Page 1

PRELIMINARY DATA SHEET

MICRONAS

HAL 800

Programmable Linear

Hall Effect Sensor

Edition Oct. 20, 1999

6251-441-1DS

MICRONAS

Page 2

HAL800

Contents

Page Section Title

3 1. Introduction

3 1.1. Major Applications

3 1.2. Features

4 1.3. Marking Code

4 1.4. Operating Junction Temperature Range (T

4 1.5. Hall Sensor Package Codes

4 1.6. Solderability

4 1.7. Pin Connections and Short Descriptions

5 2. Functional Description

5 2.1. General Function

7 2.2. Digital Signal Processing and EEPROM

9 2.3. Calibration Procedure

9 2.3.1. General Procedure

10 2.3.2. Calibration of Angle Sensor

)

J

11 3. Specifications

11 3.1. Outline Dimensions

11 3.2. Dimensions of Sensitive Area

11 3.3. Position of Sensitive Area

12 3.4. Absolute Maximum Ratings

12 3.5. Recommended Operating Conditions

13 3.6. Electrical Characteristics

14 3.7. Magnetic Characteristics

14 3.8. Typical Characteristics

17 4. Application Notes

17 4.1. Application Circuit

17 4.2. Temperature Compensation

18 4.3. Am bi ent Te mpe ratur e

18 4.4. EMC and ESD

19 5. Programming of the Sensor

19 5.1. Definition of Programming Pulses

19 5.2. Definition of the Telegram

21 5.3. Telegram Codes

22 5.4. Number Formats

23 5.5. Register Information

23 5.6. Programming Information

24 6. Data Sheet History

2 Micronas

Page 3

HAL800

Programmable Linear Hall Effect Sensor

1. Introduction

The

HAL 800 is an universal magnetic field sensor with

a linear output based on the Hall effect. The IC is

designed and produ ced in sub-mic ron CMOS techn ology and can be used for angle or distance measurements if combined wit h a rotating or moving magnet.

The major characteristics like magnetic field range,

sensitivity, output quiescent voltage (output voltage at

B = 0 mT), and output voltage range are p rogrammable in a non-volatile memo ry. The sensor has a ratiometric output ch aracter isti c, which mean s th at the output voltage is propor ti on al to the m agn eti c flux and t he

supply voltage.

HAL 800 features a temperature compensated

The

Hall plate with choppered offset compensation, an A/D

converter, digital signal processing, a D/A converter

with output driver, an EEPROM memory with redundancy and lock function for the calibration data, a serial

interface for programming the EEPROM, and protection devices at all pins. The internal di gital signal processing is of great benefit because analog offsets,

temperature shifts, and mechanical stress do not

degrade the sensor accuracy.

1.1. Major Applications

Due to the sensor’s versatile programming characteristics, the

applications such as:

– contactless potentiometers,

– rotary position measurement,

– linear position detection,

– magnetic field and current measurement.

1.2. Features

– high precision linear Hall effect sensor with

ratiometric output

– multiple programmable magnetic characteristics

with non-volatile memory

– digital signal processing

– temperature characteristics programmable for

matching all common magnetic materials

– programmable clamping voltages

– programming with a modulation of the supply

voltage

HAL 800 is the optimal system solution for

HAL 800 is programmable by modulating the sup-

The

ply voltage. No additional programming pi n is needed.

The easy programmab ility allows a 2-point calib ration

by adjusting the output voltage directly to the input signal (like mechanical angle, distance or current). An

individual adjustment of each sensor during the customers manufacturing process is possible. With this

calibration procedur e the tolera nces of the sensor, the

magnet, and the mechanical positioning can be compensated in the final assembly.

In addition, the t emperature compensation of the Hall

IC can be fit to all commo n magne tic mat er ials by programming first and second order temperature coefficients of the Hall sensor sensitivity. This enables an

operation over the full temperature range with high

accuracy.

The calculation of the indiv idual se nsor cha racteristi cs

and the programming of the EEPROM memory can

easily be done with a PC and the applic ation kit from

Micronas. The

characteristics can be programmed in a wide range.

Therefore, one Hall IC type can be used for various

applications.

HAL 800 eases logistic because its

– lock function and redundancy for EEPROM memory

– operates from −40 °C up to 150 °C

ambient temperature

– operates from 4.5 V up to 5.5 V supply voltage

– operates with static magnetic fields and dynamic

magnetic fields up to 2 kHz

– choppered offset compensa tio n

– overvoltage and reverse-voltage protection at all

pins

– magnetic characteristics extremely robust against

mechanical stress

– short-circuit protected push-pull output

– EMC optimized design

The sensor is desig ned for hostile indus trial and a utomotive applications and operates with typically 5 V

supply voltage in the amb ient temperature range from

−40 °C up to 150 °C.

The

HAL 800 is available in the very small leaded

package TO-92UT.

Micronas 3

Page 4

HAL800

HALXXXPA-T

Temperature Range: A, K, E, or C

Package: UT for TO-92UT

Type: 800

1.3. Marki n g C o de

HAL 800 has a marking on the package surface

The

(branded side). T his m ark ing in clud es the name o f th e

sensor and the temperature range.

Type Temperature Range

A K E C

HAL 800 800A 800K 800E 800C

1.4. Operating Junction Temperature Range (T

A: TJ =

K: TJ =

E: TJ =

−40 °C to +170 °C

−40 °C to +140 °C

−40 °C to +100 °C

)

J

C: TJ = 0 °C to +100 °C

The Hall sensors from Micronas are specified to the

chip temperature (junction temperature T

The relationship between ambient temperature (T

and junction temperature is explained in

on page 18

.

).

J

Section 4.3.

A

1.6. Solderability

Package TO-92UT: according to IEC68-2-58

During soldering reflow processing and manual

reworking, a component body temperature of 260 °C

should not be exceeded.

Components stored in the original packaging should

provide a shelf life of at least 12 m onths, starting fro m

the date code prin ted on the labels, even in environments as extreme as 40 °C and 90% relative humidity.

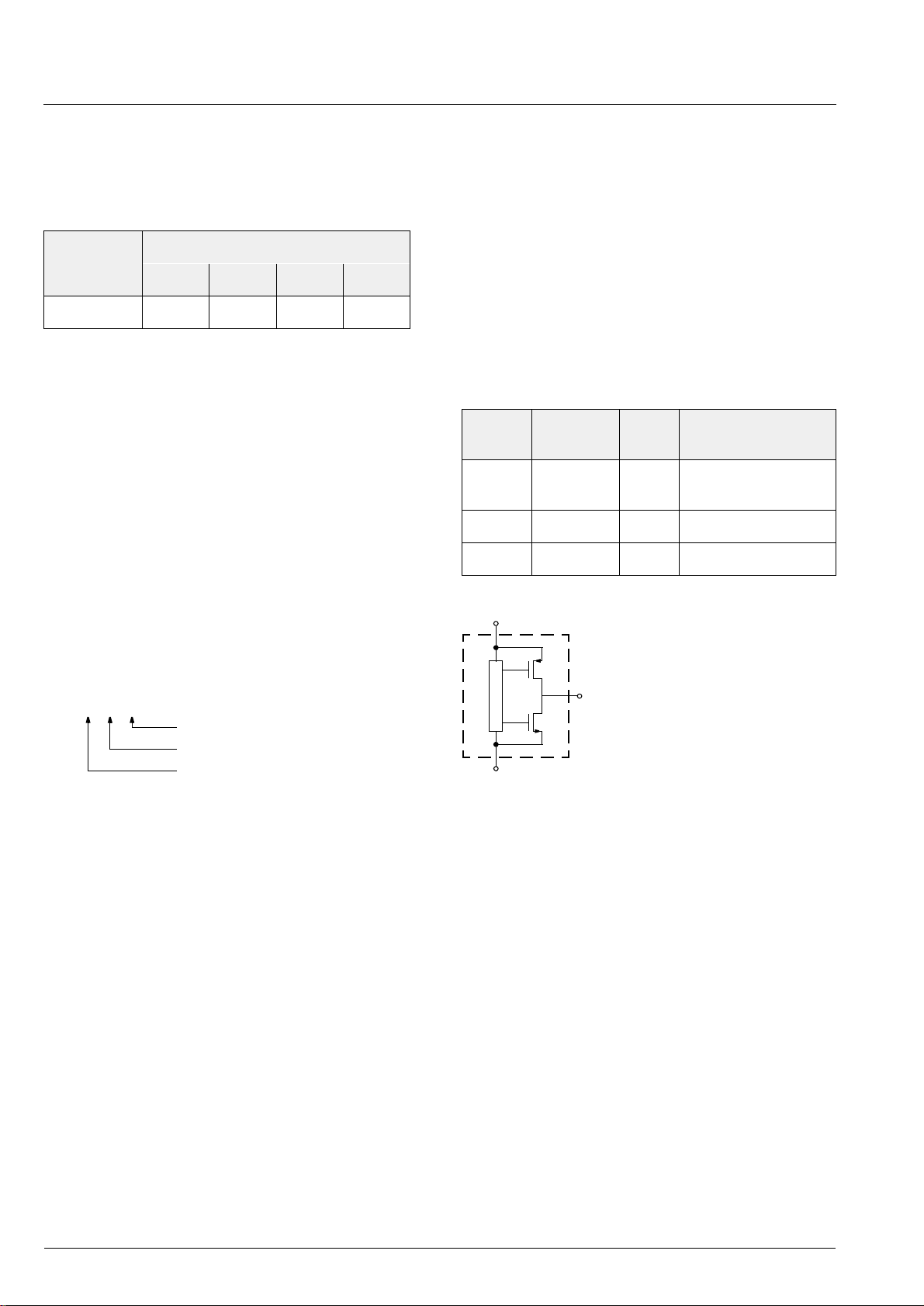

1.7. Pin Connections and Short Descriptions

Pin

Pin Name Type Short Description

No.

1V

DD

IN Supply Voltage and

Programming Pin

2 GND Ground

)

3 OUT OUT Push Pull Output

V

1

DD

1.5. Hall Sensor Package Codes

Example: HAL800UT-A

→ Type: 800

→ Package: TO-92UT

→ Temperature Range: T

= −40°C to +170°C

J

Hall sensors are available in a wide variety of packaging versions and quantities. For more detailed information, please refer to the brochure: “Ordering Co des for

Hall Sensors”.

OUT

3

2

GND

Fig. 1–1: Pin configuration

4 Micronas

Page 5

HAL800

2. Functional Description

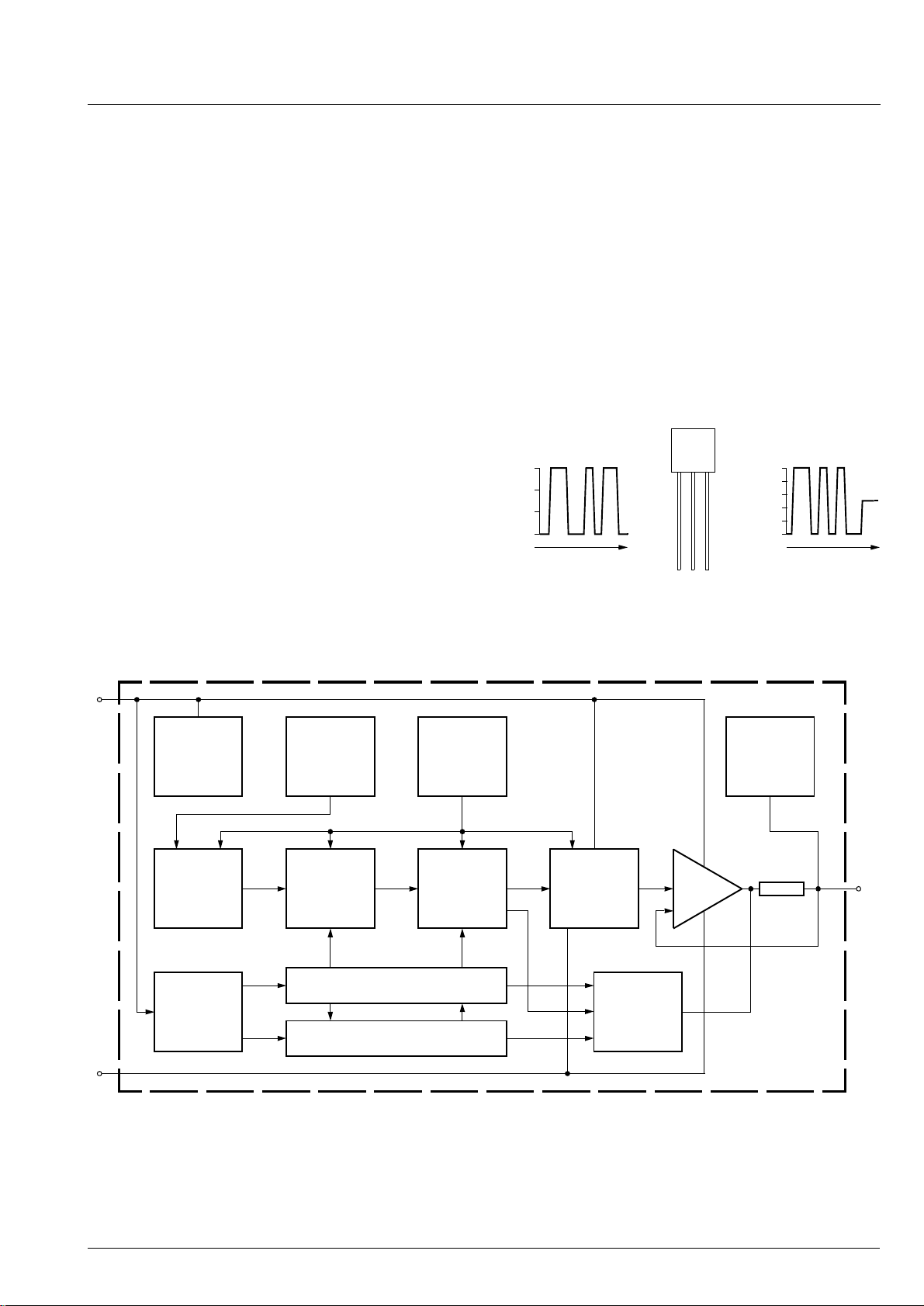

2.1. General Function

HAL 800 is a monolithic integrated circuit which

The

provides an output voltage proportional to the magnetic flux through the Hall pla te an d pr oportional to the

supply voltage.

The external magnetic field component perpendi cular

to the branded side of th e package generates a Hall

voltage. This voltage is converted to a digital value,

processed in the Digital S ignal Processing Uni t (DSP)

according to the EEPROM programming, converted to

an analog voltage with ratio metr ic behavior, and stabilized by a push-pull output transis tor stage. The function and the parameters for the DSP are detailed

explained in

Section 2.2. on page 7.

The setting of the LOCK register disables the programming of the EE PROM memor y for all time. This r egister cannot be reset.

As long as the LOCK register is not set, the output

characteristic can be adjusted by modifying the

EEPROM registers. The IC is addressed by modulating the supply voltage

(see Fig. 2–1). In the supply

voltage range from 4.5 V up to 5.5 V , the sensor gener-

ates an analog outp ut voltage. After detecting a command, the sensor reads or writes the memory and

answers with a digital signal on the output pin. The

analog output is switched off during the communication.

Internal temperature compensation circuitry and the

choppered offset compensation enables operation

over the full temperature range with minim al changes

in accuracy and high o ffset stability. The circuitry also

rejects offset shifts d ue to mechanical stres s from the

package. The non-volatile memory is equipped with

redundant EEPROM cells. In addi ti on, th e s ensor IC i s

equipped with devices for overvoltage and reverse voltage protection at all pins.

HAL

8

7

(V)

DD

6

V

5

800A

V

DD

GND

Fig. 2–1: Programming with V

OUT

DD

V

DD

(V)

OUT

V

digital

modulation

analog

V

DD

Internally

stabilized

Supply and

Protection

Devices

Switched A/D

Hall Plate Converter

Supply

Level

Detection

GND

Temperature

Dependent

Bias

Fig. 2–2: HAL800 block diagram

Digital

Signal

Processing

EEPROM Memory

Lock Control

Oscillator

D/A Analog

Converter Output

Digital

Output

Protection

Devices

100 Ω

OUT

Micronas 5

Page 6

HAL800

0

1

2

3

4

5

–40 –20 0 20 40

mT

V

B

V

OUT

Clamp-high = 4 V

Sensitivity = 0.15

V

OQ

= 2.5 V

Clamp-low = 1 V

Range = 30 mT

Fig. 2–4: Example for output characteristics

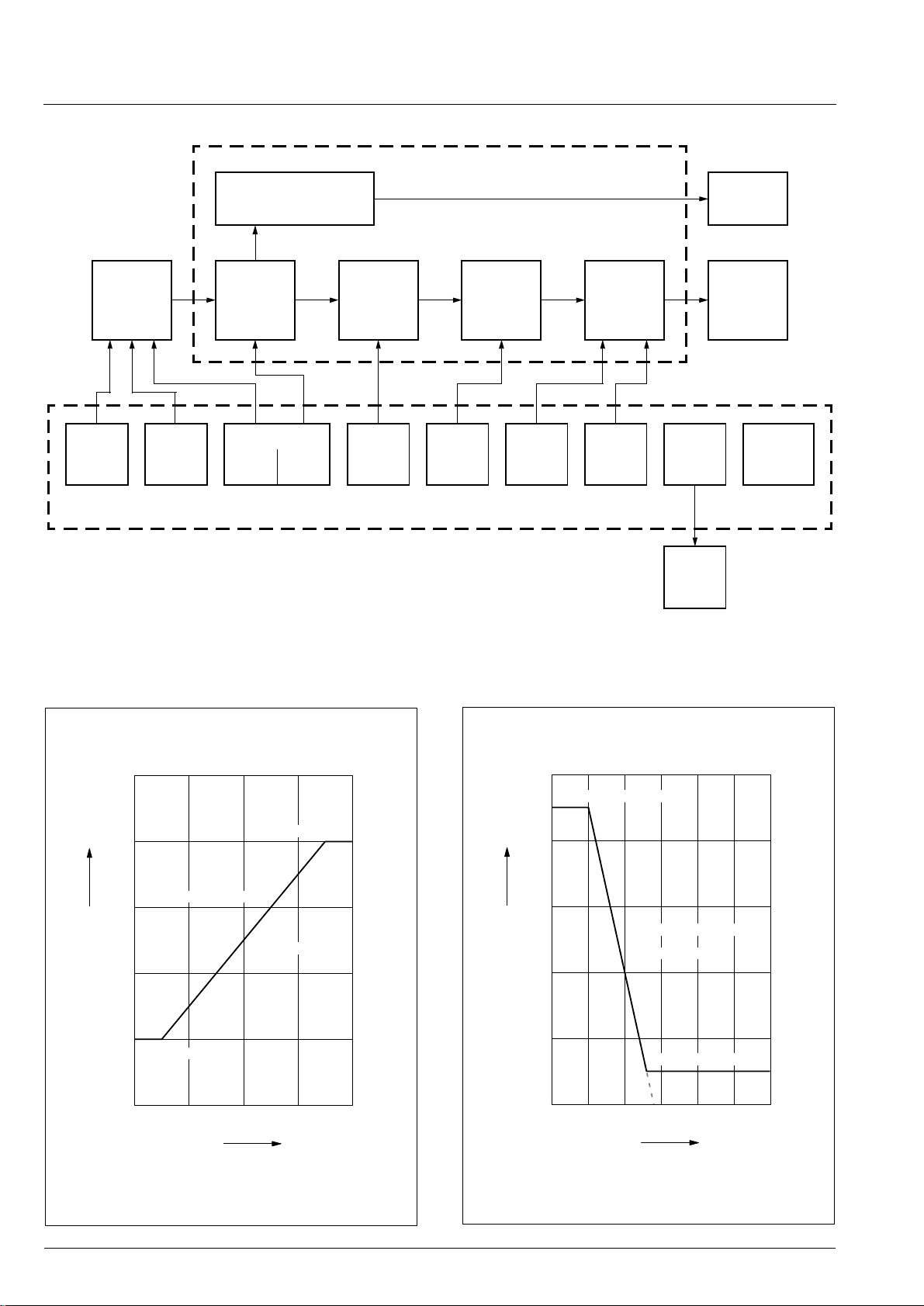

ADC-READOUT Register

14 bit

Digital Signal Processing

TC

6 bit

A/D

Converter

TCSQ

5 bit

Digital

Filter

MODE Register

RANGE

2 bit

FILTER

1 bit

Multiplier Adder Limiter D/A

SENSITIVITY LOW

14 bit

VOQ

11 bit

EEPROM Memory

Fig. 2–3: Details of EEPROM and Digital Signal Processing

CLAMP-

10 bit

CLAMPHIGH

11 bit

LOCK

1 bit

Lock

Control

Digital

Output

Converter

Micronas

Registers

V

V

5

Clamp-high = 4.5 V

OUT

4

3

2

1

0

–150 –100 –50 0 50 100 150

Range = 150 mT

Sensitivity = –0.45

V

= –0.5 V

OQ

Clamp-low = 0.5 V

B

Fig. 2–5: Example for output characteristics

mT

6 Micronas

Page 7

HAL800

2.2. Digital Signal Processing and EEPROM

The DSP is the m a jo r pa rt of thi s s ens or a nd performs

the signal conditioning. The parameters for the DSP

are stored in the EEPROM r egisters. The details are

shown in

Fig. 2–3.

Terminology:

SENSITIVITY:name of the register or register value

Sensitivity: name of the parameter

The EEPROM registers consist of three groups:

Group 1 contains the r egisters for the adaption of the

sensor to the magnetic system:

MODE for selecting the magnetic fie ld range and filter

frequency, TC and TCSQ for temperature characteristics of the magnetic sensitivity.

Group 2 contains the registers for defining the output

characteristics: SENSITIVITY, VOQ, CLAMP-LOW,

and CLAMP-HIGH. The output characteristic of the

sensor is defined by these 4 parameters (see

Fig. 2–4

and Fig. 2–5 for examples).

– The parameter V

(Output Quiescent Voltage) cor-

OQ

responds to the output voltage at B = 0 mT.

– The parameter Sensitivity is defined as:

∆V

Sensitivity =

OUT

∆B

– The output voltage can be calculated as:

∼ Sensitivity × B + V

V

OUT

OQ

The output voltage range can be clamped by setting

the registers CLAMP -LOW and CLA MP-H IGH in order

to enable failure detection (such as short-circuits to

or GND).

V

DD

Group 3 contains the Micronas registers and LOCK for

the locking of all registers. The Micronas registers are

programmed and locked during production and are

read-only for the customer. These registers are used

for oscillator frequency tr imming, A/D converter offset

compensation, and several other special settings.

The ADC converts positive or negative Hall voltages

(operates with m agnetic north and south poles at the

branded side of the package) in a digital value. This

signal is filtered in the Di gital Filter and is readable in

the ADC-READOUT regi ster as long as the LOCK b it

is not set.

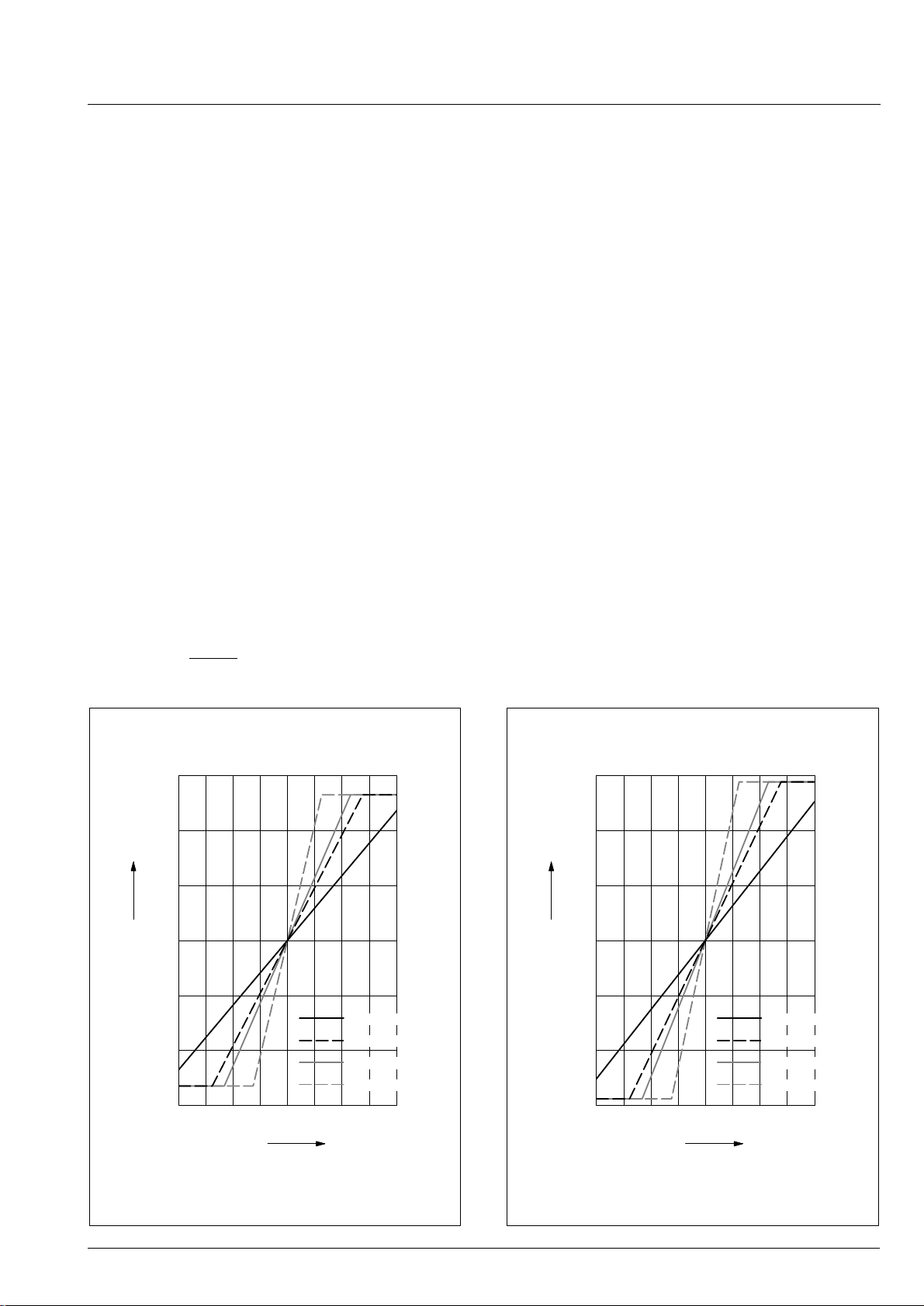

Note: The ADC-READOUT values and the resolution

of the system depe nds on the filte r freque ncy. Po sitive

values accord to a magnetic north pole on the branded

side of the package.

Fig. 2–6 and Fig. 2–7 show typi-

cal ADC-READOUT values for the different magneti c

field ranges and filter frequencies.

6000

4000

ADCREADOUT

2000

–2000

–4000

–6000

0

–200–150–100–50 0 50 100 150 200

Filter = 500 Hz

Fig. 2–6: Typical ADC-READOUT

versus magnetic field for filter = 500 Hz

Range 150 mT

Range 90 mT

Range 75 mT

Range 30 mT

B

mT

1500

1000

ADCREADOUT

500

0

–500

–1000

–1500

–200–150–100–50 0 50 100 150 200

Fig. 2–7: Typical ADC-READOUT

versus magnetic field for filter = 2 kHz

Filter = 2 kHz

Range 150 mT

Range 90 mT

Range 75 mT

Range 30 mT

mT

B

Micronas 7

Page 8

HAL800

Range

The RANGE bits are the two lowest bits of the MODE

register; they define the magnetic field range of the

A/D converter.

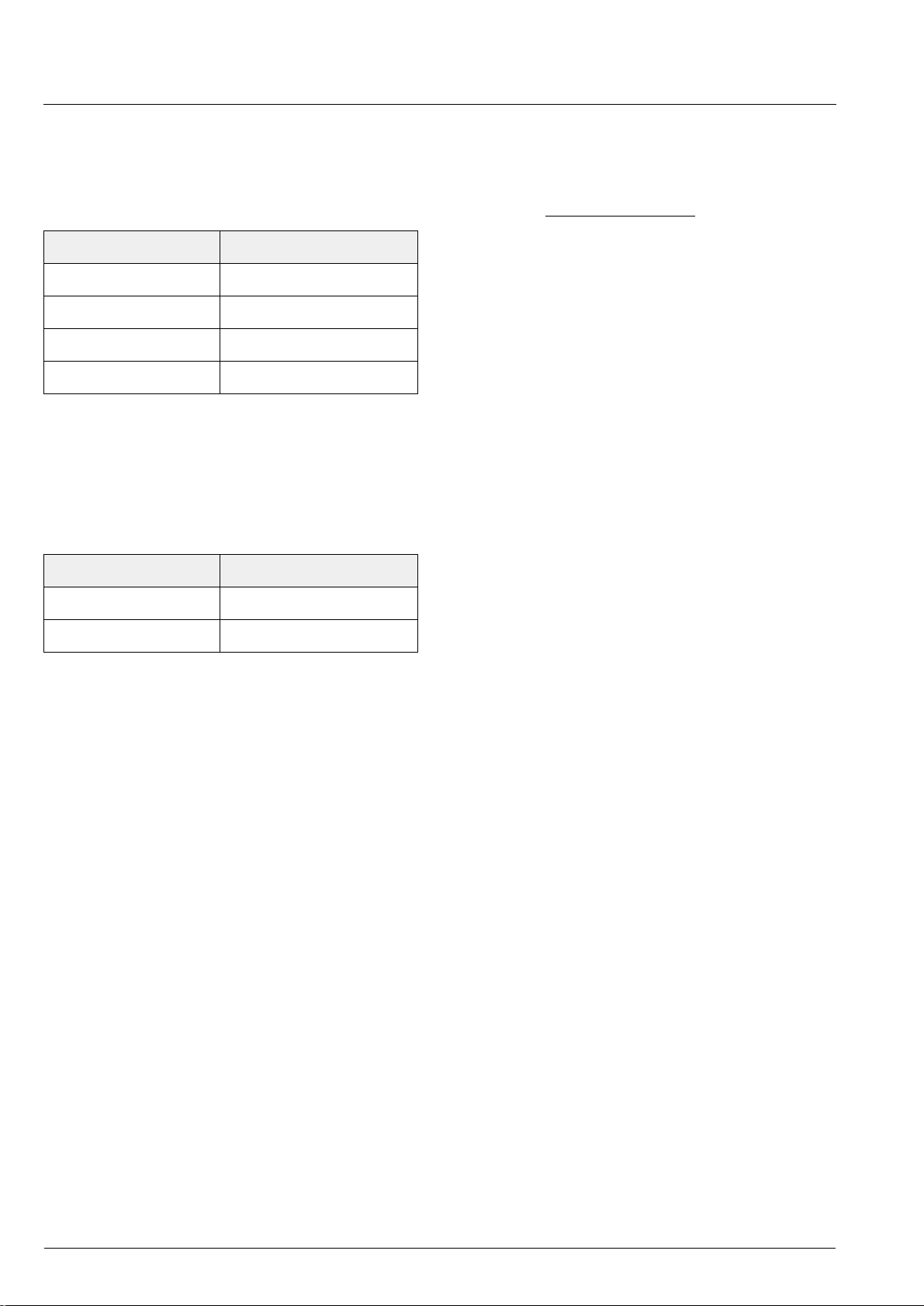

RANGE Magnetic Field Range

0 −30 mT...30 mT

1 −75 mT...75 mT

2 −90 mT...90 mT

3 −150 mT...15 0 mT

Filter

The FILTER bit is the highest bit of the MODE register;

it defines the

−3 dB frequency of the digital low pass fil-

ter

FILTER −3 dB Frequency

02 kHz

For all calculations, the di gi tal value from th e magnetic

field of the A/D converter is use d. This digital i nformation is readable from the ADC-READOUT register.

∆V

* 2048

Sensitivity =

∆ADC-READOUT * V

OUT

DD

VOQ

The VOQ register contains the parameter for the

Adder in the DSP. V

is the output voltage without

OQ

external magnetic fie ld (B = 0 mT) and programmable

− V

from

up to VDD. For VDD = 5 V the register can

DD

be changed in steps of 4.9 mV.

Note: If V

is programmed to a negative voltage, the

OQ

maximum output voltage is limited to:

V

OUTmax

= VOQ + V

DD

For calibration in the system environment, a 2-point

adjustment procedure

mended. The suitable Sensitivity and V

(see Section 2.3.) is recom-

valu es for

OQ

each sensor can be ca lculated indi viduall y by this procedure.

1 500 Hz

TC and TCSQ

The temperature dependence of the magnetic sensitivity can be adapted to different magnetic materials in

order to compensate for the change of the magnetic

strength with temperature. The adaption is done by

programming the TC (Temperature Coefficient) and

the TCSQ registers (Quadratic Temperature Coefficient). Thereby, the slope and the curvature of the

magnetic sensitivity can be matched to the magnet

and the sensor as sembly. As a result, the output voltage characteristic c an be fixed over the full temperature range. The sensor can compensate for linear temperature coefficients in the range from about -2900

ppm/K up to 700 ppm/K and quadratic coefficients

from about -5 ppm/K² to 5 ppm/K². Please refer to

Section 4.2. on page 17 for the recommended setti ngs

for different linear temperature coefficients.

Sensitivity

The SENSITIVITY register contains the parameter for

the Multiplier in the DSP. The Sensitivity is programmable between -4 and 4. For V

= 5 V the register can

DD

be changed in steps of 0.00049. Sensiti vity = 1 corresponds to an increase o f the output voltage by V

DD

if

the ADC-READOUT increases by 2048.

Clamping Voltage

The output voltage range can be clamped in order to

detect failures like shorts to V

or GND.

DD

The CLAMP-LOW register co ntains the parameter for

the lower limit. The lower clamping voltage is programmable between 0 V and V

/2. For VDD = 5 V the reg-

DD

ister can be changed in steps of 2.44 mV.

The CLAMP-HIGH reg ister contains the parameter for

the higher limit. The higher clamping voltage is programmable between 0 V and V

. For VDD = 5 V in

DD

steps of 2.44 mV.

LOCK

By setting this 1-bit register, all registers will be locked,

and the sensor will no longer respond to any supply

voltage modulation.

Warning: This register cannot be reset!

ADC-READOUT

This 14-bit register delivers the actual digital value of

the applied magnetic field before the signal processing. This regist er can be read o ut and is the bas is for

the calibration proce dure of the sensor in the s ystem

environment.

8 Micronas

Page 9

HAL800

2.3. Calibration Procedure

2.3.1. General Procedure

For calibration in the system environm ent , the applic ation kit from Micronas i s recom mended. It contai ns the

hardware for the generation of the se rial telegram for

programming and the corresponding software for the

input of the register values.

In this section, programming of the sensor with this

programming tool is explained. Please refer to

Section 5. on page 19 for information about program-

ming without this tool.

For the individual calibration of each sensor in the cus-

tomer application, a two point adjustment is recommended (see

Fig. 2–8 for an example). When using

the application ki t, the cali bration can b e done i n thr ee

steps:

Step 1: Input of the registers which need not be

adjusted individually

The magnetic circuit, the magnetic material with its

temperature characteristics, the filter frequency, and

low and high clamping voltage are given for this application.

Therefore, the values of the following registers should

be identical for all sensors of the customer application.

– FILTER

(according to the maximum signal frequency)

Step 2: Calculation of V

and Sensitivity

OQ

The calibration points 1 and 2 can be set inside the

specified range. The corresponding values for V

and V

Low clamping voltage ≤ V

result from the application requirements.

OUT2

≤ High clamping voltage

OUT1,2

OUT1

For highest accuracy of the sensor, calibration poin ts

near the minimum an d maximum input s ignal are recommended. The difference of the output voltage

between calibration point 1 and calibration point 2

should be more than 3.5 V.

Set the system to calibrat ion point 1 a nd read the reg ister ADC-READOUT. The result is the value ADCREADOUT1.

Now, set the system to calibration point 2, read the

register ADC-READOUT again, and get the value

ADC-READOUT2.

With these values and the target values V

, for the calibration points 1 and 2, respecti vely,

V

OUT2

the values for Sensitivity and V

V

− V

Sensitivity =

VOQ = V

OUT1

ADC-READOUT1 − ADC-READOUT2

ADC-READOUT1 * Sensitivity * V

−

OUT1

2048

are calculated as:

OQ

OUT2

*

DD

OUT1

2048

V

DD

and

This calculation has to be done individually for each

sensor.

– RANGE

(according to the maximum magnetic field at the

sensor position)

– TC and TCSQ

(depends on the material of the magnet and the

other temperature dependencies of the application)

– CLAMP-LOW and CLAMP-HIGH

(according to the application requirements)

Write the appr opriate settings into the

HAL 800 regis-

ters.

After writing, the information is stored in an internal

RAM and not in the EEPROM. It is valid until switching

off the supply voltage. If the values should be per manently stored in the EEPROM, the “STORE” comma nd

must be used before switching off the supply voltage.

Now, write the calculated values for Sensitivity and

for adjusting the sensor.

V

OQ

Use the “STORE” command for permanently storing

the EEPROM registers. The sensor is now calibrated

for the customer application. However, the programming can be changed again and again if necessary.

Step 3: Locking the Sensor

The last step is activating the LOCK function with the

“LOCK” command. The sensor is now locked and does

not respond to any programming or reading commands.

Warning: This register cannot be reset!

Micronas 9

Page 10

HAL800

4.5 V − 0.5 V

−2500 − 2350

Sensitivity =

5V

2048

*

=

−0.3378

VOQ = 4.5 V −

2048

−2500 * (−0.3378) * 5 V

= 2.438 V

2.3.2. Calibration of Angle Sensor

The following description explains the calibrati on procedure using an angle sensor as an example. The

required output characteristic is shown in

Fig. 2–8.

– the angle range is from −25° to 25°

– temperature coefficient of the magnet: −500 ppm/K

Step 1: Input of the registers which need not to be

adjusted individually

The register values for the following registers are given

for all applications:

– FILTER

Select the filter frequency: 500 Hz

– RANGE

Select the magnetic field range: 30 mT

– TC

For this magnetic material: 1

– TCSQ

For this magnetic material: 12

– CLAMP-LOW

For our example: 0.5 V

V

5

Clamp-high = 4.5 V

Calibration point 1

V

OUT

4

3

2

1

0

–30 –20 –10 0 10 20 30

Clamp-low = 0.5 V

Calibration point 2

Angle

Fig. 2–8: Example for output characteristics

°

– CLAMP-HIGH

For our example: 4.5 V

Enter these values in the software, and use the

“WRITE” command for wr iting the values in the registers.

Step 2: Calculation of V

There are 2 ways to calculate the values for V

and Sensitivity

OQ

OQ

and

Sensitivity

Manual Calculation:

Set the system to c alibration point 1 (angl e 1 =

−25°)

and read the register A DC-READOUT. For our example, the result is ADC-READOUT1 =

−2500.

Now, set the system to calibration point 2 (angle 2 =

25°), and read th e reg is ter ADC-READOUT again . For

our example, the result is ADC-READOUT2 =

With these measurements and the targets V

4.5 V and V

are

V

OQ

= 0.5 V, the values for Sensiti vity an d

OUT2

+2350.

OUT1

=

This calculation has to be done individually for each

sensor.

Automatic Calibration:

Use the menu CALIBRATE from the PC sof tware and

enter the values 4.5 V for V

Set the system to cali bration point 1 (angl e 1 =

and 0.5 V for V

OUT1

OUT2

−25°),

hit the button Read ADC-Readou t1, set the syst em to

calibration point 2 (angle 2 = 25 °), hit the button Read

ADC-Readout2, and hit the button Calcul ate. The software will then calc ulate th e approp riate V

and Sen-

OQ

sitivity.

Now, write the calculated values into the

HAL 800 for

programming the sensor a nd use the “STORE” command for permanently storing the EEPROM registers.

Step 3: Locking the Sensor

The last step is activating the LO CK function with the

“LOCK” command. The sensor is now locked and does

not respond to any programming or reading commands.

.

Warning: This register cannot be reset!

10 Micronas

Page 11

HAL800

3. Specifications

3.1. Outline Dimensions

±0.1

0.48

0.55

0.42

4.06

x2

x1

123

1.271.27

(2.54)

branded side

1.5

0.3

0.36

45°

SPGS0014-3-A/1E

±0.2

0.75

y

4.05

±0.2

2.1

13.0

min.

3.2. Dimensions of Sensitive Area

0.25 mm x 0.25 mm

sensitive area

3.3. Position of Sensitive Area

TO-92UT

±0.1

x1 − x2/ 2 ≤ 0.2 mm

y = 1.5 mm ± 0.2 mm

0.8

Fig. 3–1:

Plastic Transist or Single Outline Package

(TO-92UT)

Weight approximately 0.14 g

Dimensions in mm

A mechanical tolerance of

±50 µm applies to all

dimensions where no tolerance is explicitly given.

Micronas 11

Page 12

HAL800

3.4. Abso lute Max imum Ratings

Symbol Parameter Pin No. Min. Max. Unit

V

V

−I

I

V

V

DD

DD

Z

OUT

OUT

DD

− V

Supply Voltage 1 −8.5 8.5 V

Supply Voltage 1 −14.4

Reverse Supply C ur ren t 1 − 50

Current through Protection Device 1 or 3 −300

Output Voltage 3 −5

Excess of Output Voltage

DD

over Supply Voltage

I

OUT

t

Sh

T

S

T

J

1)

as long as T

2)

t < 10 minutes (V

3)

as long as T

4)

t < 2 ms

5)

t < 1000h

6)

internal protection resistor = 100 Ω

Continuous Output Current 3 −10 10 mA

Output Short Circuit Duration 3 − 10 min

Storage Temperature Range −65 150 °C

Junction Temperature Range −40

is not exceeded

Jmax

Jmax

= −15 V for t < 1min, V

DDmin

is not exceeded, output is not protected to external 14 V-line (or to −14 V)

−5

1) 2)

4)

6)

6)

14.4

1)

300

8.5

14.4

1) 2)

4)

3)

3) 2)

3,1 2 V

5)

170

= 16 V for t < 1min)

DDmax

−40

150

V

mA

mA

V

°C

°C

Stresses beyond those listed in the “Absolute Maximum Ratings” may cause permanent damage to the device. This

is a stress rating onl y. Functional operation of the device at these or any oth er condi tions beyond those indic ated i n

the “Rec ommended Operating Conditions/Character istics” of this specificati on is not i mplied. Ex posure to abs olute

maximum ratings conditions for extended periods may affect device reliability.

3.5. Recommended Operating Conditions

Symbol Parameter Pin No. Min. Typ. Max. Unit

V

I

OUT

R

C

DD

L

L

Supply Voltage 1 4.5 5 5.5 V

Continuous Output Current 3 −1 − 1mA

Load Resistor 3 4.5 −−kΩ

Load Capacitance 3 0.33 10 1000 nF

12 Micronas

Page 13

3.6. Electrical Characteristics

= −40 °C to +170 °C, VDD = 4.5 V to 5.5 V, after programming, as not otherwise specified in Conditions.

at T

J

Typical Characteristics for T

Symbol Parameter Pin No. Min. Typ. Max. Unit Conditions

= 25 °C and VDD = 5 V.

J

HAL800

I

DD

I

DD

V

DDZ

V

OZ

Supply Current 1 7 10 mA TJ = 25 °C, VDD = 4.5 V to 8.5 V

Supply Current

over Temperature Range

Overvoltage Protection

at Supply

Overvoltage Protection

at Output

Resolution 3 12 bit ratiometric to V

E

A

Accuracy Error over all 3 −202%R

INL Non-Linearity of Output Voltage

over Temperature

E

∆V

R

OUTCL

Ratiometric Error of Output

over Temperature

(Error in V

OUT

/ VDD)

Accuracy of Output Voltage at

Clamping Low Voltage over

Temperature Range

∆V

OUTCH

Accuracy of Output Voltage at

Clamping High Voltage over

Temperature Range

V

OUTH

Output High Voltage 3 4.65 4.8 V V

1710mA

1 17.5 20 V IDD = 25 mA, TJ = 25 °C, t = 20 ms

31719.5VI

3 −1 0 1 % % of supply voltage

3

3

3

−101% V

−45 0 45 mV R

−45 0 45 mV R

= 10 mA, TJ = 25 °C, t = 20 ms

O

1)

DD

= 4.7 kΩ (% of supply voltage)

L

3)

- V

OUT2

> 2 V

DD

DD

= 5 V

= 5 V

OUT

≤ 1mA

OUT1

during calibration procedure

= 4.7 kΩ, V

L

= 4.7 kΩ, V

L

= 5 V, −1 mA ≤ I

DD

3)

V

f

ADC

f

ADC

t

r(O)

t

d(O)

t

POD

OUTL

Output Low Voltage 3 0.2 0.35 V V

= 5 V, −1 mA ≤ I

DD

Internal ADC Frequency − 120 128 140 kHz TJ = 25 °C

Internal ADC Frequency over

Temperature Range

Response Time of Output 3 − 2

− 110 128 150 kHz V

1

2

4

ms

ms

= 4.5 V to 8.5 V

DD

3 dB Filter frequency = 500 Hz

3 dB Filter frequency = 2 kHz

C

= 10 nF, time from 10% to 90% of

L

final output voltage for a steplike

signal B

step

Delay Time of Output 3 0.1 0.5 ms

Power-Up Time (Time to reach

stabilized Output Voltage)

3

2

5

3

ms 3 dB Filter frequency = 500 Hz

3 dB Filter frequency = 2 kHz

90% of V

OUT

BW Small Signal Bandwidth (−3dB) 3 − 2 − kHz BAC < 10 mT;

3 dB Filter frequency = 2 kHz

V

OUTn

R

OUT

R

thJA

TO-92UT

1)

Output DAC full scale = 5 V ratiometric, Output DAC offset = 0 V, Output DAC LSB = VDD/4096

2)

peak-to-peak value exceeded: 5%

3)

if more than 50% of the selected magnetic field range are used

Noise Output Voltage

pp

Output Resistance over Recommended Operating Range

Thermal Resistance Junction to

Soldering Point

3 − 36mV2) magnetic range = 90 mT

3 − 110Ω V

OUTL

≤ V

OUT

−−150 200 K/W

OUT

from 0 mT to B

≤ V

OUTH

≤ 1mA

max

Micronas 13

Page 14

HAL800

–20

–15

–10

–5

0

5

10

15

20

–15 –10 –50 5101520

V

mA

V

DD

I

DD

T

A

= –40 °C

T

A

= 25 °C

TA=150 °C

Fig. 3–2: Typical current consumption

versus supply voltage

3.7. Magnetic Characteristics

= −40 °C to +170 °C, VDD = 4.5 V to 5.5 V, after programming, as not otherwise specified in Conditions.

at T

J

Typical Characteristics for T

Symbol Parameter Pin No. Min. Typ. Max. Unit Test Conditions

= 25 °C and VDD = 5 V.

J

B

Offset

∆B

Offset

B

Hysteresis

SR Magnetic Slew Rate 3

n

meff

f

Cflicker

f

Cflicker

Magnetic Offset 3 −101mTB = 0 mT, I

/∆T Magnetic Offset Change

due to T

J

Magnetic Hysteresis −20 0 20 µT Range = 30 mT, Filter = 500 Hz

Magnetic RMS Broadband

Noise

Corner Frequency of 1/f Noise 3 − 20 Hz B = 0 mT

Corner Frequency of 1/frms

Noise

3.8. Typical Characteristics

= 0 mA, TJ = 25 °C

OUT

−15 0 15 µT/K B = 0 mT, I

− 12

50

3 − 10 −µT BW = 10 Hz to 2 kHz

3 − 100 Hz B = 65 mT, TJ = 25 °C

− mT/ms Filter frequency = 500 Hz

Filter frequency = 2 kHz

OUT

= 0 mA

mA

10

V

= 5 V

DD

I

8

DD

6

4

2

0

–50 0 50 100 150 200

T

A

°

C

Fig. 3–3: Typical current consumption

versus ambient temperature

14 Micronas

Page 15

HAL800

mA

10

T

= 25 °C

A

V

= 5 V

DD

I

8

DD

6

4

2

0

–1.5 –1.0 –0.5 0.0 0.5 1.0 1.5

I

OUT

Fig. 3–4: Typical current consumption

versus output current

mA

%

1.0

0.8

E

R

0.6

0.4

0.2

–0.0

–0.2

V

–0.4

–0.6

–0.8

–1

45678

OUT/VDD

V

OUT/VDD

V

OUT/VDD

V

OUT/VDD

V

OUT/VDD

= 0.82

= 0.66

= 0.5

= 0.34

= 0.18

Fig. 3–6: Typical ratiometric error

versus supply voltage

V

V

DD

dB

5

0

V

OUT

–5

–10

–15

–20

–25

–30

Filter: 500 Hz

–35

Filter: 2 kHz

–40

10 100 1000 10000

Fig. 3–5: Typical output voltage

versus signal frequency

f

signal

–3

Hz

%

120

1/sensitivity

100

80

60

40

TC = 16, TCSQ = 8

20

TC = 0, TCSQ = 12

TC = –20, TCSQ = 12

TC = –31, TCSQ = 0

0

–50 0 50 100 150 200

Fig. 3–7: Typical 1/sensitivity

versus ambient temperature

°C

T

A

Micronas 15

Page 16

HAL800

–1

–0.8

–0.6

–0.4

–0.2

–0.0

0.2

0.4

0.6

0.8

1.0

–50 0 50 100 150 200

°C

mT

T

A

B

Offset

TC = 16, TCSQ = 8

TC = 0, TCSQ = 12

TC = –20, TCSQ = 12

Fig. 3–8: Typical magnetic offset

versus ambient temperature

INL

%

1.0

0.8

0.6

0.4

0.2

–0.0

–0.2

–0.4

–0.6

Range = 30 mT

–0.8

–1

–40 –20 0 20 40

Fig. 3–9: Typical nonlinearity

versus magnetic field

mT

B

16 Micronas

Page 17

HAL800

4. Application Notes

4.1. Application Circuit

For EMC protection, it is recomm ended to add eac h a

ceramic 4.7 nF capacitor between ground and the supply voltage respectively the output voltage pin. In addition, the input of the con troller unit should be pulleddown with a 4.7 k Ohm resistor and a ceramic 4.7 nF

capacitor.

Please note that during programming , the sensor will

be supplied repeatedl y with the programming voltage

of 12 V for 100 ms. All components conn ected to the

line at this time must be able to resist this voltage.

V

DD

V

DD

OUT

4.7 k

µ

C

Ω

4.7 nF

GND

HAL800

4.7 nF 4.7 nF

Temperature

TC TCSQ

Coefficient of

Magnet (ppm/K)

01110

−100 8 10

−200 6 11

−300 4 11

−400 3 12

−500 1 12

−600 −113

−700 −313

−800 −514

−900 −614

−1000 −815

−1100 −915

−1200 −11 16

Fig. 4–1: Recommended application circuit

4.2. Temperature Compensation

The relation between the temperature coefficient of the

magnet and the corresponding TC and TCSQ code s

for a linear compensation is given in the following

table. In addition to the linear chang e of the magnetic

field with temperature, the cur vature can be adjusted,

too. For that purpose, TC and TCSQ have to be

changed to combinations that are not given in the

table. Please contact Micr onas for more de tailed in formation.

Temperature

TC TCSQ

Coefficient of

Magnet (ppm/K)

700 29 8

600 26 9

500 23 9

−1300 −13 17

−1400 −14 17

−1500 −15 18

−1600 −17 18

−1700 −18 18

−1800 −19 19

−1900 −20 19

−2000 −22 20

−2100 −23 21

−2200 −24 21

−2300 −25 22

−2400 −26 22

−2500 −27 23

−2600 −28 23

400 21 9

300 18 9

200 16 9

−2700 −29 24

−2800 −30 24

−2900 −31 26

100 14 10

Micronas 17

Page 18

HAL800

4.3. Ambient Temperature

Due to the intern al power dissipation , the temperature

on the silicon c hip (junction temperature T

) is higher

J

than the temperature outside the package (ambient

temperature T

= TA + ∆T

T

J

).

A

At static conditions, the following equation is valid:

∆T = I

* VDD * R

DD

thJA

For typical values, use the typical parameters. For

worst case calculation, use the max. parameters for

and Rth, and the max. value for VDD from the appli-

I

DD

cation.

For V

temperature difference

For all sensors, the junction temperature T

fied. The maximum ambient temperature T

= 5.5 V, Rth = 200 K/W and IDD = 10 mA the

DD

∆T = 11 K.

is speci-

J

can be

Amax

calculated as:

T

Amax

= T

Jmax

−∆T

4.4. EMC and ESD

HAL 800 is designed for a stabilized 5 V supply.

The

Interferences and disturbances conducted along the

12 V onboard system (product standards DIN40839

part 1 or ISO 7637 part 1) are not relevant for these

applications.

For applications with disturbances by capacitive or

inductive coupling on the supply line or radiat ed disturbances, the application circuit shown in Fig. 4–1 is recommended.

Applications with this arrangement passed the EMC

tests according to the product standards DIN 40839

part 3 (Electrical transient transmission by capacitive

or inductive coupling) and part 4 (Radiated disturbances).

Please contact M icronas for the detailed investigation

reports with the EMC and ESD results.

18 Micronas

Page 19

HAL800

5. Programming of the Sensor

5.1. Definition of Programming Pulses

The sensor is addre ssed by modulating a serial telegram on t he su ppl y voltage. The sensor answers with a

serial telegram on the output pin.

The bits in the s er ial tel egram have a different Bit tim e

for the V

V

-line is defined through the length of the S ync Bit

DD

-line and the output. The Bit time for the

DD

at the beginning of ea ch telegram. The Bi t time for the

output is defined through the Acknowledge Bit.

A logical 0 is coded as no voltage change within the Bit

time. A logical 1 is coded as a voltage change between

50% and 80% of the Bit time. After each bi t a voltage

change occurs.

5.2. Definition of the Telegram

Each telegram starts with the Sync Bit (logical 0), 3

bits for the Command (COM), th e Comm and Parity B it

(CP), 4 bits for the Address ( ADR), and the Address

Parity Bit (AP).

command has been proces sed the sensor answers

with an Acknowledge Bit (logical 0) on the output.

– Read a register (see Fig. 5–3)

After evaluating this command the sensor answers

with the Acknowledge Bit, 14 Data Bits, and the

Data Parity Bit on the output.

– Programming the EEPROM cells (see Fig. 5–4)

After evaluating this command the sensor answers

with the Acknowledge Bit. After the delay time t

supply voltage rises up to the programming voltage.

logical 0

logical 1

V

V

V

V

DDH

DDL

DDH

DDL

t

r

t

p1

t

f

t

p0

t

p0

or

or

t

p0

t

p1

t

p0

w

the

There are 3 kinds of telegrams:

Fig. 5–1: Definition of logical 0 and 1 bit

– Write a register (see Fig. 5–2)

After the AP Bit follow 14 Data Bits (DAT) and the

Data Parity Bit (DP). If the telegram is valid and the

Table 5–1: Telegram parameters

Symbol Parameter Pin Min. Typ. Max. Unit Remarks

V

DDL

V

DDH

t

r

t

f

t

p0

t

pOUT

t

p1

V

DDPROG

Supply Voltage for Low Level

during Programming

Supply Voltage for High Level

during Programming

Rise time 1 0.05 ms

Fall time 1 0.05 ms

Bit time on V

Bit time on output pin 3 4 6 8 ms t

Voltage Change for logical 1 1, 3 50 65 80 % % of t

Supply Voltage for

Programming the EEPROM

DD

155.66V

16.88.08.5V

13.43.53.6mst

1 11.95 12 12.1 V

is defined through the Sync Bit

p0

pOUT

Acknowledge Bit

is defined through the

or t

p0

pOUT

t

PROG

t

rp

t

fp

t

w

Programming Time for EEPROM 1 95 100 105 m s

Rise time of programming voltage 1 0.2 0.5 1 ms

Fall time of programming voltage 1 0 1 ms

Delay time of programming voltage

after Acknowledge

10.50.71ms

Micronas 19

Page 20

HAL800

WRITE

Sync COM CP ADR AP DAT DP

V

DD

V

OUT

Fig. 5–2: Telegram f or coding a Write command

READ

Acknowledge

Sync COM CP ADR

V

DD

V

OUT

AP

Fig. 5–3: Telegram for coding a Read command

ERASE, PROM, LOCK, and LOCKI t

V

DDPROG

Sync COM CP ADR

V

DD

V

OUT

AP

Acknowledge

t

w

DA T DPAcknowledge

t

rp

PROG

t

fp

Fig. 5–4: Telegram for coding the EEPROM programming

20 Micronas

Page 21

HAL800

5.3. Telegram Codes

Sync Bit

Each telegram star ts with the Sync Bit. This logical 0

pulse defines the exact timing for t

Command Bits (COM)

The Command code contains 3 bits and is a binar y

number.

the corresponding codes for the

Command Parity Bit (CP)

This parity bit is 1, if the number of zeros within the 3

Command Bits is uneven. The parity bit is 0, if the

number of zeros is even.

Address Bits (ADR)

The Address code contains 4 bits and is a binary number.

HAL 800 registers.

Table 5–2 shows the available commands and

Table 5–3 s hows the available addresses for the

.

p0

HAL 800.

Address parity bit (AP)

This parity bit is 1, if the number of zeros within the 4

Address bits is uneven. The par ity bit is 0, if the number of zeros is even.

Data Bits (DAT)

The 14 Data Bits contain the register information.

The registers use different number formats for the Data

Bits. These formats are explained in

In the Write command the last bits are valid. If for

example the TC register (6 bits) is written, only the last

6 bits are valid.

In the Read command the first bits are valid. If for

example the TC register (6 bits) is re ad, on ly the fi rst 6

bits are valid.

Data Parity Bit (DP)

This parity bit is 1, if the number of zeros within the

binary number is e ven. The parity bit is 0, if th e n umb er

of zeros is uneven.

Section 5.4.

Table 5–2: Available Commands

Command Code Explanation

READ 2 read a register

WRITE 3 write a register

PROM 4 program all nonvolatile registers (except the lock bits)

ERASE 5 erase all nonvolatile registers (except the lock bits)

LOCKI 6 lock Micronas lockable register

LOCK 7 lock the whole device and switch permanently to the analog-mode

Please note:

The Micronas lock bit (LOCKI) has already been set during production and cannot be reset.

Micronas 21

Page 22

HAL800

5.4. Number Formats

Binary number:

The most significant bit is given as first, the least significant bit as last digit.

Example:

Signed binary number:

The first digit represents the sign of the following

binary number (1 for negative, 0 for positive sign).

Example:

101001 represents 41 decimal.

0101001 represents +41 decimal

1101001 represents −41 decimal

Table 5–3: Available register addresses

Parameter Code Data

Bits

Format Customer Remark

Two-complementary number:

The first digit of positive numbers is 0, the r est of the

number is a binary number. Negative numbers start

with 1. In order to calculate the abs olute value of the

number, you have to calculate the complement of the

remaining digits and to add 1.

Example:

0101001 represents +41 decimal

1010111 represents −41 decimal

CLAMP-LOW 1 10 binary read/write/program Low clamping voltage

CLAMP-HIGH 2 11 binary read/write/program High clamping voltage

VOQ 3 11 two compl.

binary

SENSITIVITY 4 14 signed binary read/write/program

MODE 5 3 binary read/write/program Range and filter parameters

LOCKR 6 1 binary lock Lock Bit

ADC-READOUT 7 14 two compl.

binary

TC 11 6 signed binary read/write/program

TCSQ 12 5 binary read/write/program

Micronas registers (read only for customers)

Parameter Code Data

Bits

Format Remark

read/write/program

read

see

Table 5–4 for details

OFFSET 8 4 two compl. binary ADC offset adjustment

FOSCAD 9 5 binary Oscillator frequency adjustment

SPECIAL 13 6 special settings

IMLOCK 14 1 binary Lock Bit for the Micronas registers

22 Micronas

Page 23

HAL800

5.5. Register Information

CLAMP-LOW

– The register range is from 0 up to 1023.

– The register value is calculated by:

Low Clamping Voltage

V

DD

* 2048CLAMP-LOW =

CLAMP-HIGH

– The register range is from 0 up to 2047.

– The register value is calculated by:

High Clamping Voltage

V

DD

* 2048CLAMP-HIGH =

VOQ

– The register range is from −1024 up to 1023.

– The register value is calculated by:

V

OQ

* 1024VOQ =

V

DD

SENSITIVITY

– The register range is from −8192 up to 8191.

– The register value is calculated by:

SENSITIVITY =

Sensitivity

2048

MODE

– The register range is from 0 up to 7 and contains the

settings for FILTER and RANGE

ADC-READOUT

– This register is read only.

– The register range is from −8192 up to 8191.

TC and TCSQ

– The TC register range is from −31 up to 31,

– The TCSQ register range is from 0 up to 31.

Please refer

Section 4.2. on page 17 for the recom-

mended values.

5.6. Programming Information

If you want to change the content of any register

(except the lock registers) you have to write the

desired value into the correspo nding RAM register at

first.

If you want to permanently store the value in the

EEPROM, you have to send an ERASE command first

and a PROM command afterwards. The address within

the ERASE and PROM command is not important.

ERASE and PROM acts on all registers in parallel.

If you want to change all r eg ist ers of the

HAL 800, you

can send all writing commands one after each other

and send one ERASE and PROM command at the

end.

Table 5–4: Parameters for the MODE register

MODE FILTER −3 dB Frequency RANGE Magnetic Field Range

00 2 kHz 0

10 2 kHz 1

20 2 kHz 2

30 2 kHz 3

4 1 500 Hz 0

5 1 500 Hz 1

6 1 500 Hz 2

7 1 500 Hz 3

−30 mT...30 mT

−75 mT...75 mT

−90 mT...90 mT

−150 mT...150 mT

−30 mT...30 mT

−75 mT...75 mT

−90 mT...90 mT

−150 mT...150 mT

Micronas 23

Page 24

HAL800

6. Data Sheet History

1. Advance information: “HAL 800 Programmable Linear Hall Effect Sensor, Aug. 24, 1998, 6251-441-1AI.

First release of the advance information.

2. Fina l data sh eet: “HAL 800 Programmable Linear

Hall Effect Sensor, Oct. 20, 1999, 6251-441-1DS. First

release of the final data sheet.

Micronas GmbH

Hans-Bunte-Strasse 19

D-79108 Freiburg (Germany)

P.O. Box 840

D-79008 Freiburg (Germany)

Tel. +49-761-517-0

Fax +49-761-517-2174

E-mail: docservice@micronas.com

Internet: www.micronas.com

Printed in Germany

Order No. 6251-441-1DS

All information and data contained in this data sheet are without any

commitment, are not to be considered as an offer for conclusion of a

contract, nor shall they be construed as to create any liability. Any new

issue of this data sheet invalidates previous issues. Product availability

and delivery are exclusively subject to our respective order confirmation

form; the same applies to orders based on development samples delivered. By this publication, Micronas GmbH does not assume responsibility for patent infr ingements or other right s of third parties whic h may

result from its use.

Further, Micronas GmbH reserves the right to revise this publication and

to make changes to its conte nt, at any t ime, withou t obligatio n to noti fy

any person or entity of such revisions or changes.

No part of this publication may be reproduced, photocopied, stored on a

retrieval system, or transmitted without the express written consent of

Micronas GmbH .

24 Micronas

Loading...

Loading...