Page 1

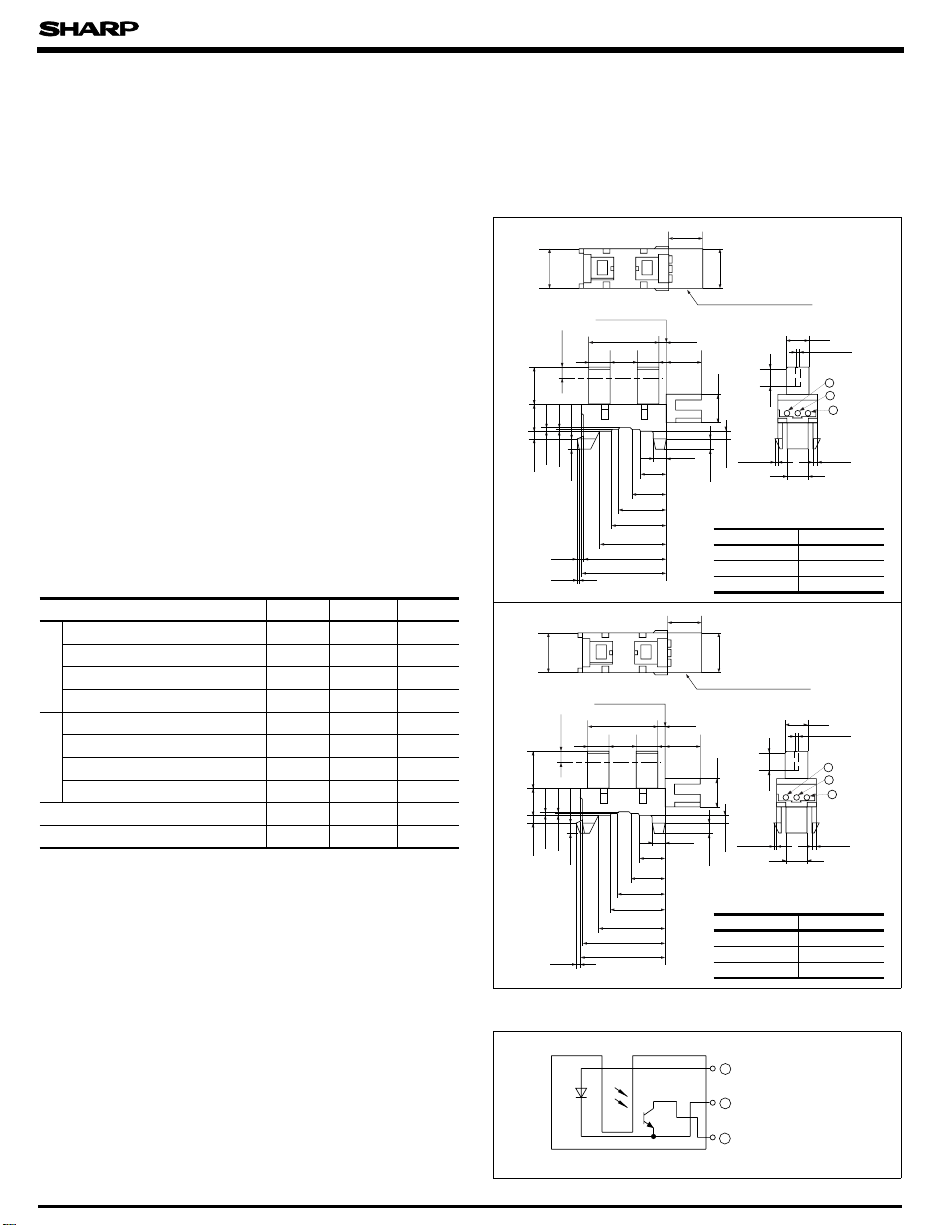

Compact Photointerrupter

GP1S73P/GP1S74P

with Connector

GP1S73P/GP1S74P

■■

1. Compact type

2. Snap-in mounting type

3. 3 kinds of mounting plate thickness

(Applicable plate thickness : 1.0, 1.2 and 1.6 mm)

■

Applications

1. Copiers

Outline DimensionsFeatures

GP1S73P

8.0

7.25.61.1

)

2.3

(

(Sensor center)

JAPAN

(Case surface)

13.6

5.0

4.3 4.3

(Unit : mm)

( 6.8 )

73

SHARP

6.8±1

( 7.8 )

JAPAN AMP made

connector 175487-3

1.6

)

5.8

(

4.7

2-0.5 ± 0.1

(Slit)

3.2

1 Collector

2 GND

3 Anode

2. Laser beam printers

3. Facsimiles

■

Absolute Maximum Ratings

Forward current

*1

Peak forward current

InputOutput

Reverse voltage

Power dissipation

Collector-emitter voltage

Emitter-collector voltage

Collector current

Collector power dissipation

Operating temperature

Storage temperature

*1 Pulse width 100µ s, Duty ratio=0.01

*2 The connector should be plugged in/out at normal temperature.

I

F

I

FM

V

R

P75mW

V

CEO

V

ECO

I

C

P

C

T

opr

T

stg

(Ta=25˚C)

Rating UnitParameter Symbol

50 mA

1A

6V

35 V

6V

20 mA

75 mW

- 25 to + 85

- 40 to + 85

˚C

˚C

0.6

0.75

GP1S74P

8.0

7.25.61.1

0.6

0.7

0.2

2.3

( 2.3 )

(Sensor center)

0.2

2.3

14.0

16.81.2

17.0

JAPAN

(Case surface)

13.6

5.0

4.3 4.3

14.0

16.8

17.0

2.4

5.4

6.9

9.9

11.4

74

5.4

6.9

9.9

11.4

1.1

2.3

* Unspecified tolerances shall be

as follows.

*

( ) : Connector dimensions for reference

Tolerance Dimension(d)

± 0.15

± 0.2

± 0.3

( 6.8 )

( 7.8 )

SHARP

6.8± 1

JAPAN AMP made

connector 175487-3

1.6

( 5.8 )

2.4

1.1

2.3

* Unspecified tolerances shall be

as follows.

*

( ) : Connector dimensions for reference

Tolerance Dimension(d)

± 0.15

± 0.2

± 0.3

3.2

4.0

5.0<= d < 15.0

15.0 <= d

4.7

2-0.5 ± 0.1

(Slit)

1 Collector

4.0

5.0<= d < 15.0

15.0 <= d

2-0.92-0.5

d < 5.0

2 GND

3 Anode

2-0.92-0.5

d < 5.0

■

Internal Connection Diagram (Both GP1S73P/GP1S74P)

3 Anode

2 GND

1 Collector

Page 2

Electro-optical Characteristics

■

Parameter Symbol MIN. TYP. MAX. UnitConditions

Forward voltage

Input

Peak forward voltage

Reverse current

Output

Dark current

Collector current

Transfer

characteristics

Collector-emitter saturation voltage

Response time

Rise time

Fall time

V

F

V

FM

I

R

I

CEO

I

C

V

CE(sat

t

r

t

f

= 20mA

I

F

I

FM

V

R

V

CE

V

CE

)

= 40mA, IC= 0.5mA

I

F

V

CE

R

L

=0.5A

=3V

= 20V

= 5V, IF= 20mA

= 2V, IC= 2mA

= 100 Ω

GP1S73P/GP1S74P

(Ta=25˚C)

- 1.2 1.4 V

-V

3.0 4.0

--10µA

- 1 100 nA

0.5 - 15 mA

-- V

-315µs

-420µs

0.4

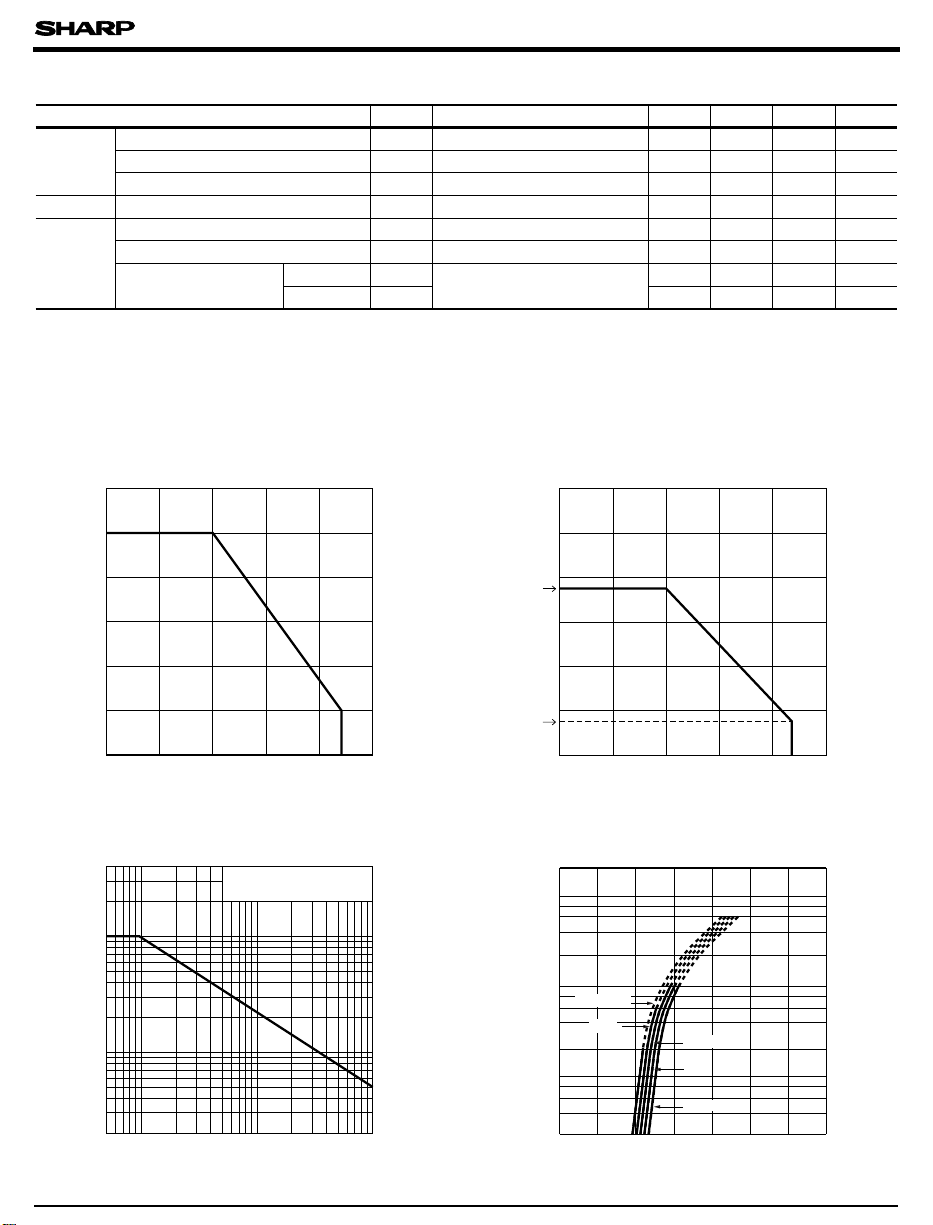

Fig. 1 Forward Current vs. Ambient

Temperature

60

50

)

mA

40

(

F

30

20

Forward current I

10

0

- 25 0 25 50 100

75 85

Fig. 2 Collector Power Dissipation vs.

Ambient Temperature

)

100

mW

(

C

80

75

60

40

20

15

Collector power dissipation P

0

- 25 0 25 50 75 100

85

Ambient temperature Ta (˚C) Ambient temperature Ta (˚C)

Fig. 3 Peak Forward Current vs. Duty Ratio Fig. 4 Forward Current vs. Forward Voltage

Pulse width<= 100µs

= 25˚C

T

2000

1000

(mA)

FM

500

200

100

50

Peak forward current I

20

-2

55252

10

a

-1

10

Duty ratio

1

1000

500

200

)

mA

100

(

F

50

Ta= 85˚C

20

50˚C

10

Forward current I

5

2

1

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

25˚C

0˚C

- 25˚C

Forward voltage VF (V

)

Page 3

GP1S73P/GP1S74P

Fig. 5 Collector Current vs. Forward Current

CE=5V

10

V

Ta= 25˚C

8

6

4

Collector current Ic (mA)

2

0

01020304050

Forward current IF (mA

)

Fig. 7 Collector Current vs. Ambient

temperature

4.0

3.5

3.0

2.5

2.0

1.5

1.0

Collector current Ic (mA)

0.5

0

- 25 0 25 50 75 100

Ambient temperature Ta (˚C)

I

F= 20mA

CE=5V

V

Fig. 6 Collector Current vs. Collector-emitter

Voltage

10

8

6

IF= 50mA

40mA

30mA

4

Collector current Ic (mA)

3

0

012345678910

20mA

10mA

Collector-emitter voltage V

Ta= 25˚C

(V

CE

)

Fig. 8 Collector-emitter Saturation Voltage

vs. Ambient Temperature

0.25

)

V

(

)

sat

(

0.20

CE

0.15

0.10

0.05

Collector-emitter saturation voltage V

0

- 25 0 25 50 75 100

Ambient temperature Ta (˚C)

I

F= 40mA

I

C= 0.5mA

Fig. 9 Response Time vs. Load Resistance

100

VCE=2V

50

I

= 2mA

C

T

= 25˚C

a

20

10

t

5

2

1

Response time (µs)

0.5

0.2

0.1

0.01 0.02 0.05 0.1 0.2 0.5 1 2 5 10

f

t

r

t

d

t

s

Road resistance RL (kΩ

)

Input

Test Circuit for Response Time

V

R

D

CC

R

L

Output

Input

Output

t

d

10%

90%

t

s

t

r

t

f

Page 4

GP1S73P/GP1S74P

Fig. 10 Frequency Characteristics

)

dB

(

-5

V

-10

Voltage gain A

-15

-20

3

205525252

10

RL=

10kΩ

4

10

Frequency f (Hz)

1kΩ 100Ω

10

V

I

C

T

5

=2V

CE

= 2mA

= 25˚C

a

6

10

Fig. 11 Dark Current vs. Ambient Temperature

-6

10

V

= 20V

CE

5

2

-7

10

)

A

5

(

CEO

2

-8

10

5

2

-9

Dark current I

10

5

2

-10

10

0 255075100

-25

Ambient temperature Ta (˚C)

Fig. 12 Detecting Position Characteristics (1) Fig. 13 Detecting Position Characteristics (2)

Sensor

Ta= 25˚C

CC =5V

V

Shield plate

L

100

90

80

70

60

50

40

30

Relative collector current (%)

20

10

12345

Shield distance L (mm)

Ta= 25˚C

CC=5V

V

L

Shield plate

Sensor

100

90

80

70

60

50

40

30

Relative collector current (%)

20

10

12345

Shield distance L (mm)

Page 5

GP1S73P/GP1S74P

Recommended Mounting Hole Drawing(Dimensions shown are recommended values.

■

Use the photointerrupters after checking the mounting strength and others on an actual machine.)

1.

It is recommended to mount the photointerrupters on the shear droop surface (punch side) of the mounting plate (metal plate).

2.

Mounting workability, shaking after mounting and mounting strength depend on the corner radius of the mounting plate and state of punching.

Determine the mounting hole dimensions after check on an actual machine.

3. General dimensional tolerances shall be ± 0.1 mm.

(Unit : mm)

General mounting type

Reverse insertion

preventive type

17

7.5 7.5

7.7

Plate thickness : 1.6 mm

17

7.5 7.5

2.42.4 2.4 2.4 2.4 2.4

7.7

Plate thickness : 1.6 mm

7.5

7.5

8 - R0.1± 0.1

66

17

66

17

8 - R0.1± 0.18 - R0.1± 0.1

3.53.5

17

7.5

Plate thickness : 1.0 mmPlate thickness : 1.2 mm

12 - R0.1± 0.112 - R0.1± 0.1 12 - R0.1± 0.1

3.53.5

17

7.5

Plate thickness : 1.0 mmPlate thickness : 1.2 mm

(Precautions for Operation)

1) In this product, the PWB is fixed with a hook, and cleaning solvent may remain inside the case;

therefore, dip cleaning or ultrasonic cleaning are prohibited.

2) Remove dust or stains, using an air blower or a soft cloth moistened in cleaning solvent.

However, do not perform the above cleaning using a soft cloth with solvent in the marking portion.

In this case, use only the following type of cleaning solvent for wiping off;

Ethyl alcohol, Methyl alcohol, Isopropyl alcohol

When the cleaning solvents except for specified materials are used, please contact us.

As for other general precautions, please refer to the chapter "Precautions for Use".

●

Loading...

Loading...