Page 1

March 1997

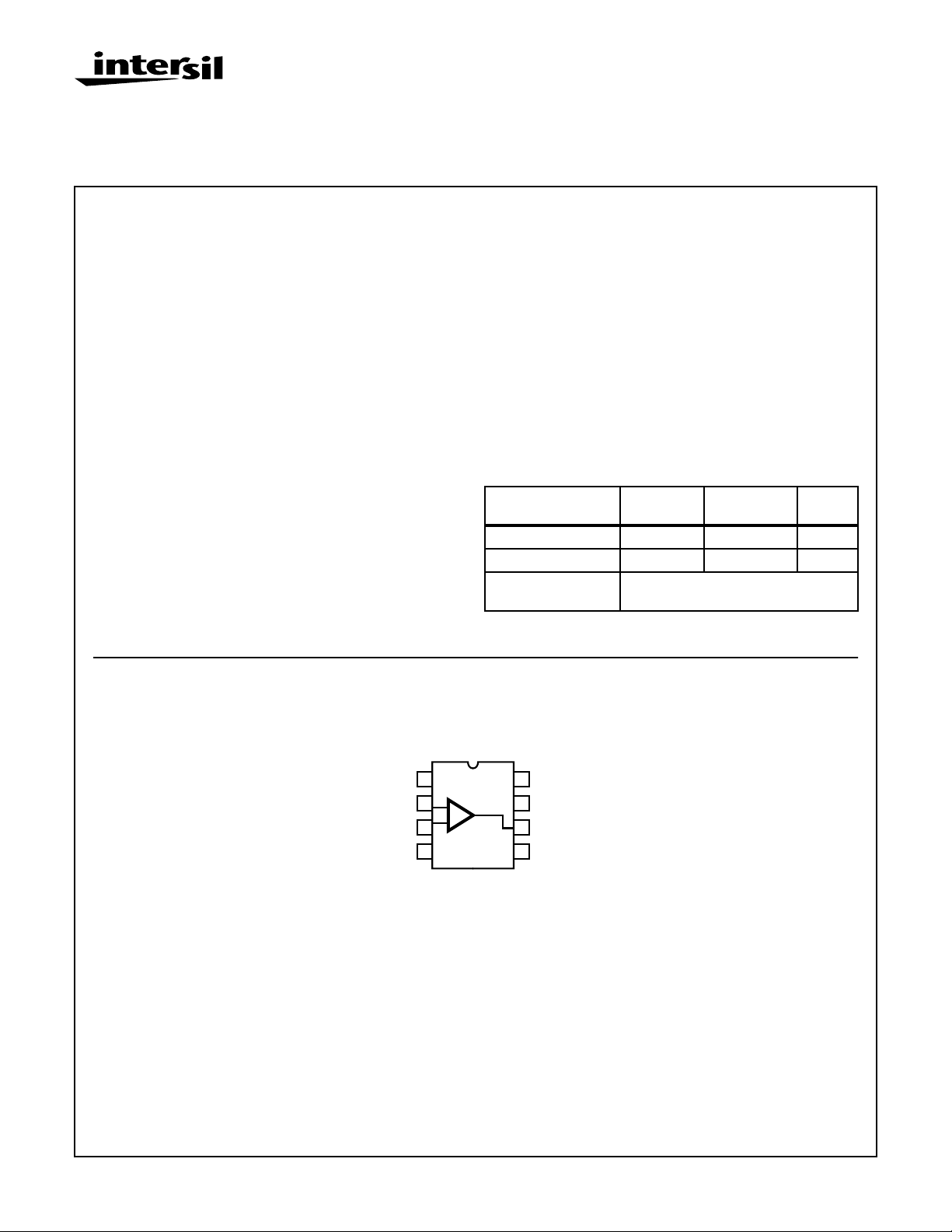

HFA1109

450MHz, Low Power, Current Feedback

Video Operational Amplifier

Features

• Wide - 3dB Bandwidth (AV = +2). . . . . . . . . . . . 450MHz

• Gain Flatness (To 250MHz) . . . . . . . . . . . . . . . . . . 0.8dB

• Very Fast Slew Rate (A

• High Input Impedance . . . . . . . . . . . . . . . . . . . . . 1.7MΩ

• Differential Gain/Phase . . . . . . . . . 0.02%/0.02 Degrees

• Low Supply Current . . . . . . . . . . . . . . . . . . . . . . . 10mA

= +2). . . . . . . . . . . . . 1100V/µs

V

Applications

• Professional Video Processing

• Video Switchers and Routers

• Medical Imaging

• PC Multimedia Systems

• Video Distribution Amplifiers

• Flash Converter Drivers

• Radar/IF Processing

Description

The HFA1109 is a high speed, low power, current feedback

amplifier built with Intersil’s proprietary complementary bipolar UHF-1 process. This amplifier features a unique combination of power and performance specifically tailored for

video applications.

The HFA1109 is a standard pinout op amp. It is a higher

performance, drop-in replacement (no feedback resistor

change required) for the CLC409.

If a comparably performing op amp with an output disable

function (useful for video multiplexing) is required, please

refer to the HFA1149 data sheet.

Ordering Information

PART NUMBER

(BRAND)

HFA1109IP -40 to 85 8 Ld PDIP E8.3

HFA1109IB (H1109) -40 to 85 8 Ld SOIC M8.15

HFA11XXEVAL DIP Evaluation Board for High Speed

TEMP.

RANGE (oC) PACKAGE

Op Amps

PKG.

NO.

Pinout

NC

-IN

+IN

V-

HFA1109

(PDIP, SOIC)

TOP VIEW

1

2

+

3

4

8

NC

7

V+

6

OUT

5

NC

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143 | Copyright © Intersil Corporation 1999

1

File Number 4019.3

Page 2

HFA1109

Absolute Maximum Ratings Thermal Information

Voltage Between V+ and V- . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12V

DC Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

SUPPLY

Differential Input Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8V

Output Current (Note 2) . . . . . . . . . . . . . . . . Short Circuit Protected

30mA Continuous

60mA ≤ 50% Duty Cycle

ESD Rating

Human Body Model (Per MIL-STD-883 Method 3015.7) . . 1400V

Charged Device Model (Per EOS/ESD DS5.3, 4/14/93). . . 2000V

Machine Model (Per EIAJ ED-4701Method C-111) . . . . . . . . 50V

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . -40oC to 85oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

2. Output is short circuit protected to ground. Brief short circuits to ground will not degrade reliability, however continuous (100% duty cycle)

output current must not exceed 30mA for maximum reliability.

Thermal Resistance (Typical, Note 1) θJA (oC/W)

PDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

SOIC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Maximum Junction Temperature (Die). . . . . . . . . . . . . . . . . . . . 175oC

Maximum Junction Temperature (Plastic Package) . . . . . . . . 150oC

Maximum Storage Temperature Range . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300oC

(SOIC - Lead Tips Only)

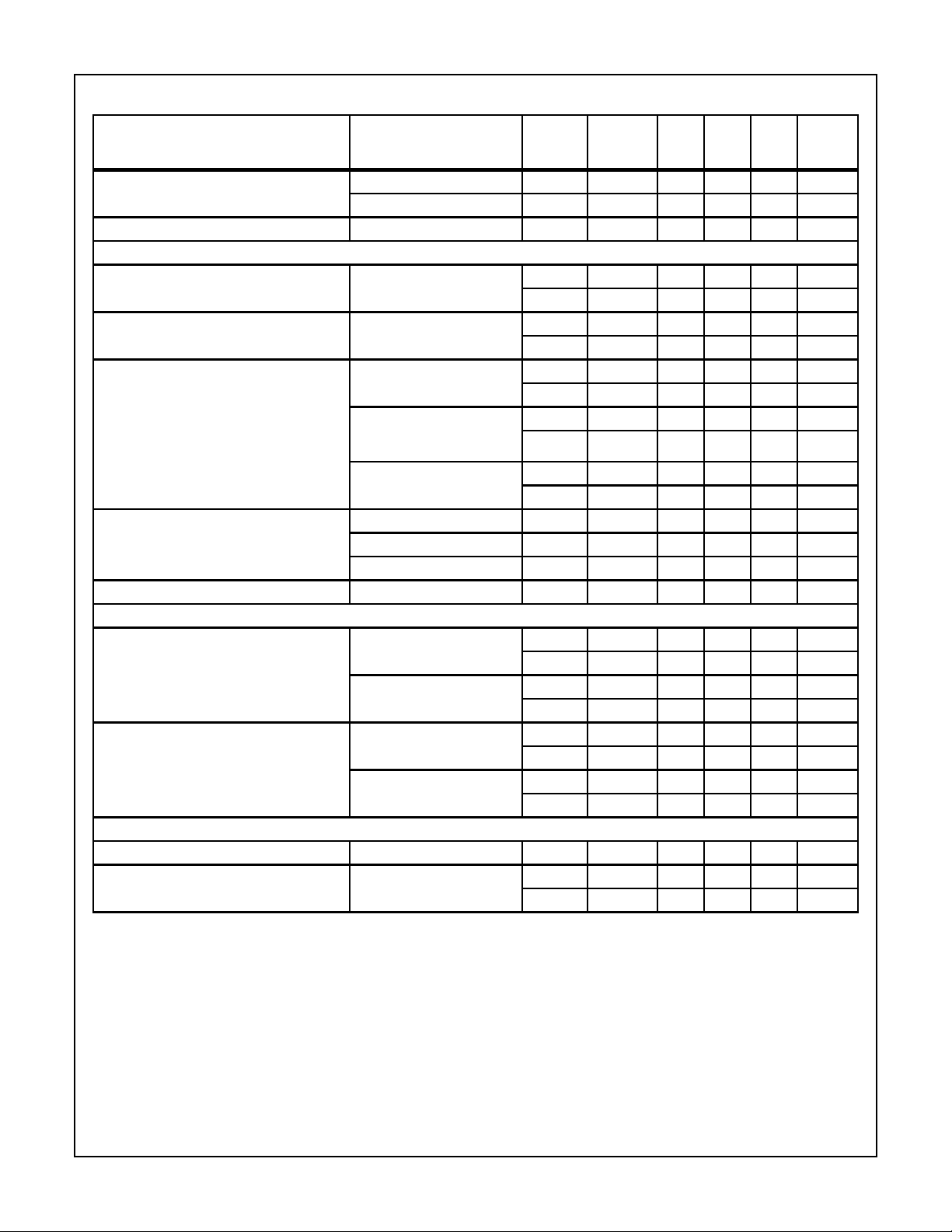

Electrical Specifications V

= ±5V, AV= +2, RF= 250Ω, RL = 100Ω, Unless Otherwise Specified

SUPPLY

(NOTE 3)

PARAMETER TEST CONDITIONS

TEST

LEVEL

TEMP.

(oC) MIN TYP MAX UNITS

INPUT CHARACTERISTICS

Input Offset Voltage A 25 - 1 5 mV

A Full - 2 8 mV

Average Input Offset Voltage Drift B Full - 10 - µV/oC

Input Offset Voltage

Common-Mode Rejection Ratio

Input Offset Voltage

Power Supply Rejection Ratio

∆V

= ±2V A 25 47 50 - dB

CM

= ±2V A Full 45 48 - dB

∆V

CM

= ±1.25V A 25 50 53 - dB

∆V

PS

∆V

= ±1.25V A Full 47 51 - dB

PS

Non-Inverting Input Bias Current A 25 - 4 10 µA

A Full - 5 15 µA

Non-Inverting Input Bias Current Drift B Full - 30 - nA/

Non-Inverting Input Bias Current

Power Supply Sensitivity

= ±1.25V A 25 - 0.5 1 µA/V

∆V

PS

∆V

= ±1.25V A Full - 0.5 3 µA/V

PS

Inverting Input Bias Current A 25 - 2 10 µA

A Full - 3 15 µA

Inverting Input Bias Current Drift B Full - 40 - nA/

Inverting Input Bias Current

Common-Mode Sensitivity

Inverting Input Bias Current

Power Supply Sensitivity

Non-Inverting Input Resistance ∆V

= ±2V A 25 - 3 6 µA/V

∆V

CM

= ±2V A Full - 3 8 µA/V

∆V

CM

= ±1.25V A 25 - 1.6 5 µA/V

∆V

PS

= ±1.25V A Full - 1.6 8 µA/V

∆V

PS

= ±2V A 25, 85 0.8 1.7 - MΩ

CM

= ±2V A -40 0.5 1.4 - MΩ

∆V

CM

Inverting Input Resistance B 25 - 60 - Ω

Input Capacitance B 25 - 1.6 - pF

o

C

o

C

2

Page 3

HFA1109

Electrical Specifications V

= ±5V, AV= +2, RF= 250Ω, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

(NOTE 3)

PARAMETER TEST CONDITIONS

Input Voltage Common Mode Range

(Implied by VIO CMRR, +RIN, and -I

TEST

LEVEL

A Full ±2 ±2.5 - V

BIAS

TEMP.

(oC) MIN TYP MAX UNITS

CMS tests)

Input Noise Voltage Density (Note 4) f = 100kHz B 25 - 4 - nV/√

Non-Inverting Input Noise Current Density

f = 100kHz B 25 - 2.4 - pA/√

(Note 4)

Inverting Input Noise Current Density

f = 100kHz B 25 - 40 - pA/√

(Note 4)

TRANSFER CHARACTERISTICS

Open Loop Transimpedance Gain (Note 4) B 25 - 500 - kΩ

Minimum Stable Gain B Full - 1 - V/V

AC CHARACTERISTICS

-3dB Bandwidth

= 0.2V

(V

OUT

P-P

, Note 4)

AV = -1, RF = 200Ω B 25 300 375 - MHz

B Full 290 360 - MHz

= +1, +RS = 550Ω(PDIP),

A

V

+RS = 700Ω (SOIC)

B 25 280 330 - MHz

B Full 260 320 - MHz

AV = +2 B 25 390 450 - MHz

B Full 350 410 - MHz

Gain Peaking A

= +2, V

V

OUT

= 0.2V

P-P

B 25 - 0 0.2 dB

B Full - 0 0.5 dB

Gain Flatness

= +2, V

(A

V

OUT

= 0.2V

P-P

, Note 4)

To 125MHz B 25 -1.0 -0.45 - dB

B Full -1.1 -0.45 - dB

To 200MHz B 25 -1.6 -0.75 - dB

B Full -1.7 -0.75 - dB

To 250MHz B 25 -1.9 -0.85 - dB

B Full -2.2 -0.85 - dB

Gain Flatness

= +1, +RS = 550Ω (PDIP),

(A

V

+RS = 700Ω (SOIC), V

Note 4)

OUT

= 0.2V

P-P

,

To 125MHz B 25 ±0.3 ±0.1 - dB

B Full ±0.4 ±0.1 - dB

To 200MHz B 25 ±0.8 ±0.35 - dB

B Full ±0.9 ±0.35 - dB

To 250MHz B 25 ±1.3 ±0.6 - dB

B Full ±1.4 ±0.6 - dB

OUTPUT CHARACTERISTICS

Output Voltage Swing, Unloaded

(Note 4)

Output Current

(Note 4)

Output Short Circuit Current A

Closed Loop Output Resistance (Note 4) DC, A

Second Harmonic Distortion

(V

OUT

= 2V

P-P

, Note 4)

= -1, RL = ∞ A25±3 ±3.2 - V

A

V

A Full ±2.8 ±3- V

AV = -1, RL = 75Ω A 25, 85 ±33 ±36 - mA

A -40 ±30 ±33 - mA

= -1 B 25 - 120 - mA

V

= +1 B 25 - 0.05 - Ω

V

20MHz B 25 - -55 - dBc

60MHz B 25 - -57 - dBc

Hz

Hz

Hz

3

Page 4

HFA1109

Electrical Specifications V

= ±5V, AV= +2, RF= 250Ω, RL = 100Ω, Unless Otherwise Specified (Continued)

SUPPLY

(NOTE 3)

PARAMETER TEST CONDITIONS

Third Harmonic Distortion

(V

OUT

= 2V

P-P

, Note 4)

TEST

LEVEL

20MHz B 25 - -68 - dBc

60MHz B 25 - -60 - dBc

TEMP.

(oC) MIN TYP MAX UNITS

Reverse Isolation (S12) 30MHz B 25 - -65 - dB

TRANSIENT CHARACTERISTICS

Rise and Fall Times V

OUT

= 0.5V

P-P

B 25 - 1.1 1.3 ns

B Full - 1.1 1.4 ns

Overshoot V

OUT

= 0.5V

P-P

B25-02%

B Full - 0.5 5 %

Slew Rate AV = -1, RF= 200Ω

V

= 5V

A

OUT

V

= +1, V

P-P

OUT

= 4V

+RS = 550Ω (PDIP),

+RS = 700Ω (SOIC)

A

= +2, V

V

OUT

= 5V

P-P

P-P

,

B 25 2300 2600 - V/µs

B Full 2200 2500 - V/µs

B 25 475 550 - V/µs

B Full 430 500 - V/µs

B 25 940 1100 - V/µs

B Full 800 950 - V/µs

Settling Time

= +2V to 0V step, Note 4)

(V

OUT

To 0.1% B 25 - 19 - ns

To 0.05% B 25 - 23 - ns

To 0.01% B 25 - 36 - ns

Overdrive Recovery Time V

= ±2V B 25 - 5 - ns

IN

VIDEO CHARACTERISTICS

Differential Gain

(f = 3.58MHz)

= 150Ω B 25 - 0.02 0.06 %

R

L

B Full - 0.03 0.09 %

= 75Ω B 25 - 0.04 0.09 %

R

L

B Full - 0.05 0.12 %

Differential Phase

(f = 3.58MHz)

RL = 150Ω B 25 - 0.02 0.06 Degrees

B Full - 0.02 0.06 Degrees

RL = 75Ω B 25 - 0.05 0.09 Degrees

B Full - 0.06 0.13 Degrees

POWER SUPPLY CHARACTERISTICS

Power Supply Range C 25 ±4.5 - ±5.5 V

Power Supply Current (Note 4) A 25 - 9.6 10 mA

A Full - 10 11 mA

NOTES:

3. Test Level: A. Production Tested; B. Typical or Guaranteed Limit Based on Characterization; C. Design Typical for Information Only.

4. See Typical Performance Curves for more information.

4

Page 5

HFA1109

Application Information

Optimum Feedback Resistor

Although a current feedback amplifier’s bandwidth dependency on closed loop gain isn’t as severe as that of a v oltage

feedback amplifier, there can be an appreciable decrease in

bandwidth at higher gains. This decrease may be minimized

by taking advantage of the current feedback amplifier’s

unique relationship between bandwidth and R

feedback amplifiers require a feedback resistor, even for

unity gain applications, and R

, in conjunction with the inter-

F

nal compensation capacitor, sets the dominant pole of the

frequency response. Thus, the amplifier’s bandwidth is

inversely proportional to R

mized for a 250Ω R

. The HFA1109 design is opti-

F

at a gain of +2. Decreasing R

F

decreases stability, resulting in excessive peaking and overshoot (Note: Capacitive feedback will cause the same problems due to the feedback impedance decrease at higher

frequencies). At higher gains the amplifier is more stable, so

R

can be decreased in a trade-off of stability for bandwidth.

F

TABLE 1. OPTIMUM FEEDBACK RESISTOR

GAIN (ACL)R

-1 200 400

+1 250 (+RS= 550Ω) PDIP

250 (+RS= 700Ω) SOIC

+2 250 450

+5 100 160

+10 90 70

Table 1 lists recommended R

(Ω) BANDWIDTH (MHz)

F

values, and the expected

F

bandwidth, for various closed loop gains. For a gain of +1, a

resistor (

+R

) in series with +IN is required to reduce gain

S

peaking and increase stability

. All current

F

350

ble oscillations. In most cases, the oscillation can be avoided

by placing a resistor (R

) in series with the output prior to

S

the capacitance.

R

and CL form a low pass network at the output, thus limit-

S

ing system bandwidth well below the amplifier bandwidth. By

decreasing R

as CL increases, the maximum bandwidth is

S

obtained without sacrificing stability. In spite of this, bandwidth still decreases as the load capacitance increases.

Evaluation Board

The performance of the HFA1109 may be evaluated using

the HFA11XX evaluation board (part number

HFA11XXEVAL). Please contact your local sales office for

F

information. When evaluating this amplifier, the two 510Ω

gain setting resistors on the evaluation board should be

changed to 250Ω.

The layout and schematic of the board are shown in Figure 1.

.

510Ω

50Ω

IN

0.1µF10µF

BOARD SCHEMATIC

510Ω

1

2

3

4

-5V

TOP LAYOUT

GND

V

H

8

7

50Ω

6

5

OUT

V

GND

10µF0.1µF

+5V

L

PC Board Layout

The frequency response of this amplifier depends greatly on

the care taken in designing the PC board. The use of low

inductance components such as chip resistors and chip

capacitors is strongly recommended, while a solid ground

plane is a must! Attention should be given to decoupling the

power supplies. A large value (10µF) tantalum in par allel with a

small value (0.1µF) chip capacitor works well in most cases.

Terminated microstr ip signal lines are recommended at the

input and output of the device. Capacitance directly on the

output must be minimized, or isolated as discussed in the

next section.

Care must also be taken to minimize the capacitance to ground

seen by the amplifier’s inverting input (-IN). The larger this

capacitance, the worse the gain peaking, resulting in pulse

overshoot and possible instability. Thus it is recommended that

the ground plane be removed under traces connected to -IN,

and connections to -IN should be kept as short as possible.

Driving Capacitive Loads

Capacitive loads, such as an A/D input, or an improperly terminated transmission line will degrade the amplifier’s phase

margin resulting in frequency response peaking and possi-

V

H

1

+IN

OUT

V

BOTTOM LAYOUT

FIGURE 1. EVALUATION BOARD SCHEMATIC AND LAYOUT

V+

L

V-

GND

5

Page 6

HFA1109

Typical Performance Curves V

200

AV = +2

150

100

50

0

-50

OUTPUT VOLTAGE (mV)

-100

-150

-200

FIGURE 2. SMALL SIGNAL PULSE RESPONSE FIGURE 3. LARGE SIGNAL PULSE RESPONSE

200

AV = +1

150

TIME (5ns/DIV.)

= ±5V, TA = 25oC, RF = Value From the Optimum Feedback Resistor Table,

SUPPLY

RL = 100Ω, Unless Otherwise Specified

2.0

AV = +2

1.5

1.0

0.5

0

-0.5

OUTPUT VOLTAGE (V)

-1.0

-1.5

-2.0

2.0

AV = +1

1.5

TIME (5ns/DIV.)

100

50

0

-50

OUTPUT VOLTAGE (mV)

-100

-150

-200

TIME (5ns/DIV.)

1.0

0.5

-0.5

OUTPUT VOLTAGE (V)

-1.0

-1.5

-2.0

0

TIME (5ns/DIV.)

FIGURE 4. SMALL SIGNAL PULSE RESPONSE FIGURE 5. LARGE SIGNAL PULSE RESPONSE

200

150

100

50

0

-50

OUTPUT VOLTAGE (mV)

-100

AV = -1

2.0

1.5

1.0

0.5

-0.5

OUTPUT VOLTAGE (V)

-1.0

AV=-1

0

-150

-200

TIME (5ns/DIV.)

-1.5

-2.0

TIME (5ns/DIV.)

FIGURE 6. SMALL SIGNAL PULSE RESPONSE FIGURE 7. LARGE SIGNAL PULSE RESPONSE

6

Page 7

HFA1109

Typical Performance Curves V

SUPPLY

RL = 100Ω, Unless Otherwise Specified (Continued)

200

150

= +5

A

V

100

50

0

-50

OUTPUT VOLTAGE (mV)

-100

-150

-200

AV = +10

AV = +5

TIME (5ns/DIV.)

A

V

FIGURE 8. SMALL SIGNAL PULSE RESPONSE

V

= 200mV

OUT

3

0

GAIN (dB)

-3

0.3 1 10 100 700

P-P

GAIN

PHASE

FREQUENCY (MHz)

AV = +1

AV = -1

AV = +1

AV = -1

FIGURE 10. FREQUENCY RESPONSE FIGURE 11. FREQUENCY RESPONSE

= ±5V, TA = 25oC, RF = Value From the Optimum Feedback Resistor Table,

2.0

1.5

AV = +5

1.0

= +10

0.5

-0.5

OUTPUT VOLTAGE (V)

-1.0

-1.5

-2.0

AV = +10

0

TIME (5ns/DIV.)

FIGURE 9. LARGE SIGNAL PULSE RESPONSE

V

= 200mV

AV = +1

OUT

3

0

-3

NORMALIZED GAIN (dB)

0

90

180

270

NORMALIZED PHASE (DEGREES)

0.3 1 10 100 700

P-P

GAIN

AV = +10

PHASE

AV = +10

FREQUENCY (MHz)

AV = +5

AV = +2

AV = +5

AV = +5

AV = +2

A

= +10

V

0

90

180

270

PHASE (DEGREES)

V

= 200mV

OUT

0.1

0

-0.1

-0.2

-0.3

-0.4

-0.5

NORMALIZED GAIN (dB)

-0.6

-0.7

1 10 100 500

P-P

AV = +2

FREQUENCY (MHz)

FIGURE 12. GAIN FLATNESS FIGURE 13. OPEN LOOP TRANSIMPEDANCE

AV = +1

7

116

106

)

96

I

O

I

86

V

()

76

66

56

(dB, 20 LOG

46

ZOL

36

A

26

0.01 0.1

0.3 1 3 6 10 30 100 500

FREQUENCY (MHz)

0

45

90

135

180

PHASE (DEGREES)

Page 8

HFA1109

Typical Performance Curves V

-30

AV=+1

-40

-50

50MHz

-60

20MHz

-70

DISTORTION (dBc)

-80

-90

-6 -3 0 9 1236

FIGURE 14. 2nd HARMONIC DISTORTION vs P

-30

AV=+2

-40

-50

-60

-70

DISTORTION (dBc)

-80

100MHz

20MHz

OUTPUT POWER (dBm)

50MHz

10MHz

= ±5V, TA = 25oC, RF = Value From the Optimum Feedback Resistor Table,

SUPPLY

RL = 100Ω, Unless Otherwise Specified (Continued)

-20

=+1

A

100MHz

10MHz

OUT

V

-30

-40

-50

-60

-70

DISTORTION (dBc)

-80

-90

-100

-6 -3 0 9 12

OUTPUT POWER (dBm)

FIGURE 15. 3rd HARMONIC DISTORTION vs P

-30

AV=+2

-40

-50

-60

-70

DISTORTION (dBc)

-80

100MHz

20MHz

50MHz

10MHz

36

OUT

100MHz

50MHz

20MHz

10MHz

-90

-6 -3 0 9 12 1536

FIGURE 16. 2nd HARMONIC DISTORTION vs P

-20

V

= 2V

OUT

-30

-40

-50

-60

DISTORTION (dBc)

-70

-80

AV=+1

0 102030405060708090100

OUTPUT POWER (dBm)

OUT

P-P

AV= +2, -1

FREQUENCY (MHz)

-90

-6 -3 0 9 12 1536

FIGURE 17. 3rd HARMONIC DISTORTION vs P

-20

V

= 2V

OUT

-30

-40

-50

-60

DISTORTION (dBc)

-70

AV=+1

-80

0 102030405060708090100

OUTPUT POWER (dBm)

OUT

P-P

AV=+1

AV=-1

AV=+2

FREQUENCY (MHz)

FIGURE 18. 2nd HARMONIC DISTORTION vs FREQUENCY FIGURE 19. 3rd HARMONIC DISTORTION vs FREQUENCY

8

Page 9

HFA1109

Typical Performance Curves V

= ±5V, TA = 25oC, RF = Value From the Optimum Feedback Resistor Table,

SUPPLY

RL = 100Ω, Unless Otherwise Specified (Continued)

AV = +2

1K

100

10

1

0.1

0.01

OUTPUT RESISTANCE (Ω)

0.3 1 10 100 1000

FREQUENCY (MHz)

3.6

3.4

3.2

3.0

2.8

2.6

2.4

2.2

OUTPUT VOLTAGE (V)

2.0

1.8

1.6

+V

+V

OUT

(RL=50Ω)

OUT

|-V

OUT

-50

(RL= 100Ω)

| (RL= 100Ω)

-25 25 75 125-75

|-V

OUT

+V

(RL=50Ω)

OUT

|-V

| (RL=50Ω)

OUT

0 50 100

TEMPERATURE (°C)

FIGURE 20. CLOSED LOOP OUTPUT RESISTANCE FIGURE 21. OUTPUT VOLTAGE vs TEMPERATURE

14

13.5

13

12.5

12

11.5

11

10.5

10

SUPPLY CURRENT (mA)

9.5

9

8.5

4.5 5.5 6.5 7.5

45678

SUPPLY VOLTAGE (±V)

17

16

15

14

13

12

11

10

9

8

7

SUPPLY CURRENT (mA)

6

5

4

-75 0 50 100

VS= ±8V

VS= ±5V

-50

VS= ±4V

-25 25 75 125

TEMPERATURE (°C)

FIGURE 22. SUPPLY CURRENT vs SUPPLY VOLTAGE FIGURE 23. SUPPLY CURRENT vs TEMPERATURE

| (RL= 100Ω)

100

I

NI-

I

NI+

10

E

NOISE VOLTAGE (nV/√Hz)

1

0.1 1 10 100

FREQUENCY (kHz)

I

NI+

100

0.1

Hz)

10

NI

NOISE CURRENT (pA/√

1

0.05

0.025

-0.025

-0.05

SETTLING ERROR (%)

-0.1

0

10 80 10090

30 50 7020 40 60

TIME (ns)

FIGURE 24. INPUT NOISE CHARACTERISTICS FIGURE 25. SETTLING RESPONSE

9

AV = +2

V

OUT

= 2V

Page 10

Die Characteristics

HFA1109

DIE DIMENSIONS:

59 mils x 80 mils x 19 mils

1500µm x 2020µm x 483µm

METALLIZATION:

Type: Metal 1: AICu(2%)/TiW

Thickness: Metal 1: 8k

Å ±0.4kÅ

Type: Metal 2: AICu(2%)

Thickness: Metal 2: 16kÅ 0.8kÅ

Metallization Mask Layout

NC

NC

GLASSIVATION:

Type: Nitride

Thickness: 4k

Å ±0.5kÅ

TRANSISTOR COUNT:

130

SUBSTRATE POTENTIAL (Powered Up):

Floating (Recommend Connection to V-)

HFA1109

NC

NC

-IN

+IN

V+

OUT

NC

NC

V-

NCNC

10

Page 11

Dual-In-Line Plastic Packages (PDIP)

N

D1

-C-

E1

-B-

A1

A2

A

L

e

C

S

INDEX

AREA

BASE

PLANE

SEATING

PLANE

1 2 3 N/2

-A-

D1

B1

B

D

e

0.010 (0.25) C AMB

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between

English and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section

2.2 of Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated

in JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.010 inch

(0.25mm).

6. E and are measured with the leads constrained to be per-

e

pendicular to datum .

A

-C-

7. eB and eC are measured at the lead tips with the leads unconstrained. eC must be zero or greater.

8. B1 maximum dimensions do not include dambar protrusions.

Dambar protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3,

E28.3, E42.6 will have a B1 dimension of 0.030 - 0.045 inch

(0.76 - 1.14mm).

HFA1109

E

C

L

e

A

C

e

B

E8.3 (JEDEC MS-001-BA ISSUE D)

8 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.210 - 5.33 4

A1 0.015 - 0.39 - 4

A2 0.115 0.195 2.93 4.95 -

B 0.014 0.022 0.356 0.558 B1 0.045 0.070 1.15 1.77 8, 10

C 0.008 0.014 0.204 0.355 -

D 0.355 0.400 9.01 10.16 5

D1 0.005 - 0.13 - 5

E 0.300 0.325 7.62 8.25 6

E1 0.240 0.280 6.10 7.11 5

e 0.100 BSC 2.54 BSC -

e

A

e

B

0.300 BSC 7.62 BSC 6

- 0.430 - 10.92 7

L 0.115 0.150 2.93 3.81 4

N8 89

NOTESMIN MAX MIN MAX

Rev. 0 12/93

11

Page 12

Small Outline Plastic Packages (SOIC)

HFA1109

N

INDEX

AREA

123

-A-

0.25(0.010) B

E

SEATING PLANE

D

-C-

H

-B-

A

M

L

h x 45

M

o

α

e

B

0.25(0.010) C AMB

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section

2.2 of Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs. Mold flash, protrusion and gate burrs shall not exceed

0.15mm (0.006 inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010

inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual

index feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions are not necessarily exact.

A1

0.10(0.004)

S

M8.15 (JEDEC MS-012-AA ISSUE C)

8 LEAD NARROW BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 D 0.1890 0.1968 4.80 5.00 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC -

H 0.2284 0.2440 5.80 6.20 -

C

h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N8 87

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries f or its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (321) 724-7000

FAX: (321) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

Taiwan Limited

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

12

Loading...

Loading...