Page 1

HC55171

Data Sheet July 1998 File Number

5 REN Ringing SLIC for

ISDN Modem/TA and WLL

The HC55171 is backward compatible to the HC5517 with

the added capability of driving 5 REN loads. The HC55171 is

ideal for any modem or remote networking access

application that requires plain old telephone service POTS,

capability. The linear amplifier design allows a choice of

Sinusoidal, Square wave or Trapezoidal ringing. The voltage

feed architecture eliminates the need for a high current gain

node achieving improved system noise immunity, an

advantage in highly integrated systems.

The device is manufactured in a high voltage Dielectric

Isolation (DI) process with an operating voltage range from

-16V,foroff-hookoperation and -80V for ring signal injection.

The DI process provides substrate latch up immunity,

resulting in a robust system design.

Ordering Information

TEMP. RANGE

PART NUMBER

HC55171IM -40 to 85 28 Ld PLCC N28.45

HC55171CM 0 to 75 28 Ld PLCC N28.45

HC55171IB -40 to 85 28 Ld SOIC M28.3

HC55171CB 0 to 75 28 Ld SOIC M28.3

(oC) PACKAGE

PKG.

NO.

4323.4

Features

• 5 REN Thru SLIC Ringing Capability to 75V

• Trapezoid, Square and Sinusoid Ringing Capability

• Bellcore Compliant Ringing Voltage Levels

• Lowest Component Count Trapezoidal Solution

• Single Additional +5V Supply

• Pin For Pin Compatible With HC5517

• DI Provides Latch-Up Immunity

PEAK

Applications

• ISDN Internal/External Modems

• ISDN Terminal Adapters/Routers

• Wireless Local Loop Subscriber Terminals

• Cable Telephony Set-Top Boxes

• Digital Added Main Line

• Integrated LAN/PBX

• Related Literature

- AN9606, Operation of the HC5517/171 Evaluation

Board

- AN9607, Impedance Matching Design Equations

- AN9628, AC Voltage Gain

- AN9608, Implementing Pulse Metering

- AN9636, Implementing an Analog Port for ISDN Using

the HC5517

- AN549, The HC-5502X/4X Telephone Subscriber Line

Interface Circuits (SLIC)

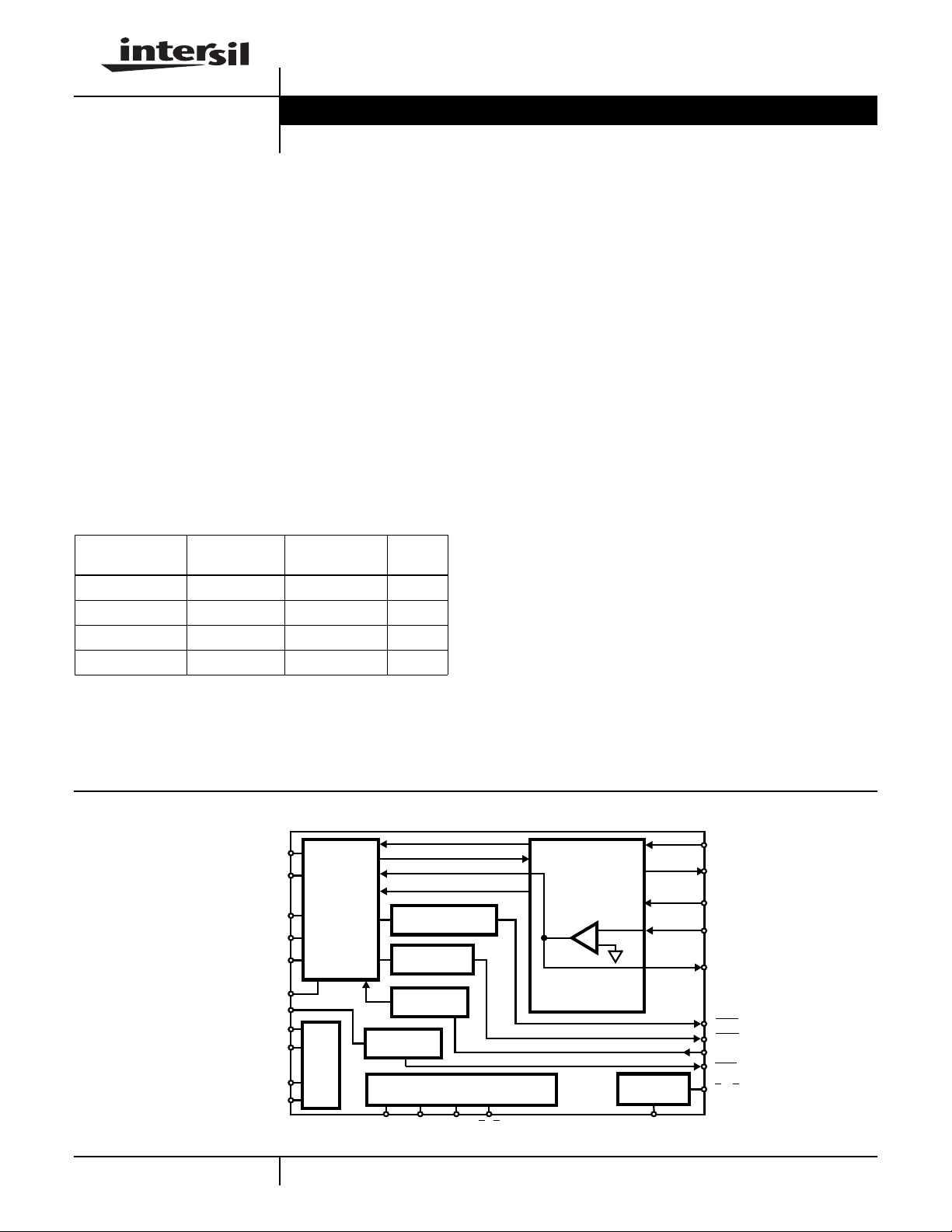

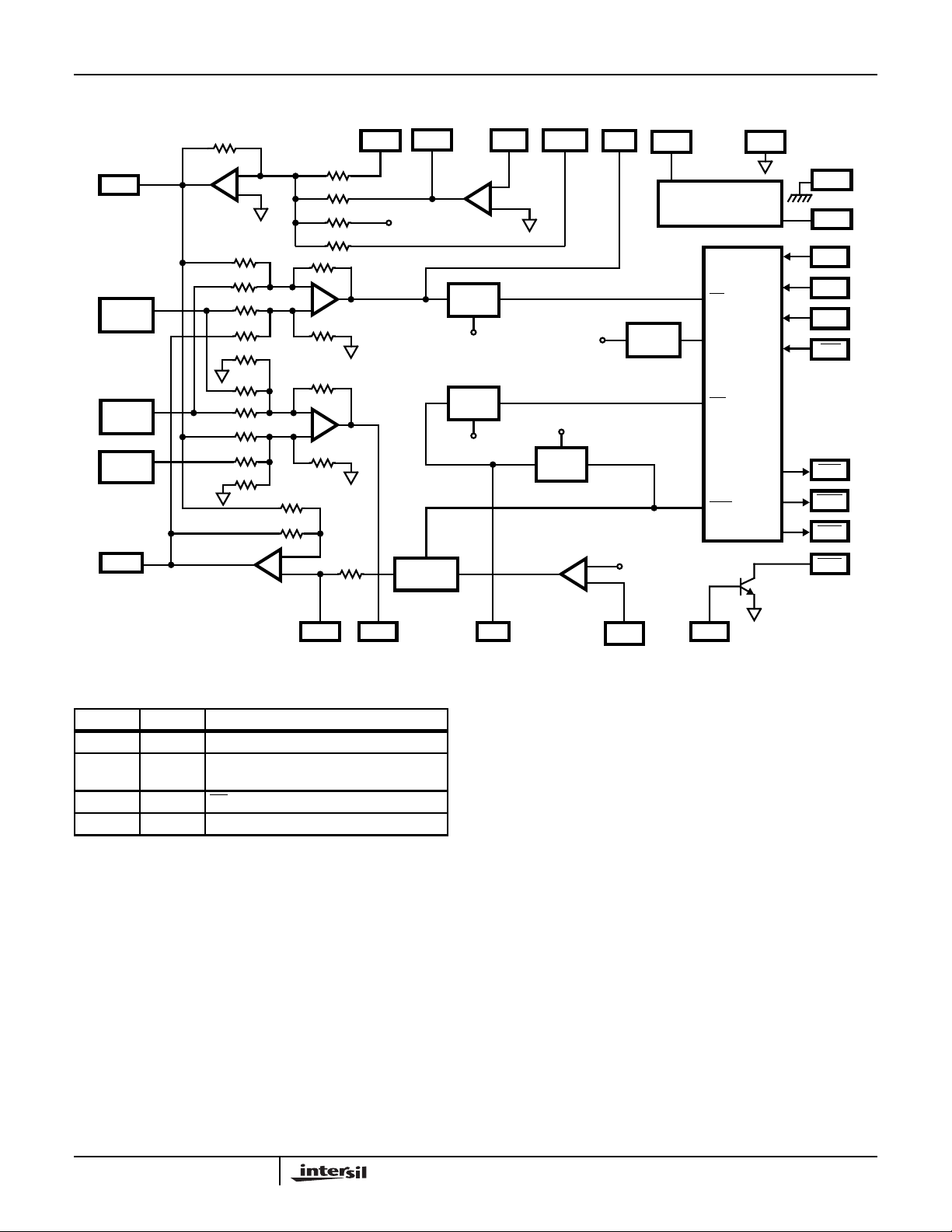

Block Diagram

TIP FEED

TIP SENSE

RING FEED

RING SENSE 1

RING SENSE 2

V

REF

RTI

V

BAT

V

CC

AGND

BGND

62

2-WIRE

INTERFACE

BIAS

V

4-WIRE

INTERFACE

LOOP CURRENT

DETECTOR

FAULT

DETECTOR

CURRENT

LIMIT

RING TRIP

DETECTOR

IIL LOGIC INTERFACE

F1 F0 RS

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

TST RDI

http://www.intersil.com or 407-727-9207 | Copyright © Intersil Corporation 1999

-

+

RELAY

DRIVER

RX

V

TX

V

RING

- IN 1

OUT 1

SHD

ALM

I

LMT

RTD

RDO

Page 2

HC55171

Absolute Maximum Ratings T

Maximum Supply Voltages

VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.5V to +7V

VCC- V

Relay Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.5V to +15V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90V

BAT

Operating Conditions

Temperature Range

HC55171IM, HC55171IB . . . . . . . . . . . . . . . . . . . . -40oC to 85oC

HC55171CM, HC55171CB . . . . . . . . . . . . . . . . . . . .0oC to 75oC

Relay Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+5V to +12V

Positive Power Supply, VCC. . . . . . . . . . . . . . . . . . . . . . . . +5V ±5%

Negative Power Supply, V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

. . . . . . . . . . . . . . . . . . . .-16V to -80V

BAT

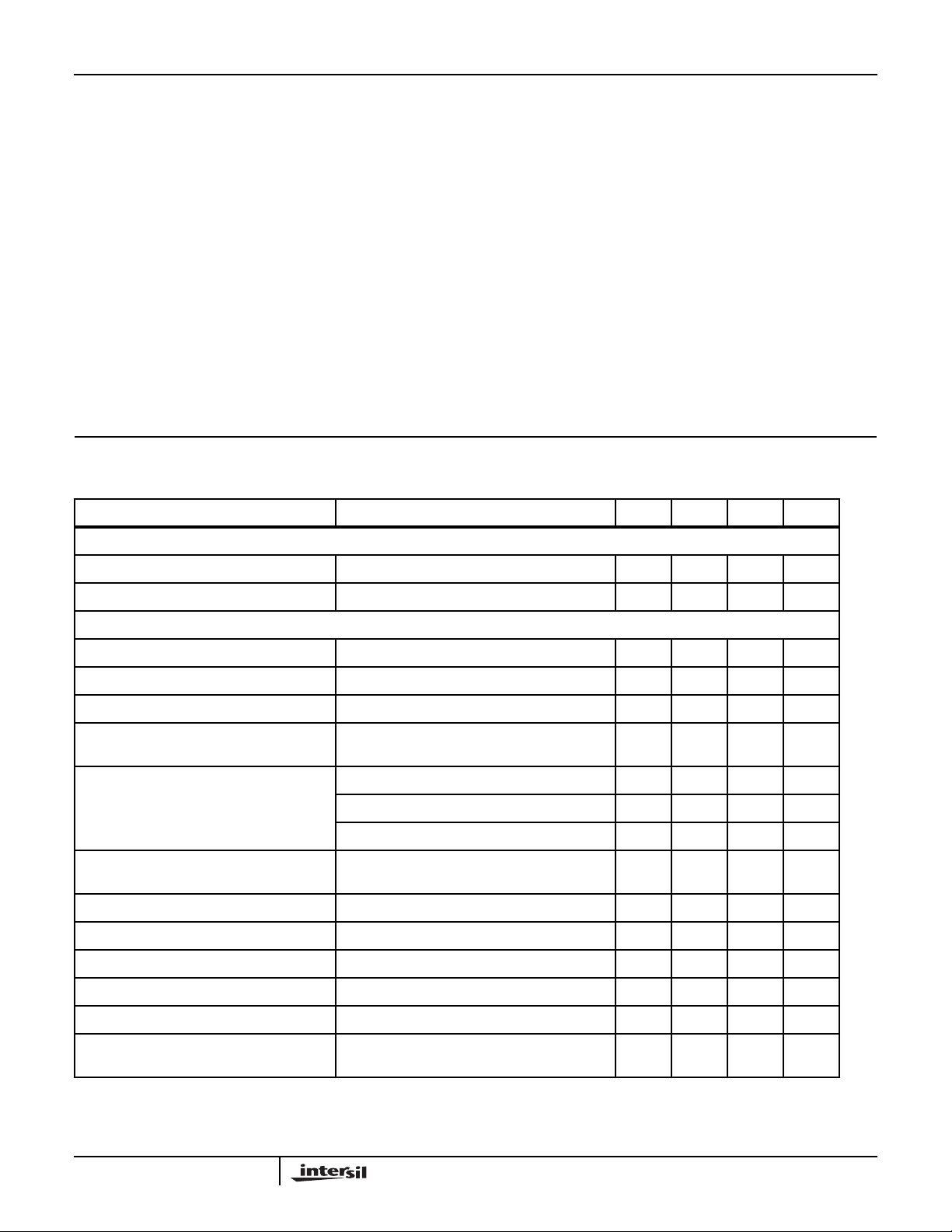

Electrical Specifications Unless Otherwise Specified, Typical Parameters are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

RINGING TRANSMISSION PARAMETERS

=25oC Thermal Information

A

Thermal Resistance (Typical, Note 1) θJA(oC/W)

PLCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

SOIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Maximum Junction Temperature Plastic . . . . . . . . . . . . . . . . .150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300oC

(SOIC, PLCC - Lead Tips Only)

Die Characteristics

Transistor Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .224

Diode Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Die Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175 x 144

Substrate Potential. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .V

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bipolar-DI

Operating TemperatureRange, V

at 600Ω 2-Wire terminating impedance.

= -24V,VCC= +5V,AGND = BGND = 0V.All AC Parametersare specified

BAT

= 25oC, Min-Max Parameters are over

A

BAT

V

Input Impedance (Note 2) - 5.4 - kΩ

RING

4-Wire to 2-Wire Gain V

AC TRANSMISSION PARAMETERS

RX Input Impedance 300Hz to 3.4kHz (Note 2) - 108 - kΩ

OUT1 Positive Output Voltage Swing RL = 10kΩ (Note 2) +2.5 - - V

OUT1 Negative Output Voltage Swing RL = 10kΩ (Note 2) -4.5 - - V

4-Wire Input Overload Level 300Hz to 3.4kHz RL = 1200Ω, 600Ω Reference

2-Wire Return Loss Matched for 600Ω, f = 300Hz (Note 2) 37 - - dB

2-Wire Longitudinal to Metallic Balance

Off Hook

4-Wire Longitudinal Balance Off Hook 300Hz to 3400Hz (Note 2) - 55 - dB

Longitudinal Current Capability I

Insertion Loss, 2W-4W 0dBmO, 1kHz, Includes Tranhybrid Amp Gain = 3 - ±0.05 ±0.2 dB

Insertion Loss, 4W-2W 0dBmO,1kHz - ±0.05 ±0.2 dB

Insertion Loss, 4W-4W 0dBmO, 1kHz, Includes Tranhybrid Amp Gain = 3 - - ±0.25 dB

to V

RING

(Note 2)

Matched for 600Ω, f = 1000Hz (Note 2) 40 - - dB

Matched for 600Ω, f = 3400Hz (Note 2) 30 - - dB

Per ANSI/IEEE STD 455-1976 300Hz to 3400Hz

(Note 2)

= 40mA, TA = 25oC (Note 2) - 40 - mA

LINE

(Note 2) - 40 - V/V

T-R

- +3.1 - V

58 63 - dB

PEAK

RMS

Frequency Response 300Hz to 3400Hz Referenced to Absolute Level

at 1kHz, 0dBm Referenced 600Ω

63

- ±0.02 ±0.06 dB

Page 3

HC55171

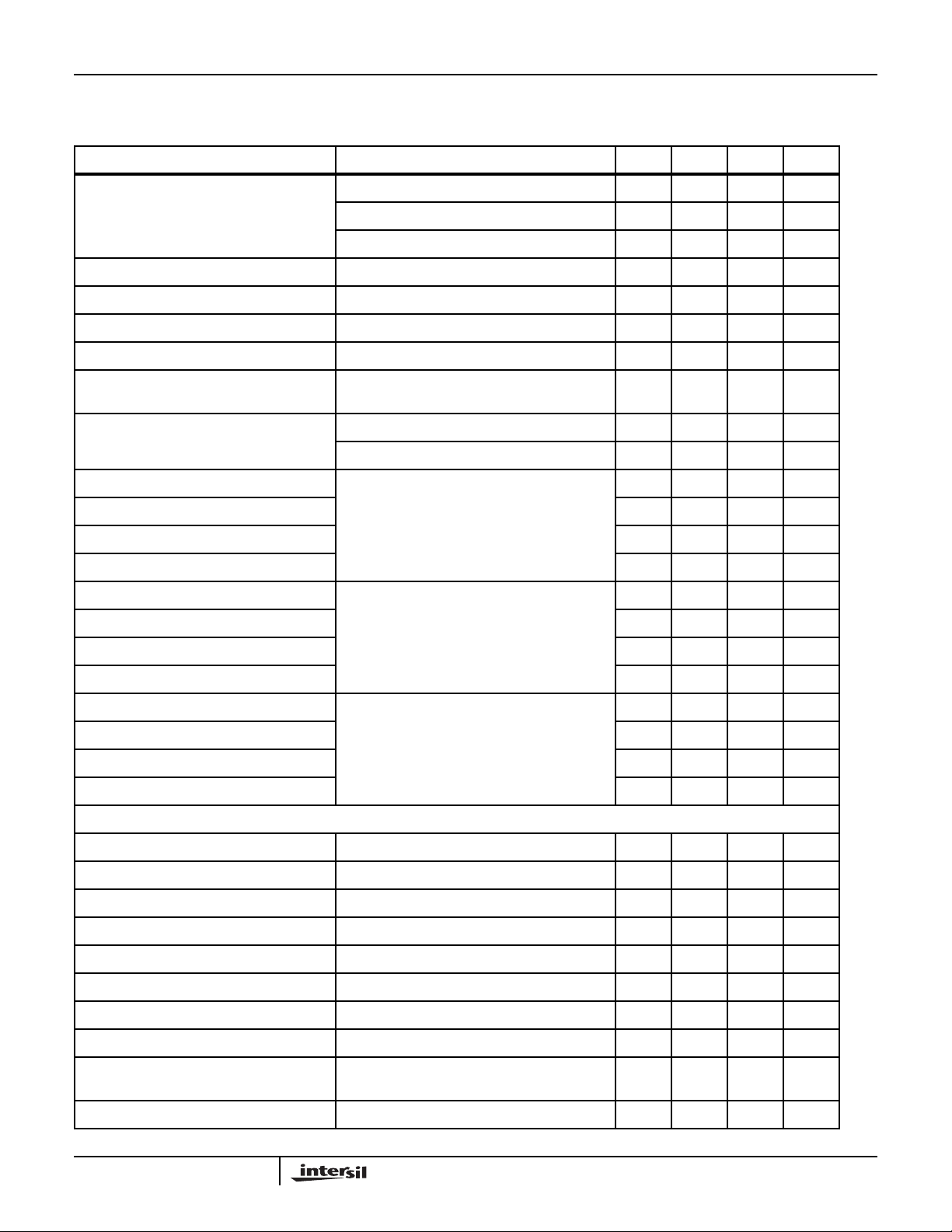

Electrical Specifications Unless Otherwise Specified, Typical Parameters are at T

Operating TemperatureRange, V

at 600Ω 2-Wire terminating impedance. (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Level Linearity +3 to 0dBm, Referenced to -10dBm (Note 2) - - ±0.10 dB

0 to -40dBm, Referenced to -10dBm (Note 2) - - ±0.12 dB

-40 to -55dBm, Referenced to -10dBm (Note 2) - - ±0.30 dB

Absolute Delay, 2W-4W 300Hz to 3400Hz (Note 2) - - 1.0 µs

Absolute Delay, 4W-2W 300Hz to 3400Hz (Note 2) - - 1.0 µs

Absolute Delay, 4W-4W 300Hz to 3400Hz (Note 2) - 0.95 - µs

Transhybrid Loss VIN = 1V

Total Harmonic Distortion

2-Wire/4-Wire, 4-Wire/2-Wire, 4-Wire/4-Wire

Idle Channel Noise

2-Wire and 4-Wire

PSRR, VCC to 2W 30Hz to 200Hz, RL = 600Ω (Note 2) 30 35 - dB

PSRR, VCC to 4W 45 47 - dB

PSRR, VBAT to 2W 23 28 - dB

Reference Level 0dBm at 600Ω

300Hz to 3400Hz (Note 2)

C-Message (Note 2) - 3 - dBrnC

Psophometric (Note 2) - -87 - dBmp

at 1kH (Note 2) 36 40 - dB

P-P

= -24V,VCC= +5V,AGND = BGND = 0V.All AC Parametersare specified

BAT

= 25oC, Min-Max Parameters are over

A

- - -50 dB

PSRR, VBAT to 4W 33 38 - dB

PSRR, VCC to 2W 200Hz to 3.4kHz, RL = 600Ω (Note 2) 33 35 - dB

PSRR, VCC to 4W 44 46 - dB

PSRR, VBAT to 2W 40 50 - dB

PSRR, VBAT to 4W 50 60 - dB

PSRR, VCC to 2W 3.4kHz to 16kHz, RL = 600Ω (Note 2) 30 34 - dB

PSRR, VCC to 4W 35 40 - dB

PSRR, VBAT to 2W 30 40 - dB

PSRR, VBAT to 4W 40 50 - dB

DC PARAMETERS

Loop Current Programming Range (Note 3) 20 - 60 mA

Loop Current Programming Accuracy -10 - +10 %

Loop Current During Power Denial RL = 200Ω, V

Fault Current, Tip to Ground (Note 2) - 90 - mA

Fault Current, Ring to Ground - 100 - mA

Fault Current, Tip and Ring to Ground (Note 2) - 130 - mA

Switch Hook Detection Threshold 9 12 15 mA

= -48V - ±4-mA

BAT

Ring Trip Comparator Voltage Threshold -0.28 -0.24 -0.22 V

Thermal ALARM Output Safe Operating Die Temperature Exceeded

(Note 2)

Dial Pulse Distortion (Note 2) - 0.1 0.5 ms

- 160 -

o

64

C

Page 4

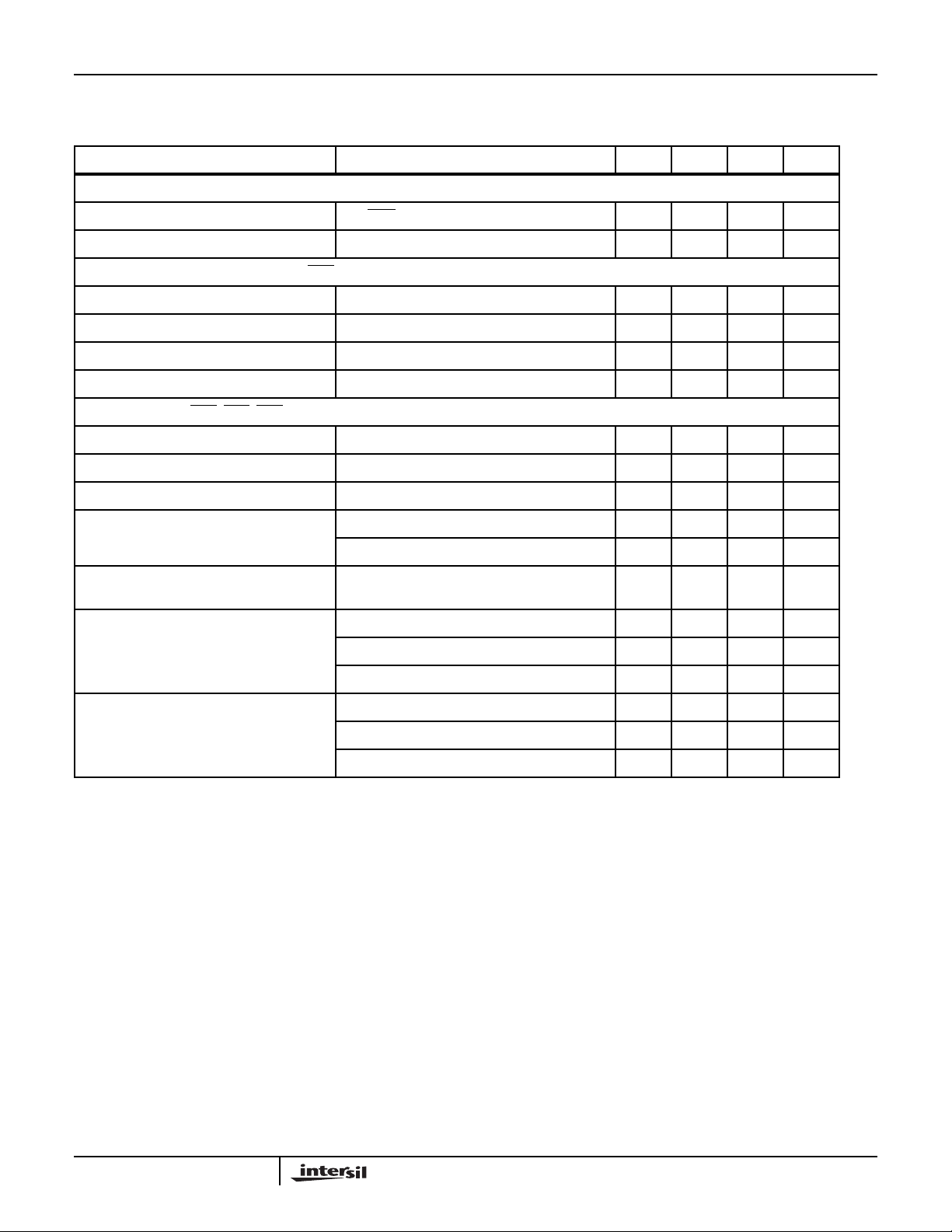

HC55171

Electrical Specifications Unless Otherwise Specified, Typical Parameters are at T

Operating TemperatureRange, V

= -24V,VCC= +5V,AGND = BGND = 0V.All AC Parametersare specified

BAT

= 25oC, Min-Max Parameters are over

A

at 600Ω 2-Wire terminating impedance. (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

UNCOMMITTED RELAY DRIVER

On Voltage, V

OL

IOL (RDO) = 30mA - 0.2 0.5 V

Off Leakage Current - ±10 ±100 µA

TTL/CMOS LOGIC INPUTS (F0, F1, RS, TST, RDI)

Logic Low Input Voltage 0 - 0.8 V

Logic High Input Voltage 2.0 - 5.5 V

Input Current IIH, 0V ≤ VIN≤ 5V - - -1 µA

Input Current IIL, 0V ≤ VIN≤ 5V - - -100 µA

LOGIC OUTPUTS (SHD, RTD, ALM)

Logic Low Output Voltage I

Logic High Output Voltage I

= 800µA - 0.1 0.5 V

LOAD

= 40µA 2.7 - 5.5 V

LOAD

POWER DISSIPATION --Power Dissipation On Hook VCC = +5V, V

VCC = +5V, V

Power Dissipation Off Hook VCC = +5V, V

= -80V, R

BAT

= -48V, R

BAT

= -24V, R

BAT

= ∞ - 300 - mW

LOOP

= ∞ - 150 - mW

LOOP

LOOP

= 600Ω,

- 280 - mW

IL = 25mA

I

CC

I

BAT

VCC = +5V, V

VCC = +5V, V

VCC = +5V, V

= -80V, R

BAT

= -48V, R

BAT

= -24V, R

BAT

VCC = +5V, VB- = -80V, R

VCC = +5V, VB- = -48V, R

VCC = +5V, VB- = -24V, R

= ∞ -36mA

LOOP

= ∞ -25mA

LOOP

= ∞ - 1.9 5 mA

LOOP

= ∞ - 3.6 7 mA

LOOP

= ∞ - 2.6 6 mA

LOOP

= ∞ - 2.3 4.5 mA

LOOP

NOTES:

2. These parameters arecontrolledby design or processparameters and are notdirectlytested. These parameters arecharacterized upon

initial design release, upon design changes which would affect these characteristics, and at intervals to assure product quality and

specification compliance.

3. This parameter directly affects device junction temperature. Refer to Power Dissipation discussion of data sheet for design information.

65

Page 5

Functional Diagram

HC55171

TF

TIP

SENSE

RING

SENSE 1

RING

SENSE 2

RF

R

2R

-

+

2R

25K

-

+

25K

R

R

R/2

R/20

TA

RA

90K

TF

25

14

15

16

26

-

+

4.5K

100K

100K

100K

100K

4.5K

R

R

R

R

90K

90K

RF

-

+

V

RX

17 12

+2V

OUT 1

VB/2

REF

SHD

RTD

-

+

-IN 1

OP AMP

V

RING

13 24 19 2

FAULT

DET

GM

V

-

+

TX

THERM

LTD

RF2

V

CC

BIAS

NETWORK

SH

TSD

GK

RFC

AGND

IIL LOGIC INTERFACE

1

22

BGND

27

V

BAT

4

F1

5

F0

6

RS

9

TST

7

SHD

8

RTD

10

ALM

21

RDO

R = 108kΩ

3

V

REF

18

HC55171 DEVICE TRUTH TABLE

F1 F0 STATE

0 0 Loop power Denial Active

0 1 Power Down Latch RESET, Power on

RESET

10

RD Active

1 1 Normal Loop feed

The truth table for the internal logic of the HC55171 is provided in the above table. This family of ringing SLICS can be

configured to support traditional unbalanced ringing and thru

SLIC balanced ringing. Refer to the HC5509A1R3060 for

unbalanced ringing application information. The device operating states used by thru SLIC ringing applications are loop

power denial and normal feed. During loop power denial, the

tip and ring amplifiers are disabled (high impedance) and the

DC voltage of each amplifier approaches ground. The SLIC

will not provide current to the subscriber loop during this mode

and will not detect loop closure. Voice transmission occurs

during the normal loop feed mode. During normal loop feed

the SLIC is completely operational and performs all transmission and supervisory functions.

28

RTINU I

11

LMT

20

RDI

Power Dissipation

Careful thermal design is required to guarantee that the

maximum junction temperature of 150

o

C of the device is not

exceeded. The junction temperature of the SLIC can be calculated using:

TJTAθJAICCVCCI

BATVBATILOOP

()2R

•()–+()+=

LOOP

Where TAis maximum ambient temperature and θJAis junction to air thermal resistance (and is package dependent).

The entire term in parentheses yields the SLIC power dissipation. The power dissipation of the subscriber loop does

not contribute to device junction temperature and is subtracted from the power dissipation term. Operating at 85

the maximum PLCC SLIC power dissipation is 1.18W. Likewise, the maximum SOIC SLIC power dissipation is 0.92W.

(EQ. 1)

o

C,

66

Page 6

HC55171

Circuit Operation and Design Information

Introduction

The HC55171 is a high voltage Subscriber Line Interface Circuit (SLIC) specifically designed for through SLIC ringing

applications. Through SLIC ringing applications are broadly

defined as any application that requires ringing capability but

does not have the standard wired central office interface. The

most common implementation of the ringing SLIC is in the

analog pots port. The analog pots port provides the ringing

function as well as interface compatibility with answering and

fax machines.

Subscriber Line Interface Basics

The basic SLIC provides DC loop current to power the handset,

supports full duplex analog transmission between the handset

and CODEC, matches the impedance of the SLIC to the

impedance of the handset and performs loop supervision functions to detect when the handset is off hook.

adds through the SLIC ringing capability to this suite of features.

The analog interfaces of the SLIC are categorized as the

2-wire interface(high voltageDC,differential AC) and the 4-wire

interface (low voltage DC, single ended AC).

DC Loop Current

The Tip and Ring terminals of the subscriber line circuit are

biased at negative potentials with respect to ground. The Tip

terminal DC potential is slightly negative with respect to

ground, and the ring terminal DC potential is slightly positive

with respect to the battery voltage (resulting in a large negative voltage). The HC55171 typical Tip DC voltage is -4V and

the typical ring DC voltage is defined as V

ple, when the battery voltage is -24V the ring voltage is -20V.

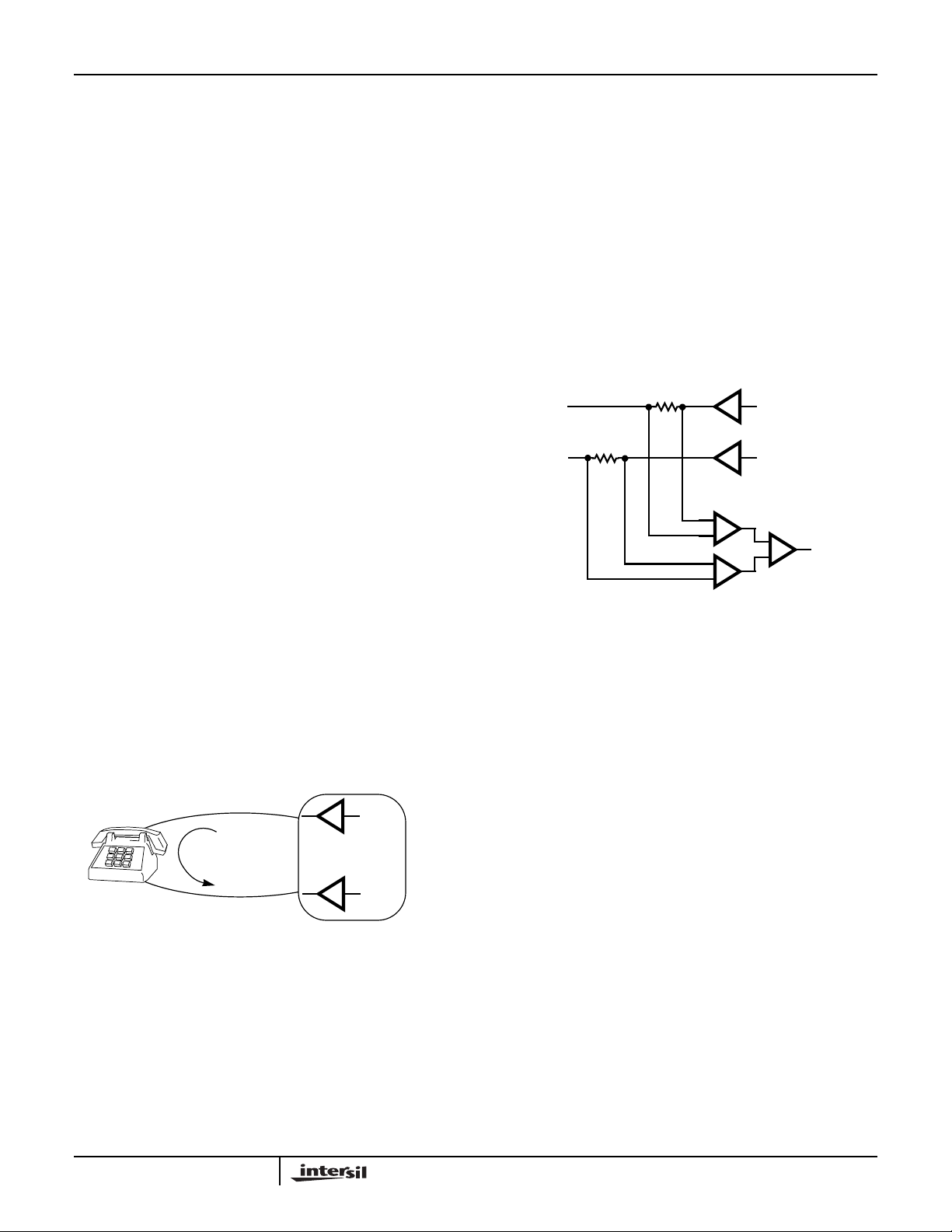

To clearly comprehend the Tip and Ring interface it is helpful

to understand that the handset and the SLIC constitute a DC

and AC current loop as shown in Figure 1. The loop is often

referred to as the subscriber loop.

LOOP

CURRENT

FIGURE 1. SUBSCRIBER LOOP

When the handset is on hook (idle) the phone is an open circuit load and the DC loop current is zero. The SLIC can still

provide AC transmission in this condition, which supports

caller id services. The DC resistance of the off hook handset

is typically 400Ω. Since the Tip DC voltage is more positive

than the ring DC voltage, DC loop current flows from Tip to

Ring when the handset is off hook. The SLIC is designed

with feedback to limit the maximum loop current when the

handset is off hook.

The ringing SLIC

+ 4V. For exam-

BAT

TIP

RING

SLIC

Full Duplex Analog Transmission

Familiarity with the signal paths of the SLIC is critical in

understanding the full duplex transmission capability of the

device. The analog interfaces of the SLIC are categorized as

2-wire interfaces and 4-wire interfaces.

The 2-wire interface of the SLIC consists of the bidirectional

Tip and Ring terminals of the device. A differential transmitter drives AC signals out of the Tip and Ring terminals to the

handset. A differential receiver across Tip and Ring receives

AC signals from the handset. The differential receiver is connected across sense resistors that are in the Tip and Ring

signal paths. The differential transmitter and receiver concept is depicted in Figure 2.

DIFFERENTIAL

TRANSMITTER

-1

-

+

-

+

FIGURE 2. DIFFERENTIAL TRANSMIT/RECEIVE CONCEPT

-

+

DIFFERENTIAL

RECEIVER

Since the receiver is connected across the transmit signal

path, one may deduce that in addition to receiving signals

from the handset, the receiver will detect part of the transmit

signal. Indeed this does occur and is the reason that all SLIC

circuits require a hybrid balance or echo cancellation function.

The 4-wire interface of the SLIC consists of the receive

(VRX) and transmit (OUT1) terminals. The 4-wire interfaces

are single ended signal paths. The receiver is a dedicated

input port and the transmitter is a dedicated output port. The

4-wire receive input of the SLIC drives the 2-wire differential

transmitter and the 2-wire differential receiver drives the 4wire transmit output.

The complete signal path for voice signals includes two digital data busses, a CODEC and a SLIC. There is a receive

data bus and transmit data bus, each with an independent 3wire serial interface. The CODEC contains a coder and

decoder. The coder converts the SLIC analog transmit output to digital data for the transmit data bus. The receive digital data bus is converted to analog data and drives the SLIC

receive input.

The CODECs use logarithmic compression schemes to

extend the resolution of the 8-bit data to 14 bits. The

accepted compression schemesareA-law(Intersil CODEC CD22357A) and µ-law (Intersil CODEC - CD22354A). The

complete signal path from the handset to the CODEC is

shown in Figure 3.

67

Page 7

HC55171

SLIC

TIP

V

RX

OUT1

RING

FIGURE 3. COMPLETE VOICE SIGNAL PATH FIGURE 4. SLIC IMPEDANCE DIAGRAM

CODEC

RX

OUT

TX

ANALOG DIGITAL

PCM

IN

IN

PCM

OUT

Impedance Matching

Impedance matching is used to match the AC source impedance of the SLIC to the AC source impedance of the load.

When the impedance is matched, the voltage level at the

receive input of the SLIC will be the same voltage levelthatis at

the 2-wire differential output (i.e., Tip and Ring). Impedance

matching applies only to the 2-wire interface, not the 4-wire

interface.

Slic AC signal power levels are most commonly assigned the

units dBmO. The term dBmO refers to milliwatts in a 600Ω

load. The typical AC power level is 0dBmO which is 1mW

referenced to a 600Ω load. The relationship between dBmO

and V

dBmO 10 1000

is provided in Equation 2.

RMS

V

()

------------------------

log⋅=

⋅

RMS

600

2

(EQ. 2)

Substituting 0dBmO into the equation should result in

0.7746 V

. For sinusoidal signals, multiply the RMS

RMS

voltage by 1.414 to obtain the peak sinusoidal voltage.

The SLIC impedance matching is achieved by applying a feed

back loop from the transmit output of the SLIC to the receive

input of the SLIC. The transmit output voltage of the HC55171

is proportional to the loop current (DC + AC) flowing in the subscriber loop. The impedance matching feedback only uses the

AC portion of the transmit output voltage. Applying a voltage

gain to the feedback term and injecting it into the receive signal

path, will cause the SLIC to “synthesize” a source impedance

that is nonzero. Recall that the impedance matching sets the

SLIC source impedance equal to the load impedance.

The SLIC application circuit requires external sense resistors

in the Tip and Ring signal paths to achieve the differential

receive function. The sense resistors contribute to the source

impedance of the SLIC and are accounted for in the design

equations. Specifically, if the load impedance is 600Ω and

each sense resistor is 50Ω, the SLIC must synthesize an

additional source impedance of 500Ω (i.e., 600Ω - 2(50Ω)).

In addition to the sense resistors, some applications may use a

protection resistor in each of the Tip and Ring leads as part of a

surge protection network. These resistors also contribute to the

SLIC source impedance and can be easily accounted for in the

design equations. If 50Ω protection resistors are added to the

prior example, the SLIC would then have to synthesize 400Ω to

match the load (i.e., 600Ω - 2(50Ω) - 2(50Ω)). A diagram

LOAD IMPEDANCE

RSYNTH

RSRP

RSRP

RSYNTH

SLIC SOURCE IMPEDANCE

TIP

RING

-1

showing the impedance terms is shown in Figure 4.

Loop Supervision

The SLIC must detect when the subscriber picks up the

handset when the SLIC is not ringing the phone and when

the SLIC is ringing the phone. The HC55171 uses a switch

hook detector output to indicate loop closure when the SLIC

is not ringing the phone. When the SLIC is ringing the

phone, loop closure is indicated by the ring trip detector.

(Recall from earlier discussions that the subscriber loop is

open when the handset is on hook and closed when off

hook. The DC impedance of the handset when off hook is

typically 400Ω.)

When the handset is off hook, DC loop current flows from

Tip to Ring and the transmit output voltage increases to a

negative value. In addition to interfacing to the CODEC and

providing the feedback for impedance matching, the transmit

output also drives the input to a voltage comparator. When

the comparator threshold is exceeded, the

SHD output goes

to a logic low, indicating the handset is off hook. When the

call is terminated and the handset is returned on hook, the

transmit voltage decreases to zero, crossing the comparator

threshold and setting

SHD to a logic high.

Loop closure must also be detected when the SLIC is ringing

the handset. The balanced ringing output of the SLIC coincides with a zero DC potential between Tip and Ring. Therefore the ring trip must be designed around an AC only

waveform at the transmit output. When the SLIC is ringing

and the handset is on hook, the echo of the ringing signal is

at the transmit output. When the handset goes off hook, the

amplitude of the ringing echo increases. The increase in

amplitude is detected by an envelope detector. When the

echo increases, the envelope detector output increases and

exceeds the ring trip comparator threshold. Then

RTD goes

to a logic low, indicating the handset is off hook. When the

system controller detects a logic low on

RTD, the ringing is

turned off and the Tip and Ring terminals return to their

typical negative DC potentials.

Design Equations and Operational Theory

The following discussion separates the SLICS’s operation

into its DC and AC path, then follows up with additional circuit design and application information.

68

Page 8

HC55171

DC Operation of Tip and Ring Amplifiers

SLIC in the Active Mode

The tip and ring amplifiers are voltage feedback op amps

that are connected to generate a differential output (e.g., if

tip sources 20mA then ring sinks 20mA). Figure 5 shows the

connection of the tip and ring amplifiers. The tip DC voltage

is set by an internal +2V reference, resulting in -4V at the

output. The ring DC voltage is set by the tip DC output voltage and an internal V

at the output. (See Equation 3, Equation 4 and Equation 5.)

V

TIPFEEDVC

R

P1

==

R

S1

V

RINGFEEDVD

V

RINGFEEDVDVBAT

TIP

/2 reference, resulting in V

BAT

R

-----------

2V–

R2⁄

V

BAT

-------------- -

2

4V–== =

R

–

1

--- -+

V

R

TIPFEED

4+==

R

TIP FEED

-

+

-

V

C

+

TRANSVERSAL

AMP

90kΩ 90kΩ

R/20

R/2

TA

-

+

+4V

BAT

(EQ. 3)

R

--- -

R

(EQ. 4)

(EQ. 5)

V

RX

R

R

OUT1

V

RING

INTERNAL

+

-

+2V REF

V

TX

R

IL1

R

IL2

RF2

GM

-

+

Current Limit

The tip feed to ring feed voltage (Equation 3 minus

Equation 5) is equal to the battery voltage minus 8V. Thus,

with a 48 (24) volt battery and a 600Ω loop resistance,

including the feed resistors, the loop current would be

66.6mA (26.6mA). On short loops the line resistance often

approaches zero and there is a need to control the maximum

DC loop current.

Current limiting is achieved by a feedback network (Figure 5)

that modifies the ring feed voltage (V

) as a function of the

D

loop current. The output of the Transversal Amplifier (TA) has

a DC voltage that is directly proportional to the loop current.

This voltage is scaled by R

IL1

and R

. The scaled voltage

IL2

is the input to a transconductance amplifier (GM) that compares it to an internal reference level. When the scaled voltage exceeds the internal reference level, the

transconductance amplifier sources current. This current

charges C

voltage (V

effectively reduces the tip feed to ring feed voltage (V

in the positive direction causing the ring feed

IL

) to approach the tip feed voltage (VC). This

D

T-R

and holds the maximum loop current constant.

The maximum loop current is programed by resistors R

and R

as shown in Equation 7 (Note: R

IL2

is typically

IL1

IL1

100kΩ).

I

LIMIT

-10

0.6()R

------------------------------------------------- -=

0

V

-5

+()

IL1RIL2

()

200xR

IL2

TIP FEED

= -4V

(EQ. 7)

CONSTANT VOLTAGE

REGION

).

R

OUT1

, V

P2

RX

RING

V

GROUNDED FOR

DC ANALYSIS

R

S2

RING FEED

-

+

+

V

D

-

90kΩ

V

-

C

IL

BAT

+

2

FIGURE 5. OPERATION OF THE TIP AND RING AMPLIFIERS

Transmit Output Voltage

The transmit output voltage in terms of loop current is

expressed as 200x I

. The 200 term is actually formed

LOOP

by the sum of twice the sense resistors and is shown in the

following equation.

200 I

× 2RS1⋅ 2RS2⋅+()I

LOOP

×=

LOOP

(EQ. 6)

This is a relationship that is critical when modifying the

sense resistor (R

S1,RS2

). The 200 term factors into the loop

current limit and loop detector functions of the SLIC.

69

-15

V

RING FEED

-20

TIP AND RING VOLTAGE (V)

-25

CURRENT LIMIT

REGION I

0

FIGURE 6. V

= 25mA

LOOP

250

LOOP RESISTANCE (Ω)

vs RL(V

T-R

500 750

= -24V, I

BAT

LIMIT

Figure 6 illustrates the relationship between V

= 25mA)

T-R

= -20V

∞

and the

loop resistance. The conditions are shown for a battery

voltage of -24V and the loop current limit set to 25mA. For an

open circuit loop the tip feed and ring feed are at -4V and

-20V respectively. When the loop resistance decreases from

infinity to about 640Ω the loop current (obeying Ohm’s Law)

increases from 0mA to the set loop current limit. As the loop

resistance continues to decrease, the ring feed voltage

approaches the tip feed voltage as a function of the

programmed loop current limit (Equation 7).

Page 9

HC55171

AC Voltage Gain Design Equations

The HC55171 uses feedback to synthesize the impedance

at the 2-wire tip and ring terminals. This feedback network

defines the AC voltage gains for the SLIC.

The 4-wire to 2-wire voltage gain (V

feedback loop shown in Figure 7. The feedback loop senses

the loop current through resistors R

age drop and multiplies it by 2 to produce an output voltage at

the V

pin equal to +4RS∆IL. The VTXvoltage is then fed into

TX

the -IN1 input of the SLIC’s internal op amp. This signal is multiplied by the ratio R

Z0/RRF

and fed into the tip current summing

node via the OUT1 pin. (Note: the internal V

(ring feed amplifier) and the internal +2V reference (tip feed

amplifier) are grounded for the AC analysis .)

The current into the summing node of TF amp is equal to:

I

OUT1

=

4RSIL∆

--------------------

–

R

R

Z0

-----------

R

RF

Equation 9 is the node equation for the tip amplifier summing

node. The current in the tip feedback resistor (I

Equation 7.

4RSIL∆

--------------------

I

–

–

R

–

I

R

R

4RSIL∆

--------------------

R

R

Z0

-----------

R

RF

R

Z0

-----------

R

RF

V

RX

-----------+ 0=

R

V

RX

-----------+=

R

to VTR) is set by the

RX

and RS2, sums their volt-

S1

/2 reference

BAT

) is given in

R

(EQ. 8)

(EQ. 9)

(EQ. 10)

R

∆

SIL

Z0

-----------

R

RF

VRX+

(EQ. 15)

24– R

×

I

∆

L

------------------------------------------------------------------------------=

++++

R

LRP1RP2RS1RS2

Equation 15 simplifies to

2V

400 IL∆–

RX

I

∆

----------------------------------------=

L

Solving for ∆I

V

RX

∆

-----------=

I

L

600

800

results in

L

(EQ. 16)

(EQ. 17)

Equation 17 is the loop current with respect to the feedback

network. From this, the 4-wire to 2-wire and the 2-wire to

4-wire AC voltage gains are calculated. Equation 18 shows

the 4-wire to 2-wire AC voltage gain is equal to 1.00.

V

RX

-----------

A

4W 2W–

V

TR

-----------

V

RX

()

I∆

LRL

-------------------- -

V

RX

600()

600

--------------------------- 1== = =

V

RX

(EQ. 18)

Equation 19 shows the 2-wire to 4-wire AC voltage gain is

equal to -0.333.

R

A

2W 4W–

V

OUT1

-------------------

V

TR

Z0

∆

SIL

I∆

()

LRL

-----------

R

RF

4– R

----------------------------------------- -

V

RX

-----------

200–

600

----------------------------------

V

RX

-----------

600()

600

1()

1

-- -–== = =

3

(EQ. 19)

The AC voltage at V

V

()R()=

CIR

4– RSIL∆

V

C

and the AC voltage at V

VD4RSIL∆

The values for R

is then equal to:

C

R

Z0

-----------

V

+=

R

R

Z0

-----------

R

RF

RX

RF

is:

D

–=

V

RX

and RRFare selected to match the

Z0

(EQ. 11)

(EQ. 12)

(EQ. 13)

impedance requirements on tip and ring, for more

information refer to AN9607 “Impedance Matching Design

Equations for the HC5509 Series of SLICs”. The following

loop current calculations will assume the proper R

R

values for matching a 600Ω load.

RF

∆I

The loop current (

) with respect to the feedback network, is

L

calculated in Equations 14 through 17. Where R

R

= 40kΩ, RL = 600Ω, RP1 = RP2 = RS1 = RS1 = 50Ω.

RF

V

–

∆

------------------------------------------------------------------------------=

I

L

++++

R

LRP1RP2RS1RS2

Substituting the expressions for V

CVD

and V

C

D

Z0

and

Z0

= 40kΩ,

(EQ. 14)

Impedance Matching

The feedback network, described above, is capable of

synthesizing both resistive and complex loads. Matching the

SLIC’s 2-wire impedance to the load is important to maximize power transfer and maximize the 2-wire return loss.

The 2-wire return loss is a measure of the similarity of the

impedance of a transmission line (tip and ring) and the

impedance at it’s termination. It is a ratio, expressed in decibels, of the power of the outgoing signal to the power of the

signal reflected back from an impedance discontinuity.

Requirements for Impedance Matching

Impedance matching of the HC55171 application circuit to the

transmission line requires that the impedance be matched to

points “A” and “B” in Figure 7. To do this, the sense and protection resistors R

P1,RP2,RS1

for by the feedback network to make it appear as if the output

of the tip and ring amplifiers are at points “A” and “B”. The

feedback network takes a voltage that is equal to the voltage

drop across the sense resistors and feeds it into the summing

node of the tip amplifier. The effect of this is to cause the tip

feed voltage to become more negative by a value that is proportional to the voltage drop across the sense resistors R

and RS1. At the same time the ring amplifier becomes more

positive by the same amount to account for resistors R

and RS2.

The net effect cancels out the voltage drop across the feed

resistors. By nullifying the effects of the feed resistors the

and RS2must be accounted

P1

P2

70

Page 10

∆

I

HC55171

feedback circuitry becomes relatively easy to match the

impedance at points “A” and “B”.

Impedance Matching Design Equations

Matching the impedance of the SLIC to the load is

accomplished by writing a loop equation starting at V

going around the loop to V

.

C

and

D

The loop equation to match the impedance of any load is as

follows (note: V

R

4RSIL∆–

∆ 8RSIL∆–

-----------

R

RF

V

IN

VIN∆ IL∆ 8RS–

= 0 for this analysis):

RX

Z0

2R

+++

∆–∆ RLIL∆ 2RSIL∆ 4RSIL∆–

SILVIN

R

Z0

-----------

4R

∆ RLIL∆++=

Z0

SIL

++=

4R

SRL

R

RF

R

-----------

R

RF

R

Z0

-----------

R

RF

(EQ. 20)

(EQ. 21)

(EQ. 22)

Equation 22 can be separated into two terms, the feedback

(-8R

S(RZ0/RRF

V

∆

IN

------------- 8– R

∆

I

L

)) and the loop impedance (+4RS+RL).

R

Z0

-----------

S

R

RF

4R

+[]+=

SRL

(EQ. 23)

R

L

∆V

LOAD

+

IN

-

SLIC

8RS

R

Z0

------------ -

4RS+

R

RF

FIGURE 8. SCHEMATIC REPRESENTATION OF EQUATION 20

The result is shown in Equation 23. Figure 8 is a schematic

representation of Equation 18. To match the impedance of

the SLIC to the impedance of the load, set:

R

Z0

-----------

8R

S

R

RF

If R

is made to equal 8RS then:

RF

4R

=+

SRL

RZ04RSRL=+

Therefore to match the HC5517, with R

equal to 50Ω,toa

S

(EQ. 24)

(EQ. 25)

600Ω load:

R

8RS850Ω()400Ω== =

RF

(EQ. 26)

and

R

Z0RL

To prevent loading of the V

R

RF

KR

Z0

4– RS600Ω 200Ω– 400Ω== =

output, the value of RZ0and

TX

are typically scaled by a factor of 100:

40kΩ= KR

RF

40kΩ=

(EQ. 27)

(EQ. 28)

4– RSIL∆()

----------------------------- -

I

R

TIP

A

R

+

R

∆I

L

P1

R

Z0

------------ -

R

RF

∆I

+

-

R

S1

V

RX

------------ -+=

R

L

-

I

R

R

-

+

-

V

C

+

R

R

R/20

R/2

V

4– R

=

C

S

Since the impedance matching is a function of the voltage

gain, scaling of the resistors to achieve a standard value is

recommended.

For complex impedances the above analysis is the same.

KRRF40kΩ=()KRZ0100 Resistive 200–()

Reactive

--------------------------+=

100

(EQ. 29)

Refer to application note AN9607 (“Impedance Matching

Design Equations for the HC5509 Series of SLICs”) for the

values of KRRFand KRZ0for many worldwide typical line

impedances.

V

TR

R

∆V

-

∆I

L

IN

L

+

RP1 = RP2 = RS1 = RS2 = R

S

-

+

∆I

L

+

B

RING

R

∆I

R

P2

S2

∆I

L

-

L

+-

+

90kΩ 90kΩ

-

+

+

V

D

-

VD4RS=

Through SLIC Ringing

The HC55171 uses linear amplification to produce the ringing

signal. As a result the ringing SLIC can produce sinusoid,

trapezoid or square wave ringing signals. Regardless of the

wave shape, the ringing signal is balanced. The balanced

waveform is another way of saying that the tip and ring DC

potentials are the same during ringing. The following figure

shows the Tip and Ring waveforms for sinusoid and trapezoid

wave shapes as can be displayed using an oscilloscope.

Pertinent Bellcore Ringing Specifications

Bellcore has defined bounds around the existing unbalanced

FIGURE 7. AC VOLTAGE GA

ringing signal that is supplied by the central office. The

71

Page 11

HC55171

GROUND

TIP

RING

BATTERY

(A) SINUSOID

GROUND

TIP

RING

BATTERY

(B) TRAPEZOID

FIGURE 9. BALANCED RINGING WAVESHAPES

HC55171 ringing SLIC meets the REN drive requirement, the

crest factor limitations and the minimum RMS ringing voltage.

The foremost requirement is that the ringing source must be

able to drive 5 REN. A REN is a ringer equivalence number

modeled by a 6.93kΩ resistor in series with a 8µF capacitor

(see Figure 10). The impedance of 1 REN at 20Hz is approximately 7kΩ. 5 REN is equivalent to five of the networks in

parallel. Figure 10 provides the Bellcore REN models.

The crest factor of the ringing waveform is the ratio of the

peak voltage to the RMS voltage. For reference, the crest

factor of a sinusoid is 1.414 and of a square wave is 1.0.

Bellcore defines the crest factor range from 1.2 to 1.6. A signal with a crest factor between 1.2 and 1.414 resembles the

trapezoid of Figure 9. A signal with a crest factor between

1.414 and 1.6 resembles a “rounded triangular” wave shape

and is an inefficient waveform for the ringing SLIC.

40µF

8µF

FIGURE 10. BELLCORE RINGER EQUIVALENCE MODELS

1386Ω

5 REN

6930Ω

1 REN

The third pertinent Bellcore requirement is the that RMS ringing

voltage must be greater than 40V

ment. The HC5517 is able to deliver 40V

at the telephone instru-

RMS

at the end of

RMS

500Ω loops. The 500Ω loop drive capability of the HC5517 is

achieved with trapez oidal ringing.

Sinusoidal Ringing

The HC55171 uses the same sinusoidal application circuit

as the HC5517. The only difference being the values of three

components in the ring trip filter. The following table lists the

components and the different values required by each

device. All reference designators refer to the application

circuit published in the HC5517 and HC55171 data sheet.

TABLE 1. RING TRIP COMPONENT DIFFERENCES

COMPONENT HC5517 COMPONENT HC55171

R

15

R

17

C

10

47kΩ R

56.2kΩ R

1.0µFCRT0.47µF

RT3

RT1

51.1kΩ

49.9kΩ

The sinusoidal circuit published in the HC5517 can be used

as an additional reference circuit for the HC55171. To generate a sinusoid ringing signal, two conditions must be met on

the ringing (V

) input of the SLIC.

RING

The first condition is that a positive DC voltage, which is directly

related to the battery voltage, must be present at the ringing

input. The DC voltage is used to force the Tip and Ring DC outputs to half the battery voltage. Having both the Tip and Ring

amplifiers biased at the same DC voltage during ringing is one

characteristic of balanced ringing. The centering voltage (V

C

can be calculated from the following equation.

V

V

BAT

-------------- -

C

2

20⁄=

4–

(EQ. 30)

Substituting values of battery voltage, the centering voltage

is +1.8V for a -80V battery and +1.3V for a -60V battery.

The second condition that must be met for sinusoidal ringing

is a low level ringing signal must be applied to the ringing

input of the SLIC. The AC signal that is present at V

RING

will

be amplified by a gain of 20 through the Tip amplifier and a

then inverted through the ring amplifier, resulting in a differential gain of 40. The maximum low level amplitude that can

be injected for a given battery voltage can be determined

from the following equation.

V

RING Max()VBAT

8–()20⁄=

(EQ. 31)

The maximum output swing may be increased by driving the

V

negative by 200mV. Equation 31 can then by

RING

rewritten as:

V

RING Max()VBAT

5–()20⁄=

(EQ. 32)

Exceeding the maximum signal calculated from the above

equation will cause the peaks of the sinusoid to clip at

ground and battery. The compression will reduce the crest

factor of the waveform, producing a trapezoidal waveform.

This is just one method, though inefficient, for achieving trapezoidal ringing. The application circuit provided with the

HC55171 has been specifically developed for trapezoidal

ringing and may also be used with the HC5517.

Trapezoidal Ringing

The trapezoidal ringing waveform provides a larger RMS

voltage to the handset. Larger RMS voltages to the handset

provide more power for ringing and also increase the loop

length supported by the ringing SLIC.

The HC55171 trapezoidal ringing application circuit will operate for loop lengths ranging from 0Ω to 500Ω. In addition, one

)

72

Page 12

HC55171

set of component values will satisfy the entire ringing loop

range of the SLIC. A single resistor sets the open circuit RMS

ringing voltage, which will set the crest factor of the ringing

waveform. The crest factor of the HC55171 ringing waveform

is independent of the ringing load (REN) and the loop length.

Another robust feature of the HC55171 ringing SLIC is the

ring trip detector circuit. The suggested values for the ring trip

detector circuit cover quite a large range of applications.

The assumptions used to design the trapezoidal ringing

application circuit are listed below:

• Loop current limit set to 25mA.

• Impedance matching is set to 600Ω resistive.

• 2-wire surge protection is not required.

• System able to monitor

RTD and SHD.

• Logic ringing signal is used to drive RC trapezoid network.

Crest Factor Programming

As previously mentioned, a single resistor is required to set

the crest factor of the trapezoidal waveform. The only design

variable in determining the crest factor is the battery voltage.

The battery voltage limits the peak signal swing and

therefore directly determines the crest factor.

A set of tables will be provided to allow selection of the crest

factor setting resistor. The tables will include crest factors

below the Bellcore minimum of 1.2 since many ringing SLIC

applications are not constrained by Bellcore requirements.

TABLE 2. CREST FACTOR PROGRAMMING RESISTOR FOR

V

= -80V

BAT

R

TRAP

0Ω 1.10 65.0 825Ω 1.25 57.6

389Ω 1.15 62.6 964Ω 1.30 55.4

640Ω 1.20 60.0 1095Ω 1.35 53.3

CF RMS R

TRAP

CF RMS

The RMS voltage listed in the table is the open circuit RMS

voltage generated by the SLIC.

TABLE 3. CREST FACTOR PROGRAMMING RESISTOR FOR

R

TRAP

0Ω 1.10 60.9 1010Ω 1.25 53.7

500Ω 1.15 58.3 1190Ω 1.30 51.6

791Ω 1.20 55.9 1334Ω 1.35 49.7

TABLE 4. CREST FACTOR PROGRAMMING RESISTOR FOR

R

TRAP

0Ω 1.10 52.5 1330Ω 1.25 45.9

660Ω 1.15 49.8 1600Ω 1.30 44.1

1040Ω 1.20 47.8 1800Ω 1.35 42.5

= -75V

V

BAT

CF RMS R

= -65V

V

BAT

CF RMS R

TRAP

TRAP

CF RMS

CF RMS

TABLE 5. CREST FACTOR PROGRAMMING RESISTOR FOR

V

= -60V

BAT

R

TRAP

0Ω 1.10 48.2 1460Ω 1.25 42.0

740Ω 1.15 45.6 1760Ω 1.30 40.4

1129Ω 1.20 43.7 2030Ω 1.35 38.8

CF RMS R

TRAP

CF RMS

Ringing Voltage Limiting Factors

As the load impedance decreases (increasing REN), the

feedback used for impedance synthesis slightly attenuates

the ringing signal. Another factor that attenuates the ringing

signal is the voltage divider formed by the sense resistors

and the impedance of the ringing load. As the load impedance decreases, the 100Ω of sense resistors becomes a

larger percentage of the load impedance.

If surge protection resistance must be used with the

trapezoidal circuit, the loop length performance of the circuit

will decrease. The decrease in ringing loop length is caused

by the addition of protection resistors in series with the Tip

and Ring outputs. The amount of protection resistance that

is added will subtract directly from the loop length. For example if 30Ω protection resistors is used in each of the Tip and

Ring leads, the ringing loop length will decrease by a total of

60Ω. Therefore, subtracting 60Ω from the graphs will provide

the reduced loop length data.

Lab Measurements

The lab measurements of the trapezoidal ringing circuit were

made with the crest factor programming resistor set to 0Ω

and the battery voltage set to -80V. The Bellcore suggested

REN model was used to simulate the various ringing loads.

A resistor in series with the Tip terminal was used to emulate

loop length.

A logic gate is used to drive the RC shaping network. When

the crest factor programming resistor is set to 0Ω, the output

impedance of the logic gate results in a 0.8V/ms slewing

voltage on C

TRAP

.

Each graph shows the RMS ringing voltage into a fixed REN

load versus loop length. The ringing voltage was measured

across the test load. Each test also verified proper operation

of the ring trip detector. Proper ring trip detector operation is

defined as a constant logic high while ringing and on hook

and a constant logic low when off hook is detected. The

component values in the application circuit provide a ring trip

response in the 100ms to 150ms range.

73

Page 13

HC55171

60

59

58

57

RMS RINGING VOLTAGE

56

0 100 200 300 400 500

LOOP IMPEDANCE

FIGURE 11. RMS RINGING VOLTAGE vs LOOP LENGTH REN = 1

58

56

54

52

55

52

49

46

RMS RINGING VOLTAGE

43

0 100 200 300 400 500

LOOP IMPEDANCE

FIGURE 14. RMS RINGING VOL TAGE vs LOOP LENGTH REN = 4

56

52

48

44

RMS RINGING VOLTAGE

40

RMS RINGING VOLTAGE

50

0 100 200 300 400 500

LOOP IMPEDANCE

FIGURE 12. RMS RINGING VOLTAGE vs LOOP LENGTH REN = 2

58

55

52

49

RMS RINGING VOLTAGE

46

0 100 200 300 400 500

LOOP IMPEDANCE

FIGURE 13. RMS RINGING VOLTAGE vs LOOP LENGTH REN = 3

0 100 200 300 400 500

LOOP IMPEDANCE

FIGURE 15. RMS RINGING VOLTAGE vs LOOP LENGTH REN = 5

Low Level Ringing Interface

The trapezoidal application circuit only requires a cadenced

logic signal applied to the wave shaping RC network to

achieve ringing. When not ringing, the logic signal should be

held low. When the logic signal is low, Tip will be near

ground and Ring will be near battery. When the logic signal

is high, Tip will be near battery and Ring will be near ground.

74

Page 14

HC55171

Loop Detector Interface

RTD output should be monitored for off hook detection

The

during the ringing period. At all other times, the

SHD should

be monitored for off hook detection. The application circuit

can be modified to redirect the ring trip information through

the

SHD interface. The change can be made by rewiring the

application circuit, adding a pullup resistor to pin 23 and setting F0 low for the entire duration of the ringing period. The

modifications to the application circuit for the single detector

interface are shown in Figure 16.

HC55171

NU 23

RDI 20

RDO 21

V

24

RING

FIGURE 16. APPLICATION CIRCUIT WIRING FOR SINGLE

LOOP DETECTOR INTERFACE

ADDITIONAL PULL UP RESISTOR

V

CC

R

TRAP

V

D

TRAP

C

TRAP

RING

SLIC Operating State During Ringing

The SLIC control pin F1 should always be a logic high during

ringing. The control pin F0 will either be a constant logic high

(two detector interface) or a logic low (single detector interface). Figure 17 shows the control interface for the dual

detector interface and the single detector interface.

Additional Application Information

(DUAL DETECTOR INTERFACE)

MODE

F1

F0

V

RING

VALID DET

MODE

F1

F0

V

RING

VALID DET

ACTIVE

(LOGIC HI)

(LOGIC HI)

SHD

(SINGLE DETECTOR INTERFACE)

ACTIVE

(LOGIC HI)

(LOGIC HI)

SHD

RINGING

RTD

RINGING

SHD

ACTIVE

SHD

ACTIVE

SHD

Tip-to-Ring Open Circuit Voltage

The tip-to-ring open-circuit voltage, V

, of the HC55171

OC

may be programmed to meet a variety of applications. The

design of the HC5517 defaults the value of V

V

OCVBAT

8–≅

OC

to:

Using a zener diode clamping circuit, the default open circuit

voltage of the SLIC may be defeated. Some applications that

have to meet Maintenance Termination Unit (MTU) compliance have a few options with the HC55171. One option is to

reduce the ringing battery voltage until MTU compliance is

achieved. Another option is to use a zener clamping circuit

on V

to over ride the default open circuit voltage when

REF

operating from a high battery.

If a clamping network is used it is important that it is disabled

during ringing. The clamping network must be disabled to

allow the SLIC to achieve its full ringing capability. A zener

clamping circuit is provided in Figure 18.

HC55171

V

REF

FIGURE 18. ZENER CLAMP CIRCUIT WITH DISABLE

C

IL

3

+5V

47kΩ

2N2907

EN

The following equations are used to predict the DC output of

the ring feed amplifier when using the zener clamping network, V

V

BAT

-------------- -

2

V

BAT

-------------- -

2

Where V

.

RDC

V

BAT

VZ< V

VZ≥ V

Z

RDC

RDC

is the zener diode voltage and VCEand VBEare

-------------- -

2

2V–

4+=

2

ZVCEVBE

–()+()4+=

(EQ. 33)

(EQ. 34)

the saturation voltages of the pnp transistor. Using Equations 31 and 32, the tip-to-ring open-circuit voltage can be

calculated for any value of zener diode and battery voltage.

V

BAT

-------------- -

2

V

BAT

-------------- -

2

VZ< V

VZ≥ V

OCVTDC

OCVTDC

V

BAT

-------------- -

2

2

2V–

ZVCEVBE

4––=

(EQ. 35)

–()+()4––=

(EQ. 36)

When the base of the pnp transistor is pulled high (+5V), the

transistor is off and the zener clamp is disabled. When the

base of the transistor is pulled low (0V) the transistor is on

and the zener will clamp as long as half the battery voltage is

greater than the zener voltage.

FIGURE 17. DETECTOR LOGIC INTERFACES

75

Page 15

HC55171

Polarity Reversal

The HC55171 supports applications that use polarity reversal

outside the speech phase of a call connection. The most common implementation of this type of polarity reversal is used

with pay phones. By reversing the polarity of the tip and ring

terminals of a pay phone, DC current changes direction in a

solenoid and the coins are released from the phone. To

reverse the polarity of the HC55171, simply toggle the V

input high. Setting the V

input high will cause Tip and

RING

RING

Ring to reverse polarity.

Transhybrid Balance

Since the receive signal and its echo are 180 degrees out of

phase, the summing node of an operational amplifier can be

used to cancel the echo. Nearly all CODECs have an internal amplifier for echo cancellation. The following Figure 19

shows the cancellation amplifier circuit.

R

V

RX

V

OUT1

FIGURE 19. TRANHYBRID AMPLIFIER CIRCUIT

A

R

B

R

F

-

+

VO

When the SLIC is matched to a 600Ω load, the echo amplitude is 1/3 the receive input amplitude. Therefore, by configuring the transhybrid amplifier with a gain of 3 in the echo

path, cancellation can be achieved. The following equations:

R

–=

V

O

V

RX

F

------- -

+

R

A

V

OUT1

R

F

------- -

R

B

(EQ. 37)

The DC reference from the CODEC is used to bias the

analog signals between +5V and ground. The capacitors are

required so that the DC gain is unity for proper biasing from

the CODEC reference. Also, the capacitors block DC signals

that may interfere with SLIC or CODEC operation.

Layout Guidelines and Considerations

The printed circuit board trace length to all high impedance

nodes should be kept as short as possible. Minimizing length

will reduce the risk of noise or other unwanted signal pickup.

The short lead length also applies to all high gain inputs. The

set of circuit nodes that can be categorized as such are:

•V

pin 27, the 4-wire voice input.

RX

• -IN1 pin 13, the inverting input of the internal amplifier.

•V

•V

For multi layer boards, the traces connected to tip should not

cross the traces connected to ring. Since they will be carrying high voltages, and could be subject to lightning or surge

depending on the application, using a larger than minimum

trace width is advised.

The 4-wire transmit and receive signal paths should not

cross. The receive path is any trace associated with the V

input and the transmit path is any trace associated with V

output. The physical distance between the two signal paths

should be maximized to reduce crosstalk.

The mode control signals and detector outputs should be

routed away from the analog circuitry. Though the digital signals are nearly static, care should be taken to minimize coupling of the sharp digital edges to the analog signals.

pin 3, the noninverting input to ring feed amplifier.

REF

pin 24, the 20V/V input for the ringing signal.

RING

RX

TX

Substituting the fact that V

R

V

–=

O

V

RX

F

------- -

–

R

A

V

RX

OUT1

1

-- -

3

is -1/3 of V

R

F

------- -

R

B

RX

(EQ. 38)

Since cancellation implies that under these conditions, the

output V

solve for R

R

B

should be zero, set Equation 37 equal to zero and

O

.

B

R

A

------- -=

3

(EQ. 39)

Another outcome of the transhybrid gain selection is the 2wire to 4-wire gain of the SLIC as seen by the CODEC. The

1/3 voltage gain in the transmit path is relevant to the receive

input as well as any signals from the 2-wire side. Therefore

by setting the V

gain to three in the previous analysis,

OUT1

the 2-wire to 4-wire gain was set to unity.

Single Supply Codec Interface

The majority of CODECs that interface to the ringing SLIC

operate from a single +5V supply and ground. Figure 20

shows the circuitry required to properly interface the ringing

SLIC to the single supply CODEC.

The CODEC signal names may vary from different

manufacturers, but the function provided will be the same.

The part has two ground pins, one is labeled AGND and the

other BGND. Both pins should be connected together as

close as possible to the SLIC. If a ground plane is available,

then both AGND and BGND should be connected directly to

the ground plane.

A ground plane that provides a low impedance return path

for the supply currents should be used. A ground plane provides isolation between analog and digital signals. If the layout density does not accommodate a ground plane, a single

point grounding scheme should be used.

CODEC

+2.5V

RX OUT

TX IN

+

-

V

RX

VOUT1

HC55171

FIGURE 20. SINGLE SUPPLY CODEC INTERFACE

R

A

R

R

F

B

+

76

Page 16

HC55171

Pin Descriptions

PLCC SYMBOL DESCRIPTION

1 AGND Analog Ground - Serves as a reference for the transmit output and receive input terminals.

2VCCPositive Voltage Source - Most Positive Supply.

3V

4 F1 Power Denial - An active low TTL compatible logic control input. When enabled, the output of the ring amplifier will

5 F0 TTL compatible logic control input that must be tied high for proper SLIC operation.

6 RS TTL compatible logic control input that must be tied high for proper SLIC operation.

7 SHD Switch Hook Detection - An active low TTL compatible logic output. Indicates an off-hook condition.

8 RTD Ring Trip Detection - An active low TTL compatible logic output. Indicates an off-hook condition when the phone is

9 TST A TTL logic input. A low on this pin will keep the SLIC in a power down mode. The TST pin in conjunction with the

10 ALM A TTL compatible active low output which responds to the thermal detector circuit when a safe operating die

11 I

12 OUT1 The analog output of the spare operational amplifier.

13 -IN1 The inverting analog input of the spare operational amplifier. The non-inverting input is internally connected to AGND.

14 TIP SENSE An analog input connected to the TIP (more positive) side of the subscriber loop through a feed resistor. Functions

15 RING SENSE 1 An analog input connected to the RING (more negative) side of the subscriber loop through a feed resistor. Functions

REF

LMT

An external voltage connected to this pin will override the internal V

ramp close to the output voltage of the tip amplifier.

ringing.

ALM pin can provide thermal shutdown protection for the SLIC. Thermal shutdown is implemented by a system

controller that monitorstheALM pin. When the ALM pin isactive(low) the system controller issuesa command to the

TST pin (low) to power down the SLIC. The timing of the thermal recovery is controlled by the system controller.

temperature has been exceeded.

Loop Current Limit - Voltage on this pin sets the short loop current limiting conditions.

with the RING terminal to receive voice signals and for loop monitoring purpose.

with the TIP terminal to receive voice signals and for loop monitoring purposes.

/2 reference.

BAT

16 RING SENSE2 This is an internal sense mode that must be tied to RING SENSE 1 for proper SLIC operation.

17 V

18 NU Not used in this application.This pin should be left floating.

19 V

20 RDI TTL compatible input to drive the uncommitted relay driver.

21 RDO This is the output of the uncommitted relay driver.

22 BGND Battery Ground - All loop current and some quiescent current flows into this terminal.

23 NU Not used in this application. This pin should be either grounded or left floating.

24 V

25 TF This is the output of the tip amplifier.

26 RF This is the output of the ring amplifier.

27 V

28 RTI Ring Trip Input - This pin is connected to the external negative peak detector output for ring trip detection.

RX

TX

RING

BAT

Receive Input, 4-Wire Side - A high impedance analog input. AC signals appearing at this input drive the Tip Feed

and Ring Feed amplifiers deferentially.

Transmit Output, 4-Wire Side - A low impedance analog output which represents the differential voltage across TIP

andRING.Since theDC levelof this outputvaries withloopcurrent, capacitivecoupling to thenext stageis necessary.

Ring signal input.

The negative battery source.

77

Page 17

HC55171

Pinouts

HC55171 (PLCC)

TOP VIEW

BAT

RS

SHD

RTD

TST

ALM

ILMT

F0

VCCAGND

VREF

F1

4

3

RTI

12

28

5

6

7

8

9

10

11

12

13

14

15

16

-IN 1

OUT 1

TIP SENSE

RING SENSE 2

RING SENSE 1

RF

V

27

26

TF

25

VRING

24

NU

23

22

BGND

RDO

21

RDI

20

V

19

TX

17

18

RX

NU

V

Trapezoidal Ringing Application Circuit

AGND

V

CC

VREF

F1

F0

RS

SHD

RTD

TST

ALM

ILMT

OUT 1

-IN 1

TIP SENSE

HC55171 (SOIC)

TOP VIEW

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

28

28

RTI

27

27

V

BAT

26

26

RF

25

25

TF

24

24

VRING

23

23

NU

BGND

22

22

RDO

21

21

20

20

RDI

V

19

19

TX

NU

18

18

17

17

V

RX

16

16

RING SENSE 2

15

15

RING SENSE 1

TIP

RING

V

CC

V

BAT

TST

F1

F0

VCC

U1

HC55171

S1

14 TIP SENSE

25 TF

R

26 RF

16 RING SENSE 2

R

S2

15 RING SENSE 1

17

V

RX

ILIMT 11

V

19

TX

R

IL2

R

IL1

C

AC

R

RF

C

RX

V-REC

-IN1 13

R

2 V

CC

C

PS1

1 AGND

RTI 28

22 BGND

C

PS2

27 V

BAT

V

24

RING

V

3

REF

OUT1 12

ZO

V-XMIT

RT2

TRAP

R

RT1

D

RT

C

R

TRAP

TRAP

RT

V

RING

C

R

R

RT3

D

C

IL

4 F1

5 F0

6 RS

SHD 7

RTD 8

ALM 109 TST

SHD

RTD

ALM

20 RDI

FIGURE 21. TRAPEZOIDAL RINGING APPLICATION CIRCUIT

78

Page 18

HC55171

HC55171 Trapezoidal Ringing Application Circuit Parts List

COMPONENT VALUE TOLERANCE RATING COMPONENT VALUE TOLERANCE RATING

U1 - Ringing Slic HC55171 N/A N/A R

RS1, R

RZO, R

R

RT1

R

RT2

R

RT3

R

RF

S2

IL1

49.9Ω 1% 1/2W R

56.2kΩ 1% 1/8W C

49.9kΩ 1% 1/8W CIL, CRT, CAC, C

1.5MΩ 1% 1/8W C

51.1kΩ 1% 1/8W DRT, D

45.3kΩ 1% 1/8W

IL2

TRAP

PS1

TRAP

, C

TRAP

PS2

7.68kΩ 1% 1/8W

App Driven 1% 1/8W

0.1µF 10% 100V

0.47µF 10% 50V

RX

4.7µF 10% 10V

1N914 Generic Rectifier Diode

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly,the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor forany infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

79

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...