Page 1

FEATURES

• Propagation Delay of 2.4 ns (typ)

• Propagation Delay Skew <300 ps

• Low Offset ±3 mV

• Latch Control

GENERAL DESCRIPTION

The HCMP96850 is a single, very high speed monolithic

comparator. It is pin-compatible with and has improved

performance over the AD9685 and the AM6685. The

HCMP96850 is designed for use in Automatic Test Equipment (ATE), high speed instrumentation, and other high

speed comparator applications.

APPLICATIONS

• High Speed Instrumentation, ATE

• High Speed Timing

• Window Comparators

• Line Receivers

• A/D Conversion

• Threshold Detection

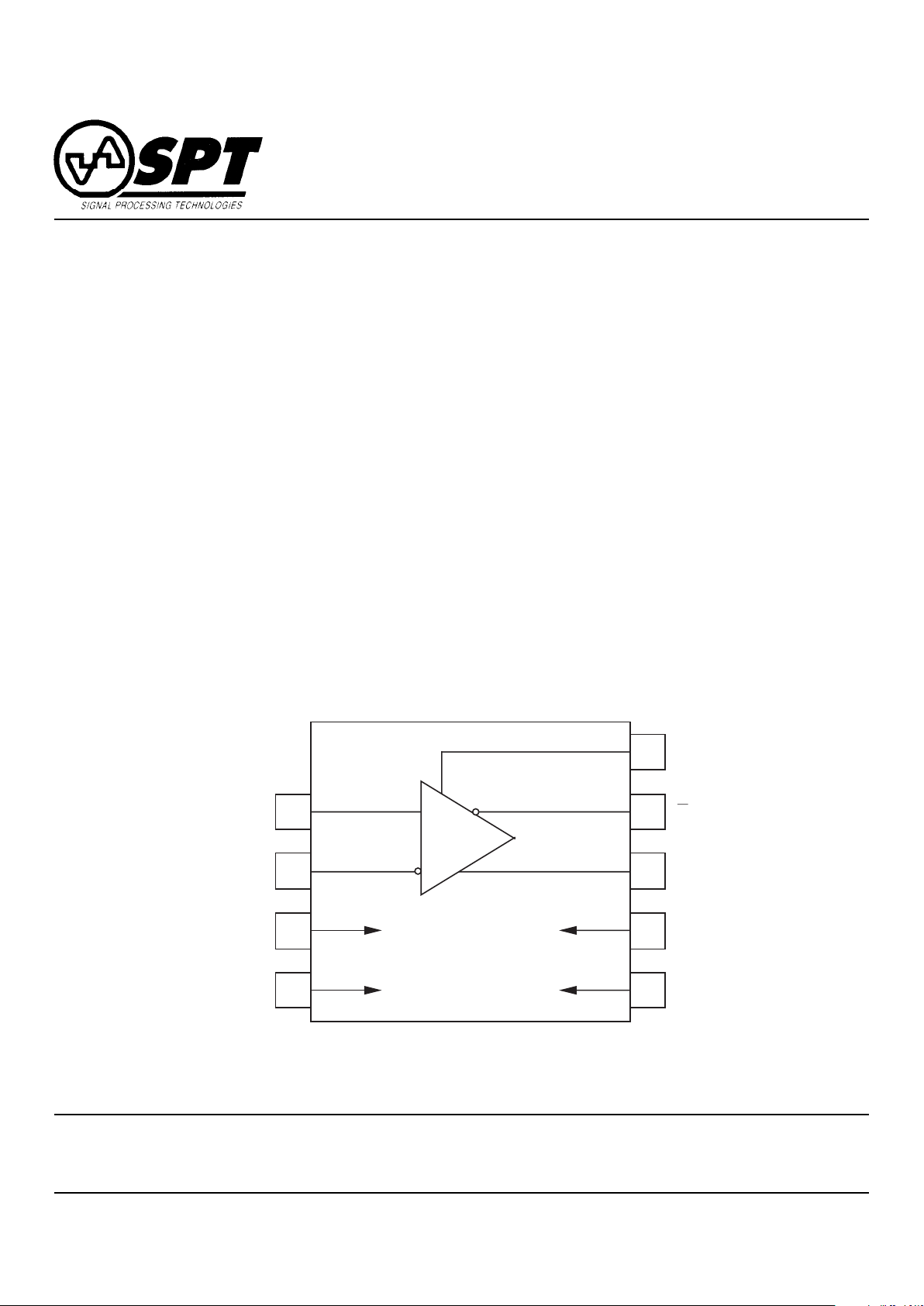

HCMP96850

SINGLE UL TRAFAST VOL T AGE COMPARA TOR

BLOCK DIAGRAM

-

+

NONINVERTING

INPUT

INVERTING

INPUT

GND

1

V

EE

GND

2

V

CC

LATCH ENABLE

Q OUTPUT

Q OUTPUT

Improvements over other sources include reduced power

consumption, reduced propagation delays, and higher input

impedance.

The HCMP96850 is available in a 16-lead ceramic DIP

package over the industrial temperature range. It is also

available in die form.

Signal Processing Technologies, Inc.

4755 Forge Road, Colorado Springs, Colorado 80907, USA

Phone: (719) 528-2300 FAX: (719) 528-2370 Website: http://www.spt.com E-Mail: sales@spt.com

Page 2

SPT

2 3/18/97

HCMP96850

ELECTRICAL SPECIFICATIONS

T A = +25 °C, VCC = +5.0 V, VEE = -5.2 V, RL = 50 Ohms, unless otherwise specified.

TEST TEST

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

DC ELECTRICAL CHARACTERISTICS

Input Offset Voltage RS = 0 Ohms

1

IV -3 +3 mV

Input Offset Voltage (Vos)R

S

= 0 Ohms,

1

T

MIN

<TA<T

MAX

IV -3.5 +3.5 mV

(Vos) Tempco V 4 µV/°C

Input Bias Current I 4 ±20 µA

Input Bias Current T

MIN

<TA<T

MAX

IV 7 µA

Input Offset Current I -1.0 +1.0 µA

Input Offset Current T

MIN

<TA<T

MAX

IV -1.5 +1.5 µA

Positive Supply Current I 3.3 5 mA

Negative Supply Current I 13.5 18 mA

Positive Supply Voltage, V

CC

IV +4.75 +5.0 +5.25 V

Negative Supply Voltage, V

EE

IV -4.95 -5.2 -5.45 V

Input Common Mode Range I -2.5 +2.5 V

Latch Enable

Common Mode Range IV -2 0 V

Open Loop Gain V 4000 V/V

Input Resistance V 60 kΩ

Input Capacitance V 3 pF

Input Capacitance (LCC Package) V 1 pF

Power Supply Sensitivity VCC and V

EE

V70dB

Common Mode Rejection Ratio V 80 dB

Power Dissipation I

OUTPUT

= 0 mA IV 90 120 mW

ABSOLUTE MAXIMUM RATINGS (Beyond which damage may occur)1 25 °C

Supply Voltages

Positive Supply Voltage (VCC to GND) .... -0.5 to +6.0 V

Negative Supply Voltage (VEE to GND) ... -6.0 to +0.5 V

Ground Voltage Differential ...................... -0.5 to +0.5 V

Input Voltages

Input Voltage ............................................ -4.0 to +4.0 V

Differential Input Voltage .......................... -5.0 to +5.0 V

Input Voltage, Latch Controls ..................... VEE to 0.5 V

Output

Output Current......................................................30 mA

Temperature

Operating Temperature, ambient .............-25 to +85 °C

junction ...................... +150 °C

Lead Temperature, (soldering 60 seconds) ...... +300 °C

Storage Temperature ..............................-65 to +150 °C

Note: 1. Operation at any Absolute Maximum Rating is not implied. See Electrical Specifications for proper nominal

applied conditions in typical applications.

Page 3

SPT

3 3/18/97

HCMP96850

ELECTRICAL SPECIFICATIONS

T A = +25 °C, VCC = +5.0 V, VEE = -5.2 V, RL = 50 Ohms, unless otherwise specified.

TEST TEST

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

OUTPUT LOGIC LEVELS (ECL 10 KH Compatible)

Output High 50 Ohms to -2 V I -.98 -.81 V

Output Low 50 Ohms to -2 V I -1.95 -1.63 V

AC ELECTRICAL CHARACTERISTICS

2

Propagation Delay 10 mV O.D. III 2.4 3.0 ns

Latch Set-up Time IV 0.6 1 ns

Latch to Output Delay 50 mV O.D. IV 3 ns

Latch Pulse Width V 2 ns

Latch Hold Time IV 0.5 ns

Rise Time 20% to 80% V 1.76 ns

Fall Time 20% to 80% V 1.76 ns

1

RS = source impedance.

2

100 mV input step.

TEST LEVEL CODES

All electrical characteristics are subject to the

following conditions:

All parameters having min/max specifications

are guaranteed. The Test Level column indicates the specific device testing actually performed during production and Quality Assurance inspection. Any blank section in the data

column indicates that the specification is not

tested at the specified condition.

TEST PROCEDURE

100% production tested at the specified temperature.

100% production tested at TA=25 °C, and sample

tested at the specified temperatures.

QA sample tested only at the specified temperatures.

Parameter is guaranteed (but not tested) by design

and characterization data.

Parameter is a typical value for information purposes

only.

100% production tested at TA = 25 °C. Parameter is

guaranteed over specified temperature range.

TEST LEVEL

I

II

III

IV

V

VI

Page 4

SPT

4 3/18/97

HCMP96850

Figure 1 - Timing Diagram

t

pLOL

LATCH ENABLE TO OUTPUT LOW DELAY - The

propagation delay measured from the 50% point of the

Latch Enable signal LOW to HIGH transition to the 50%

point of an output HIGH to LOW transition.

t

H

MINIMUM HOLD TIME - The minimum time after the

negative transition of the Latch Enable signal that the

input signal must remain unchanged in order to be

acquired and held at the outputs.

t

pL

MINIMUM LATCH ENABLE PULSE WIDTH - The

minimum time that the Latch Enable signal must be

HIGH in order to acquire an input signal change.

t

S

MINIMUM SET-UP TIME - The minimum time before

the negative transition of the Latch Enable signal that

an input signal change must be present in order to be

acquired and held at the outputs.

t

pdH

INPUT TO OUTPUT HIGH DELAY - The propagation

delay measured from the time the input signal crosses

the input reference voltage (± the input offset voltage)

to the 50% point of an output LOW to HIGH transition.

t

pdL

INPUT TO OUTPUT LOW DELAY - The propagation

delay measured from the time the input signal crosses

the input reference voltage (± the input offset voltage)

to the 50% point of an output HIGH to LOW transition.

t

pLOH

LATCH ENABLE TO OUTPUT HIGH DELAY - The

propagation delay measured from the 50% point of the

Latch Enable signal LOW to HIGH transition to 50%

point of an output LOW to HIGH transition.

V

OD

VOLTAGE OVERDRIVE - The difference between the

differential input and reference input voltages.

SWITCHING TERMS (Refer to figure 1)

TIMING INFORMATION

The timing diagram for the comparator is shown in figure 1.

The latch enable (LE) pulse is shown at the top. If LE is high

in the HCMP96850, the comparator tracks the input difference voltage. When LE is driven low, the comparator outputs are latched into their existing logic states.

The leading edge of the input signal (which consists of a

10 mV overdrive voltage) changes the comparator output

50%

V

REF

±V

OS

50%

50%

t

pLOL

t

pLOH

t

pL

t

S

t

pdL

t

pdH

VIN+=100 mV (P-P), V

OD

=10 mV

LATCH ENABLE

DIFFERENTIAL

INPUT VOLTAGE

OUTPUT Q

OUTPUT Q

t

H

V

OD

The set-up and hold times are a measure of the time required for an input signal to propagate through the first

stage of the comparator to reach the latching circuitry. Input signal changes occurring before tS will be detected

and held; those occurring after tH will not be detected. Changes between tS and tH may or may not be detected.

after a time of t

pdL

or t

pdH

(Q or Q). The input signal must be

maintained for a time ts (set-up time) before the latch enable

falling edge and held for time tH after the falling edge for the

comparator to accept data. After tH, the output ignores the

input status until the latch is strobed again. A minimum latch

pulse width of tpL is needed for strobe operation, and the

output transitions occur after a time of t

pLOH

or t

pLOL

.

Page 5

SPT

5 3/18/97

HCMP96850

TYPICAL INTERFACE CIRCUIT

A typical interface circuit using the comparator is shown in

figure 3. Although it needs few external components and is

easy to apply, there are several considerations that should

be noted to achieve optimal performance. The very high

operating speeds of the comparator require careful layout,

decoupling of supplies, and proper design of transmission

lines.

Since the HCMP96850 comparator is a very high frequency

and high gain device, certain layout rules must be followed

to avoid spurious oscillations. The comparator should be

soldered to the board with component lead lengths kept as

short as possible. A ground plane should be used, while the

input impedance to the part is kept as low as possible, to

decrease parasitic feedback. If the output board traces are

longer than approximately one-half inch, microstripline techniques must be employed to prevent ringing on the output

waveform. Also, the microstriplines must be terminated at

the far end with the characteristic impedance of the line to

prevent reflections. All voltage supply pins should be decoupled with high-frequency capacitors as close to the

device as possible. All ground pins and no connects should

be connected to a common ground plane to further improve

noise immunity.

On the HCMP96850, all outputs, whether used or unused,

should have identical terminations to minimize ground current switching.

Noninverting

Input

Inverting

Input

.1 µF

.1 µF

-2 V

Pulldown

+

-

LE

= Represents line termination.

V

CC

V

EE

50 Ω

50 Ω

GND

2

GND

1

V

REF

V

IN

Q Outpu

t

Q Outpu

t

R

L

Figure 2 - Internal Function Diagram

REF1

REF

2

VEEV

CC

CLK

BUF

LE

LATCH

ECL

OUT

PRE

AMP

+

-

V

IN

V

IN

Q

GND

1

GND

2

GENERAL INFORMATION

The HCMP96850 is an ultrahigh speed single voltage comparator. It offers tight absolute characteristics which guarantee matching from package to package. The device has

differential analog inputs and complementary logic outputs

compatible with ECL systems. The output stage is adequate

for driving terminated 50 Ohm transmission lines.

The HCMP96850 has one latch enable control and should be

driven by standard ECL logic levels. It also has two separate

ground pins, one for the output to accommodate large

ground currents without affecting the rest of the circuit, while

the other is for the small signal intermediate stages. The

input stage is referenced to VCC and VEE.

Figure 3 - Typical Interface Circuit

Page 6

SPT

6 3/18/97

HCMP96850

Q

22

Q

21

4.5 mA

V

1

Q Output

Q Output

Q

23

Q

24

R

8

240 Ω

R

7

240 Ω

V

2

Figure 4 - Equivalent Input Circuit Figure 5 - Output Circuit

NOTES: 1. ALL BNC & SEMIRIGID COAX SHIELD ARE

GROUNDED.

2. ALL RESISTORS 1% (10 Ω = 49.9 Ω).

3. KEEP ALL LEADS AS SHORT AS POSSIBLE

WITH ELECTRICAL LENGTHS L1 = L2 + L3.

4. D.U.T. PLUGS INTO A 16 PIN HIGH

FREQUENCY PIN SOCKET.

5. MONITOR INPUT IMPEDANCE 50 Ω TO GND.

6. SEMIRIGID COAX SHIELD SHOULD BE

CONNECTED AS CLOSE TO THE DEVICE AS

POSSIBLE.

Figure 6 - Test Load

50 Ω Coax

50 Ω

R

z

V

pd

(-4.0 V)

100 Ω

R

L

100 Ω

R

Z

Figure 7 - AC Test Fixture

SEMI

RIGID

SEMI

RIGID

SEMI

RIGID

SEMI

RIGID

DUT

0.1 µF

0.1 µF

15 µF

50 Ω

16.7 Ω

100 Ω

50 Ω

6

6

SEMI

RIGID

15 µF

L1

L2

L2

L1

L3

4

V+

V-

+

-

LE

V

IN

-

V

IN

+

V

IN

+

MONITOR

V

CC

(+5.0V)

16.7 Ω

16.7 Ω

50 Ω

16.7 Ω

16.7 Ω

16.7 Ω

66

Q

Q

6

Q

3

R

2

R

1

V

CC

V

IN

R

IN

V

IN

V

R2

V

R1

V

EE

R

3

R

4

R

5

Q

2

Q

6

Q

8

Q

5

Q

7

Q

1

Q

4

IN

1PF

C

IN

1PF

C

100Ω

100Ω

R

IN

Page 7

SPT

7 3/18/97

HCMP96850

Figure 8 - HCMP96850 with Hysteresis

100 Ω

-5.2 V

V

LE

0.1 µF

300 Ω

V

O

V

IN

Noninverting

Input

Inverting

Input

.1 µF

.1 µF

-2 V

Pulldown

+

-

LE

Hysteresis is obtained by applying a DC bias to the LE pin.

VLE = -1.3 V ±100 mV

= Represents line termination.

V

CC

V

EE

50 Ω

50 Ω

GND

2

GND

1

V

REF

V

IN

Q Output

Q Output

R

L

PACKAGE OUTLINE

16-Lead Cerdip

INCHES MILLIMETERS

SYMBOL MIN MAX MIN MAX

A 0.005 0.13

B 0.200 5.08

C 0.125 0.150 3.18 3.81

D 0.015 0.023 0.38 0.58

E 0.090 0.110 2.29 2.79

F 0.030 0.065 0.76 1.65

G0° 15° 0° 15°

H 0.008 0.015 0.20 0.38

I 0.290 0.320 7.37 8.13

J 0.250 0.310 6.35 7.87

K 0.140 0.200 3.56 5.08

L 0.015 0.050 0.38 1.27

M 0.745 0.785 18.92 19.94

N 0.015 0.050 0.38 1.27

E F

K

L

B

C

D

1

16

A

M

N

G

H

I

J

Page 8

SPT

8 3/18/97

HCMP96850

PIN ASSIGNMENTS

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE TYPE

HCMP96850SID -25 to +85 °C 16-Lead Cerdip

HCMP96850SCU +25 °C Die*

*Please see the die specification for guaranteed electrical performance.

1

2

3

16

15

14

4

5

6

7

89

10

11

12

13

GND

1

16 LEAD DIP

V

+IN

-IN

N/C

LE

N/C

V

CC

EE

N/C

N/C

Q

Q

N/C

N/C

N/C

GND

2

OUT

OUT

PIN FUNCTIONS

Name Function

GND

1

Circuit Ground

V

CC

Positive Supply Voltage

+IN Noninverting Input

-IN Inverting Input

N/C No Connection

LE Latch Enable

V

EE

Negative Supply Voltage

Q

OUT

Output

Q

OUT

Inverted Output

GND

2

Output Ground

Signal Processing Technologies, Inc. reserves the right to change products and specifications without notice. Permission is hereby

expressly granted to copy this literature for informational purposes only. Copying this material for any other use is strictly prohibited.

WARNING - LIFE SUPPORT APPLICATIONS POLICY - SPT products should not be used within Life Support Systems without the specific

written consent of SPT. A Life Support System is a product or system intended to support or sustain life which, if it fails, can be reasonably

expected to result in significant personal injury or death.

Signal Processing Technologies believes that ultrasonic cleaning of its products may damage the wire bonding, leading to device

failure. It is therefore not recommended, and exposure of a device to such a process will void the product warranty.

Loading...

Loading...