Page 1

Semiconductor

HC5549

Data Sheet January 1999 File Number

Low Power SLIC with Battery Switch

The HC5549 Subscriber line

interface circuit is a 100V

diellectrically isolated bipolar

integrated circuit for use in

short loop ISDN, P ABX and

Pairgain applications. The HC5549 has been optimized for low

power as required for battery backed remote terminals or for

applications requiring emergency powering from the line such

as European ISDN NT1+ designs.

A high and low voltage battery supply may be connected to

the HC5549 so that power dissipation can be lowered in the

off hook condition in these short loop applications. The high

battery supply can beused in the on-hook condition to allow

interfacing to fax and answering machines that require 48V

to detect end of call status. The HC5549 also has a low

power standby state with very low power consumption

(35mW) resulting in exceptionally low battery drain while

providing continued loop supervision.

The HC5549 provides loop current, ground key and ring trip

detect functions as well as an alarm output to indicate

thermal overload.

2-wire to 4-wire and 4-wire to 2-wire conversion is provided

and impedance matching is achievedusing a single external

network. The HC5549 is compatible with dual and single

supply switched capacitor or DSP codec/filters

Features

• Dual Battery Operation

• Single Additional +5V Supply

• Low Standby Power Consumption (48V, 35mW)

• On Hook Transmission

• Tip and Ring Disconnect

• Soft or Hard Polarity Reversal

• Supports 12 kHz or 16 kHz Pulse Metering

• Ring Relay Driver

• On Chip 2-wire AC/DC Loopback

• No Latch-Up or Power Supply Sequencing

o

to 70o or -40o to 85o Ambient Temp Range

•0

• Low External Component Count

Applications

• ISDN NT1+ Terminals

• Pairgain Remote Termination

• PABX and Key Systems

Related Literature

• AC SPICE Macromodel

4539.1

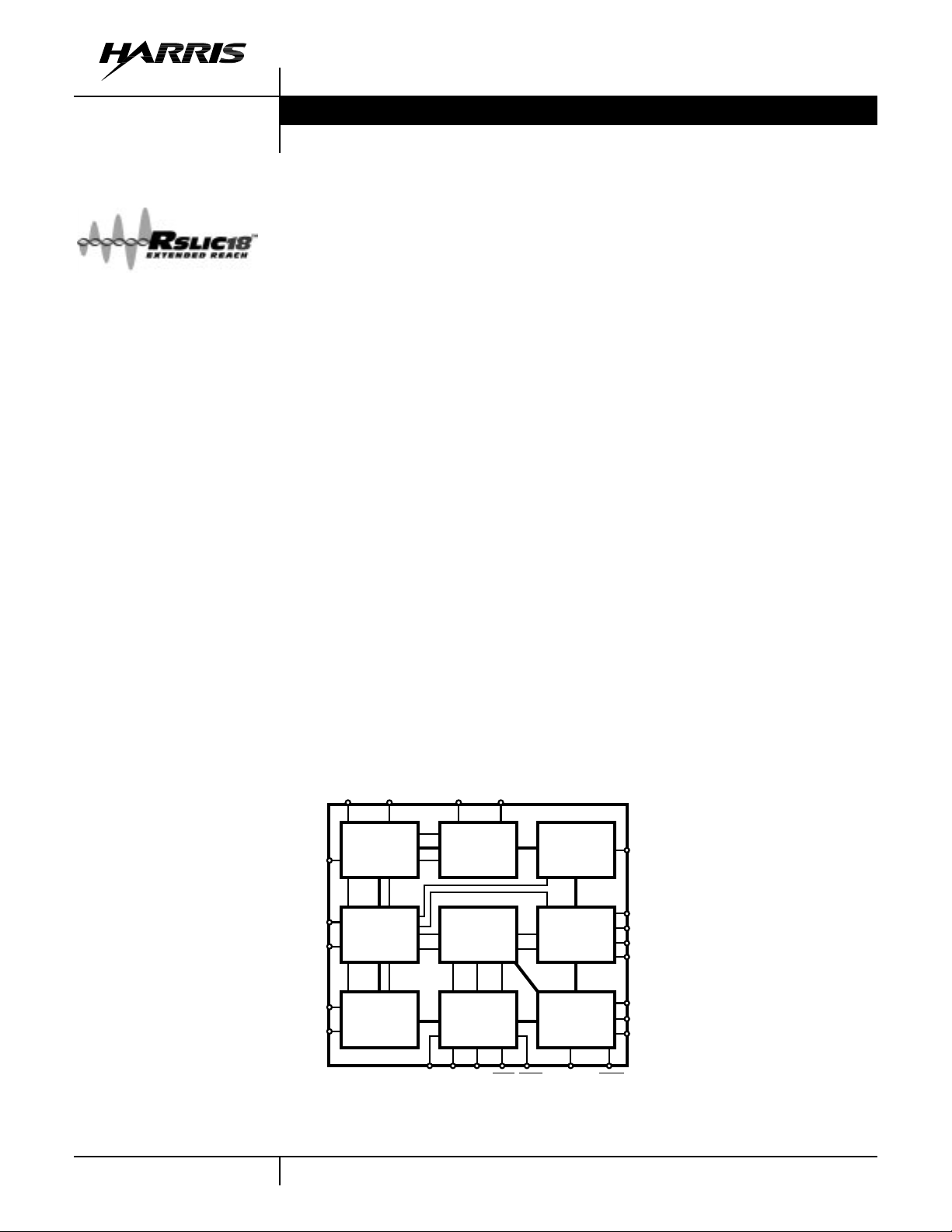

Block Diagram

4-80

POL CDC VBHVBL

DC

ILIM

TIP

RING

SW+

SW-

CONTROL

2-WIRE

PORT

TEST

ACCESS

BATTERY

SWITCH

TRANSMIT

SENSING

DETECTOR

LOGIC

RTD RD

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

E0

DET ALM

RINGING

PORT

4-WIRE

PORT

CONTROL

LOGIC

BSEL

1-800-4-HARRIS or 407-727-9207

VRS

VRX

VTX

-IN

VFB

F2

F1

F0

SWC

RSLIC18™ is a trademark of Harris Corporation.

| Copyright © Harris Corporation 1999

Page 2

HC5549

Ordering Information (PLCC Package Only)

BATSWPOL

PART NUMBER 48V

HC5549CM ••

HC5549IM

•

•

REV

•

•

RING

DELAY

DRIVER

•

•

2W

LOOP

BACK LB = 53dB

••

••

TEMP.

RANGEoC PACKAGE

PACKAGE

NO.

0 to 70 28 Ld PLCC N28.45

-40 to 85 28 Ld PLCC N28.45

Device Operating Modes

OPERATING MODE F2 F1 F0 E0 = 1 E0 = 0 DESCRIPTION

Low Power Standby 0 0 0 SHD GKD MTU compliant standby mode with active loop

detector.

Forward Active 0 0 1 SHD GKD Forward battery loop feed.

Unused 0 1 0 n/a n/a Reserved internal test mode.

Reverse Active 0 1 1 SHD GKD Reverse battery loop feed.

Ringing 1 0 0 RTD RTD Enabler internal ring trip detector.

Unused 1 0 1 n/a n/a Reserved internal test mode.

Unused 1 1 0 n/a n/a Reserved internal test mode.

Power Denial 1 1 1 n/a n/a Device shutdown.

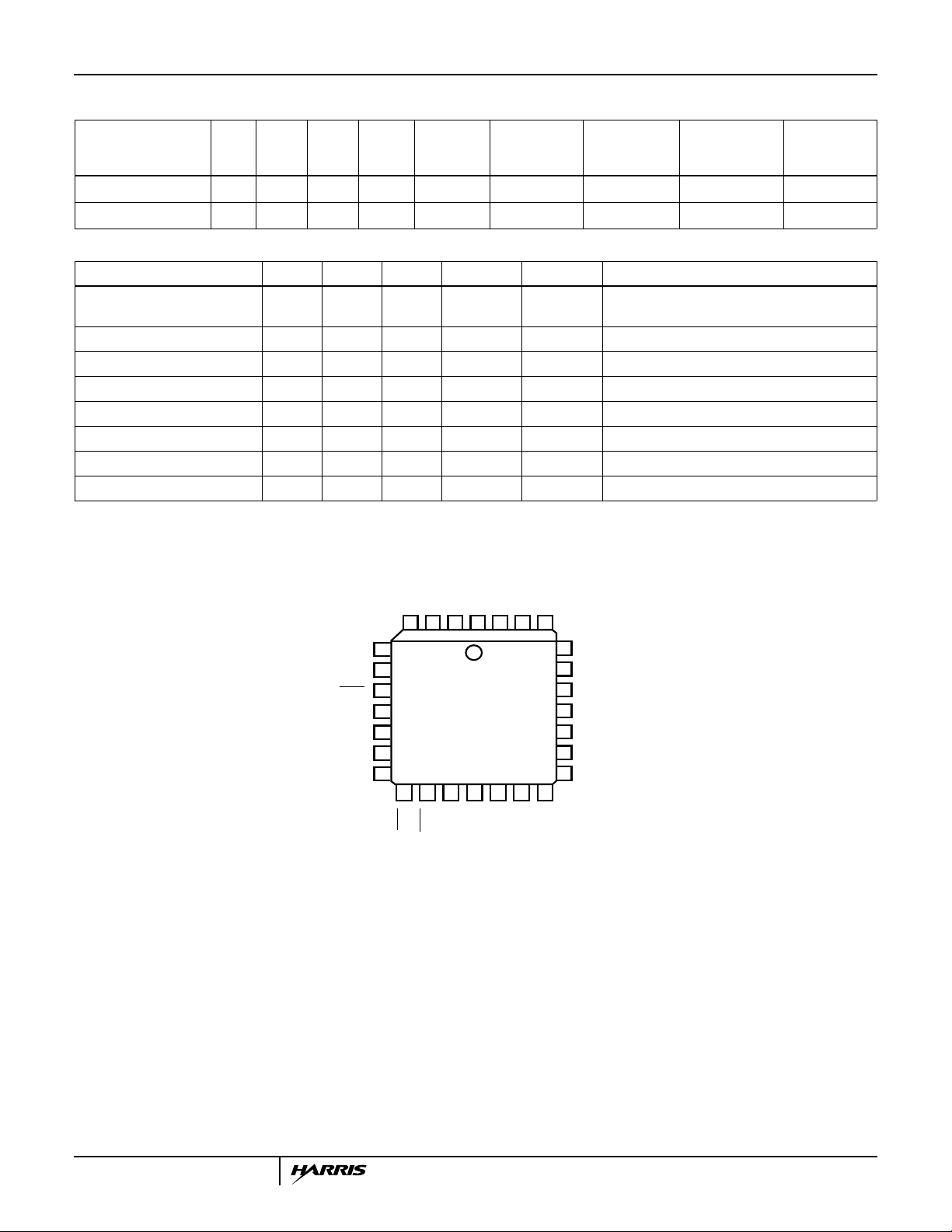

Pinouts

HC5549 (PLCC)

TOP VIEW

SW+

SW-

SWC

F2

F1

F0

E0

RD

RING

NC

ILIM

27

26

RTD

25

CDC

24

V

23

CC

22

-IN

VFB

21

VTX

20

VRX

19

17

18

VRB

POL

TIP

VBL

VBH

13

3

ALM

14

BGND

15

AGND

12

28

16

NC

4

5

6

7

8

9

10

11

12

DET

4-81

Page 3

HC5549

Absolute Maximum Ratings T

Maximum Supply Voltages

VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +7V

VCC - V

Uncommitted Switch Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . -80V

ESD (Human Body Model). . . . . . . . . . . . . . . . . . . . . . . . . . . . 500V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80V

BAT

Operating Conditions

Temperature Range

Industrial (I suffix). . . . . . . . . . . . . . . . . . . . . . . . . . -40oC to 85oC

Commercial (C suffix). . . . . . . . . . . . . . . . . . . . . . . . 0oC to 75oC

Positive Power Supply (VCC). . . . . . . . . . . . . . . . . . . . . . . +5V ±5%

Negative Power Supply (VBH, VBL) (180, 181, 182) . . -16V to -80V

Uncommitted Switch (loop back or relay driver). . . . . . . +5V to -80V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

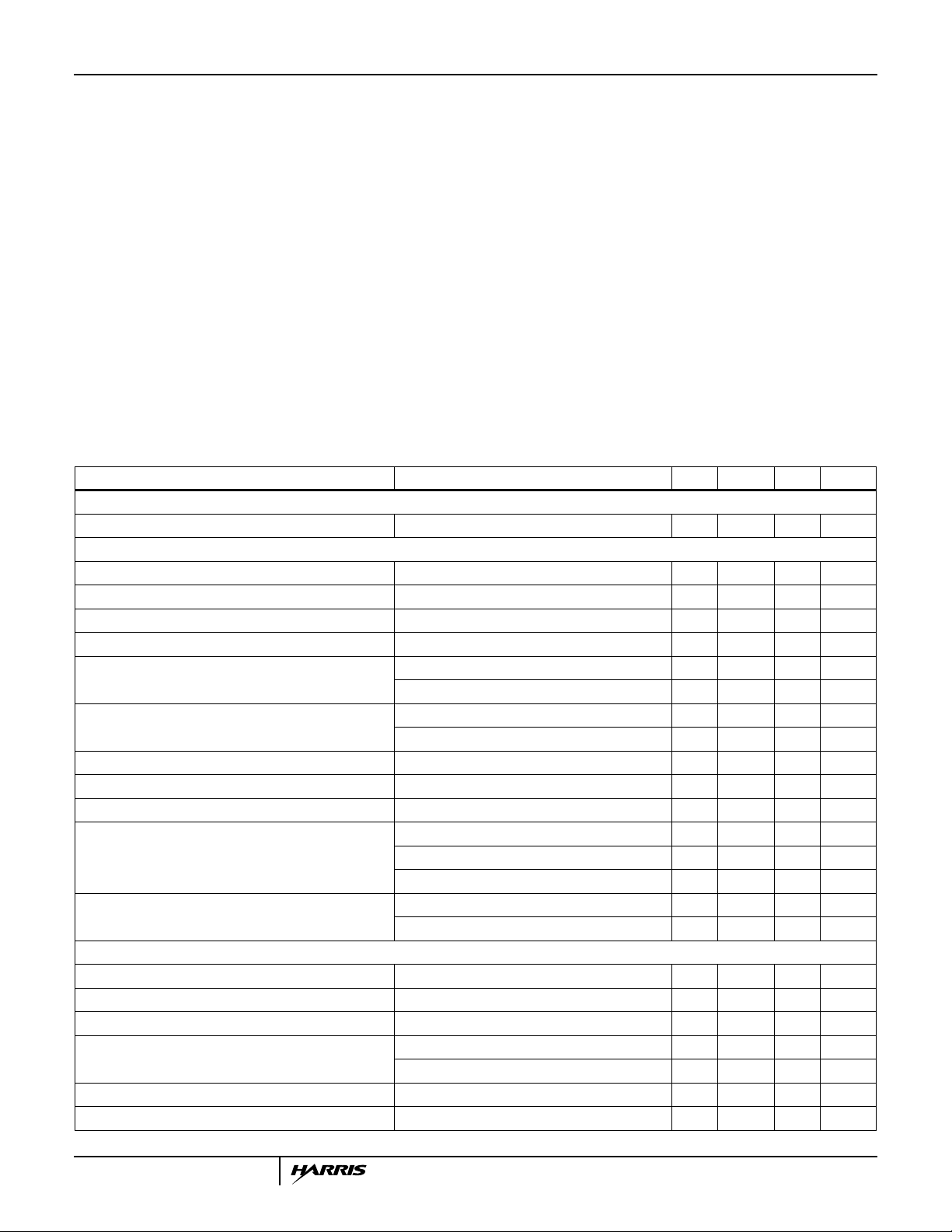

Electrical Specifications Unless Otherwise Specified, T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

RINGING PARAMETERS

VRB Input Impedance 480 - - kΩ

AC TRANSMISSION PARAMETERS (Forward Active and Reverse Active, BSEL = 0, unless otherwise specified.)

Receive Input Impedance 160 - - kΩ

Transmit Output Impedance --1Ω

4-Wire Port Overload Level THD = 1% 3.1 3.5 - V

2-Wire Port Overload Level THD = 1% 3.1 3.5 - V

2-Wire Return Loss 300Hz ≤ f < 1kHz 30 45 - dB

Longitudinal Current Capability (Per Wire) Test for False Detect - 20 - mA

2-Wire Longitudinal Balance Tested per IEEE455-1985, with 368Ω per wire. 53 - - dB

4-Wire Longitudinal Balance Tested per IEEE455-1985, with 368Ω per wire. 59 - - dB

4-Wire to 4-Wire Insertion Loss -6.22 -6.02 -5.82 dB

2-Wire to 4-Wire Level Linearity

4-Wire to 2-Wire Level Linearity

Referenced to -10dBm

Idle Channel Noise 2-Wire C-Message - 16 19 dBrnC

DC PARAMETERS

Loop Current Limit Programming Range Max Low Battery = -52V, BSEL = 0 15 - 45 mA

Loop Current Accuracy I

Loop Current During Low Power Standby Forward polarity only. 17 - 26 mA

Open Circuit Voltage

(|Tip - Ring|)

Low Power Standby Open Circuit Voltage (Tip - Ring) BSEL = 1 43 45 47 V

Ring Trip Programming Current Accuracy - - 10 %

=25oC Thermal Information

A

Thermal Resistance (Typical, Note 1) θJA(oC/W)

PLCC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Maximum Junction Temperature Plastic . . . . . . . . . . . . . . . . 150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300oC

(PLCC - Lead Tips Only)

Die Characteristics

Substrate Potential. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bipolar-DI

= -40oC to 85oC, VBL = -24V, VBH= -48V, VCC = +5V, AGND = BGND = 0V , loop

current limit = 25mA. All AC Parameters are specified at 600Ω 2-wire terminating impedance over the frequency

band of 300Hz to 3.4kHz. Protection resistors = 0Ω.

A

PK

PK

1kHz ≤ f ≤ 3.4kHz 35 45 - dB

RMS

Test forFalseDetect,Low PowerStandby, BSEL=0 - 10 - mA

+3 to -40dBm, 1kHz - 0.025 - dB

-40 to -50dBm, 1kHz - 0.050 - dB

-50 to -55dBm, 1kHz - 0.100 - dB

Psophometric - -74 -71 dBmp

= 25mA, BSEL = 0 - - 10 %

L

BSEL = 0 14 15.5 17 V

BSEL = 1 37.5 40 42.5 V

RMS

BAT

4-82

Page 4

HC5549

Electrical Specifications Unless Otherwise Specified, T

= -40oC to 85oC, VBL = -24V, VBH= -48V, VCC = +5V, AGND = BGND = 0V , loop

A

current limit = 25mA. All AC Parameters are specified at 600Ω 2-wire terminating impedance over the frequency

band of 300Hz to 3.4kHz. Protection resistors = 0Ω. (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Ground Key Threshold 10 12 13.5 mA

o

Thermal Alarm Output IC junction temperature - 175 -

C

RELAY DRIVER

On Voltage I

= 45 mA - - 0.60 V

L

LOGIC INPUTS (F0, F1, F2, E0, SWC)

Input Low Voltage - - 0.8 V

Input High Voltage 2.0 - - V

Input Low Current V

Input High Current V

LOGIC OUTPUTS (

DET, ALM)

Output Low Voltage I

Output High Voltage I

= 0.4V -20 - - µA

IL

= 2.4V - - 5 µA

IH

= 5mA - - 0.4 V

OL

= 100 µA 2.4 - - V

OH

SUPPLY CURRENTS (Supply currents not listed are considered negligible and do not contribute significantly to total power dissipation. All

measurements made under open circuit load conditions.)

Low Power Standby I

Forward or Reverse (Note 5) I

Forward I

Power Denial I

CC

, BSEL = 1 - 0.375 0.600 mA

I

BH

CC

I

, BSEL = 0 - 1.0 2.0 mA

BL

CC

, BSEL = 1 - 0.7 1.5 mA

I

BL

I

, BSEL = 1 - 1.0 2.0 mA

BH

CC

, BSEL = 1 or 0 - 0.2 0.5 mA

I

BL

2.0 3.7 5.0 mA

2.5 4.0 5.0 mA

3.5 4.5 6.5 mA

0.5 3.0 5.0 mA

ON HOOK POWER DISSIPATION

Forward or Reverse BSEL = 0 - 44 60 mW

Forward or Reverse BSEL = 1 - 90 150 mW

Low Power Standby BSEL = 1 - 37 60 mW

OFF HOOK POWER DISSIPATION

Forward or Reverse BSEL = 0 - 290 310 mW

POWER SUPPLY REJECTION RATIO

V

to 2-Wire f = 300Hz - 40 - dB

CC

f = 1kHz - 35 - dB

f = 3.4kHz - 28 - dB

to 4-Wire f = 300Hz - 45 - dB

V

CC

f = 1kHz - 43 - dB

f = 3.4kHz - 33 - dB

to 2-Wire 300Hz ≤ f ≤ 3.4kHz - 30 - dB

V

BL

V

to 4-Wire 300Hz ≤ f ≤ 3.4kHz - 35 - dB

BL

to 2-Wire 300Hz ≤ f ≤ 3.4kHz - 33 - dB

V

BH

to 4-Wire 300Hz ≤ f ≤ 1kHz - 40 - dB

V

BH

1kHz < f ≤ 3.4kHz - 45 - dB

4-83

Page 5

HC5549

Design Equations

Loop Supervision Thresholds

SWITCH HOOK DETECT

The switch hook detect threshold is set by a single e xternal

resistor, RSH. Equation 1 is used to calculate the value of RSH.

R

600 ISH⁄=

SH

The term I

is the desired DC loop current threshold. The

SH

loop current threshold programming range is from 5mA to

15mA.

GROUND KEY DETECT

The ground key detector senses a DC current imbalance

between the Tip and Ring terminals when the ring terminal is

connected to ground. The ground key detect threshold is not

externally programmable and is internally fixed to 12mA

regardless of the switch hook threshold.

RING TRIP DETECT

The ring trip detect threshold is set by a single external

resistor, R

. IRT should be set between the peak ringing

RT

current and the peak off hook current while still ringing.

R

1800 IRT⁄=

RT

The capacitor C

, in parallel with RRT, will set the ring trip

RT

response time.

Loop Current Limit

The loop current limit of the device is programmed by the

external resistor R

using Equation 3.

1760

R

------------ -=

IL

I

LIM

. The value of RIL can be calculated

IL

(EQ. 1)

(EQ. 2)

(EQ. 3)

4-WIRE TO 2-WIRE GAIN

The 4-wire to 2-wire gain is defined as the receive gain. It is

a function of the terminating impedance, synthesized

impedance and protection resistors. Equation 6 calculates

the receive gain, G

G

42

----------------------------------------- -

2

–=

ZO+2RP+Z

.

42

Z

L

L

(EQ. 6)

When the device source impedance and protection resistors

equals the terminating impedance, the receive gain equals

unity.

2-WIRE TO 4-WIRE GAIN

The 2-wire to 4-wire gain (G

) is the gain from tip and ring to

24

the VTX output. The transmit gain is calculated in Equation 7.

Z

G

–=

24

O

----------------------------------------- -

ZO+2RP+Z

(EQ. 7)

L

When the protection resistors are set to zero, the transmit

gain is -6dB.

TRANSHYBRID GAIN

The transhybrid gain is defined as the 4-wire to 4-wire gain

(G

).

44

Z

G

44

ZO2RPZ

++

L

O

---------------------------------------

–=

(EQ. 8)

When the protection resistors are set to zero, the transhybrid

gain is -6dB.

COMPLEX IMPEDANCE SYNTHESIS

Substituting the impedance programmingresistor,R

, with a

S

complex programming network provides complex

impedance synthesis.

The term I

is the desired loop current limit. The loop

LIM

current limit programming range is from 15mA to 45mA.

Impedance Matching

The impedance of the device is programmed with the

external component R

the feedback amplifier that provides impedance matching. If

complex impedance matching is required, then a complex

network can be substituted for R

RESISTIVE IMPEDANCE SYNTHESIS

The source impedance of the device, Z

in Equation 4.

RS400 ZO()=

The required impedance is defined by the terminating

impedance and protection resistors as shown in Equation 5.

Z

–=

OZL2RP

. RS is the gain setting resistor for

S

.

S

, can be calculated

O

4-84

(EQ. 4)

(EQ. 5)

2-WIRE

NETWORK

C

2

R

1

R

2

FIGURE 1. COMPLEX PROGRAMMING NETWORK

PROGRAMMING

NETWORK

C

P

R

S

R

P

The reference designators in the programming network

match the evaluation board. The component R

different design equation than the R

used for resistive

S

has a

S

impedance synthesis. The design equations for each

component are provided below.

RS400 R12RP()–()×=

RP400 R2×=

C

PC2

400⁄=

(EQ. 10)

(EQ. 11)

(EQ. 9)

Page 6

HC5549

Low Power Standby

Overview

The low power standby mode (LPS, 000) should be used

during idle line conditions. The device is designed to operate

from the high battery during this mode. Most of the internal

circuitry is powered down, resulting in low power dissipation.

If the 2-wire (tip/ring) DC voltage requirements are not

critical during idle line conditions, the device may be

operated from the low battery. Operation from the low

battery will decrease the standby power dissipation.

TABLE 1. DEVICE INTERFACES DURING LPS

INTERFACE

Receive x AC transmission, impedance

Ringing x

Transmit x

2-Wire x Amplifiers disabled.

Loop Detect x Switch hook or ground key.

2-WIRE INTERFACE

During LPS, the 2-wire interface is maintained with internal

switches and voltage references. The Tip and Ring

amplifiers are turned off to conserve power. The device will

provide MTU compliance, loop current and loop supervision.

Figure 2 represents the internal circuitry providing the 2-wire

interface during low power standby.

FIGURE 2. LPS 2-WIRE INTERFACE CIRCUIT DIAGRAM

MTU Compliance

Maintenance Termination Unit or MTU compliance places

DC voltage requirements on the 2-wire terminals during idle

line conditions. The minimum idle voltage is 42.75V. The

high side of the MTU range is 56V. The voltage is expressed

as the difference between Tip and Ring.

The Tip voltage is held near ground through a 600Ω resistor

and switch. The Ring voltage is limited to a maximum of

-49V (by MTU REF) when operating from either the high or

low battery. A switch and 600Ω resistor connect the MTU

reference to the Ring terminal. When the high battery

voltage exceeds the MTU reference of -49V (typically), the

ON OFF NOTES

matching and ringing are disabled during this mode.

GND

600Ω

TIP AMP

TIP

RING

RING AMP

600Ω

MTU REF

Ring terminal will be clamped by the internal reference. The

same Ring relationships apply when operating from the low

battery voltage. For high battery voltages (VBH) less than or

equal to the internal MTU reference threshold:

V

RINGVBH

4+=

(EQ. 12)

Loop Current

During LPS, the device will provide current to a load. The

current path is through resistors and switches, and will be

function of the off hook loop resistance (R

LOOP

). This

includes the off hook phone resistance and copper loop

resistance. The current available during LPS is determined

by Equation 13.

I

LOOP

1– 49–()–()600 600 R

++()⁄=

LOOP

(EQ. 13)

Internal current limiting of the standby switches will limit the

maximum current to 20mA.

Another loop current related parameter is longitudinal

current capability. The longitudinal current capability is

reduced to 10mA

per pin. The reduction in longitudinal

RMS

current capability is a result of turning off the Tip and Ring

amplifiers.

On Hook Power Dissipation

The on hook power dissipation of the device during LPS is

determined by the operating voltages and quiescent currents

and is calculated using Equation 14.

P

LPSVBHIBHQ

× VBLI

× VCCI

BLQ

×++=

CCQ

(EQ. 14)

The quiescent current terms are specified in the electrical

tables for each operating mode. Load power dissipation is

not a factor since this is an on hook mode. Some

applications may specify a standby current. The standby

current may be a charging current required for modern

telephone electronics.

Standby Current Power dissipation

Any standby line current, I

power dissipation term P

power contribution is zero when the standby line current is

zero.

P

SLCISLCVBH

49– 1I

If the battery voltage is less than -49V (the MTU clamp is

off), the standby line current power contribution reduces to

Equation 16.

P

SLCISLCVBH

1I

Most applications do not specify charging current

requirements during standby. When specified, the typical

charging current may be as high as 5mA.

, introduces an additional

SLC

. Equation 15 illustrates the

SLC

x1200++()×=

SLC

x1200++()×=

SLC

(EQ. 15)

(EQ. 16)

4-85

Page 7

HC5549

Forward Active

Overview

The forward active mode (FA, 001) is the primary AC

transmission mode of the device. On hook transmission, DC

loop feed and voice transmission are supported during forward

active. Loop supervision is provided by either the switch hook

detector (E0 = 1) or the ground key detector (E0= 0). The

device may be operated from either high or lo w battery for onhook transmission and low battery for loop feed.

On-Hook Transmission

The primary purpose of on hook transmission will be to

support caller ID and other advanced signalling features.

The transmission over load levelwhile on hook is 3.5V

When operating from the high battery, the DC voltages at Tip

and Ring are MTU compliant. The typical Tip voltage is -4V

and the Ring voltage is a function of the battery voltage for

battery voltages less than -60V as shown in Equation 17.

V

RINGVBH

4+=

Loop supervision is provided by the switch hook detector at

the

DET output. When DET goes low, the low battery should

be selected for DC loop feed and voice transmission.

Feed Architecture

The design implements a voltage feed current sense

architecture. The device controls the voltage across Tip and

Ring based on the sensing of load current. Resistors are

placed in series with Tip and Ring outputs to provide the

current sensing. The diagram below illustrates the concept.

R

B

R

V

OUT

R

L

FIGURE 3. VOLTAGE FEED CURRENT SENSE DIAGRAM

CS

-

+

-

+

K

S

R

A

By monitoring the current at the amplifier output, a negative

feedback mechanism sets the output voltage for a defined

load. The amplifier gains are set by resistor ratios (R

R

) providing all the performance benefits of matched

C

resistors. The internal sense resistor, R

, is much smaller

CS

than the gain resistors and is typically 20Ω for this device.

The feedback mechanism, K

, represents the amplifier

S

configuration providing the negative feedback.

DC Loop Feed

The feedback mechanism for monitoring the DC portion of

the loop current is the loop detector. A low pass filter is used

in the feedback to block voice band signals from interfering

with the loop current limit function. The pole of the low pass

PEAK

(EQ. 17)

V

IN

R

C

, RB,

A

filter is set by the external capacitor C

. The value of the

DC

external capacitor should be 4.7µF.

Most applications will operate the device from low battery

while off hook. The DC feed characteristic of the device will

drive Tip and Ring towards half battery to regulate the DC

loop current. For light loads, Tip will be near -4V and Ring

will be near V

+ 4V. The following diagram shows the DC

VBL

feed characteristic.

V

TR(OC)

, DC (V)

TR

.

V

(mA)

I

FIGURE 4. DC FEED CHARACTERISTIC

LOOP

The point on the y-axis labeled V

m = (∆VTR/∆IL) = 10kΩ

I

LIM

is the open circuit

TR(OC)

Tip to Ring voltage and is defined by the feed battery

voltage.

V

TR OC()VBL

8–=

(EQ. 18)

The curve of Figure 5 determines the actual loop current for

a given set of loop conditions. The loop conditions are

determined by the low battery voltage and the DC loop

impedance. The DC loop impedance is the sum of the

protection resistance, copper resistance (ohms/foot)and the

telephone off hook DC resistance.

I

A

I

B

R

(Ω)

KNEE

LOAD CHARACTERISTIC

FIGURE 5. I

I

(mA)

LOOP

I

LOOP

SC

I

LIM

2R

P

VERSUS R

R

LOOP

LOOP

The slope of the feed characteristic and the battery voltage

define the maximum loop current on the shortest possible

loop as the short circuit current I

I

SCILIM

The term I

V

------------------------------------------------------+=

is the programmed current limit, 1760/RIL.

LIM

The line segment I

–

TR OC()2RPILIM

10e3

represents the constant current region

A

SC

.

(EQ. 19)

of the loop current limit function.

IAI

LIM

V

--------------------------------------------------------------+=

–

TR OC()RLOOPILIM

10e3

(EQ. 20)

The maximum loop impedance for a programmed loop

current is defined as R

V

TR OC()

R

KNEE

------------------------=

I

LIM

KNEE

.

(EQ. 21)

4-86

Page 8

HC5549

When R

is exceeded, the device will transition from

KNEE

constant current feedto constant voltage,resistive feed. The

line segment I

represents the resistive feed portion of the

B

load characteristic.

V

I

B

TR OC()

------------------------=

R

LOOP

(EQ. 22)

Voice Transmission

The feedback mechanism for monitoring the AC portion of

the loop current consists of two amplifiers, the sense

amplifier (SA) and the transmit amplifier (TA). The AC

feedback signal is used for impedance synthesis. A detailed

model of the AC feed back loop is provided below.

T

SA

R

VRX

R

VTX

A

+

-

8K

R

S

-IN

C

FB

VFB

TIP

RING

R

20

20

-

+

+

-

R

3R

3R

3R

3R

1:1

0.75R

-

+

R/2

V

The AC feed back loop produces an echo at the V

of the signal injected at V

. The echo must be cancelled to

RX

TX

output

maintain voice quality. Most applications will use a summing

amplifier in the CODEC front end as shown below to cancel

the echo signal.

R

VRX

R

1:1

VTX

T

A

+

-

HC5518x

FIGURE 7. TRANSHYBRID BALANCE INTERFACE

The resistor ratio, R

the transmit gain, G

R

S

-IN

, provides the final adjustment for

F/RB

. The transmit gain is calculated using

TX

R

A

R

F

R

B

-

+

+2.4V

RX OUT

TX IN

CODEC

Equation 25.

R

F

G

=

TX

Most applications set R

G–

------- -

24

R

B

= RB, hence the device 2-wire to

F

4-wire equals the transmit gain. Typically R

is greater than

B

(EQ. 25)

20kΩ to prevent loading of the device transmit output.

FIGURE 6. AC SIGNAL TRANSMISSION MODEL

The gain of the transmit amplifier, set by R

programmed impedance of the device. The capacitor C

, determines the

S

FB

blocks the DC component of the loop current. The ground

symbols in the model represent AC grounds, not actual DC

potentials.

The sense amp output voltage, V

, as a function of Tip and

SA

Ring voltage and load is calculated using Equation 23.

10

=

V

SA

VTVR–()–

------

Z

L

(EQ. 23)

The transmit amplifier provides the programmable gain

required for impedance synthesis. In addition, the output of

this amplifier interfaces to the CODEC transmit input. The

output voltage is calculated using Equation 24.

V

VTX

–=

V

----------

SA

8e3

(EQ. 24)

R

S

Once the impedance matching components have been

selected using the design equations, the above equations

provide additional insight as to the expected AC node

voltages for a specific Tip and Ring load.

Transhybrid Balance

The final step in completing the impedance synthesis design

is calculating the necessary gains for transhybrid balance.

The resistor ratio, R

gain of the device, G

transmit gain requirement and R

, is determined by the transhybrid

F/RA

. RF is previously defined by the

44

is calculated using

A

Equation 26.

R

B

----------=

R

A

G

44

(EQ. 26)

Power Dissipation

The power dissipated by the device during on hook

transmission is strictly a function of the quiescent currents

for each supply voltage during Forward Active operation.

P

FAQVBH

BHQ

× VCCI

BLQ

×++=

CCQ

I×

VBLI

Off hook power dissipation is increased above the quiescent

power dissipation by the DC load. If the loop length is less

than or equal to R

current, I

, and the power dissipation is calculated using

A

, the device is providing constant

KNEE

Equation 28.

P

FA IA()PFA Q()VBLxIA

()R

If the loop length is greaterthan R

()–+=

KNEE

2

xI

LOOP

A

, the device is operating

in the constant voltage, resistive feed region. The power

dissipated in this region is calculated using Equation 29.

P

FA IB()PFA Q()VBLxIB

()R

()–+=

LOOP

2

xI

B

(EQ. 27)

(EQ. 28)

(EQ. 29)

4-87

Page 9

HC5549

Since the current relationships are different for constant

current versus constant voltage, the region of device

operation is critical to valid power dissipation calculations.

Reverse Active

Overview

The reverse active mode (RA, 011) provides the same

functionality as the forward active mode. On hook

transmission, DC loop feed and voice transmission are

supported. Loop supervision is provided by either the switch

hook detector (E0 = 1) or the ground key detector (E0 = 0).

The device may be operated from either high or low battery.

During reverse active the Tip and Ring DC voltage

characteristics exchange roles. That is, Ring is typically 4V

below ground and Tip is typically 4V more positive than

battery. Otherwise, all feed and voice transmission

characteristics are identical to forward active.

Silent Polarity Reversal

Changing from forward active to reverse active or vice versa

is referred to as polarity reversal. Many applications require

slew rate control of the polarity reversalevent. Requirements

range from minimizing cross talk to protocol signalling.

The device uses an external low voltage capacitor, C

set the reversal time. Once programmed, the reversal time

will remain nearly constant over various load conditions. In

addition, the reversal timing capacitor is isolated from the AC

loop, therefore loop stability is not impacted.

The internal circuitry used to set the polarity reversal time is

shown below.

I

1

POL

75kΩ

I

2

C

POL

POL

,to

POL pin and minimal voltage excursion ±0.75V, are well

suited to polarized capacitors.

Power Dissipation

The power dissipation equations for forwardactive operation

also apply to the reverse active mode.

Ringing

Overview

The ringing mode (RNG, 100) provides the low side return

path for externally supplied battery backed ringing. The

ringing signal must be injected through a relay at the ring

terminal. The device should be operated from the low battery

voltage during this mode to minimize the overall power

dissipation during ringing. Current flowing through the Tip

terminal will provide the necessary ring trip information.

Ringing Bias Input

The ringing bias input, VRB, is a high impedance input. The

VRB input is only selected during the ringing mode. The gain

from the VRB input to the Tip output is typically 40V/V. The

following equation shows the relationship of the Tip output

voltage to the VRB input voltage.

VBL

----------- - 40 VRB×+=

V

TIP

2

A positive DC voltage at VRB is required to shift the Tip

output voltage towards ground to provide the low side ringing

return path. Tying the logic input F2 to VRB provides the

positive voltage to offset Tip during ringing. A voltage divider

is suggested to provide control the actual voltage applied to VRB.

Logic Control

Ringing patterns consist of silent intervals. The ringing to

silent pattern is called the ringing cadence. During the silent

portion of ringing, the device can be programmed to any

other operating mode. The most likely candidates are low

power standby or forward active. Depending on system

requirements, the low or high battery may be selected.

(EQ. 31)

FIGURE 8. REVERSAL TIMING CONTROL

During forward active,the current from source I1 charges the

external timing capacitor C

and the switch is open. The

POL

internal resistor provides a clamping function for voltages on

the POL node. During reverse active, the switch closes and

I2 (roughly twice I1) pulls current from I1 and the timing

capacitor. The current at the POL node provides the drive to

a differential pair which controls the reversal time of the Tip

and Ring DC voltages.

C

POL

∆time

----------------=

75000

(EQ. 30)

Where ∆time is the required reversal time. Polarized

capacitors may be used for C

. The low voltage at the

POL

4-88

Loop supervision is provided with the ring trip detector. The

ring trip detector senses the change in loop current when the

phone is taken off hook. The loop detector full wave rectifies

the ringing current, which is then filtered with external

components RRT and CRT. The resistor RRT sets the trip

threshold and the capacitor CRT sets the trip response time.

Most applications will require a trip response time less than

150 milliseconds.

Three very distinct actions occur when the devices detects a

ring trip. First, the

DET output is latched low. The latching

mechanism eliminates the need for software filtering of the

detector output. The latch is cleared when the operating

mode is changed externally. Second, the VRS input is

disabled,removing the Tip biasing signal from the line. Third,

the device is internally forced to the forward active mode.

Page 10

HC5549

Power Dissipation

The power dissipation during ringing is dictated by the load

driving requirements and the ringing waveform. The key to

valid power calculations is the correct definition of average

and rms currents. The average current defines the high

battery supply current. The rms current defines the load

current.

The cadence provides a time averaging reduction in the

peak power. The total power dissipation consists of ringing

power, P

P

RNGPr

, and the silent interval power, Ps.

r

t

r

--------------

⋅ P

trts+

t

s

--------------

⋅+=

s

trts+

(EQ. 32)

The terms, tr and ts, represent the cadence. The ringing

interval is tr and the silent interval is ts. The typical cadence

ratio tr:ts is 1:2.

The quiescent power of the device in the ringing mode is

defined in Equation 34.

P

rQ()

VBH IBH

⋅ VBL IBLQ⋅ VCC ICC

Q

⋅++=

Q

(EQ. 33)

During ringing, the device is operated from the low battery,

therefore the VBH power contribution is negligible. The total

power during the ringing interval is the sum of the quiescent

power and loading power:

2

V

P

rPrQ()

VBL I

⋅

AVG

rms

------------------------------------------–+=

Z

+

RENRLOOP

For sinusoidal waveforms, the average current, I

AVG

(EQ. 34)

, is

defined in equation 36.

I

AVG

2

-- -

------------------------------------------

=

π

Z

V

RENRLOOP

rms

2⋅

+

(EQ. 35)

The only amplifier providing load current during ringing is the

Tip amplifier. Therefore the total power contribution from the

device is half the average power required by the load.

I

AVG

1

-- -

------------------------------------------

=

π

Z

V

RENRLOOP

rms

2⋅

+

(EQ. 36)

The silent interval power dissipation will be determined by

the quiescent power of the selected operating mode.

Power Denial

Overview

The power denial mode (111) will shutdown the entire device

except for the logic interface. Loop supervision is not

provided. This mode may be used as a sleep mode or to

shutdown in the presence of a persistent thermal alarm.

Switching between high and low battery will have no effect

during power denial.

Functionality

During power denial, both the Tip and Ring amplifiers are

disabled, representing high impedances. The voltages at

both outputs are near ground.

Thermal Shutdown

In the event the safe die temperature is exceeded, the ALM

output will go low and

automatically shut down. When thedevicecools,

high and

persists,

DET will reflect the loop status. If the thermal fault

ALM will go low again and the part will shutdown.

DET will go high and the part will

ALM will go

Programming power denial will permanently shutdown the

device and stop the self cooling cycling.

Battery Switching

Overview

The integrated battery switch selects between the high

battery (VBH) and low battery (VBL). The battery switch is

controlled with the logic input BSEL. When BSEL is a logic

high, the high battery is selected and when a logic low, the

low battery is selected. All operating modes of the device will

operate from high or low battery except forward loop back.

Functionality

The logic control is independent of the operating mode

decode. Independent logic control provides the most

flexibility and will support all application configurations.

When changing device operating states, battery switching

should occur simultaneously with or prior to changing the

operating mode. In most cases, this will minimize overall

power dissipation and prevent glitches on the

The only external component required to support the battery

switch is a diode in series with the VBH supply lead. In the

event that high battery is removed, the diode allows the

device to transition to low battery operation.

Low Battery Operation

All off hook operating conditions and ringing should use the

low battery. The prime benefit will be reduced power

dissipation. The typical low battery for the device is -24V.

However this may be increased to support longer loop

lengths or high loop current requirements. Standby

conditions may also operate from the low battery if MTU

compliance is not required, further reducing standby power

dissipation.

High Battery Operation

The high battery should be used for standby conditions

which must provide MTU compliance. During standby

operation the power consumption is typically 40 mW with 48V battery. If standby requirements do not require high

battery operation, then a lower battery will result in lower

standby power.

DET output.

4-89

Page 11

HC5549

Uncommitted Switch

Overview

The uncommitted switch is a three terminal device designed

for flexibility. The independent logic control input,

allows switch operation regardless of device operating

mode. The switch is activated by a logic low. The positive

and negative terminals of the device are labeled SW+ and

SW- respectively.

Relay Driver

The uncommitted switch may be used as a relay driver by

connecting SW+ to the relay coil and SW- to ground. The

switch is designed to have a maximum on voltage of 0.6V

with a load current of 45mA.

+5V

RELAY

SW+

SW-

FIGURE 9. EXTERNAL RELAY SWITCHING

Since the device provides the ringing waveform, the relay

functions which may be supported include subscriber

disconnect, test access or line interface bypass. An external

SWC,

SWC

snubber diode is not required when using the uncommitted

switch as a relay driver.

Test Load

The switch may be used to connect test loads across Tip

and Ring. The test loads can provide external test

termination for the device. Proper connection of the

uncommitted switch to Tip and Ring is shown below.

TIP

RING

TEST

LOAD

SW+

SW-

FIGURE 10. TEST LOAD SWITCHING

The diode in series with the test load blocks current from

flowing through the uncommitted switch when the polarity of

the Tip and Ring terminals are reversed. In addition to the

reverseactive state, the polarity of Tip and Ring are reversed

for half of the ringing cycle. With independent logic control

and the blocking diode, the uncommitted switch may be

continuously connected to the Tip and Ring terminals.

SWC

4-90

Page 12

Basic Application Circuit

HC5549

CPS1

CPS2

RP1

RP2

PROTECTION

NETWORK

-48V

VCC

CPS3

CRT

RRT

RSH

RIL

CDC

CPOL

CIL

VCC

TIP

HC5549

RING

SW+

SW-

RTD

RD

ILIM

CDC

POL

VBL

U1

VBH

SWC

BSEL

BGNDAGND

VRX

VRB

VTX

-IN

VFB

E0

F0

F1

F2

DET

ALM

D1

RS

CRX

CTX

CFB

RB1

RB2

FIGURE 11. HC5549 BASIC APPLICATION CIRCUIT

Basic Application Circuit Component List

COMPONENT VALUE TOLERANCE RATING COMPONENT VALUE TOLERANCE RATING

U1 HC5549 N/A N/A n/a n/a n/a n/a

RRT 20kΩ 1% 0.1W CDC 4.7µF 20% 10V

RSH 49.9kΩ 1% 0.1W CPS1 0.1µF 20% >100V

RIL 71.5kΩ 1% 0.1W CPS2, CPS3 0.1µF 20% 100V

RS 210kΩ 1% 0.1W D1 1N400X type with breakdown > 100V.

CRX, CRS, CTX, CRT,

CPOL, CFB

Design Parameters: Ring Trip Threshold = 90 mA peak., Switch Hook Threshold = 12 mA, Loop Current Limit = 24.6 mA, Synthesize Device

Impedance = 210kΩ/400= 525Ω, with 39Ω protection resistors, impedance across Tip and Ring terminals = 603Ω.

0.47µF 20% 10V RP1, RP2 Protection resistor values are application

dependent and will be determined byprotection

requirements. Standard applications will use ≥

35Ω per side.

4-91

Page 13

HC5549

Pin Description

PLCC SYMBOL DESCRIPTION

1 TIP TIP power amplifier output.

2 BGND Battery Ground - To be connected to zero potential. All loop current and longitudinal current flow from this ground.

Internally separate from AGND but it is recommended that it is connected to the same potential as AGND.

3 VBL Low battery supply connection.

4 VBH High battery supply connection.

5 SW+ Uncommitted switch positive terminal.

6 SW- Uncommitted switch negative terminal.

7 SWC Switch control input. This TTL compatible input controls the uncommitted switch, with a logic “0” enabling the switch and

logic “1” disabling the switch.

8 F2 Mode control input - MSB. F2-F0 for the TTL compatible parallel control interface for controlling the various modes of

operation of the device.

9 F1 Mode control input.

10 F0 Mode control input.

11 E0 DetectorOutput Selection Input. This TTL inputcontrolsthe multiplexing of the SHD (E0=1) andGKD (E0 =0) comparator

outputs to the DET output based upon the state at the F2-F0 pins.

12 DET Detector Output - This TTL output provides hook status of the loop based upon the selected operating mode. The

detected output will either be switch hook, ground key or ring trip.

13 ALM Thermal Shutdown Alarm. This pin signals the internal die temperature has exceeded safe operating temperature and

the device has been powered down automatically.

14 AGND Analog ground reference. This pin should be externally connected to BGND.

15 BSEL Selects between high and low battery, with a logic “1” selecting the high battery and logic “0” the low battery.

16 NC This pin is a “no connect” and should remain floating proper device operation.

17 POL Capacitor connected to this pin sets the polarity reversal slew rate.

18 VRB Ringing Bias Input - Analog input to offset Tip output towards ground while in Ringing Mode.

19 VRX Analog Receive Voltage - 4-wire analog audio input voltage. AC couples to codec.

20 VTX Transmit output voltage - Output of impedance matching amplifier, AC couples to codec.

21 VFB Feedback voltage for impedance matching. This voltage is scaled to accomplish impedance matching.

22 -IN Impedance matching amplifier summing node.

23 VCC Positive voltage power supply.

24 CDC DC Biasing Filter Capacitor - Connects between this pin and VCC.

25 RTD Ring trip filter network.

26 ILIM Loop Current Limit programming resistor.

27 RD Switch hook detection threshold programming resistor.

28 RING RING power amplifier output.

4-92

Loading...

Loading...