Page 1

Low Current Bar Code

Digitizer IC

Technical Data

H

HBCC-0500

Features

• Compatible with HP Bar

Code Sensors

– HBCC-1570 - 0.013 in.

0.33 mm

- HBCC-1580 - 0.007 in.

0.185 mm

- HBCC-1590 - 0.005 in.

0.13 mm

• Ambient Light Rejection

> 100 K Lux

• Accurate Digitizing of a

Wide Range of Bar Code

Labels

Description

The Hewlett-Packard Low Current

Bar Code Digitizer IC allows

designers to incorporate the high

ambient light rejection and low

power consumption features of

the HBCS-AXXX/TXXX wands

into their own bar code circuitry.

The HBCC-0500 is packaged in a

24 pin SOIC plastic package.

output of different sensor “bins”

is equalized by varying the

amplitude of the LED drive

current.

The sensor output has two components; DC due to ambient light,

and AC from the bar code label.

Photocurrent from the sensor is

amplified and high pass filtered

to remove the ambient light

signal. The AC component is

amplified and sent to an AM

detector to recover the bar code

information. The recovered bar

code signal is low pass filtered to

eliminate the 30 kHz carrier. The

signal is input to a digitizer

consisting of positive and negative

Block Diagram

SENSOR LED DRIVER

peak detectors and a comparator.

The comparator threshold is

generated from the peak

detectors using a resistor ladder.

This threshold, along with the

current bar code signal, is input

to a comparator. The output of

the comparator drives an external

output transistor.

Theory of Operation

The digitizer IC uses the techniques in US Patent 4,682,015 to

reduce power consumption and

sensitivity to ambient light.

Power is reduced by pulsing the

LED every 33 microseconds with

a 1 microsecond pulse. The

5964-1563E

AM

DETECTOR

AMPLIFIER

LOW PASS

FILTER

HIGH PASS

FILTER

DIGITIZER

AMPLIFIER

OUTPUT

4-33

Page 2

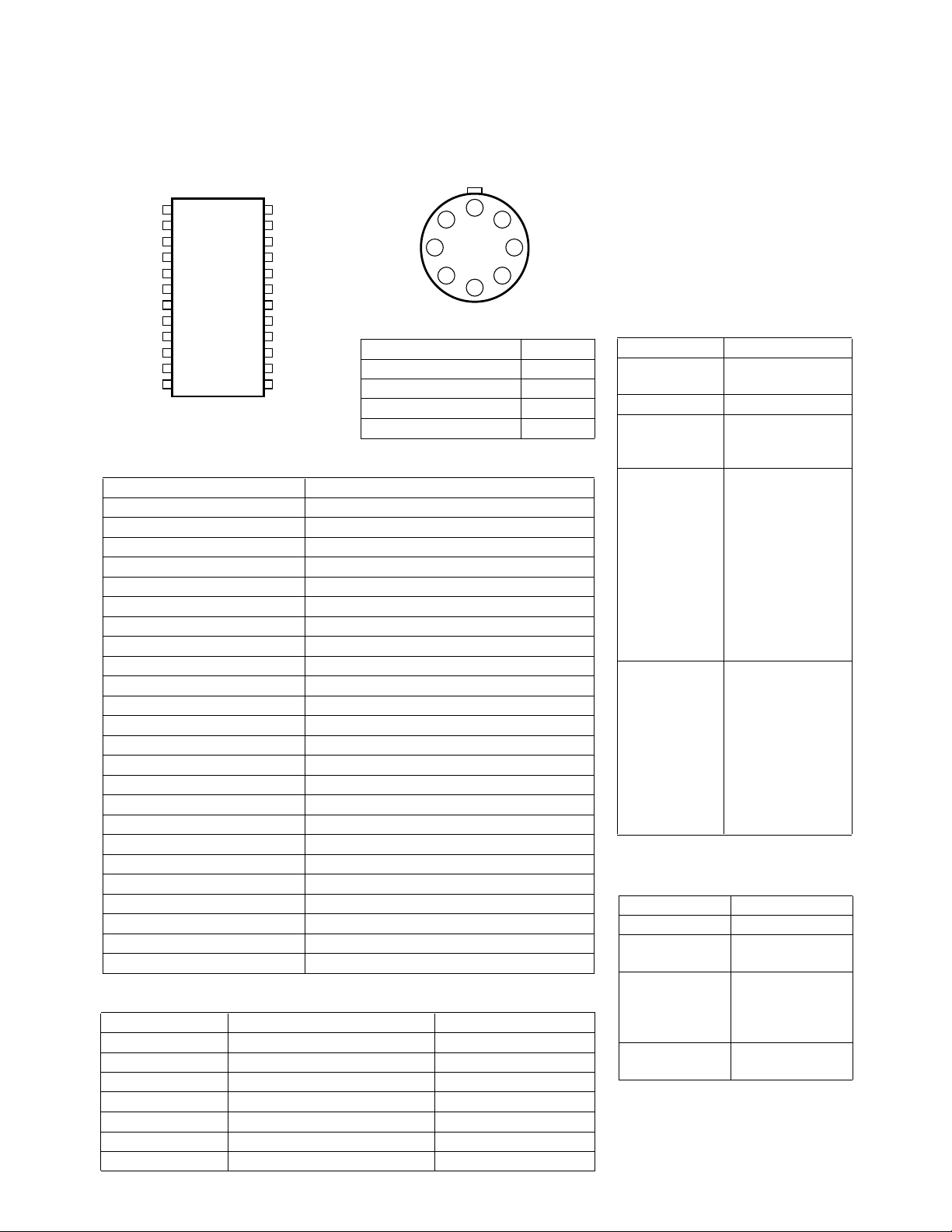

Pinout

RPER 1

RPWD 2

CTIM 3

V

CC

AGND 5

EMIN 6

PREO 7

A8

V

CC

PPKD 9

PRBP 10

PSTB 11

ACMP 12

4

HBCC-0500

24

LEDD

23

GND

22

LPFO

21

LPFI

20

IWSR

19

CMPO

18

CTHR

17

CMPI

16

NPKD

15

PSTI

14

CMPA

13

AMDT

Sensor Pinout

1 7

2 6

3 5

TOP VIEW

Function Pin #

LED Anode 6

LED Cathode 2

Detector Anode 8

Detector Cathode 1

Pin Description

Mnemonic Description

RPER Timer Period

RPWD Timer Pulse Width

CTIM Timer Capacitor

V

CC

Filtered Power

AGND Analog Ground

EMIN Preamp Emitter Input

PREO Preamp Output

VCCA Analog Power

PPKD Positive Peak Detector

PRBP Preamp Bias Point

PSTB Postamp Bypass

ACMP Compensation Cap

AMDT AM Detector

CMPA Compensation Cap

PSTI Postamp Input

NPKD Negative Peak Detector

CMPI Comparator Input

CTHR Comparator Threshold

CMPO Comparator Output

IWSR White State Return Current

LPFI Low Pass Filter Input

LPFO Low Pass Filter Output

GND Ground

LEDD LED Drive

Bin Table

Bin # 1570, 1580 Rb Ω 1590 Rb Ω

1 8.2 22

21127

31536

41847

52456

63075

73691

Sensor Marking

Sensors are marked with an eight

8

digit code, the last digit being the

“bin” number. The bin number is

used to determine the bin

resistor, Rb, using the Bin Table.

4

Parts List

Quantity Part

1 Sensor

1 HBCC-0500

1 1N4148

1 2N3904

1 2N4403

1 2N5088

2 39 Ω

1 9.1 kΩ

2 20 kΩ

2 56 kΩ

1 390 kΩ

2 470 kΩ

1 680 kΩ

1 1.3 MΩ

1 2.0 MΩ

2 6.8 MΩ

1 Bin resistor R

b

1 12 pF

1 75 pF

1 330 pF

1 680 pF

2 1.0 nF

1 2.2 nF

1 8.2 nF

4 0.1 µF

3 0.22 µF

1 0.47 µF

Optional Parts List

Quantity Part

1 1N4148

1 2N5088

1 2N3904

2 10 kΩ

1 220 kΩ

1 1.0 MΩ

1 2.0 MΩ

1 3.3 nF

1 1.0 µF

4-34

Page 3

Recommended Schematic

Shown is the recommended

schematic for the HBCC-0500.

Here are some construction tips.

1. Place the sensor, 2N4403, bin

resistor, and the 0.47 µF cap

close to each other to minimize

loop area.

2. If the 0.47 µF cap is tantalum,

its ESR must be used in series

with Rb to determine the

correct value for Rb.

3. A 1.0 µF ceramic cap may be

used in place of the 0.47 µF

cap.

4. Place the 0.22 µF cap attached

to pins 4 and 23 close to the

IC.

5. Use a single point ground close

to pin 23.

Options

There are four options on the

recommended schematic.

1. Output pull up resistor

2. Inverted output

3. Black state return

4. Threshold adjust

Pull Up Resistor

The 10 kΩ pull up resistor on the

standard or inverted output

transistor is optional. If the

transistor is driving a cable, the

resistor should be on the far end

of the cable.

Schematic

2N4403

LED ANODE

LED CATHODE

DETECTOR

CATHODE

DETECTOR

ANODE

SENSOR

Rb Ω

6

2

1

8

0.47

µF

+5 V

+5 V

680 KΩ

39 Ω39 Ω

0.22µF0.22

8.2 nF

470 KΩ

9.1 KΩ

6.8 MΩ

µF

2N5088

75 pF

0.1 µF

24

LEDD

4

V

CC

23

GND

15

PSTI

7

PREO

6

EMIN

5

AGND

1

RPER

2

RPWD

3

CTIM

9

PPKD

1 nF 1 nF

HBCC-

0500

CTHR

18

1N4148

CMPO

CMPI

LPFO

AMDT

CMPA

ACMP

IWSR

V

PRBP

PSTB

NPKD

390 KΩ470 KΩ

LPFI

CC

19

17

22

13

21

14

12

20

8

A

10

11

16

2.0 MΩ

20 KΩ

680 pF

56 KΩ 56 KΩ

2.2 nF

330 pF

12 pF

NC

0.22 µF

0.1 µF

0.1 µF

0.1 µF

1.3 MΩ

+5 V

10 KΩ (OPTIONAL)

20 KΩ

2N3904

+5 V

10 KΩ

(OPTIONAL)

INVERTED OUTPUT

(OPTIONAL)

+5 V

3.3 nF

1.0 MΩ

220 KΩ

2N5088

2.0 MΩ

BLACK STATE RETURN

(OPTIONAL)

1.0 pF

1N4148

OUTPUT

INVERTED

OUTPUT

4-35

Page 4

Inverted Output

The standard output of the

HBCC-0500 is high when the

sensor is looking at black bars,

increase the values of the 1.0 µF

and the 3.3 nF caps. The ratio of

values should be no more than

300:1.

and low when the sensor is looking at white spaces. If inverted

output is needed, add the extra

circuitry in the inverted output

block. Make sure that the 10 kΩ

pull up resistor on the normal

output transistor is loaded.

Threshold Adjustment

The standard circuit uses a

threshold designed for most bar

codes. If the bar codes to be read

consistently have narrow bars

that are lighter than the wide

bars, then the 470 kΩ and the

Black State Return

The HBCC-0500 normally returns

390 kΩ resistors attached to pin

18 should be swapped.

to the white state 100 milliseconds after the last transition. The

extra circuitry forces the black

state after a time out period set

by the 1.0 µF cap. The normal

time out period is about 1.5 seconds. If a longer time is needed,

Warranty and Service

HP Digitizer ICs are warranted

for a period of one year after

purchase covering defects in

material and workmanship.

Hewlett-Packard will repair or, at

Recommended Operating Conditions

Parameter Min. Max. Units Notes

Scan Velocity 7.6 (3) 76 (30) cm/sec (in/sec) 1

Edge Contrast 40 % 2

V

CC

Ambient Temperature -20 +65 °C

Ambient Light 100,000 Lux

Notes:

1. Narrow element width = 0.19 mm (0.0075 in.).

2. Contrast is defined as Rw - Rb, where Rw is the reflectance of the spaces in Rb is the

reflectance of the bars, measured at the sensor wavelength (655 or 820 nm). 100%

reflectance is barium sulfate.

3. Power supply ripple and noise should be less than 100 mV peak to peak.

4.5 6.0 V 3

its option, replace products that

prove to be defective in material

or workmanship under proper

use during the warranty period.

NO OTHER WARRANTIES ARE

EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED

TO THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR

PURPOSE. HEWLETT-PACKARD

IS NOT LIABLE FOR

CONSEQUENTIAL DAMAGES.

For additional warranty or service

information, please contact your

local Hewlett-Packard sales

representative or authorized

distributor.

Electrical Characteristics

Parameter Symbol Typical Max. Units Notes

Supply Current, IC and Sensor I

High Level Output Current I

Low Level Output Voltage V

Output Rise Time t

Output Fall Time t

Wake Up Time t

Notes:

4. Rise and fall time will be dependent upon the capacitance of the cable.

5. Wake up time is defined as the time from initial power turn on until the circuit is

digitizing bar codes within data sheet limits.

4-36

CC

OH

OL

r

f

w

2.7 4.0 mA

1.0 µA

0.4 V

4.5 20 µs4

0.3 20 µs4

50 200 ms 5

Loading...

Loading...