Page 1

Differential Magnetoresistive Sensor FP 210 D 250-22

Features

• High operating

temperature

• High output voltage

• Robust cylindrical

housing

• Biasing magnet build in

• Signal amplitude

independent of speed

• Easily connectable

Typical applications

• Detection of speed

• Detection of position

• Detection of sense of

rotation

• Angle encoder

• Linear position sensing

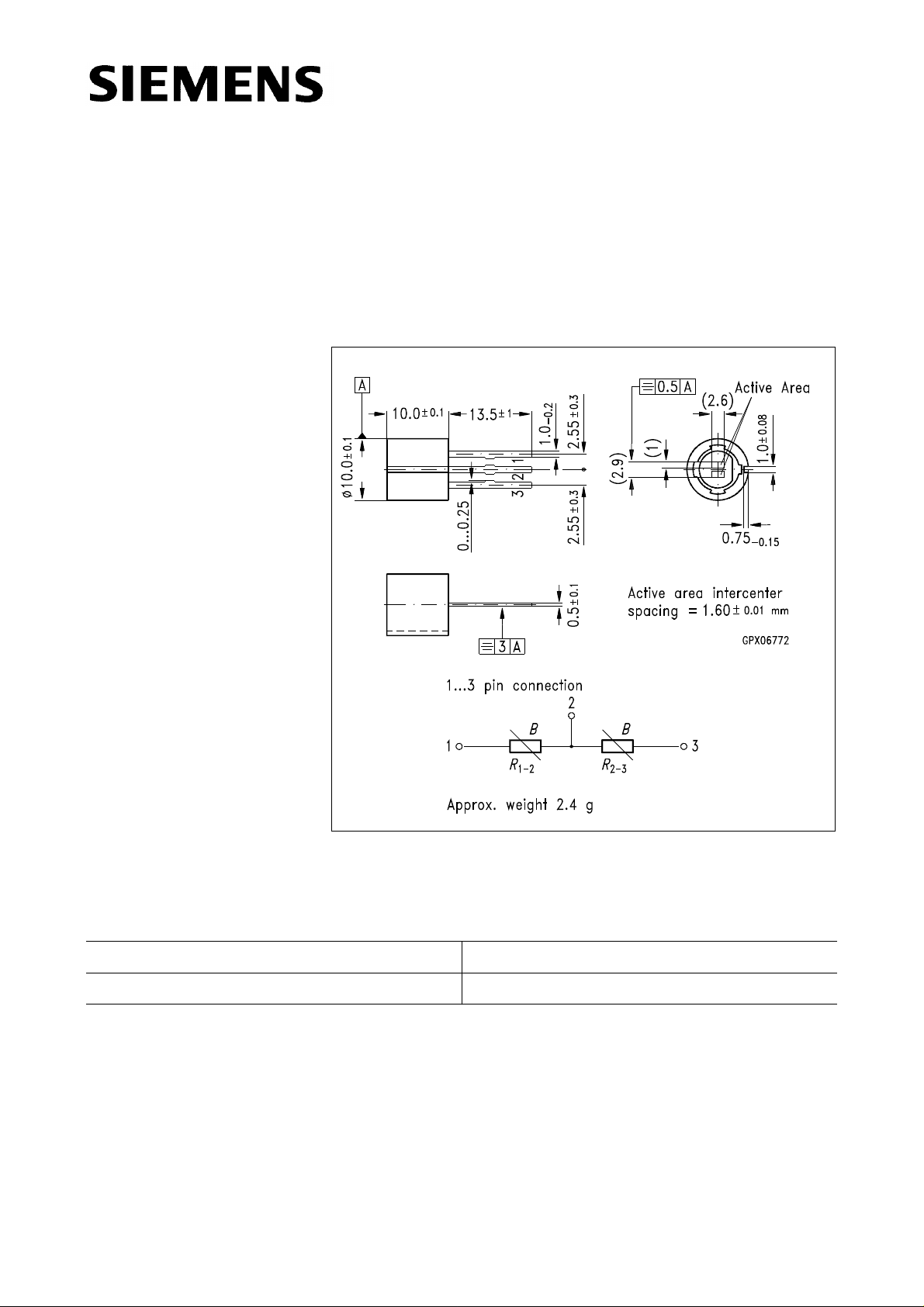

Dimensions in mm

Type Ordering Code

FP 210 D 250-22 Q65210-D250-W5

The differential magnetoresistive sensor FP 201 D 250-22 consists of two series coupled

D-type InSb/NiSb semiconductor resistors. The resitance value of the MRs, which are

mounted onto an insulated ferrite substrate, can be magnetically controlled. The sensor

is encapsuled in a plastic package with three in-line contacts extending from the base.

The basic resistance of the total system in the unbiased state is 2 × 250 Ω. A permanent

magnet which supplies a biasing magnetic field is built into the housing.

Semiconductor Group 1 07.96

Page 2

FP 210 D 250-22

Maximum ratings

Parameter Symbol Value Unit

Operating temperature

Storage temperature

Power dissipation

Supply voltage

1)

2)

Insulation voltage between

terminals and casing

Thermal conductivity

Characteristics (

T

= 25 °C)

A

Nominal supply voltage

Total resistance, (δ = ∞,

4)

3)

(δ = ∞)

Center symmetry

Offset voltage

(at V

and δ = ∞)

IN N

I ≤ 1 mA) R

Open circuit output voltage

(at V

and δ = 0.2 mm)

IN N

5)

T

T

P

V

V

G

V

M

V

V

A

stg

tot

IN

I

thA

IN N

1-3

0

out pp

– 40 / + 140 °C

– 40 / + 150 °C

400 mW

7.5 V

> 100 V

≥ 5 mW/K

5V

1000…1600 Ω

≤ 10 %

≤ 130 mV

> 1100 mV

Cut-off frequency

f

c

> 20 kHz

Measuring arrangements

By approaching a soft iron part close to the sensor a change in its resistance is obtained.

The potential divider circuit of the magneto resistor causes a reduction in the

temperature dependence of the output voltage

1) Corresponding to diagram P

2) Corresponding to diagram

3)

M

4) Corresponding to measuring circuit in Fig. 2

5) Corresponding to measuring circuit in Fig. 2 and arrangement as shown in Fig.

R

----------------------------=

–

12–R23–

R

12–

= f(TA)

tot

V

= f(T

IN

A

× 100% for R

)

> R

1-2

2-3

V

OUT

.

1

Semiconductor Group 2

Page 3

FP 210 D 250-22

1. Digital revolution counting

For digital revolution counting, the sensor should be actuated by a magnetically soft iron

toothed wheel. The tooth spacing should correspond to about twice the magneto resistor

intercenter spacing (see Fig. 1).

The two resistors of the sensor are supplemented by two additional resistors in order to

V

obtain the sensor output voltage as a bridge voltage

without excitation then is 0 V when the offset is compensated.

. The output voltage V

OUT

OUT

Fig. 1

Schematic representation of a toothed wheel actuating an FP 210 D 250-22

Fig. 2

Measuring circuit and output voltage V

waveform

OUT

Semiconductor Group 3

Page 4

FP 210 D 250-22

2. Linear distance measurement

To convert small distances into a proportional electric signal, a small soft iron part of

definite width (e.g.

Proportional signals for distances up to 1.5 mm can be obtained in this way. The

sinusoidal output signal gives a voltage proportional to distance in the zero crossover

region (see Fig. 3).

b = 1.8 mm) is moved over the face of the sensor.

Fig. 3

Arrangement for analogue application

Maximum supply voltage

versus temperature

V

= f(TA), δ = ∞

IN

Semiconductor Group 4

Page 5

FP 210 D 250-22

Output voltage (typical) versus

temperature

V

at TA = 25 °C 100%

OUTpp

V

OUTpp

= f(TA), δ = 0.2 mm

^

=

Output voltage (typical) versus

airgap

V

OUTpp

V

at δ = 0.2 mm 100%

= f(δ), TA = 25 °C

OUTpp

^

=

Total resistance (typical)

versus temperature

R

= f(TA), δ = ∞

1-3

Max. power dissipation

versus temperature

P

= f(TA), δ = ∞

tot

Semiconductor Group 5

Loading...

Loading...