Page 1

1

FLOPPY DISK SUBSYSTEM CONTROLLER

General Description

The GM82C765B is a CMOS LSI device which interfaces a host

microprocessor to the floppy disk drive. It integrates the function of the

Formatter/Controller, Data Separator. Write Precompensation, Data rate

selection, Clock Generation, High Current Output Drivers, and TTL

compatible Schmitt Trigger Receivers. The GM82C765B consists of a

microprocessor interface, a microsequencer and a disk drive interface.

The host microprocessor interface of the GM82C765B supports a

12MHz, 286 microprocessor bus without the use of wait states. All inputs

within host microprocessor are Schmitt triggers, except for the data bus,

XTAL, and the host output sink 12mA.

Output drive capability is 20 LSTTL load, allowing direct

interconnection to bus structures without the use of buffers or transceivers.

On the disk drive interface, the GM82C765B includes data seperation that

has been designed to address high performance error rate on floppy disk

drives, and contains all the necessary logic to achieve classical 2nd order,

type2, phase locked loop performance. Write precompensation is included,

in addition to the usual formatting, encoding, decoding, step motor control,

and status sensing functions For PC/XT and PC/AT applications, the

device provides qualification of interrupt and DMA requests.

The disk drive interface of the GM82C765B connects directly to up to

four drives. All drive-related inputs are Schmitt triggers and the drive

outputs are open drain, and sink 48 mA.

The GM82C765B uses two clock inputs which provide the necessary

signals for internal timing. A 16MHz oscillator controls the data rate of

500, 250 and 125Kbits/sec, while a 9.6MHz oscillator controls the

300Kbit/sec data rate used in PC/AT designs.

The two XTAL oscillator circuits may be used for the 44-pin PLCC

package, while TTL clock inputs must be provided when using the 40-pin

DIP package.

In the PLCC version of the GM82C765B pins 17 and 40, which were

not utilized in DIP version of the GM82C765B, became

Change Enable) and

LOW.

DCHGEN

original GM82C765B part where

chip.

The GM82C765B has eight internal Registers. The 8 bit main status

register contains status information of the GM82C765B and may be

accessed any time. Another four status register under system control also

give various status and error information. The Control Register provides

support logic that latches the two LSBs used to select the desired data rate

that controls internal clock generation. The Operations Register replaces

the standard latched port used in floppy subsystem.

is offered as an option for those designs that used the

(Disk Change) respectively. Both are active

DCHG

did not exist as direct into the

DCHG

DCHGEN

(Disk

GM82C765B

GM82C765B

Features

∗ IBM PC compatible format

(single and double density)

– Floppy disk control and

operations on chip

– In PC AT mode, provides required

signal qualification DMA channel

– BIOS compatible and dual speed

Spindle Drive support

∗ Integrates Formatter/Controller/Data

Separation, Write Precompensation,

Data rate Selection, Clock

Generation, and drive interface

Drivers and Receivers into one chip

∗ Multisector and Multitrack transfer

capability.

∗ Direct Floppy Disk Drive interface

with no buffers needed

– 48mA sink output drivers

– Schmitt trigger Line Receivers

∗ Enhanced Host Interface:

– Supports 12MHz, 286 u-processor

– Capable of driving 20 LSTTL

Load

∗ Address mark detection circuitary

internal to Floppy Disk Controller

∗ On chip Clock Generation

Two TTL Clock Inputs for 40-DIP

∗ Two XTAL oscillator circuits for

44-Quad, PLCC

∗ User programmable Track Stepping

Rate and Head load/unload time

∗ Drivers up to four Floppy or micro

Floppy Disk Drives

∗ Data transfer DMA or non-DMA

mode

∗ Parallel seek operations on up to

four Drives

∗ Internal power up reset circuitry

∗ READ/WRITE access compatible

register with 8 or 12MHz 286

microprocessor with 0 wait states.

∗ DMA timing corrected.

∗ LOW POWER CMOS, +5V SUPPLY

Page 2

2

and A0=1. In special or PC AT mode, this

11 12 13 14 15 16 17 18

23 22 21

37

32 31 30 29 28 27

24

19

23 24 25 26 27 28 29 30 31 32 33 34 35 36

41

43 44

DS2

VSS HDL DIR

STEP

WD

DS4., MO2

DS3., MO1

Pin Configuration

RD

WR

CS

AO

DACK

TC

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DMA

IRQ

LDOR

LDCR

RST

RDD

1. Pin Descriptions

1

2

3

4

5

6

7

8

9

10

GM82C765B

19

20

GM82C765B

VCC

40

39

IDX

38

TROO

WP

HDL

MO2. DS4

MO1, DS3

DS2

VSS

DS1

STEP

DIRC

WD

WE

HS

PCVAL

CLK1

DRV

CLK2

RPM, RWC

DCHG

WP

TROO

IDX

VCC

RD

WR

CS

A0

CACK

TC

36

35

34

33

26

25

38 39

37

40

42

1

2

3

4

5

6

7 8 9 10 11 12 13 14 15 16 17

DBO

DB1

GM82C765B PL

DB2

DB4

DB3

DB5

DB6

DB7

DMA

DCHGEN

IRQ

HS

PCVAL

XT1

XT1

DRV

XT2

XT2

22

RDD

21

RST

20

LDCR

18

LDOR

PIN NO

DIP PLCC

1 1

2 2

3 3

MNEMOMIC SIGNAL NAME I/O

RD

WR

CS

A0 ADDRESS LINE I

4 4

DACK

5 5

(condinued on next page)

READ

WRITE

DMA

SELECTCHIP

FUNCTION

I

Control Signal for transfer of data or status onto the

ST

data bus by the GM82C765B

I Control signal for latching data form the bus into the

GM82C765B buffer register.

ST

Selected when 0 (Low) allowing RDorWR

operation from the host

Address line selecting data (=1) or status (=0)

ST

information

(A0 = Logic 0 during WR is illegal)

I

Used by the DMA Controller to transfer data from

ST

EACKNOWLEDG

the GM82C765B onto the bus. Logical equivalent to

CS

signal is qualified by DMAEN from the Operation

Register.

Page 3

3

PIN

DIP PLCC

6 6 TC

7-14 7-14

15

16

15 DMA

16 IRQ

17

17

18

19

20

18

19

20 RST RESET

21 RDD

22 2XT 2XTAL

23 XT2 XTAL2

21

(condinued on next page)

MENMO

-MIC

SIGNAL

NAME

TERMINAL

COUNT

DBO thru

DB7

DATA BUS 0

Thru

DATA BUS 7

DIRECT

MEMORY

ACCESS

INTERRUPT

REQUEST O BI

DISK

CHANGE

ENABLE

LOAD

OPERATIONS

REGISTER

LOAD

CINTROL

REGISTER

DATA

DISKREAD

DCHGEN

LDOR

LDCR

CLK2 CLOCK2

I/O

FUNCTION

This signal indicates to GM82C765B that data transfer is

complete. If DMA operational mode is selected for

command execution, TC will be qualified by

not in the programmed I/O execution. In PC AT or Special

mode, qualification by

I

mode, qualification by

ST

resister signal DMAEN to be logically true. Note also that

in PC AT mode, TC will be qualified by

requires the Operations

DACK

requires the operations

DACK

DACK

DMA or non-DMA host operation. programmed I/O in PC

AT mode will cause an abnormal termination error at the

completion of a command.

8-Bit bi-directional, tri-state, data bus.

I/O

D0 is the least significant bit (LSB).

BI

D7 is the most significant bit (MSB)

DMA request for byte transfer of data.

O

In Special or PC AT mode, this pin is tristated, enabled by

BI

the DMAEN signal from the Operation Register. This pin is

driven in the Base mode.

Interrupt request indicating the completion of command

execution or data transfer requests (in non DMA mode).

Normally driven in base mode. In special or PC AT mode,

this pin is tri-stated, enabled by the DMAEN signal from the

Operations Resister.

This input must be at logic = 0 to enable

I

status at pin 40 to be placed on DB7 during a RD = 0 of

ST

= 0. Internal pull-up.

LDCR

Address decode which enables the loading of the Operations

I

Resister. Internally gated with WR creates the strobe

ST

which latches the two LSBS from the data bus into the

Operation Resister.

Address decode which enables the loading of the Control

I

Resister. Internally gated with WR creates the strobe

which latches the two LSRs from thedata bus into the

ST

Control Resister.

Reset controller, placing microsequencer in idle. Resets

I

device outputs. Puts in base mode, not PC AT or Special

ST

mode.

This is the raw serial bit stream from the disk drive. Each

I

falling edge of the pulses represents a flux transition of the

ST

encoded data.

O N XTAL oscillator drive output for 44 pin PLCC should be

left floating if TTL inputs used at pin 23.

I N XTAL oscillator input used for non-standard data rates. It

may be driven with a TTL level signal

TTL level clock input used for non-standard data rates is

I

9.6MHz for 300 kbs, and can only be selected from the

N

Control Register. * XT2 (PIN23) of 44 pin-PLCC

GM82C765B

, but

DACK

, whether in

input

DCHG

Page 4

4

22 24 DRV DRIVE TYPE

25

1XI

1XTAL

26 XT1 XTAL1

23 CLK1 CLOCK1

24 27 PCVAL

25 28

26 29

27 30

28 31

29 32

30 33

HS

WE

WD

DIRC DIRECTION

STEP

PRECOMPEN-SATION

VALUE

HEAD

SELECT

1DS

PULSESTEP

CONTROL

ENABLEWRITE

DATAWRITE

1SELECTDRIVE

31 34 VSS GROUND Ground

32 35

33 36

2DS

,

1MO

3DS

2SELECTDRIVE

1ONMOTOR

3SELECTDRIVE

I

ST

O

ST

I

N

I

N

I

ST

O

HCD

O

HCD

O

HCD

O

HCD

O

HCD

O

HCD

O

HCD

O

HCD

GM82C765B

Drive type input indicates to the device that a two-speed

spindle motor is used if logic is O. In that case, the

second clock input will never be selected and must be

grounded.

XTAL oscillator drive output for 44 pin PLCC should

be left floating if TTL inputs used at pin 26.

XTAL oscillator input requiring 16MHz crystal. This

oscillator is used for all standard data rates, and may be

driven with a TTL level signal.

TTL level clock input is used to generate all internal

timings for standard data rates. Frequency must be

16MHz ± 0.1%, and may 40/60 or 60/40 duty cycle.

*

XT1 (PIN 26) of 44-PLCC

PRECOMPENSATION VALUE select input. This pin

determines the amount of write precompensation used

on the inner tracks of the diskette. Logic 1 = 125nS,

Logic 0 = 187nS

High Current drive (HCD) output selects the head (side)

of the floppy disk that is being read or written. Logic 1

= side 0. Logic 0 = side 1.

This HCD output becomes true, active low, just prior to

writing on the diskette. This allows current to flow

through the write head.

This HCD output DATAWRITE . Each failing edge of

the encoded data pulse stream causes a flux transition

on the media.

This HCD output determines the direction of the HEAD

step motor. Logic 1 = outward motion. Logic 0 =

inward motion.

This HCD output issues an active low pulse for each

track to track movement of the head.

This HCD output, when active low, is

1SELECTDRIVE in PC AT mode, enables the interface

in disk drive. This signal comes from the Operations

Register. In Base or Special mode, this output is #1 of

the four decoded Unit Selects, as specified in the device

command syntax.

This HCD output, when active low, is

2SELECTDRIVE in PC AT mode, enables the

interface in disk drive. This signal comes from the

Operations Register. In Base or Special mode, this

output is # 2 of the four decoded Unit Selects, as

specified in the device command syntax.

This HCD output, when active low, is MOTOR ON

enable for disk drive #1, in PC AT mode. This signal

comes from the OPERATIONS Register in the BASE or

Special mode, this output is #3 of the four decoded Unit

Selects as specified in the device command syntax.

Page 5

5

MNEMOMIC

PIN NO

DIP PLCC

34 37

2MO

4DS

SIGNAL NAME I/O

,

O

2 ON MOTOR

4SELECT DRIVE

This HCD output, when active low, is MOTOR ON

HCD

enable for disk drive #2, in PC AT mode. This signal

comes from the Operations Reg. In the Base or Special

mode, this output is #4 of the four decoded Unit

Selects as specified in the device command syntax

35 38 HDL HEAD

LOADED

36 39

RWC

RPM

REDUCED

WRITE

MINUTE PER

,CURRENT

SREVOLUTION

O

This HCD output, when active low, causes the head to

HCD

be loaded against the media in the selected drive.

O

This HCD output, when active los, causes a

HCD

REDUCED CURRENT WRITE

increased toward the inner tracks, becoming active

when tracks>28 are accessed. This condition is valid

for Base or Special mode, and is indicative of when

write precompensation is necessary. In the PC AT

mode, this signal will be active when CR0=1

40

DCHG

DISK

CHANGE

I

This ST input senses status from the drive, indicating

ST

active low that drive door is open or that the diskette

has possibly changed since last drive selection.

37 41 WP WRITE

PROTECTED

38 42

00TR

00 TRACK

I ST

I

This Schmitt Trigger (ST) input senses status from the

disk drive, indicating active low when a diskette is

WRITE PROTECTED

This ST input senses status from disk drive indicating

ST

active low when the head is positioned over the

outermost track,

39 43 IDX

INDEX

I

ST

This ST input senses status from the disk drive,

indicating active low when the head is positioned over

the beginning of a track marked by an index hole.

40 44 VCC +5V DC Input power supply.

Note: N – NORMAL INPUT, OUTPUT PAD

BI – BIDIRECTIONAL I/O PAD

ST – SCHMITT TRIGGER INPUT PAD

HCD – OPEN DRAIN HIGH CURRENT DRIVE OUTPUT PAD

FUNCTION

when bit density is

00 TRACK

GM82C765B

Page 6

6

2. Electrical Specifications.

2.1 Absolute Maximum Ratings

— OPERATING TEMPERATURE …………………...……………………. 0°C (32°F) to 70°C (158°F)

— STORAGE TEMPERATURE ………………………………………-55°C (-67°F) to +125°C (257°F)

— VOLTAGE on any pin with respect to ground …………………………. –0.3 V to Vcc +0.3V

— SUPPLY VOLTAGE with respect to ground ……………………………………………. 7.0V

2.2 DC ELECTRICAL CHARACTERISTICS

NOTE: Maximum limits indicate where permanent device damage occurs.

Continous operation at these limits is not intended and should be limited to those conditions specified in the DC operating Characteristics

DC Operating Caracteristics: )F32( C0T

A

SYMBOL PARAMETER MIN MAX UNITS

V +5V DC POWER SUPPLY 4.5

CC

VIL Input LOW Voltage-DATA BUS & XTOSC

VIH Input HIGH Voltage-DATA BUS & XTOSC 2.0

VILT

VIHT Input HIGH Threshold Voltage-Schmitt Trigger

VOL Output LOW-DBX, IRQ, DMA: lo=12.0mA

VOH Output HIGH-DBX, IRQ, DMA: lo=-5.0mA 2.8

VOLHC Output LOW-HIGH CURRENT: lo=48mA

ILUL Latch up CURRENT LOW 40.0

ILUH Latch up CURRENT HIGH -40.0

ILLX Leakage CURRENT LOW

ILHX Leakage CURRENT HIGH

ICC Supply Current-100uA source Loads

ICCHL Supply Current-5mA source Loads

PD Power Dissipation-ICC Max*

PDHL Power Dissipation-ICCHL Max*

VPQR Power Qualified Reset Threshold 2.8

NOTE:*:Includes open DRAIN High current drives at VOL=0.4V

Input LOW Threshold Voltage-Schmitt Trigger 0.8

°°= to )F158( C70 °° ; %10V5V

CC

±=

GM82C765B

5.5 V

0.8 V

V

V

2.0 V

0.4 V

V

0.4 V

mA

mA

20.0 mA

-20.0 mA

45.0 mA

95.0 mA

425.0 mA

575.0 mA

4.35 V

Page 7

7

%10V

5

VCC

±+=

=

5

5

90

65

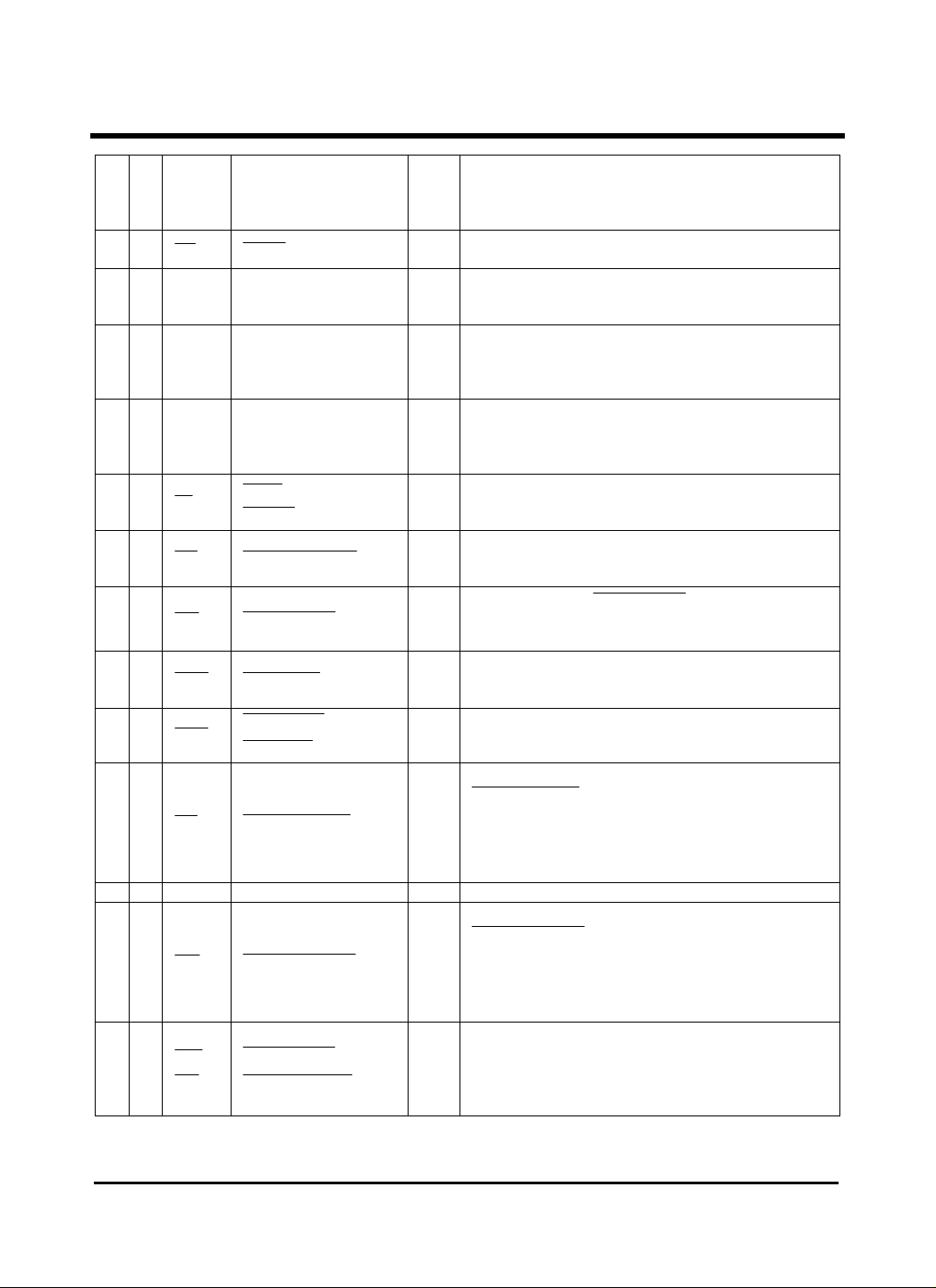

2.3 AC Timing Specifications

GM82C765B

)F32( C0TA °°= to )F158( C70 °° :

SYMBOL

t

CY

Clock Period 60

t

PH

Clock Active (High or Low) 25

t

R

Clock Rise Time (Vin 0.8 to 2.0)

t

F

Clock Fall Time (Vin 2.0 to 0.8)

t

AR

A0, CS,

t

RA

A0, CS,

t

RR

RD Width 90

t

RD

Data Access Time from RD Low

t

DF

DB To Float Delay from RD High 10

t

A0, CS,

AW

t

WA

A0, CS , DACK , LDCR , LDOR , Hold Time from WR High 0

t

WW

t

Data Set Up Time to WR High 80

DW

t

Data Hold Time from WR High 0

WD

t

RI

IRQ Reset Delay Time from RD High 0

t

WI

IRQ Reset Delay Time from WR High 0

t

MCY

DMA Cycle Time 52

t

AM

DMA Reset Delay Time from

t

MA

t

AA

DACK Width 90

t

TC

TC Width 60

t

Reset Width-TTL Driven CLK1 250

RST

t

Reset Width-Software Reset 5

SRST

t

RDD

RDD Active Time Low 40

t

WDD

WD Write Data Width Low 1/2 (TYP) MCY

t

DST

t

STU

t

STP

t

SC

(continued on next page)

Width 60

WR

Delay Time from DMA High 0

DACK

Hold & Set Up to

DIRC

Hold Time from

DSX

Active Time Low 24

STEP

Cycle Time 132

STEP

Set Up Time to RD Low 0

DACK

Hold Time from RD High 0

DACK

DACK,LDCR,LDOR

: pF 100CL

PARAMETER MIN MAX UNITS

nS

nS

nS

nS

nS

nS

nS

nS

nS

, Set Up Time to WR Low 0

nS

nS

nS

nS

nS

1MCY + 150nS

1MCY + 150nS

MCY

DACK

Low

140

nS

nS

nS

nS

nS

MCY

nS

Low 4

STEP

Low 20

STEP

MCY

MCY

MCY

MCY

Page 8

8

48

uS

SYMBOL

t

IDX

IDX Index Pulse Width 2

t

STD

t

MR

RD Delay from DMA 0

t

MW

t

MRW

t

Chip Access Delay from RST Low-TTL 32

CA

t

CAS

t

XCA

t

XTS

t

TCR

t

TCW

Note: CY specifies CLK1 or XT1 period

MCY specifies MCLK period, dependent on selected data rate

WCY specifies WCLK period, dependent on selected data rate

DIRC

WR

RD or WR Response from DMA High

Chip Access Delay from

Chip Access Delay from RST-OSC XT1 at 16MHz 500

XT2 Access Delay after RST 9.6MHz 1000

TC Delay from Last DMA or IRQ, RD 0

TC Delay from Last DMA or IRQ, WR 0

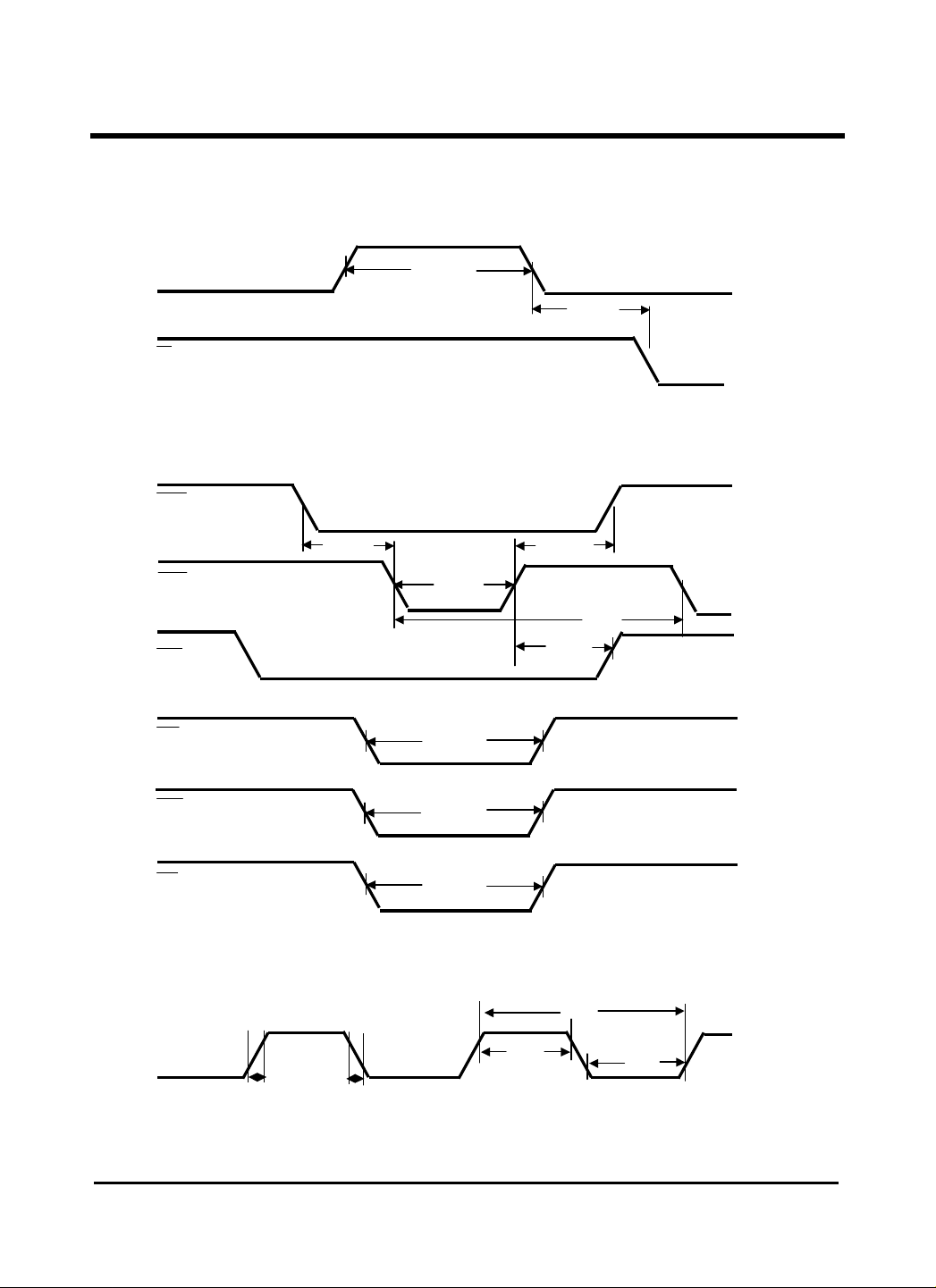

2.4 AC Timing Diagrams

(1) READ Timing

A0

PARAMETER MIN MAX UNITS

Hold Time after

96

STEP

Delay from DMA 0

t

Low 40

SRST

,

.DACK,CS

t

t

t

Data Valid

t

t

t

GM82C765B

MCY

MCY

nS

nS

MCY

MCY

MCY

uS

192 MCY

384 MCY

Page 9

9

WR

DATA

IRQ

Data Valid

tAW

tWW

tWA

tWD

tWI

tDW

DMA or IRQ

TC

tCR

tCW

tTC

tMCY

tMA

tAM

tAA

tMRW

tMR

tRD

tDW

tDF

tWD

Data Valid

DMA

DACK

DATA

RD

orWR

(2) WRITE Timing

(3) TERMINAL COUNT (TC) COUNTING

(4) DMA TIMING

,A0

DACK,CS

tMW

GM82C765B

Page 10

10

CS

DIRC

STEP DSX

WD

(5) RESET Timing

(6) DISK DRIVE SELECT TIMING

(7) CLOCK Timing

RESET

CLOCK

tR

tDST

tF

tRST

tSTP

tIDX

tRDD

tWDD

tPH

GM82C765B

tCA

tSTD

tSC

tSTU

tCY

tPH

Page 11

11

REGISTER

STATUS REG

SEPARATOR

24 × 8

DECODE

PRECOMPENSATION

BUS

TC

DMA

IRQ

A0

CLK1

CLK2

SCLK

MCLK

WD

PCVAL

01

02

WCLK

WRCSDACK

LDCR

LDORHSSTEP

DIRC

RWC

4

1DS

−

TROOWP*

DCHG

WE

3. ARCHITECTURE

The GM82C765B Floppy Disk Subsystem

Controller is a CMOS LSI device that provides

all the needed functionality between the host

u-processor peripheral Bus and the cable

Connec-tor to the Floppy Disk Drive. This CHIP

in-tegrates; Formatter/Controller Data Separation,

Write Precompensation, Data rate Seletion,

Clock generation, Drive interface drivers and

receivers.

8 Bit

DATA

CONTROL

MASTER

HOST

INTERFACE

CLOCK

AND

TIMING

GENERATOR

ALU

MS

SATE

MACHINE

CRYSTAL

OSc×2

DIGITAL DATA

DATA ENCODER

DECODER

Fig 1. GM82C765B Internal Block Diagram

GM82C765B

HOST INTERFACE

The host interface is the host microprocessor

peripheral bus. This bus is composed of eight

control signals and eight data signals. In the

special or PC AT modes, IRQ and DMA request

are tri-stated and qualified enable, internally

provided by the operations register. The data bus,

DMA, and IRQ outputs are designed to handle 20

LS-TTL loading.

DATA

8 Bit INTERNAL DATA BUS

RAM

INSTRUCTION

PROGRAM

FLAG

CRC GENERATOR

ROM

1KÏ16

OPERATION

WRITE

DISK

INTERFACE

CONTROL

REGISTER

Page 12

12

GM82C765B

40 VCC

2.WR

4 A0

3 17 18

22 DRV

*

40

36

37

27

26

29

28

25 1 30

2DS 32

VCC

* PLCC version of

Fig 2. TYPICAL GM 82C765B APPLICATION SYSTEM

Inputs, except the data bus, are Schmitt

trig-ger receivers and can be hooked up to a bus

or backplane without any additional buffering.

During the command or result phases, the

main status Register must be ready by the

processor before each byte of information is

written into or read from the data Register. After

each byte of data is read from or written into the

data Register, the CPU should wait for 12uS

before reading the main status Register. Bits D6

and D7 in the main status Register must be in a 0

and 1 state, respectively, before each byte of the

command word may be written into the

GM82C765B. Many of the command require

multiple bytes. As a result, the Main status

Register must be read prior to each byte transfer

to the GM82C765B. During the result phase,

MICROPROCESSOR

INTERFACE

ADDRESS

RECODE

MAIN

BUS

CKT

CLOCK

CKTS

GND

GND

1 RD

16 IRQ

19 RST

7-14 DB0-DB7

15 DMA

6 TC

24 PCVAL

23 CLK1

21 CLK2

GM82C765B

HDL 35

1MO 3DS 33

34

2MO 4DS

36

RPM RWC

RDD 20

IDX 39

VSS 31

Bits D6 and D7 in the Main status Register must

both be 1’s (D6-1 and D7-1) before reading

each byte from the Data Register. Note that this

regarding of the main status Register before

each byte transfer to the GM82C765B is

re-quired only in the Command and result phases,

and not during the Execution phase. Note also

that DB6 and DB7 in the MSR can be polled

in-stead of waiting 12uS. When they have the

right bit settings, the GM82C765B is ready for

com-mands. This might save some time.

During the Execution phase, the main status

register need not be read. If the GM82C765B

is in the non-DMA Mode, then the receipt of

each data byte is indicated by an interrupt signal

on pin 16 (IRQ-1). The generation of a Read

signal (RD-0) will clear the interrupt as well as

FLOPPY

DISK

DRIVE

INTERFACE

CONNECTOR

GM82C765B

Page 13

13

output the data onto the data bus.

If the processor can not handle interrupt fast

enough (every 13uS for the MFM mode and

27uS for the FM mode), then it may poll the

main status Register and bit D7 (RQM) functions

as the Interrupt signal.

If a Write Command is in process then the

Signal performs the reset to the Interrupt

WR

signal.

All timings mentioned above double for mini

floppy data rates. Note that in the non-DMA

mode it is necessary to examine the main Status

Register to determine the cause of the interrupt

signs is could be a data interrupt or a command

terminaton interrupt, either normal or abnormal.

If the GM82C765B is in the DMA mode, no

inter-rupt signals are generated during the

Execution phase. This signifies the beginning of

the Result phase. When the first byte of data is

read during the Result phase, the Interrupt is

auto-matically cleared (IRQ=0). It should be

noted that in PC AT usage, non-DMA Host

transfers and not the normal procedure. If the

user chooses to do so, the GM82C765B will

successfully complete commands, but will

always give abnormal termination error status

since TC is qualified by an inactive

The RD or WR signals should be asserted

while Dack is true. The CS signal is used in

conjunction with RD and WR as a gating

function during programmed I/O operations.

If the non-DAM mode is chosen, the

signal should be pulled up to

V . It is important

CC

to note that during the Result phase all bytes

shown in the Command Table must be read. The

Read Data Command for example, has several

bytes of data in the Result phase. All seven bytes

must be read Data command. The GM82C765B

will not accept a new command until all seven

bytes have been read. Other commands may

require fewer bytes to be read during the Result

phase. The GM82C765B contains five Status

Registers. The Main Status Registers (ST0, ST1,

ST2, and ST3) are available only during the

Result phase and may be read only after

completing a command.

The particular command that has been

executed determines how many of the Status

Registers will be read.

The byte of data which are sent to the

DACK

.

DACK

GM82C765B

GM82765B to form the command phase, and are

read out of the GM82C765B in the result phase,

must occur in the order shown in the command

Table. The command code must be sent first and

the other bytes sent in the prescribed sequence.

No foreshortening of the command or Result

phase is allowed. After the last byte of data in the

Command phase is sent to the GM83C765B, the

Execution phase of automatically starts. In a

similar fashion, when the last byte of data is read

out in the result phase, the command is

automatically ended and the GM82C765B is

ready for a new command.

CONTROL REGISTER

The Control Register provides support logic that

latches the two LSBs of the data bus upon

receiving

active when this happens. These bits are used to

select the desired data rate, which in turn controls

the internal clock generation. Clock switchover is

internally “deglitched” allowing continuous

operation after change data rates.

If the Control Register is not used, the data rate is

governed by the supplied clock or crystal. The

frequency must be 64X the desired MFM data

rate, up to a maximum frequency of 16 MHz.

This implies a maximum data rate of 250 kb/S.

unless the Control Register is used. Switching

this clock must be “glitchless” or the device will

need to be reset.

Table 1 presents the Control Register.

and WR. CS should not be

LDCR

Page 14

14

GM82C765B

TABLE 1. CONTROL REGISTER

CR1 CR0 DRV DATA RATE COMMENTS RPM (In PC AT MODE)

0 0 X 500K MFM 1

0 0 X 250K FM 1

0 1 0 250K MFM 0

0 1 1 300K MFM 0

1 0 X 250K MFM, RST Default 1

1 0 X 125K FM, RST Default 1

1 1 X 125K 0

MASTER STATUS REGISTER

The Master Status Register is an eight-bit

register that contains the status information of

the FDC, any may be accessed at any time.

Only the Master Status Register may be read

and used to facilitate the transfer of data

between the processor and GM82C765B. The

DIO and RQM bits in the Master Status

Register indicate when data is ready and in

which direction data will be transferred on the

data bus. The maximum time between the last

RD or

during a Command or Result

WR

phase and DIO and RQM getting set is 12us if

500 kb/S MFM data rate is selected. (If 250

kb/s MFM is selected, the delay is 24uS.) For

this reason, everytime the Master Status

Register is read, the CPU should 12us. The

maximum time from the trailing edge of the

last RD in the result phase to when DB4

(FDC busy) goes low is 12 uS.

TABLE 2. MASTER STATUS REGISTER BITs

BIT

NO. NAME SYMBOL

DB0 FDD 0 BUSY D0B FDD number 0 is in the Seek Mode. If any of the bits is set,

FDC will not accept READ or WRITE commands.

DB1 FDD 1 BUSY D1B FDD number 1 is in the Seek Mode. If any of the bits is set,

FDC will not accept READ or WRITE commands.

DB2 FDD 2 BUSY D2B FDD number 2 is in the Seek Mode. If any of the bits is set,

FDC will not accept READ or WRITE commands.

DB3 FDD 3 BUSY D3B FDD number 3 is in the Seek Mode. If any of the bits is set,

FDC will not accept READ or WRITE commands.

DB4 FDC BUSY CB A READ or READ command is in progress. FDC will not accept

any other commands.

DB5 EXECUTION

MODE

DB6 DATA INPUT DI0 Indicates direction of data transfer between FDC and DATA

DB7 REQUEST FOR

MASTER

EXM This bit is set only during Execution phase in non-DMA Mode.

When DBS goes low Execution phase has ended and Results phase

has started. It operates only during non-DMA Mode of operation.

Register. If DIO=1, then transfer is from DATA Register to the

Processor. If DIO=0, transfer is from Processor to the Data Register.

RQM Indicates Data Register is ready to send or receive data to or from

the Process. Both bits DIO and RQM should be used to perform the

handshaking function of “ready” and “direction” to the Processor.

DESCRIPTION

Page 15

15

TABLE 3. STATUS REGISTER 0 BITs

GM82C765B

BIT

NO

D7 INTERRUPT

D6

D5

#D4 EQUIPMENT

#D3 NOT READY NR Since drive ready is always persumed true. This will always be a LOGIC

D2 HEAD SELECT

D1 UNIT SELECT 1 US1 This flag is used to indicate a DRIVE UNIT Number at interrupt

D0 UNIT SELECT 0 US0 This flag is used to indicate a DRIVE UNIT Number at interrupt

NAME SYMBOL

IC D7 = 0 and D6 = 0, Normal termination of command was completed

CODE

D7 = 1 and D6 = 0.

SEEK END SE When FDC completes the SEEK comand, this flag is set to 1 (HIGH)

EC If the Track 0, signal fails to occur after 255 step pulses (Recalibrate

CHECK

HS This flag is used to indicate the state of HEAD at interrupt

properly executed.

D7 = 0 and D6 = 1, Abnormal termination of command (AT).

Execution of command was started but was not successfully completed.

Invalid comand issue, (IC). Command which was issued was never

started.

command). Then this flag is set.

0.

DESCRIPTION

TABLE 4. STATUS REGISTER 1 BITs

BIT

NO

D7 END OF

D6 Not used. This bit is always 0 (low)

D5 DATA ERROR DE When the FDC detects a * CRC error in either the ID field or a cylinder,

D4 OVERRUN OR If the FDC is not serviced by the host system during data transfers within

D3 NOT DATA Not used. This bit is always 0 (low)

D2 NO DATA ND During execution of READ DATA, WRITE DELETED DATA, or SCAN

D1 NOT

NAME SYMBOL

CYCLINDER

WRITEABLE

EN When the FDC tries to access a sector beyond the final sector of a

cylinder,this flag is set.

this flag is set.

a certain time interval, this flag is set.

command, if the FDC cannot find the sector specified in the * * IDR

Register, this flag is set. During execution of the READ ID command, if

the FDC cannot read the ID field without an error, then this flag is set.

During execution of the READ A TRACK command, if the starting sector

cannot be found, then this flag is set.

NW During execution of WRITE DATA, WRITE DELETED DATA or

RORMAT A TRACK commands. If the FDC detects a WP signal from

the FDC, then this flag is set.

DESCRIPTION

Page 16

16

TABLE 4. STATUS REGISTER 1 BITs

BIT

NO

D0 MISSING

NAME SYMBOL

ADDRESS

MARK

MA If the FDC cannot detect the ID Address Mark after encountering the

index hole twice, then this flag is set.

If the FDC cannot detect the Data Address Mark or Deleted Data Address

Mark, this flag is set. At the same time the MD (Missing Address Mark in

data field) of Status Register 2 is set.

TABLE 5. STATUS REGISTER 2 BITs

GM82C765B

DESCRIPTION

BIT

NO

D7 Not Used. This bit is always 0 (low)

D6 CONTROL

D5 DATA ERROR DD If the FDC detects a CRC error in the data field, then this flag is set.

D4 WRONG

D3 SCAN EQUAL SH During execution of the SCAN command, if the condition of “equal” is

D2 SCAN NOT SN During execution of the SCAN command, if the FDC cannot find a sector

D1 BAD

D0 MISSING

NAME SYMBOL

MARK

CYLINDER

CYLINDER

ADDRES

MARK

IN DATA FIELD

CM During executing of the READ DATA or SCAN Command, if the FDC

encounters a sector which contains a Deleted Data Address Mark, this flag

is set.

WC This bit is related to the ND bit, and when the contents of * * * C on the

medium is different from that stored in the IDR, this flag is set.

satisfied this flag is set.

on the cylinder which meets the condition, then this flag is set.

BC This bit is related to the ND bit, and when the contents of C on the

medium is different from that stored in the IDR, and the contents of C is

FF, then this flag is set.

MD When data is read from the medium, if the FDC cannot find a Data

Address Mark or Deleted data Address Mark, then this flag is set.

DESCRIPTION

TABLE 6. STATUS REGISTER 3 BITs

BIT

NO

#D7 Not used. Will always be logic 0.

D6

#D5 READY RY

D4 TRACK 0 TO This bit is used to indicate the status of the Track 0 signal from the FDD.

#D3

D2 HEAD SELECT

D1 UNIT SELECT 1

D0 UNIT SELECT 2

NAME SYMBOL

WRITE

PROTECTED

WRITE

PROTECTED

CYLINDER

WP

WP

HS This bit is used to indicate the status of the Side Select signal to the FDD

US1

US0

signal from the FDD

This bit will always be a logic 1.

Drive is presumed to be ready.

This bit is used to indicate the status of the WRITE PROTECTED

signal from the FDD

This bit is used to indicate the status of the Unit Select 1 signal to the

FDD

This bit is used to indicate the status of the Unit Select 0 signal to the

FDD

This bit is used to indicate the status of the

Note : * CRC - Cyclic Redundancy Check

* * IDR - internal Data Register

* * * C - Cylinder

# - Different from NEC765

DESCRIPTION

WRITE PROTECTED

Page 17

17

RD

RD

* DATA REGISTER

GM82C765B

The eight-bit data Register stores data, commands, parameters, and FDD status information.

Data bytes are read out of, or written into, the

Data Register in order to program or obtain the

results after a particular command.

The relationship between the Master Status

Register and the Data Register Status Register

and the Data Register and the signals

,WR, and A0 are shown in Table 7.

TABLE 7. MASTER STATUS AND DATA REGISTERS Relationships

A0

0

0

0

1

1

1

WR FUNCTION

0

1

0

0

0

1

1

0

0

0

1

0

Read Main Status Register

ILLEGAL

ILLEGAL

ILLEGAL

READ from DATA REGISTER

WRITE into DATA REGISTER

* OPERATIONS REGISTER

The Operations Register provides support logic

that latches the data bus upon receiving

ad WR. CS should not be active

LDOR

when this happens. The Operations

Register replaces the typical latched port found

.

in floppy subsystems used to control disk drive

spindle motors and to select the desired disk

drive. Table 8 represents the operations

Register

TABLE 8. OPERATIONS REGISTER

OR0

OR1

OR2

OR3

OR4

OR5

OR6

OR7

DSEL

(X)

SRST

DMAEN

MOEN1

MOEN2

(X)

(MSEL)

: Drive Select, if low and MOEN1 = 1, then

MOEN2 = 1, then

: In GM82C765B this mist be logic 0 for 1DS and

No defined function in GM82C765B.

: Soft reset, active low.

: DMA enable, active in Special and PC AT modes, Qualifies DMA and IRQ

outputs and

: Motor On enable, inverted output

: Motor On enable, inverted output 2MO is active in PC AT

: Has no defined function. A spare.

: Mode Select, During a soft reset condition, may be used to select

between Special mode (1) and PC AT mode (0).

DACK

is active. If high and

1DS

is active, but only in the PC AT mode

2DS

to become active.

2DS

input.

is active only in PC AT

1MO

Page 18

18

RPM

* BASE, SPECIAL, AND PC AT MODES

Base, Special, and PC AT modes allow subtle

differences which the user may find desirable.

The Control Register may be used in any mode

without altering functionality.

* BASE MODE

After a hardware reset, RST active, the

GM82C765B will be held on soft reset,

active, with the normally driven signals, DMA

request and IRQ request outputs tristated. Base

mode may be initiated at this time by a chip

access by the host. Although this may be any

read or write, it is strongly recommended that

the Base mode user’s first chip access be a read

of the Master Status Register. Once Base mode

is entered, the soft reset is released, and IRQ

and DMA are driven. Base mode prohibits the

use of the Operations Register, hence there can

be no qualifying by DMAEN and no soft resets.

The Drive Select outputs,

1DS

to

a 1 of 4 decoding of the Unit Select bits

resident in the command structure.

Pin

represents Reduce Write Current

RWC

and is indicative of when write

precompensation is necessary.

SRST

, offer

4DS

GM82C765B

AT mode can also be entered from Special

mode by loading the Operations Mode Select

to a logic 0, disabling MOEN1 and MOEN2,

and causing

of the Control Register address sets the device

into PC AT mode. The DS outputs are now

replaced with the DSEL and MOEN signals

buffered from the Operations Register.

DMAEN and

compatible with the current BIOS.

pinfunction is now

two speed drives may reduce spindle speed per

minute to 300 revolutions per minute when

active low, used to reduce write current when a

slower data rate is selected for a given drive.

Figure 3 illustrates the relationship among the

three modes.

to be active. Then a read

SRST

are supported and

SRST

so that users with

RWC

* SPECIAL MODE

Special mode allows use of the Operations

Register for the DMAEN signal as a qualifier

and to do a software driven device reset,

. To enter Special mode, the Operations

SRST

Register is loaded with (1X00X0XX), setting

mode Select to a logic 1 disabling MOEN1 and

MOEN2 and causing SRST to be active.

Then a read of the Control Register address,

and RD, will set the device into

LDCR

Special mode. The

again offered in this mode, as is

through

1DS

RWC

.

is

4DS

* PC AT Mode

For PC AT compatibility, users will write to

the Operations Register,

this action, performed after a hardware reset,

or in the Base mode, initiates PC AT mode. PC

LDOR

and

WR

;

Page 19

19

READ MASTER

STATUS REG.

BASE

MODE

Fig. 3 Flow Diagram Depicting Relationship of Base, Special, and PC AT

modes.

l POLLING ROUTINE

DS1

DS2

DS3

DS4

HARDWARE

RESET

WRITE TO

OPER REG.

PC AT

MODE

WRITE 80 TO

OPER REG

READ CONT REG

LDCR, RD

SPECIAL

MODE

WRITE 00 TO

OPER REG

READ CONT

REG. LDCR, RD

Fig. 4. Drive select polling timing

GM82C765B

After any reset the GM82C765B, (a hard

RST or soft

a Polling routine. In between commands (and

between step pulse in the SEEK Command),

the GM82C765B polls all four FDDs looking

for a change in the ready line from any of the

drives. Since the drive is always presumed

ready, an interrupt will only be generated

following a reset. This occurs because a reset

forces Not ready status, which then promptly

becomes ready.

Note that in special or PC AT mode if

DMAEN is not valid prior to 1mS after reset

goes inactive, then IRQ may be already set and

pending when finally enabled onto the bus.

The polling of the ready line by the

GM82C765B occurs continuously between

commands. Each drive is polled every

1,024mS, except during the READ/WRITE

commands. For minifloppies, the polling rate is

2,048mS. The drive polling sequence is

1-2-4-3. Please note that in the PC AT mode,

the user will not see the polling at the Drive

Select signals, figure 4 illustrates the Drive

Select Polling time

, will automatically go into

SRST

* DEVECE RESETS

The GM82C765B supports both hardware reset

(RST) pin (19) and a software reset (

SRST

through use of the Operations Register. The RST

pin will cause a device reset for the active

duration. RST causes a default to Base mode, and

default selects 250k MFM (or 125k FM, code

dependent) as the data rate (16 MHz input clock).

will reset the microcontroller as did the

SRST

If the XTAL oscillators are used, instead of the

TTL driven clock inputs, the hardware RST

)

active time requirement will bootstrap the circuit

into guaranteed oscillation in a fixed amount of

time.

The extended reset time allows the growth of the

oscillation to produce stable internal clock timing

RST, but will not affect the value set for the

internal timers-HUT, FTL, and SRT.

Page 20

20

∗

DATA SEPARATOR

The Data Separator is a Digital Phase Lock

Loop Floppy Disk Data Separator (DPLL). It was

designed to address high performance error rates on

floppy disk drives, and to provide superior

performance in terms of available bit jitter tolerance. It

contains the necessary logic to achieve classical 2nd

order, type 2, phase locked loop performance. DPLL is

used as the Data Separator in the GM82C765B system.

Figure 5 illustrates the DPLL implified block diagram.

The bit jitter tolerance for the data separator is 60%,

Which guarantees an error rate of < 10E-9.

∗

WRITE PRECOMPENSATION

The BM82C765B maintains the stand first level

algorithm to determine when write precompensation

should be applied.

The EARLY and LATE signals are used internally to

DSKD

DATA

SYNCHRONIZATION

P

H

A

S

E

DETE-

CTION

TRANSIENT RESPONSE

STATE FILTERING

STEADY STATE

FREQUENCY

FILTERING

REFCLK

CLOCK GENERATION

CD1

CD2

Fig. 5. DPLL Simplified BLOCK DIAGRAM

GM82C765B

select the appropriate delay in the write data pulse

stream.

The encoded WRITE DATA signal is synchronized to

the 16 MHz clock if this is the frequency on CLK1 pin

(23), and clocked through a shift register before a

multiplexer gates the chosen bit to the output.

The output data pulse width has a 25% duty cycle,

i.e., one fourth of the bit cell period, and equal to one

half the WCLK period.

When PCVAL pin (24) = 1, all data will be

precompensated by + 187nS precompensation will be

generated. For frequencies other than 16 MHz on the

CLK1 pin, the precompensation values will be two and

three clock cycles respectively.

When the non-standard data rate using CLK2 is chosen,

the MFM precompensation will always be two clock

cycles.

For 9.6MHz, this is +208nS. In this case, this PCVAL

function is disabled

Phase

SEPCLK

DIGITAL

CONTROLLED

OSCILLATOR

SCLK

RDATA

RESYNCHRONIZATIO

SUMMER

SEPD

SEPCLK

Page 21

21

23 22

XT2

RESONANT

* CLOCK GENERATION

GM82C765B

TABLE 9. CLOCK DATA RATE

This logical block provides all the clocks needed by

the GM82C765B. They are: Sampling clock (SCLK),

Write clock (WCLK), and the MASTER CLOCK

(MCLK). SCLK drives the DPLL Data Separator used

during data recovery. This Clocks’s frequency is

always 32 times the selected data rate. WCLK is used

by the encoder logic to place MFM or FM on the serial

WD-stream to the disk. WCLK always has a frequency

two times the selected data rate. MCLK is used by the

microsequencer. MCLK and MCLK clock all latches

in a two-phase scheme.

One microinstruction cycle is four MCLK cycles.

MCLK has a frequency times the FM data rate.

Table 9 presents the Clock Data Rate. Figure 6

illustrates the XTAL oscillator circuits for the 44-pin

PLCC configuration.

XT1

XT1

26

C

4

25

C

3

XT2

XT2

C

1

C

2

DATA RATE CODE SLCK MCLK WCLK

500Kbit/S MFM 16.0MHz 4.0MHz 1.0MHz

250Kbit/S FM 8.0MHz 4.0MHz 500.0MHz

250Kbit/S MFM 8.0MHz 2.0MHz 500.0MHz

125Kbit/S FM 4.0MHz 2.0MHz 250.0MHz

300Kbit/S MFM 9.6MHz 2.4MHz 600.0MHz

9.6MHz + 100 ppm

R Series = 30 ohm Max

C Shunt = 10 pf Max

C1 = 68 pf 5% mica

C2 = 56 pf 5% mica

9.6MHz + 100 ppm

R Series = 30 ohm Max

C Shunt = 10 pf Max

C3 = 47 pf 5% mica

C4 = 15 pf 5% mica

SERIES RESONANT

SERIES

Fig 6. XTAL Oscillator circuits for the 44 pin PLCC

Page 22

22

∗

COMMAND PARAMETERS

GM82C765B

TABLE 10. GM82C765B COMMANDS

The GM82C765B is capable of performing 15

different commands. Each command is initiated by a

multibyte transfer from the processor. The results

after execution of the command may also be a

multibyte transfer back to the processor. The

commands consist of three phases : Command phase,

Execution phase, and the Result phase.

Command phase − The Floppy Disk Controller

(FDC) receives all information

required to perform a

particular operation from the

processor.

Execution phase − The FDC performs the operation

it was in structed to do.

Result phase − After completion of the operation,

status and other housekeeping in

formation are made available to the

processor

READ DATA

READ DELETED DATA

WRITE DATA

WRITE DELETED DATA

READ A TRACK

READ ID

FORMAT A TRACK

SCAN EQUAL

SCAN LOW OR EQUAL

SCAN HIGH OR EQUAL

Table 10. lists the 15 GM82C765B commands.

Table 11. through 25 are presented to show the

required parameters and results for each command.

Most commands require nine command bytes during

the result phase. The “W” to the left of each byte

indicates a command phase byte to be written. An

“R” indicates a result byte.

TABLE 11. READ DATA

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND

EXECUTION

RESULTS

W W MT X MF X SK X 0

W

W

W

W

W

W

W

R

R

R

R

R

R

R

X

0 X 1

C

H

R

N

EOT

GPL

DTL

STO

ST1

ST2

C

H

R

N

HS 1 US1 0 US0

Command Codes

Sector ID information prior to

command execution. The four bytes

are compared against header on

floppy disk.

Data transfer between FDD and main

system

Status information after command

execution.

Sector ID information after command

execution.

Page 23

23

TABLE 12. READ DELETED DATA

COMMAND

EXECUTION

RESULTS

TABLE 13. WRITE DATA

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND

EXECUTION

RESULTS

R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

W W MT X MF X SK X 0

X

W

W

W

W

W

W

W

R

R

R

R

R

R

R

W W MT X MF X 0 X 0

X

W

W

W

W

W

W

W

R

R

R

R

R

R

R

C

H

R

N

EOT

GPL

DTL

STO

ST1

ST2

C

H

R

N

C

H

R

N

EOT

GPL

DTL

STO

ST1

ST2

C

H

R

N

1 X 1

HS 0 US1 0 US0

0 X 1

HS 0 US1 1 US0

Command Codes

Sector ID information prior to

command execution. The four bytes

are compared against header on floppy

disk.

Data transfer between FDD and main

system

Status information after command

execution.

Sector ID information after command

execution.

Command Codes

Sector ID information prior to

command execution. The four bytes

are compared against header on

floppy disk.

Data transfer between FDD and main

system

Status information after command

execution.

Sector ID information after command

execution.

GM82C765B

Page 24

24

TABLE 14. WRITE DELETED DATA

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND

EXECUTION

RESULTS

TABLE 15. READ A TRACK

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND

EXECUTION

RESULTS

W W MT X MF X 0 X 0

W

W

W

W

W

W

W

R

R

R

R

R

R

R

W W 0 X MF X SK X 0

W

W

W

W

W

W

W

R

R

R

R

R

R

R

X

X

1 X 0

C

H

R

N

EOT

GPL

DTL

STO

ST1

ST2

C

H

R

N

C

H

R

N

EOT

GPL

DTL

STO

ST1

ST2

C

H

R

N

HS 0 US1 1 US0

0 X 0

HS 1 US1 0 US0

Command Codes

Sector ID information prior to

command execution. The four bytes

are compared against header on

floppy disk.

Data transfer between FDD and main

system

Status information after command

execution.

Sector ID information after command

execution.

Command Codes

Sector ID information prior to

command execution.

Data transfer between FDD and main

system. FDD reads all data fields from

index hole to EOT

Status information after command

execution.

Sector ID information after command

execution.

GM82C765B

Page 25

25

TABLE 16. READ ID

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND

EXECUTION

RESULTS

TABLE 17. FORMAT A TRACK

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND

EXECUTION

RESULTS

W W 0 X MF X 0 X 0

R

R

R

R

R

R

R

W W 0 X MF X 0 X 0

W

W

W

W

R

R

R

R

R

R

R

X

X

1 X 0

STO

ST1

ST2

C

H

R

N

N

SC

GPL

D

STO

ST1

ST2

C

H

R

N

HS 1 US1 0 US0

1 X 1

HS 0 US1 1 US0

Command Codes

The first correct ID information on the

cylinder is stored in Data Register.

Status information after command

execution.

Sector ID information after command

execution.

Command Codes

Bytes / Sector

Sector/Track

Gap 3

Filler Byte

Floppy Disk Controller (FDC) formats

an entire track.

Status information after command

execution.

In this case, ID information has no

meaning.

GM82C765B

Page 26

26

TABLE 18. SCAN EQUAL

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND

W W MT X MF X SK X 1

X

0 X 0

HS 0 US1 1 US0

Command Codes

GM82C765B

EXECUTION

RESULTS

W

W

W

W

W

W

W

R

R

R

R

R

R

R

C

H

R

N

EOT

GPL

STP

STO

ST1

ST2

C

H

R

N

Sector ID information prior to command

execution.

Data transfer between FDD and main

system

Status information after command

execution.

Sector ID information after command

execution.

TABLE 19. SCAN LOW OR EQUAL

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND

EXECUTION

RESULTS

W W MT X MF X SK X 1

W

W

W

W

W

W

W

R

R

R

R

R

R

R

X

1 X 0

C

H

R

N

EOT

GPL

STP

STO

ST1

ST2

C

H

R

N

HS 0 US1 1 US0

Command Codes

Sector ID information prior to ommand

execution.

Data transfer between FDD and main

system

Status information after command

execution.

Sector ID information after command

execution.

Page 27

27

TABLE 20. SCAN HIGH OR EQUAL

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND

W W MT X MF X SK X 1

X

1 X 1

HS 0 US1 1 US0

Command Codes

GM82C765B

EXECUTION

RESULTS

W

W

W

W

W

W

W

R

R

R

R

R

R

R

C

H

R

N

EOT

GPL

STP

STO

ST1

ST2

C

H

R

N

Sector ID information prior to command

execution.

Data transfer between FDD and main

system

Status information after command

execution.

Sector ID information after command

execution.

TABLE 21. RECALIBARTE ∗

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND

EXECUTION Head retracted to Track zero

W W 0 X 0 X 0 X 0

X

0 X 1

HS 1 US1 1 US0

Command Codes

TABLE 22. SENSE INTRRUPT STATUS

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND W 0 0 0 0 0 1 1 1 Command Codes

RESULTS R

Status information about the FDC at

the end of seak operation

TABLE 23. SPECIFY

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

W

EXECUTION

0 0 0 0 0 0 1 1 COMMAND

W

SRT HUT

HLT

Command Codes

N D

Head retracted to Track zero

Page 28

28

GM82C765B

TABLE 24. SENSE DRIVE STATUS

PHASE R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

COMMAND

EXECUTION ST3 Status information about the FDC

W W 0 X 0 X 0 X 0

X

0 X 0

HS 0 US1 0 US0

Command Codes

TABLE 25. SEEK

COMMAND

EXECUTION

Table 26 defines, in alphabetical order, the symbols used in Command Tables 11 through 25.

R/W D7 D6 D5 D4 D3 D2 D2 D0 REMARKS

W

W

W

0 X 0 X 0 X 0

X

NCN

1 X 1

HS 1 US1 1 US0

Command Codes

Head is positioned over proper cylinder

on the diskette.

TABLE 26. COMMAND SYMBOL DESCRIPTIONS

SYMBOL NAME DESCRIPTION

A0 ADDRESS LINE 0

C CYLINDER NUMBER C stands for the current/selected cylinder (track) numbers 0 through 255 of the

D DATA

D7-D0 DATA BUS

DTL DATA LENGTH

EOF END OF TRACK

GPL GAP LENGTH

H HEAD ADDRESS H stands for head number 0 or 1, as specified in the ID field.

HLT HEAD LOAD TIME HLT stands for the HEAD LOAD TIME in FDD (2 to 254ms in 2ms increments)

HS HEAD SELECT

HUT HEAD UNLOAD TIME

MF FM or MFM

A0 Controls selection of Main Status Register (A0 = 0) or Data Register (A0 =1)

medium.

D stands for the data pattern which is going to be written into a sector.

8-bit DATA BUS, where D7 stands for a most significant bit, and D) stands for a

least significant bit.

When N is defined as 00, DTL stands for the DATA LENGTH which users are

going to read out or write into the sector.

EOT stands for the final sector number on a cylinder. During read or Write

operations. FDC will stop data transfer after a sector number equal to EOT.

GPL stands for the length of Gap 3. During the FORMAT Command. It

determines the size of Gap 3.

HS stands for a selected head number 0 or 1 and controls the polarity of pin 25

(in 40 pin DIP) or pin 28 (in 44 pin PLCC)

HUT stands for the HEAD UNLOAD TIME after a Read or Write operation has

occurred (16 to 240ms in 16ms increments).

If MF is low, FM mode is selected. If it is high, MFM mode is selected.

MT

MULTITRACK

If MT is high, a MULTITRACK operation is performed.

If MT =1 after finishing Read / Write operation on side 0, FDC will

automatically start searching for sector 1 on side 1

Page 29

29

SYMBOL NAME DESCRIPTION

N NUMBER N stands for the NUMBER of data bytes written in a sector.

NCN

ND NON-DMA MODE ND stands for operation in the NON-DMA MODE.

PCN PRESENT CYLINDER

R RECORD R stands for the sector number which will be read or written.

R/W READ/WRITE R/W stands for either READ or WRITE signal.

SC SECTOR SC indicates the number of sectors per cylinder.

SK SKIP SK stands for SKIP Deleted Data Address mark.

SRT STEP RATE TIME

ST0

ST1

ST2

ST3 STATUS 3

STP

US0, US1 UNIT SELECT US stands for a selected drive; binary encoded, 1 of 4.

NEWCYLINDER

NUMBER

STATUS 0

STATUS 1

STATUS 2

NCN stands for a NEW CYLINDER NUMBER which is going to be reached as

a result of the Seek operation. Desired position of head.

PCN stands for the cylinder number at the completion of the SENSE

INTERRUPT STATUS Command position of head at present time..

STR stands for the Stepping Rate for the FDD (1 to 16ms in 1ms increments).

Stepping Rate applies to all drives. In 2’s complement format, F(Hes) = 1ms,

E(Hex) =2ms, etc

STO = 3 stands for one of four registers which store the STATUS information

after a command has been executed. This information is available during the

result phase after command execution.

These registers should not be confused with the main Status Register (selected by

A0 = 0). ST0=3 may be read only after 3 command has been executed and

contains information relevant to that particular command.

During a SCAN operation, if STP=1, the data in contiguous sectors is compared

byte by byte with data sent from the processor (or DMA); if STP=2, then

alternate sectors are read and compared.

GM82C765B

COMMAND DESCRIPTIONS

Read Data

A set of nine byte words are required to place the

FDC into the Read Data Mode.

After the Read Data command has been issued,

the FDC loads the head (if it is unloaded state),

warts the specified head setting time (defined in

the Specify Command begins reading ID Address

Marks and ID fields. When the current sector

number (“R”) stored in the ID Register (IDR)

compares with the sector number read off the

diskette, then the FDC outputs data (from the

data bit) byte-to-byte to the main system via the

data bus.

After completion of the read operation from the

current sector, the Sector number is incremented

by one, and the data from the next sector is read

and output on the data bus.

This continuous read function is called a

“Multi-sector Read Operation.” The Read Data

Command may be terminated by the receipt of a

Terminal Count signal.

TC should be issued at the same time that the

for the last byte of data is sent.

DACK

Upon receipt of this signal, the FDC stops

outputting data to the processor, but will continue

to read data from the current sectors, check CRC

(Cyclic Redundancy Count) bytes, and the end of

the sector terminate the read data command.

The amount of data which can be handled with a

single command to the FEC depends upon MT

(multi-track), MF(MFM/FM), and N(number of

bytes/sector). Table 27 lists the transfer Capacity.

The “Multi-track” function (MT) allows the FDC

to read data from both sides of the diskette. For a

particular cylinder, data will be transferred

starting at Sector 1, Side 0 and

completing at Sector L, Side 1 (Sector L = last

sector on the side). Note, this function pertains to

only one cylinder (the same track) on each side of

the diskette.

When N=0, then DTL defines the data length

which the FDC must treat as a sector. If DTL is

smaller than the actual data length in a sector, the

Page 30

30

GM82C765B

data beyond DTL in the sector is not sent to the

Data Bus. The FDC reads (internally) the

complete sector performing the CRC check, and

depending upon the manner of command

termination, may perform a Multi-Sector Read

operation. When N is non-zero, then DTL has no

meaning and should be set to FF Hexadecimal.

TABLE 27. TRANSFER CAPACITY

Multi-

track

MT

0 0 0 1 00

1 1 0 1 00

0 0 0 1 01

1 1 0 1 01

0 0 0 1 02

1 1 0 1 02

MFM/FM

MF

Bytes/

Maximum Transfer

Sector

N

(Number of Sectors)

(128) (26) – 3.328

01

(256) (26) – 6.656

(128) (52) – 6.658

01

(256) (52) –13.312

(256) (15) – 3.840

02

(512) (15) – 7.680

(256) (30) – 7.680

02

(512) (30) – 15,360

(512) (8) – 4.096

03

(1024) (8) – 8.192

(512) (16) – 8.192

03

(1024) (16) – 16.384

Capacity

26 at Side 0

or 26 at Side 1

15 at Side 0

or 15 at Side 1

15 at Side 1

or 8 at Side 1

At the completion of the Real data Command,

the head is not unloaded until after head unload

time interval (specified in the specify Command)

has elapsed. If the processor issues another

command before the head unloads, then the head

setting time may be saved between subsequent

reads. This time out is particularly valuable when

a diskette is copied from one drive to another.

If the FDC detects the index Hole twice

without finding the right sector, (indicated in ‘R’ ),

then the FDC sets the ND (No Data) flag in status

Register 1to a 1 (high), and terminates the Read

Data command (Status Register 0 also has bits 7

and 6 set to 0 and 1 respectively.)

After reading the ID and Data Fields in each

sector, the FDC checks the CRC bytes If a read

error is detected (incorrect CRC in ID field), the

FDC sets the DE(Data Error) flag in Status

Register 1 to 1 (High) If a CRC error occurs in

the data field, the FDC also sets the DD(Data

Error in Data Field) flag in Status Register 2 to

1(High) and terminates the Read data command.

(Status Register 0 also has bits 7 and 6 set to 0

and 1 respectively.)

If the FDC reads a Deleted Data Address Mark

Final Sector

Read from

Diskettes

26 at Side1

8 at Side 0

8 at Side 1

off the diskette, and the SK bit (bit D5 in the first

Command Word) is not set (SK =0), then the

FDC sets the CM(control Mark) flag in Status

Register 2 to a 1 (high), and terminates the Read

Data command, after reading all the data in the

sector. If SK = 1, the FDC skips the sector with

the Deleted Data Address Mark and reads the

next sector. The CRC bits in the deleted data field

are not checked when SK = 1.

During disk Data transfers between the FDC and

the processor, via the data bus, the FDC must be

serviced by the processor every 27 us in the FM

mode, land every 13 us in the MFM mode, or the

FDC sets the OR (Overrun) flag in status Register.

1 to a 1 (high), and terminates the Read Data

command.

TABLE 28. C, H, R, and VALUES

MT HD

0

1

Notes : NC (No Change) : The same value the one at the beginning

Final Sector

Transferred

to processor

0 Less then EOT NC NC R+1 NC

0 Equal to EOT C+ 1 NC R=01 NC

1 Less then EOT NC NC R+1 NC

1 Equal to EOT C+1 NC R=01 NC

0 Less then EOT NC NC R+1 NC

0 Equal to EOT NC LSB R=01 NC

1 Less then EOT NC NC R+1 NC

1 Equal to EOT C+1 LSB R=01 NC

of command execution. LSB (Least Significant Bit): The

Least significant bit of H is complemented.

ID information at Resul t Phase

C H R N

Page 31

31

Write Data

A set of nine bytes is required to set the into

DC the Write Data mode, after the commawrite

data and has been issued the FDC loads the head

(if is in the unloaded state), waits the specified

head settling time (defined in the specify

command), and beings reading ID fields, when

all four bytes loaded during the command

(C,H,R,N) match the four byte of ID field from

the processor byte-by-byte via the data bus and

outputs it to the FDD. After writing data into the

current sector, the sector number stored in ‘Rr’ is

incremented by one, and the next data field is

written into. The FDC continues this multisector

Write Operation’ until the issuance of Terminal

Count signal. If a Terminal Count signal is sent

to the FDC it continues writing into the current

sector to complete the data field. If the Terminal

Count signal is received while a data field is

being written remainder of the data field is filled

zeros.

The FDC reads the ID field of each sector

and checks the CRC bytes. If the FDC detects a

read error (CRC error) in one of the ID fields, it

sets the DE (DATA Error) flag of Status Register

1 to a 1 (high) and terminates the Write Data

command. (Status Register 0 also has bit 7 and 6

set to 0 and 1 respectively.)

The Write command operates in much the

same manner as the Read command. The

following items are the same., and one should

refer to the Read data command for details.

The Write command operates in much the

same manner as the Read command. The

following items are the same, and one should

refer to following items are the same, and one the

Read Data command for details:

• Transfer capacity

• EN (End of Cylinder) flag

• ND (No Data) flag

• Head Unload Time interval

• ID information When the processor

terminates command

•Definition of DTL when N=0 and when N=0

In the Write Data mode, data transfers

between the processor and FDC via the data bus,

GM82C765B

must occur every 27 uS in the FM mode and

every 13 us in the MFM mode. If the time

interval between data transfers is longer than this,

then the FDC sets the OR (Overrun) flag in

Status Register 1 to a 1 (high) and terminal the

Write Data Address mark.

Write Deleted Data

This command is the same as the Write Data

command except a Deleted Data Address mark is

written at the beginning of the data field instead

of the normal Data Address mark.

Read Deleted Data

This command is the same as the Read Data

command except that when the FDC detects a

Data Address mark at the beginning of a data

field (and SK = 0 (low)), it will read all the data

in the sector and set the CM flag in Status

Register 2 to a 1 (high), and then terminate the

command. If SK = 1, then the FDC skps the

sector with the Data Address mark and reads the

next sector.

Read A Track

This command is similar to the Read Data

command except that this is a continuous Read

operation where the entire data field from each of

the sectors is read. Immediately of the sectors is

read. Immediately after sensing the index hole.

The FDC starts reading all data fields on the

track as continuous biocks of data.

If the FDC finds an error in the ID or Data

CRC check bytes, it continues to. This command

terminates when the number of sectors read is

equal to EOT. If the FDC does not find an ID

Address mark on the diskette after it senses index

hole for the second time, it sets the MA (Missing

Address mark) flag in Status Register 1 to a 1

(high) and terminates the command. (Status

Register 0 has bits 7 and 6 set to 0 and 1

respectively.)

Page 32

32

00

01

02

03

04

05

01

02

30

05

06

00

00

01

02

03

04

01

01

02

03

04

05

0

1

2

1

2

3

GM82C765B

READ ID

The Read ID command is used to give the

present position of the recording head. The FDC

stores the values from the first ID field it is able

to read. If no proper ID Address mark is found on

the diskette before the index hole is encountered

for the second time, then the MA (Missing

Address mark) flag in Status Register 1 is set to a

1 (high), and if no data is found then the ND (No

Data) flag is also set in Status Register 1to a 1 to

a 1 (high). The command is then terminated with

bits 7 and 6 in Status Register 0 set to 0 and 1

respectively. During this command there is no

data transfer between FDC and the CPU except

during the result phase.

Format A Track

The format command allows an entire track to

be formatted. After the index hold is detected,

data is written on the diskette; Gaps , Address

marks, ID fields and data fields, all per the IBM

System 34 (double density) or System 3740

(single density ) format are recorded. The

particular format which will be written is

controlled by the values Programed into N

(number of bytes/sector), SC (secros/cylinder),

GPL (gap length), and D (data pattern) which are

supplied by the processor during the Command

phase. The data field for each sector is supplied

by the processor; that is four data requests per

sector are made by the FDC for C (cylinder

number). H (Head number), R (sector number)

and N (number of bytes/sector). This allows the

diskette to be formatted with nonsequential

sector numbers, if desired.

The processors must send new values for C, H,

R, and N to the WD37C65/A/B for each sector

on the track. If FDC is set for the DMA mode, it

will issue four DMA interrupts per sector and the

processor must supply C,H,R, and N loads for

each sector. The contents of the R register are

incremented by 1 after each sector is formatted;

thus, the R register contains a value of R when it

is read during the Result phase. This

incrementing and formatting continues for the

whole track until the FDC deterts the index hole

for the second time, where upon it terminates the

command. Table 29 shows the relationship

between N, SC, and GPL for various sector sizes

TABLE 29. N, SC AND GPL RELATIONSHIP

Format Sector Size N SC GPL’ GPL”

8” Standard Floppy

FM Mode

MFM Mode

FM Mode

MFM Mode

FM Mode

MFM Mode

128 bytes/sector

256

512

1024

2048

4096

256

512

4

1024

4096

8192

1

5

” Minifloppy

4

128

128

256

512

1024

2048

256

256

512

4

1024

2048

4096

1

3

”Sony Microfloppy

2

128

258

512

256

4

512

1024

1A 07 1B

0F 0E 2A

08 1B 3A

04 47 8A

02 C8 FF

01 C8 FF

1A 0E 36

0F 1B 54

08 35 74

02 C3 FF

01 C3 FF

12 07 09

10 10 19

08 18 30

04 46 87

02 C8 FF

01 C8 FF

12 0A 0C

10 20 32

08 2A 50

04 80 F0

04 C8 FF

01 C8 FF

0F 07 1B

09 0E 2A

05 1B 3A

0F 1B 54

09 1B 54

05 35 74

Page 33

33

Scan Commands

The Scan commands allow data which is being

read from the diskette to be compared against

data which is being supplied from the main

system. The FDC compares the data on a

byte-by-byte basis and looks for a sector of data

which meets the conditions of D FDD=D

Processor, D FDD<D Processor, or D FDD>D

Processor. The hexidecimal byte of FF either