Datasheet GS818QV36D-333I, GS818QV36D-333, GS818QV36D-300I, GS818QV36D-300, GS818QV36D-250I Datasheet (GSI)

...Page 1

Rev: 1.01 11/2002 1/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

18Mb Σ2x2B2V

SigmaQuad SRAM

133 MHz–200 MHz

2.5 V V

DD

1.8 V and 1.5 V I/O

165-Bump BGA

Commercial Temp

Industrial Temp

Features

• Simultaneous Read and Write SigmaQuad™ Interface

• JEDEC-standard pinout and package

• Dual DoubleData Rate interface

• Echo Clock outputs track data output drivers

• Byte Write controls sampled at data-in time

• Burst of 2 Read and Write

• 1.5 V or 1.8 V HSTL Interface

• Pipelined read operation

• Fully coherent read and write pipelines

• ZQ mode pin for programmable output drive strength

• IEEE 1149.1 JTAG-compliant Boundary Scan

• 165-bump, 13 mm x 15 mm, 1 mm bump pitch BGA package

• Pin-compatible with future 36Mb, 72Mb, and 144Mb devices

SigmaRAM™ Family Overview

GS818QV18/36 are built in compliance with the SigmaQuad SRAM

pinout standard for Separate I/O synchronous SRAMs. They

are18,874,368-bit (18Mb) SRAMs. These are the first in a family of

wide, very low voltage HSTL I/O SRAMs designed to operate at the

speeds needed to implement economical high performance

networking systems.

SigmaQuad SRAMs are offered in a number of configurations. Some

emulate and enhance other synchronous separate I/O SRAMs. A

higher performance SDR (Single Data Rate) Burst of 2 versionis also

offered. The logical differences between the protocols employed by

these RAMs hinge mainly on various combinations of address

bursting, output data registering, and write cueing. Along with the

Common I/O family of SigmaRAMs, the SigmaQuad family of SRAMs

allows a user to implement the interface protocol best suited to the

task at hand.

Clocking and Addressing Schemes

A Σ2x2B2SigmaQuad SRAM is a synchronous device. It employs two

input register clock inputs, K and K

. K and K are independent singleended clock inputs, not differential inputs to a single differential clock

input buffer. The device also allows the user to manipulate the output

register clock inputs quasi independently with the C and C

clock

inputs. C and C

are also independent single-ended clock inputs, not

differential inputs. If the C clocks are tied high, the K clocks are routed

internally to fire the output registers instead. Each

Σ

2x2B2 igmaQuad

SRAM also supplies Echo Clock outputs, CQ and CQ

, that are

synchronized with read data output. When used in a source

synchronous clocking scheme, these Echo Clock outputs can be used

to fire input registers at the data’s destination.

Because Separate I/O

Σ

2x2B2 RAMs always transfer data in two

packets, A0 is internally set to 0 for the first read or write transfer, and

automatically incremented by 1 for the next transfer. Because the LSB

is tied off internally, the address field of a

Σ

2x2B2 RAM is always one

address pin less than the advertised index depth (e.g., the 1M x 18

has a 512K addressable index).

-200 -167 -133

tKHKH 5.0 ns 6.0 ns 7.5 ns

tKHQV 2.3 ns 2.5 ns 3.0 ns

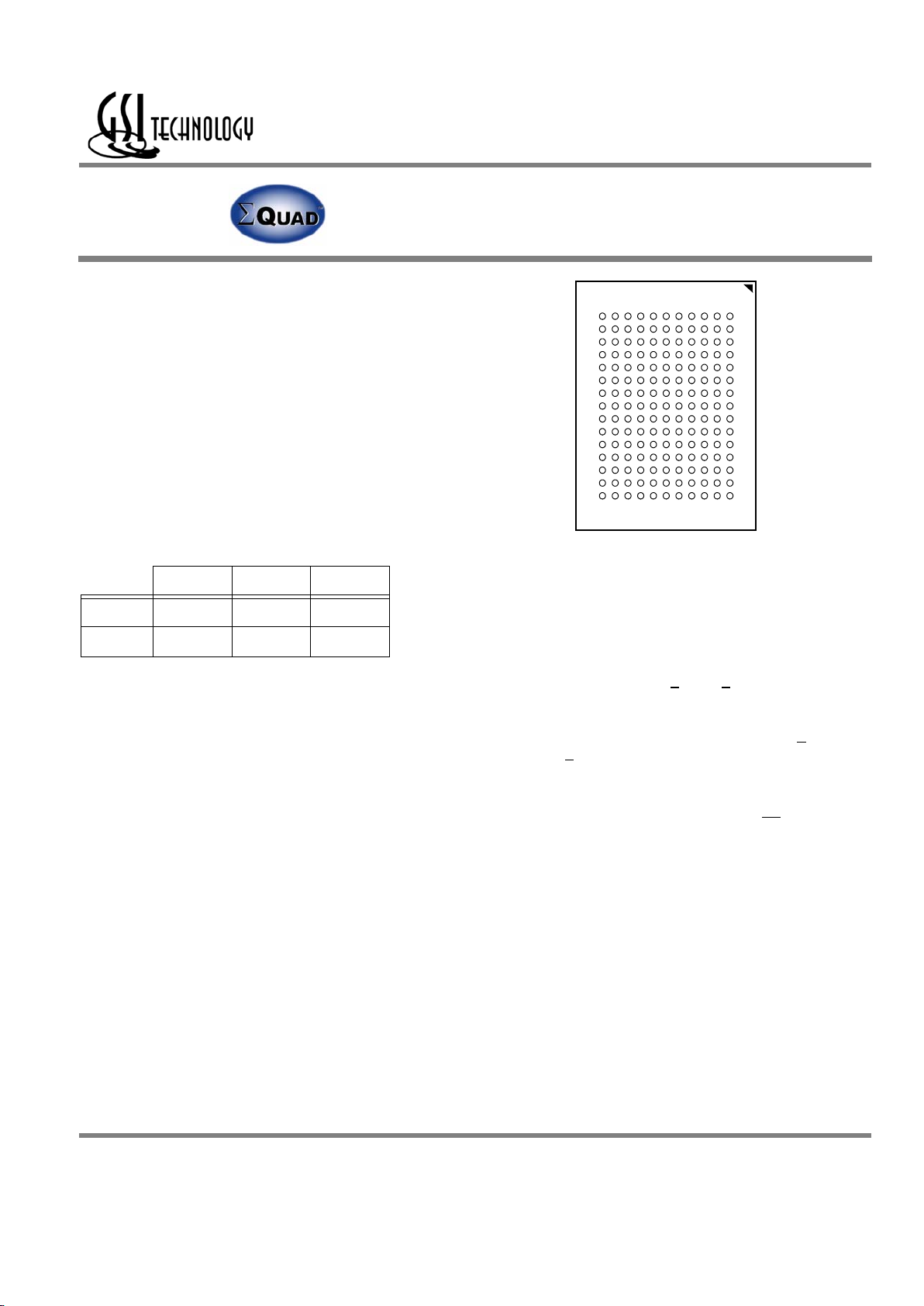

165-Bump, 13 mm x 15 mm BGA

1 mm Bump Pitch, 11 x 15 Bump Array

Bottom View

JEDEC Std. MO-216, Variation CAB-1

Page 2

Rev: 1.01 11/2002 2/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

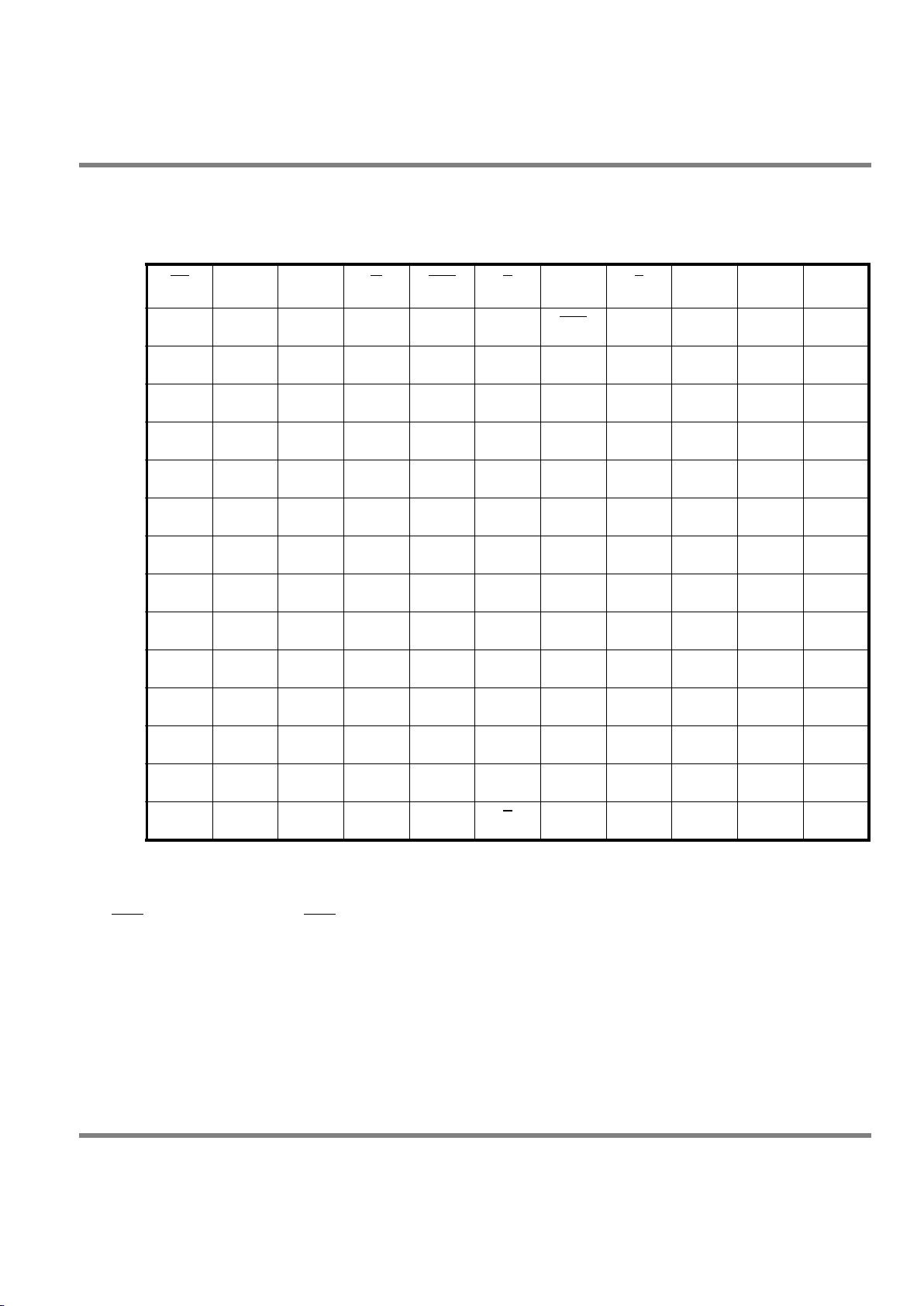

1M x 18 SigmaQuad SRAM — Top View

1234567891011

A CQ

MCL/SA

(144Mb)

NC/SA

(36Mb)

W

BW1 K NC R SA

MCL/SA

(72Mb)

CQ

B NC Q9 D9 SA NC K BW0

SA NC NC Q8

C NC NC D10 V

SS

SA

SA SA V

SS

NC Q7 D8

D NC D11 Q10 V

SS

V

SS

V

SS

V

SS

V

SS

NC NC D7

E NC NC Q11 V

DDQ

V

SS

V

SS

V

SS

V

DDQ

NC D6 Q6

F NC Q12 D12 V

DDQ

V

DD

V

SS

V

DD

V

DDQ

NC NC Q5

G NC D13 Q13 V

DDQ

V

DD

V

SS

V

DD

V

DDQ

NC NC D5

H NC V

REF

V

DDQ

V

DDQ

V

DD

V

SS

V

DD

V

DDQ

V

DDQ

V

REF

ZQ

J NC NC D14 V

DDQ

V

DD

V

SS

V

DD

V

DDQ

NC Q4 D4

K NC NC Q14 V

DDQ

V

DD

V

SS

V

DD

V

DDQ

NC D3 Q3

L NC Q15 D15 V

DDQ

V

SS

V

SS

V

SS

V

DDQ

NC NC Q2

M NC NC D16 V

SS

V

SS

V

SS

V

SS

V

SS

NC Q1 D2

N NC D17 Q16 V

SS

SA SA SA V

SS

NC NC D1

P NC NC Q17 SA SA C SA SA NC D0 Q0

R TDO TCK SA SA SA C

SA SA SA TMS TDI

11 x 15 Bump BGA—13 x 15 mm2 Body—1 mm Bump Pitch

Notes:

1. Expansion addresses: A3 for 36Mb, A10 for 72Mb, A2 for 144Mb

2. BW0

controls writes to D0:D8. BW1 controls writes to D9:D17.

3. MCL = Must Connect Low

4. It is recommended that H1 be tied low for compatibility with future devices.

Page 3

Rev: 1.01 11/2002 3/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

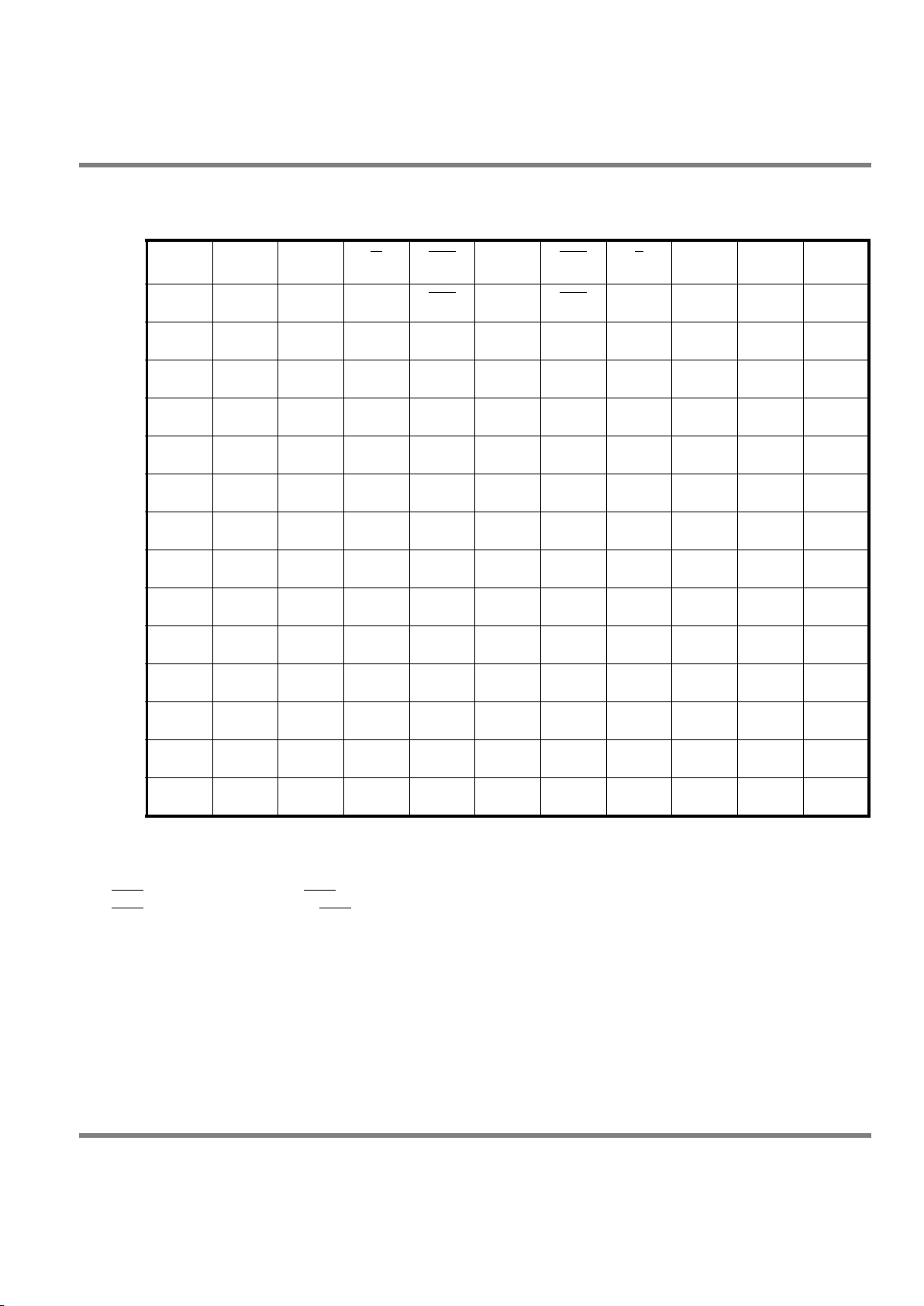

512K x 36 SigmaQuad SRAM — Top View

1234567891011

A

MCL/SA

(288Mb)

NC/SA

(72Mb)

W

BW2 BW1 R

NC/SA

(36Mb)

MCL/SA

(144Mb)

CQ

B Q27 Q18 D18 SA BW3

KBW0SA D17 Q17 Q8

C D27 Q28 D19 V

SS

SA

SA SA V

SS

D16 Q7 D8

D D28 D20 Q19 V

SS

V

SS

V

SS

V

SS

V

SS

Q16 D15 D7

E Q29 D29 Q20 V

DDQ

V

SS

V

SS

V

SS

V

DDQ

Q15 D6 Q6

F Q30 Q21 D21 V

DDQ

V

DD

V

SS

V

DD

V

DDQ

D14 Q14 Q5

G D30 D22 Q22 V

DDQ

V

DD

V

SS

V

DD

V

DDQ

Q13 D13 D5

H NC V

REF

V

DDQ

V

DDQ

V

DD

V

SS

V

DD

V

DDQ

V

DDQ

V

REF

ZQ

J D31 Q31 D23 V

DDQ

V

DD

V

SS

V

DD

V

DDQ

D12 Q4 D4

K Q32 D32 Q23 V

DDQ

V

DD

V

SS

V

DD

V

DDQ

Q12 D3 Q3

L Q33 Q24 D24 V

DDQ

V

SS

V

SS

V

SS

V

DDQ

D11 Q11 Q2

M D33 Q34 D25 V

SS

V

SS

V

SS

V

SS

V

SS

D10 Q1 D2

N D34 D26 Q25 V

SS

SA SA SA V

SS

Q10 D9 D1

P Q35 D35 Q26 SA SA C SA SA Q9 D0 Q0

R TDO TCK SA SA SA SA SA SA TMS TDI

11 x 15 Bump BGA—13 x 15 mm2 Body—1 mm Bump Pitch

Notes:

1. Expansion addresses: A9 for 36Mb, A3 for 72Mb, A10 for 144Mb, A2 for 288Mb

2. BW0

controls writes to D0:D8. BW1 controls writes to D9:D17.

3. BW2

controls writes to D18:D26. BW3 controls writes to D27:D35.

4. MCL = Must Connect Low

5. It is recommended that H1 be tied low for compatibility with future devices.

Page 4

Rev: 1.01 11/2002 4/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

Note: NC = Not Connected to die or any other pin

Background

Separate I/O SRAMs, from a system architecture point of view, are attractive in applications where alternating reads and writes are needed.

Therefore, the SigmaQuad SRAM interface and truth table are optimized for alternating reads and writes. Separate I/O SRAMs are unpopular in

applications where multiple reads or multiple writes are needed because burst read or write transfers from Separate I/O SRAMs can cut the

RAM’s bandwidth in half.

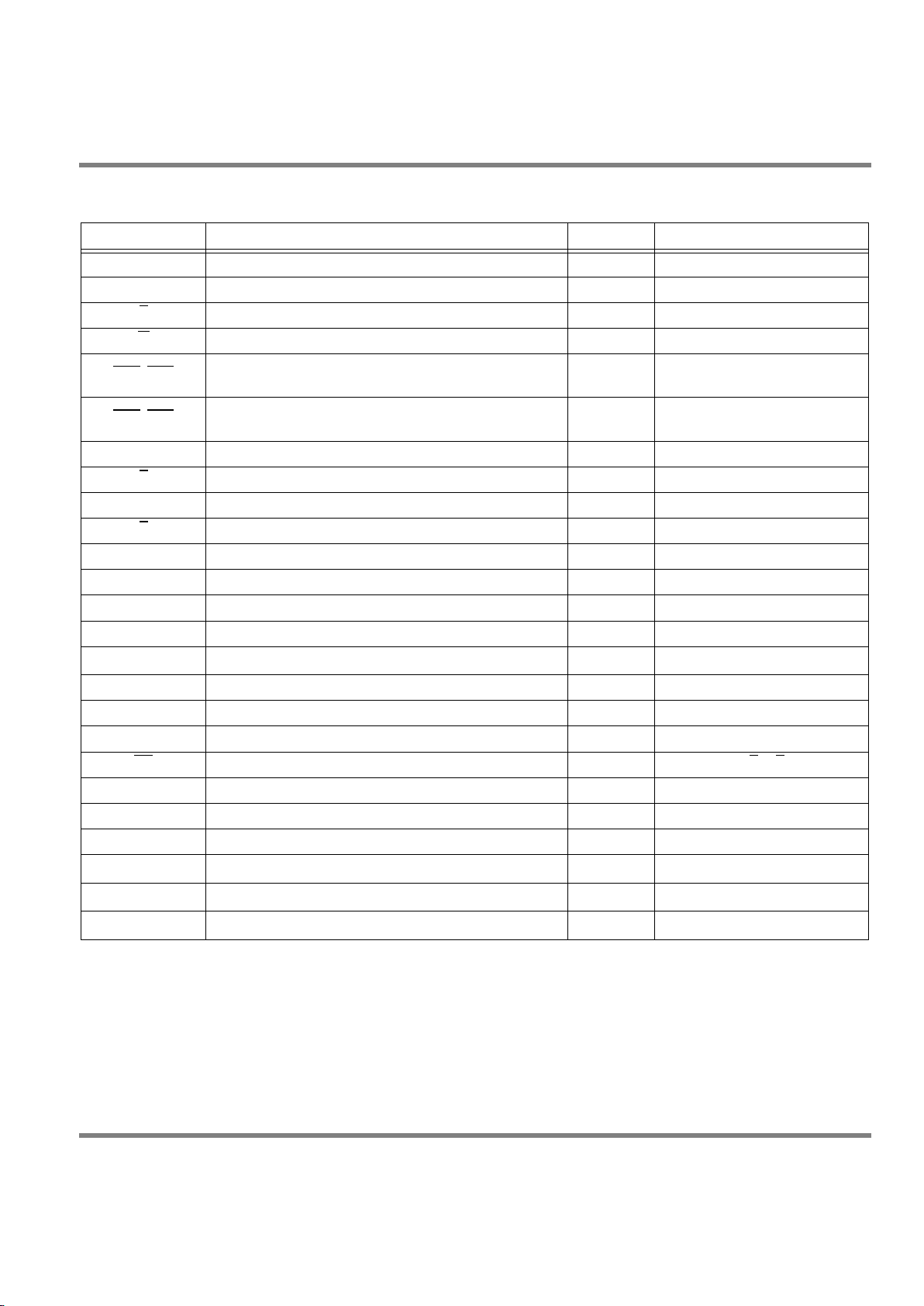

Pin Description Table

Symbol Description Type Comments

SA Synchronous Address Inputs Input —

NC No Connect — —

R

Synchronous Read Input Active Low

W

Synchronous Write Input Active Low

BW0

–BW1 Synchronous Byte Writes Input

Active Low

x18 Version

BW0

–BW3 Synchronous Byte Writes Input

Active Low

x36 Version

K Input Clock Input Active High

K

Input Clock Input Active Low

C Output Clock Input Active High

C

Output Clock Input Active Low

TMS Test Mode Select Input —

TDI Test Data Input Input —

TCK Test Clock Input Input —

TDO Test Data Output Output —

V

REF

HSTL Input Reference Voltage Input —

ZQ Output Impedance Matching Input Input —

MCL Must Connect Low — —

CQ Synchronous Echo Clock Output Output Echoes C or K Clock

CQ

Synchronous Echo Clock-bar Output Output Echoes C or K Clock

Q0–Q35 Synchronous Data Outputs Output x36 Version

D0–D17 Synchronous Data Inputs Input x18 Version

Q0–Q17 Synchronous Data Outputs Output x18 Version

V

DD

Power Supply Supply 2.5 V Nominal

V

DDQ

Isolated Output Buffer Supply Supply 1.5 V Nominal

V

SS

Power Supply: Ground Supply —

Page 5

Rev: 1.01 11/2002 5/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

A SigmaQuad SRAM can begin an alternating sequence of reads and writes with either a read or a write. In order for any separate I/O SRAM that

shares a common address between its two ports to keep both ports running all the time, the RAM must implement some sort of burst transfer

protocol. The burst must be at least long enough to cover the time the opposite port is receiving instructions on what to do next. The rate at which

a RAM can accept a new random address is the most fundamental performance metric for the RAM. Each of the three SigmaQuad SRAMs

support similar address rates because random address rate is determined by the internal performance of the RAM and they are all based on the

same internal circuits. Differences between the truth tables of the different SigmaQuad SRAMs, or any other Separate I/O SRAMs, follow from

differences in how the RAM’s interface is contrived to interact with the rest of the system. Each mode of operation has its own advantages and

disadvantages. The user should consider the nature of the work to be done by the RAM to evaluate which version is best suited to the application

at hand.

Alternating Read-Write Operations

SigmaQuad SRAMs follow a few simple rules of operation.

- Read or Write commands issued on one port are never allowed to interrupt an operation in progress on the other port.

- Read or Write data transfers in progress may not be interrupted and re-started.

- R

and W high always deselects the RAM but does not disable the CQ or CQ output pins.

- All address, data, and control inputs are sampled on clock edges.

In order to enforce these rules, each RAM combines present state information with command inputs. See the Truth Table for details.

Page 6

Rev: 1.01 11/2002 6/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

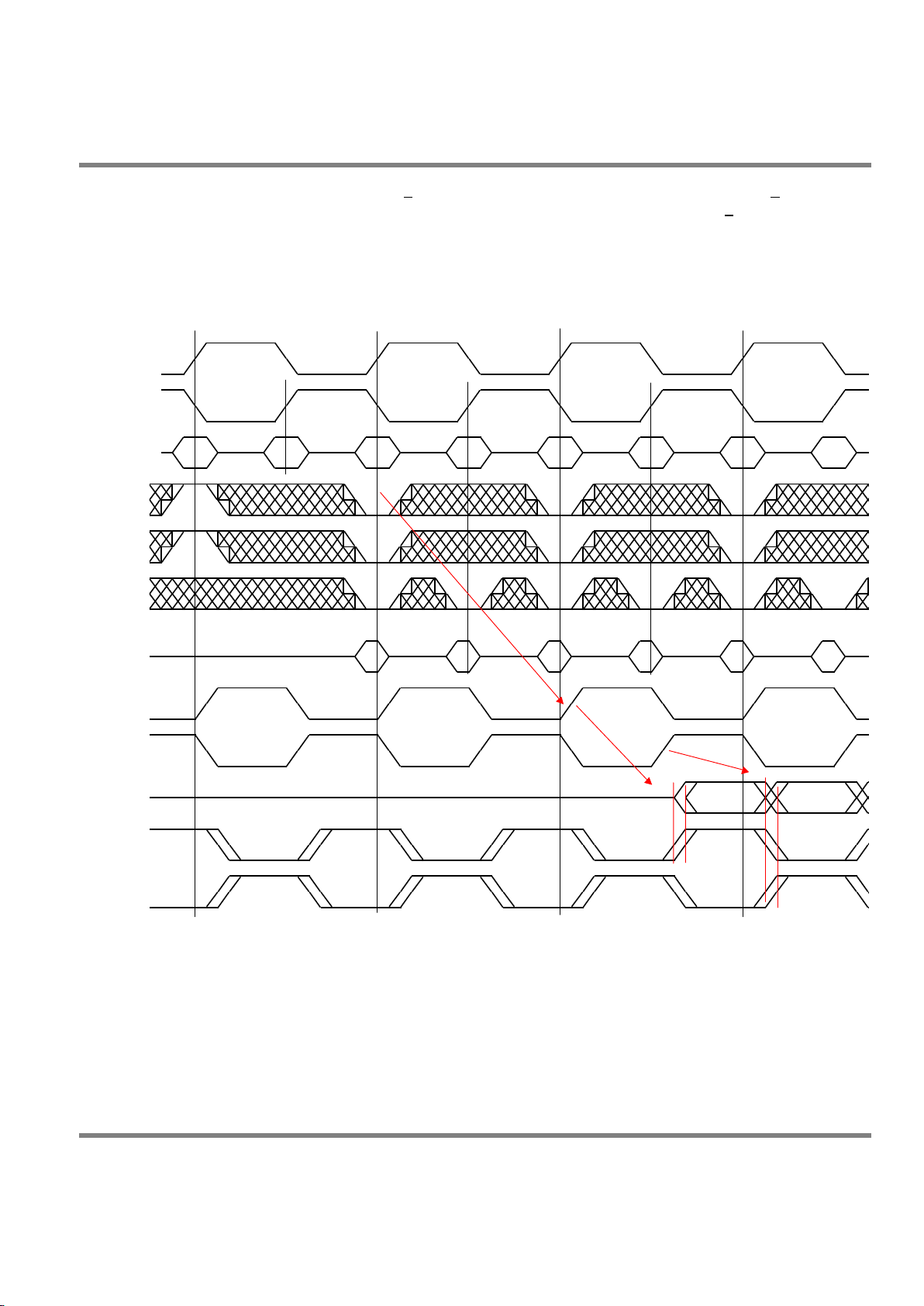

Σ

2x2B2 SigmaQuad SRAM DDR Read

The read port samples the status of the Address Input and R

pins at each rising edge of K. A low on the Read Enable-bar pin, R, begins a read

cycle. Data can be clocked out one cycle later and again one half cycle after that. A high on the Read Enable-bar pin, R

, begins a read port

deselect cycle.

Σ

2x2B2 Double Data Rate SigmaQuad SRAM Read First

Dwg Re v. G

DC0 DC1 DE0 DE1 DG0 DG1

Wri t eRead

GF

No Op

C

/C

CQ

D

Q

/R

/W

/BWx

/CQ

Wri t e

XX

K

/K

Address XX B C D

No Op Read Write Read

QB0 QB1

E

Page 7

Rev: 1.01 11/2002 7/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

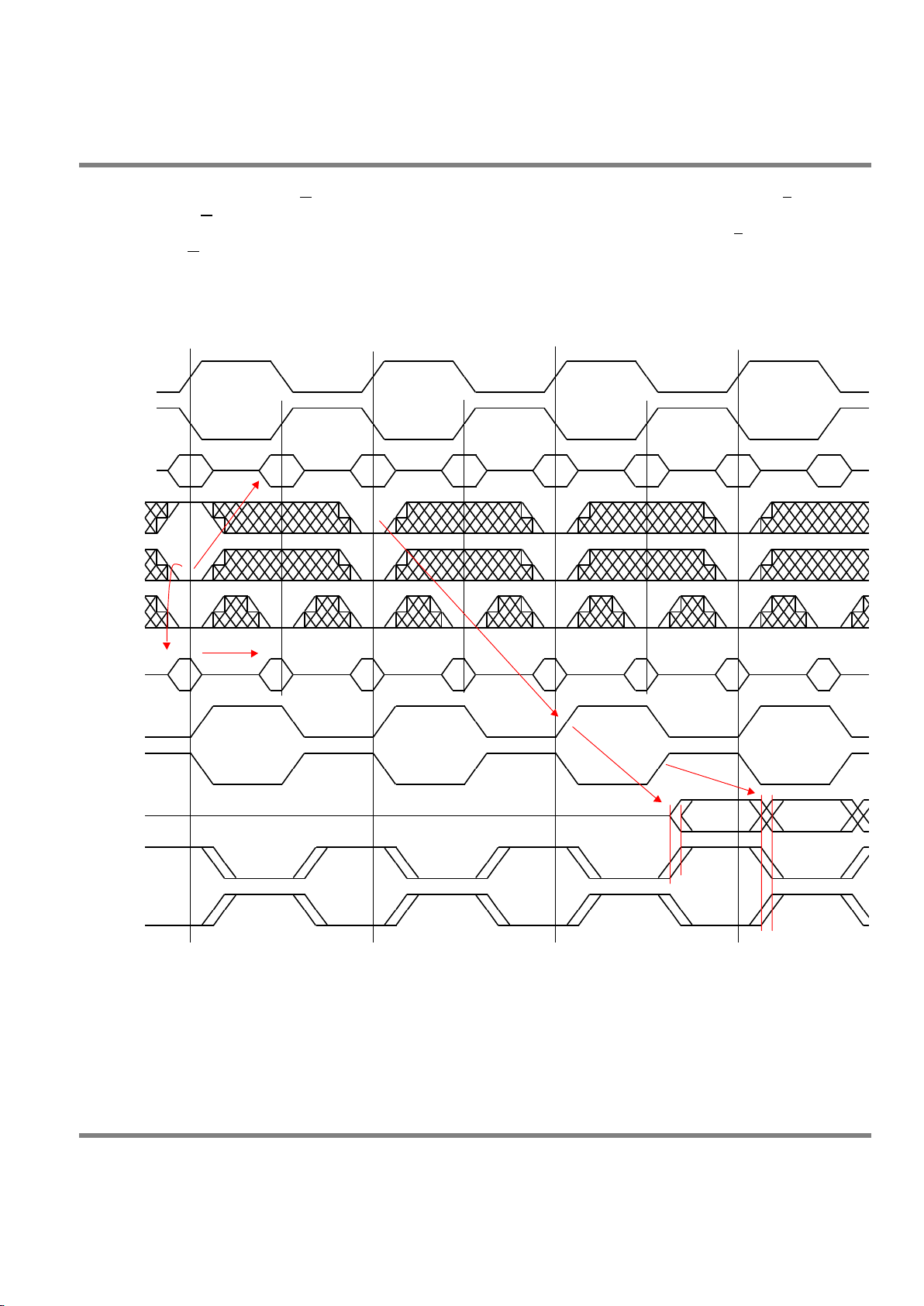

Σ

2x2B2 SigmaQuad SRAM DDR Write

The write port samples the status of the W

pin at each rising edge of K and the Address Input pins on the following rising edge of K. A low on the

Write Enable-bar pin, W

, begins a write cycle. The first of the data-in pairs associated with the write command is clocked in with the same rising

edge of K used to capture the write command. The second of the two data in transfers is captured on the rising edge of K

along with the write

address. A high on W

causes a write port deselect cycle.

Σ2x2B2 Double Data Rate SigmaQuad SRAM Write First

Dwg Re v. G

DB0 DB1 DD0 DD1 DF0 DF1 DH0 DH1

Wri t eRead

H

QC0 QC1

G

Wri t e Rea d Wr it e

C

/R

/W

/BWx

Read Write

AddressXXBCDE F

No Op

/C

CQ

/CQ

K

/K

D

Q

Page 8

Rev: 1.01 11/2002 8/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

Special Functions

Byte Write Control

Byte Write Enable pins are sampled at the same time that Data In is sampled. A high on the Byte Write Enable pin associated with a particular

byte (e.g., BW0

controls D0–D8 inputs) will inhibit the storage of that particular byte, leaving whatever data may be stored at the current address

at that byte location undisturbed. Any or all of the Byte Write Enable pins may be driven high or low during the data in sample times in a write

sequence.

Each write enable command and write address loaded into the RAM provides the base address for a 2 beat data transfer. The x18 version of the

RAM, for example, may write 36 bits in association with each address loaded. Any 9-bit byte may be masked in any write sequence.

Example x18 RAM Write Sequence using Byte Write Enables

Resulting Write Operation

Output Register Control

SigmaQuad SRAMs offer two mechanisms for controlling the output data registers. Typically, control is handled by the Output Register Clock

inputs, C and C

. The Output Register Clock inputs can be used to make small phase adjustments in the firing of the output registers by allowing

the user to delay driving data out as much as a few nanoseconds beyond the next rising edges of the K and K

clocks. If the C and C clock inputs

are tied high, the RAM reverts to K and K

control of the outputs, allowing the RAM to function as a conventional pipelined read SRAM.

Echo Clock

SigmaQuad SRAMs feature Echo Clock outputs, CQ and CQ

, that track the performance of the output drivers. The Echo Clocks are delayed

copies of the Output Register clocks, C and C

or K and K (if the C and C clock inputs are tied high). Echo Clocks are designed to track changes

in output driver delays due to variance in die temperature and supply voltage. The Echo Clocks are designed to fire with the rest of the data

output drivers. SigmaQuad SRAMs provide both in-phase, or true, Echo Clock output, CQ and inverted Echo Clock output CQ

.

Echo Clocks are always active.

Neither inhibiting reads via holding R

high, nor deselection of the RAM via holding R and W high will

deactivate the Echo Clocks.

Data In Sample

Time

BW0 BW1 D0–D8 D9–D17

Beat 1 0 1 Data In Don’t Care

Beat 2 1 0 Don’t Care Data In

Byte 1

D0–D8

Byte 2

D9–D17

Byte 3

D0–D8

Byte 4

D9–D17

Written Unchanged Unchanged Written

Page 9

Rev: 1.01 11/2002 9/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

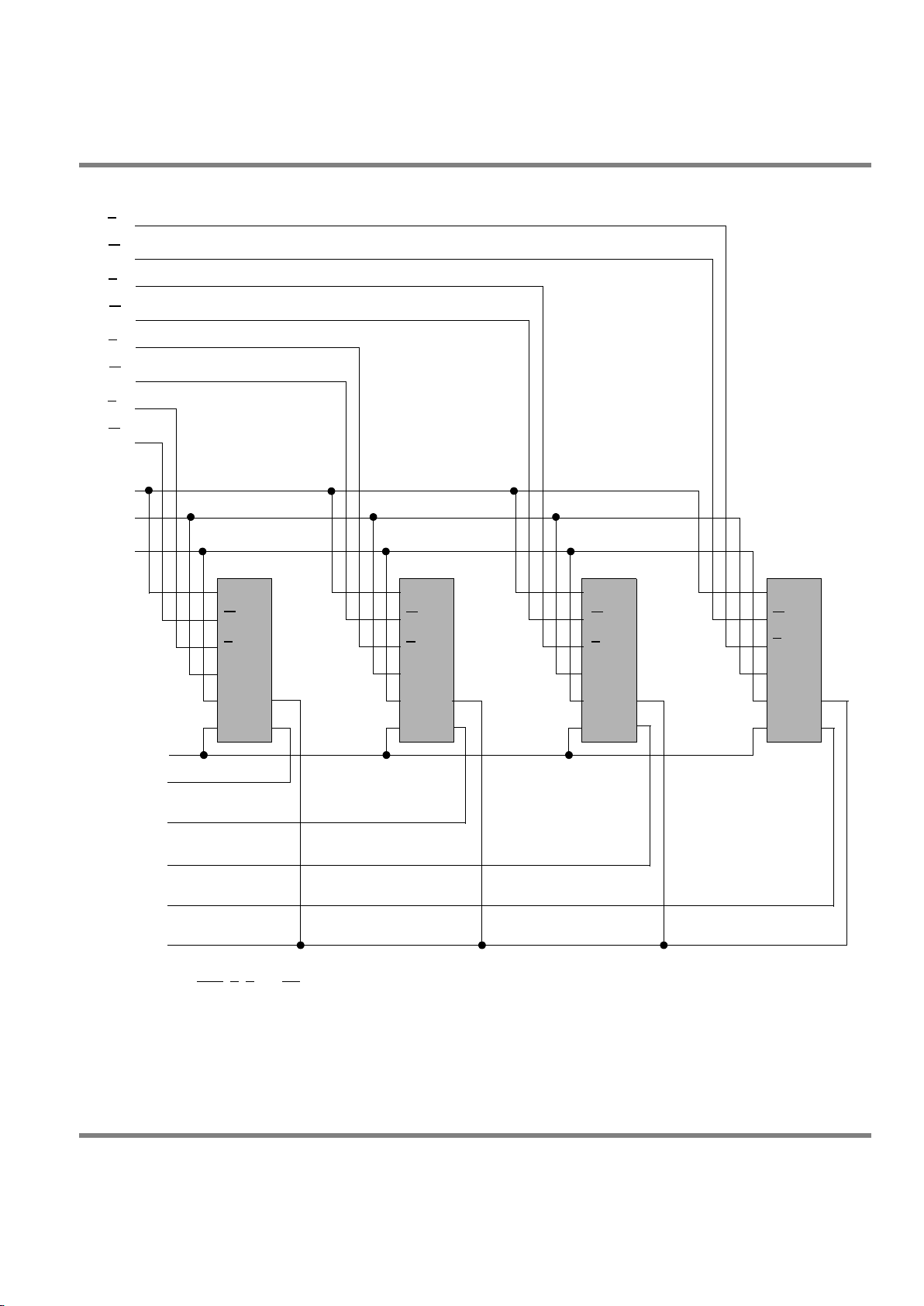

Example Four Bank Depth Expansion Schematic

A

K

R

W

A0–A

n

K

W

0

D1–D

n

Bank 0

Bank 1 Bank 2

Bank 3

R

0

CQ

D

A

K

W

CQ

D

A

K

W

CQ

D

A

K

W

CQ

D

R

R

R

QQQ Q

CC CC

Q1–Q

n

C

CQ

0

CQ

1

CQ

2

CQ

3

W

1

R

1

W

2

R

2

W

3

R

3

Note: For simplicity BWn, K, C and CQ are not shown.

Page 10

Rev: 1.01 11/2002 10/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

Σ

2x2B2 SigmaQuad SRAM Depth Expansion

FLXDrive-II Output Driver Impedance Control

HSTL I/O SigmaQuad SRAMs are supplied with programmable impedance output drivers. The ZQ pin must be connected to V

SS

via an external

resistor, RQ, to allow the SRAM to monitor and adjust its output driver impedance. The value of RQ must be 5X the value of the intended line

impedance driven by the SRAM. The allowable range of RQ to guarantee impedance matching with a vendor-specified tolerance is between

150Ω and 300Ω. Periodic readjustment of the output driver impedance is necessary as the impedance is affected by drifts in supply voltage and

temperature. A clock cycle counter periodically triggers an impedance evaluation, resets and counts again. Each impedance evaluation may

move the output driver impedance level one step at a time towards the optimum level. The output driver is implemented with discrete binary

Dwg Re v. G

DG0 DG1

DC0 DC1 DE0 DE1

QB0 QB1 QD0

QD0

Q

Bank 2

QB0 QB1

/W2

D

Bank 1

D

Bank 2

C

No Op Read Write Read Write Read Write

- Bank 2 Bank 2 Bank 1 Bank 2 Bank 1 Bank 1

Q Bank 1 +

Q Bank 2

CQ

Bank 1

CQ

Bank 2

/C

Q

Bank 1

K

/K

G

/R1

HEFAddress XX B

/R2

/W1

CD

Page 11

Rev: 1.01 11/2002 11/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

weighted impedance steps. Impedance updates for “0s” occur whenever the SRAM is driving “1s” for the same DQs (and vice-versa for “1s”) or

the SRAM is in HI-Z. The SRAM requires 32K start-up cycles, selected or deselected, after V

DD

reaches its operating range to reach its

programmed output driver impedance.

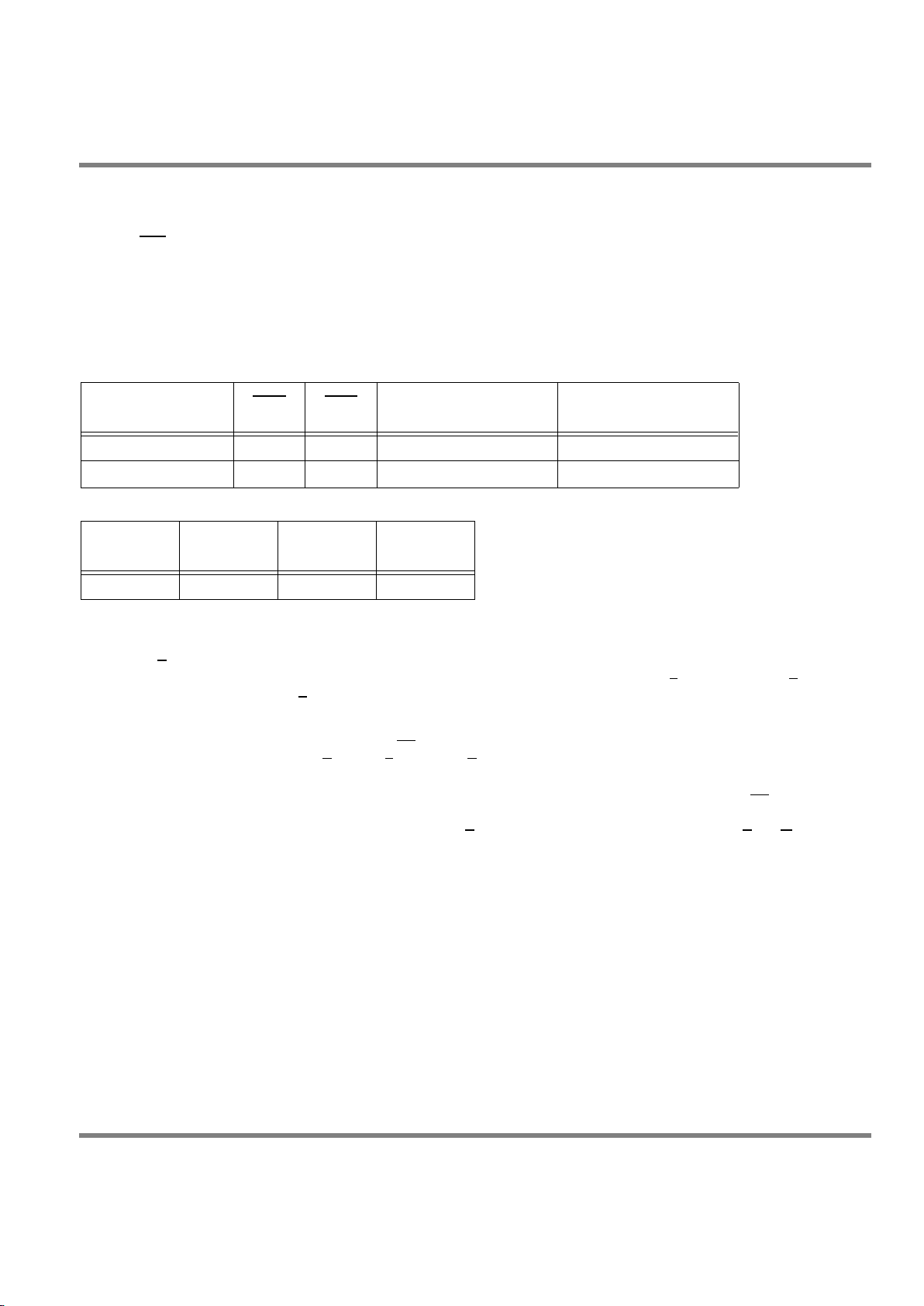

Σ

2x2B2 Coherency and Pass Through Functions

Because the

Σ

2x2B2 read and write commands are loaded at the same time, there may be some confusion over what constitutes “coherent”

operation. Normally, one would expect a RAM to produce the just-written data when it is read immediately after a write. This is true of the

Σ

2x2B2 except in one case, as is illustrated in the following diagram. If the user holds the same address value in a given K clock cycle, loading

the same address as a read address and then as a matching write address, the

Σ

2x2B2 will read or “Pass-thru” the latest data input, rather than

the data from the previously completed write operation.

Σ

2x2B2 Coherency and Pass Through Functions

Dwg Rev. G

DB0 DB1 DD0 DD1 DF0 DF1 DH0 DH1 DI0

QA0 QA 1 QC0 QC 1 QE0 QE1

HIABCD EFG

4682719

??

5

/C

CQ

/CQ

K

/K

D

Q

Read Wri te

Add re ss

OO OI OI OO OO OO

Read Wri te Read Wri te

C

/R

/W

/BWx

71

WriteRead

OOIO

56

OI

3

COHERENT

PAS S- THRU

Page 12

Rev: 1.01 11/2002 12/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

Separate I/O Σ2x2B2 SigmaQuad SRAM Read Truth Table

Separate I/O Σ2x2B2 SigmaQuad SRAM Write Truth Table

AR Output Next State Q Q

K

↑

(tn)

K

↑

(tn)

K

↑

(tn)

K

↑

(t

n+1

)

K

↑

(t

n+1½

)

X 1 Deselect Hi-Z Hi-Z

V 0 Read Q0 Q1

Notes:

1. X = Don’t Care, 1 = High, 0 = Low, V = Valid.

2. R

is evaluated on the rising edge of K.

3. Q0 and Q1 are the first and second data output transfers in a read.

AWBWn BWn Input Next State D D

K ↑

(t

n + ½

)

K ↑

(tn)

K ↑

(tn)

K ↑

(t

n + ½

)

K ↑, K ↑

(tn), (tn + ½)

K ↑

(tn)

K ↑

(t

n + ½

)

V 0 0 0 Write Byte Dx0, Write Byte Dx1 D0 D1

V 0 0 1 Write Byte Dx0, Write Abort Byte Dx1 D0 X

V 0 1 0 Write Abort Byte Dx0, Write Byte Dx1 X D1

X 0 1 1 Write Abort Byte Dx0, Write Abort Byte Dx1 X X

X1XX Deselect X X

Notes:

1. X = Don’t Care, H = High, L = Low, V = Valid.

2. W

is evaluated on the rising edge of K.

3. D0 and D1 are the first and second data input transfers in a write.

4. BWn

represents any of the Byte Write Enable inputs (BW0, BW1, etc.).

Page 13

Rev: 1.01 11/2002 13/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

x36 Byte Write Enable (BWn) Truth Table

x18 Byte Write Enable (BWn) Truth Table

BW0 BW1 BW2 BW3 D0–D8 D9–D17 D18–D26 D27–D35

1 1 1 1 Don’t Care Don’t Care Don’t Care Don’t Care

0 1 1 1 Data In Don’t Care Don’t Care Don’t Care

1 0 1 1 Don’t Care Data In Don’t Care Don’t Care

0 0 1 1 Data In Data In Don’t Care Don’t Care

1 1 0 1 Don’t Care Don’t Care Data In Don’t Care

0 1 0 1 Data In Don’t Care Data In Don’t Care

1 0 0 1 Don’t Care Data In Data In Don’t Care

0 0 0 1 Data In Data In Data In Don’t Care

1 1 1 0 Don’t Care Don’t Care Don’t Care Data In

0 1 1 0 Data In Don’t Care Don’t Care Data In

1 0 1 0 Don’t Care Data In Don’t Care Data In

0 0 1 0 Data In Data In Don’t Care Data In

1 1 0 0 Don’t Care Don’t Care Data In Data In

0 1 0 0 Data In Don’t Care Data In Data In

1 0 0 0 Don’t Care Data In Data In Data In

0 0 0 0 Data In Data In Data In Data In

BW0 BW1 D0–D8 D9–D17

1 1 Don’t Care Don’t Care

0 1 Data In Don’t Care

1 0 Don’t Care Data In

0 0 Data In Data In

Page 14

Rev: 1.01 11/2002 14/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

Recommended Operating Conditions

Absolute Maximum Ratings

(All voltages reference to V

SS

)

Symbol Description Value Unit

V

DD

Voltage on VDD Pins

–0.5 to 3.6 V

V

DDQ

Voltage in V

DDQ

Pins

–0.5 to 2.5 V

V

REF

Voltage in V

REF

Pins –0.5 to V

DDQ

V

V

I/O

Voltage on I/O Pins

–0.5 to V

DDQ

+0.5 (≤ 2.5 V max.)

V

V

IN

Voltage on Other Input Pins

–0.5 to V

DDQ

+0.5 (≤ 2.5 V max.)

V

I

IN

Input Current on Any Pin +/–100 mA dc

I

OUT

Output Current on Any I/O Pin +/–100 mA dc

T

J

Maximum Junction Temperature 125

o

C

T

STG

Storage Temperature –55 to 125

o

C

Note:

Permanent damage to the device may occur if the Absolute Maximum Ratings are exceeded. Operation should be restricted to Recommended

Operating Conditions. Exposure to conditions exceeding the Recommended Operating Conditions, for an extended period of time, may affect

reliability of this component.

Power Supplies

Parameter Symbol Min. Typ. Max. Unit Notes

Supply Voltage

V

DD

2.4 2.5 2.6 V

1.8 V I/O Supply Voltage

V

DDQ

1.7 1.8 1.95 V 1

1.5 V I/O Supply Voltage

V

DDQ

1.4 1.5 1.6 V 1

Ambient Temperature

(Commercial Range Versions)

T

A

02570°C2

Ambient Temperature

(Industrial Range Versions)

T

A

–40 25 85 °C2

Notes:

1. Unless otherwise noted, all performance specifications quoted are evaluated for worst case at both 1.4 V ≤ V

DDQ

≤ 1.6 V (i.e., 1.5 V I/O)

and 1.7 V ≤ V

DDQ

≤ 1.95 V (i.e., 1.8 V I/O) and quoted at whichever condition is worst case.

2. The power supplies need to be powered up simultaneously or in the following sequence: V

DD

,

V

DDQ

, V

REF

, followed by signal inputs. The

power down sequence must be the reverse. V

DDQ

must not exceed VDD.

3. Most speed grades and configurations of this device are offered in both Commercial and Industrial Temperature ranges. The part number

of Industrial Temperature Range versions end the character “I”. Unless otherwise noted, all performance specifications quoted are

evaluated for worst case in the temperature range marked on the device.

Page 15

Rev: 1.01 11/2002 15/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

HSTL I/O AC Input Definitions

HSTL I/O DC Input Characteristics

Parameter Symbol Min Max Units Notes

DC Input Logic High

V

IH

(dc) V

REF

+ 200

mV 1

DC Input Logic Low

V

IL

(dc) V

REF

– 200

mV 1

V

REF

DC Voltage V

REF

(dc) V

DDQ

(min)/2 V

DDQ

(max)/2

V1

Notes:

1. Compatible with both 1.8 V and 1.5 V I/O drivers

HSTL I/O AC Input Characteristics

Parameter Symbol Min Max Units Notes

AC Input Logic High

V

IH

(ac) V

REF

+ 400

mV 3,4

AC Input Logic Low

V

IL

(ac) V

REF

– 400

mV 3,4

V

REF

Peak to Peak AC Voltage V

REF

(ac) 5% V

REF

(DC)

mV 1

Notes:

1. The peak to peak AC component superimposed on V

REF

may not exceed 5% of the DC component of V

REF

.

2. To guarantee AC characteristics, V

IH,VIL

, Trise, and Tfall of inputs and clocks must be within 10% of each other.

3. For devices supplied with HSTL I/O input buffers. Compatible with both 1.8 V and 1.5 V I/O drivers.

4. See AC Input Definition drawing below.

VIH (ac)

V

REF

VIL (ac)

Page 16

Rev: 1.01 11/2002 16/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

Package Thermal Characteristics

Rating Layer Board Symbol Max Unit Notes

Junction to Ambient (at 200 lfm) single

R

ΘJA

TBD °C/W 1,2

Junction to Ambient (at 200 lfm) four

R

ΘJA

TBD °C/W 1,2

Junction to Case (TOP) —

R

ΘJC

TBD °C/W 3

Notes:

1. Junction temperature is a function of SRAM power dissipation, package thermal resistance, mounting board temperature,

ambient. Temperature air flow, board density, and PCB thermal resistance.

2. SCMI G-38-87

3. Average thermal resistance between die and top surface, MIL SPEC-883, Method 1012.1

AC Test Conditions

Parameter Conditions

Input high level

V

DDQ

Input low level 0 V

Max. input slew rate 2 V/ns

Input reference level

V

DDQ

/2

Output reference level

V

DDQ

/2

Notes: Test conditions as specified with output loading as shown unless otherwise noted.

20% tKHKH

V

SS

– 1.0 V

50%

V

SS

V

IH

Undershoot Measurement and Timing Overshoot Measurement and Timing

20% tKHKH

V

DD

+ 1.0 V

50%

V

DD

V

IL

Page 17

Rev: 1.01 11/2002 17/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

AC Test Load Diagram

Input and Output Leakage Characteristics

Parameter Symbol Test Conditions Min. Max Notes

Input Leakage Current

(except mode pins)

I

IL

V

IN

= 0 to V

DD

–2 uA 2 uA

Mode Pin Input Current

I

INM

V

DD ≥

V

IN

≥

VIL

0 V

≤ V

IN

≤ V

IL

–100 uA

–2 uA

2 uA

2 uA

Output Leakage Current

I

OL

Output Disable,

V

OUT

= 0 to V

DDQ

–2 uA 2 uA

Programmable Impedance HSTL Output Driver DC Electrical Characteristics

Parameter Symbol Min. Max. Units Notes

Output High Voltage

V

OH

V

DDQ / 2

V

DDQ

V 1,3

Output Low Voltage

V

OL

Vss

V

DDQ / 2

V 2,3

Notes:

1. I

OH

= (V

DDQ

/2) / (RQ/5) +/– 15% @ VOH = V

DDQ

/2 (for: 150Ω ≤ RQ ≤ 300Ω).

2. I

OL

= (V

DDQ

/2) / (RQ/5) +/– 15% @ VOL = V

DDQ

/2 (for: 150Ω ≤ RQ ≤ 300Ω).

3. Parameter tested with RQ = 250Ω and V

DDQ

= 1.5 V or 1.8 V

DQ

VT = V

DDQ

/2

50Ω

RQ = 250 Ω (HSTL I/O)

Page 18

Rev: 1.01 11/2002 18/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

Operating Currents

Parameter Org Symbol

-200 -167 -133

Test Conditions

0°C to

70°C

–40°C to

+85°C

0°C to

70°C

–40°C to

+85°C

0°C to

70°C

–40°C to

+85°C

Operating

Current

x18

I

DD

460 mA TBD mA 400 mA TBD mA 340 mA TBD mA

R

and W ≤ V

IL

Max.

tKHKH ≥ tKHKH Min.

All other inputs

V

IN

≤ V

IL

Max. or V

IN

≥ V

IH

Min.

I

DDQ

55 mA TBD mA 45 mA TBD mA 40 mA TBD mA

Operating

Current

x36

I

DD

525 mA TBD mA 440 mA TBD mA 380 mA TBD mA

R

and W ≤ V

IL

Max.

tKHKH ≥ tKHKH Min.

All other inputs

V

IN

≤ V

IL

Max. or V

IN

≥ V

IH

Min.

I

DDQ

110 mA TBD mA 95 mA TBD mA 75 mA TBD mA

Chip Disable

Current

x18

I

SB1

130 mA TBD mA 120 mA TBD mA 115 mA TBD mA

R

and W ≥ V

IH

Min.

tKHKH ≥ tKHKH Min.

All other inputs

V

IN

≤ V

IL

Max. or V

IN

≥ V

IH

Min.

I

SBQ1

5 mA TBD mA 5 mA TBD mA 5 mA TBD mA

Chip Disable

Current

x36

I

SB1

155 mA TBD mA 145 mA TBD mA 140 mA TBD mA

R

and W ≥ V

IH

Min.

tKHKH ≥ tKHKH Min.

All other inputs

V

IN

≤ V

IL

Max. or V

IN

≥ V

IH

Min.

I

SBQ1

5 mA TBD mA 5 mA TBD mA 5 mA TBD mA

Note: Power measured with output pins floating.

Page 19

Rev: 1.01 11/2002 19/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

AC Electrical Characteristics

Parameter Symbol

-200 -167 -133

Units Notes

Min Max Min Max Min Max

K, K Clock Cycle Time

C, C

Clock Cycle Time

t

KHKH

t

CHCH

5.0 — 6.0 — 7.5 — ns

K, K

Clock High Pulse Width

C, C Clock High Pulse Width

t

KHKL

t

CHCL

2.0 — 2.4 — 3.0 — ns

K, K

Clock Low Pulse Width

C, C

Clock Low Pulse Width

t

KLKH

t

CLCH

2.0 — 2.4 — 3.0 — ns

K Clock High to K

Clock High

C Clock High to C Clock High

t

KHKH

t

CHCH

2.2 — 2.7 — 3.4 — ns 4

K

Clock High to K Clock High

C

Clock High to C Clock High

t

KHKH

t

CHCH

2.2 — 2.7 — 3.4 — ns

K, K

Clock High to C, C Clock High

t

KHCH

0 2.3 0 2.8 0 3.55 ns

Address Input Setup Time

t

AVKH

0.4 — 0.5 — 0.6 — ns

Address Input Hold Time

t

KHAX

0.4 — 0.5 — 0.6 — ns

Control Input Setup Time

t

BVKH

0.4 — 0.5 — 0.6 — ns 1

Control Input Hold Time

t

KHBX

0.4 — 0.5 — 0.6 — ns 1

Data and Byte Write Input Setup Time

t

DVKH

0.4 — 0.5 — 0.6 — ns

Data and Byte Write Input Hold Time

t

KHDX

0.4 — 0.5 — 0.6 — ns

K, K

Clock High to Data Output Valid

C, C Clock High to Data Output Valid

t

KHQV

t

CHQV

— 2.3 — 2.5 — 3.0 ns

K, K

Clock High to Data Output Hold

C, C

Clock High to Data Output Hold

t

KHQX

t

CHQX

1.2 — 1.2 — 1.2 — ns 2

K Clock High to Data Output Low-Z

C Clock High to Data Output Low-Z

t

KHQX1

t

CHQX1

1.2 — 1.2 — 1.2 — ns 2,3

K Clock High to Data Output High-Z

C Clock High to Data Output High-Z

t

KHQZ

t

CHQZ

— 2.3 — 2.5 — 3.0 ns 2,3

K, K

Clock High to CQ, CQ Clock High

C, C Clock High to CQ, CQ Clock High

t

KHCQH

t

CHCQH

1.2 2.2 1.2 2.4 1.2 2.9 ns

CQ, CQ

Clock High to Data Output Valid

t

CQHQV

— 0.3 — 0.35 — 0.4 ns 2

CQ, CQ

Clock High to Data Output Hold

t

CQHQX

–0.3 — –0.35 — –0.4 — ns 2

Page 20

Rev: 1.01 11/2002 20/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

CQ, CQ Clock High Pulse Width

t

CQHCQL

t

KHKL

± 0.1 t

KHKL

± 0.1 t

KHKL

± 0.1

ns 2

CQ, CQ

Clock Low Pulse Width

t

CQLCQH

t

KLKH

± 0.1 t

KLKH

± 0.1 t

KLKH

± 0.1

ns 2

CQ, CQ

Clock High Pulse Width

t

CQHCQL1

t

CHCL

± 0.1 t

CHCL

± 0.1 t

CHCL

± 0.1

ns 2

CQ, CQ

Clock Low Pulse Width

t

CQLCQH1

t

CLCH

± 0.1 t

CLCH

± 0.1 t

CLCH

± 0.1

ns 2

Notes:

1. These parameters apply to control inputs R

and W.

2. These parameters are guaranteed by design and characterization. Not 100% tested.

3. These parameters are measured at ±50mV from steady state voltage.

4. t

KHKH

Max is specified by t

KHKH

Min. t

CHCH

Max is specified by t

CHCH

Min.

Parameter Symbol

-200 -167 -133

Units Notes

Min Max Min Max Min Max

Page 21

Rev: 1.01 11/2002 21/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

K and K Controlled Read-Write-Read Timing Diagram

A4 A5 A6

K

K

A

R

Q

CQ

CQ

t

KHAX

t

AVKH

t

KHBX

t

BVKH

t

KHKH

t

KHKL

t

KLKH

Read Write Read Deselect Read Write Deselect Write Read Write Deselect

A2 A3

W

A7

D

t

KHDX

t

DVKH

D21 D50

D60

D51 D61 D80

A8A1

t

KHCQH

t

CQHCQL

t

KHQX1

t

KHQZ

t

KHQV

t

KHQX

t

CQHQX

t

CQHQV

Q10 Q11 Q30 Q31 Q40 Q41

BWn

t

CQLCQH

D20

D81

t

KHQV

t

KHQX

t

CQHQX

t

CQHQV

t

KHAX

t

AVKH

t

KHBX

t

BVKH

t

KHDX

t

DVKH

t

KHKH

t

KHKH

t

KHCQH

Page 22

Rev: 1.01 11/2002 22/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

C and C Controlled Read-Write-Read Timing Diagram

A4 A5 A6

K

K

A

R

Read Write Read Deselect Read Write Deselect Write Read Write Deselect

A2 A3

W

A7

D

A8A1

BWn

D21 D50 D60D51 D61 D80D20 D81

Q

CQ

CQ

t

CHCQH

t

CQHCQL1

t

CHQX1

t

CHQZ

t

CHQV

t

CHQX

t

CQHQX

t

CQHQV

Q10 Q11 Q30 Q31 Q40 Q41

t

CQLCQH1

t

CHQV

t

CHQX

t

CQHQX

t

CQHQV

t

CHCQH

C

C

t

KHCH

t

CHCH

t

CHCL

t

CLCH

t

KHCH

t

CHCH

t

CHCH

Page 23

Rev: 1.01 11/2002 23/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

JTAG Port Operation

Overview

The JTAG Port on this RAM operates in a manner that is compliant with IEEE Standard 1149.1-1990, a serial boundary scan interface standard

(commonly referred to as JTAG). The JTAG Port input interface levels scale with V

DD

. The JTAG output drivers are powered by VDD.

Disabling the JTAG Port

It is possible to use this device without utilizing the JTAG port. The port is reset at power-up and will remain inactive unless clocked. TCK, TDI,

and TMS are designed with internal pull-up circuits.To assure normal operation of the RAM with the JTAG Port unused, TCK, TDI, and TMS may

be left floating or tied to either V

DD

or VSS. TDO should be left unconnected.

JTAG Port Registers

Overview

The various JTAG registers, referred to as Test Access Port or TAP Registers, are selected (one at a time) via the sequences of 1s and 0s

applied to TMS as TCK is strobed. Each of the TAP Registers is a serial shift register that captures serial input data on the rising edge of TCK

and pushes serial data out on the next falling edge of TCK. When a register is selected, it is placed between the TDI and TDO pins.

Instruction Register

The Instruction Register holds the instructions that are executed by the TAP controller when it is moved into the Run, Test/Idle, or the various

data register states. Instructions are 3 bits long. The Instruction Register can be loaded when it is placed between the TDI and TDO pins. The

Instruction Register is automatically preloaded with the IDCODE instruction at power-up or whenever the controller is placed in Test-Logic-Reset

state.

Bypass Register

The Bypass Register is a single bit register that can be placed between TDI and TDO. It allows serial test data to be passed through the RAM’s

JTAG Port to another device in the scan chain with as little delay as possible.

JTAG Pin Descriptions

Pin Pin Name I/O Description

TCK Test Clock In

Clocks all TAP events. All inputs are captured on the rising edge of TCK and all outputs propagate

from the falling edge of TCK.

TMS Test Mode Select In

The TMS input is sampled on the rising edge of TCK. This is the command input for the TAP

controller state machine. An undriven TMS input will produce the same result as a logic one input

level.

TDI Test Data In In

The TDI input is sampled on the rising edge of TCK. This is the input side of the serial registers

placed between TDI and TDO. The register placed between TDI and TDO is determined by the

state of the TAP Controller state machine and the instruction that is currently loaded in the TAP

Instruction Register (refer to the TAP Controller State Diagram). An undriven TDI pin will produce

the same result as a logic one input level.

TDO Test Data Out Out

Output that is active depending on the state of the TAP state machine. Output changes in

response to the falling edge of TCK. This is the output side of the serial registers placed between

TDI and TDO.

Note:

This device does not have a TRST (TAP Reset) pin. TRST is optional in IEEE 1149.1. The Test-Logic-Reset state is entered while TMS is

held high for five rising edges of TCK. The TAP Controller is also reset automatically at power-up.

Page 24

Rev: 1.01 11/2002 24/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

Boundary Scan Register

The Boundary Scan Register is a collection of flip flops that can be preset by the logic level found on the RAM’s input or I/O pins. The flip flops are

then daisy chained together so the levels found can be shifted serially out of the JTAG Port’s TDO pin. The Boundary Scan Register also

includes a number of place holder flip flops (always set to a logic 1). The relationship between the device pins and the bits in the Boundary Scan

Register is described in the Scan Order Table following. The Boundary Scan Register, under the control of the TAP Controller, is loaded with the

contents of the RAMs I/O ring when the controller is in Capture-DR state and then is placed between the TDI and TDO pins when the controller is

moved to Shift-DR state. SAMPLE-Z, SAMPLE/PRELOAD and EXTEST instructions can be used to activate the Boundary Scan Register.

JTAG TAP Block Diagram

Identification (ID) Register

The ID Register is a 32-bit register that is loaded with a device and vendor specific 32-bit code when the controller is put in Capture-DR state with

the IDCODE command loaded in the Instruction Register. The code is loaded from a 32-bit on-chip ROM. It describes various attributes of the

RAM as indicated below. The register is then placed between the TDI and TDO pins when the controller is moved into Shift-DR state. Bit 0 in the

register is the LSB and the first to reach TDO when shifting begins.

Tap Controller Instruction Set

Overview

There are two classes of instructions defined in the Standard 1149.1-1990; the standard (Public) instructions, and device specific (Private)

instructions. Some Public instructions are mandatory for 1149.1 compliance. Optional Public instructions must be implemented in prescribed

ways. The TAP on this device may be used to monitor all input and I/O pads, and can be used to load address, data or control signals into the

RAM or to preload the I/O buffers.

When the TAP controller is placed in Capture-IR state the two least significant bits of the instruction register are loaded with 01. When the

controller is moved to the Shift-IR state the Instruction Register is placed between TDI and TDO. In this state the desired instruction is serially

loaded through the TDI input (while the previous contents are shifted out at TDO). For all instructions, the TAP executes newly loaded

instructions only when the controller is moved to Update-IR state. The TAP instruction set for this device is listed in the following table.

Instruction Register

ID Code Register

Boundary Scan Register

012

012

····

31 30 29

012

···

······

n

0

Bypass Register

TDI

TDO

TMS

TCK

Test Access Port (TAP) Controller

Page 25

Rev: 1.01 11/2002 25/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

JTAG Tap Controller State Diagram

Instruction Descriptions

BYPASS

When the BYPASS instruction is loaded in the Instruction Register the Bypass Register is placed between TDI and TDO. This occurs when

the TAP controller is moved to the Shift-DR state. This allows the board level scan path to be shortened to facilitate testing of other devices

in the scan path.

SAMPLE/PRELOAD

SAMPLE/PRELOAD is a Standard 1149.1 mandatory public instruction. When the SAMPLE / PRELOAD instruction is loaded in the Instruction Register, moving the TAP controller into the Capture-DR state loads the data in the RAMs input and I/O buffers into the Boundary Scan

Register. Boundary Scan Register locations are not associated with an input or I/O pin, and are loaded with the default state identified in the

Boundary Scan Chain table at the end of this section of the datasheet. Because the RAM clock is independent from the TAP Clock (TCK) it

is possible for the TAP to attempt to capture the I/O ring contents while the input buffers are in transition (i.e. in a metastable state). Although

allowing the TAP to sample metastable inputs will not harm the device, repeatable results cannot be expected. RAM input signals must be

stabilized for long enough to meet the TAPs input data capture set-up plus hold time (tTS plus tTH). The RAMs clock inputs need not be

paused for any other TAP operation except capturing the I/O ring contents into the Boundary Scan Register. Moving the controller to ShiftDR state then places the boundary scan register between the TDI and TDO pins.

EXTEST

EXTEST is an IEEE 1149.1 mandatory public instruction. It is to be executed whenever the instruction register is loaded with all logic 0s. The

EXTEST command does not block or override the RAM’s input pins; therefore, the RAM’s internal state is still determined by its input pins.

Select DR

Capture DR

Shift DR

Exit1 DR

Pause DR

Exit2 DR

Update DR

Select IR

Capture IR

Shift IR

Exit1 IR

Pause IR

Exit2 IR

Update IR

Test Logic Reset

Run Test Idle

0

0

1

0

1

1

0

0

1

1

1

0

0

1

1

0

0

0

0

1

1

0 0

1

10

0

0

1

1

1

1

Page 26

Rev: 1.01 11/2002 26/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

Typically, the Boundary Scan Register is loaded with the desired pattern of data with the SAMPLE/PRELOAD command. Then the EXTEST

command is used to output the Boundary Scan Register’s contents, in parallel, on the RAM’s data output drivers on the falling edge of TCK

when the controller is in the Update-IR state.

Alternately, the Boundary Scan Register may be loaded in parallel using the EXTEST command. When the EXTEST instruction is selected,

the sate of all the RAM’s input and I/O pins, as well as the default values at Scan Register locations not associated with a pin, are transferred in parallel into the Boundary Scan Register on the rising edge of TCK in the Capture-DR state, the RAM’s output pins drive out the

value of the Boundary Scan Register location with which each output pin is associated.

IDCODE

The IDCODE instruction causes the ID ROM to be loaded into the ID register when the controller is in Capture-DR mode and places the ID

register between the TDI and TDO pins in Shift-DR mode. The IDCODE instruction is the default instruction loaded in at power up and any

time the controller is placed in the Test-Logic-Reset state.

SAMPLE-Z

If the SAMPLE-Z instruction is loaded in the instruction register, all RAM outputs are forced to an inactive drive state (high-Z) and the Boundary Scan Register is connected between TDI and TDO when the TAP controller is moved to the Shift-DR state.

RFU

These instructions are Reserved for Future Use. In this device they replicate the BYPASS instruction.

JTAG TAP Instruction Set Summary

Instruction Code Description Notes

EXTEST 000 Places the Boundary Scan Register between TDI and TDO. 1

IDCODE 001 Preloads ID Register and places it between TDI and TDO. 1, 2

SAMPLE-Z 010

Captures I/O ring contents. Places the Boundary Scan Register between TDI and TDO.

Forces all RAM output drivers to High-Z.

1

RFU 011 Do not use this instruction; Reserved for Future Use. 1

SAMPLE/PRELOAD 100 Captures I/O ring contents. Places the Boundary Scan Register between TDI and TDO. 1

RFU 101 Do not use this instruction; Reserved for Future Use. 1

RFU 110 Do not use this instruction; Reserved for Future Use. 1

BYPASS 111 Places Bypass Register between TDI and TDO. 1

Notes:

1. Instruction codes expressed in binary, MSB on left, LSB on right.

2. Default instruction automatically loaded at power-up and in test-logic-reset state.

Page 27

Rev: 1.01 11/2002 27/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

JTAG Port Recommended Operating Conditions and DC Characteristics

Parameter Symbol Min. Max. Unit Notes

Test Port Input High Voltage

V

IHJ

0.6 * V

DD

V

DD

+0.3

V1

Test Port Input Low Voltage

V

ILJ

–0.3

0.3 * V

DD

V1

TMS, TCK and TDI Input Leakage Current

I

INHJ

–300 1 uA 2

TMS, TCK and TDI Input Leakage Current

I

INLJ

–1 100 uA 3

TDO Output Leakage Current

I

OLJ

–11uA4

Test Port Output High Voltage

V

OHJ

VDD – 400 mV

— V5, 6

Test Port Output Low Voltage

V

OLJ

— 0.4 V 5, 7

Test Port Output CMOS High

V

OHJC

VDD – 100 mV

— V5, 8

Test Port Output CMOS Low

V

OLJC

— 100 mV V 5, 9

Notes:

1. Input Under/overshoot voltage must be –2 V > Vi < V

DD

+2 V not to exceed 2.6 V maximum, with a pulse width not to

exceed 20% tTKC.

2. V

ILJ

≤ V

IN

≤ V

DD

3. 0 V

≤ V

IN

≤ V

ILJn

4. Output Disable, V

OUT

= 0 to V

DD

5. The TDO output driver is served by the VDD supply.

6. I

OHJ

= –4 mA

7. I

OLJ

= + 4 mA

8. I

OHJC

= –100 uA

9. I

OHJC

= +100 uA

Notes:

1. Distributed scope and test jig capacitance.

2. Test conditions as shown unless otherwise noted.

JTAG Port AC Test Conditions

Parameter Conditions

Input high level

V

DD

Input low level 0.2 V

Input slew rate 1 V/ns

Input reference level

V

DD

/2

Output reference level

V

DD

/2

DQ

V

T

= VDD/2

50Ω

30pF

*

JTAG Port AC Test Load

* Distributed Test Jig Capacitance

Page 28

Rev: 1.01 11/2002 28/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

JTAG Port Timing Diagram

JTAG Port AC Electrical Characteristics

Ordering Information—GSI SigmaQuad SRAM

Parameter Symbol Min. Max Unit

TCK Cycle Time tTKC 50 — ns

TCK Low to TDO Valid tTKQ — 20 ns

TCK High Pulse Width tTKH 20 — ns

TCK Low Pulse Width tTKL 20 — ns

TDI & TMS Set Up Time tTS 10 — ns

TDI & TMS Hold Time tTH 10 — ns

Org

Part Number

1

Type Package

Speed

(MHz)

T

A

3

512Kx 36 GS818QV36D-333 SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 333 C

512Kx 36 GS818QV36D-300 SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 300 C

512Kx 36 GS818QV36D-250 SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 250 C

512Kx 36 GS818QV36D-333I SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 333 I

512Kx 36 GS818QV36D-300I SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 300 I

512Kx 36 GS818QV36D-250I SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 250 I

1M x 18 GS818QV18D-333 SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 333 C

Notes:

1. Customers requiring delivery in Tape and Reel should add the character “T” to the end of the part number. Example:

GS818x36D-300T.

2. T

A

= C = Commercial Temperature Range. TA = I = Industrial Temperature Range.

tTKQ

tTS tTH

tTKH

tTKL

TCK

TMS

TDI

TDO

tTKC

Page 29

Rev: 1.01 11/2002 29/29

Specifications cited are design targets and are subject to change without notice. For latest documentation contact your GSI representative.

Preliminary

GS818QV18/36D-200/167/133

1M x 18 GS818QV18D-300 SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 300 C

1M x 18 GS818QV18D-250 SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 250 C

1M x 18 GS818QV18D-333I SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 333 I

1M x 18 GS818QV18D-300I SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 300 I

1M x 18 GS818QV18D-250I SigmaQuad SRAM 1 mm Pitch, 165-Pin BGA 250 I

Org

Part Number

1

Type Package

Speed

(MHz)

T

A

3

Notes:

1. Customers requiring delivery in Tape and Reel should add the character “T” to the end of the part number. Example:

GS818x36D-300T.

2. T

A

= C = Commercial Temperature Range. TA = I = Industrial Temperature Range.

Loading...

Loading...