A

input is ignored.

O

. This allows an 8-bit data bus

O

is usually tied to

O

the least significant bit of the address bus, for storing the

HI-X74(A) output in two consecutive memory locations.

(With A

low, the 8 MSBs only are enabled. With AO high, 4

O

MSBs are disabled, bits 4 through 7 are forced low, and the 4

LSBs are enabled). This two byte format is considered “left

justified data,” for which a decimal (or binary!) point is

assumed to the left of byte 1:

BYTE 1 BYTE 2

XXXXXXXX XXXX0000

•

MSB LSB

Further, A

may be toggled at any time without damage to

O

the converter. Break-before-make action is guaranteed

between the two data bytes, which assures that the outputs

strapped together in Figure 6 will never be enabled at the

same time.

A read operation usually begins after the conversion is

complete and STS is low. For earliest access to the data,

however, the read should begin no later than (t

DD

+ tHS)

before STS goes low. See Figure 5.

CE

CS

R/

A

STS

DB11-DB0

t

SSR

C

t

O

SRR

t

SAR

HIGH IMPEDANCE

t

DD

t

HSR

t

HRR

t

HAR

t

HS

See HI-774 Timing Specifications for more information.

FIGURE 5. READ CYCLE TIMING

A

O

ADDRESS BUS

DAT A

VALID

t

HD

t

HL

t

CE

CS

R/

A

STS

DB11-DB0

t

SSC

t

SRC

C

t

t

SAC

HRC

t

HAC

t

DSC

HIGH IMPEDANCE

O

HEC

t

HSC

See HI-774 Timing Specifications for more information.

FIGURE 4. CONVERT START TIMING

1

2

8

DB11 (MSB)

12/

3

4

A

O

5

6

7

8

9

t

C

10

11

12

13

14

HI-774

DB0 (LSB)

STS

DIG.

COM.

28

27

26

25

24

23

22

21

20

19

18

17

16

15

DAT A

BUS

FIGURE 6. INTERFACE TO AN 8-BIT DATA BUS

6-966

HI-574A, HI-674A, HI-774

NIBBLE B ZERO

OVERRIDE

INPUT BUFFERS

8

12/

CS

A

O

R/

C

CE

CK

Q

D

Q

AO LATCH

EOC9

EOC13

READ CONTROL

POWER UP

RESET

FIGURE 7. HI-774 CONTROL LOGIC

t

HRL

CONVERT

CONTROL

CURRENT

CONTROLLED

OSCILLATOR

NIBBLE A, B

NIBBLE C

STATUS

STROBE

CLOCK

RESET

R/C

t

DS

STS

DB11-DB0

DAT A

VALID

t

HDR

t

C

FIGURE 8. LOW PULSE FOR R/C - OUTPUTS ENABLED AFTER CONVERSION

R/

C

STS

DB11-DB0

t

DDR

t

HRH

DAT A

VALID

t

HDR

t

DS

t

C

HIGH-ZHIGH-Z

t

HS

DAT A

VALID

FIGURE 9. HIGH PULSE FOR R/C - OUTPUTS ENABLED WHILE R/C HIGH, OTHERWISE HIGH-Z

6-967

Die Characteristics

HI-574A, HI-674A, HI-774

DIE DIMENSIONS:

Analog: 3070mm x 4610mm

Digital: 1900mm x 4510mm

METALLIZATION:

Digital Type: Nitrox

Thickness: 10k

Å ±2kÅ

Metal 1: AlSiCu

Thickness: 8k

Å ±1kÅ

Metal 2: AlSiCu

Thickness: 16k

Å ±2kÅ

Analog Type: Al

Thickness: 16k

Å ±2kÅ

Metallization Mask Layout

O

R/C

CE

V

A

CC

CS

PASSIVATION:

Type: Nitride Over Silox

Nitride Thickness: 3.5k

Silox Thickness: 12kű1.5kÅ

WORST CASE CURRENT DENSITY:

1.3 x 10

HI-574A, HI-674A, HI-774

5

A/cm

Å ±0.5kÅ

2

LOGIC

LOGIC

V

STS

12/8

V

DB11

DB10

DB9

V

REFOUT

ANALOG

COMMON

ANALOG

COMMON

ANALOG

COMMON

V

REFIN

V

EE

10VIN20V

OFFSET

BIPOLAR

DB8

DB7

DB6

DB5

DB4

DB3

DB2

IN

DIGITAL

COMMON

DB0

DB1

6-968

HI-574A, HI-674A, HI-774

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (321) 724-7000

FAX: (321) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

6-969

ASIA

Intersil (Taiwan) Ltd.

Taiwan Limited

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...