Page 1

HAL710

Hall-Effect Sensor

with Direction Detection

Edition Feb. 20, 2001

6251-478-1AI

ADVANCE INFORMATION

MICRONAS

MICRONAS

Page 2

HAL710 ADVANCE INFORMATION

Contents

Page Section Title

3 1. Introduction

3 1.1. Features

3 1.2. Applications

4 1.3. Marking Code

4 1.3.1. Special Marking of Prototype Parts

4 1.4. Operating Junction Temperature Range

4 1.5. Hall Sensor Package Codes

4 1.6. Solderability

5 2. Functional Description

7 3. Specifications

7 3.1. Outline Dimensions

7 3.2. Dimensions of Sensitive Areas

7 3.3. Positions of Sensitive Areas

8 3.4. Absolute Maximum Ratings

8 3.5. Recommended Operating Conditions

9 3.6. Electrical Characteristics

10 3.7. Magnetic Characteristics

10 3.7.1. Magnetic Thresholds

10 3.7.2. Matching B

10 3.7.3. Hysteresis Matching

and B

S1

S2

11 4. Application Notes

11 4.1. Ambient Temperature

11 4.2. Extended Operating Conditions

11 4.3. Signal Delay

11 4.4. Test Mode Activation

11 4.5. Start-up Behavior

12 4.6. EMC and ESD

12 5. Data Sheet History

2 Micronas

Page 3

ADVANCE INFORMATION HAL710

Hall-Effect Sensor with Direction Detection

1. Introduction

The HAL 710 is a monolithic integrated Hall-effect sensor manufactured in CMOS technology with two independent Hall plates S1 and S2 spaced 2.35 mm apart.

The device has two open-drain outputs:

The ’Count Output’ operates like a single latched Hall

switch according to the magnetic field present at Hall

plate S1 (see Fig. 3–3).

The ‘Direction Output’ indicates the direction of a linear

or rotating movement of magnetic objects.

In combination with an active target providing a

sequence of alternating magnetic north and south

poles, the sensor forms a system generating the signals required to control position, speed, and direction

of the target movement.

The internal circuitry evaluates the direction of the

movement and updates the ‘Direction Output’ at every

edge of the ‘Count Signal’ (rising and falling). The

Direction Output is high if the target moves from Hall

plate S1 to Hall plate S2. It is low if the target first

passes plate S2 and later plate S1. The state of the

Direction Output only changes at a rising or falling

edge of the Count Output.

1.1. Features

– generation of ‘Count Signals’ and ‘Direction Signals’

– delay of the ‘Count Signals’ with respect to the

‘Direction Signal’ of 1 µs minimum

– switching type latching

– low sensitivity

–typical B

–typical B

: 14.9 mT at room temperature

ON

: −14.9 mT at room temperature

OFF

– temperature coefficient of −2000 ppm/K in all mag-

netic characteristics

– switching offset compensation at typically 150 kHz

– operation from 3.8 V to 24 V supply voltage

– operation with static magnetic fields and dynamic

magnetic fields up to 10 kHz

– overvoltage protection at all pins

– reverse-voltage protection at V

DD

-pin

– robustness of magnetic characteristics against

mechanical stress

– short-circuit protected open-drain outputs by ther-

mal shut down

– constant switching points over a wide supply voltage

range

– EMC corresponding to DIN 40839

The design ensures a setup time for the Direction Output with respect to the corresponding Count Signal

edge of 1/2 clock periods (1 µs minimum).

The device includes temperature compensation and

active offset compensation. These features provide

excellent stability and matching of the switching points

in the presence of mechanical stress over the whole

temperature and supply voltage range. This is required

by systems determining the direction from the comparison of two transducer signals.

The sensor is designed for industrial and automotive

applications and operates with supply voltages from

3.8 V to 24 V in the ambient temperature range from

−40 °C up to 125 °C.

The HAL 710 is available in the SMD package

SOT-89B.

1.2. Applications

The HAL 710 is the optimal sensor for position-control

applications with direction detection and alternating

magnetic signals such as:

– multipole magnet applications,

– rotating speed and direction measurement,

position tracking (active targets), and

– window lifters.

Micronas 3

Page 4

HAL710 ADVANCE INFORMATION

HALXXXPA-T

Temperature Range: K, or E

Package: SF for SOT-89B

Type: 710

Example: HAL 710SF-K

→ Type: 710

→ Package: SOT-89B

→ Temperature Range: T

J

= −40 °C to +140 °C

1.3. Marking Code

All Hall sensors have a marking on the package surface (branded side). This marking includes the name

of the sensor and the temperature range.

Type Temperature Range

K E

HAL710 710K 710E

1.3.1. Special Marking of Prototype Parts

Prototype parts are coded with an underscore beneath

the temperature range letter on each IC. They may be

used for lab experiments and design-ins but are not

intended to be used for qualification test or as production parts.

1.4. Operating Junction Temperature Range

1.6. Solderability

All packages: according to IEC68-2-58

During soldering, reflow processing and manual

reworking, a component bod y temperature of 260 °C

should not be exceeded.

Components stored in the original packaging should

provide a shelf life of at least 12 months, starting from

the date code prin ted on the labels, even in environments as extreme as 40 °C and 90% relative humidity.

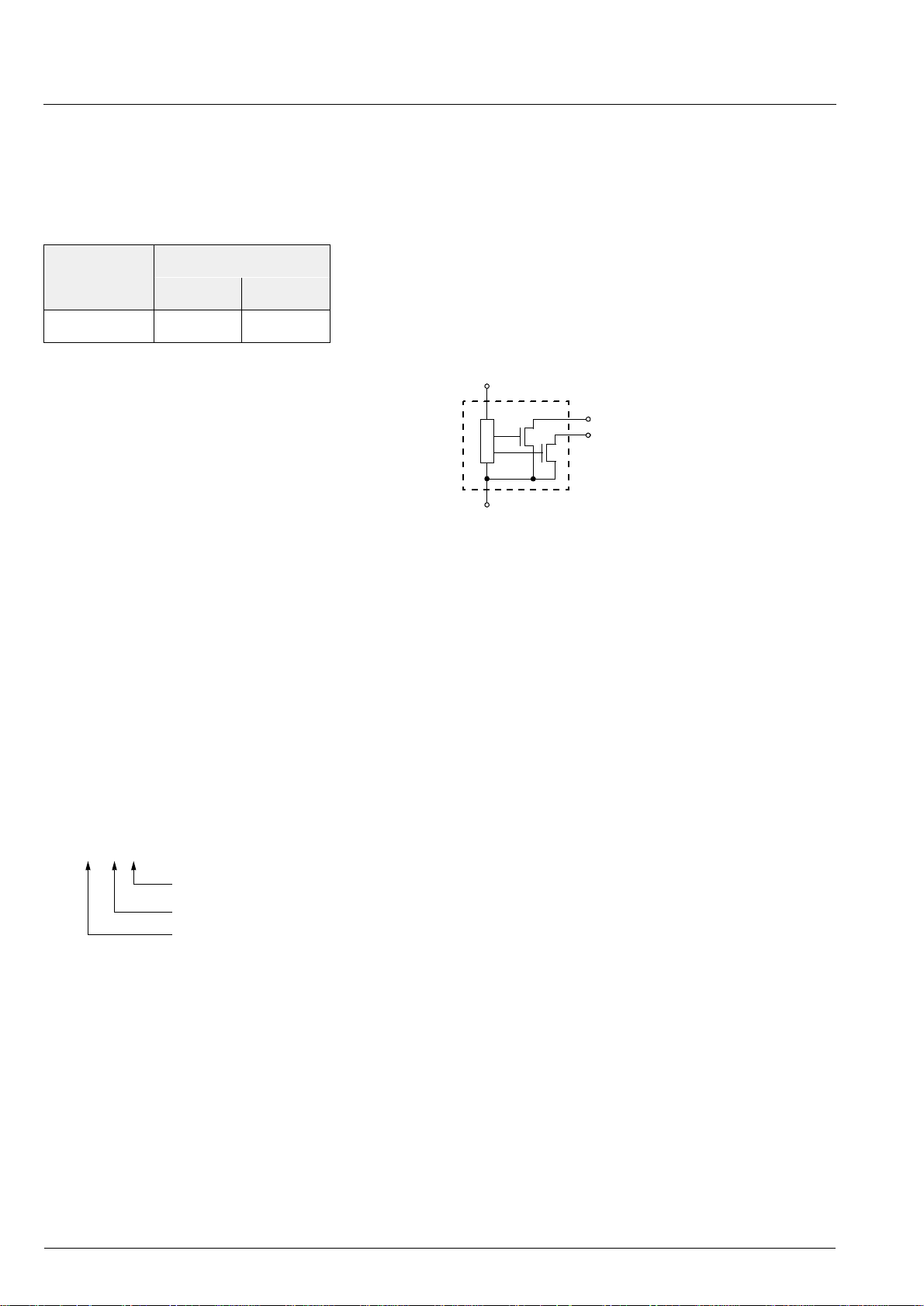

V

1

DD

3 Count Output

2 Direction Output

4GND

Fig. 1–1: Pin configuration

The Hall sensors from Micronas are specified to the

chip temperature (junction temperature T

= −40 °C to +140 °C

K: T

J

= −40 °C to +100 °C

E: T

J

The relationship between ambient temperature (T

).

J

A

and junction temperature is explained in Section 4.1.

on page 11.

1.5. Hall Sensor Package Codes

)

Hall sensors are available in a wide variety of packaging quantities. For more detailed information, please

refer to the brochure: “Ordering Codes for Hall Sensors”.

4 Micronas

Page 5

ADVANCE INFORMATION HAL710

2. Functional Description

The HAL 710 is a monoli thic int egrated circu it with two

independent subblocks consisting eac h of a Hall plate

and the corresponding comparator. Each subblock

independently switches the comparator output in

response to the magnetic field at the location of the

corresponding sens itive area. If a magnetic fiel d with

flux lines perpendicular to the sensitive area is

present, the biased Hall plate generate s a Hall voltage

proporti onal to this field. The Hal l voltage is compa red

with the actual thresho ld level in the comparato r. The

subblocks are designed to have closely matched

switching points.

The temperature-dependent bias – common to both

subblocks – increases the supply voltage of the Hall

plates and adjust s the switching poin ts to the de creasing induction of ma gnets a t highe r temperatu res. If the

magnetic field exceeds the threshold levels, the comparator switches to the appropri ate state. The built-in

hysteresis prevents oscillations of the outputs.

In order to achieve good matching of the switching

points of both subblocks, the magnetic offset caused

by mechanical stress is compensated for by use of

“switching offset compensation techniques”. Therefore,

an internal oscillator provides a two-phase clock to

both subblocks. For each subblock the Hall voltage is

sampled at the end of the first phase. At the end of the

second phase, both sampled and actual Hall voltages

are averaged and compared with the actual switching

point.

Clock

B

S1

BS1

on

B

S2

B

S2on

Count

Output

V

OH

V

OL

Direction

Output

V

OH

V

OL

I

I

dd

dd

1/f

osc

Fig. 2–1: Timing diagram

t

t

t

t

t

t

f

The output of comp arator 1 (co nnected to S1) directly

controls the ‘Cou nt Output’. The outputs of both comparators enter the ‘Dir ection Detection Block’ controlling the state of the ‘Direction Output’. The ‘Direction

Output’ is ’high’ if the edge at the output of

comparator 1 precedes that at comparator 2. In the

opposite case, ‘Directi on Output’ is ’low’. The previous

state of the ‘Direction Output’ is maintained be tween

edges of the ‘Count Output’ and i n case the edge s at

comparator 1 and comparator 2 occur in the same

clock period.

Shunt protection devices clamp voltage peaks at the

output pins and V

resistors. Reverse current is limited at the V

-pin together with external series

DD

DD

-pin by

an internal series resistor up to −15 V. No external

reverse protection diode is needed at the V

-pin for

DD

reverse voltages ranging from 0 V to −15 V.

Micronas 5

Page 6

HAL710 ADVANCE INFORMATION

V

4

GND

1

DD

Reverse

Voltage and

Overvoltage

Protection

Clock

Temperature

Dependent

Bias

Hall Plate 1

S1

Hall Plate 2

S2

Hysteresis

Control

Switch

Switch

Fig. 2–2: HAL 710 block diagram

Comparator

Comparator

Test-Mode

Control

Direction

Detection

Short Circuit

and

Overvoltage

Protection

Output

Output

3

Count Output

2

Direction Output

6 Micronas

Page 7

ADVANCE INFORMATION HAL710

4

3. Specifications

3.1. Outline Dimensions

4.55

±0.2

min.

0.25

1.15

SPGS0022-5-B4/1E

0.15

0.3

1.7

4

x1x

2

123

0.40.4

0.4

1.5

3.0

branded side

y

Fig. 3–1:

Plastic Small Outline Transistor Package

(SOT-89B)

Weight approximately 0.035 g

Dimensions in mm

sensitive area S

sensitive area S

2.55

0.06

∅0.2

1

2

∅0.2

top view

±0.04

3.2. Dimensions of Sensitive Areas

Dimensions: 0.25 mm × 0.12 mm

3.3. Positions of Sensitive Areas

SOT-89B

x

1+x2

x

1=x2

(2.35±0.001) mm

1.175 mm nominal

y 0.975 mm nominal

Note: For all package diagrams, a mechanical tolerance of ±0.05 mm applies to all dimen sions where no

tolerance is explicitly given.

Micronas 7

Page 8

HAL710 ADVANCE INFORMATION

3.4. Absolute Maximum Ratings

Symbol Parameter Pin No. Min. Max. Unit

28

100

1)

1)

1)

V

V

mA

3)

mA

V

-V

−I

I

DDZ

DD

P

DD

Supply Voltage 1 −15 28

Supply Voltage 1 −24

2)

Reverse Supply Current 1 − 50

Supply Current through Protection

1 −100

3)

Device

200

1)

1)

3)

3)

V

mA

mA

mA

V

O

I

O

I

Omax

I

OZ

Output Voltage 2, 3 −0.3 28

Continuous Output On Current 2, 3 − 20

Peak Output On Current 2, 3 − 150

Output Current through Protection

3 −200

3)

Device

170

150

5)

4)

°C

°C

°C

T

S

T

J

Storage Temperature Range −65 150

Junction Temperature Range −40

−40

1)

as long, as T

2)

with a 220-Ω series resistance at pin 1 corresponding to test circuit 1

3)

t < 2 ms

4)

t < 1000 h

5)

Components stored in the original packaging should provide a shelf life of at least 12 months, starting from the

is not exceeded

Jmax

date code printed on the labels, even in environments as extreme as 40 °C and 90% relative humidity.

Stresses beyond those listed in the “Absolute Maximum Ratings” may cause per ma nen t damage to the device. This

is a stress rating onl y. Functional operation of the device at these or any oth er condi tions beyond those indic ated i n

the “Rec ommended Operating Conditions/Character istics” of this specificati on is not i mplied. Ex posure to abs olute

maximum ratings conditions for extended periods may affect device reliability .

3.5. Re commended Operating Conditions

Symbol Parameter Pin No. Min. Typ. Max. Unit

V

DD

I

O

V

O

Supply Voltage 1 3.8 − 24 V

Continuous Output Current 3 0 − 10 mA

Output Voltage

30− 24 V

(output switch off)

8 Micronas

Page 9

ADVANCE INFORMATION HAL710

5.0

2.0

2.0

1.0

3.6. Electrical Characteristics

= −40 °C to +140 °C, VDD = 3.8 V to 24 V, as not otherwise specified in Conditions.

at T

J

Typical Characteristics for T

Symbol Parameter Pin No. Min. Typ. Max. Unit Conditions

= 25 °C and VDD = 5 V.

J

I

I

V

V

V

V

DD

DD

DDZ

OZ

OL

OL

Supply Current 1 2 5.5 9 mA TJ = 25 °C

Supply Current

over Temperature Range

Overvoltage Protection

at Supply

Overvoltage Protection

at Output

Output Voltage 2 ,3 130 280 mV IOL = 10 mA, TJ = 25 °C

Output Voltage over

Temperature Range

I

OH

I

OH

Output Leakage Current 2,3 0.06 0.1 µA Output switched off, TJ = 25 °C,

Output Leakage Current over

Temperature Range

f

osc

f

osc

t

(O) Enable Time of Output after

en

Internal sampling frequency − 130 150 − kHz TJ = 25 °C

Internal sampling frequency

over Temperature Range

Setting of V

DD

1710mA

1 28.5 32 V IDD = 25 mA, TJ = 25 °C, t = 20 ms

2,3 2832V IOH = 25 mA, TJ = 25 °C, t = 20 ms

2,3 130 400 mV IOL = 10 mA,

V

= 3.8 V to 24 V

OH

2,3 − 10 µA Output switched off, TJ ≤ 140 °C,

V

= 3.8 V to 24 V

OH

− 100 150 − kHz

50 100 µsVDD = 12 V,

B>B

+ 2 mT or B<B

on

− 2mT

off

t

r

t

f

R

thSB

SOT-89B

Output Rise Time 2,3 1.2 µsVDD = 12 V, RL= 20 kΩ, CL= 20 pF

Output FallTime 2,3 0.2 1.6 µsVDD = 12 V, RL= 20 kΩ, CL= 20 pF

Thermal Resistance Junction to

Substrate Backside

Fig. 3–2: Recommended pad size for SOT-89B

Dimensions in mm

−−150 200 K/W Fiberglass Substrate

30 mm x 10mm x 1.5mm,

pad size see Fig. 3–2

Micronas 9

Page 10

HAL710 ADVANCE INFORMATION

B

OFF

B

ON

0

V

OL

V

O

Output Voltage

B

B

HYS

3.7. Magnetic Characteristics

Fig. 3–3: Definition of magnetic switching points for

the HAL710

Positive flux density values refer to magnetic south

pole at the branded side of the package.

3.7.1. Magnetic Thresholds

(quasistationary: dB/dt<0.5 mT/ms)

at T

= −40 °C to + 140 °C, VDD = 3.8 V to 24 V, as not

J

otherwise specified

3.7.2. Matching B

and BS2

S1

(quasistationary: dB/dt<0.5mT/ms)

= −40 °C to +140 °C, VDD = 3.8 V to 24 V, as not

at T

J

otherwise specified

Typical Characteristics for T

Parameter

T

j

−40 °C −7.5 0 7.5 −7.5 0 7.5 mT

25 °C −7.5 0 7.5 −7.5 0 7.5 mT

100 °C −7.5 0 7.5 −7.5 0 7.5 mT

140 °C −7.5 0 7.5 −7.5 0 7.5 mT

B

− B

S1on

S2on

Min. Typ Max. Min. Typ Max.

= 25 °C and VDD = 5 V

J

B

− B

S1off

S2off

3.7.3. Hysteresis Matching

(quasistationary: dB/dt<0.5mT/ms)

= −40 °C to +140 °C, VDD = 3.8 V to 24 V, as not

at T

J

otherwise specified

Unit

Typical Characteristics for T

Parameter

T

j

−40 °C 12.5 16.3 20 −20 −16.3 −12.5 mT

25 °C 10.7 14.9 19.1 −19.1 −14.9 −10.7 mT

100 °C tbd tbd tbd tbd tbd tbd mT

140 °C 6.0 1 0.9 16.0 −16.0 −10.9 −6.0 mT

On point

B

S1on, BS2on

Min. Typ. Max. Min. Typ. Max.

= 25 °C and VDD = 5 V

J

Off point

B

, B

S1off,

S2off

Unit

Typical Characteristics for T

Parameter (B

T

j

−40 °C 0.85 1.0 1.2 −

25 °C 0.85 1.0 1.2 −

100 °C 0.85 1.0 1.2 −

140 °C 0.85 1.0 1.2 −

S1on

Min. Typ. Max.

= 25 °C and VDD = 5 V

J

− B

S1off

) / (B

S2on

− B

) Unit

S2off

10 Micronas

Page 11

ADVANCE INFORMATION HAL710

4. Application Notes

4.1. Ambient Temperature

Due to the intern al power dissipatio n, the temperature

on the silicon chip (junction temperature T

) is higher

J

than the temperature outside the package (ambient

temperature T

= TA + ∆T

T

J

).

A

At static conditions, the following equation is valid:

∆T = I

* VDD * R

DD

th

For typical values, use the typical parameters. For

worst case calculation, use the max. parameters for

I

and Rth, and the max. value for VDD from the appli-

DD

cation.

For all sensors, the junction temperature range T

specified. The maximum ambient temperature T

is

J

Amax

can be calculated as:

T

Amax

= T

Jmax

− ∆T

4.4. Test Mode Activation

In order to obtain the nor mal operation as described

above, two external pull-up resistors with app ropriate

values are required to connect each output to an external supply, such that the potential at the open-drain

output rises to at least 3 V in less than 10 µs after having turned off the corresponding pull-down transistor or

after having applied V

DD

.

If the ‘Direction Output’ is pulled low externally (the

potential does not rise after the internal pull-down transistor has been turned off), the device enters Manufacturer Test Mode.

Direction Detection is not functional in Manufacturer

Test Mode. The device retu rns to ‘Normal Opera tion’

as soon as the ‘Count Output’ goes high.

Please note, that the pre sence of a Ma nufacturer Test

Mode requires app ropriate measures to prevent accidental activation (e.g. in response to EMC events).

4.5. Start-up Behavior

4.2. Extended Operating Conditions

All sensors fulfil the ele ctric al and magneti c characteristics when operated within the Recommen ded Operating Conditions (see page 8)

Supply Voltage Below 3.8 V

Typically, the sensors operate with supply voltages

above 3 V, however, below 3.8 V some characteristics

may be outside the specification.

Note: The functionality of the sensor below 3.8 V is not

tested. For special test conditions, please contact Micronas.

4.3. Signal Delay

The extra circuitry r equired for the direction detection

increases the latency of the ‘Count and Direction Signal’ compared to a simple switch (e.g. HAL 525). This

extra delay corresponds to 0.5 and 1 clo ck period for

the ‘Direction Signal’ and ‘Count Signa l’ respectively.

Due to the active offset compensation, the sensors

have an initialization time (enable time t

applying the supply voltage. The parameter t

en(O)

) after

en(O)

is

specified in the Electrical Characteristics (see page 9)

During the initia lization time, the output sta tes are not

defined and the outputs can toggle. After t

en(O)

both

outputs will be either high or low for a stable magnetic

field (no toggling) and the ‘Count Output’ will be low if

the applied magneti c field B exceeds B

Output’ will be high if B drops below B

. The ‘Count

ON

. The ‘Direc-

OFF

tion Output’ will have the correct state after the se co nd

edge (rising or falling) in the same direction.

The device contains a Power-On Reset circuit (POR)

generating a reset when V

rises. This signal is used

DD

to initialize both outputs in the ‘Off-state’ (i.e. Output

High) and to dis able Test Mode. The generation of this

Reset Signal is guaranteed when V

at the chip rises

DD

to minimum 3.8 V in less than 4 µs monotonically. If

this condition is violated, the internal reset signal might

be missing. Under these circumstances the chip will

still operate according to the spec ification, but the risk

of toggling outputs during t

netic fields between B

OFF

of the Hall sensor after applying V

increases and for mag-

en(O)

and BON, the output states

will be either low

DD

or high. In order t o ac hieve a well defined ou tput state,

the applied mag netic field then must exceed B

respectively drop below B

OFFmin

.

ONmax

,

Micronas 11

Page 12

HAL710 ADVANCE INFORMATION

4.6. EMC and ESD

For applications that cause disturbances on the supply

line or radiated disturbances, a series resistor and a

capacitor are recommended (see Fig. 4–1). Th e series

resistor and the capac itor should b e placed as cl osely

as possible to the Hall sensor.

Please contact Micronas for detailed investigation

reports with EMC and ESD results.

R

V

220 Ω

V

1

DD

V

V

EMC

P

4.7 nF

4GND

3 Count Output

2 Direction Output

Fig. 4–1: Test circuit for EMC investigations

5. Data Sheet History

1. Advance Information: “HAL710 Hall-Effect Sensor

with Direction Detection”, Feb. 20, 2001,

6251-478-1AI. First release of the advance information.

R

2.4 kΩ

L

20 pF

R

2.4 kΩ

L

20 pF

Micronas GmbH

Hans-Bunte-Strasse 19

D-79108 Freiburg (Germany)

P.O. Box 840

D-79008 Freiburg (Germany)

Tel. +49-761-517-0

Fax +49-761-517-2174

E-mail: docservice@micronas.com

Internet: www.micronas.com

Printed in Germany

Order No. 6251-478-1AI

All information and data contained in this data sheet are without any

commitment, are not to be considered as an offer for conclusion of a

contract, nor shall they be construed as to create any liability. Any new

issue of this data sheet invalidates previous issues. Product availability

and delivery are exclusively subject to our respective order confirmation

form; the same applies to orders based on development samples delivered. By this publication, Micronas GmbH does not assume responsibility for patent infr ingements or other right s of third parties whic h may

result from its use.

Further, Micronas GmbH reserves the right to revise this publication and

to make changes to its conte nt, at any t ime, withou t obligatio n to noti fy

any person or entity of such revisions or changes.

No part of this publication may be reproduced, photocopied, stored on a

retrieval system, or transmitted without the express written consent of

Micronas GmbH .

12 Micronas

Loading...

Loading...