Page 1

422

HG-RELAYS

20 AMP POWER RELAY

36

1.417

56

2.205

a

mm inch

a

HG2 34.0 1.339

HG3 50.0 1.969

HG4 68.0 2.667

FEATURES

•

Large capacity — 20 A 250 V A C resistive and 1.5 kW 3 phase

220 V AC motor loads

• High contact reliability after long use

• Usable with direct soldering,

quick-connect and plug-in terminals. (.250)

SPECIFICATIONS

Contacts

Expected life (min. operations)

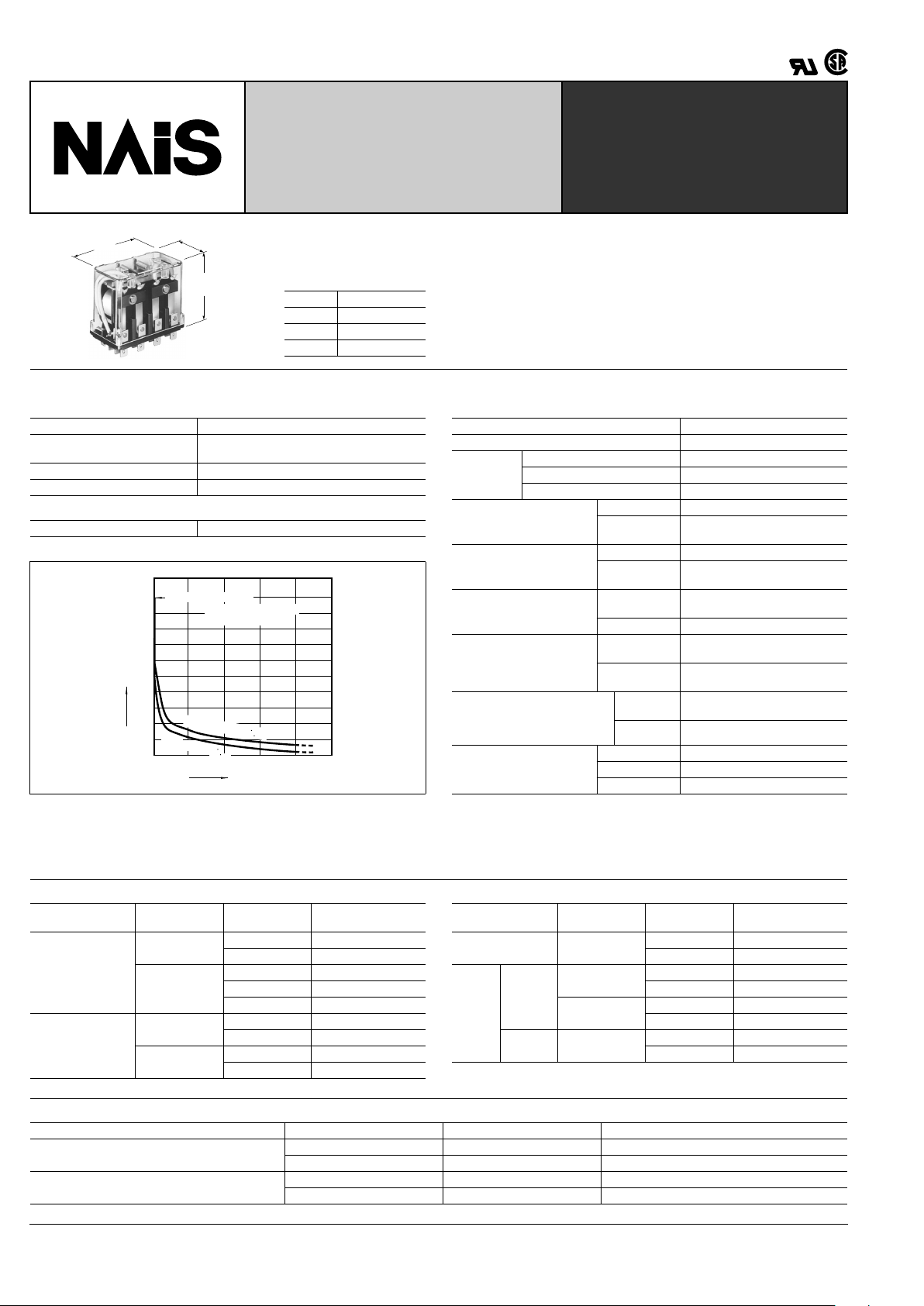

Life curve for AC types

Characteristics (at 60 Hz, 20 ° C 68 ° F)

Arrangement 2 Form C, 3 Form C, 4 Form C

Initial contact resistance, max.

(By voltage drop 6 V DC 1A)

15 m

Ω

Contact material Silver alloy

Nominal switching capacity 20 A 250 V AC (resistive)

Mechanical (at 180 cpm) AC type: 10

7

, DC type: 10

6

5101520

0

100

200

300

400

500

600

700

800

900

1,000

Load current, A

Operations, ×10

4

125 V AC cosϕ = 1

2

5

0

V

A

C

c

o

s

ϕ

=

1

Mechanical life : 10

7

Operating frequency:

180 op./min.

Maximum operating speed 20 cpm

Initial insulation resistance*

1

Min. 100 M Ω at 500 V DC

Initial

breakdown

voltage*

2

Between open contacts 2,000 Vrms for 1 min.

Between contacts sets 2,000 Vrms for 1 min.

Between contacts and coil 2,000 Vrms for 1 min.

Operate time*

3

(approx.)

(at nominal voltage)

2 Form C type 15 ms

3 Form C &

4 Form C type

25 ms

Release time

(without diode)*

3

(approx.)

(at nominal voltage)

2 Form C type 15 ms

3 Form C &

4 Form C type

25 ms

Shock resistance

Functional*

4

98 m/s

2

{10 G} (except for the

contact moving direction)

Destructive*

5

980 m/s

2

{100 G}

Vibration resistance

Functional*

6

58.8 m/s

2

{6 G}, 10 to 55 Hz

at 1 mm double amplitude

Destructive

117.6 m/s

2

{12 G}, 10 to 55 Hz

at 2 mm double amplitude

Conditions for operation,

transport and storage*

7

(Not freezing and condensing

at low temperature)

Ambient

temp.

–50

°

C to +40 ° C

–58

°

F to +104 ° F

Humidity 5 to 85% R.H.

Unit weight

2 Form C type Approx. 130 g 4.59 oz

3 Form C type Approx. 185 g 6.53 oz

4 Form C type Approx. 240 g 8.47 oz

Remarks

* Specifications will vary with foreign standards certification ratings.

*

1

Measurement at same location as "Initial breakdown voltage" section

*

2

Detection current: 10 mA

*

3

Excluding contact bounce time

*

4

Half-wave pulse of sine wave: 11ms; detection time: 10 µ s

*

5

Half-wave pulse of sine wave: 6ms

*

6

Detection time: 10 µ s

*

7

Refer to 5. Conditions for operation, transport and storage mentioned in

AMBIENT ENVIRONMENT (Page 61).

Electrical life with AC load

Note: In case of an electromagnet or exiting coil load (solenoid, etc.), the value of the motor or lamp load is applicable.

AC load Voltage, V AC Current, A

Expected life

(min. operations)

Resistive

(cos

ϕ

]

1)

125

20 5

×

10

5

15 7.5 × 10

5

250

20 2

×

10

5

15 5 × 10

5

10 7.5 × 10

5

Inductive

(cos

ϕ

]

0.4)

125

15 2

×

10

5

10 5 × 10

5

250

10 2

×

10

5

7.5 5 × 10

5

AC load Voltage, V AC Capacity, kW

Expected life

(min. operations)

Lamp 125

0.5 2

×

10

5

0.3 5 × 10

5

Motor

Single

phase

125

0.75 2

×

10

5

0.4 5 × 10

5

250

0.75 2

×

10

5

0.4 5 × 10

5

Three

phase

250

1.5 2

×

10

5

0.75 5 × 10

5

Electrical life with DC load

Note: For DC inductive load, use of an arc extinguishing circuit is recommended.

DC load Voltage, V DC Current, A Expected life (min. operations)

Resistive

24 15 5

×

10

5

125 0.8 5 × 10

5

Inductive (L/R

]

7 ms)

24 10 5

×

10

5

125 0.4 5 × 10

5

Page 2

HG

423

TYPICAL

APPLICATIONS

Industrial machinery, machine tools, food

processing and packing machines, office

machines, transportation equipment and

amusement devices.

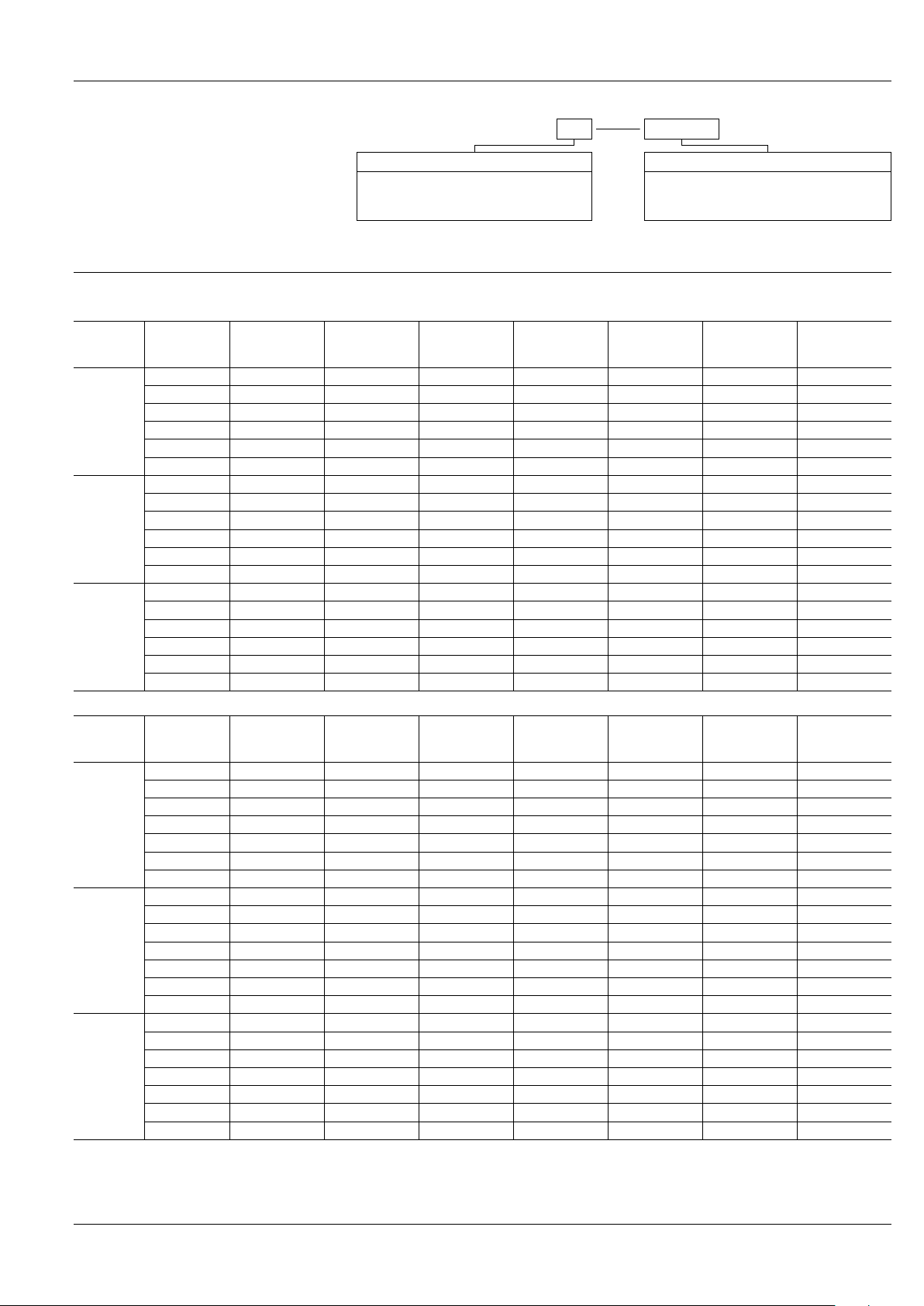

ORDERING INFORMATION

Ex. HG 2 AC 240 V

Contact arrangement

(Note) Standard packing Carton: HG2 20 pcs.

HG3, HG4 10 pcs.

UL/CSA approved type is standard.

2: 2 Form C

3: 3 Form C

4: 4 Form C

Coil voltage

AC 6, 12, 24, 48, 115, 220, 240 V

DC 6, 12, 24, 48, 110, 200 V

Case: HG2 100 pcs.

HG3, HG4 50 pcs.

TYPES AND COIL DATA

DC TYPES at 20 ° C 68 ° F

AC TYPES (50/60 Hz) at 60 HZ, 20 ° C 68 ° F

Type Part No.

Nominal coil

voltage, V DC

Pick-up

voltage,

V DC (max.)

Drop-out

voltage,

V DC (min.)

Max.

allowable,

V DC voltage

Coil

resistance,

Ω ( ±

10%)

Nominal coil

current,

mA

Operating

power, W

HG2

(2 Form C)

HG2-DC6V 6 4.8 0.9 6.6 26.4 230 (approx.) 1.4

HG2-DC12V 12 9.6 1.8 13.2 100 119.6 (approx.) 1.4

HG2-DC24V 24 19.2 3.6 26.4 416 57.6 (approx.) 1.4

HG2-DC48V 48 38.4 7.2 52.8 1585 30.3 (approx.) 1.4

HG2-DC110V 110 88 16.5 121 7650 14.4 (approx.) 1.4

HG2-DC200V 200 160 20 220 27,800 7.2 (approx.) 1.4

HG3

(3 Form C)

HG3-DC6V 6 4.8 0.9 6.6 22.7 264 (approx.) 1.6

HG3-DC12V 12 9.6 1.8 13.2 89.5 134 (approx.) 1.6

HG3-DC24V 24 19.2 3.6 26.4 364 66 (approx.) 1.6

HG3-DC48V 48 38.4 7.2 52.8 1450 33.1 (approx.) 1.6

HG3-DC110V 110 88 16.5 121 6670 16.5 (approx.) 1.6

HG3-DC200V 200 160 20 220 23,800 8.4 (approx.) 1.6

HG4

(4 Form C)

HG4-DC6V 6 4.8 0.9 6.6 18.5 325 (approx.) 2.1

HG4-DC12V 12 9.6 1.8 13.2 71.4 168 (approx.) 2.1

HG4-DC24V 24 19.2 3.6 26.4 296 81.2 (approx.) 2.1

HG4-DC48V 48 38.4 7.2 52.8 1050 45.7 (approx.) 2.1

HG4-DC110V 110 88 16.5 121 5420 20.3 (approx.) 2.1

HG4-DC200V 200 160 20 220 15,500 12.9 (approx.) 2.1

Type Part No.

Nominal coil

voltage,

V AC

Pick-up

voltage,

V AC (max.)

Drop-out

voltage,

V AC (min.)

Max.

allowable,

V AC voltage

Inductance,

H

Nominal coil

current,

mA

Operating

power,

VA

HG2

(2 Form C)

HG2-AC6V 6 4.8 1.8 6.6 0.026 600 (approx.) 3.6

HG2-AC12V 12 9.6 3.6 13.2 0.104 300 (approx.) 3.6

HG2-AC24V 24 19.2 7.2 26.4 0.416 150 (approx.) 3.6

HG2-AC48V 48 38.4 14.4 52.8 1.660 75 (approx.) 3.6

HG2-AC115V 115 92 34.5 126.5 9.531 31.3 (approx.) 3.6

HG2-AC220V 220 176 66 242 34.96 16.4 (approx.) 3.6

HG2-AC240V 240 192 72 264 41.68 15 (approx.) 3.6

HG3

(3 Form C)

HG3-AC6V 6 4.8 1.8 6.6 0.018 864 (approx.) 5.2

HG3-AC12V 12 9.6 3.6 13.2 0.073 432 (approx.) 5.2

HG3-AC24V 24 19.2 7.2 26.4 0.290 216 (approx.) 5.2

HG3-AC48V 48 38.4 14.4 52.8 1.163 108 (approx.) 5.2

HG3-AC115V 115 92 34.5 126.5 6.648 45.2 (approx.) 5.2

HG3-AC220V 220 176 66 242 24.26 23.6 (approx.) 5.2

HG3-AC240V 240 192 72 264 29.06 21.6 (approx.) 5.2

HG4

(4 Form C)

HG4-AC6V 6 4.8 1.8 6.6 0.012 1264 (approx.) 7.6

HG4-AC12V 12 9.6 3.6 13.2 0.050 632 (approx.) 7.6

HG4-AC24V 24 19.2 7.2 26.4 0.199 316 (approx.) 7.6

HG4-AC48V 48 38.4 14.4 52.8 0.795 158 (approx.) 7.6

HG4-AC115V 115 92 34.5 126.5 4.557 66.1 (approx.) 7.6

HG4-AC220V 220 176 66 242 16.89 34 (approx.) 7.6

HG4-AC240V 240 192 72 264 19.87 31.6 (approx.) 7.6

Notes:

1. The coil current ranges is ± 15% for AC (60 Hz), ± 10% for DC (20 ° C 68 ° F).

2. These relays are applicable to a r ange of 80% to 110% of the nominal coil voltage.

However , it is recommended that the rela y be used in a range of 85% to 110% of the

nominal coil voltage, taking the temporary voltage variation into consideration. For

AC types, when operating voltage is 70% of nominal coil voltage, "buzzing" will oc-

cur, and a large amount of current will flow, burning the coil.

3. Each coil resistance of DC types is the measured value at coil temperature of

20 ° C 68 ° F. Please compensate the coil resistance by ± 0.4%, each time the coil temperature changes by ± 1 ° C.

Page 3

HG

424

DIMENSIONS

HG2 (2 Form C)

8.4

.3317

.276

16

.630

20.5

.807

15

.591

34

1.339

56

2.205

17

.669

7 .276

8.5 .335

10.5 .413

7.5 .295

7.26 .286

36

1.417

2.5 DIA. 9 DEEP HOLE for

3 DIA. TAPPING SCREW

.098 DIA. .354 DEPTH

2.5 DIA. 8 DEEP HOLE for

3 DIA. TAPPING SCREW

.098 DIA. .315 DEPTH

AMP SERIES

FASTON 250

CONNECTORS

CAN BE USED

Schematic (Bottom view)

HG3 (3 Form C)

8.4

.331

8.4

.331

7

.276

16

.630

20.5

.807

17

.669

50

1.969

17

.66917.669

7 .276

10.5 .413

7.5 .295

7.26 .286

36

1.417

2.5 DIA. 9 DEEP HOLE for

3 DIA. TAPPING SCREW

.098 DIA. .354 DEPTH

2.5 DIA. 8 DEEP HOLE for

3 DIA. TAPPING SCREW

.098 DIA. .354 DEPTH

AMP SERIES

FASTON 250

CONNECTORS

CAN BE USED

8.5 .335

56

2.205

Schematic (Bottom view)

HG4 (4 Form C)

8.4

.331

8.4

.331

7

.276

16

.630

20.5

.807

34

1.339

68

2.667

17

.66917.66917.669

7 .276

10.5 .413

7.5 .295

7.26 .286

36

1.417

2.5 DIA. 9 DEEP HOLE for

3 DIA. TAPPING SCREW

.098 DIA. .354 DEPTH

2.5 DIA. 8 DEEP HOLE for

3 DIA. TAPPING SCREW

.098 DIA. .315 DEPTH

AMP SERIES

FASTON 250

CONNECTORS

CAN BE USED

8.5 .335

56

2.205

Schematic (Bottom view)

General tolerance: ± 0.5 ± .020

mm inch

ACCESSORIES

Please refer to "MOUNTING METHOD" for further information.

Note: Tapping-screw holes are provided on the cover top for direct mounting.

HG Relay

Screw terminal socket

for DIN rail assembly

(with hold-down clip)

Solder terminal socket

for rectangular hole

(with hold-down clip)

Bracket for direct mounting

HG2

(2 Form C)

HG2-SFD HG2-SS HP-BRACKET

1 pc.

HG3

(3 Form C)

HG3-SFD HG3-SS HP-BRACKET

2 pcs.

HG4

(4 Form C)

No screw terminal socket for

HG4 use 2 screw terminal

sockets (HG2-SFD)

HG4-SS HP-BRACKET

2 pcs.

Page 4

HG

425

MOUNTING METHOD AND DIMENSIONS

Screw terminal socket (Hold-down clips included)

HG2-SFD HG3-SFD

26

±0.6

1.024

±.024

17

±0.2

.669

±.008

4.5

±0.3

.177

±.012

21

±0.6

.827

±.024

HOLD DOWN

CLIP

Lot No.

HG2 RELAY

Installation screw block

(installation screw, hexagonal nut, spring washer)

35.4

±0.5

1.394

±.020

6

±0.3

.236

±.012

7.56

±0.2

.298

±.008

10.44

±0.2

.411

±.008

0.56

±0.15

.022

±.006

7.26

±0.2

.286

±.008

80

±1

3.150

±.039

58

±1

2.283

±.039

69

±1

2.717

±.039

10

±0.6

.394

±.024

36

±0.6

1.417

±.024

34.5

±0.6

1.358

±.024

26

±0.2

1.024

±.008

10

.394

26

±0.2

1.024

±.008

2-M4 (4.2

±0.1

)

Panel hole dimensions for side-by-side installation

34

1.339

2 .079

34

1.339

80

3.150

69

±0.5

2.717

±.020

7

8

5

6

1

4

3

2

Note: Hold down clip

and installation

screw block

are included in

package.

4.5

±0.3

.177

±.012

21

±0.6

.827

±.024

10

±0.6

.394

±.024

80

±1

3.150

±.039

35.4

±0.5

1.394

±.020

HOLD

DOWN

CLIP

Lot No.

Installation screw block

(installation screw, hexagonal nut, spring washer)

HG3 RELAY

58

±1

2.283

±.039

6

±0.3

.236

±.012

10.44

±0.2

.411

±.008

0.56

±0.15

.022

±.006

7.26

±0.2

.286

±.008

7.56

±0.2

.298

±.008

69

±1

2.717

±.039

43

±0.6

1.693

±.024

36

±0.6

1.417

±.024

34.5

±0.6

1.358

±.024

17

±0.2

.669

±.008

17

±0.2

.669

±.008

10

.394

2-M4 (4.2

±0.1

)

Panel hole dimensions for side-by-side installation

51

2.008

2 .079

51

2.008

80

3.150

69

±0.5

2.717

±.020

43

±0.2

1.693

±.008

43

±0.2

1.693

±.008

4

1

5

2

6

3

7

12

9

11

8

10

Note: Hold down

clip and installation

screw

block are

included in

package.

mm inch

Solder terminal socket (Hold-down clips included)

HG2-SS HG3-SS HG4-SS

22

.866

17

±0.1

.669

±.004

22

.866

approx. 23.5

.925

30.5

1.201

17

±0.1

.669

±.004

14.5

.571

48

1.890

59

±1

2.323

±.039

40.5

1.594

36.5

1.437

6.2

±0.3

.244

±.012

34

1.339

4.2

±0.3

.165

±.012

6

±0.3

.236

±.012

6

±0.3

.236

±.012

31.5±0.5

1.240±.020

48±0.5

1.890±.020

37.5

±0.5

1.476

±.020

4.2 DIA. HOLE or

4 mm SCREW HOLE

.165 DIA. HOLE

28

1.102

34

1.339

47

1.850

28

1.102

51

±1

2.008

±.039

approx. 23.5

.925

14.5

.571

6

±0.3

.236

±.012

36.5

1.437

59

±1

2.323

±.039

17

±0.1

.669

±.004

6

±0.3

.236

±.012

48

1.890

40.5

1.594

6.2

±0.3

.244

±.012

4.2

±0.3

.165

±.012

48±0.5

1.890±.020

48±0.5

1.890

±.020

37.5±0.5

1.476

±.020

4.2 DIA. HOLE or

4 mm SCREW HOLE

.165 DIA. HOLE

45

1.772

51

2.008

64.5

±1

2.539

±.039

45

1.772

68

±1

2.677

±.039

36.5

1.437

approx. 23.5

.925

14.5

.571

6

.236

59

2.323

17

.669

6

.236

48

1.890

40.5

1.594

6.2

±0.3

.244

±.012

17

±0.1

.669

±.004

4.2

±0.3

.165

±.012

65.5±0.5

2.579±.020

48±0.5

1.890

±.020

37.5±0.5

1.476

±.020

4.2 DIA. HOLE or

4 mm SCREW HOLE

.165 DIA. HOLE

General tolerance: ±0.6 ±.024Note: HG sockets accept Faston 250.

Page 5

HG

426

Direct mounting

Faston 250 series quick-connectors

can be used.

3 DIA. TAPPING SCREW

.118 DIA.

3.5 DIA. HOLE

.138 DIA.

A: HG 2: 15mm .591

HG 3: 17mm .669

HG 4: 34mm 1.339

A

Direct mounting with HP-BRACKET

Faston 250 series quick-connectors can be used.

Use two brackets for HG3 and HG4

Notes:

1. This bracket is unavailable for UL, CSA and VDE applications.

2. When using any other non-standard bracket mounting-screw length should not exceed bracket

thickness plus 7 mm .276 inch to avoid damage to relay coils.

8

.315

14

.551

2 .079

4

.158

1

.039

23

.906

20

.787

3.5 DIA. HOLE

.138 DIA.

3 DIA. HOLE

.118 DIA.

14

.551

8.5

.335

90°±3

3 mm DIA. TAPPING SCREW

Socket Combinations

NOTES

Please use the hold-down clip whenever

HG relays will be used in applications

where strong vibrating or shock force occurs. When used in such applications,

mount the relay so that this force does not

parallel the direction of contact movement.

For Cautions for Use, see Relay Technical Information (Page 48 to 76).

9/1/2000 All Rights Reserved, © Copyright Matsushita Electric Works, Ltd.

Go To Online Catalog

Loading...

Loading...