Page 1

Fiber Optic Transmitter

and Receiver Data Links

for 155 MBd

Technical Data

HFBR-1116T Transmitter

HFBR-2116T Receiver

Features

• Full Compliance with the

Optical Performance

Requirements of the ATM

Forum UNI SONET OC-3

Multimode Physical Layer

Specification

• Other Versions Available for:

- FDDI

- Fibre Channel

• Compact 16-pin DIP Package

with Plastic ST* Connector

• Wave Solder and Aqueous

Wash Process Compatible

Package

• Manufactured in an ISO

9001 Certified Facility

Applications

• ATM Switches, Hubs, and

Network Interface Cards

• Multimode Fiber ATM

Wiring Closet-to-Desktop

Links

• Point-to-Point Data

Communications

• Replaces DLT/R1040-ST1

Model Transmitters and

Receivers

Description

The HFBR-1116/-2116 series of

data links are high-performance,

cost-efficient, transmitter and

receiver modules for serial

optical data communication

applications specified at 155 MBd

for ATM UNI applications.

These modules are designed for

50 or 62.5 µm core multimode

optical fiber and operate at a

nominal wavelength of 1300 nm.

They incorporate our highperformance, reliable, longwavelength, optical devices and

proven circuit technology to give

long life and consistent

performance.

Transmitter

The transmitter utilizes a 1300 nm

surface-emitting InGaAsP LED,

packaged in an optical subassembly. The LED is dc-coupled to a

custom IC which converts

differential-input, PECL logic

signals, ECL-referenced (shifted)

to a +5 V power supply, into an

analog LED drive current.

Receiver

The receiver utilizes an InGaAs

PIN photodiode coupled to a

custom silicon transimpedance

preamplifier IC. The PINpreamplifier combination is accoupled to a custom quantizer IC

which provides the final pulse

shaping for the logic output and

the Signal Detect function. Both

the Data and Signal Detect

Outputs are differential. Also,

both Data and Signal Detect

Outputs are PECL compatible,

ECL-referenced (shifted) to a

+5 V power supply.

Package

The overall package concept for

the Data Links consists of the

following basic elements: two

optical subassemblies, two

electrical subassemblies, and the

outer housings as illustrated in

Figure 1.

*ST is a registered trademark of AT&T Lightguide Cable Connectors.

5965-3482E (8/96)

189

Page 2

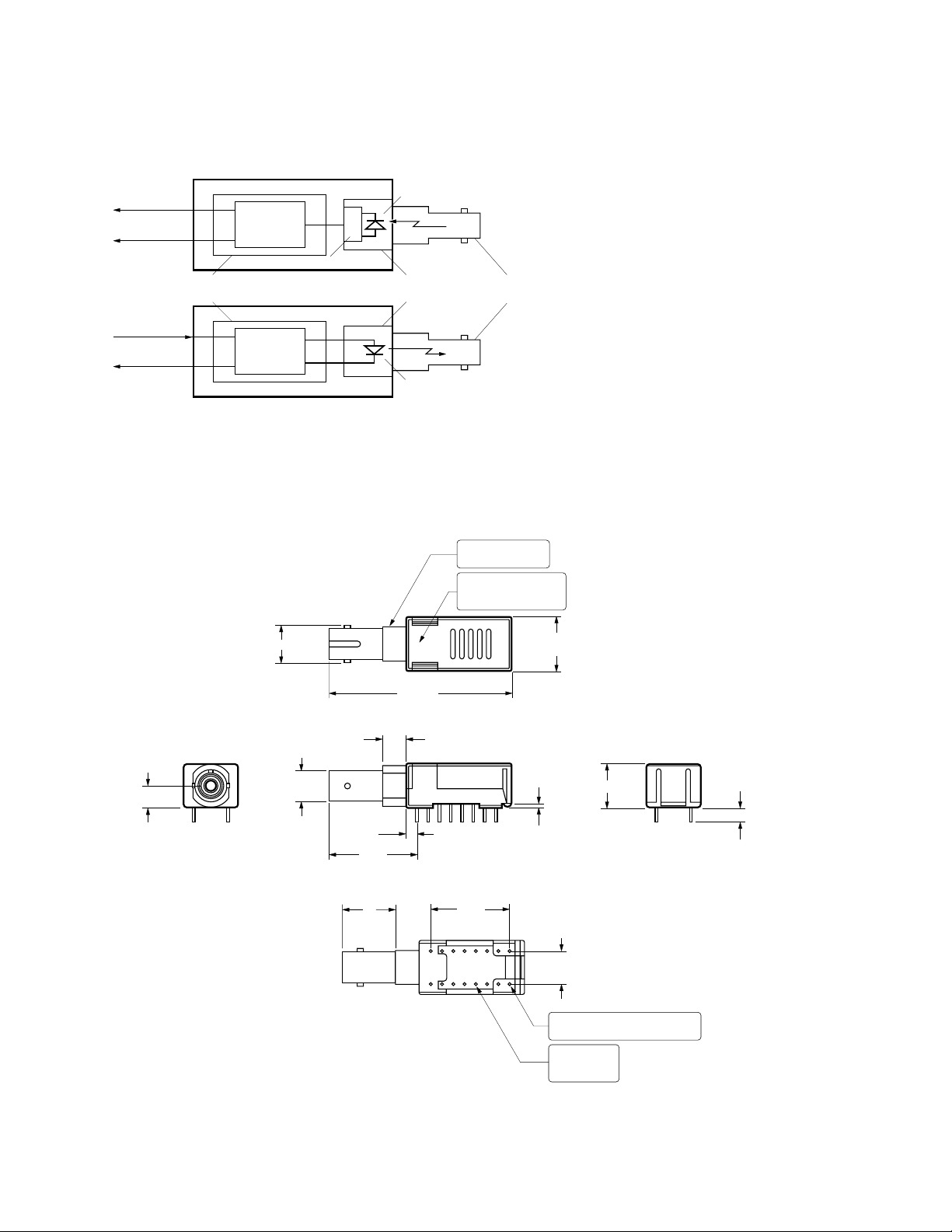

DIFFERENTIAL

DATA IN

DIFFERENTIAL

SIGNAL

DETECT OUT

DIFFERENTIAL

DATA IN

V

BB

RECEIVER

QUANTIZER

IC

ELECTRICAL

SUBASSEMBLIES

TRANSMITTER

DRIVER IC

PREAMP IC

PIN PHOTODIODE

OPTICAL

SUBASSEMBLIES

LED

SIMPLEX ST

RECEPTACLE

The package outline drawing and

pinout are shown in Figures 2

and 3. The details of this package

outline and pinout are compatible

with other data-link modules from

®

other vendors.

The optical subassemblies consist

of a transmitter subassembly in

which the LED resides and a

receiver subassembly housing the

PIN-preamplifier combination.

TOP VIEW

Figure 1. Transmitter and Receiver Block Diagram.

8.31

41 MAX.

5.05

5.0

7.01

2.45

19.72

THREADS

3/8 – 32 UNEF-2A

HFBR-111X/211XT

DATE CODE (YYWW)

SINGAPORE

12.19

MAX.

0.9

The electrical subassemblies consist of a multi-layer printed circuit

board on which the IC chips and

various surface-mounted, passive

circuit elements are attached.

9.8 MAX.

3

NOTES:

1. MATERIAL ALLOY 194 1/2H – 0.38 THK

FINISH MATTE TIN PLATE 7.6 µm MIN.

2. MATERIAL PHOSPHOR BRONZE WITH

120 MICROINCHES TIN LEAD (90/10)

OVER 50 MICROINCHES NICKEL.

3. UNITS = mm

Figure 2. Package Outline Drawing.

190

12

17.78

(7 x 2.54)

8 x 7.62

HOUSING PINS 0.38 x 0.5 mm

NOTE 1

PCB PINS

DIA. 0.46 mm

NOTE 2

Page 3

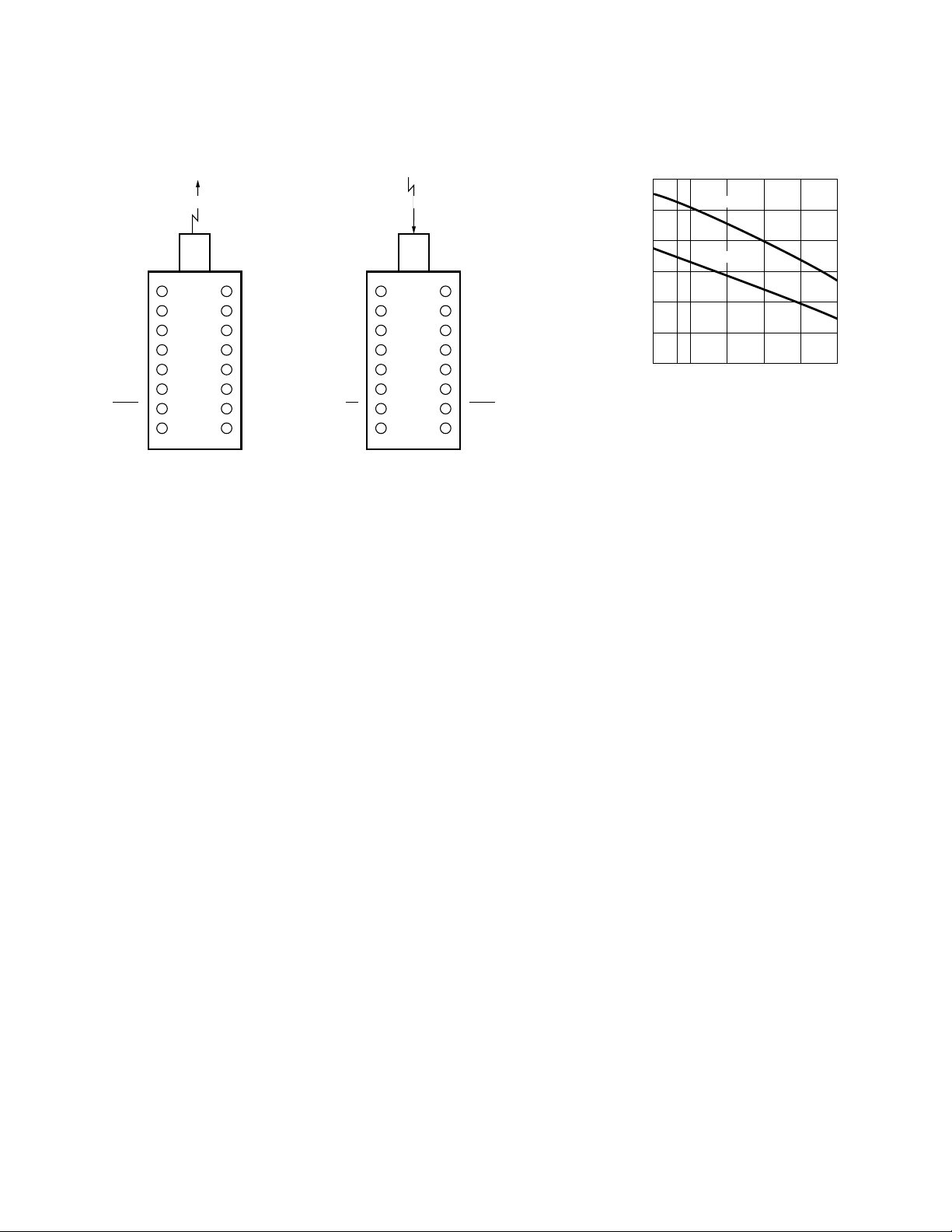

NC

GND

V

CC

V

CC

GND

DATA

DATA

NC

OPTICAL PORT

9NC

8

10 NO PIN

7

11 GND

6

12 GND

5

13 GND

4

14 GND

3

15 V

2

BB

16 NC

1

NC

NO PIN

GND

GND

GND

SD

SD

NO PIN

OPTICAL PORT

9NC

8

10 GND

7

11 V

6

CC

12 V

5

CC

13 V

4

CC

14 DATA

3

15 DATA

2

16 NC

1

12

10

8

6

4

2

OPTICAL POWER BUDGET (dB)

0

Figure 4. Optical Power Budget at

BOL vs. Fiber Optic Cable Length.

62.5/125 µm

50/125 µm

0.5

0 1.0 1.5

0.3 2.0

FIBER OPTIC CABLE LENGTH (km)

2.5

TRANSMITTER

Figure 3. Pinout Drawing.

Each transmitter and receiver

package includes an internal shield

for the electrical subassembly to

ensure low EMI emissions and high

immunity to external EMI fields.

The outer housing, including the

ST* port, is molded of filled, nonconductive plastic to provide

mechanical strength and electrical

isolation. For other port styles,

please contact your HewlettPackard Sales Representative.

Each data-link module is attached

to a printed circuit board via the

16-pin DIP interface. Pins 8 and 9

provide mechanical strength for

these plastic-port devices and will

provide port-ground for forthcoming metal-port modules.

Application Information

The Applications Engineering

group of the Optical Communication Division is available to assist

you with the technical understanding and design tradeoffs associated

with these transmitter and receiver

modules. You can contact them

through your Hewlett-Packard

sales representative.

RECEIVER

The following information is

provided to answer some of the

most common questions about the

use of these parts.

Transmitter and Receiver Optical Power Budget versus Link Length

The Optical Power Budget (OPB)

is the available optical power for a

fiber-optic link to accommodate

fiber cable losses plus losses due to

in-line connectors, splices, optical

switches, and to provide margin for

link aging and unplanned losses

due to cable plant reconfiguration

or repair.

Figure 4 illustrates the predicted

OPB associated with the transmitter and receiver specified in this

data sheet at the Beginning of Life

(BOL). This curve represents the

attenuation and chromatic plus

modal dispersion losses associated

with 62.5/125 µm and 50/125 µm

fiber cables only. The area under

the curve represents the remaining

OPB at any link length, which is

available for overcoming non-fiber

cable related losses.

*ST is a registered trademark of AT&T Lightguide Cable Connectors.

191

Page 4

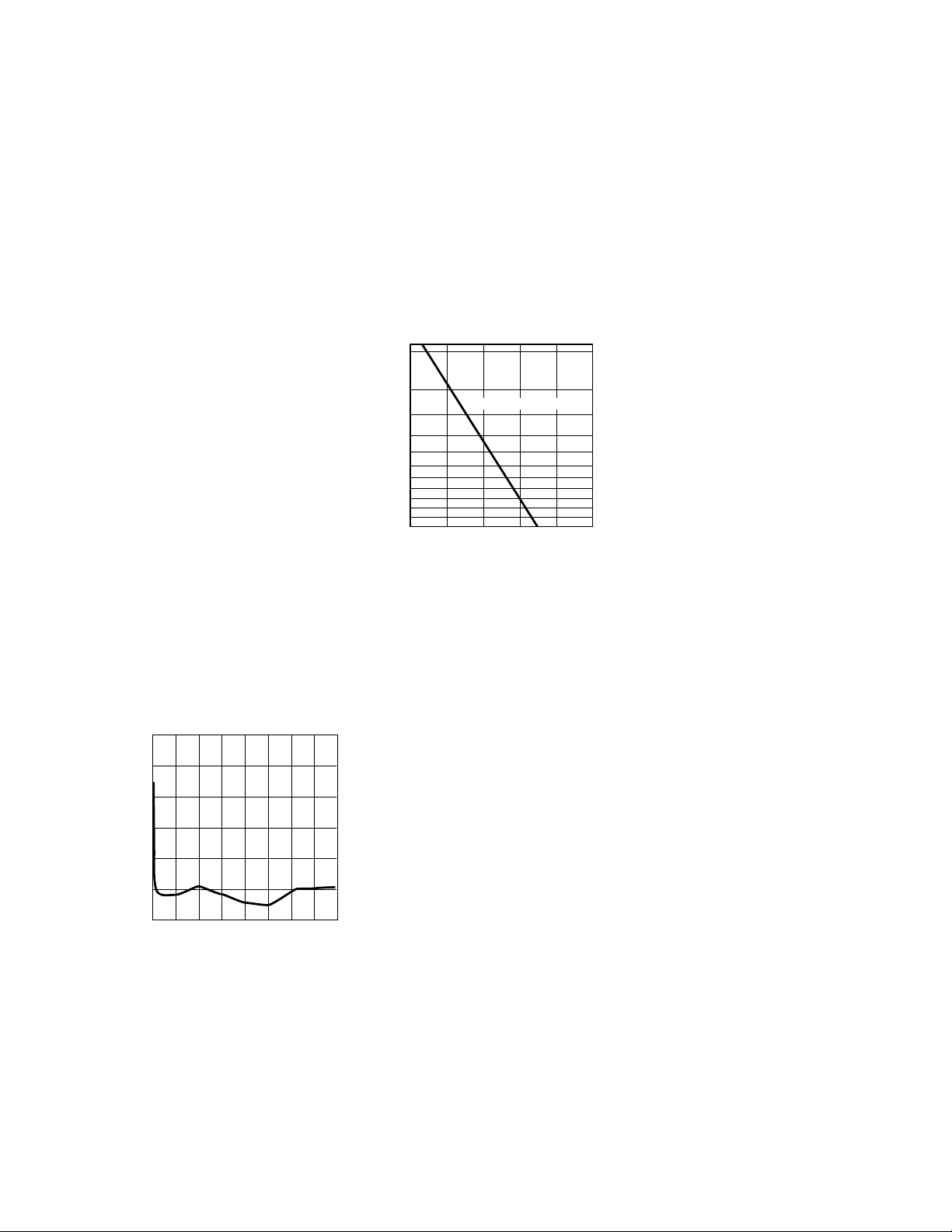

Transmitter and Receiver Signaling Rate Range and BER Performance

For purposes of definition, the

symbol rate (Baud), also called

signaling rate, is the reciprocal of

the symbol time. Data rate (bits/

sec) is the symbol rate divided by

the encoding factor used to encode

the data (symbols/bit).

When used in 115 Mbps SONET

OC-3 applications, the performance of Hewlett-Packard’s

1300 nm data link modules, HFBR1116/-2116, is guaranteed to the

full conditions listed in the individual product specification tables.

The data link modules may be used

for other applications at signaling

rates different than the 155 Mbps

with some variation in the link

optical power budget. Figure 5

gives an indication of the typical

performance of these 1300 nm

products at different rates.

2.5

2.0

1.5

1.0

0.5

0

0.5

0 200

25 75 100 125

POWER BUDGET AT CONSTANT BER (dB)

TRANSMITTER/RECEIVER RELATIVE OPTICAL

CONDITIONS:

1. PRBS 2

2. DATA SAMPLED AT CENTER OF DATA SYMBOL.

3. BER = 10

4. TA = 25° C

5. V

= 5 Vdc

CC

6. INPUT OPTICAL RISE/FALL TIMES = 1.0/2.1 ns.

Figure 5. Transmitter/Receiver

Relative Optical Power Budget at

Constant BER vs. Signaling Rate.

50 150

SIGNAL RATE (MBd)

7

-1

-6

175

These data link modules can also

be used for applications which

require different bit-error-ratio

(BER) performance. Figure 6

illustrates the typical trade-off

between link BER and the receiver

input optical power level.

-2

1 x 10

-3

1 x 10

-4

1 x 10

-5

1 x 10

-6

1 x 10

-7

1 x 10

-8

1 x 10

BIT ERROR RATIO

-9

1 x 10

-10

1 x 10

-11

1 x 10

-12

1 x 10

-6 4

RELATIVE INPUT OPTICAL POWER – dB

CONDITIONS:

1. 155 MBd

2. PRBS 2

= 25° C

3. T

A

4. V

CC

5. INPUT OPTICAL RISE/FALL TIMES = 1.0/2.1 ns.

Figure 6. Bit Error Ratio vs. Relative

Receiver Input Optical Power.

CENTER OF SYMBOL

-4 2-2

7

-1

= 5 Vdc

0

Data Link Jitter Performance

The Hewlett-Packard 1300 nm data

link modules are designed to

operate per the system jitter

allocations stated in Table B1 of

Annex B of the ANSI T1E1.2

Revision 3 standard.

The 1300 nm transmitter will

tolerate the worst-case input

electrical jitter allowed in Annex B

without violating the worst-case

output jitter requirements.

The 1300 nm receiver will tolerate

the worst-case input optical jitter

allowed in Annex B without

violating the worst-case output

electrical jitter allowed.

The jitter specifications stated in

the following transmitter and

receiver specification table are

derived from the values in Table

B1 of Annex B. They represent the

worst-case jitter contribution that

the transmitter and receiver are

allowed to make to the overall

system jitter without violating the

Annex B allocation example. In

practice, the typical jitter

contribution of the HewlettPackard data link modules is well

below the maximum allowed

amounts.

Recommended Handling Precautions

It is advised that normal static precautions be taken in the handling

and assembly of these data link

modules to prevent damage which

may be induced by electrostatic

discharge (ESD). The HFBR-1116/2116 series meets MIL-STD-883C

Method 3015.4 Class 2.

Care should be taken to avoid

shorting the receiver Data or

Signal Detect Outputs directly to

ground without proper currentlimiting impedance.

Solder and Wash Process Compatibility

The transmitter and receiver are

delivered with protective process

caps covering the individual ST*

ports. These process caps protect

the optical subassemblies during

wave solder and aqueous wash

processing and act as dust covers

during shipping.

These data link modules are

compatible with either industry

standard wave- or hand-solder

processes.

192

Page 5

Shipping Container

The data link modules are

packaged in a shipping container

designed to protect it from

mechanical and ESD damage

during shipment or storage.

Board Layout–Interface Circuit and Layout Guidelines

It is important to take care in the

layout of your circuit board to

achieve optimum performance

from these data link modules.

Figure 7 provides a good example

of a power supply filter circuit that

works well with these parts. Also,

suggested signal terminations for

the Data, Data-bar, Signal Detect

and Signal Detect-bar lines are

shown. Use of a multilayer,

ground-plane printed circuit board

will provide good high-frequency

circuit performance with a low

inductance ground return path. See

additional recommendations noted

in the interface schematic shown in

Figure 7.

Tx

*

130

9 NC

10 GND

11 V

12 V

13 GND

14 D

15 D

R1

16 NC

A

L2

R3

R2

82

82

C5

0.1

TERMINATE D, D

AT Tx INPUTS

1

C2

0.1

R4

130

+5 Vdc

GND

DATA

DATA

NOTES:

1. RESISTANCE IS IN OHMS. CAPACITANCE IS IN MICROFARADS. INDUCTANCE IS IN MICROHENRIES.

2. TERMINATE TRANSMITTER INPUT DATA AND DATA-BAR AT THE TRANSMITTER INPUT PINS. TERMINATE THE RECEIVER OUTPUT DATA, DATA-BAR, AND SIGNAL DETECTBAR AT THE FOLLOW-ON DEVICE INPUT PINS. FOR LOWER POWER DISSIPATION IN THE SIGNAL DETECT TERMINATION CIRCUITRY WITH SMALL COMPROMISE TO THE

SIGNAL QUALITY, EACH SIGNAL DETECT OUTPUT CAN BE LOADED WITH 510 OHMS TO GROUND INSTEAD OF THE TWO RESISTOR, SPLIT-LOAD PECL TERMINATION

SHOWN IN THIS SCHEMATIC.

3. MAKE DIFFERENTIAL SIGNAL PATHS SHORT AND OF SAME LENGTH WITH EQUAL TERMINATION IMPEDANCE.

4. SIGNAL TRACES SHOULD BE 50 OHMS MICROSTRIP OR STRIPLINE TRANSMISSION LINES. USE MULTILAYER, GROUND-PLANE PRINTED CIRCUIT BOARD FOR BEST HIGHFREQUENCY PERFORMANCE.

5. USE HIGH-FREQUENCY, MONOLITHIC CERAMIC BYPASS CAPACITORS AND LOW SERIES DC RESISTANCE INDUCTORS. RECOMMEND USE OF SURFACE-MOUNT COIL

INDUCTORS AND CAPACITORS. IN LOW NOISE POWER SUPPLY SYSTEMS, FERRITE BEAD INDUCTORS CAN BE SUBSTITUTED FOR COIL INDUCTORS. LOCATE POWER

SUPPLY FILTER COMPONENTS CLOSE TO THEIR RESPECTIVE POWER SUPPLY PINS. C7 IS AN OPTIONAL BYPASS CAPACITOR FOR IMPROVED, LOW-FREQUENCY NOISE

POWER SUPPLY FILTER PERFORMANCE.

6. DEVICE GROUND PINS SHOULD BE DIRECTLY AND INDIVIDUALLY CONNECTED TO GROUND.

7. CAUTION: DO NOT DIRECTLY CONNECT THE FIBER-OPTIC MODULE PECL OUTPUTS (DATA, DATA-BAR, SIGNAL DETECT, SIGNAL DETECT-BAR, V

PROPER CURRENT LIMITING IMPEDANCE.

8. (*) OPTIONAL METAL ST OPTICAL PORT TRANSMITTER AND RECEIVER MODULES WILL HAVE PINS 8 AND 9 ELECTRICALLY CONNECTED TO THE METAL PORT ONLY AND

NOT CONNECTED TO THE INTERNAL SIGNAL GROUND.

CC

CC

NC 8

PIN

GND 6

GND 5

GND 4

GND 3

V

NO

BB

NC 1

*

7

2

*

TOP VIEWS

9 NC

NO

10

PIN

11 GND

12 GND

13 GND

14 SD

15 SD

NO

16

PIN

Rx

CC

CC

CC

D 3

D

NC 1

*

6

0.1

C1

0.1

C6

R10

130

5

4

2

L1

1

C7

10

(OPTIONAL)

R9

82

R11

82

R12

130

TERMINATE D, D, SD, SD AT

INPUTS OF FOLLOW-ON DEVICES

C3

0.1C410

R8

R5

R7

82

130

82

) TO GROUND WITHOUT

BB

SD

NC 8

GND 7

V

V

V

130

A

DATA

DATA

R6

SD

Figure 7. Recommended Interface Circuitry and Power Supply Filter Circuits.

193

Page 6

Board Layout–Hole Pattern

The Hewlett-Packard transmitter

and receiver hole pattern is

compatible with other data link

modules from other vendors. The

drawing shown in Figure 8 can be

used as a guide in the mechanical

layout of your circuit board.

17.78

.700

(16X)

0.8 ± 0.1

ø

.032 ± .004

Ø 0.000

–A–

MA

(7X)

7.62

.300

Figure 8. Recommended Board Layout Hole Pattern.

TOP VIEW

2.54

.100

UNITS = mm/INCH

194

Page 7

Regulatory Compliance

These data link modules are

intended to enable commercial

system designers to develop

equipment that complies with the

various international regulations

governing certification of Information Technology Equipment.

Additional information is available

from your Hewlett-Packard sales

representative.

All HFBR-1116T LED transmitters

are classified as IEC-825-1

Accessible Emission Limit (AEL)

Class 1 based upon the current

proposed draft scheduled to go

into effect on January 1, 1997. AEL

Class 1 LED devices are

considered eye safe. See

Application Note 1094, LED

Device Classifications with

Respect to AEL Values as

Defined in the IEC 825-1

Standard and the European

EN60825-1 Directive.

The material used for the housing

in the HFBR-1116/-2116 series is

Ultem 2100 (GE). Ultem 2100 is

recognized for a UL flammability

rating of 94V-0 (UL File Number

E121562) and the CSA (Canadian

Standards Association) equivalent

(File Number LS88480).

200

180

1.0

160

1.5

140

2.0

2.5

120

3.0

SPECTRAL WIDTH (FWHM) –nm

100

∆λ – TRANSMITTER OUTPUT OPTICAL

1260

λC – TRANSMITTER OUTPUT OPTICAL

CENTER WAVELENGTH –nm

HFBR-1116T TRANSMITTER TEST RESULTS

, ∆λ AND t

OF λ

C

COMPLY WITH THE ALLOWED SPECTRAL WIDTH

AS A FUNCTION OF CENTER WAVELENGTH FOR

VARIOUS RISE AND FALL TIMES.

t

– TRANSMITTER

r/f

OUTPUT OPTICAL

RISE/FALL TIMES – ns

1280 1300 1320

ARE CORRELATED AND

r/f

3.0

Figure 9. HFBR-1116T Transmitter

Output Optical Spectral Width

(FWHM) vs. Transmitter Output

Optical Center Wavelength and Rise/

Fall Times.

5

4

3

2

1

0

RELATIVE INPUT OPTICAL POWER (dB)

-3 -1 0 1

-2 2

EYE SAMPLING TIME POSITION (ns)

CONDITIONS:

= 25° C

1.T

A

= 5 Vdc

2. V

CC

3. INPUT OPTICAL RISE/FALL TIMES = 1.0/2.1 ns.

4. INPUT OPTICAL POWER IS NORMALIZED TO

CENTER OF DATA SYMBOL.

5. NOTE 15 AND 16 APPLY.

13601340

3

Figure 10. HFBR-2116T Receiver

Input Optical Power vs. Eye Sampling

Time Position.

195

Page 8

HFBR-1116T Transmitter Pin-Out Table

Pin Symbol Functional Description Reference

1 NC No internal connect, used for mechanical strength only

2VBBVBB Bias output

3 GND Ground Note 3

4 GND Ground Note 3

5 GND Ground Note 3

6 GND Ground Note 3

7 OMIT No pin

8 NC No internal connect, used for mechanical strength only Note 5

9 NC No internal connect, used for mechanical strength only Note 5

10 GND Ground Note 3

11 V

12 V

CC

CC

Common supply voltage Note 1

Common supply voltage Note 1

13 GND Ground Note 3

14 DATA Data input Note 4

15 DATA Inverted Data input Note 4

16 NC No internal connect, used for mechanical strength only

HFBR-2116T Receiver Pin-Out Table

Pin Symbol Functional Description Reference

1 NC No internal connect, used for mechanical strength only

2 DATA Inverted Data input Note 4

3 DATA Data input Note 4

4VCCCommon supply voltage Note 1

5VCCCommon supply voltage Note 1

6VCCCommon supply voltage Note 1

7 GND Ground Note 3

8 NC No internal connect, used for mechanical strength only Note 5

9 NC No internal connect, used for mechanical strength only Note 5

10 OMIT No pin

11 GND Ground Note 3

12 GND Ground Note 3

13 GND Ground Note 3

14 SD Signal Detect Note 2, 4

15 SD Inverted Signal Detect Note 2, 4

16 OMIT No pin

Notes:

1. Voltages on VCC must be from the same power supply (they are connected together internally).

2. Signal Detect is a logic signal that indicates the presence or absence of an input optical signal. A logic-high, VOH, on Signal Detect

indicates presence of an input optical signal. A logic-low, VOL, on Signal Detect indicates an absence of input optical signal.

3. All GNDs are connected together internally and to the internal shield.

4. DATA, DATA, SD, SD are open-emitter output circuits.

5. On metal-port modules, these pins are redefined as “Port Connection.”

196

Page 9

Specifications–Absolute Maximum Ratings

Parameter Symbol Min. Typ. Max. Unit Reference

Storage Temperature T

Lead Soldering Temperature T

Lead Soldering Time t

SOLD

SOLD

Supply Voltage V

Data Input Voltage V

Differential Input Voltage V

Output Current I

S

CC

I

D

O

-40 100 °C

-0.5 7.0 V

-0.5 V

Recommended Operating Conditions

Parameter Symbol Min. Typ. Max. Unit Reference

Ambient Operating Temperature T

Supply Voltage V

A

CC

Data Input Voltage–Low VIL - V

Data Input Voltage–High VIH - V

Data and Signal Detect Output Load R

L

CC

CC

070°C

4.5 5.5 V

-1.810 -1.475 V

-1.165 -0.880 V

HFBR-1116T Transmitter Electrical Characteristics

(TA = 0°C to 70°C, VCC = 4.5 V to 5.5 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Supply Current I

Power Dissipation P

Threshold Voltage VBB - V

Data Input Current–Low I

Data Input Current–High I

CC

DISS

IL

IH

-1.42 -1.3 -1.24 V Note 24

CC

-350 0 µs

260 °C

10 sec.

CC

V

1.4 V Note 1

50 mA

50 Ω Note 2

145 185 mA Note 3

0.76 1.1 W Note 5

14 350 µs

HFBR-2116T Receiver Electrical Characteristics

(TA = 0°C to 70°C, VCC = 4.5 V to 5.5 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Supply Current I

Power Dissipation P

Data Output Voltage–Low VOL - V

Data Output Voltage–High VOH - V

Data Output Rise Time t

Data Output Fall Time t

Signal Detect Output VOL - V

Voltage–Low (De-asserted)

Signal Detect Output VOH - V

Voltage–High (Asserted)

Signal Detect Output Rise Time t

Signal Detect Output Fall Time t

CC

DISS

r

f

r

f

-1.840 -1.620 V Note 6

CC

-1.045 -0.880 V Note 6

CC

0.35 2.2 ns Note 7

0.35 2.2 ns Note 7

-1.840 -1.620 V Note 6

CC

-1.045 -0.880 V Note 6

CC

0.35 2.2 ns Note 7

0.35 2.2 ns Note 7

82 145 mA Note 4

0.3 0.5 W Note 5

197

Page 10

HFBR-1116T Transmitter Optical Characteristics

(TA = 0°C to 70°C, VCC = 4.5 V to 5.5 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Output Optical Power PO, BOL -19 -14 dBm Note 8

62.5/125 µm, NA = 0.275 Fiber PO, EOL -20 -14 avg.

Output Optical Power PO, BOL -22.5 -14 dBm Note 8

50/125 µm, NA = 0.20 Fiber PO, EOL -23.5 -14 avg.

Optical Extinction Ratio 0.001 0.03 % Note 9

-50 -35 dB

Output Optical Power at Logic “0” State PO(“0”) -45 dBm Note 10

avg.

Center Wavelength λ

C

Spectral Width–FWHM ∆λ 137 nm Note 11, 23

–nm RMS 58 nm RMS Figure 9

Optical Rise Time t

Optical Fall Time t

r

f

Systematic Jitter Contributed by SJ 0.04 1.2 ns p-p Note 13

the Transmitter

Random Jitter Contributed by the RJ 0 0.52 ns p-p Note 14

Transmitter

1270 1310 1380 nm Note 23

Figure 9

0.6 1.0 3.0 ns Note 12, 23

Figure 9

0.6 2.1 3.0 ns Note 12, 23

Figure 9

HFBR-2116T Receiver Optical Characteristics

(TA = 0°C to 70°C, VCC = 4.5 V to 5.5 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Input Optical Power PIN Min. (W) -31 dBm Note 15,

Minimum at Window Edge avg. Figure 10

Input Optical Power PIN Min. (C) -31 dBm Note 16,

Minimum at Eye Center avg. Figure 10

Input Optical Power Maximum PIN Max. -14 dBm Note 15

avg.

Operating Wavelength λ 1260 1360 nm

Systematic Jitter Contributed by SJ 0.2 1.2 ns p-p Note 17

the Receiver

Random Jitter Contributed by the RJ 1 1.91 ns p-p Note 18

Receiver

Signal Detect–Asserted P

Signal Detect–Deasserted P

Signal Detect–Hysteresis PA-P

Signal Detect Assert Time t

SDA

(off to on)

Signal Detect De-assert Time t

SDD

(on to off)

A

D

D

PD+1.5 dB -31 dBm Note 19

avg.

-45 dBm Note 20

avg.

1.5 dB

0 55 100 µs Note 21

0 110 350 µs Note 22

198

Page 11

Notes:

1. This is the maximum voltage that can

be applied across the Differential

Transmitter Data Inputs to prevent

damage to the input ESD protection

circuit.

2. The outputs are terminated with 50 Ω

connected to VCC - 2 V.

3. The power supply current needed to

operate the transmitter is provided to

differential ECL circuitry. This

circuitry maintains a nearly constant

current flow from the power supply.

Constant current operation helps to

prevent unwanted electrical noise

from being generated and conducted

or emitted to neighboring circuitry.

4. This value is measured with the outputs terminated into 50 Ω connected

to VCC - 2 V and an Input Optical

Power level of -14 dBm average.

5. The power dissipation value is the

power dissipated in the transmitter

and receiver itself. Power dissipation

is calculated as the sum of the products of supply voltage and currents,

minus the sum of the products of the

output voltages and currents.

6. This value is measured with respect to

VCC with the output terminated into

50 Ω connected to VCC - 2 V.

7. The output rise and fall times are

measured between 20% and 80%

levels with the output connected to

VCC - 2 V through 50 Ω.

8. These optical power values are

measured with the following

conditions:

• The Beginning of Life (BOL) to the

End of Life (EOL) optical power

degradation is typically 1.5 dB per

the industry convention for long

wavelength LEDs. The actual

degradation observed in HewlettPackard’s 1300 nm LED products

is < 1 dB, as specified in this data

sheet.

• Over the specified operating

voltage and temperature ranges.

• With 25 MBd (12.5 MHz squarewave) input signal.

• At the end of one meter of noted

optical fiber with cladding modes

removed.

The average power value can be

converted to a peak power value by

adding 3 dB. Higher output optical

power transmitters are available on

special request.

9. The Extinction Ratio is a measure of

the modulation depth of the optical

signal. The data “0” output optical

power is compared to the data “1”

peak output optical power and

expressed as a percentage. With the

transmitter driven by a 25 MBd

(12.5 MHz square-wave) signal, the

average optical power is measured.

The data “1” peak power is then

calculated by adding 3 dB to the

measured average optical power. The

data “0” output optical power is found

by measuring the optical power when

the transmitter is driven by a logic “0”

input. The extinction ratio is the ratio

of the optical power at the “0” level

compared to the optical power at the

“1” level expressed as a percentage or

in decibels.

10. The transmitter will provide this low

level of Output Optical Power when

driven by a logic “0” input. This can

be useful in link troubleshooting.

11. The relationship between Full Width

Half Maximum and RMS values for

Spectral Width is derived from the

assumption of a Gaussian shaped

spectrum which results in a 2.35 X

RMS = FWHM relationship.

12. The optical rise and fall times are

measured from 10% to 90% when the

transmitter is driven by a 25 MBd

(12.5 MHz square-wave) input signal.

The ANSI T1E1.2 committee has

designated the possibility of defining

an eye pattern mask for the transmitter output optical power as an

item for further study. HP will

incorporate this requirement into the

specifications for these products if it

is defined. The HFBR-1116T

transmitter typically complies with

the template requirements of CCITT

(now ITU-T) G.957 Section 3.25,

Figure 2 for the STM-1 rate,

excluding the optical receiver filter

normally associatd with single-mode

fiber measurements which is the

likely source for the ANSI T1E1.2

committee to follow in this matter.

13. Systematic Jitter contributed by the

transmitter is defined as the

combination of Duty Cycle Distortion

and Data Dependent Jitter.

Systematic Jitter is measured at 50%

threshold using a 155.52, 27 - 1

pseudo-random bit stream data

pattern input signal.

14. Random Jitter contributed the the

transmitter is specified with a 155.52

MBd (77.5 MHz square-wave) input

signal.

15. This specification is intended to

indicate the performance of the

receiver when Input Optical Power

signal characteristics are present per

the following definitions. The Input

Optical Power dynamic range from

the minimum level (with a window

time-width) to the maximum level is

the range over which the receiver is

guaranteed to provide output data

with a Bit-Error-Ratio (BER) better

than or equal to 2.5 x 10

• At the Beginning of Life (BOL).

• Over the specified operating

voltage and temperature ranges.

• Input is a 155.52 MBd, 223 - 1

PRBS data pattern with a 72 “1”s

and 72 “0”s inserted per the CCITT

(now ITU-T) recommendation

G.958 Appendix 1.

• Receiver data window time-width is

1.23 ns or greater for the clock

recovery circuit to operate in. The

actual test window time-width is set

to simulate the effect of worst-case

input optical jitter based on the

transmitter jitter values from the

specification tables. The test

window time-width is 3.32 ns.

16. All conditions of Note 15 apply

except that the measurement is made

at the center of the symbol with now

window time-width.

17. Systematic Jitter contributed by the

receiver is defined as the combination

of Duty Cycle Distortion and Data

Dependent Jitter. The input optical

power level is at the maximum of

“PINMin. (W).” Systematic Jitter is

measured at 50% threshold using a

155.52 MBd (77.5 MHz square-wave),

27 - 1 pseudo-random bit stream data

pattern input signal.

18. Random Jitter contributed by the

receiver is specified with a 155.52

MBd (77.5 MHz square-wave) input

signal.

19. This value is measured during the

transition from low to high levels of

input optical power.

20. This value is measured during the

transition from high to low levels of

input optical power.

21. The Signal Detect output shall be

asserted, logic-high (VOH), within

100 µs after a step increase of the

Input Optical Power.

22. Signal Detect output shall be

deasserted, logic-low (VOL), within

350 µs after a step decrease in the

Input Optical Power.

23. The HFBR-1116T transmitter complies with the requirements for the

tradeoffs between center wavelength,

spectral width, and rise/fall times

shown in Figure 9. This figure is

derived from the FDDI PMD standard

(ISO/IEC 9314-3: 1990 and ANSI

X3.166 - 1990) per the description in

ANSI T1E1.2 Revision 3. The

interpretation of this figure is that

values of Center Wavelength and

Spectral Width must lie along the

appropriate Optical Rise/Fall Time

curve.

24. This value is measured with an

output load RL = 10 kΩ.

-10

.

199

Loading...

Loading...