Page 1

HC5517

Data Sheet July 1998 File Number

3 REN Ringing SLIC For ISDN Modem/TA

and WLL

he HC5517 is a ringing SLIC designed to accommodate a wide

variety of local loop applications. The various applications

include, basic POTS lines with ans w ering machines and fax

capabilities, ISDN networks, wireless local loop, and h ybrid

fiber coax (HFC) terminals. The HC5517 provides a high

degreeofflexibilitywith open circuit tip to ring DC voltages,user

defined ringing waveforms(sinusoidal to square wave),ring trip

detection thresholds and loop current limits that can be tailored

for many applications. Additional f eatures of the HC5517 are

complex impedance matching, pulse metering and transhybrid

balance. The HC5517 is designed for use in systems where a

separate ring generator is not economically feasible.

The device is manufacturedin a high voltage Dielectric Isolation

(DI) process with an operating voltage range from -16V, for offhook operation and -80V for ring signal injection. The DI

process provides substrate latch up immunity, resulting in a

robust system design. Together with a secondary protection

diode bridge and “feed” resistors, the device will withstand

1000V lightning induced surges, in a plastic package.

A thermal shutdown with an alarm output and line fault

protection are also included for operation in harsh

environments.

Ordering Information

PART

NUMBER

HC5517IM -40 to 85 28 Ld PLCC N28.45

HC5517CM 0 to 75 28 Ld PLCC N28.45

HC5517IB -40 to 85 28 SOIC M28.3

HC5517CB 0 to 75 28 SOIC M28.3

TEMP.RANGE

(oC) PACKAGE PKG. NO.

4147.2

Features

• Thru-SLIC Open Circuit Ringing Voltage up to

77V

PEAK

/54V

, 3 REN Capability at 44V

RMS

RMS

• Sinusoidal Ringing Capability

• DI Process Provides Substrate Latch Up Immunity when

Driving Inductive Ringers

• Adjustable On-Hook Voltage for Fax and Answering

Machine Compatibility

• Resistive and Complex Impedance Matching

• Programmable Loop Current Limit

• Switch Hook and Adjustable Ring Trip Detection

• Pulse Metering Capability

• Single Low Voltage Positive Supply (+5V)

Applications

• Solid State Line Interface Circuit for Wireless Local Loop,

Hybrid Fiber Coax, Set Top Box, Voice/Data Modems

• Related Literature

- AN9606, Operation of the HC5517 Evaluation Board

- AN9607, Impedance Matching Design Equations

- AN9628, AC Voltage Gain

- AN9608, Implementing Pulse Metering

- AN9636, Implementing an Analog Port for ISDN Using

the HC5517

- AN549, The HC-5502S/4X Telephone Subscriber Line

Interface Circuits (SLIC)

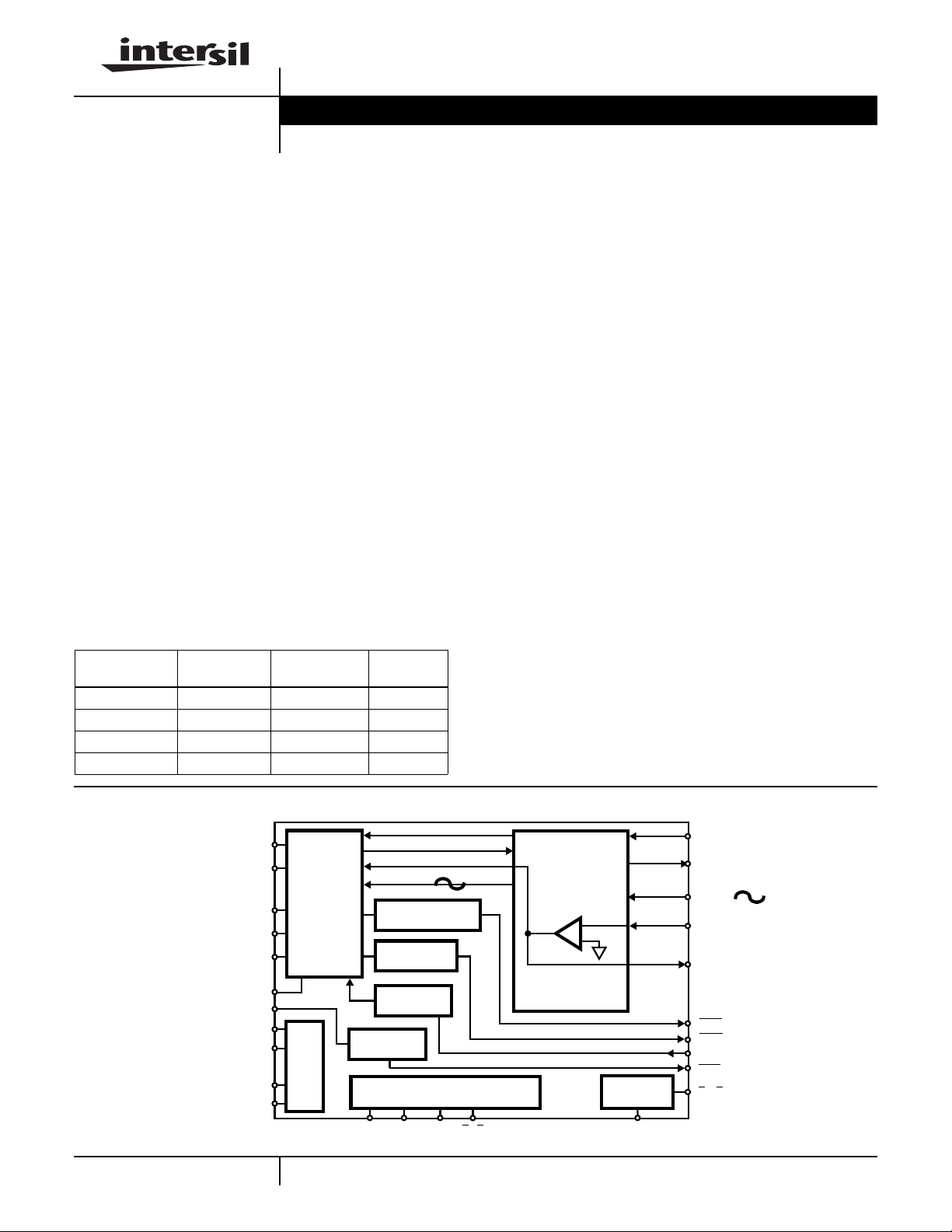

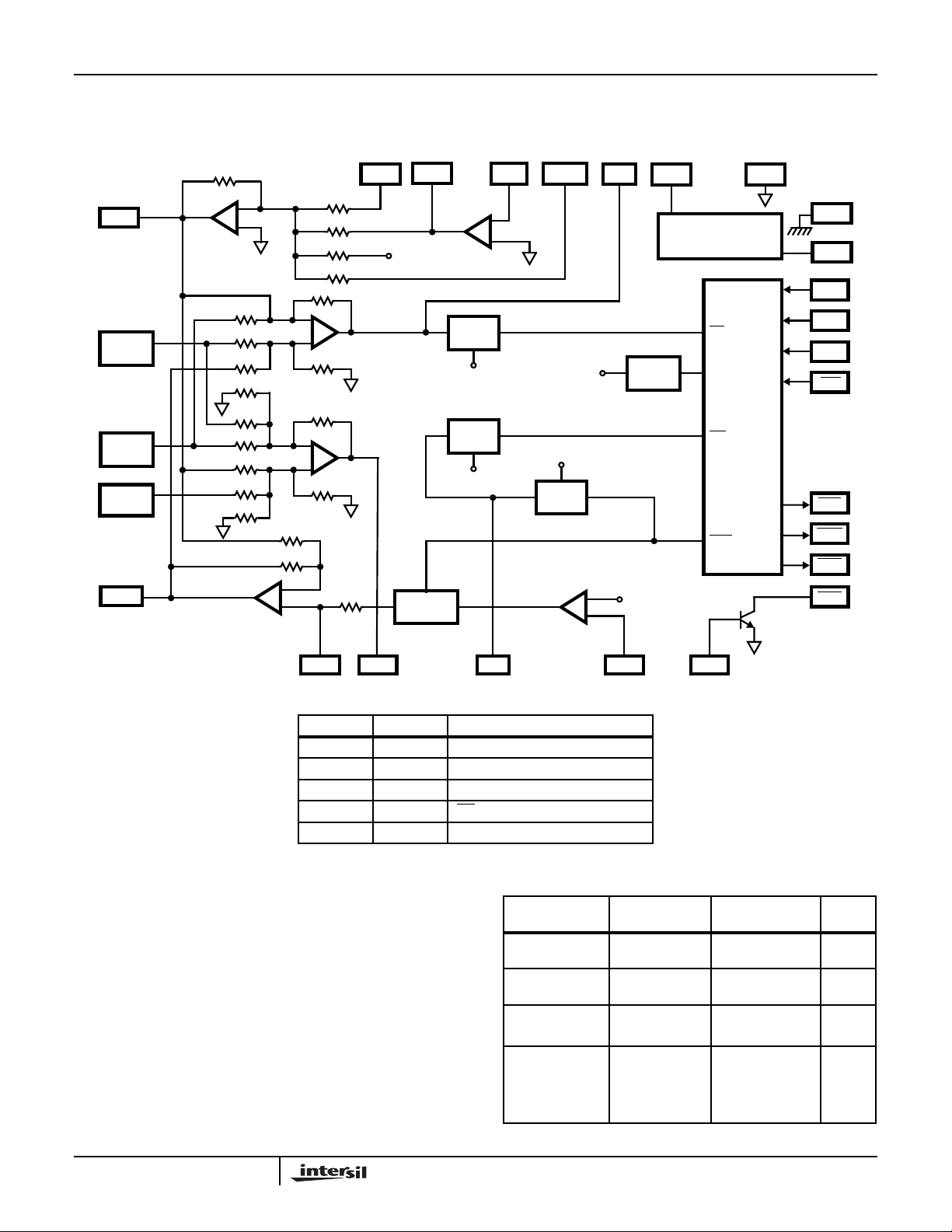

Block Diagram

RING SENSE 1

RING SENSE 2

TIP FEED

TIP SENSE

RING FEED

V

REF

RTI

V

BAT

V

CC

AGND

BGND

60

2-WIRE

INTERFACE

BIAS

V

4-WIRE

INTERFACE

LOOP CURRENT

DETECTOR

FAULT

DETECTOR

CURRENT

LIMIT

RING TRIP

DETECTOR

IIL LOGIC INTERFACE

F1 F0 RS

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

TST RDI

http://www.intersil.com or 407-727-9207 | Copyright © Intersil Corporation 1999

-

+

RELAY

DRIVER

RX

V

TX

V

RING

- IN 1

OUT 1

SHD

ALM

I

LMT

RTD

RDO

Page 2

HC5517

Absolute Maximum Ratings T

Maximum Supply Voltages

(VCC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.5V to +7V

(VCC)-(V

Relay Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.5V to +15V

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90V

BAT

Operating Conditions

Operating Temperature Range

HC5517IM, HC5517IB . . . . . . . . . . . . . . . . . . . . . . -40oC to 85oC

HC5517CM, HC5517CB . . . . . . . . . . . . . . . . . . . . . . 0oC to 75oC

Relay Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+5V to +12V

Positive Power Supply (VCC). . . . . . . . . . . . . . . . . . . . . . . +5V ±5%

Negative Power Supply (V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

2. All grounds (AGND, BGND) must be applied before VCCor V

to run separate grounds off a line card, the AG must be applied first.

) . . . . . . . . . . . . . . . . . . .-16V to -80V

BAT

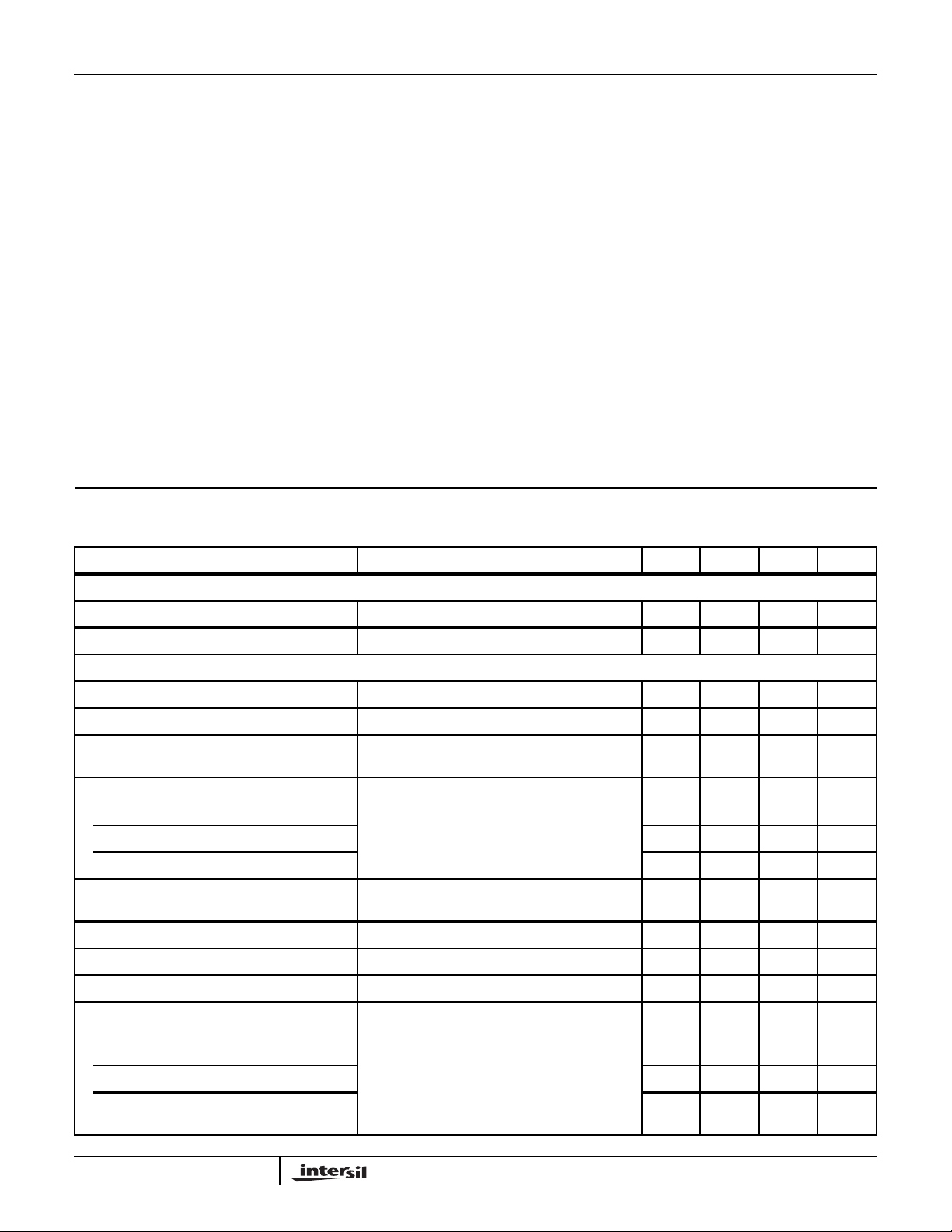

Electrical Specifications Unless Otherwise Specified, Typical Parameters are at T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

=25oC Thermal Information

A

Thermal Resistance (Typical, Note 1) θJA(oC/W)

PLCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

SOIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Maximum Junction Temperature Plastic . . . . . . . . . . . . . . . . .150oC

Maximum Storage Temperature Range. . . . . . . . . . -65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300oC

(SOIC, PLCC - Lead Tips Only)

Die Characteristics

Transistor Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .224

Diode Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Die Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 x 120

Substrate Potential. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .V

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bipolar-DI

ESD (Human Body Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . .500V

. Failure to do so may result in premature failure of the part. If a user wishes

BAT

Operating TemperatureRange, V

at 600Ω 2-Wire terminating impedance.

= -24V,VCC= +5V,AGND = BGND = 0V. All AC Parametersare specified

BAT

= 25oC, Min-Max Parameters are over

A

BAT

RINGING TRANSMISSION PARAMETERS

Input Impedance (Note 3) - 5.4 - kΩ

V

RING

4-Wire to 2-Wire Gain V

AC TRANSMISSION PARAMETERS

RX Input Impedance 300Hz to 3.4kHz (Note 3) - 108 - kΩ

TX Output Impedance 300Hz to 3.4kHz (Note 3) - - 20 Ω

4-Wire Input Overload Level 300Hz to 3.4kHz R

2-Wire Return Loss Matched for 600Ω (Note 3)

SRL LO 26 35 - dB

ERL 30 40 - dB

SRL HI 30 40 - dB

2-Wire Longitudinal to Metallic Balance

Off Hook

4-Wire Longitudinal Balance Off Hook 300Hz to 3400Hz (Note 3) 50 55 - dB

Low Frequency Longitudinal Balance I

Longitudinal Current Capability I

Insertion Loss 0dBm at 1kHz, Referenced 600Ω

2-Wire/4-Wire (Includes external transhybrid

amplifier with a gain of 3)

to Vt-r (Note 3) - 40 - V/V

RING

= 1200Ω, 600Ω Reference

(Note 3)

Per ANSI/IEEE STD 455-1976 (Note 3)

300Hz to 3400Hz

= 40mA TA = 25oC (Note 3) - 10 23 dBrnC

LINE

= 40mA TA = 25oC (Note 3) - - 40 mA

LINE

L

+1.0 - - V

58 63 - dB

- ±0.05 ±0.2 dB

PEAK

RMS

4-Wire/2-Wire - ±0.05 ±0.2 dB

4-Wire/4-Wire (Includes external transhybrid

amplifier with a gain of 3)

--±0.25 dB

61

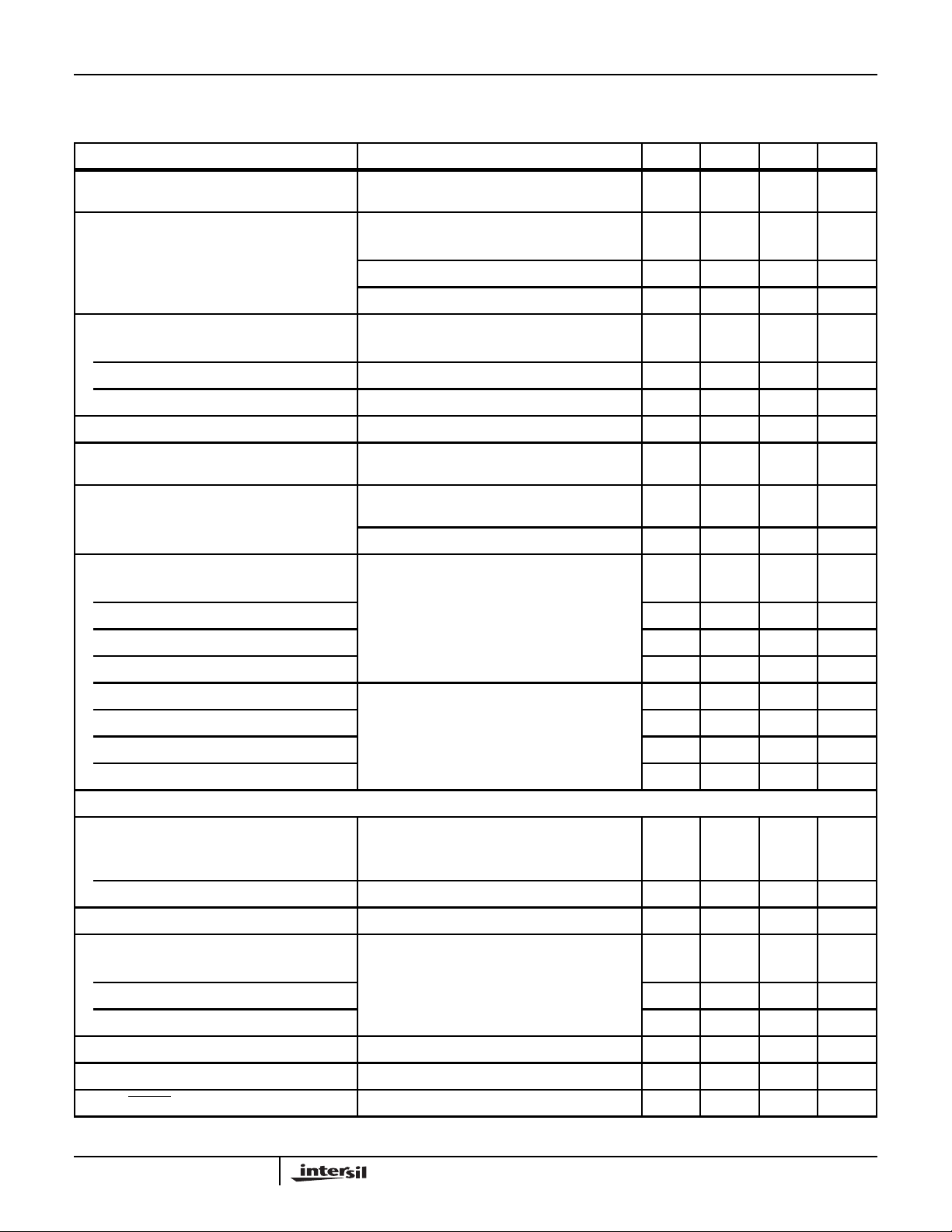

Page 3

HC5517

Electrical Specifications Unless Otherwise Specified, Typical Parameters are at T

Operating TemperatureRange, V

= -24V,VCC= +5V,AGND = BGND = 0V. All AC Parametersare specified

BAT

= 25oC, Min-Max Parameters are over

A

at 600Ω 2-Wire terminating impedance. (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Frequency Response 300Hz to 3400Hz (Note 3) Referenced to

- ±0.02 ±0.06 dB

Absolute Level at 1kHz, 0dBm Referenced 600Ω

Level Linearity Referenced to -10dBm (Note 3)

2-Wire to 4-Wire and 4-Wire to 2-Wire +3 to -40dBm - - ±0.08 dB

-40 to -50dBm - - ±0.12 dB

-50 to -55dBm - - ±0.3 dB

Absolute Delay (Note 3)

2-Wire/4-Wire 300Hz to 3400Hz - - 1.0 µs

4-Wire/2-Wire 300Hz to 3400Hz - - 1.0 µs

4-Wire/4-Wire 300Hz to 3400Hz - 0.95 1.5 µs

Transhybrid Loss V

Total Harmonic Distortion

2-Wire/4-Wire, 4-Wire/2-Wire, 4-Wire/4-Wire

Idle Channel Noise

2-Wire and 4-Wire

= 1V

IN

Reference Level 0dBm at 600Ω

300Hz to 3400Hz (Note 3)

(Note 3)

C-Message

at 1kH (Notes 3, 4) 30 40 dB

P-P

- - -50 dB

- 3 - dBrnC

Psophometric (Note 3) - -87 - dBmp

Power Supply Rejection Ratio (Note 3)

to 2-Wire 20 40 - dB

V

CC

to 4-Wire 20 40 - dB

V

CC

to 2-Wire 20 40 - dB

V

BAT

to 4-Wire 20 50 - dB

V

BAT

to 2-Wire (Note 3)

V

CC

to 4-Wire 20 28 - dB

V

CC

to 2-Wire 20 50 - dB

V

BAT

to 4-Wire 20 50 - dB

V

BAT

30Hz to 200Hz, RL = 600Ω

30 40 - dB

200Hz to 16kHz, RL = 600Ω

DC PARAMETERS

Loop Current Programming

Limit Range 20

-60mA

(Note 5)

Accuracy 10 - - %

Loop Current During Power Denial R

= 200Ω - ±4 ±7mA

L

Fault Currents

TIP to Ground (Note 3) -30-mA

RING to Ground - 120 - mA

TIP and RING to Ground (Note 3) - 150 - mA

Switch Hook Detection Threshold -1215mA

Ring Trip Comparator Voltage Threshold -0.28 -0.24 -0.22 V

Thermal

ALARM Output (Note 3) Safe Operating Die Temperature Exceeded 140 - 160

o

C

62

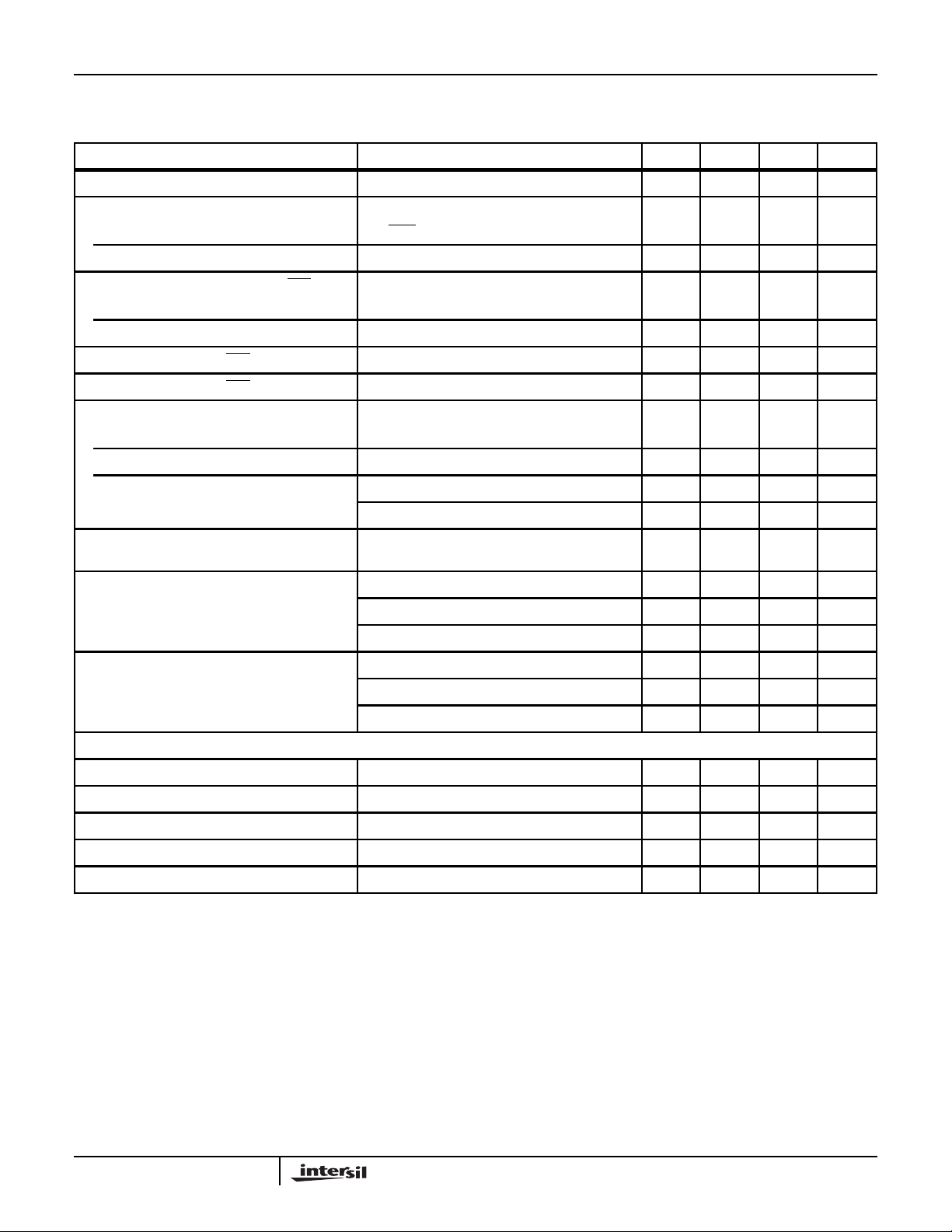

Page 4

HC5517

Electrical Specifications Unless Otherwise Specified, Typical Parameters are at T

Operating TemperatureRange, V

= -24V,VCC= +5V,AGND = BGND = 0V. All AC Parametersare specified

BAT

= 25oC, Min-Max Parameters are over

A

at 600Ω 2-Wire terminating impedance. (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Dial Pulse Distortion (Note 3) - 0.1 0.5 ms

Uncommitted Relay Driver

On Voltage V

OL

IOL (RDO) = 30mA - 0.2 0.5 V

Off Leakage Current - ±10 ±100 µA

TTL/CMOS Logic Inputs (F0, F1, RS,

Logic ‘0’ V

Logic ‘1’ V

Input Current (F0, F1, RS,

Input Current (F0, F1, RS,

IL

IH

TST, RDI) IIH, 0V ≤ VIN≤ 5V - - -1 µA

TST, RDI) IIL, 0V ≤ VIN≤ 5V - - -100 µA

TST, RDI)

0 - 0.8 V

2.0 - 5.5 V

Logic Outputs

Logic ‘0’ V

Logic ‘1’ V

OL

OH

Power Dissipation On Hook V

Power Dissipation Off Hook V

I

= 800µA - 0.1 0.5 V

LOAD

I

= 40µA 2.7 - - V

LOAD

CC

V

CC

CC

= +5V, V

= +5V, V

= +5V, V

= -80V, R

BAT

= -48V, R

BAT

= -24V, R

BAT

= ∞ - 300 - mW

LOOP

= ∞ - 150 - mW

LOOP

LOOP

= 600Ω,

- 280 - mW

IL = 25mA

I

CC

I

BAT

VCC = +5V, V

= +5V, V

V

CC

= +5V, V

V

CC

= -80V, R

BAT

= -48V, R

BAT

= -24V, R

BAT

VCC = +5V, VB- = -80V, R

= +5V, VB- = -48V, R

V

CC

= +5V, VB- = -24V, R

V

CC

= ∞ -36mA

LOOP

= ∞ -25mA

LOOP

= ∞ - 1.9 4 mA

LOOP

= ∞ - 3.6 7 mA

LOOP

= ∞ - 2.6 6 mA

LOOP

= ∞ - 1.8 4 mA

LOOP

UNCOMMITTED OP AMP PARAMETERS

Input Offset Voltage - ±5-mV

Input Offset Current - ±10 - nA

Differential Input Resistance (Note 3) - 1 - MΩ

Output Voltage Swing (Note 3) R

= 10kΩ - ±3-V

L

P-P

Small Signal GBW (Note 3) - 1 - MHz

NOTES:

3. These parameters are controlled by design or process parameters and are not directly tested. These parameters are characterized upon initial

design release, upon design changes which would affect these characteristics, and at intervals to assure product quality and specification compliance.

4. For transhybrid circuit as shown in Figure 10.

5. Application limitation based on maximum switch hook detect limit and metallic currents. Not a part limitation.

63

Page 5

Functional Diagram

HC5517

PLCC/SOIC

TF

TIP

SENSE

RING

SENSE 1

RING

SENSE 2

RF

R

TF

25

14

15

16

26

-

+

100K

100K

100K

100K

R

R

R

R

4.5K

4.5K

RF

2R

-

+

2R

25K

-

+

25K

90K

90K

-

+

VRX

R

R

R/2

R/20

TA

RA

90K

OUT 1

17 12

+2V

VB/2

REF

SHD

RTD

-

+

-IN 1

OP AMP

V

RING

13 24 19 2

FAULT

DET

GM

V

+

TX

THERM

LTD

RF2

V

CC

BIAS

NETWORK

SH

TSD

GK

RFC

AGND

IIL LOGIC INTERFACE

1

22

BGND

27

V

BAT

4

F1

5

F0

6

RS

9

TST

7

SHD

8

RTD

10

ALM

21

RDO

R = 108kΩ

V

REF

3

18

HC5517 TRUTH TABLE

F1 F0 ACTION

0 0 Loop power Denial Active

0 1 Power Down Latch RESET

0 1 Power on RESET

10

1 1 Normal Loop feed

Over Voltage Protection and Longitudinal Current

Protection

The SLIC device, in conjunction with an external protection

bridge, will withstand high voltage lightning surges and

power line crosses.

High voltage surge conditions are as specified in Table 1.

The SLIC will withstand longitudinal currents up to a

maximum or 30mA

RMS

, 15mA

per leg, without any

RMS

performance degradation

.

28

RTINU ILMT

RD Active

PARAMETER

Longitudinal

Surge

Metallic Surge 10µs Rise/

T/GND 10µs Rise/

R/GND

50/60Hz Current

T/GND 11 Cycles 700 (Plastic) V

R/GND Limited to

11

TABLE 1.

TEST

CONDITION

10µs Rise/

1000µs Fall

1000µs Fall

1000µs Fall

10A

RMS

20

RDI

PERFORMANCE

(MAX) UNITS

±1000 (Plastic) V

±1000 (Plastic) V

±1000 (Plastic)

PEAK

PEAK

PEAK

RMS

64

Page 6

HC5517

Circuit Operation and Design Information

The HC5517 is a voltage feed current sense Subscriber Line

Interface Circuit (SLIC). This means that for long loop appli-

cations the SLIC provides a constant voltage to the tip and

ring terminals while sensing the tip to ring current. For short

loops, where the loop current limit is exceeded, the tip to ring

voltage decreases as a function of loop resistance.

The following discussion separates the SLIC’s operation into

its DC and AC path, then follows up with additional circuit

design and application information.

DC Operation of Tip and Ring Amplifiers

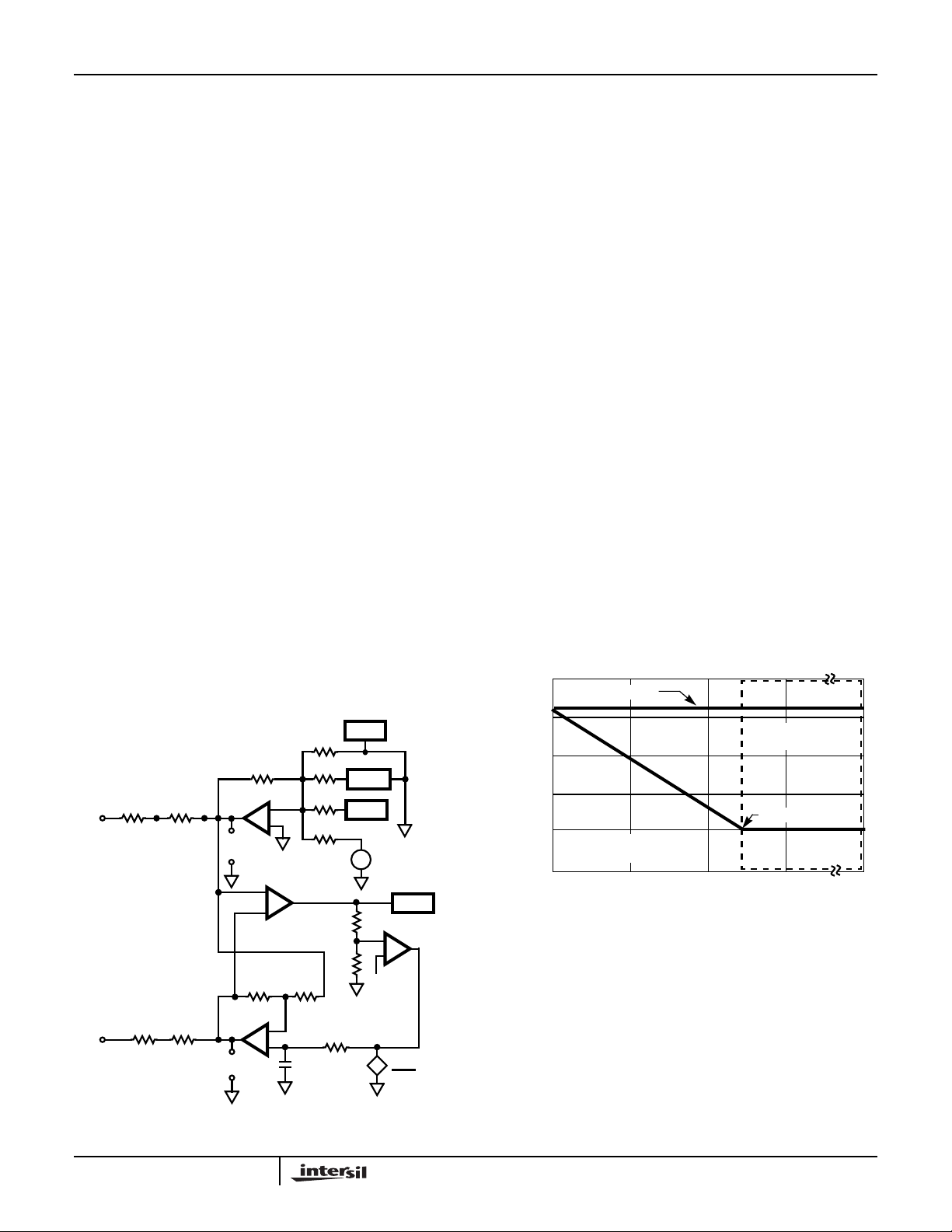

SLIC in the Active Mode

The tip and ring amplifiers are voltage feedback op amps

that are connected to generate a differential output (e.g. if tip

sources 20mA then ring sinks 20mA). Figure 1 shows the

connection of the tip and ring amplifiers. The tip DC voltage

is set by an internal +2V reference, resulting in -4V at the

output. The ring DC voltage is set by the tip DC output voltage and an internal V

at the output. (See Equation 1, Equation 2 and Equation 3.)

V

TIPFEEDVC

V

RINGFEEDVD

==

/2 reference, resulting in V

BAT

R

-----------

2V–

R2⁄

V

BAT

-------------- -

2

4V–== =

R

1

V

--- -+

–

R

TIPFEED

R

--- -

R

BAT

(EQ. 1)

(EQ. 2)

+4V

Current Limit

The tip feed to ring feed voltage (Equation 1 minus

Equation 3) is equal to the battery voltage minus 8V. Thus,

with a 48 (24) volt battery and a 600Ω loop resistance,

including the feed resistors, the loop current is 66.6mA

(26.6mA). On short loops the line resistance often

approaches zero and the need exists to control the

maximum DC loop current.

Current limiting is achieved by a feedback network (Figure 1)

that modifies the ring feed voltage (V

) as a function of the

D

loop current. The output of the Transversal Amplifier (TA) has

a DC voltage that is directly proportional to the loop current.

This voltage is scaled by R

and R28. The scaled voltage is

10

the input to a transconductance amplifier (GM) that

compares it to an internal reference level. When the scaled

voltage exceeds the internal reference level, the

transconductance amplifier sources current. This current

charges C

voltage (V

effectively reduces the tip feed to ring feed voltage (V

in the positive direction causing the ring feed

16

) to approach the tip feed voltage (VC). This

D

T-R

and holds the maximum loop current constant.

The maximum loop current is programed by resistors R

10

and R28as shown in Equation 4 (Note: R10is typically

100kΩ).

I

LIMIT

0.6()R10R28+()

---------------------------------------------=

()

200xR

28

(EQ. 4)

),

V

RINGFEEDVDVBAT

R

TIP

RING

V

, V

OUT1

GROUNDED FOR

DC ANALYSIS

R

11

R

RX

13

R

14

12

4+==

R

TIP FEED

-

+

-

V

C

+

TRANSVERSAL

AMP

90kΩ 90kΩ

RING FEED

-

+

+

V

D

-

(EQ. 3)

V

RX

R

R

OUT1

R/20

V

RING

R/2

INTERNAL

+

-

+2V REF

TA

-

+

R

10

R

28

90kΩ

C

16

RF2

V

TX

GM

-

+

V

-

BAT

+

2

FIGURE 1. OPERATION OF THE TIP AND RING AMPLIFIERS

0

V

TIP FEED

-5

-10

-15

-20

TIP AND RING VOLTAGE (V)

-25

CURRENT LIMIT

REGION I

0

FIGURE 2. V

Figure 2 illustrates the relationship between V

= -4V

= 25mA

LOOP

250

LOOP RESISTANCE (Ω)

vs RL(V

T-R

CONSTANT VOLTAGE

V

RING FEED

500 750

= -24V, I

BAT

LIMIT

REGION

= 25mA)

T-R

= -20V

∞

and the

loop resistance. The conditions are shown for a battery voltage of -24V and the loop current limit set to 25mA. For a infinite loop resistance both tip feed and ring feed are at -4V

and -20V respectively. When the loop resistance decreases

from infinity to about 640Ω the loop current (obeying Ohm’s

Law) increases from 0mA to the set loop current limit. As the

loop resistance continues to decrease, the ring feed voltage

approaches the tip feed voltage as a function of the programed loop current limit (Equation 4).

65

Page 7

HC5517

AC Voltage Gain Design Equations

The HC5517 uses feedback to synthesize the impedance at

the 2-wire tip and ring terminals. This feedback network

defines the AC voltage gains for the SLIC.

The 4-wire to 2-wire voltage gain (V

feedback loop shown in Figure 3. The feedback loop senses

the loop current through resistors R

voltage drop and multiplies it by 2 to produce an output voltage at the V

pin equal to +4RS∆IL. The VTXvoltage is

TX

then fed into the -IN1 input of the SLIC’s internal op amp.

This signal is multiplied by the ratio R

tip current summing node via the OUT1 pin. (Note: the internal V

/2 reference (ring feed amplifier) and the internal

BAT

+2V reference (tip feed amplifier) are grounded for the AC

analysis.)

The current into the OUT1 pin is equal to:

I

OUT1

=

4RSIL∆

--------------------–

R

R

8

-------

R

9

Equation 6 is the node equation for the tip amplifier summing

node. The current in the tip feedback resistor (I

Equation 7.

4RSIL∆

--------------------

I

–

–

R

I

–

R

The AC voltage at V

R

4RSIL∆

--------------------

R

R

8

-------

R

9

R

8

-------

R

9

V

RX

-----------+ 0=

R

V

RX

-----------+=

R

is then equal to:

C

to VTR) is set by the

RX

and R14, sums their

13

and fed into the

8/R9

) is given in

R

(EQ. 5)

(EQ. 6)

(EQ. 7)

Substituting the expressions for V

R

∆

SIL

8

-------

R

9

VRX+

24– R

×

I

∆

L

--------------------------------------------------------------------------=

++++

R

LR11R12R13R14

and VD:

C

(EQ. 12)

Equation 12 simplifies to:

2V

400 IL∆–

RX

I

----------------------------------------=

∆

L

Solving for ∆I

V

RX

I

∆

-----------=

L

600

800

results in:

L

(EQ. 13)

(EQ. 14)

Equation 14 is the loop current with respect to the feedback

network. From this, the 4-wire to 2-wire and the 2-wire to

4-wire AC voltage gains are calculated. Equation 15 shows

the 4-wire to 2-wire AC voltage gain is equal to one.

V

RX

-----------

A

4W 2W–

V

TR

-----------

V

RX

I∆

()

LRL

-------------------- -

V

RX

600()

600

--------------------------- 1== = =

V

RX

(EQ. 15)

Equation 16 shows the 2-wire to 4-wire AC voltage gain is

equal to negative one-third.

R

A

2W 4W–

V

OUT1

-------------------

V

TR

-------

∆

4– R

SIL

R

-------------------------------------

I∆LRL()

8

9

V

RX

-----------

200–

600

----------------------------------

V

RX

-----------

600()

600

1()

1

-- -–== = =

3

(EQ. 16)

V

()R()=

CIR

R

8

V

4– RSIL∆

C

-------

R

9

+=

V

and the AC voltage at V

R

8

VD4RSIL∆

The values for R

-------

–=

R

9

V

RX

and R9are selected to match the

8

RX

is:

D

(EQ. 8)

(EQ. 9)

(EQ. 10)

impedance requirements on tip and ring, for more

information reference AN9607 “Impedance Matching Design

Equations for the HC5509 Series of SLICs”. The following

loop current calculations will assume the proper R

and R

8

values for matching a 600Ω load.

∆I

The loop current (

is calculated in Equations 11 through 14. Where R

R

= 40kΩ, RL = 600Ω, R11 = R12 = R13 = R14 = 50Ω.

9

IL∆

--------------------------------------------------------------------------=

++++

R

LR11R12R13R14

) with respect to the feedback network,

L

–

V

CVD

= 40kΩ,

8

(EQ. 11)

Impedance Matching

The feedback network, described above, is capable of

synthesizing both resistive and complex loads. Matching the

SLIC’s 2-wire impedance to the load is important to maximize power transfer and minimize the 2-wire return loss. The

2-wire return loss is a measure of the similarity of the impedance of a transmission line (tip and ring) and the impedance

at it’s termination. It is a ratio, expressed in decibels, of the

power of the outgoing signal to the power of the signal

reflected back from an impedance discontinuity.

Requirements for Impedance Matching

Impedance matching of the HC5517 application circuit to the

9

transmission line requires that the impedance be matched to

points “A” and “B” in Figure 3. T o do this, the sense resistors

R

11,R12,R13

and R14must be accounted for by the feedback network to make it appear as if the output of the tip and

ring amplifiers are at points “A” and “B”. The feedback network

takes a voltage that is equal to the voltage drop across the

sense resistors and feeds it into the summing node of the tip

amplifier. The effect of this is to cause the tip feed voltage to

become more negative by a value that is proportional to the

voltage drop across the sense resistors R

and R13. At the

11

same time the ring amplifier becomes more positive by the

66

Page 8

HC5517

R

R

R/20

R/2

4– RSIL∆

V

OUT1

V

RING

4– RSIL∆()

----------------------------- -

I

R

+

TIP

A

V

TR

R

∆V

-

∆I

L

L

+

IN

-

+

∆I

L

-

+

B

RING

R

V

8

RX

-------

------------ -+=

R

R

R

9

∆I

R

R

∆I

∆I

+

L

L

-

11

12

L

+-

-

R

13

R11 = R12 = R13 = R14 = R

R

14

∆I

L

-

+

I

R

R

-

+

-

V

C

+

90kΩ 90kΩ

-

+

+

V

D

-

V

C

S

VD4RSIL∆

RX

R

8

-------

R

9

-

+

+

-

R

8

-------

R

9

VRX+=

+RS∆I

-RS∆I

VRX–=

1V

P

4RS∆I

R

L

I

OUT1

=

2R

8

R

9

†

+

2V

DC

-

L

R

+

2

V

-

L

TX

+

4RS∆I

-

9

-IN

L

R

8

-

1

+

-

R

4RS∆I

8

L

R

9

+

†

V

-

BAT

+

2

† GROUNDED FOR AC ANALYSIS

FIGURE 3. AC VOLTAGE GAIN AND IMPEDANCE MATCHING

same amount to account for resistors R12 and R14.

The net effect cancels out the voltage drop across the feed

resistors. By nullifying the effects of the feed resistors the

feedback circuitry becomes relatively easy to match the

impedance at points “A” and “B”.

IMPEDANCE MATCHING DESIGN EQUATIONS

Matching the impedance of the SLIC to the load is

accomplished by writing a loop equation starting at V

going around the loop to V

impedance of any load is as follows (Note: V

. The loop equation to match the

C

RX

and

D

= 0 for this

analysis):

R

8

-------

R

9

2R

SILVIN

R

8

------ -

R

9

R

8

-------

R

9

∆–∆+

R

-------

R

4R

4R

++=

8

9

∆ RLIL∆++=

SIL

SRL

+

0=+

(EQ. 17)

(EQ. 18)

(EQ. 19)

4RSIL∆–

RLIL∆ 2RSIL∆ 4RSIL∆–

V

∆ 8RSIL∆–

IN

VIN∆ IL∆ 8RS–

(-8R

S(R8/R9

VIN∆

------------- 8– R

∆

I

L

)) and the loop impedance (+4RS+RL).

R

8

-------

4RSR

++=

S

R

9

L

(EQ. 20)

The result is shown in Equation 20. Figure 4 is a schematic

representation of Equation 15.

R

L

∆V

LOAD

+

IN

-

SLIC

8RS

R

8

-------

R

9

4RS+

FIGURE 4. SCHEMATIC REPRESENTATION OF EQUATION 20

To match the impedance of the SLIC to the impedance of the

load, set:

R

8

RL8R

If R

9

-------

4RS+=

S

R

9

is made to equal 8RS then:

RLR84RS+=

(EQ. 21)

(EQ. 22)

Equation 19 can be separated into two terms, the feedback

67

Page 9

HC5517

Therefore to match the HC5517, with RSequal to 50Ω,toa

600Ω load:

R98RS850Ω()400Ω== =

(EQ. 23)

and:

R8RL4– RS600Ω 200Ω– 400Ω== =

To prevent loading of the V

output, the value of R8and R

TX

(EQ. 24)

are typically scaled by a factor of 100:

KR840kΩ= KR940kΩ=

(EQ. 25)

Since the impedance matching is a function of the voltage

gain, scaling of the resistors to achieve a standard value is

recommended.

For complex impedances the above analysis is the same.

KR940kΩ= KR8100 Resistive 200–()

Reactive

--------------------------+=

100

(EQ. 26)

Reference application note AN9607 (“Impedance Matching

Design Equations for the HC5509 Series of SLICs”) for the

values of KR

and KR8for several worldwide Typical line

9

impedances.

Tip-to-Ring Open-Circuit Voltage

The tip-to-ring open-circuit voltage, VOC, of the HC5517 is

programmable to meet a variety of applications. The design

of the HC5517 defaults the value of V

V

OCVBAT

8–≅

The HC5517 application circuit overrides the default V

operation when operating from a -80V battery. While operating from a -80V battery, the SLIC will be in either the ringing

mode or on-hook standby mode. In the ringing mode, V

designed to switch from 0V (centering voltage) to -47V

(Maintenance Termination Unit voltage). The centering voltage is active during the ringing portion of the ringing waveform and the Maintenance TerminationUnit (MTU) voltage is

active during the silent portion of the ringing signal. In the

on-hook standby mode, the application circuit is designed to

maintain V

at the MTU voltage.

OC

Centering Voltage Application Circuit Overview

The centering voltage is used during ringing to center the

DC outputs of the tip feed and ring feed amplifiers. Centering

the amplifier outputs allows for the maximum undistorted

voltage swing of the ringing signal. Without centering, the

output of each amplifier would saturate at ground or V

minimizing the ringing capability of the HC5517. The

required centering voltage, V

, is +1.8VDCwhen operating

C

from a -80V battery.

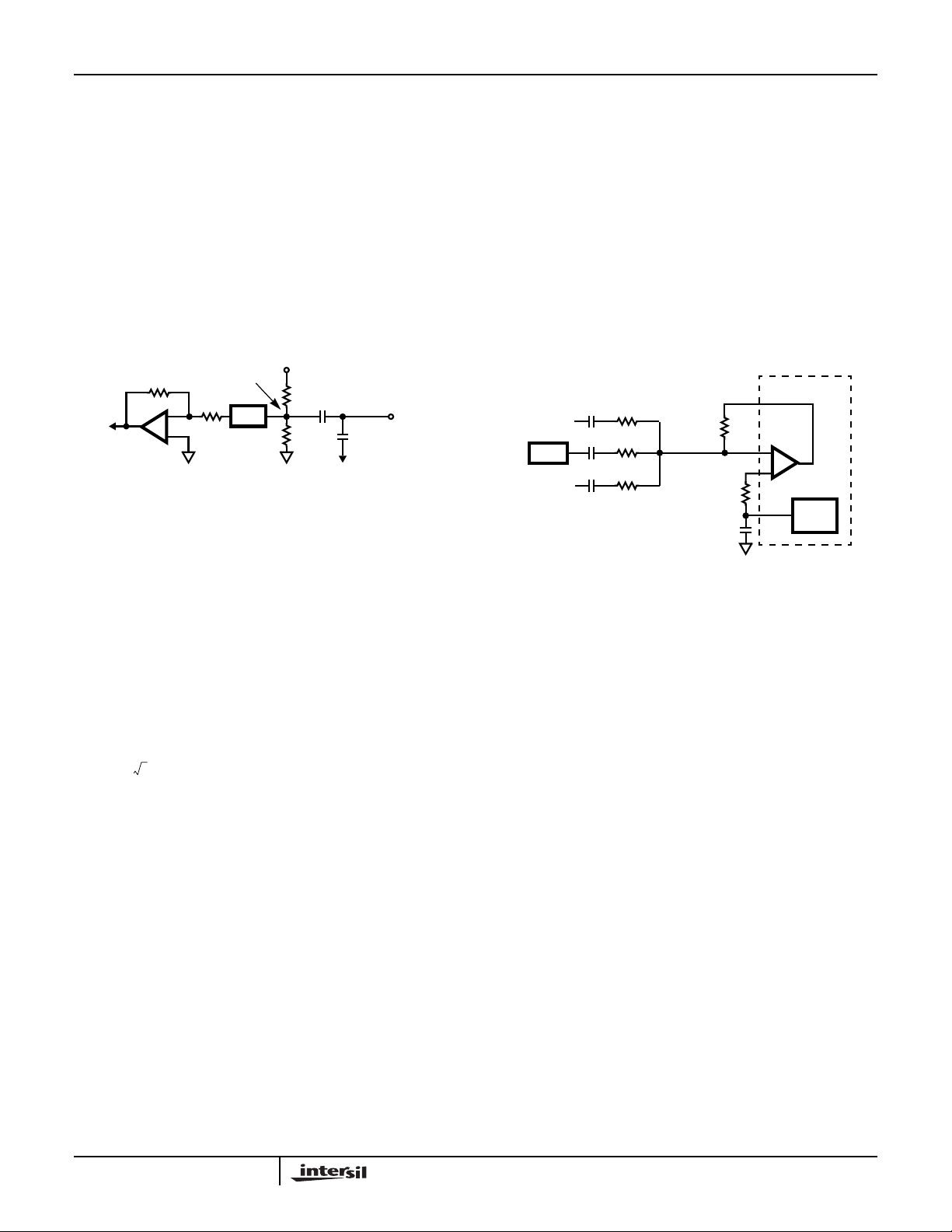

Centering Voltage Application Circuit Operation

The circuit used to generate the centering voltage is shown

in Figure 5.

OC

to:

OC

BAT

OC

is

+5V

+

-

V

-----------------

BAT

R

19

T

2

TO ZENER

DIODE D

V

2

RING

11

V

C

D

13

D

6

R

18

R

24

RC

9

TF

RF

FIGURE 5. CENTERING VOLTAGE APPLICATION CIRCUIT

R R/20

-

+

TIP FEED

AMPLIFIER

90kΩ 90kΩ

-

+

RING FEED

AMPLIFIER

R/2

+2V

90kΩ

The circuitry within the dotted lines is internal to the

HC5517. The value of the resistor designated as R is 108kΩ

and the resistor R/20 is 5.4kΩ. The tip amplifier gain of

20V/V amplifies the +1.8V

the internal 4V

offset, generating -40VDCat the tip

DC

amplifier output. The -40V

at VCto +36VDCand adds it to

DC

offset also sums into the ring

DC

amplifier, adding to the battery voltage, achieving -40V at the

ring amplifier output.

Centering Voltage Design Equations

The centering voltage (V

voltage. A battery voltage of -80V requires a +1.8V

) is dependent on the battery

C

DC

centering voltage. The equation used to calculate the

centering voltage is shown below.

V

V

BAT

-------------- -

C

2

4–

20⁄=

(EQ. 27)

The DC voltage at the outputs of the centered tip and ring

amplifiers can be calculated from Equation 28 and

Equation 29.

V

,

V

20VC4+()–=

TC

RCVBAT

20VC4+()+=

The shunt resistor of the divider network, R

(EQ. 28)

(EQ. 29)

, is not

18

determined from a design equation. It is selected based on

the trade-off of power dissipation in the voltage divider (low

value of R

(high value of R

) and loading affects of the internal R/20 resistor

18

). The suggested range of R18is between

18

1.0kΩ and 2.0kΩ. The application circuit design equation

used to calculate the value of R

of the divider network is

19

as follows:

68

Page 10

HC5517

R

19

where: V

VCCV

----------------------------------------------------------------------------------------------------=

V

R

R

V

V

D13VD6VC

+()RINVCR

V

CVD6

forward drop of D13, 0.63V.

D13

forward drop of D6, 0.54V.

D6

is the shunt resistor of the divider, 1.1kΩ.

18

is the input impedance of V

IN

is the required centering voltage, 1.8V,V

C

is the +5V supply.

CC

–––()R18RIN•()

+

18

, 5.4kΩ.

RING

BAT

(EQ. 30)

= -80V.

Centering Voltage Logic Control

The pnp transistor T2is used to defeat the voltage divider

formed by R

high), +5V

19,R18,D13

is divided to produce +1.8VDCat the V

DC

and D6. When T2is off (RC is logic

RING

input. When T2is on (RC is logic low), its emitter base voltage of +0.9V

D

, hence reverse biasing the diode (D6) and floating the

6

V

pin.

RING

is divided resulting in +0.2V at the anode of

DC

MTU Voltage Application Circuit Overview

According to Bellcore specification TR-NWT-000057, an

MTU voltage may be required by some operating

companies. The minimum allowable voltage to meet MTU

requirements is -42.75V, which is used by measurement

equipment to verify an active line. Also, some facsimile and

answering machines use the MTU voltage as an indication

that the telephone is on-hook or not answered. In addition to

the Bellcore specification, FCC Part 68.306 requires that the

maximum tip to ground or ring to ground voltage not exceed

-56.5V for hazardous voltage limitations. These two requirements have been combined and the resulting range is

defined as the MTU voltage. The HC5517 application circuit

can be programmed to any voltage within this range using

the zener clamping circuit.

MTU Voltage Application Circuit Operation

The circuit used to generate the MTU voltage is shown in

Figure 6.

90K 90K

RF

RING FEED

AMPLIFIER

FIGURE 6. RING FEED AMPLIFIER CIRCUIT CONNECTIONS

-

+

V

3

REF

C

16

The ring feed amplifier DC output voltage, V

function of the internal V

diode D

. When the magnitude of V

11

/2 reference and external zener

BAT

TIP FEED OUTPUT

90K

D

11

V

BAT

----------------2

R

19

/2 is less than the

BAT

+5V

T

2

RDC

R

24

RC

,isa

zener voltage, the zener is off and the input to the ring feed

amplifier is V

/2. When the magnitude of V

BAT

BAT

/2 is

greater than the zener voltage, the zener conducts and

clamps the noninverting terminal of the ring amplifier to the

zener voltage.

Internal to the HC5517 are connections to the tip feed amplifier

output and V

output, V

TDC

/2 reference. The DC voltage at the tip feed

BAT

, is a constant -4V during on-hook standby.

MTU Voltage Design Equations

The following equations are used to predict the DC output of

the ring feed amplifier, V

V

BAT

-------------- -

V

-------------- -

Where V

V

VZ< V

2

BAT

VZ≥ V

2

Z

are the saturation voltages of T2. Using Equations 31

BE

RDC

RDC

is the zener diode voltage of D11and VCEand

.

RDC

V

BAT

-------------- -

2

2

2V–

ZVCEVBE

4+=

–()+()4+=

(EQ. 31)

(EQ. 32)

and 32, the tip-to-ring open-circuit voltage can be calculated

for any value of zener diode and battery voltage.

V

BAT

2

BAT

2

VZ< V

VZ≥ V

-------------- -

V

-------------- -

Figure 7 plots V

OCVTDC

OCVTDC

as a function of battery voltage. The

OC

V

BAT

-------------- -

2

2

2V–

ZVCEVBE

4––=

–()+()4––=

(EQ. 33)

(EQ. 34)

graph illustrates the clamping function of the zener circuitry.

+50

+40

+30

+20

TIP TO RING

+10

OPEN CIRCUIT VOLTAGE (V)

0

-16 -28 -40 -52 -58 -68 -80

FIGURE 7. VOC AS A FUNCTION OF BATTERY VOLTAGE

MTU Voltage Logic Control

The same pnp transistor, T

, that is used to control the

2

centering voltage is also used to control the MTU voltage.

The application circuit uses T

of the zener diode D

anode of D

is referenced to ground through the collector

11

. When RC is a logic low (T2on) the

11

to ground or float the anode

2

base junction of the transistor. Current then flows through

the zener, allowing the ring amplifier input to be clamped.

When RC is a logic high (T

off) the anode of D11floats,

2

inhibiting the clamping action of the zener.

HC5517 Modes of Operation

The four modes of operation of the HC5517 Ringing SLIC

are ringing, on-hook standby, off-hook active and power

denial. Three control signals select the operating mode of

69

Page 11

HC5517

the SLIC. The signals are Battery Switch, F1 and Ring

Cadence (RC). The active application circuit and active

supervisory function are different for each mode, as shown

in the Table 2.

Mode Control Signals

The Battery Switch selects between the -80V and -24V

supplies. The Battery Switch circuitry is described in the

“Operation of the Battery Switch” section. A system alternative to the battery switch signal is to use a buffered version of

the

SHD output to select the battery voltage. Another alternative is to control the output of a programmable battery

supply, removing the battery switch entirely from the application circuit. F1 is used to put the SLIC in the power denial

mode. RC drives the base of T

, which is the transistor used

2

to control the centering voltage and MTU voltage. The three

control signals can be driven from a TTL logic source or an

open collector output

RINGING MODE

The ringing state, as the name indicates, is used to ring the

telephone with a -80V battery supply. The SLIC is designed

for balanced ringing with a differential gain of 40V/V across tip

and ring. Voltage feed amplifiers operating in the linear mode

are used to amplify the ringing signal. The linear amplifier

approach allows the system designer to define the shape and

amplitude of the ringing waveform. Both supervisory function

outputs,

SHD and RTD, are active during ringing.

Spectral Content of the Ringing Signal

The shape of the waveform can range from sinusoidal to

trapezoidal. Sinusoidal waveforms are spectrally cleaner

than trapezoidal waveforms, although the latter does result

in lower power dissipation across the SLIC for a given RMS

amplitude. Systems where the ringing signal will be in proximity to digital data lines will benefit from the sinusoidal ringing capability of the HC5517. The slow edge rates of a

sinusoid will minimize coupling of the large amplitude ringing

signal. The linear amplifier architecture of the HC5517

allows the system designer to optimize the design for power

dissipation and spectral purity.

Amplitude of the Ringing Signal

Amplitude control is another benefit of the linear amplifier

architecture. Systems that require less ringing amplitude are

able to do so by driving the HC5517 with a lower level ringing

waveform. Solutions that use saturated amplifiers can only

vary the amplitude of the ringing signal by changing the

negative battery voltage to the SLIC.

HC5517 Through SLIC Ringing

The HC5517 is designed with a high gain input, V

the system drives while ringing the phone. V

RING

, that

RING

is one of

many signals summed at the inverting input to the tip feed

amplifier. The gain of the V

signal through the tip feed

RING

amplifier is set to 20V/V. The output of the tip feed amplifier

is summed at the inverting input of the ring feed amplifier,

configured for unity gain. The result is a differential gain of

40V/V across tip and ring of the ringing signal.

The ringing function requires an input ringing waveform and

a centering voltage. The ringing waveform is the signal from

the 4-wire side that is amplified by the SLIC to ring the telephone. The centering voltage, as previously discussed, is a

positive DC offset that is applied to the V

RING

input along

with the ringing waveform. The HC5517 application circuit

provides the centering voltage, simplifying the system

interface to an AC coupled ringing waveform.

Ringer Equivalence Number

Before any further discussion, the Ringer Equivalence

Number or REN must be discussed. Based on FCC Part

68.313 a single REN can be defined as 5kΩ,7kΩ or 8kΩ of

AC impedance at the ringing frequency. The ringing frequency is based on the ringing types listed in Table 1 of the

FCC specification. The impedance of multiple REN is the

paralleling of a single REN. Therefore 5 REN can either be

1kΩ, 1.4kΩ or 1.6kΩ. The 7kΩ model of a single REN will be

used throughout the remainder of the data sheet.

Ringing Waveform

An amplitude of 1.2V

to a 1 REN load, and 42V

will deliver approximately 46V

RMS

to a 3 REN load. The ampli-

RMS

RMS

tude is REN dependent and is slightly attenuated by the

feedback scheme used for impedance matching. The ringing

waveform is cadenced, alternating between a 20Hz burst

and a silent portion between bursts. Bellcore specification

TR-NWT-000057 defines seven distinct ringing waveforms or

alerting (ringing) patterns. The following table lists each type.

TABLE 1. DISTINCTIVE ALERTING PATTERNS

INTERVAL DURATION IN SECONDS

P ATTERN

RINGING SILENT RINGING SILENT RINGING SILENT

A 0.4 0.2 0.4 0.2 0.8 4.0

B 0.2 0.1 0.2 0.1 0.6 4.0

C 0.8 0.4 0.8 0.4

D 0.4 0.2 0.6 4.0

E 1.2 4.0

F1±0.2 3 ± 0.3

G 0.3 0.2 1.0 0.2 0.3 4.0

Figure 8 shows the relationship of the cadenced ringing

waveform and the Battery Switch and RC control signals.

Also shown are the states of the MTU voltage and the

centering voltage.

The state of Battery Switch is indicated by the desired

battery voltage to the SLIC. The RC signal is used to enable

and disable the centering voltage and MTU voltage. RC

follows the ring signal in that it is high during the 20Hz burst

and low during the static part of the waveform.

Open Circuit Voltage During the Ringing Mode

The mutually exclusive relationship of the centering voltage

and MTU implies that both functions will not exist at the

same time. During the silent portion of the ringing waveform

70

Page 12

HC5517

CADENCED

WAVEFORM

RC

MTU

-80V

-24V

OFF ON OFF OFF OFFON ON

ON OFF ON ON ONOFF OFF

BATTERY

SWITCH

CENTERING

VOLTAGE

FIGURE 8. RINGING WAVEFORM AND CONTROL SIGNALS

the HC5517 application circuit meets the hazardous voltage

requirements of FCC Part 68.306 by forcing the MTU voltage. Without the zener clamping solution, a programmable

power supply would have to be designed. The intervals listed

in Table 1 would require the power supply to switch voltages

and settle to stable operation well within 100ms. The design

of such a power supply may prove quite a challenge. The

zener solution provides a cost effective, low impact to

meeting a wide variety of tip to ring open circuit voltages.

Ringing Design Equations

The differential tip to ring voltage during ringing, as a

function of REN, can be approximated from Equation 35.

VTRRL()2

The voltage V

V

------------------

5.4e3

RING

input ringing signal. V

ential output voltage, calculated as V

0.702()200()V

RING

---------------------------------------------------–×≅ 108e3•

108e3()R

TRO

L

is defined as the RMS amplitude of the

is the open circuit tip to ring differ-

TRO

multiplied by the

RING

(EQ. 35)

differential gain of 40V/V. The REN impedance is shown as

R

. Figure 9 shows the relationship of REN load to maxi-

L

mum differential tip to ring RMS voltage during ringing. The

maximum ringing signal amplitude herein assumes an infinite source and sink capability of the tip feed and ring feed

amplifiers. Due to the amplifier output design, the HC5517 is

limited to 3 REN ringing capability for this reason.

47.00

46.00

45.00

44.00

43.00

42.00

41.00

AMPLITUDE (RMS)

MAXIMUM RINGING

40.00

39.00

1 REN 2 REN 3 REN 4 REN 5 REN

FIGURE 9. MAXIMUM RINGING OUTPUT VOLTAGE

(V

RING

= 1.2V

RMS

)

ON-HOOK STANDBY MODE

On-hook standby mode is with the phone on-hook (i.e., not

answered) and ready to accept an incoming voice signal or electronic data. The HC5517 application circuit is designed to maintain the MTU voltage during this mode of operation. During this

mode, the

SHD output is valid and the RTD output is invalid.

OFF-HOOK ACTIVE MODE

Off-hook active accommodates voice and data communications, including pulse metering, with a batter y voltage of

-24V. The MTU voltage dur ing this mode is defeated by the

zener clamp design regardless of the state of RC. It is

important to have RC low to disable the ringing voltage.

Only the

SHD output is valid during this mode.

POWER DENIAL MODE

The HC5517 will enter the power denial mode whenever F1

is a logic low. During power denial, the tip and ring amplifiers

are active. The DC voltages of both amplifiers are near

ground, resulting in a maximum loop current of 7mA. Both

the

SHD and the RTD detector output are invalid.

71

Table 2 summarizes the operating modes of the HC5517

application circuit. The table indicates the valid detectors in

each mode as well as valid application circuit operation.

Page 13

HC5517

TABLE 2. HC5517 APPLICATION CIRCUIT OPERATING MODES SUMMARY

BATTERY

SWITCH F1 RC MODE

-24V 0 0 Power Denial

-24V 0 1 Invalid

-24V 1 0 Off-Hook Active √

-24V 1 1 Invalid

-80V 0 0 Power Denial √

-80V 0 1 Invalid

-80V 1 0 On-Hook Standby √√

-80V 1 1 Ringing (Note) √√

NOTE: During Ringing, the SHD output will be active for both on-hook and off-hook conditions. The AC current, for the on-hook condition, exceeds

the SHD threshold of 12mA. Valid off-hook detection during ringing is provided by the RTD output only.

DETECTORS VALID APPLICATION CIRCUIT VALID

SHD RTD MTU CENTERING

Operation of the Battery Switch

The battery switch is used to select between the off-hook

battery of -24V and the ringing/standby battery of -80V.

When T

is off and the -24V battery is supplied to the SLIC through

D

10

flows through the collector of T

When D

respect to the drain (-80V) and T

connects the -80V battery to the SLIC through D

turn reverse biases D

Transhybrid Balance

The purpose of the transhybrid circuit is to remove the

receive signal (V-REC) from the transmit signal (V-XMIT),

thereby preventing an echo on the transmit side. This is

accomplished by using an external op amp (usually part of

the CODEC) and by the inversion of the signal from the

SLIC’s 4-wire receive port (V

transmit port (OUT1).

The external transhybrid circuit is shown in Figure 10. The

effects of capacitors C

fore omitted from the analysis. The input signal (V-REC) will

be subtracted from the output signal (V-XMIT) if I

are equal and opposite in phase. A node analysis yields the

following equation:

VREC–

-------------------- -

The value of R

R

2

Given that OUT1 is equal to -1/3 of V-REC (Equation 16) and

V-REC is equal to VTR (A

then R

be achieved by using 1% resistors values.

is off (battery switch is logic low) the MOSFET T

1

. When T1is on (battery switch is logic high) current

turning on the zener D9.

turns on, the gate of the MOSFET is positive with

9

, isolating the two supplies.

10

1

turns on. Turning T3on

3

7

. This in

(Voice Signal)

) to the SLIC’s 4-wire

RX

and C8are negligible and there-

5,C7

equals I

1

OUT1

---------------- -+ 0=

R

R

2

3

is then:

2

V REC–

-------------------- -

R–

•=

3

OUT1

=3R3.A transhybrid balance greater than 30dB can

2

4-Wire-2-Wire

= 1, Equation 15),

(EQ. 36)

(EQ. 37)

EXTERNAL

HC5517

3

PHASE

SHIFT

OF AC

SIGNAL

FIGURE 10. TRANSHYBRID CIRCUIT (VOICE SIGNAL)

V

RX

C

-

+

180

8

-IN1

OUT1

SUMMING NODE CANCELS OUT

INCOMING AC TRANSMISSION FROM

OUT GOING TRANSMISSION

Transhybrid Balance

TRANSHYBRID CIRCUIT

C

7

C

5

R

9

R

8

I

1

R

2

R

3

I

2

(Pulse Metering)

V-REC

INCOMING

AC TRANSMISSION

R

1

-

+

V-XMIT

OUTGOING

AC TRANSMISSION

Transhybrid balance of the pulse metering signal is

accomplished in 2 stages. The first stage uses the SLIC’s

2

internal op amp to invert the phase of the pulse metering signal. The second stage sums the inverted pulse metering signal with the incoming signal for cancellation in the

transhybrid amplifier. A third network can be added to offset

both tip and ring by the peak amplitude of the pulse metering

signal. This will allow both the maximum voice and pulse

metering signals to occur at the same time with no distortion.

Pulse Metering

Pulse metering or Teletax is used outside the United States

for billing purposes at pay phones. A 12kHz or 16kHz burst

is injected into the 4-wire side of the SLIC and transmitted

across the tip and ring lines from the central office to the pay

phone. For more information about pulse metering than covered here reference application note AN9608 “Implementing

Pulse Metering for the HC5509 Series of SLICs”.

72

Page 14

HC5517

Inverting Amplifier (A1)

The pulse metering signal is injected in the -IN1 pin of the

SLIC. This pin is the inverting input of the internal amplifier

(A

) that is used to invert the pulse metering signal for later

1

cancellation. The components required for pulse metering

are C

and R5, are shown in Figure 11. The pulse metering

6

signal is AC coupled to prevent a DC offset on the input of

the internal amplifier. The value of C

should be 10µF. The

6

expression for the voltage at OUT1 is given in Equation 38.

C6R

C

8

DESIGN

R

-------

• V

R

5

-IN

PM

R

8

1

-

+

R

8

-------

•–=

R

5

R

9

8

9

V

PM

V

TX

FIGURE 11. PULSE METERING PHASE SHIFT AMPLIFIER

V

OUT1

VTX–

A

1

TO EXTERNAL

TRANSHYBRID AMP

OUT

1

(EQ. 38)

The first term is the gain of the feedback voltage from the

2-wire side and the second term is the gain of the injected

pulse metering signal. The effects of C

and C8are

6

negligible and therefore omitted from the analysis.

The injected pulse metering output term of Equation 38 is

shown below in Equation 39 and rearranged to solve for R

in Equation 40.

V

R

OUT1

=

5R8

injected()V

The ratio of R

8

-------

• 1==

PM

R

5

to R5is set equal to one and results in unity

8

(EQ. 39)

(EQ. 40)

R

gain of the pulse metering signal from 4-wire side to 2-wire

side. The value of R

is considered to be a constant since it

8

is selected based on impedance matching requirements.

Cancellation of the Pulse Metering Signal

The transhybrid cancellation technique that is used for the

voice signal is also implemented for pulse metering. The

technique is to drive the transhybrid amplifier with the signal

that is injected on the 4-wire side, then adjust its level to

match the amplitude of the feedback signal, and cancel the

signals at the summing node of an amplifier.

NOTE: The CA741C operational amplifier is used in the application

as a “stand in” forthe operational amplifier that is traditionally located

in the CODEC, where transhybrid cancellation is performed.

Referring to Figure 3, VTXis the 2-wire feedback used to

drive the internal amplifier (A1) which in turn drives the

OUT1 pin of the SLIC. The voltage measured at V

TX

related to the loop impedance as follows:

200–

------------ -

V

TX

VPM• GPM•=

R

L

(EQ. 41)

For a 600Ω termination and a pulse metering gain (G

1, the feedback voltage (V

) is equal to one third the

TX

PM

)of

injected pulse metering signal of the 4-wire side. Note,

depending upon the line impedance characteristics and the

degree of impedance matching, the pulse metering gain may

differ from the voice gain. The pulse metering gain (G

PM

)

must be accounted for in the transhybrid balance circuit.

The polarity of the signal at OUT1 (Equation 38) is opposite

of V

allowing the circuit of Figure 12 to perform the final

PM

stage of transhybrid cancellation.

R

V

RX

OUT

V

PM

FIGURE 12. CANCELLATION OF THE PULSE METERING SIGNAL

2

R

3

1

R

4

R

1

-

+

CA741C

V

TXO

The following equations do not require much discussion.

They are based on inverting amplifier design theory. The

voice path V

signal has been omitted for clarity. All refer-

RX

ence designators refer to components of Figures 11 and 12.

V

TXO

V

V

TX

R–

•

8

PM

---------- -–

------------–

R

• V

5

R

9

R

-------

R

1

–=

3

R

PM

1

-------

•

R

4

(EQ. 42)

The first term refers to the signal at OUT1 and the second

term refers to the 4-wire side pulse metering signal. Since

5

ideal transhybrid cancellation implies V

TXO

when a signal is injected on the 4-wire side, V

equals zero

is set to

TXO

zero and the resulting equation is shown below.

0R

8

TX

---------- -

•

------------+

R

R

9

PM

5

1

-------

• V

–=

R

3

R

V

V

Rearranging terms of Equation 43 and solving for R

R

PM

1

-------

•

R

4

(EQ. 43)

results

4

in Equation 44. This is the only value to be calculated for the

transhybrid cancellation. All other values either exist in the

application circuit or have been calculated in previous

sections of this data sheet.

R

200– GPM•

8

-------

R

=

4

The value of R

------------------------------- -

•

R

3

•

R

LR9

(Figure 12) is 12.37kΩ given the following

4

1–

1

-------+

R

5

(EQ. 44)

set of values:

R

= 40kΩ

8

R

= 40kΩ

9

R

= 600Ω

L

R

= 8.25kΩ

3

R

= 40kΩ

5

G

= 1

PM

is

Substituting the same values into Equation 41 and Equation 42,

it can be shown that the signal at OUT

This result, along with Equation 44 where R

is equal to -2/3VPM.

1

equals to 2/3R4,

3

indicates the signal levels into the transhybrid amplifier are

equalized by the amplifier gains and opposite in polarity,

thereby achieving transh ybrid balance at V

TXO

.

73

Page 15

HC5517

Additional Tip and Ring Offset Voltage

A DC offset is required to level shift tip and ring from ground

and V

respectively. By design, the tip amplifier is offset

BAT

4V below ground and the ring amplifier is offset 4V above

V

. The 4V offset was designed so that the peak voice

BAT

signal could pass through the SLIC without distortion. Therefore, to maintain distortion free transmission of pulse metering and voice, an additional offset equal to the peak of the

pulse metering signal is required.

The tip and ring voltages are offset by a voltage divider

network on the V

pin. The VRXpin is a unity gain input

RX

designed as the 4-wire side voice input for the SLIC.

Figure 13 details the circuit used to generate the additional

offset voltage.

+5V

R

-

2-WIRE SIDE

FIGURE 13. PULSE METERING OFFSET GENERATION

+

V

PMO

R

V

RX

R

6

C

7

R

7

TO VOICE INPUT OF

TRANSHYBRID AMP

4-WIRE SIDE

C

VOICE INPUT

5

The amplifier shown is the tip amplifier. Other signals are connected to the summing node of the amplifier but only those

components used for the offset generation are shown. The offset generated at the output of the tip amplifier is summed at the

ring amplifier inverting input to provide a positive offset from the

battery voltage. The connection to the ring amplifier was omitted from Figure 13 for clarity, refer to Figure 3 for details.

The term V

is defined to be the offset required for the

PMO

pulse metering signal. The value of the offset voltage is calculated as the peak value of the pulse metering signal.

Equation 45 assumes the amplitude of the pulse metering

signal is expressed as an RMS voltage.

V

PMO

The value of R

2VPM•=

can be calculated from the following

6

(EQ. 45)

equation:

R

=

6

R7R

----------------- -

R

7

–

5V

PMO

------------------------- -

R+

V

PMO

(EQ. 46)

The component labeled R is the internal summing resistor of

the tip amplifier and has a typical value of 108kΩ. The value

of R

should be selected in the range of 4.99kΩ and 10kΩ.

7

Staying within these limits will minimize the parallel loading

effects of the internal resistor R on R

as well as minimize

7

the constant power dissipation introduced by the divider.

Solving Equation 45 for 1V

requirement for V

. Setting R7of Equation 46 to 10kΩ

PMO

and substituting the values for V

R

. The value of R6can be rounded to the nearest standard

6

results in a 1.414V

RMS

and R yields 23.2kΩ for

PMO

value without significantly changing the offset voltage.

Single Low Voltage Supply Operation

The application circuit shown Figure 15 requires 2 low

voltage supplies (+5V, -5V). The following application offers

away to make use of a 2.5V reference, provided with some

CODEC, to operate the transhybrid balance amplifier from

a single +5V supply. The implementation is shown in

Figure 14. Notice that the three inputs from the SLIC must all

be AC coupled to insure the proper DC gain through the

CODECs internal op amp. The resistor Ra is not used for

gain setting and is only intended to balance the DC offsets

generated by the input bias current of the CODEC amplifier.

If the DC offsets generated by the input bias currents are

negligible, then Ra may be omitted from the circuit. Ca may

be required for decoupling of the voltage reference pin and

does not contribute to the response of the amplifier.

CODEC

R

0.1µF

V

RX

0.1µF

OUT

1

0.1µF

V

PM

FIGURE 14. SINGLE LOW VOLTAGE SUPPLY OPERATION

2

R

3

R

4

R

24.9kΩ

24.9kΩ

1

Ra

Ca

0.1µF

+

2.4V

REF

Layout Guidelines and Considerations

The printed circuit board trace length to all high impedance

nodes should be kept as short as possible. Minimizing length

will reduce the risk of noise or other unwanted signal pickup.

The short lead length also applies to all high gain inputs. The

set of circuit nodes that can be categorized as such are:

•V

pin 27, the 4-wire voice input.

RX

• -IN1 pin 13, the inverting input of the internal amplifier.

•V

•V

• U1 pin 2, inverting input of external amplifier.

For multi layer boards, the traces connected to tip should not

cross the traces connected to ring. Since they will be carrying

high voltages, and could be subject to lightning or surge

depending on the application, using a larger than minimum

trace width is advised.

The 4-wire transmit and receive signal paths should not

cross. The receive path is any trace associated with the V

input and the transmit path is any trace associated with V

output. The physical distance between the two signal paths

should be maximized to reduce crosstalk.

The mode control signals and detector outputs should be

routed away from the analog circuitry. Though the digital

signals are nearly static, care should be taken to minimize

coupling of the sharp digital edges to the analog signals.

pin 3, the noninverting input to ring feed amplifier.

REF

pin 24, the 20V/V input for the ringing signal

RING

RX

TX

74

Page 16

HC5517

The part has two ground pins, one is labeled AGND and the

other BGND. Both pins should be connected together as

close as possible to the SLIC. If a ground plane is available,

then both AGND and BGND should be connected directly to

the ground plane.

A ground plane that provides a low impedance return path

for the supply currents should be used. A ground plane

provides isolation between analog and digital signals. If the

layout density does not accommodate a ground plane, a

single point grounding scheme should be used.

Application Pin Descriptions

PLCC SYMBOL DESCRIPTION

1 AGND Analog Ground - To be connected to zero potential. Serves as a reference for the transmit output and receive input

terminals.

2VCCPositive Voltage Source - Most Positive Supply.

3V

4 F1 PowerDenial -A low activeTTL compatiblelogic control input. When enabled, the output of the ring amplifier will ramp

5 F0 TTL compatible logic control input that must be tied high for proper SLIC operation.

6 RS TTL compatible logic control input that must be tied high for proper SLIC operation.

7 SHD Switch Hook Detection - An active low TTL compatible logic output. Indicates an offhook condition.

8 RTD Ring Trip Detection - An active low TTL compatible logic output. Indicates an off-hook condition when the phone is

9 TST A TTL logic input. A low on this pin will keep the SLIC in a power down mode. The TST pin in conjunction with the ALM pin

10 ALM A TTL compatible active low output which responds to the thermal detector circuit when a safe operating die

11 I

12 OUT1 The analog output of the spare operational amplifier.

13 -IN1 The inverting analog input of the spare operational amplifier. Note that the non-inverting input of the amplifier is

14 TIP

15 RING SENSE 1 An analog input connected to the RING (more negative) side of the subscriber loop through a feed resistor. Functions

16 RING SENSE 2 This is an internal sense mode that must be tied to RING SENSE 1 for proper SLIC operation.

17 V

18 NU Not used in this application.This pin should be left floating.

19 V

20 RDI TTL compatible input to drive the uncommitted relay driver.

21 RDO This is the output of the uncommitted relay driver.

22 BGND Battery Ground - To be connected to zero potential. All loop current and some quiescent current flows into this

23 NU Not used in this application. This pin should be either grounded or left floating.

24 V

25 TF This is the output of the tip amplifier.

26 RF This is the output of the ring amplifier.

27 V

28 RTI Ring Trip Input - This pin is connected to the external negative peak detector output for ring trip detection.

REF

LMT

SENSE

RX

TX

RING

BAT

Ring amplifier referenceoverride.An external voltageconnected tothis pinwill overridethe internal V

close to the output voltage of the tip amplifier.

ringing.

can provide thermal shutdown protection for the SLIC. Thermal shutdown is implemented by a system controller that

monitors the ALM pin. When the ALM pin is active (low) the system controller issues a command to the TST pin (low) to

power down the SLIC. The timing of the thermal recovery is controlled by the system controller.

temperature has been exceeded.

Loop Current Limit - Voltageon this pin sets the short loop current limiting conditions using a resistive voltage divider.

internally connected to AGND.

An analog input connected to the TIP (more positive) side of the subscriber loop through a feed resistor and ring relay

contact. Functions with the RING terminal to receive voice signals from the telephone and for loop monitoring

purpose.

with the TIP terminal to receive voice signals from the telephone and for loop monitoring purposes.

Receive Input, 4-Wire Side - A high impedance analog input. AC signals appearing at this input drive the Tip Feed

and Ring Feed amplifiers deferentially.

Transmit Output, 4-Wire Side-Alowimpedance analog output which represents the differential voltage across TIP

andRING. Since the DC levelof this output varies with loop current, capacitivecoupling to the next stage isnecessary.

terminal.

Ring signal input (0V to 3V

The negative battery source.

PEAK

at 20Hz).

/2 reference.

BAT

75

Page 17

HC5517

Pinouts

HC5517 (PLCC)

TOP VIEW

VREF

F1

4

3

F0

5

RS

6

SHD

7

8

RTD

TST

9

ALM

10

ILMT

11

12

13

14

-IN 1

OUT 1

Applications Circuit

VCCAGND

12

28

15

16

TIP SENSE

RING SENSE 1

BAT

RTI

RF

V

27

26

25

24

23

20

19

17

18

RX

NU

V

RING SENSE 2

22

21

TF

VRING

NU

BGND

RDO

RDI

V

TX

1

1

AGND

2

2

V

CC

3

3

VREF

F1

4

4

F0

5

5

RS

6

6

SHD

7

7

RTD

8

8

TST

9

9

ALM

10

10

11

11

ILMT

OUT 1

12

12

-IN 1

13

13

14

TIP SENSE

+5V

14

PULSE METERING OPTION

HC5517 (SOIC)

TOP VIEW

28

28

RTI

27

27

V

BAT

26

26

RF

25

25

TF

24

24

VRING

23

23

NU

BGND

22

22

RDO

21

21

20

20

RDI

V

19

19

TX

NU

18

18

17

17

V

RX

16

16

RING SENSE 2

15

15

RING SENSE 1

R

TIP

RING

V

CC

BAT

SWITCH

BGND

-24V

-80V

11

R

C

17

D

2

C

9

D

4

††

C

18

R

22

D

10

R

14

R

12

C

15

D

12

T

1

C

13

D

7

T

3

†D

R

21

D

9

14 TIP SENSE

13

25 TF

D

1

V

BAT

D

3

26 RF

16 RING SENSE 2

15 RING SENSE 1

2 V

CC

C

14

1 AGND

22 BGND

C

12

27 V

BAT

8

SHD RTD ALM TST RS

† Not required for MOSFETs with body diodes.

†† Diode bridge optional for in-house use.

HC5517

V

ILIMT 11

V

-IN1 13

OUT1 12

VR

RDI 20

RDO

V

RING

R

29

17

RX

TX

F1 4

FO 5

EF

24

RTI 28

+5V

R

6

C

7

V-REC

R

C

1

R

7

R

28

R

10

19

C

8

R

9

R

8

R

3

R

5

5

R

2

U1

2

R

3

4

C

1

7

6

-

+

4

C

6

-5V+5V

C

2

C

C

4

3

V-XMIT

V-TELETAX

F1

R

31

+5V

3

D

13

21

691087

R

30

D

6

R

18

R

16

R

15

C

D

5

R

17

C

10

+5V

R

R

24

19

T

2

RC

11

D

11

C

16

V

RING

76

FIGURE 15. APPLICATION CIRCUIT

Page 18

HC5517

HC5517EVAL Evaluation Board Parts List

COMPONENT VALUE TOLERANCE RATING COMPONENT VALUE TOLERANCE RATING

SLIC HC5517 n/a n/a C2, C4, C

R1, R

2

R

3

R

4

R5, R8, R

9

R6(Not Provided) 23.2kΩ 1% 1/4W C

R7(Not Provided) 10kΩ 1% 1/4W C

R

10

R

11-14

R

15

R

16

R

17

R

18

R

19

24.9kΩ 1% 1/4W C5, C

8.25kΩ 1% 1/4W C6, C

12.1kΩ 1% 1/4W C9, C

40kΩ 1% 1/4W C

100kΩ 5% 1/4W C

50Ω 1% 1/4W C17, C

47kΩ 1% 1/4W D

7

8

12

10

11

13

16

18

, D7, D8, D

1-4

1.5MΩ 1% 1/4W D5, D6, D12, D

56.2kΩ 1% 1/4W D

1.1kΩ 1% 1/4W D

825Ω 1% 1/4W T

9

11

1

15

0.1µF 20% 50V

10µF 20% 20V

0.47µF 20% 20V

0.01µF 20% 100V

1.0µF 20% 50V

100µF 20% 5V

0.1µF 20% 100V

0.5µF 20% 50V

3300pF 20% 100V

1N4007 100V, 1A

10

1N914 100V, 1A

13

1N4744 15V, 1W

1N5255 28V, 1/2-

NTE 383 100V, 1A

Wire

R22, R29, R30, R

R

24

10kΩ 5% 1/4W T

31

47kΩ 5% 1/4W T

2

3

2N2907 60V,150mA

RFP2N10 or

100V, 2A

equivalent

R

25-27

R

28

R

21

C1, C3, C

14

560Ω 5% 1/4W F1, RC, BATTERY SPDT Toggle switches, center off.

20kΩ Potentiometer 1/4W U1 CA741C OpAmp

47kΩ 5% 1/4W Textool Socket 228-5523

0.01µF 20% 50V

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only.Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly,the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

77

Loading...

Loading...