Datasheet GS4981-ITA, GS4981-IKA, GS4981-IDA, GS4981-CTA, GS4981-CKA Datasheet (Gennum Corporation)

...

GS1881, GS4881, GS4981

Monolithic Video Sync Separators

DATA SHEET

FEATURES

• noise tolerant odd/even flag, back porch and

horizontal sync pulse

• fast recovery from impulse noise

• excellent temperature stability

• 0.5 V to 4 Vpp input signal amplitude with 5 V

supply

• well-controlled clamp discharge current and

slicing level

• programmable horizontal scan rate (up to 130 kHz)

• composite, vertical, back porch, odd/even

(GS1881, GS4881), horizontal (GS4981) outputs

• predictable vertical output pulse width with

default trigger for non-standard video signals

• 5 V to 12 V supply voltage range

• pin compatible with LM1881 sync separator

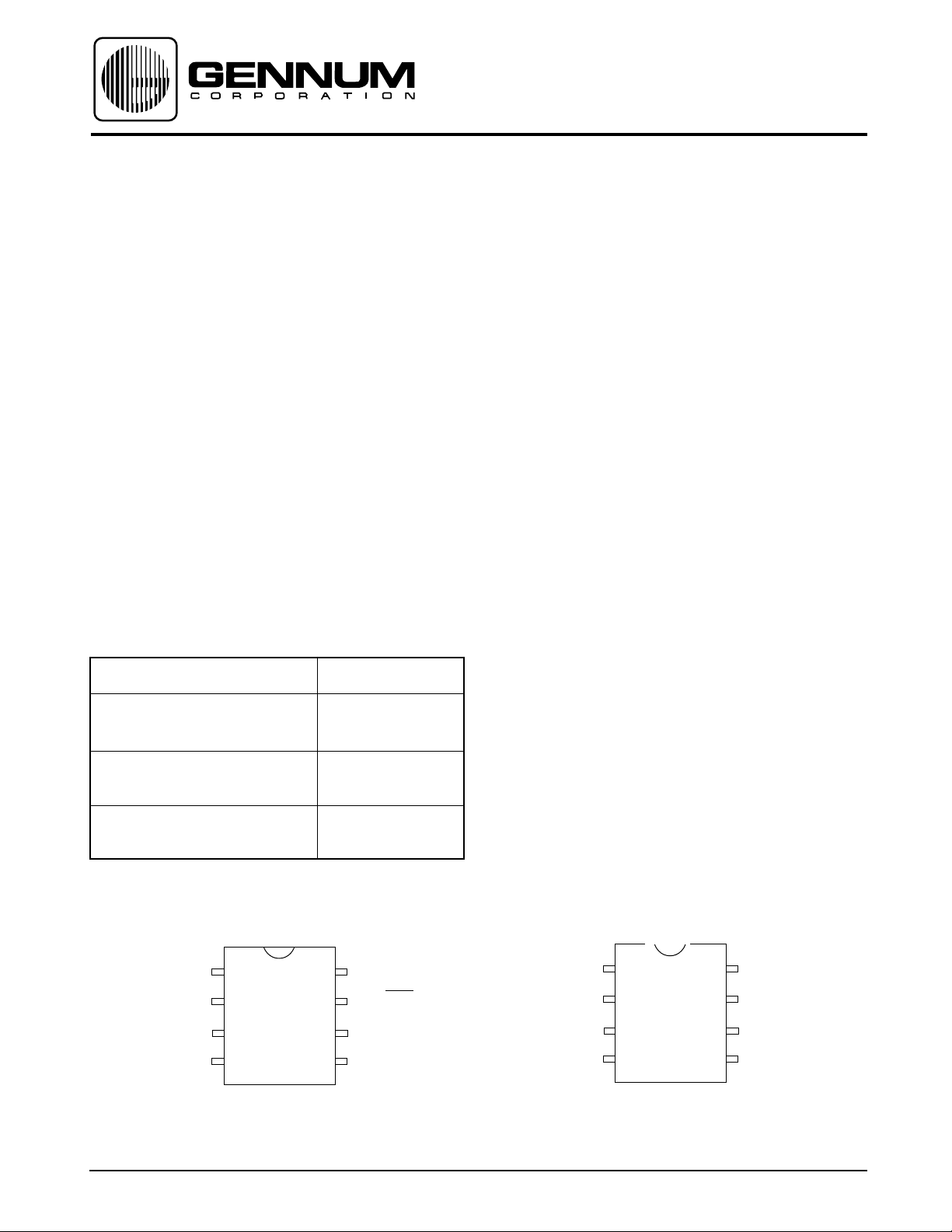

SELECTION CHART

APPLICATION CHOOSE DEVICE:

Direct LM1881 Replacement GS1881

with Improved Performance

New Applications GS4881

Substitution for LM1881

New Applications Requiring GS4981

Horizontal Sync Output

DESCRIPTION

The GS1881, GS4881 and GS4981 are general purpose sync

separators for use in a wide variety of video applications. The

devices extract the timing information from composite video

signals with scan rates from 15 to 130 kHz.

The GS1881 is a drop-in replacement for the industry standard

LM1881 with much improved performance. The device

generates composite sync, vertical sync, back porch and

odd/even field signals. The GS4881 is identical to the GS1881

but features a noise immune back porch pulse which maintains

a constant H rate during the vertical interval. The GS4981 is

identical to the GS4881, except that it provides horizontal sync

in place of the odd/even output.

All three devices feature a self-adjusting windowing circuit for

noise immunity, which synchronizes to H rate. This

windowing circuit determines the odd or even field

in the GS1881 and GS4881, gates the back porch pulse in

the GS4881 and GS4981, and generates the horizontal sync

output in the GS4981.

The devices feature an improved input stage which ensures

that the input signal is sliced at a predictable point due to

well-controlled input clamp discharge current and sync

slicing level. A missing pulse detector enables the devices to

recover quickly from impulse noise disturbances by temporarily

increasing the clamp discharge current by roughly ten times.

The input stage will operate with signals from 0.5 to 4 volts

peak to peak with a 5 volt supply.

The GS1881, GS4881 and GS4981 also feature a predictable

vertical output pulse width with a default trigger for non-standard

video signals. All three are available in commercial and

industrial temperature ranges and are packaged in both DIP

and SOIC.

PIN CONNECTIONS

GS1881, GS4881

COMPOSITE

SYNC OUT

COMPOSITE

VIDEO IN

VERTICAL

SYNC OUT

GROUND

Patent No. 5,432,559

Revision Date: October 1995

GENNUM CORPORATION P.O. Box 489, Stn A, Burlington, Ontario, Canada L7R 3Y3 tel. (905) 632-2996 fax: (905) 632-2055

Japan Branch: A-302 Miyamae Village, 2-10-42 Miyamae, Suginami-ku, Tokyo 168, Japan tel. (03) 3247-8838 fax (03) 3247-8839

1

2

3

4

8 PIN DIP

8 PIN SOIC

8

7

6

5

V

cc

ODD/EVEN

R

SET

BACK PORCH

COMPOSITE

SYNC OUT

COMPOSITE

VIDEO IN

VERTICAL

SYNC OUT

GROUND

GS4981

1

2

3

4

8 PIN DIP

8 PIN SOIC

V

8

cc

HORIZONTAL

7

6

R

SET

5

BACK PORCH

Document No. 520 - 23 - 03

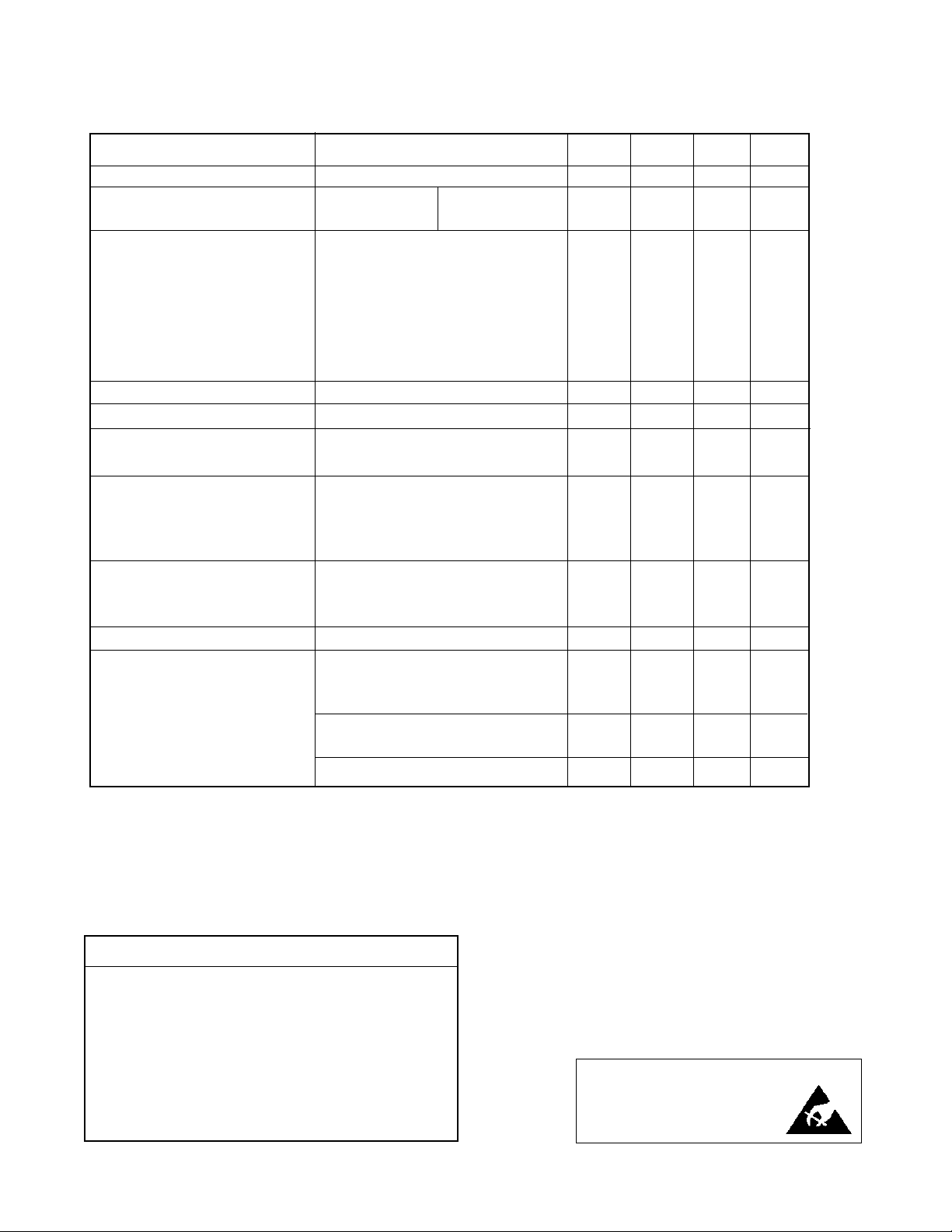

GS1881 ELECTRICAL CHARACTERISTICS

(VCC= 5 V, R

= 680 kΩ, TA = 25° C, unless otherwise specified)

SET

PARAMETER CONDITIONS MIN TYP MAX UNITS

Supply Voltage 4.5 5 13.2 V

Supply Current Outputs at Logic 1 V

V

= 5 V - 4.6 6.5 mA

CC

= 12 V - 5.0 7.0 mA

CC

Video Input (Pin 2)

(a) Signal Level V

= 5 V 0.5 - 4 Vp-p

CC

(b) Clamp Current Charge 500 650 850 µA

Discharge - normal 9 11 13 µA

- Nosync flag raised 65 95 115 µ A

(c) Delay to raising of Nosync flag Video input held high 64 95 130 µs

(d) Sync Tip Clamp Voltage - 1.55 - V

Sync Slice Level Relative to sync tip clamp voltage 70 77 84 mV

R

Pin Reference Voltage (Pin 6) See Note 1 1.14 1.24 1.34 V

SET

Composite Sync Out (Pin 1) See Note 2 40 60 80 ns

Delay from Video CL = 15p

Back Porch Pulse Out (Pin 5) CL = 15p

(a) Delay from Rising

Edge of Sync 400 500 650 ns

(b) Pulse Width 2.0 2.5 3.2 µs

Vertical Sync Out (Pin 3)

(a) Pulse Width Serrations during vertical interval 197.7 197.7 197.7 µs

(b) Default Starting Time No serrations during the vertical interval 48 65 82 µs

Horizontal Scan Rate Modified R

SET

15 - 130 kHz

Logic Outputs

(a) V

OH

I

= 40 µA VCC = 5 V 4.2 4.6 - V

OH

VCC = 12 V 11.2 11.6 - V

IOH = 1.6 mA VCC = 5 V 2.4 3.4 - V

VCC = 12 V 9.4 10.4 - V

(b) V

OL

IOL = -1.6 mA - 0.3 0.6 V

Note 1: When placing the R

as possible to pin 6. Care should also be taken to avoid parasitic capacitive coupling from any output pin (pins 1, 3, 5 and 7) to pin 6.

Note 2: Measured from slicing point of input falling edge to 50% point of composite sync falling edge.

resistor and the 0.1µF decoupling capacitor careful attention should be made to ensure that they are as close

SET

ORDERING INFORMATION

Part Number Package Type Temperature Range

GS1881 - CDA 8 PDIP 0° to 70° C

GS1881 - CKA 8 SOIC 0° to 70° C

GS1881 - CTA 8 TAPE 0° to 70° C

GS1881 - IDA 8 PDIP -25° to 85° C

GS1881 - IKA 8 SOIC -25° to 85° C

GS1881 - ITA 8 TAPE -25° to 85° C

520 - 23 - 03

2

CAUTION

ELECTROSTATIC

SENSITIVE DEVICES

DO NOT OPEN PACKAGES OR HANDLE

EXCEPT AT A STATIC-FREE WORKSTATION

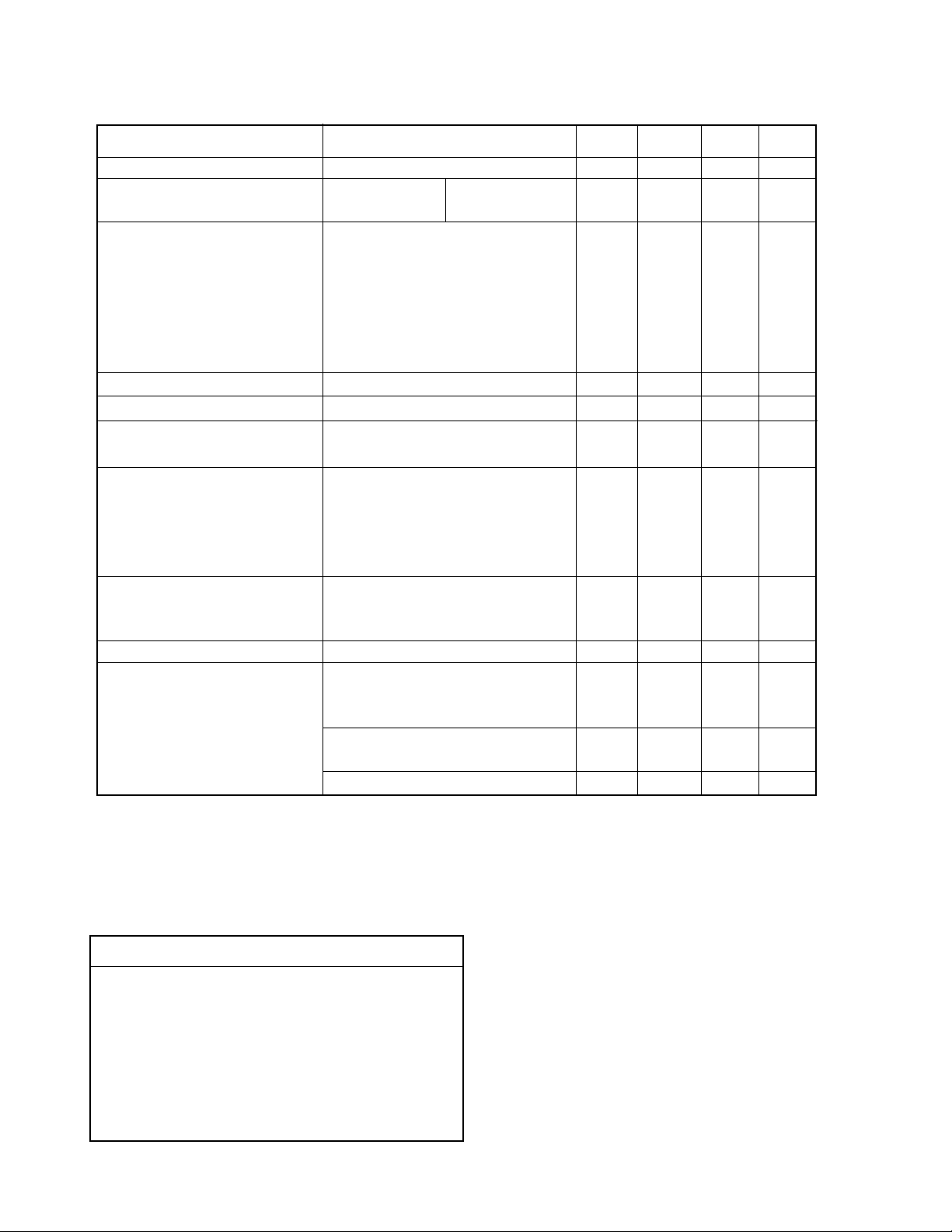

GS4881 ELECTRICAL CHARACTERISTICS

(VCC= 5 V, R

= 680 kΩ, TA = 25° C, unless otherwise specified)

SET

PARAMETER CONDITIONS MIN TYP MAX UNITS

Supply Voltage 4.5 5 13.2 V

Supply Current Outputs at Logic 1 V

V

= 5 V - 4.6 6.5 mA

CC

= 12 V - 5.0 7.0 mA

CC

Video Input (Pin 2)

(a) Signal Level V

= 5 V 0.5 - 4 Vp-p

CC

(b) Clamp Current Charge 500 650 850 µA

Discharge - normal 9 11 13 µA

- Nosync flag raised 65 95 115 µA

(c) Delay to raising of Nosync flag Video input held high 64 95 130 µs

(d) Sync Tip Clamp Voltage - 1.55 - V

Sync Slice Level Relative to sync tip clamp voltage 70 77 84 mV

R

Pin Reference Voltage (Pin 6) See Note 1 1.14 1.24 1.34 V

SET

Composite Sync Out (Pin 1) See Note 2 40 60 80 ns

Delay from Video CL = 15p

Back Porch Pulse Out (Pin 5) CL = 15p

(a) Delay from Rising

Edge of Sync 400 500 650 ns

(b) Pulse Width 2.0 2.5 3.2 µs

(c) Occurence Rate H H H

Vertical Sync Out (Pin 3)

(a) Pulse Width Serrations during vertical interval 197.7 197.7 197.7 µs

(b) Default Starting Time No serrations during the vertical interval 48 65 82 µs

Horizontal Scan Rate Modified R

SET

15 - 130 kHz

Logic Outputs

(a) V

OH

I

= 40 µA VCC = 5 V 4.2 4.6 - V

OH

VCC = 12 V 11.2 11.6 - V

IOH = 1.6 mA VCC = 5 V 2.4 3.4 - V

VCC = 12 V 9.4 10.4 - V

(b) V

OL

IOL = -1.6 mA - 0.3 0.6 V

Note 1: When placing the R

as possible to pin 6. Care should also be taken to avoid parasitic capacitive coupling from any output pin (pins 1, 3, 5 and 7) to pin 6.

Note 2: Measured from slicing point of input falling edge to 50% point of composite sync falling edge.

resistor and the 0.1µF decoupling capacitor careful attention should be made to ensure that they are as close

SET

ORDERING INFORMATION

Part Number Package Type Temperature Range

GS4881 - CDA 8 PDIP 0° to 70° C

GS4881 - CKA 8 SOIC 0° to 70° C

GS4881 - CTA 8 TAPE 0° to 70° C

GS4881 - IDA 8 PDIP -25° to 85° C

GS4881 - IKA 8 SOIC -25° to 85° C

GS4881 - ITA 8 TAPE -25° to 85° C

3

520 - 23 - 03

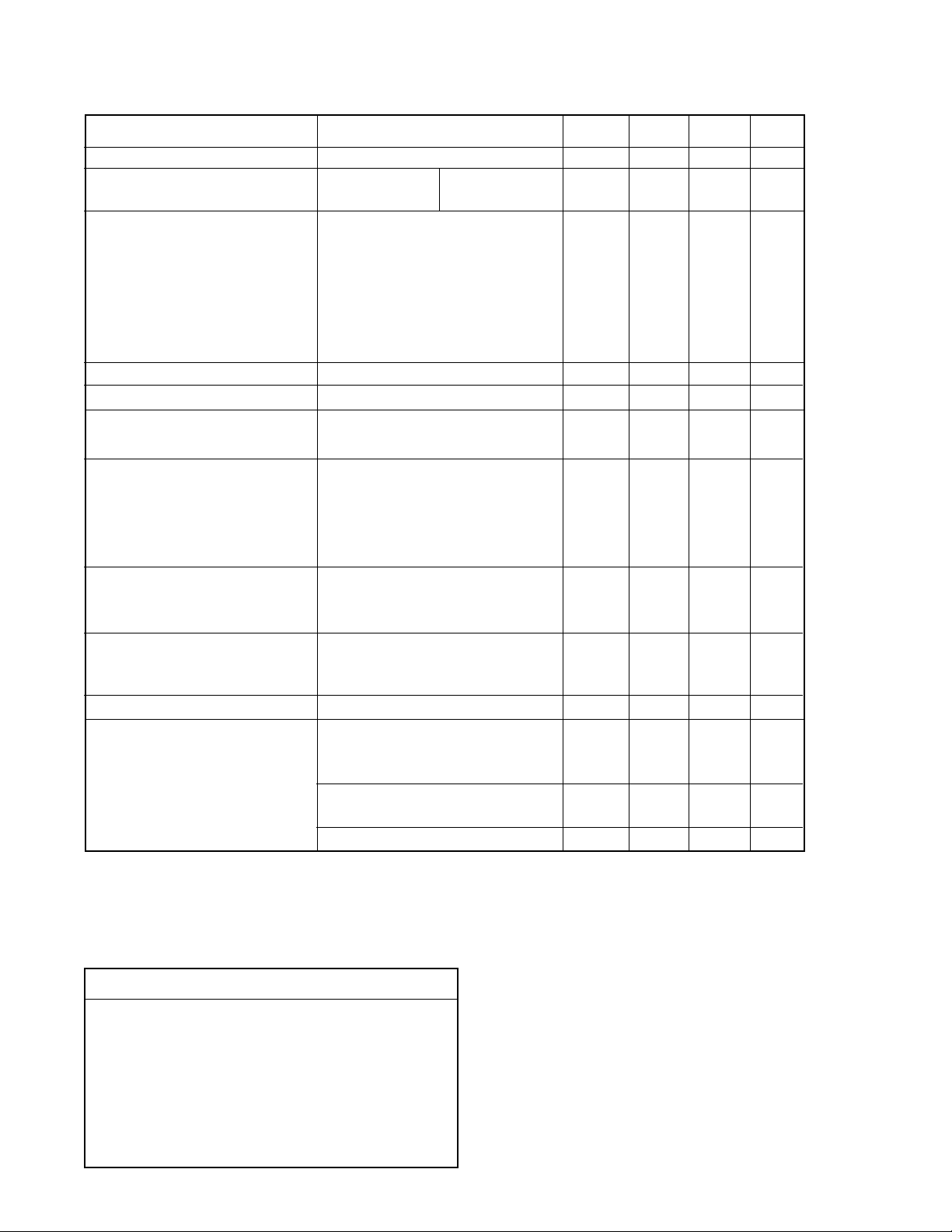

GS4981 ELECTRICAL CHARACTERISTICS

(VCC= 5 V, R

= 680 kΩ, TA = 25° C, unless otherwise specified)

SET

PARAMETER CONDITIONS MIN TYP MAX UNITS

Supply Voltage 4.5 5 13.2 V

Supply Current Outputs at Logic 1 V

V

= 5 V - 4.6 6.5 mA

CC

= 12 V - 5.0 7.0 mA

CC

Video Input (Pin 2)

(a) Signal Level V

= 5 V 0.5 - 4 Vp-p

CC

(b) Clamp Current Charge 500 650 850 µA

Discharge - normal 9 11 13 µA

- Nosync flag raised 65 95 115 µA

(c) Delay to raising of Nosync flag Video input held high 64 95 130 µs

(d) Sync Tip Clamp Voltage - 1.55 - V

Sync Slice Level Relative to sync tip clamp voltage 70 77 84 mV

R

Pin Reference Voltage (Pin 6) See Note 1 1.14 1.24 1.34 V

SET

Composite Sync Out (Pin 1) See Note 2 40 60 80 ns

Delay from Video CL = 15p

Back Porch Pulse Out (Pin 5) CL = 15p

(a) Delay from Rising

Edge of Sync 400 500 650 ns

(b) Pulse Width 2.0 2.5 3.2 µs

(c) Occurence Rate H H H

Vertical Sync Out (Pin 3)

(a) Pulse Width Serrations during vertical interval 197.7 197.7 197.7 µs

(b) Default Starting Time No serrations during the vertical interval 48 65 82 µs

Horizontal Sync Out (Pin 7) CL = 15p

(a) Delay from Video 90 190 290 ns

(b) Pulse Width 5.0 7.0 9.0 µs

Horizontal Scan Rate Modified R

SET

15 - 130 kHz

Logic Outputs

(a) V

OH

I

= 40 µA VCC = 5 V 4.2 4.6 - V

OH

VCC = 12 V 11.2 11.6 - V

IOH = 1.6 mA VCC = 5 V 2.4 3.4 - V

Note 3 VCC = 12 V 9.4 10.4 - V

(b) V

OL

Note 1: When placing the R

as possible to pin 6. Care should also be taken to avoid parasitic capacitive coupling from any output pin (pins 1, 3, 5 and 7) to pin 6.

Note 2: Measured from slicing point of input falling edge to 50% point of composite sync falling edge.

Note 3: Applies only to composite sync, vertical sync, and back porch outputs. Horizontal sync has a passive 10 kΩ pull-up to V

resistor and the 0.1µF decoupling capacitor careful attention should be made to ensure that they are as close

SET

IOL = -1.6 mA - 0.3 0.6 V

.

CC

ORDERING INFORMATION

Part Number Package Type Temperature Range

GS4981 - CDA 8 PDIP 0° to 70° C

GS4981 - CKA 8 SOIC 0° to 70° C

GS4981 - CTA 8 TAPE 0° to 70° C

GS4981 - IDA 8 PDIP -25° to 85° C

GS4981 - IKA 8 SOIC -25° to 85° C

GS4981 - ITA 8 TAPE -25° to 85° C

520 - 23 - 03

4

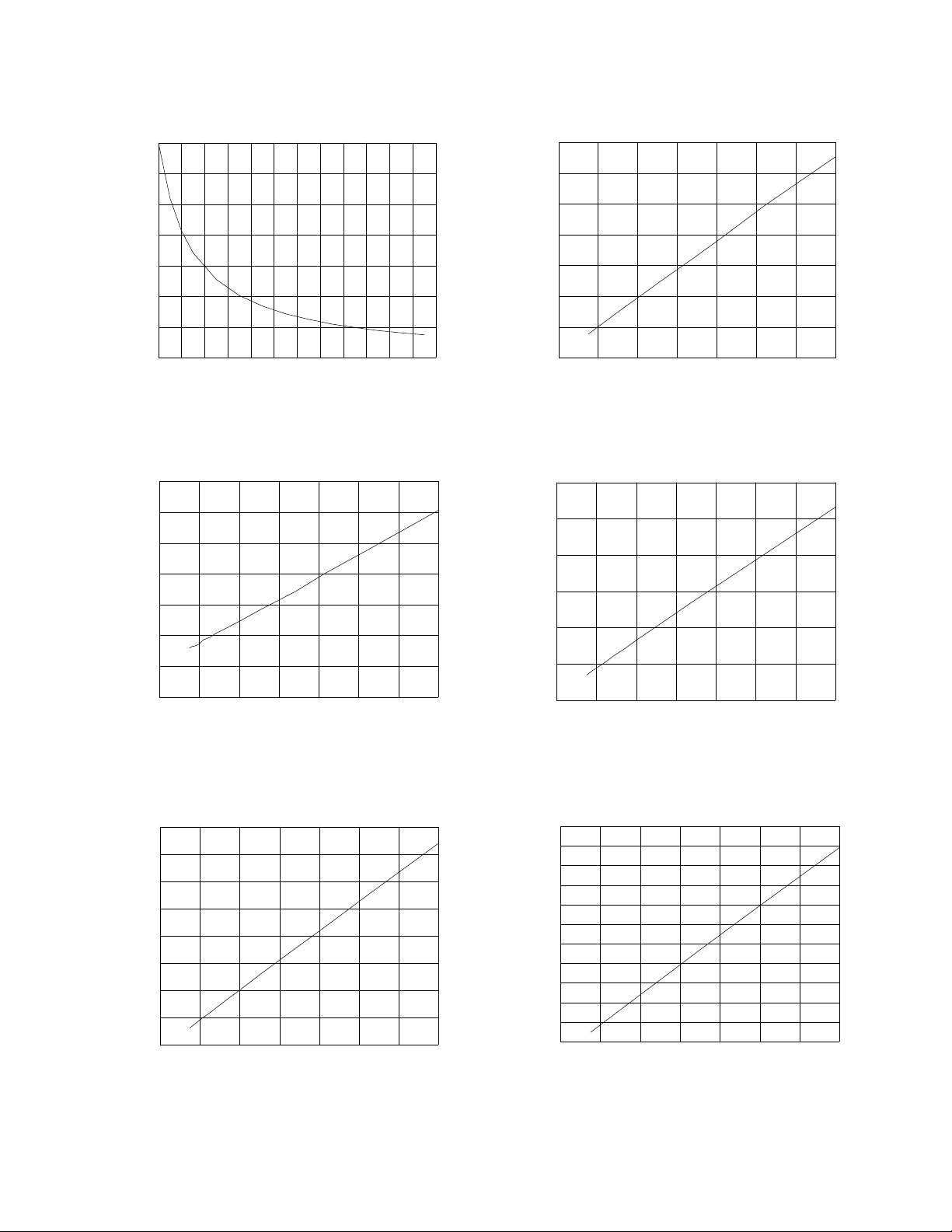

TYPICAL PERFORMANCE CHARACTERISTICS (VS = 5V, TA = 25° C unless otherwise shown)

700

600

500

400

(kΩ)

SET

R

300

200

100

0

15 35 55 75 95 115 135

SCAN RATE (kHz)

Fig. 1 R

700

600

500

400

300

200

vs Scan Rate

SET

BACK PORCH DELAY (ns)

100

70

60

50

40

30

20

VERTICAL DEFAULT TIME (µs)

10

0

0 100 200 300 400 500 600 700

R

(kΩ)

SET

Fig. 2 Vertical Sync Default Starting Time

vs R

SET

3000

2500

2000

1500

1000

BACK PORCH WIDTH (ns)

500

0

0 100 200 300 400 500 600 700

R

(kΩ)

SET

Fig. 3 Back Porch Delay vs R

8000

7000

6000

5000

4000

3000

HORIZONTAL WIDTH (µs)

2000

1000

0

0 100 200 300 400 500 600 700

R

(kΩ)

SET

Fig. 5 Horizontal Width vs R

SET

SET

0

0 100 200 300 400 500 600 700

R

(kΩ)

SET

Fig. 4 Back Porch Width vs R

110

100

90

80

70

60

50

40

30

NOSYNC DELAY TIME (µs)

20

10

0

0 100 200 300 400 500 600 700

R

(kΩ)

SET

Fig. 6 Nosync Delay Time vs R

SET

SET

5

520 - 23 - 03

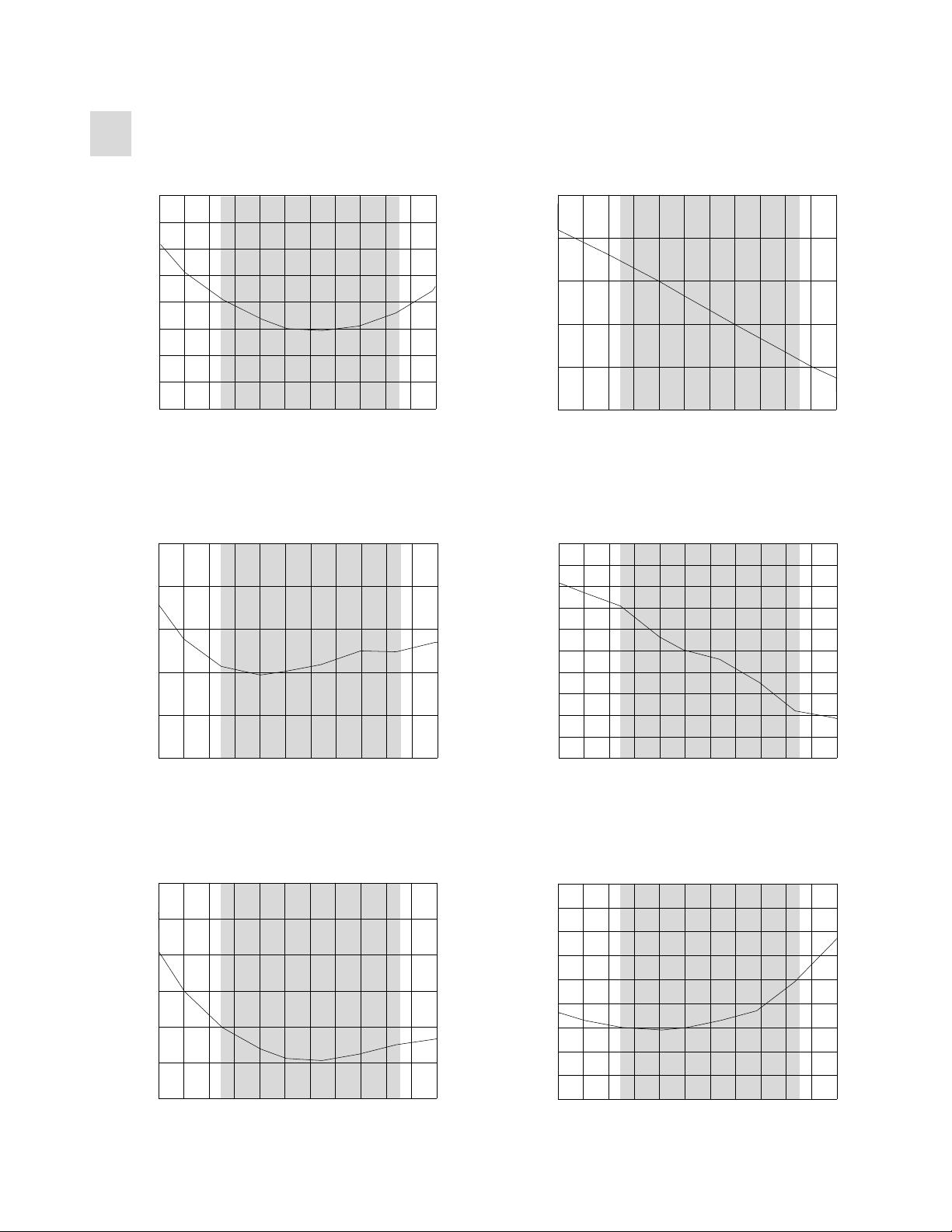

TEMPERATURE CHARACTERISTICS (V

Commercial Temperature Range (0 - 70 °C)

= 5V, R

S

= 680 kΩ unless otherwise shown)

SET

10

8

6

4

2

0

-2

COMPOSITE SYNC DELAY

VARIATION (ns)

-4

-6

-25 -15 -5 5 15 25 35 45 55 65 75 85

TEMPERATURE (°C)

Fig. 7 Composite Sync Delay Variation

vs Temperature

30

20

10

0

-10

BACK PORCH DELAY VARIATION (ns)

-20

-25 -15 -5 5 15 25 35 45 55 65 75 85

TEMPERATURE (°C)

Fig. 9 Back Porch Delay Variation

vs Temperature

850

740

650

550

450

CLAMPING CURRENT (µA)

350

-25 -15 -5 5 15 25 35 45 55 65 75 85

TEMPERATURE (°C)

Fig. 8 Clamping Current vs Temperature

125

100

75

50

25

0

-25

-50

-75

100

BACK PORCH WIDTH VARIATION (ns)

-125

-25 -15 -5 5 15 25 35 45 55 65 75 85

TEMPERATURE (°C)

Fig. 10 Back Porch Width Variation

vs Temperature

25

20

15

10

5

0

HORIZONTAL DELAY VARIATION (ns)

-5

-25 -15 -5 5 15 25 35 45 55 65 75 85

Fig. 11 Horizontal Delay Variation

520 - 23 - 03

TEMPERATURE (°C)

vs Temperature

600

500

400

300

200

100

0

-100

-200

HORIZONTAL WIDTH VARIATION (ns)

-300

-25 -15 -5 5 15 25 35 45 55 65 75 85

6

TEMPERATURE (°C)

Fig. 12 Horizontal Width Variation

vs Temperature

CIRCUIT DESPCRIPTION

BACK PORCH OUTPUT (pin 5)

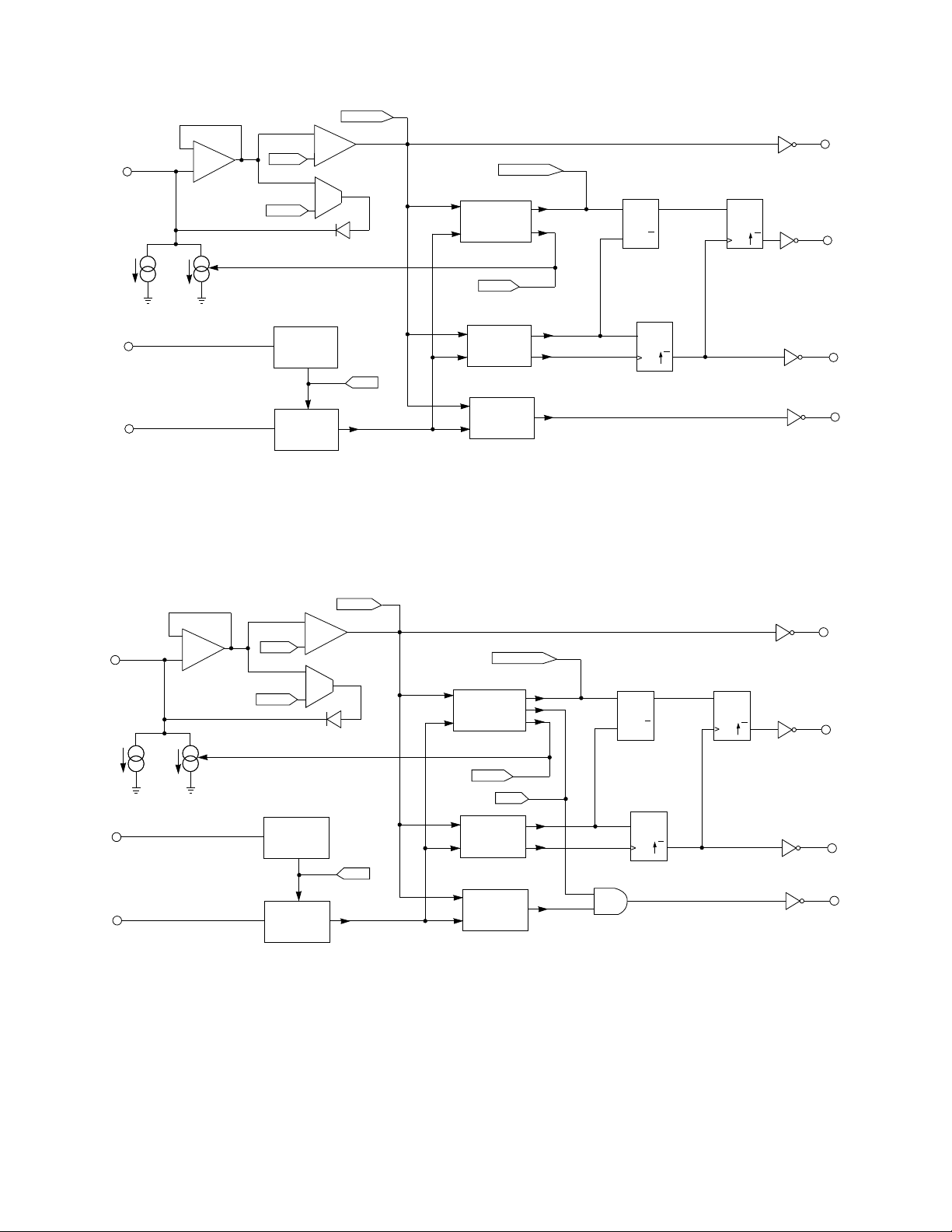

The block diagrams for the GS1881, GS4881 and GS4981,

are shown in Figures 17 through 19, with timing diagrams for

the devices shown in Figure 20.

When stimulated by a composite input signal, the GS1881

and GS4881 sync separators output composite sync,

vertical sync, back porch, and odd/even field information.

The GS4981 substitutes the odd/even output of the GS4881

with a horizontal output. An external resistor on pin 6 is used

to define internal currents allowing the devices to accommodate

horizontal scan rates from 15 kHz to 130 kHz.

COMPOSITE VIDEO INPUT (pin 2) and COMPOSITE

SYNC OUTPUT (pin 1)

Composite video is AC coupled via an external coupling

capacitor to pin 2. The device clamps the sync tip of the input

video to 1.5 V ( V

clamp voltage ( V

) and then slices at 77 mV above the

clamp

). The resultant signal, provided at

slice

pin 1, is a reproduction of the input signal with the active video

portion removed. As V

clamp

and V

are supply and input

slice

signal independent, for 0.5 V p-p signals (sync height of 143

mV) slicing will occur at just above the 50% point and for 2 V

p-p signals (sync height of 572 mV) slicing will occur at

approximately 13% of sync height.

The video signal path and composite sync slicing circuitry

have been optimized and compensated to achieve a low

propagation delay that is stable over temperature. The typical

delay is 60 ns with less than 3 ns drift over the commercial

temperature range.

In an NTSC composite video signal, horizontal sync pulses are

followed by the back porch interval. The device generates a

negative going pulse on pin 5 during this time. It is delayed

typically 500 ns from the rising edge of sync and has a typical

width of 2.5 µs. Both of these times are set by the external R

SET

resistor.

During the pre-equalizing, vertical sync, and post-equalizing

periods, composite sync doubles in frequency. The GS4881

and GS4981 maintain the back porch output at the horizontal

rate due to Back Porch Enable (BPEN), generated by the

internal windowing circuit, which forces back porch to be

asserted at the horizontal rate. This gating circuit is also the

reason for the excellent impulse noise immunity of the back

porch output as shown in Figure 14.

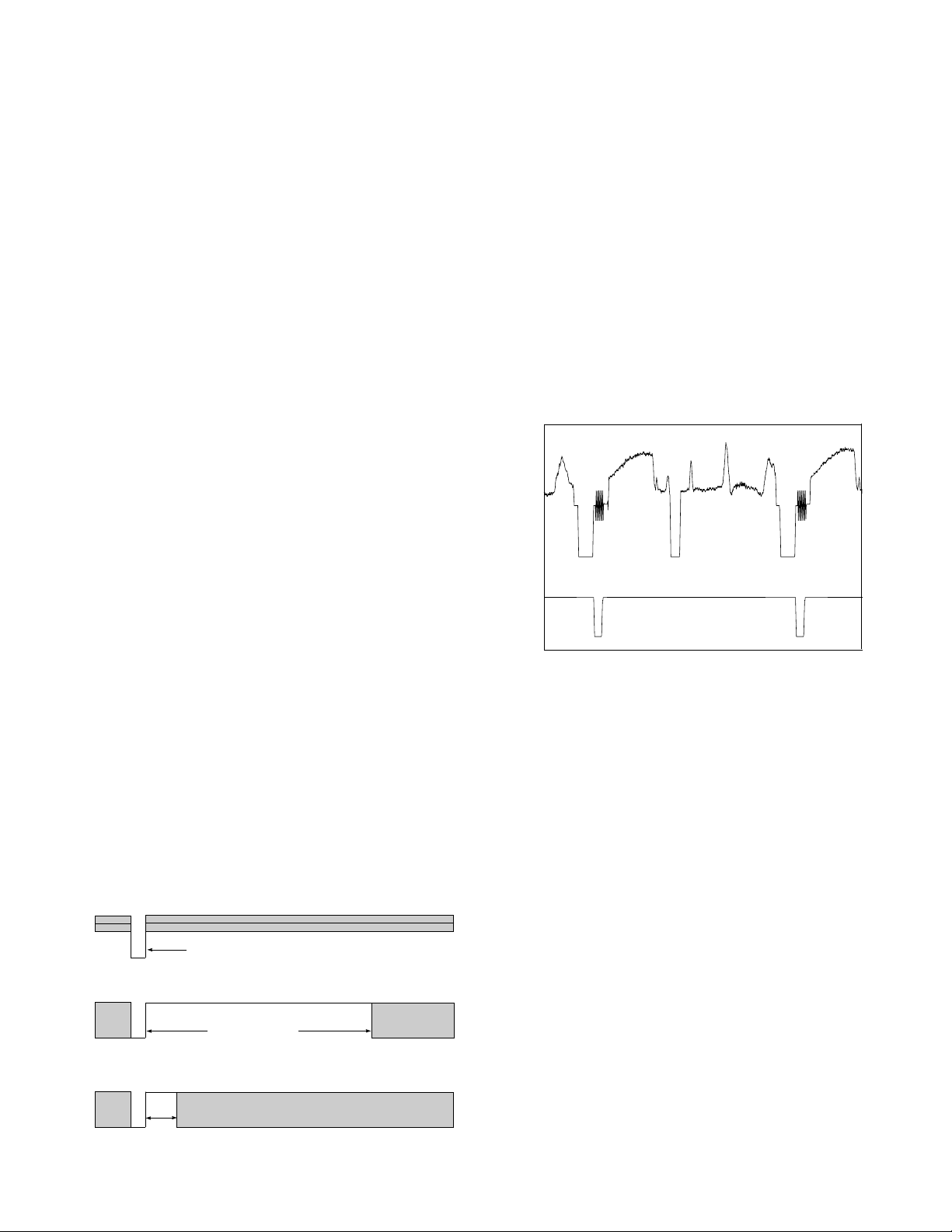

Video

Input

Impulse

Noise

Back

Porch

Output

GS4881

GS4981

Fig. 14 Back Porch Noise Immunity

The typical input clamp discharge current is 11µA. This

current is optimal under normal operating circumstances but

needs to be increased when the clamp is trying to recover

from negative going impulse noise. The device improves the

recovery time by raising a NOSYNC flag when there has not

been a sync pulse for approximately 1

1

/2 horizontal lines.

When this flag is raised the discharge current is increased by

85 µA so that the recovery time is sped up by nearly 10 times.

Figure 13 shows a comparison between the recovery times

with and without the increased discharge current.

VIDEO INPUT

IMPULSE NOISE

COMPOSITE SYNC RECOVERY TIME without INCREASED DISCHARGE CURRENT (LM1881)

RECOVERY TIME T1

COMPOSITE SYNC RECOVERY TIME with INCREASED DISCHARGE CURRENT (GS1881, GS4881, GS4981)

RECOVERY TIME

T1 / 10

Fig. 13 Impulse Noise: Recovery Time Comparison

The GS1881 does not gate the Back Porch which allows for

total pin compatibility with the LM1881.

VERTICAL SYNC OUTPUT (pin 3)

The vertical sync interval is detected by integrating the

composite sync pulses. The first broad vertical sync pulse

causes an internal capacitor to charge past a fixed threshold

and raises an internal vertical flag. Once the vertical flag is

raised, the positive edge of the next serration clocks out the

vertical output. When the vertical sync interval ends, the first

post equalizing pulse is unable to charge the capacitor

sufficiently, causing the internal vertical flag to go high. The

rising edge of the second post-equalizing pulse then clocks

out the high flag to end the vertical sync pulse. The vertical

output is clocked in and out and therefore is a fixed width of

197.7 µs (3H + 4.7 µs + 2.3 µs). In the case of a non-standard

vertical interval that has no serrations, a second internal

capacitor is charged and clocks the vertical pulse out after

typically 65 µs. In this case the end of the vertical pulse will still

be the rising edge of the second post-equalizing pulse. As the

vertical detector is designed as a true integrator, it provides

improved noise immunity.

7

520 - 23 - 03

ODD/EVEN FIELD OUTPUT (pin 7 GS1881, GS4881)

HORIZONTAL OUTPUT (pin 7 GS4981)

NTSC PAL and SECAM composite video standards are

interlaced video schemes and therefore have odd and even

fields. For odd fields the first broad vertical sync pulse is

coincident with the start of horizontal, while for even fields the

first broad vertical sync pulse starts in the middle of a horizontal

line. Therefore by comparing the vertical sync with an internally

generated horizontal sync the odd/even field information is

determined. This output is clocked out by the falling edge of

vertical sync. The odd/even output is low during even fields

and high during odd fields. This method of detecting odd and

even fields is very noise tolerant.

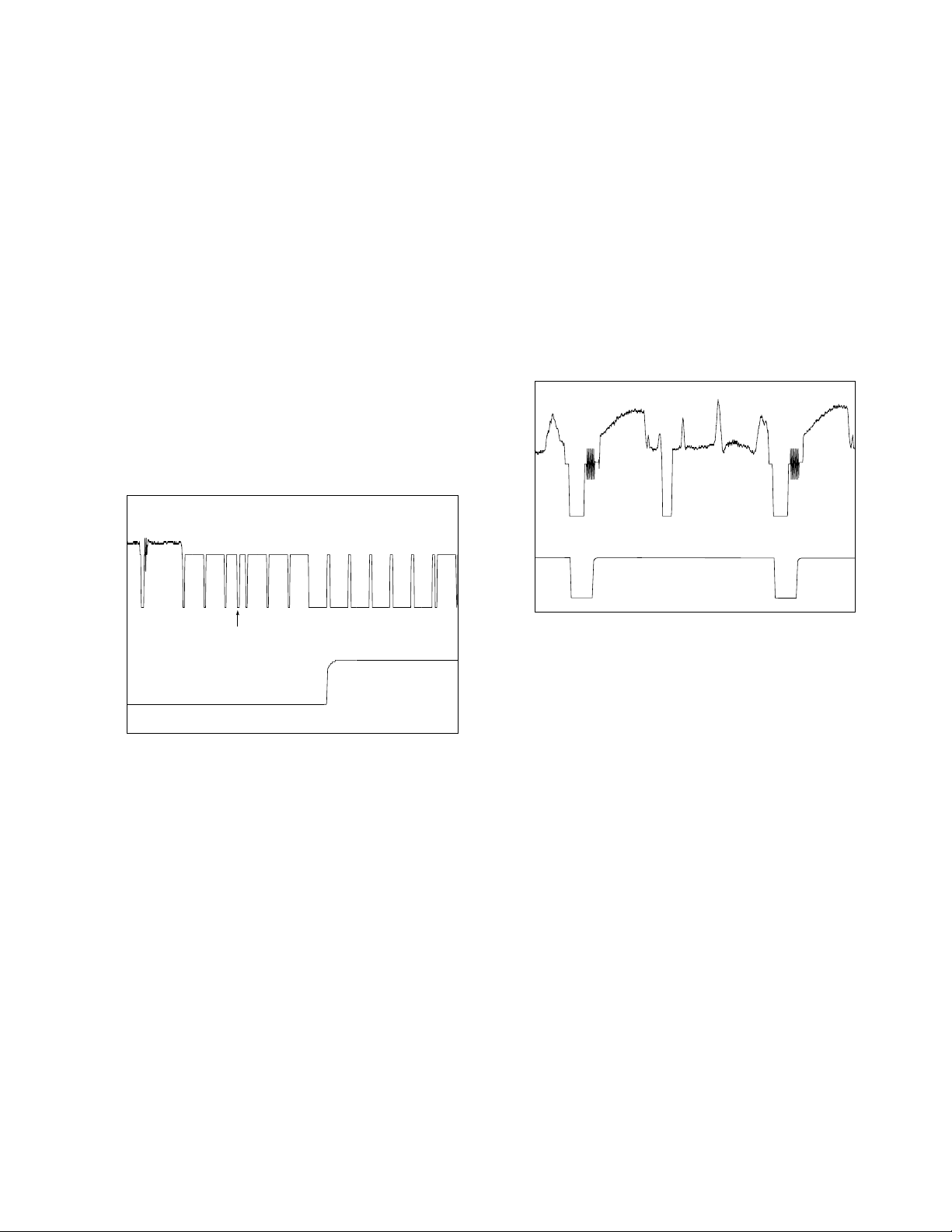

Noise during the pre-equalizing pulses does not affect the

output since the field decision is made at the beginning of the

vertical interval. This noise immunity is displayed in Figure 15

in which an extra pre-equalizing pulse has been added to the

video input with no negative effect on the odd/even field

information.

Video

Input

As mentioned above, the odd/even field output of the

GS1881 and GS4881 is generated by comparing vertical

sync with an internal horizontal sync signal. This horizontal

sync signal is a true horizontal signal (i.e. maintained during

the vertical interval) and is outputted on pin 7 for the

GS4981. A delay of 190 ns from the video input and a width

of 6.5 µs are typically characteristics for this signal.

The windowing circuit which generates horizontal provides

excellent impulse noise immunity as shown in Figure 16. This

output buffer is an open collector stage with an internal

10 kΩ pull up resistor.

Video

Input

Impulse

Noise

Horizontal

Output

Odd/Even

Output

Impulse

Noise

Even Odd

Fig. 15 Odd/Even Output

Fig. 16 Horizontal Output

520 - 23 - 03

8

VIDEO

INPUT

(Pin 2)

11µ

V

(Pin 8)

R_SET

(Pin 6)

C SYNC

-

-

V SLICE

+

V CLAMP

+

-

HORIZONTAL

+

WINDOWING

CIRCUIT

Q

D

Q

G

D

CLK

Q

Q

COMPOSITE

SYNC OUTPUT

(Pin 1)

ODD / EVEN

OUTPUT

(Pin 7)

85µ

NOSYNC

CC

VOLTAGE

REGULATOR

VERTICAL

DETECTOR

D

CLK

Q

Q

1.2V

BACK PORCH

TIMING

CURRENTS

DETECTOR

VERTICAL SYNC

OUTPUT

(PIN 3)

BACK PORCH

OUTPUT

(Pin 5)

Fig. 17 GS1881 Block Diagram

VIDEO

INPUT

(Pin 2)

11µ

V

(Pin 8)

R_SET

(Pin 6)

C SYNC

-

-

+

V CLAMP

V SLICE

+

-

HORIZONTAL

+

WINDOWING

CIRCUIT

D

Q

Q

G

D

CLK

Q

Q

COMPOSITE

SYNC OUTPUT

(Pin 1)

ODD / EVEN

OUTPUT

(Pin 7)

85µ

NOSYNC

B PEN

CC

VOLTAGE

REGULATOR

VERTICAL

DETECTOR

D

CLK

Q

Q

1.2V

BACK PORCH

TIMING

CURRENTS

DETECTOR

VERTICAL SYNC

OUTPUT

(PIN 3)

BACK PORCH

OUTPUT

(Pin 5)

Fig. 18 GS4881 Block Diagram

9

520 - 23 - 03

VIDEO

INPUT

(Pin 2)

C SYNC

-

+

-

+

V 1

-

+

V 2

WINDOWING

10k

CIRCUIT

COMPOSITE

SYNC OUTPUT

(Pin 1)

HORIZONTAL

OUTPUT

(Pin 7)

11µ

V

(Pin 8)

R_SET

(Pin 6)

COMPOSITE SYNC OUTPUT

GS1881, GS4881, GS4981

BACK PORCH OUTPUT

85µ

CC

COMPOSITE

VIDEO INPUT

GS4881, GS4981

NOSYNC

B PEN

D

CLK

Q

Q

VOLTAGE

REGULATOR

VERTICAL

DETECTOR

1.2V

BACK PORCH

TIMING

CURRENTS

DETECTOR

Fig. 19 GS4981 Block Diagram

525 1 2 3 4 5 6 7 8

VERTICAL SYNC

OUTPUT

(PIN 3)

BACK PORCH

OUTPUT

(Pin 5)

BACK PORCH OUTPUT

HORIZONTAL OUTPUT

VERTICAL SYNC OUTPUT

GS1881, GS4881, GS4981

GS1881

GS4981

ODD/EVEN OUTPUT

GS1881, GS4881

600ns

2.5µs

COMPOSITE

VIDEO INPUT

BACK PORCH

OUTPUT

500ns

2.5µs

Fig. 20 GS1881, GS4881, GS4981 Video Sync Separator Timing Diagram

520 - 23 - 03

10

APPLICATION NOTES

(1) Choosing the Appropriate Input Coupling Capacitor to

Optimize Slicing Level and Hum Rejection

The video designer can adjust the slicing level by choosing the

value of the input coupling capacitor. The relationship between

slicing level and input coupling capacitor is described by the

following equation.

I

∆V

where: I

∆T = T

C

SLICE

DIS

= ∆T = V

C

C

= clamp discharge current = 11 µA

DIS

- T

LINE

= input coupling capacitor

C

DROOP

= (63.5 µs - 4.7 µs)

SYNC

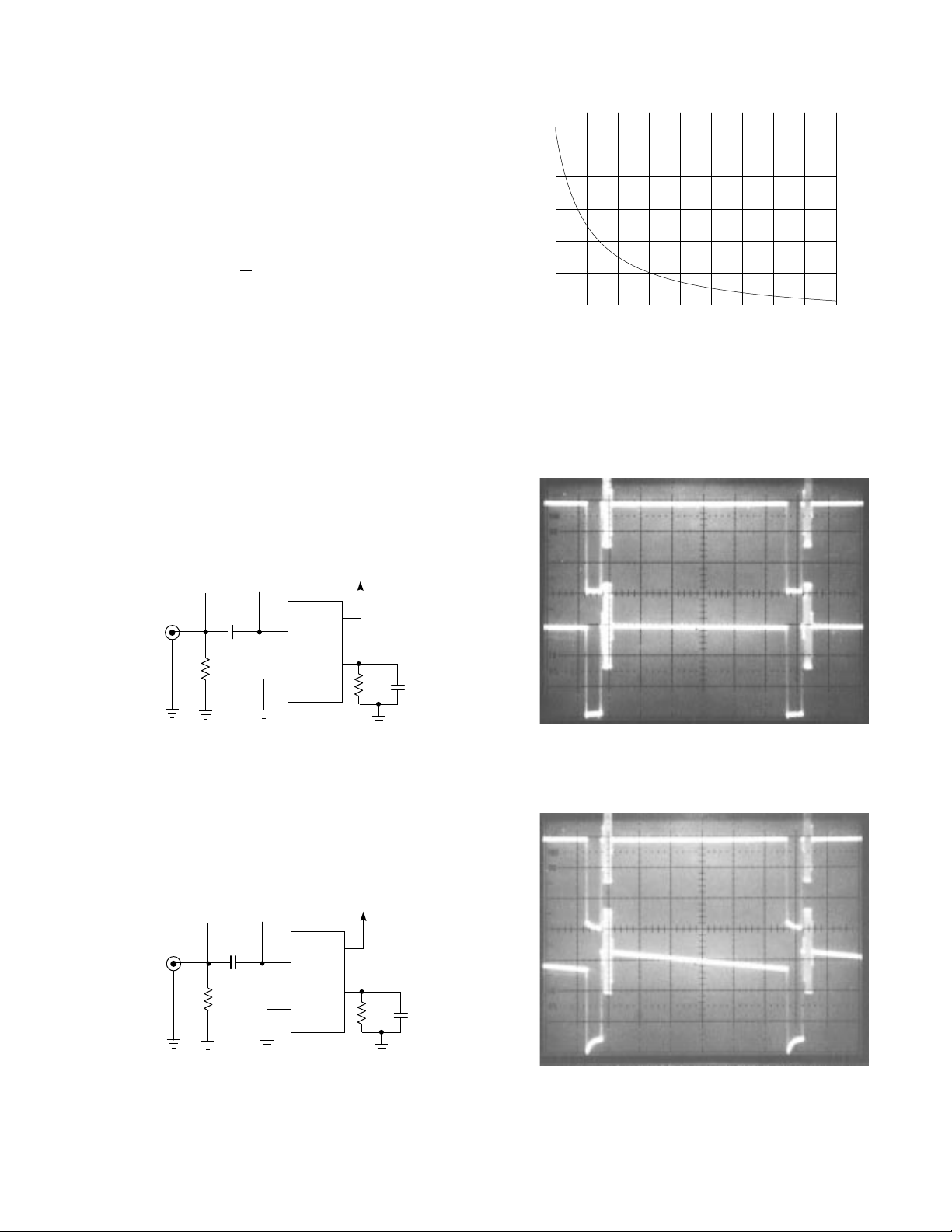

Figure 21 is a graphical representation of this equation and

photographs 1 and 2 show the input video waveforms

for 0.1 µF and 0.01 µF input capacitors respectively. The

advantage in choosing a smaller input coupling capacitor, is

increased hum rejection as the following analyses illustrates.

137

127

117

107

97

SLICING LEVEL (mV)

87

77

0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10

Fig. 21 Slicing Level vs Input Coupling Capacitor

CH1

INPUT COUPLING CAPACITOR (µF)

VIDEO

VIDEO

CH1

CH2

0.1µF

75Ω

Test Circuit 1

CH1

0.01µF

75Ω

CH2

8

2

6

4

680k

0.1µ

CH2

Photograph 1

CH1

8

2

6

4

680k

0.1µ

CH2

Test Circuit 2

11

Photograph 2

520 - 23 - 03

The interfering hum component is defined by:

verifying that there is enough clamping current

v

where: V

ƒ

HUM

HUM

(t) = V

cos(2πƒ

P

= Peak voltage of AC hum

P

HUM

t)

= Frequency of hum (50 Hz or 60 Hz)

The maximum rate of change of this hum signal occurs at the

zero crossing points and is:

dv

HUM

= ± V

dt

t =

π 3π

,

2 2

P

2πƒ

HUM

Since the horizontal scan period is much faster than the period

of the interference ( 63.5 µs << 1/ƒ

is to assume that the maximum line to line voltage change

) a good approximation

HUM

resulting from the interfering hum is:

∆V

where: T

The total line to line voltage change (∆V

by adding the hum component (∆V

component (V

∆V

DROOP

T

= ± VP2πƒ

HUM

= 63.5 µs

LINE

). This calculation results in two cases:

T

HUM

LINE

) can then be calculated

T

) and the droop

HUM

∆V

T

Case A Case B

∆VT = ∆V

To correct for ∆V

in case A, the input stage must be able to

T

charge the input capacitor ∆V

+ V

HUM

DROOP

volts in 4.7 µs. This is not a

T

constraint as the typical clamping current of 650 µA can

accomplish this for practical values of coupling capacitor.

The only way to compensate for ∆VT in case B is to make

V

DROOP

> ∆ V

HUM

. V

is increased by decreasing the input

DROOP

coupling capacitor value. Therefore the video designer can

increase hum rejection by decreasing the value of this capacitor.

The following is a numerical example:

∆V

= 29.4 mV + 29.4 mV = 58.8 mV

t

.

. i = 0.022 µ = 275 µA

.

58.8 mV

( )

4.7 µ

which is less than 650 µA.

(2) FIltering

In order to keep the input to output delay small and temperature

stable, no chrominance filtering is done within the device.

External filtering may be necessary if the input signal contains

large chrominance components (less than 77 mV from sync

tip) or has significant amounts of high frequency noise. This

filter can be a simple low pass RC network constructed by a

resistance (R

to ground. A single pole low pass filter having a corner

) in series with the source and a capacitor (Cƒ)

S

frequency of approximately 500 kHz will provide ample

bandwidth for passing sync pulses with almost 18 dB

attenuation at 3.58 MHz. Care should be taken in choosing

the value of the series resistor in the filter since the source

resistance seen by the sync separator affects its performance.

As the source resistance rises, the video input sync tip starts

to be clipped due to the clamping current during the sync.

This clamping current is relatively large due to the

non-symmetric duty cycle of video. To a good approximation

the amount of sync clamp current can be calculated as

follows:

I

( I

CLAMP

CLAMP

.

) (T

AVG

(4.7 µs) = (11 µA) (63. 5 µs - 4.7 µs)

AVG

.

. I

CLAMP

) = (I

SYNC

AVG

DIS

= 137.6 µA

) (T

LINE

- T

SYNC

)

This clamp current flows in the source resistance causing a

voltage drop equal to :

V

= ( I

CLIP

CLAMP

= (137.6 µ) (R

AVG

) (RS)

)

S

... V

choosing C

= (63.5 µ - 4.7 µ) = 29.4 mV

DROOP

11

0.022

= 0.022 µF

c

the maximum amount of 60 Hz hum that could be rejected

would be when:

∆V

... VP = = =1.23v

520 - 23 - 03

DROOP

= ∆V

∆V

DROOP

2

πƒ

HUMTLINE

= V

HUM

2πƒ

P

29.4mV

2π(60) (63.5 µ)

HUM TLINE

PEAK

HUM

12

VIDEO

INPUT

I

CLAMP

R

S

- +

V

CLIP

75Ω

Fig. 22 Simple Chrominance Filtering

CC

C

ƒ

2

4

8

6

680k

0.1µ

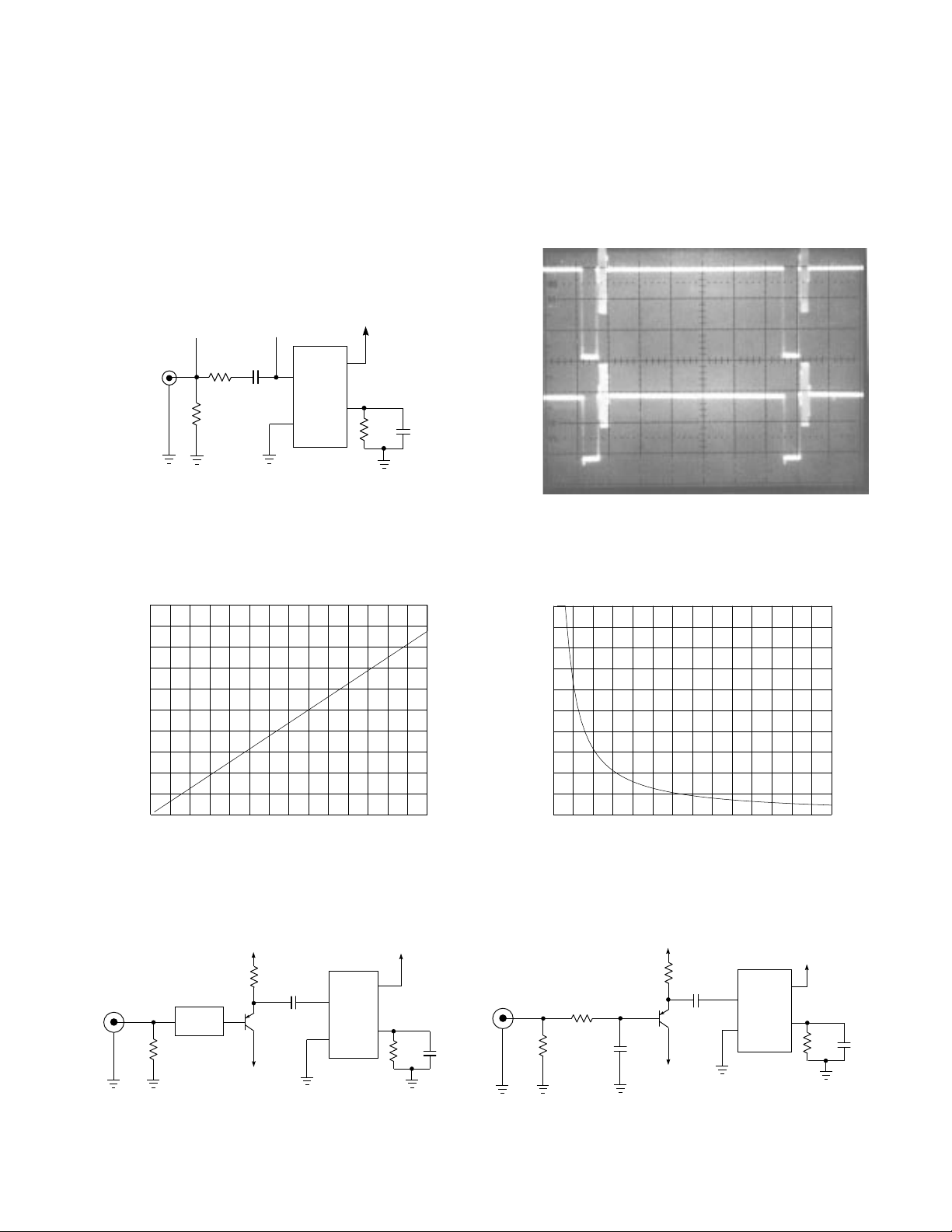

Photograph 3 shows the amount of sync clipping for a 560 Ω

source resistor. A graph of V

Figure 23, and Figure 24 shows the corresponding capacitor

versus RS is shown in

CLIP

value for a particular series resistor to provide a corner

frequency of 500 kHz.

In applications where signal levels are small the amount of

attenuation should be minimized. It follows from Figure 23 and

Figure 24 that in order to minimize attenuation a small series

resistor and a larger capacitor to ground should be chosen.

This however, increases the capacitive loading of the signal

source.

Another way to minimize the amount of attenuation is to control

the source resistance seen by the sync separator by using a

PNP emitter follower (Figure 25). A PNP emitter follower works

well to drive the sync separator, and does not require much

DC current because the transistor provides the current when

it is needed during sync. Figure 26 is a typical application

circuit that minimizes sync tip clipping.

CH1

CH1

VIDEO

560Ω

75Ω

CH2

8

2

0.1µF

6

4

Test Circuit 3

100

90

80

70

60

(mV)

50

CLIP

40

V

30

20

10

0

0 100 200 300 400 500 600 700

SERIES RESISTOR (Ω)

Fig. 23 V

vs Series Resistor

CLIP

680k

0.1µ

CH2

Photograph 3

10

9

8

7

6

5

Cƒ (nF)

4

3

2

1

0

0 100 200 300 400 500 600 700

SERIES RESISTOR (Ω)

Fig. 24 Cƒ vs Series Resistor

VIDEO

INPUT

V

CC

5.6k

2

C

4

75Ω

FILTER

C

-5V

Fig. 25 PNP Emitter Follower Buffer

V

CC

-5V

5.6k

CC

8

2

6

4

680k

0.1µ

8

6

680k

0.1µ

VIDEO

INPUT

75Ω

5.6k

56p

Fig. 26 Typical NTSC Application Circuit

13

520 - 23 - 03

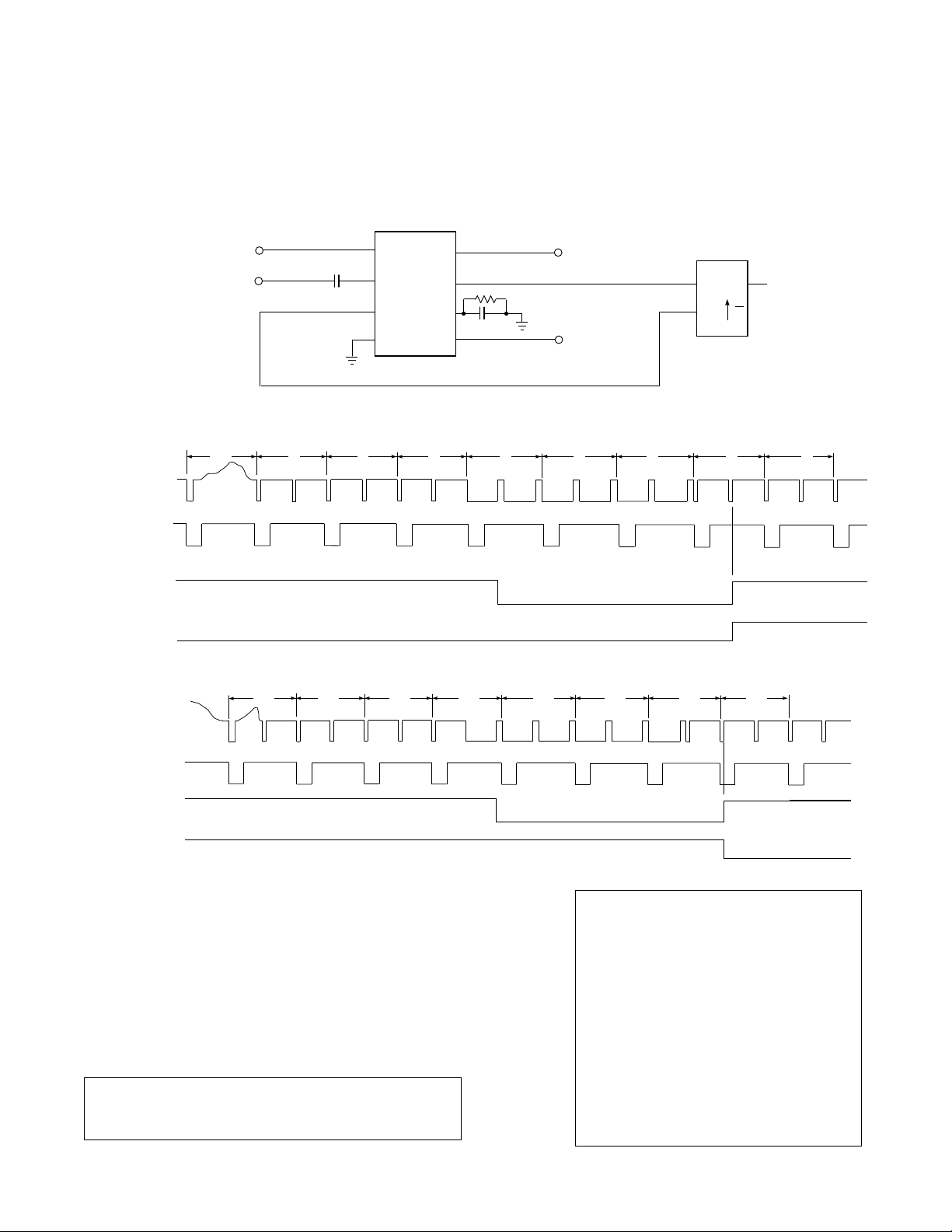

(3) Deriving Odd/Even Using the GS4981

Odd/even field information can be derived using the vertical

and horizontal outputs from the GS4981 along with an external

positive edge D flip/flop. The horizontal output is used

as the D input and the vertical output as the clock, as

shown in Figure 27.

GS4981

1

2

3

4

Fig. 27 Derivation of Odd/Even with GS4981

START OF ODD FIELD

COMPOSITE

VIDEO INPUT

HORIZONTAL OUTPUT

VERTICAL SYNC OUTPUT

GS4981

GS4981

COMPOSITE

SYNC OUTPUT

COMPOSITE

VIDEO INPUT

VERTICAL

SYNC OUTPUT

525 1 2 3 4 5 6 7 8

0.1µF

At the start of an odd field the vertical output ends in the middle

of the horizontal line and a high will be latched. At the start of

an even field, the vertical output ends near the beginning of

the horizontal line and since the horizontal output is low, a low

will be latched. This timing sequence is shown in Figure 28.

5 - 12V

V

8

7

680kΩ

6

0.1µF

5

CC

HORIZONTAL

R

SET

BACK PORCH

OUTPUT

D FLIP/FLOP

D Q

CLK Q

V

ODD/EVEN

OUTPUT

ODD/EVEN OUTPUT

START OF EVEN FIELD

263 264 265 266 267 268 269 270

COMPOSITE

VIDEO INPUT

HORIZONTAL

GS4981

VERTICAL SYNC OUTPUT

GS4981

ODD/EVEN OUTPUT

REVISION NOTES

The only change from 520-23-02 to 520-23-03 is that the document has been

upgraded to a full DATA SHEET. It is no longer Preliminary.

Fig. 28 Timing Diagram

DOCUMENT

IDENTIFICATION

PRODUCT PROPOSAL

This data has been compiled for market investigation purposes

only, and does not constitute an offer for sale.

ADVANCE INFORMATION NOTE

This product is in development phase and specifications are

subject to change without notice. Gennum reserves the right to

remove the product at any time. Listing the product does not

constitute an offer for sale.

PRELIMINARY

The product is in a preproduction phase and specifications are

subject to change without notice.

DATA SHEET

The product is in production. Gennum reserves the right to

make changes at any time to improve reliability, function or

design, in order to provide the best product possible.

Gennum Corporation assumes no responsibility for the use of any circuits described herein and makes no representations that they are free from patent infringement.

520 - 23 - 03

© Copyright March 1991 Gennum Corporation. All rights reserved. Printed in Canada.

14

Loading...

Loading...