Page 1

www.fairchildsemi.com

FMS3810/3815

Triple Video D/A Converters

3 x 8 bit, 150 Ms/s

Features

• 8-bit resolution

• 150 megapixels per second

– 0.2% linearity error

• Sync and blank controls

• 1.0V p-p video into 37.5 Ω or 75 Ω load

• Internal bandgap voltage reference

• Double-buffered data for low distortion

• TTL-compatible inputs

• Low glitch energy

• Single +5 Volt power supply

Applications

• Video signal conversion

– RGB

– YC

C

B

R

– Composite, Y, C

• Multimedia systems

• Image processing

• True-color graphics systems

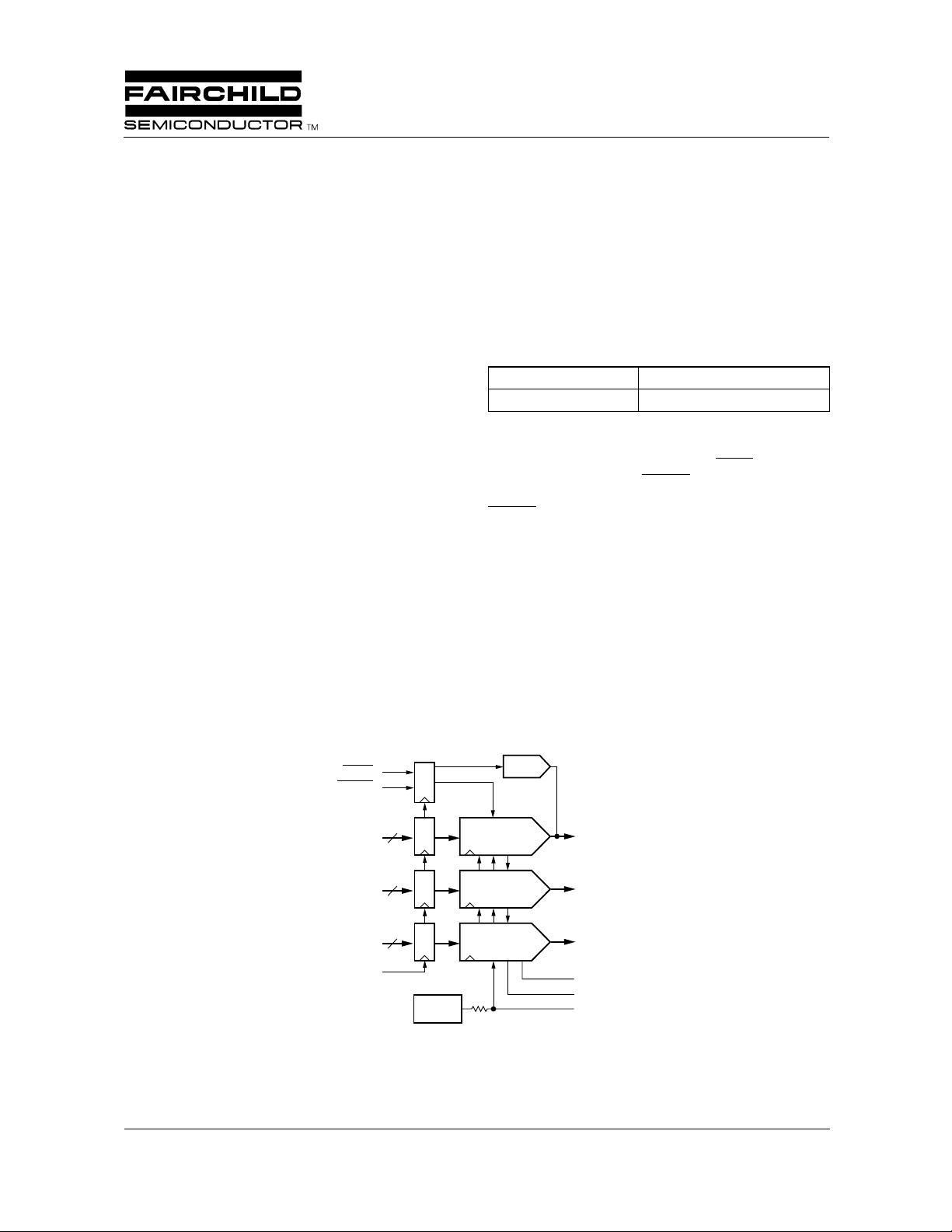

Block Diagram

Description

FMS3810/3815 products are low-cost triple D/A converters

that are tailored to fit graphics and video applications where

speed is critical. Two speed grades are available:

FMS3810 100 Ms/s

FMS3815 150 Ms/s

TTL-level inputs are converted to analog current outputs that

can drive 25–37.5 Ω loads corresponding to doubly-terminated

50–75 Ω loads. A sync current following SYNC input timing

is added to the I

inputs, setting I

BLANK = L. Although appropriate for many applications

the internal 1.235V reference voltage can be overridden by

the V

REF

input.

Few external components are required, just the current

reference resistor, current output load resistors, and

decoupling capacitors.

Package is a 48-lead LQFP. Fabrication technology is

CMOS. Performance is guaranteed from 0 to 70°C.

output. BLANK will override RGB

OG

, I

OG

OB

and I

currents to zero when

OR

SYNC

BLANK

G

7-0

B

7-0

R

7-0

CLOCK

SYNC

8

8

8

+1.235V

Ref

8 bit D/A

Converter

8 bit D/A

Converter

8 bit D/A

Converter

IO

G

IO

B

IO

R

COMP

R

REF

V

REF

REV. 1.08 12/21/00

Page 2

FMS3810/3815 PRODUCT SPECIFICATION

Functional Description

Within the FMS3810/3815 are three identical 10-bit D/A

converters, each with a current source output. External loads

are required to convert the current to voltage outputs. Data

inputs RGB

= H activates, sync current from I

signals.

Digital Inputs

All digital inputs are TTL-compatible. Data is registered on

the rising edge of the CLK signal. Following one stage of

pipeline delay, the analog output changes t

edge of CLK.

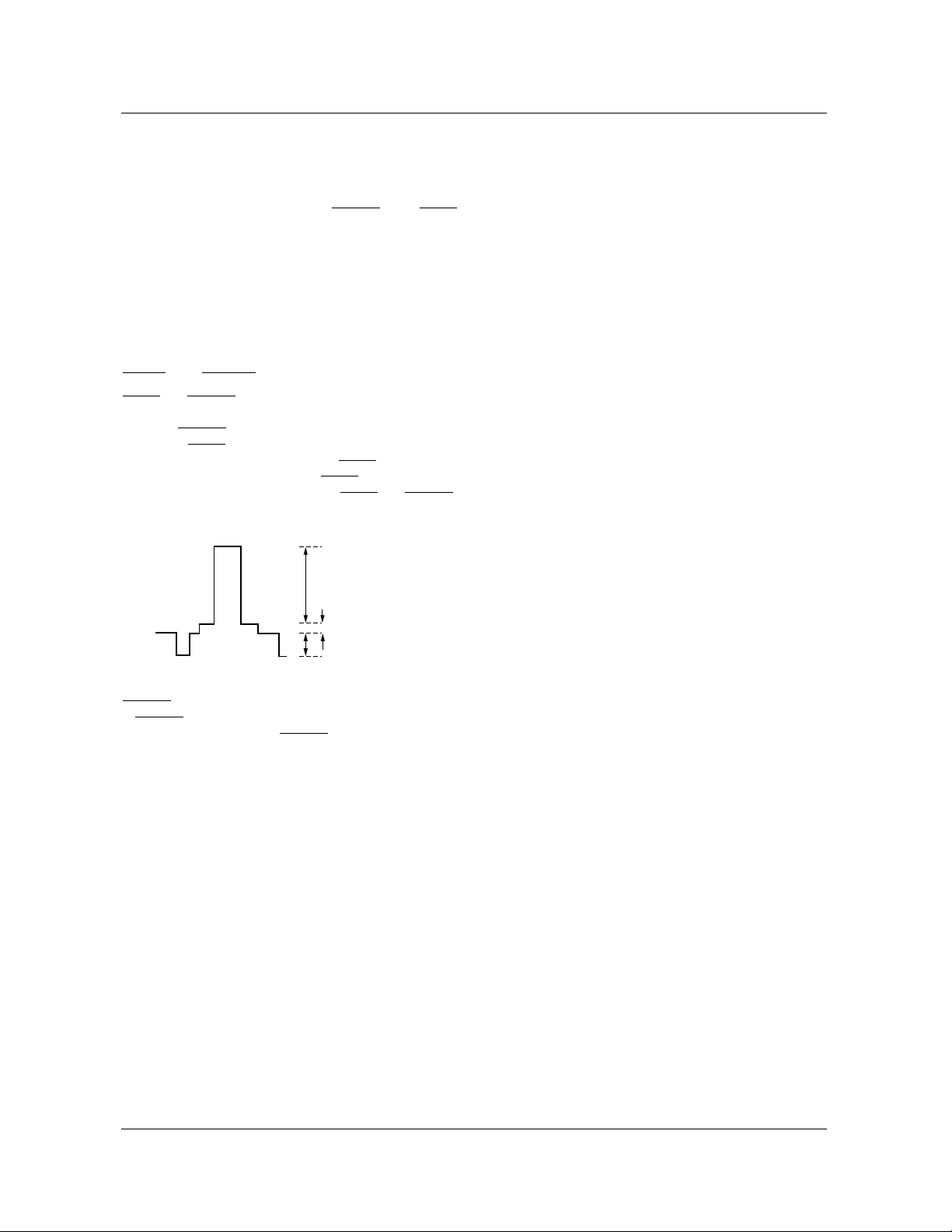

SYNC

SYNC and BLANK inputs control the output level (Figure 1

and Table 1) of the D/A converters during CRT retrace

intervals. BLANK forces the D/A outputs to the blanking

level while SYNC = L turns off a current source that is

connected to the green D/A converter. SYNC = H adds a 40

IRE sync pulse to the green output, SYNC = L sets the green

output to 0.0 Volts during the sync tip. SYNC and BLANK

are registered on the rising edge of CLK.

are overridden by the BLANK input. SYNC

7-0

for sync-on-green video

OS

DO

and BLANK

data: 660 mV max.

after the rising

D/A Outputs

Each D/A output is a current source. To obtain a voltage

output, a resistor must be connected to ground. Output

voltage depends upon this external resistor, the reference

voltage, and the value of the gain-setting resistor connected

between R

and GND.

REF

Normally, a source termination resistor of 75 Ohms is

connected between the D/A current output pin and GND

near the D/A converter. A 75 Ohm line may then be

connected with another 75 Ohm termination resistor at the

far end of the cable. This “double termination” presents the

D/A converter with a net resistive load of 37.5 Ohms.

The FMS3810/3815 may also be operated with a single 75

Ohm terminating resistor. To lower the output voltage swing

to the desired range, the nominal value of the resistor on

should be doubled.

R

REF

Voltage Reference

All three D/A converters are supplied with a common

voltage reference. Internal bandgap voltage reference voltage

is +1.235 Volts with a 3K Ω source resistance. An external

voltage reference may be connected to the V

overriding the internal voltage reference.

A 0.1µF capacitor must be connected between the COMP

pin and V

to stabilize internal bias circuitry and ensure

DD

low-noise operation.

REF

pin,

pedestal: 54 mV

sync: 286 mV

Figure 1. Nominal Output Levels

BLANK gates the D/A inputs and sets the pedestal voltage.

If BLANK = H, the D/A inputs are added to a pedestal which

offsets the current output. If BLANK = L, data inputs and the

pedestal are disabled.

Power and Ground

Required power is a single +5.0 Volt supply. To minimize

power supply induced noise, analog +5V should be

connected to V

capacitors placed adjacent to each V

High slew-rate of digital data makes capacitive coupling to

the outputs of any D/A converter a potential problem. Since

the digital signals contain high-frequency components of the

CLK signal, as well as the video output signal, the resulting

data feedthrough often looks like harmonic distortion or

reduced signal-to-noise performance. All ground pins should

be connected to a common solid ground plane for best

performance.

pins with 0.1 and 0.01 µF decoupling

DD

pin or pin pair.

DD

2

REV. 1.08 12/21/00

Page 3

PRODUCT SPECIFICATION FMS3810/3815

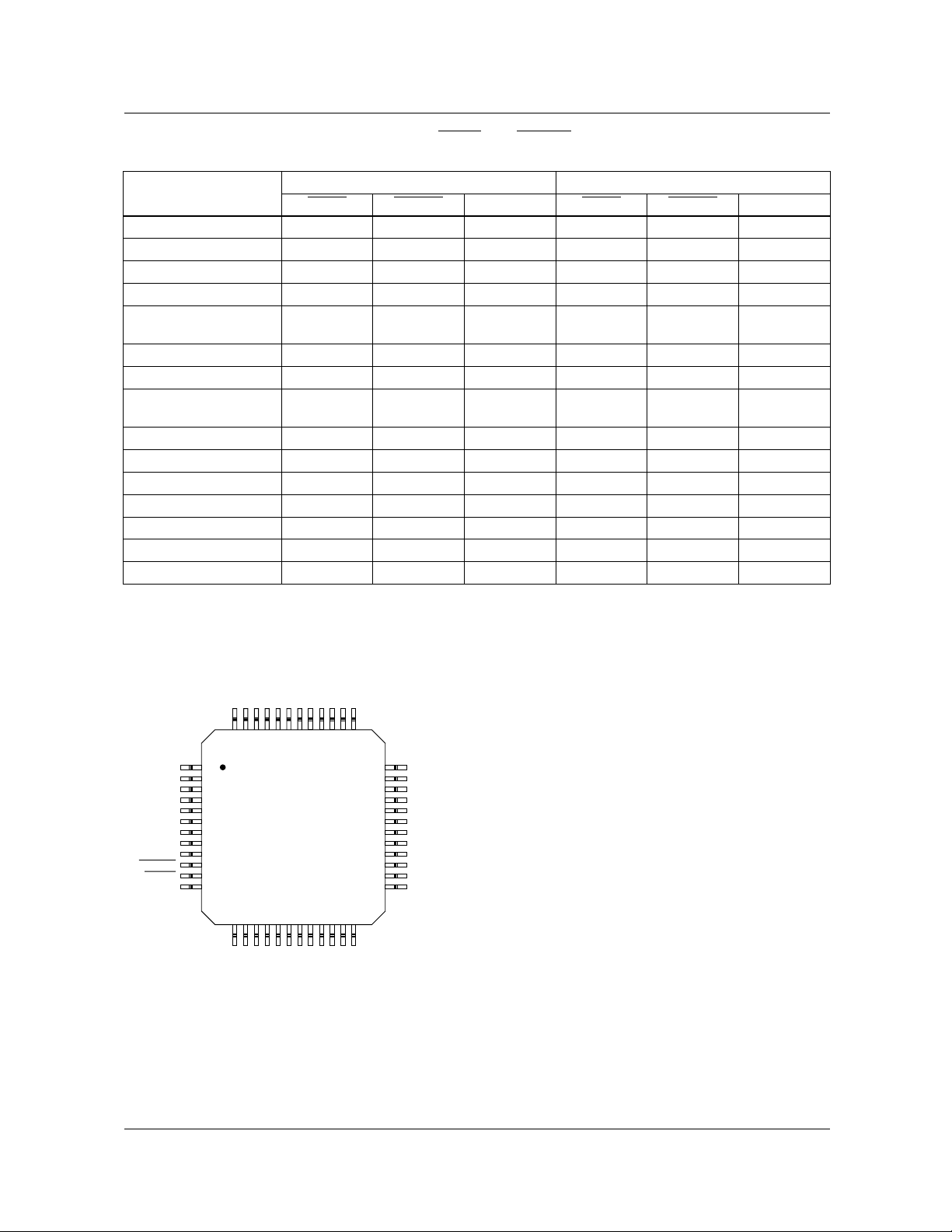

Table 1. Output Voltage versus Input Code, SYNC

V

= 1.235 V, R

REF

= 590 Ω , R

REF

= 37.5 Ω

L

and BLANK

Blue and Red Green

RGB7-0 (MSB…LSB)

SYNC BLANK V

OUT

SYNC BLANK V

1111 1111 X 1 0.714 1 1 1.000

1111 1111 X 1 0.714 0 1 0.714

1111 1110 X 1 0.711 1 1 0.997

1111 1101 X 1 0.709 1 1 0.995

•

•

•

•

•

•

•

•

•

•

•

•

0000 0000 X 1 0.385 1 1 0.671

1111 1111 X 1 0.383 1 1 0.669

•

•

•

•

•

•

•

•

•

•

•

•

0000 0010 X 1 0.059 1 1 0.345

0000 0001 X 1 0.057 1 1 0.343

0000 0000 X 1 0.054 1 1 0.340

0000 0000 X 1 0.054 0 1 0.054

XXXX XXXX X 0 0.000 1 0 0.286

XXXX XXXX X 0 0.000 0 0 0.000

XXXX XXXX X 1 valid 0 1 valid

OUT

•

•

•

•

Pin Assignments

LQFP Package

GND

R7R6R5R4R3R2R

484746454443424140

G

G

G

G

G

G

G

G

DD

1

2

0

3

1

4

2

5

3

6

4

7

5

8

6

7

9

10

11

12

FMS3810/3815

131415161718192021

NC

GND

GND

GND

BLANK

SYNC

V

1

B0B1B2B3B4B6B

R0GND

GND

39

38

22

23

5

B

NC

37

R

36

35

34

33

32

31

30

29

28

27

26

25

24

7

NC

REF

V

REF

COMP

IO

R

IO

G

V

DD

V

DD

IO

B

GND

GND

CLOCK

NC

REV. 1.08 12/21/00

3

Page 4

)

FMS3810/3815 PRODUCT SPECIFICATION

Pin Descriptions

Pin

Name

Pin Number

Value Pin Function DescriptionLQFP

Clock and Pixel I/O

CLK 26 TTL

R

7-0

G

7-0

B

7-0

47-40

9-2

23-16

TTL

Controls

SYNC 11 TTL

BLANK 10 TTL

Video Outputs

IO

IO

IO

R

G

B

33

32

29

0.714 V

Clock Input. The clock input is TTL-compatible and all pixel data is

registered on the rising edge of CLK. It is recommended that CLK be

driven by a dedicated TTL buffer to avoid reflection induced jitter,

overshoot, and undershoot.

Red, Green, and Blue Pixel Inputs. TTL-compatible RGB digital inputs

are registered on the rising edge of CLK.

Sync Pulse Input. Bringing SYNC LOW, turns off a 40 IRE (7.62 mA)

current source which forms a sync pulse on any D/A converter output

connected to IO

. SYNC is registered on the rising edge of CLK along

S

with pixel data and has the same pipeline latency as BLANK and pixel

data. SYNC does not override any other data and should be used only

during the blanking interval. If the system does not require sync pulses,

SYNC and IO

should be connected to GND.

S

Blanking Input. When BLANK is LOW, pixel inputs are ignored and the

D/A converter outputs are driven to the blanking level. BLANK is

registered on the rising edge of CLK and has the same two-pipe latency

as SYNC and Data.

Red, Green, and Blue Current Outputs. Current source outputs can

p-p

drive RS-343A/SMPTE-170M compatible levels into doubly-terminated

75 Ohm lines. Sync pulses may be added to the green output.

When SYNC is HIGH, the current added to I

OG

is:

IO

= 3.64 (V

S

REF

/ R

REF

Voltage Reference

V

REF

35 +1.235 V Voltage Reference Input/Output. Internal 1.235V voltage reference is

available on this pin. An external +1.235 Volt reference may be applied to

this pin to override the internal reference. Decoupling V

to GND with

REF

a 0.1µF ceramic capacitor is required.

R

REF

36 590 Ω Current-setting Resistor. Full-scale output current of each D/A

converter is determined by the value of the resistor connected between

R

and GND. Nominal value of R

REF

R

REF

where I

= 9.1 (V

is the full-scale (white) output current (amps) from the

FS

REF

/I

)

FS

D/A converter (without sync). Sync is 0.4 I

is found from:

REF

.

FS

D/A full-scale (white) current may also be calculated from:

I

= V

FS

Where V

(ohms) on each D/A converter. V

/R

FS

L

is the white voltage level and R

FS

FS

is the total resistive load

L

is the blank to full-scale voltage.

COMP 34 0.1 µF Compensation Capacitor. A 0.1 µF ceramic capacitor should be

connected between COMP and V

to stabilize internal bias circuitry.

DD

4

REV. 1.08 12/21/00

Page 5

PRODUCT SPECIFICATION FMS3810/3815

Pin Descriptions

Pin

Pin Number

(continued)

Name

Power, Ground

V

DD

12, 30, 31 +5 V

GND 1, 14, 15, 27,

28, 38, 39, 48

NC 13, 24, 25, 37 —

Equivalent Circuits

Digital

Input

Value Pin Function DescriptionLQFP

0.0V

Power Supply.

Ground.

No Connect

V

DD

p

n

V

DD

np

V

DD

GND

Figure 1. Equivalent Digital Input Circuit

R

REF

V

REF

Figure 3. Equivalent Analog Input Circuit

OUT

GND

Figure 2. Equivalent Analog Output Circuit

V

DD

p

GND

p

27012B

REV. 1.08 12/21/00

5

Page 6

PRODUCT SPECIFICATION FMS3810/3815

Absolute Maximum Ratings

(beyond which the device may be damaged)

1

Parameter Min Typ Max Unit

Power Supply Voltage

V

(Measured to GND) -0.5 7.0 V

DD

Inputs

Applied Voltage (measured to GND)

Forced Current

3,4

2

-0.5 V

+ 0.5 V

DD

-10.0 10.0 mA

Outputs

Applied Voltage (measured to GND)

Forced Current

3,4

2

-0.5 V

+ 0.5 V

DD

-60.0 60.0 mA

Short Circuit Duration (single output in HIGH state to ground) unlimited sec.

Temperature

Operating, Ambient -20 110 °C

Junction 150 °C

Lead Soldering (10 seconds) 300 °C

Vapor Phase Soldering (1 minute) 220 °C

Storage -65 150 °C

Notes:

1. Functional operation under any of these conditions is NOT implied. Performance and reliability are guaranteed only if

Operating Conditions are not exceeded.

2. Applied voltage must be current limited to specified range.

3. Forcing voltage must be limited to specified range.

4. Current is specified as conventional current flowing into the device.

Operating Conditions

Parameter Min Nom Max Units

V

DD

f

S

t

PWH

t

PWL

t

W

t

s

t

h

V

REF

C

C

R

L

V

IH

V

IL

T

A

Power Supply Voltage 4.75 5.0 5.25 V

Conversion Rate FMS3810 100 Msps

FMS3815 150 Msps

CLK Pulsewidth, HIGH FMS3810 3.1 ns

FMS3815 2.5 ns

CLK Pulsewidth, LOW FMS3810 3.1 ns

FMS3815 2.5 ns

CLK Pulsewidth FMS3810 10 ns

FMS3815 6.6 ns

Input Data Setup Time 1.7 ns

Input Date Hold Time 0 ns

Reference Voltage, External 1.0 1.235 1.5 V

Compensation Capacitor 0.1 µF

Output Load 37.5 Ω

Input Voltage, Logic HIGH 2.0 V

DD

Input Voltage, Logic LOW GND 0.8 V

Ambient Temperature, Still Air 0 70 °C

V

REV. 1.08 12/21/00

6

Page 7

FMS3810/3815 PRODUCT SPECIFICATION

Electrical Characteristics

Parameter Conditions

I

DD

Power Supply Current

PD Total Power Dissipation

R

O

C

O

I

IH

I

IL

I

REF

V

REF

V

OC

C

DI

Notes:

1. Values shown in Typ column are typical for V

2. Minimum/Maximum values with V

3. V

Output Resistance 100 kΩ

Output Capacitance I

Input Current, HIGH VDD = Max, VIN = 2.4V -5 µA

Input Current, LOW VDD = Max, VIN = 0.4V 5 µA

V

Input Bias Current 0 ±100 µA

REF

Reference Voltage Output 1.235 V

Output Compliance Referred to V

Digital Input Capacitance 4 10 pF

= 1.235V, R

REF

LOAD

= 37.5Ω, R

2

DD

VDD = Max 125 mA

2

V

= Max 655 mW

DD

= 0mA 30 pF

OUT

= +5V and TA = 25°C

= Max and TA = Min

REF

DD

= 590Ω

3

DD

Min Typ

-0.4 0 +1.5 V

1

Max Units

Switching Characteristics

Parameter Conditions

t

D

t

SKEW

t

R

t

F

Notes:

1. Values shown in Typ column are typical for V

2. V

Clock to Output Delay VDD = Min 10 15 ns

Output Skew 1 2 ns

Output Risetime 10% to 90% of Full Scale 3 ns

Output Falltime 90% to 10% of Full Scale 3 ns

= +5V and TA = 25°C.

= 1.235V, R

REF

LOAD

= 37.5Ω, R

REF

DD

= 590Ω.

2

Min Typ

1

Max Units

System Performance Characteristics

Parameter Conditions

E

LI

E

LD

E

DM

Integral Linearity Error VDD, V

Differential Linearity Error VDD, V

DAC to DAC Matching VDD, V

2

= Nom ±0.2 ±0.3 %/FS

REF

= Nom ±0.2 ±0.3 %/FS

REF

= Nom 5 10 %

REF

Min Typ

PSRR Power Supply Rejection Ratio 0.05 %/%

Notes:

1. Values shown in Typ column are typical for V

2. V

= 1.235V, R

REF

LOAD

= 37.5Ω, R

REF

= 590Ω.

= +5V and TA = 25°C.

DD

7 REV. 1.08 12/21/00

1

Max Units

Page 8

FMS3810/3815 PRODUCT SPECIFICATION

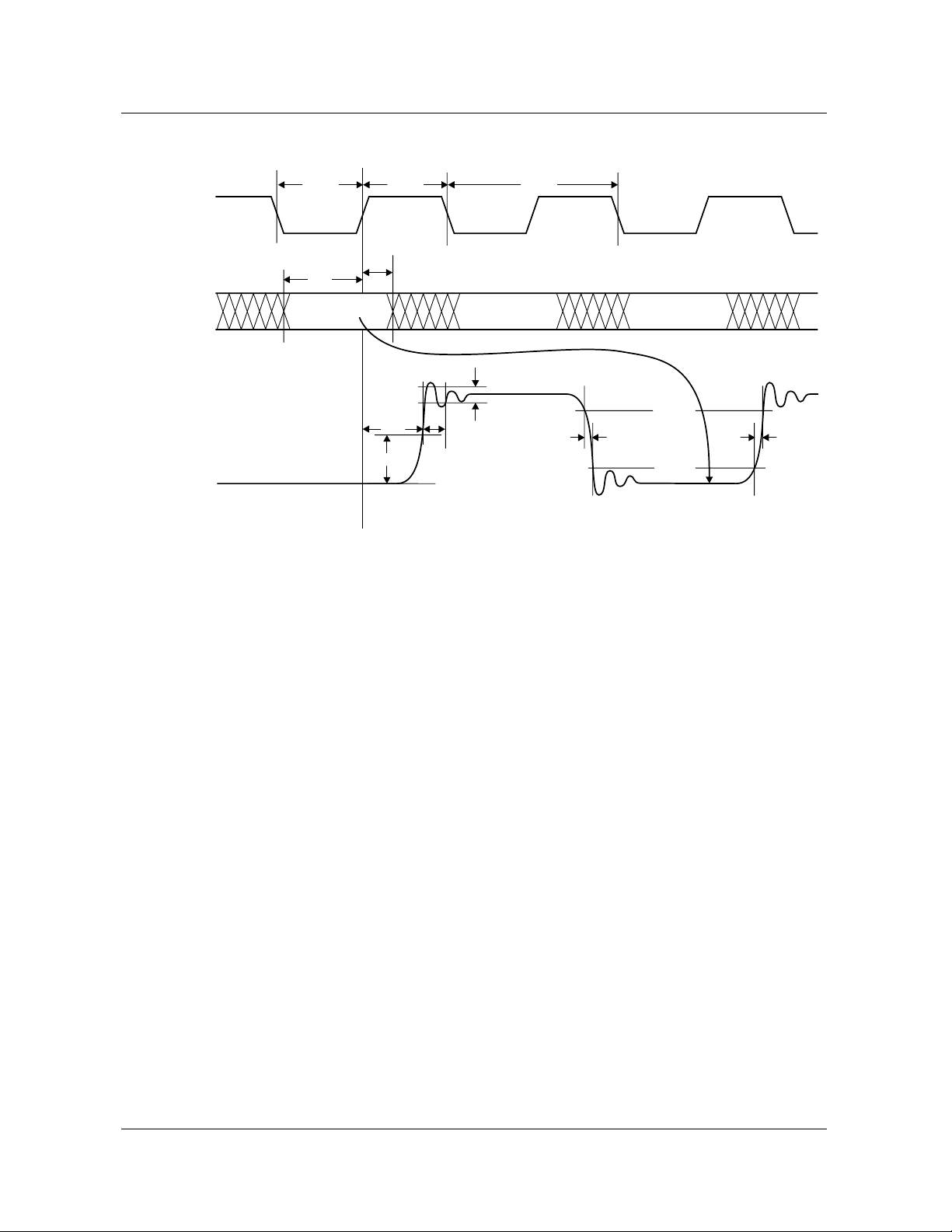

Timing Diagram

1/f

S

90%

t

F

10%

t

R

CLK

PIXEL DATA

& CONTROLS

OUTPUT

t

PWL

t

S

DataN DataN+1 DataN+2

50%

t

PWH

t

H

3%/FS

t

D

t

SET

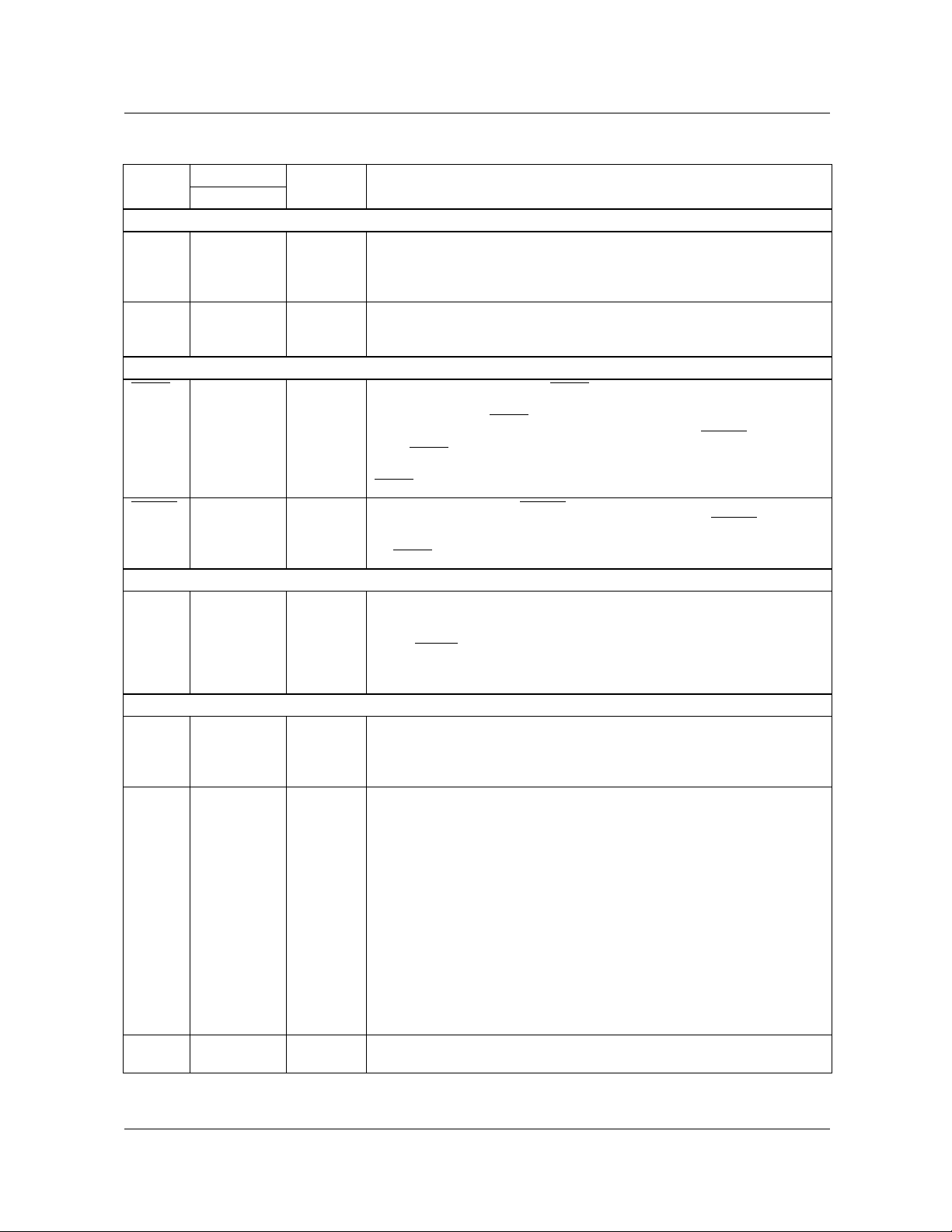

Applications Information

Figure 4 illustrates a typical FMS3810/3815 interface

circuit. In this example, an optional 1.2 Volt bandgap

reference is connected to the V

internal voltage reference source.

Grounding

It is important that the FMS3810/3815 power supply is

well-regulated and free of high-frequency noise. Careful

power supply decoupling will ensure the highest quality

video signals at the output of the circuit. The FMS3810/3815

has separate analog and digital circuits. To keep digital

system noise from the D/A converter, it is recommended that

power supply voltages (VDD) come from the system analog

power source and all ground connections (GND) be made to

the analog ground plane. Power supply pins should be

individually decoupled at the pin.

Printed Circuit Board Layout

Designing with high-performance mixed-signal circuits

demands printed circuits with ground planes. Overall system

performance is strongly influenced by the board layout.

Capacitive coupling from digital to analog circuits may

result in poor D/A conversion. Consider the following

suggestions when doing the layout:

1. Keep the critical analog traces (V

IOS, IOR, IOG) as short as possible and as far as

possible from all digital signals. The FMS3810/3815

should be located near the board edge, close to the

analog output connectors.

output, overriding the

REF

, I

REF

REF

, COMP,

2. The power plane for the FMS3810/3815 should be

separate from that which supplies the digital circuitry.

A single power plane should be used for all of the VDD

pins. If the power supply for the FMS3810/3815 is the

same as that of the system's digital circuitry, power to

the FMS3810/3815 should be decoupled with 0.1µF and

0.01µF capacitors and isolated with a ferrite bead.

3. The ground plane should be solid, not cross-hatched.

Connections to the ground plane should have very short

leads.

4. If the digital power supply has a dedicated power plane

layer, it should not be placed under the FMS3810/3815,

the voltage reference, or the analog outputs. Capacitive

coupling of digital power supply noise from this layer to

the FMS3810/3815 and its related analog circuitry can

have an adverse effect on performance.

5. CLK should be handled carefully. Jitter and noise on

this clock will degrade performance. Terminate the

clock line carefully to eliminate overshoot and ringing.

8 REV. 1.08 12/21/00

Page 9

PRODUCT SPECIFICATION FMS3810/3815

+5V

10µF

0.1µF

RED PIXEL

INPUT

GREEN PIXEL

INPUT

BLUE PIXEL

INPUT

CLOCK

SYNC

BLANK

R

7-0

G

7-0

B

7-0

CLK

SYNC

BLANK

VDD

GND

FMS38XX

Triple 8-bit

D/A Converter

Figure 4. Typical Interface Circuit

Related Products

• FMS3110/3115 Triple 10-bit 250 Msps D/A Converters

• FMS9884A 3 x 8 bit 140 Ms/s A/D Converter

IO

IO

IO

COMP

V

REF

R

REF

Red

R

75Ω

G

75Ω

B

ZO=75Ω

Green w/Sync

ZO=75Ω

Blue

Z

O

=75Ω

75Ω

75Ω

75Ω

75Ω

+5V

0.1µF

3.3kΩ (not required without

external reference)

0.1µF

590Ω

LM185-1.2

(Optional)

REV. 1.08 12/21/00 9

Page 10

FMS3810/3815 PRODUCT SPECIFICATION

Mechanical Dimensions

48-Lead LQFP Package

Symbol

A .055 .063 1.40 1.60

A1 .001 .005 .05 .15

A2 .053 1.35

B .006 .010 .17 .27

D/E

D1/E1

e

L .017 .029 .45 .75 6

N48 48

ND

α 0° 7° 0° 7°

ccc .004 0.08

E

Inches

Min. Max. Min. Max.

.057 1.45

.346 .362 8.8 9.2

.268 .284 6.8 7.2

.019 BSC

12 12

E1

Millimeters

.50 BSC

D

D1

PIN 1

IDENTIFIER

Notes

Notes:

All dimensions and tolerances conform to ANSI Y14.5M-1982.

1.

Dimensions "D1" and "E1" do not include mold protrusion.

2.

Allowable protrusion is 0.25mm per side. D1 and E1 are maximum

plastic body size dimensions including mold mismatch.

Pin 1 identifier is optional.

3.

7

8

2

4

5

Dimension ND: Number of terminals.

4.

Dimension ND: Number of terminals per package edge.

5.

"L" is the length of terminal for soldering to a substrate.

6.

Dimension "B" does not include dambar protrusion. Allowable

7.

dambar protrusion shall not cause the lead width to exceed the

maximum B dimension by more than 0.08mm. Dambar can not be

located on the lower radius or the foot. Minimum space between

protrusion and an adjacent lead is 0.07mm for 0.4mm and 0.5mm

pitch packages.

8.

To be determined at seating place —C—

e

C

L

0.063" Ref (1.60mm)

See Lead Detail

A2

A

B

A1

Seating Plane

Base Plane

-C-

LEAD COPLANARITY

ccc

C

α

10 REV. 1.08 12/21/00

Page 11

FMS3810/3815 PRODUCT SPECIFICATION

Ordering Information

Product Number

Conversion

Rate Temperature Range Screening Package

Package

Marking

FMS3810KRC 100 Ms/s TA = 0°C to 70°C Commercial 48-Lead LQFP 3810KRC

FMS3815KRC 150 Ms/s TA = 0°C to 70°C Commercial 48-Lead LQFP 3815KRC

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO

ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME

ANY LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN;

NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES

OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body,

or (b) support or sustain life, and (c) whose failure to

perform when properly used in accordance with

instructions for use provided in the labeling, can be

reasonably expected to result in a significant injury of the

user.

www.fairchildsemi.com

2. A critical component in any component of a life support

device or system whose failure to perform can be

reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

12/21/00 0.0m 003

2000 Fairchild Semiconductor Corporation

Stock#DS30003810

Loading...

Loading...